Abstract

The sustainable development of human society in today’s high-tech world depends on some form of eco-friendly energy source because existing technologies cannot keep up with the rapid population expansion and the vast amounts of wastewater that result from human activity. A green technology called a microbial fuel cell (MFC) focuses on using biodegradable trash as a substrate to harness the power of bacteria to produce bioenergy. Production of bioenergy and wastewater treatment are the two main uses of MFC. MFCs have also been used in biosensors, water desalination, polluted soil remediation, and the manufacture of chemicals like methane and formate. MFC-based biosensors have gained a lot of attention in the last few decades due to their straightforward operating principle and long-term viability, with a wide range of applications including bioenergy production, treatment of industrial and domestic wastewater, biological oxygen demand, toxicity detection, microbial activity detection, and air quality monitoring, etc. This review focuses on several MFC types and their functions, including the detection of microbial activity.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sensors are devices that detect signals and provide a way for these signals to be measured and recorded. They have played a vital role in different sectors such as home, medicine, and automobiles. The commercial potential of using biological systems has led to increased research in the area of biosensors [1,2,3,4]. The development of biosensors has led to revolutionizing different areas such as healthcare, agriculture, veterinary care, and pollution monitoring. A conventional biosensor consists of a biological element, a transducer that converts the biochemical signal to a quantifiable electrical signal. The biological element may be an enzyme, microbial cell, or mammalian or plant tissues [5,6,7,8,9]. Microorganisms are ubiquitous, are able to adapt to adverse conditions, and have the ability to degrade different metabolites. Microbial fuel cells (MFCs) are bioelectrochemical systems that utilize microorganisms (mainly, electroactive bacteria) to produce electricity. Insufficient non-renewable sources like oil paved way for interest in renewable sources of energy. MFCs are ideal because they not only produce electricity with the help of electroactive bacteria, but they can also be used for wastewater treatment, bioremediation, and toxicity detection [10,11,12,13]. Current research has been focused on the use of these MFCs as biosensors for environmental monitoring, toxicity detection, etc.

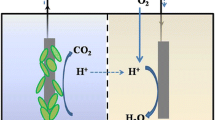

The electroactive bacteria converted organic substances into carbon dioxide, electrons, and protons, the anode which yields energy in MFCs. The process includes three main steps: the first step involves degradation of the organic substrate into electrons by the electroactive bacteria. During the second step, the extracellular transfer of electrons is done by the electroactive bacteria and transported to the anode [14,15,16]. For instance, direct transportation of electrons via conductive pili is observed in the family Geobacteraceae, whereas, in Shewanella oneidensis, electron transfer is mediated by cytochrome c in the absence of oxygen in order to convert lactate into acetate. These electrons are transported from the anode to the cathode via an external circuit. The third step involves the oxygen reduction reaction (ORR), where oxygen is converted into water, thereby resulting in the production of electricity. Moreover, some microbes reduce CO2 to CH4 or C2H3O2 in which acetyl-CoA is an intermediate, as G. sulfurreducens produces succinate from fumarate by obtaining a negative charge. Surprisingly, all the products and by-products which are produced in the anode chamber aid in the simultaneous wastewater treatment and electricity production.

The development of MFC-based biosensors for BOD measurement requires a thorough understanding of the chemical kinetics governing the biological oxygen demand (BOD) of wastewater as well as a sharp understanding of these kinetics. MFC-type BOD sensors have a number of benefits over conventional BOD detection techniques, such as a way for online monitoring and real-time management of biological wastewater-treatment processes, a quick measurement time, long-term stability, and a wide range of BOD concentrations [17,18,19,20,21]. Additionally, MFC-based biosensors can also be used to detect toxic compounds in wastewater.

A microbial fuel cell (MFC), a cutting-edge bio-electrochemical device, has new capabilities such uses for biosensors, wastewater treatment, and energy generation. Recent advances in the chemical, electrochemical, and microbiological aspects of MFC research have resulted in its remarkable applications in the sensing sector (Table 1) [22,23,24,25]. Consequently, the objective of this review was to present an overview of the most intriguing new applications of MFCs in sensors, including providing the required electrical current and power for remote sensors (energy supply device for sensors) and detecting pollutants, biochemical oxygen demand (BOD), and specific DNA strands by MFCs without the need for an external analytical device (self-powered biosensors) (Figs. 1, 2, 3) [26].

Working of Microbial Fuel Cell

A fuel cell is a machine that uses fuel to create electricity chemically. The type of fuel cell most frequently used to generate energy is a hydrogen fuel cell, which uses hydrogen. In contrast to traditional biomass energy, which is mostly produced by burning the biomass to produce heat, which is subsequently utilized to produce electricity, the microbial fuel cell uses bacteria as a biocatalyst to convert biomass, such as sugars, to produce electricity. When biomass is exposed to oxygen, it breaks down into carbon dioxide and water, releasing energy that can be increased by combustion or by bacteria. Although biomass cannot completely break down into carbon dioxide and water in anaerobic circumstances, bacteria may nevertheless partially break down biomass in the absence of oxygen. Electroactive bacteria, sometimes referred to as electrogens, are anaerobic microorganisms that can break down biomass and generate carbon dioxide, hydrogen ions, and electrons. These electrons can be used in MFCs to generate electricity with the goal of completing the reaction between hydrogen ions and electrons joining with oxygen to form water in a separate location. In order to prevent oxygen from harming bacteria or combining with hydrogens and electrons without causing them to enter the circuit, it must be kept away from the bacterial area.

Two half-cells submerged in water make up an MFC. Electroactive bacteria consume biomass, also known as the substrate, in the first half of the cell, where they produce hydrogen ions and electrons. The anode, the surface of an electrode, is where the bacteria are found. The hydrogen ions move inside the cell and cross the membrane to enter the other half [46]. As the electrons are unable to migrate through the water, they must travel through the electrode and further get transferred into the wire which connects them in an electric load such as a light bulb. The overall reactions Eqs. 1 and 2 can be observed as seen below [47]:

At the anode:

At the cathode:

The membrane is a crucial component of the system since it is an ion exchange membrane, allowing only specific ions to pass through. In this situation, hydrogen molecules can flow through with ease but not oxygen molecules. This is necessary to allow hydrogen ions or proton to move to the right compartment of the cell and to prevent oxygen from entering the left cell.

MFC as Biosensor

MFCs have certain limitations, which include activation, ohmic, and mass transfer losses [48]. These losses prevent the output voltage from ever reaching the theoretical level. MFC biosensors appear to be a superior solution for MFCs’ lack of power, making it simple and affordable to remotely or in vivo monitor target reagents in marine ecosystems. The electrical current generated by an MFC, in which charged particles are transported from the biofilm to the oxidative electrode surface by direct electron transfer, i.e., nanowires or cytochrome c and mediated electron transfer, is directly related to the electrocatalytic biochemical action of the evolved thermionic biofilm. Any changes to the metabolic activity of bacteria can cause disruptions in the production of electricity. When functional parameters like temperature, pH, and feed conductivity are maintained constant, it will cap the voltage [49]. The theory for employing MFCs as electrochemical biosensors is based on an anode biofilm that functions as a receptor [50].

MFCs could be used as biosensors to measure the amount of atmospheric carbon in wastewater. A rapid change in the current generation will happen as a result of the presence of anomalous materials in the input, on the other hand, if the MFC is frequently used in saturated fuel conditions with all other factors, such as pH, temperature, salinity, and steady potential of positive electrode constant. Mixed microbial cultures have been employed frequently despite research on the use of pure cultures [51]. The use of heterogeneous microbial culture ensures greater consistency and results in more effective MFC biosensors. The electroactive biofilm is typically formed on the accessible surface of the positive anode, allowing the MFC setup to physiologically monitor hazardous compounds in water [52].

MFCs may even be employed as biosensors to monitor levels of emissions to the environment. The intensity of the effluent and the coulombic efficiency are linked with each other. As a result, it could be used to detect BOD (biological oxygen demand). BOD and coulombic yield have a straight affiliation [53]. The power increases linearly as the BOD levels increase. Because of their stability and precision, MFCs’ BOD sensors are more trustworthy than conventional BOD sensors. Especially compared to certain other sensors, MFC-based BOD biosensors have a long durability (over 5 years) requiring no maintenance [54].

Types of MFCs

An anode chamber, cathode chamber, membrane, and electrode assembly make up any microbial fuel cell. The design and manner of functioning of microbial fuel cells were used to classify them into their different types which are mentioned below.

-

Dual-Chambered MFCs

These consist of an anode and cathode chamber divided by a proton exchange membrane or salt bridge. Microbes, media (glucose, acetate, etc.), and electrodes are the materials found in the anode chamber, and electrode, clean water, and oxygen are found in the cathode chamber. Electrodes are primarily made of copper, stainless steel mesh, graphite, carbon paper, graphite fiber brush, and carbon cloth [36, 52]. Nitrogen should be continually provided if the anaerobic state in the anode compartment is to be maintained. The H type MFC is the most basic design in this category. The basic H type MFC was invented by Logan et al. in 2004. Two 300-mL borosilicate glass bottles were used to create it. A clamp method was used to join the two rooms by glass bridges. PEM is being used to divide the two compartments (Nafion). Each anode and cathode electrode is composed of 2.5 × 4.5 cm carbon paper. The cathode, on the other hand, was imbued with a platinum catalyst (0.35 mg/cm2). The microbes were cultured in mineral salts medium (MSM) and kept at 4 °C for later use.

-

Single-Chambered MFCs

Only the anode compartment is present in single-chambered MFCs, while the cathode is exposed to the environment. Since the cathode is immediately exposed to air, no aeration or O2 supply is required. The concept is straightforward, and it may be run in batches or continuously. Because of the simplicity of the design, scaling it up is straightforward, and the design is cost effective [38]. A basic flat plate MFC was created by Min and Logan in 2004. The MFC was made out of a non-conductive polycarbonate plate that was 15 cm × 15 cm × 3 cm in size (L × B × H). The zigzag route, which has a total surface area of about 55 cm2 and a volume of around 22 cm3, was designed for wastewater retention. A screw and bolt method was used to secure the plates. The anode was porous carbon paper with a 10 cm × 10 cm dimension, while the cathode was carbon cloth with the same surface area treated with a platinum catalyst. The proton exchange membrane was made of Nafion, and the electrodes interacted with the external circuit by copper wire [34].

The effluent is fed into the system from the base and the effluent is pushed out of the system from the head in an up-flow MFC design that functions in a continuous mode [55]. Jang et al. built a standard up-flow MFC without a porous membrane in 2004 [39]. The MFC was produced of polyacrylic plastic and had a cylindrical shape with a maximum height of 100 cm and a diameter of 10 cm. The anode was constructed of graphite felt (196 g), while the cathode was made of the same material (53.3 g). A succession of layers of glass beads and glass wool were utilized between the anode and cathode, and sampling ports were placed along the reactor length. The anode had a total size of 465 cm2, while the cathode had an area of 89 cm2. The fuel (artificial wastewater containing glucose and glutamate) was delivered from the bottom of the reactor at a rate of 0.28 mL/min, and the effluent was removed from the top. The electrodes were connected to an external circuit using platinum wire resistance 10 and aerators to aerate the cathode layer. The absence of a proton exchange membrane is the primary benefit of this design, which may also be run in continuous mode, lowering costs.

-

Stacked MFCs

A large number of MFCs are connected in series or parallel. Although numerous MFCs are linked together, high output or current generation is possible. Aelterman et al. developed the stacked MFC in 2006, which consists of six separate continuous microbial fuel cells stacked together. The anode and cathode were made of graphite granules [56]. Graphite granules give the most surface area for microbes to transfer electrons, and a graphite rod was utilized to link the external circuit to the microbes. One MFC unit has a volume of 60 mL, while piled MFC has a volume of 360 mL [57]. Ultrex CMI7000 was the bioelectrochemical membrane that separated the anode and cathode. Due to high quality and improved chemical oxygen demand (COD) elimination, parallel cell linkages have been found to function superior to series cell connections [40].

The MFC was made of paper, which was low cost, chemical free, and disposable. The design was basic, consisting of an anode and a cathode. Four distinct pencil strokes were used as electrodes to deposit graphite particles on the paper. As a PEM, parchment paper was applied, which allows H + to flow through. To make it hydrophobic, the crayon was added to the corners. The microorganisms, together with a few milliliters of the growth medium, were put into the anode chamber. The electrons were absorbed by O2 at the air cathode. Shewanella oneidensis was the microbe employed in the paper MFC. The greatest voltage and current produced, respectively, were determined to be 300 mV and 11 μA [41]

-

Microfluidic Microbial Fuel Cells (MMFCs)

Microbial fuel cells (MFCs) are bioelectrochemical technologies that use microbial metabolism to transform the chemical energy of organic substrates into electrical energy. Microfluidic MFCs (MMFCs) have been created recently for biosensors, colony screening, or micro-power sources. The mass transfer of the reactants and the product is improved in mMFC due to a drop in the characteristic scale, which also lowers the buildup of hydrogen ions on the anode side and strengthens the reaction kinetics. High surface area to volume ratio and rapid reactant response are two characteristics of the downsized MFCs. The physical separator is replaced in this device by a constrained anolyte-catholyte mixing area in the center of the microchannel. The internal resistance is significantly reduced and the power density is drastically increased when the separator between the anode and cathode is removed. They are miniaturistic cell which work on the carbon–neutral policy of not increasing carbon emissions but fulfilling the reduction process from the first step. MMFCs utilize self-assembling bacteria as an inoculum for the anodic compartment for catalyzing all the substrates present out there and producing ions and other metabolites. The electrons migrate to the load while the positive ions migrates into the cathodic chamber for the redox reaction [58,59,60,61]. In the beginning, non-polymeric materials like silicon and glass were utilized as the building blocks for creating microfluidic devices. Glass materials were chosen because of their excellent biocompatibility and outstanding resistance to high temperatures and solvents. The non-optical transparency of silicon, the high cost of production, and the intricacy of micromachining with silicon and glass were the main causes of the constraints. A wide range of mechanical and chemical properties, biocompatibility, affordability, transparency, durability, design freedom, and low cost have all contributed to the polymeric or plastic materials’ significant rise in popularity in recent years.

Based on different forms like macro, meso, and micro, MFCs are of several types. One of the well-performing MFCs is micro-MFC or microfluidic MFC comprising a volume of 1–200 μL including electrodes, membrane, fluid delivery system, biochip, and other integrations [62]. MMFCs have small dimensions that is why they are very compatible and reliable and this quality can be increased by some microfabrication techniques like photolithography and soft-photolithography. Remarkably, their tiny typical length provides significant benefits over other-sized MFCs, such as a high surface area-to-volume (SAV) ratio, fast reaction to reactants, and accurate programming [47, 63]. Microfluidic MFCs also serve as a laboratory tool to influence the production of large-scale MFCs due to their expedited inoculation technique and reduced labor participation [64]. Some investigators have used a micro-MFC to investigate a novel electro catalyst [65] and confirm its potential applicability in MFC. Because of the nature of the laminar flow, blending different fluids is mostly restricted to a small junction and is governed by diffusion rather than turbulence. The resulting mixing interface may abolish the membrane in typical MFCs [66, 67]. Lee et al. [54] proposed and Li et al. [68] developed the co-laminar MFC based on this approach. In conventional MFC, a physical separator separates the two compartments, allowing hydrogen ions and certain other cations to easily flow between them. Exoelectrogens, generally Geobacter and Shewanella species, or other sludge-derived mixed bacteria, are injected into the anode [69,70,71,72,73,74]. The metabolic activity of the microbiomes catalyzes the oxidation of organic compounds in the electrode material. Direct transfer, conductive pili, and electron shuttles are three methods for donating electrons from the outer surface to the anode surface [75,76,77]. The negative ions are then fed to the cathode through a load resistance. Oxidants (such as oxygen, ferricyanide, or permanganate) can devour protons and electrons transported to the cathode. Conventional MFCs show great reactor chamber capacities ranging from a few liters to several liters [78,79,80,81,82,83]. Some researchers have begun to reduce storage capacity from liters to milliliters or sub-milliliters in order to obtain information on the observable interaction between microbial colonization and power production. When all of the reaction components are constrained to a micro-scale space, a new form of the microfuel cell, known as micro- or microfluidic MFCs, is created. Often, these micro-MFCs are essentially calibrated macro-scale MFCs with two-chamber structures and a proton exchange membrane (PEM). Commonly available components such as plastic tubes [84, 85] and polymer sheets [86] are preferred in these circumstances. To swiftly create the appropriate designs for the MFCs generated by photolithography, several readily nanostructured and affordable polymers such as PDMS (polydimethylsiloxane), PTFE (polytetrafluoroethylene), and rubber [87,88,89,90,91,92] are used. Aside from its expertise among device makers, photolithography is used for electrode manufacturing because the electrode form and size may be regulated by creating the photomask structures.

Pathogenic Bacteria

The fecal contamination is indicated by the presence of Escherichia coli; a statistically valid amount of E. coli might be regarded a crucial element for ensuring human safety. MFCs can also be optimized as a sensor for sensing the presence of E. coli by detecting the enzymes present in it like -d-galactosidase (GAL) and b-d-glucuronidase (GUS)[93]. The reagent used for GAL detection is 4-aminophenyl-b-d galactopyranoside and for the sensing of GUS, 4-nitrophenyl b-d-glucuronide and 8-hydroxyquinoline glucuronide are utilized. All these reagents come into action by the hydrolysis reaction followed by the electrochemical activation along with oxidation reaction in anode chamber [41].

Volatile Fatty Acids

Volatile fatty acid contents are exploited to assess the effectiveness of a variety of bioprocesses, including anaerobic digestion [94]. Esters of propionic acid, ethanoate, and butyric acid are the most readily accessible VFAs and hence have a significant impact on bioprocess performance [94]. The development of a simple and inexpensive sensor, such as an MFC, to recognize tiny-chain VFAs would enable its use in this critical bioprocess [95]. However, the use of MFCs as detectors needs the presence of dependable microbiological catalysts in the anolyte. Electricity-inducing polymer and/or carbon composite electrodes were used to increase sensor signal stability with respect to time, reliability, and reaction time to detect changes in acetate, propionate, and butyrate concentrations [96]. Deactivation of negatively charged microbes on the anode carbon-based electrode has been improved by modifying its interface with nanostructured polymeric films such as polypyrole and polyacrylamide [97]. Furthermore, the remodelling of the anodic electrode with these polymers can boost the current output, voltage production, stability, and success rate of the sensor’s response. When compared with fresh electrodes, the greatest accomplishments were gained in sensitivity, stability, and predictability, which was attributable to the use of favorable poly pyrrole functionalization. The presence of these organic compounds in aqueous solutions at concentrations ranging from 0 to 60 mg L−1 can produce the very same indications [98].

MFC-Based Biosensor for BOD Detection

The biological oxygen demand (BOD) of wastewater effluents is used to estimate the short-term influence on receiving water oxygen levels. The decrease of BOD is used to assess the efficacy of wastewater treatment systems. Ordinarily, a testing method is used which takes 5 days (BOD5), and is performed for the estimation of standardized BOD, which is examined by the quantity of the oxygen used by microbes present in the given sample after 5 days of incubating the sample at 20 °C for 120 h [99]. As this approach takes a lot of time and is labor strenuous, it is vital to design an alternate method for monitoring BOD on site that is quick and convenient. Karube et al. [100] presented the utilization of MFC as a BOD sensor for the first time ever. Clostridium butryicum bacteria were grown on the anodic compartment electrode and a linear connection across MFC current output as BOD concentration was deleted, confirming the practicality of the MFC-based biosensors. Following that, different types of MFC-based biosensors were described, as well as the uses of various microorganisms were seen [101, 102] and they used arbiters to encourage exchange of electron from the microbial fuel cell to the cathode, but some of the sensors were shown to be suffering from the insecurity over the operation for longer term.

As a result, Chang et al. [30] demonstrated that a conciliator-free MFC could also be utilized to repeatedly quantify BOD in the wastewater for real-time observation. Furthermore, a biosensor which was based on the MFC was found to be stable for a term of 5 years [103], which was substantially longer than earlier described BOD biosensors which were found to be stable for only 7 to 141 days [104]. This revealed the benefit of MFC-based biosensors throughout lengthy periods of operation. MFC-based biosensors, as opposed to traditional biosensors, directly employ output signals, or the measured current or voltage [105], allowing them to be interpreted and presented in a much easier way. Moreover, because of their potential to self-generate electric power, they may be built and utilized for distant places [106].

Environmental Parameters

Some parameters that probably can affect the functioning of the MFC-based biosensors for BOD monitoring such as conductivity of the electrolyte, temperature, pH [107], and composition of water as well as the feeding rates [30, 108]. Peixoto et al. [107] investigated the outcome of changing environment on biosensor efficiency utilizing the household wastewater by a BOD% of 144 mg/L. When the temperature was raised by 1 °C ranging from 11 to 30 °C, the current density output rose by 66 mA/m2. During this study, changing the conductivity of the electrolyte (i.e., domestic wastewater) had a comparable effect: increasing the conductivity from 1.1 to 7.51 mS/cm increased the current output from 199 to 316 mA/m2. Furthermore, maximal current density (288 mA/m2) was obtained at pH 7.0, but either acidic or alkaline conditions decreased current density (186 mA/m2 at pH 6.0 and 184 mA/m2 at pH 8.0). Chang et al. [30] investigated the impact of anode and cathode feeding rates on sensor performance. The anode was fed man-made wastewater (BOD% of 102.4 mg/L); the current was increased to 5.2 mA as the rate of feeding rose from 0.48 to 1.08 mL/min (the flow rate of cathode was found to be 5 mL/min). The oxygen in the chamber which comprises a cathode was supplied by supplying tap water which was air-saturated. When the cathodic flow rate was found to be 5, 10, and 15 mL/min (the feeding rate of anode was 1.37 mL/min), the maximal current observed was 5.3, 5.7, and 5.9 mA, respectively, suggesting the restriction of electron acceptor (oxygen) at a very high rate of fuel feeding. Furthermore, the influent’s effects with different fuels and some ions that were coexisting on the establishment of valid calibration curves between output signals and BOD content were investigated [108]. Monosaccharides were found to be a superior fuel for power generation than methionine, phenylalanine, and ethanol. This study also discovered that Cu2+, Mn2+, Fe2+ and Zn2+ (below 5 mg/L) had no influence on MFC performance; however, Cr6+ (above 3 mg/L) reduced current density by 5 to 7%.

Upper Limit of Measurement

Not only do operational parameters influence the functioning of MFC-based BOD sensors, but also somehow the upper limit of the linear range is also limited by the capacity of the electrochemically active biofilm [109]. Several attempts have been devoted to raise the top boundary. Modin et al. [32] built a customized membrane-less single-chamber MFC for BOD monitoring (Fig. 2). The supplied voltage provided extra driving power for electron transfer from microbes to the anode, whereas the membrane-less arrangement reduced anolyte pH reduction that could disrupt metabolic activity on the anode. The holding duration was also raised from 5 to 20 h, resulting in an increase in the upper limit of linear range from 320 to 1280 mg/L. Another method for improving the upper boundary was to connect multi-stage MFCs in series [110]. By standardizing the total current output against BOD5 concentrations, the three-stage MFC array increased the linear range (R2 = 0.97) to 720 mg/L at a flow rate of 0.52 mL/min, whereas the single MFC design only had a linear range of 340 mg/L.

Oxygen Diffusion

The current output of a MFC was found to be reduced in the presence of other electron acceptors such as oxygen and nitrate as they were found to be competing with anode for the electrons from biofilm [111]. This effect might be eliminated by using inhibitors of terminal oxidase and nitrate reductase, such as azide and cyanide [112]. They did, although, have “side effects” on cellular metabolism [113, 114], which might interfere with extracellular electron transport. Furthermore, as these compounds are hazardous to mammalian cells, the effluents must be treated before being released into the environment.

MFC-Based Biosensors for Toxicity Detection

Industrial revolution not only enhances the development of our society but also introduces heaps of toxic compounds into the ecosystem [115]. Loads of them are harmful to mankind along with living creatures; hence, detection is mandatory. Orthodox handling includes ex situ chemical examination via physio-chemical techniques, for instance high-pressure liquid chromatography, gas chromatography-mass spectrometry, and liquid chromatography-mass spectrometry [116]. All such procedures require a lot of time; therefore, instantaneous detection is important for bona fide functioning of the biosensors. MFC-based biosensors are conceivably a mindful strategy perhaps of pernicious consequence of the bioaccumulations. The presence of virulent substances can hinder the pursuit of electrogens, hence disturbing the ionic flow induced by MFCs [41]. More toxins lead to the decrement of ionic flow; consequently, several sensors formed the basis of the relation of toxic substances and volume of reduced current [117]. Toxic sensors are basically coming in usage for demonstrating if the flock of toxic substances in the discharge surpasses the utmost permitted magnitude. Hence, finding out the linear order is not the focus here; preferably, detection of pollutants limit is the ultimate goal in toxicity tests. Toxicity biosensors are generally classified into four classes based on the type of target of pollutants, i.e., heavy metals biosensors, antibiotics biosensors, organic toxicants biosensors, and acidic toxicity biosensors.

Heavy Metals

One of the remarkable properties of heavy metals is their long half-life which makes them barely degradable by microorganisms. Heavy metals sometimes cause health issues as they are carried in through the food chain inside the body but are also crucial for maintaining health [118]. Heavy metal particles can hinder respiration process in several microorganisms [119], which leads the ionic outflow of MFCs. Metal ions like Cu2+, Hg2+, Zn2+, Cd2+, Pb2+, and Cr3 + were experimented in a dual-chambered MFC apparatus and their inhibition rate on outflow of ions was observed as 12.56%, 13.99%, 8.81%, 9.29%, 5.29%, and 1.95%, respectively [120]. Xu et al. [121] developed a MFC-based sensor on a flat membrane for improvising the stability and sensitivity of MFC-based biosensors. They tested the system with Cr6+ and Ni2+. They started by reducing voltage from 180 to 40 mV in 40 min by adding 10 mg/L Cr6+; upon adding 20 mg/L of Cr6+, it turned to 50 mV in 6 min. Later, the MFC-based biosensor was tested with 20 mg/L of Ni2+ into the anolyte which results in a slight drop of voltage to 150 from 180 mV in the duration of 180 min. A rapid drop of voltage in the same range values was observed upon the addition of higher concentrations of Ni2+ [120]. Theoretically, heavy metal ions compete with electrons at the anode in the MFC, which in return transfers less negative ions to the other chamber. Under anaerobic conditions, Cr6+-reducing anaerobes reduce Cr6+ to act as terminal electron acceptors [122]. Therefore, the voltage of the cells will reduce with increase in concentration of Cr6+ in Cr6+-reducing anaerobes–based MFC. On this basis, an experiment using Ochrabactrum anthropi YC152 was done, in which the result shows that the biosensor can detect quantification in Cr6+ between the range 0.0125 and 5 mg/L [123]. Furthermore, Wu et al. developed a similar system but by utilizing Exiguobacterium aeutuarii YC211 which ranges 2.5–60 mg/L [124]. A relation between the ions and MFC outflow was shown by Tran et al. [125]. Tran et al. inoculated ion-oxidizing bacteria, i.e., consortia, in the anode to develop an MFC-deployed sensor, and a relation between Fe2+ and ion output was observed in the range of 3–20 mM. Lately, Zhao et al. [126] developed a MFC to scan Cr6+ in industrial wastewater over a range of 0.2–0.7 mg/L, which was the best allowed range by Chinese National Standard. MFC was utilized to detect Cu2+ accumulated on the surface of cathode over a concentration range of 5–160 mg/L [127]. Presently, this research is focused on developing MFC-based sensors which are used to observe the heavy metal ions in tap water [128]. For detecting toxicity in tap water, O2-reducing microbial cathodes were used.

Antibiotics

Antibiotics is a savior for this world. However, improper disposal of antibiotics into the water interferes with the essential progression, causing safety health issues to living beings [129]. So, there is an urgent need to trace and manage them. Nowadays, antibiotics are being detected in wastewater with the help of emerging real-time technology, i.e., MFC. Wu et al. [130] developed a single-compartment MFC with water-based carbon cloth as an anode to detect tobramycin. No effect was detected with concentrations of 0.1, 0.24, and 0.47 g/L, but when the concentration reached 0.93 g/L a notable drop of current was detected. Voltage output was dropped to half after addition of tobramycin. This experiment showed the validity of the MFC-based sensors for antibiotics detection. Furthermore, Schneider et al. [131] developed an approach by \(\beta\)-lactam antibiotics examination by miniaturizing MFC into a cabinet. Escherichia coli strain ATCC 25,922 and Staphylococcus aureus strain ATCC 29,213 with ten non-identical β-lactam antibiotics (penicillin, ampicillin, cefoxitin, ticarcillin, cefazolin, cefuroxime, cefoperazone, cefepime, cefaclor, and imipenem) were tested at individual concentrations ranging from 1 to 75 μg/mL; voltage changes could be measured within 4 h after injecting the cell suspensions in the MFC, whereas Kirby-Bauer disc dissemination requires 24–28 h. Levofloxacin was detected in a single-chamber MFC by sensing up to 1000 μg/L, obtaining a concentration range of 0.1–100 μg/L [132].

Organic Toxicants

Wastewater consists of many toxic compounds like carbons, polyenyls, phosphates, etc., which have adverse effects to the environment [111,112,]. Kim et al. [41] tested the toxicity of diazinon and PCBs in dual-chamber MFC which results in inhibition ratios of 61% and 38%, respectively. Yang et al. [133] developed a one-chambered microsized MFC for observing methanediol in water, which was integrated by a thin-film trap to prevent tiny air bubbles from interfering sensors. When formaldehyde of concentration ranging from 0.001 to 0.1% is introduced into the medium, a decrease in the voltage was observed. A single-unit paper MFC was also developed for detection of organic contaminants in wastewater [79]. In this, carbon-based electrodes were imprinted on a single sheet of paper, while the anode was immerged in fluid and cathode lasted in air itself [134]. The use of vellum here is undisguisable while it acted as a separator between the two electrodes and also as a mediator for mass transferring in the influence of capillary force. In a study, formaldehyde was observed as it was inducing a drop in current output with its addition of 0.1%. Additionally, it was found that two MFCs can be impressed on a single paper which could be connected in parallel. Chen et al. [27] set up a two-compartment MFC by utilizing p-nitrophenol (PNP) as a substrate. The reactor was infused with Pseudomonas montelli LZU by giving aerobic conditions to the anode. Under the optimum conditions, the voltage of cell increased with the increase in PNP concentration, giving the linear relation of maximum voltages and PNP’s concentration range of 16 ± 5 to 44 ± 4.5 mg/L.

Toxicants

Online monitoring of various toxicants from home or industrial wastewaters is essential for the safe cyclic use of water resources. The current generation of chemical detection sensors is complex and expensive to operate. MFCs can offer this issue a minimal maintenance, long-term stable solution. The activity of electrogenic microorganisms in biofilms can be impacted by toxic components, which adds to an abrupt change (either rise or fall) in voltage. MFC-based toxicity biosensors can be categorized into two primary groups: organic matter biosensors and heavy metals biosensors, depending on the type of substrates being monitored. However, since toxin biosensors frequently exhibit overlapping functions and properties, the criteria used to construct this classification are frequently confusing.

Acidic Toxicity

Acidic toxicity in wastewater leads to changes in the pH of the water, which might be responsible for the slow microbial activity in the wastewater. This might affect the self-purification system of water bodies [112]. Shen et al. [135] developed a single-compartment gas-phase cathode MFC and operated in continuous batch mode. The alkalinity was reduced by adding HCl to the influent. When the pH was maintained at 3–4, voltage output also reduced but recuperated by decreasing the HCl, although maintaining the influent’s pH to 2 reflected depletions in the output voltage, which resulted in irreversible damage to the biofilm under low pH. Jiang et al. [136] designed a cathode-comprised MFC sensor series to determine the intoxications. The series was operated in continuous mode. When array reached equilibrium, acidity was increased by anolyte. As the basicity was decreased from 6 to 4, voltage amplitude reduced to 0 from 200 mV. However, this process provides capability to access the pH in liquid phase which was deployed by the difference in cell voltages. It was observed that, along with the acidic toxicity in water, degradation of water bodies because of exalation was also reported. In MFC, nitrogen-fixing bacteria [137] can provide power by mortifying the excretes of rhizo deposits. Li et al. [138] designed a MFC to utilize acidic rain degradation by concentrated sulfuric acid and nitric acid to restore acid rain. Instantaneous voltage drops were obtained within 2 min of stimulated acidic rain sprinkled on greens, which had a better compatibility with the changes in rhizospheric biological concentrations.

Toxicity Sensors

Toxic chemical detection is frequently carried out with the aid of chemical analysis tools like GC, GC–MS, HPLC, and LC–MS. However, they are either unsuitable for on-site real-time monitoring or too expensive. MFC-based sensors can fill the gap by offering a straightforward, quick, accurate, and low-maintenance approach. Biofilms are hindered in their ability by toxic chemicals. The impact of a harmful material is demonstrated using an inhibition rate (I). I can be determined using the subsequent equation:

The current output of the MFC is integrated over time to determine the coulombic yield (CY). The CYs of the MFC reactor supplied with normal wastewater and toxic wastewater, respectively, are CYnor and CYtox. The electrogenic biofilm covering the anode is impeded in its ability to oxidize the organic matter in the effluent when a toxin is present in the effluent to the MFC reactor. Less electrons are captured, and as a result, the biofilm transfers less electrons to the anode. A decrease in the observed current output reflects this. Because the rate of inhibition or the fall in current output is correlated with the concentrations of the harmful compounds, MFC-based toxicity biosensors may therefore be standardized to produce quantitative data.

Using MFC-based sensors to find harmful substances offers numerous benefits over conventional techniques. There are still some issues, though, like the non-specificity of the substances involved and the demand for microorganisms with high enough biological activity. Additionally, their low sensitivity, which requires tuning in terms of control modes and flow configurations, is the principal drawback restricting their utilization.

Microbial Activity Detection

Ancient techniques for detecting microorganisms and phenotyping are assessable but laborious. To overcome the limitations, use of MFCs was preferable and can also be used to store the original data or characteristics of microorganisms [139]. Miller et al. used MFC for detecting arsenate-respiring microbes in soda lakes [140]. One more speculative implementation to utilize MFC to detect microbes in other planets is by presuming that they must retain electrons during in their living [141]. Liu et al. [142] developed a flow-cell MFC for detecting the oxygen less digestor behavior and noticed the voltage changes corresponded to changes in functional restrictions, i.e., pH, airflow, and COD up to straight 6 months. Besides these, Sun et al. [110] also suggested that voltage amplitude of MFC was directly related to ethanoate concentration up to 20 mM and only slight disturbances can be measured from other vaporous fatty acids residing in the anaerobic digestor. These experiments compiled the possibility to design a MFC-based sensor to scan the metabolic yielding rates of organic compounds in an anaerobic digestor. It may be possible to manufacture a MFC-based biosensor for detecting the metabolic yielding rates of natural components in an anaerobic digestor.

Challenges and Future Perspective

MFC-based biosensors rapidly gained attention worldwide as they are a kind of self-powered, as well as eco-friendly, devices using whole cells. A lot of progress has been done in many fields but most of the research is focused on BOD and toxicity detection. However, according to scientific communities, some minor issues need to be addressed before MFC is confirmed as mature sensing technology [143]. First, it is important to check the stability of MFC-based biosensors. Due to the self-renewable nature of bacteria, it is used as a biocatalyst. However, because bacteria may develop quickly in response to environmental changes over time, the biosensor’s sensitivity, selectivity, and reproducibility will be affected in the end [144]. Additionally, screening of bacteria with high extracellular electron transfer is a promising technique for improving this biosensor. Also, to enhance biosensor performance, it is required to construct genetically engineered microorganisms. Electrogenic genes linked to electron transport and metabolic pathways have been discovered, which not only improves the current applications of MFC-based biosensors, but also increases their use for various types of study.

Although numerous studies have been conducted to study the function of MFC-based biosensors in actual effluents, it is critical to investigate the sensorial behavior of MFC in real-world contexts since long-term operation may modify the characteristics of this system. Furthermore, MFC biosensors must be capable of detecting harmful chemicals in a variety of conditions while also providing a reliable output signal [145]. Assessing the mix and dynamic fluctuations of microbial assemblages under diverse substrates is important for mixed cultures, which could lower perceived risk and expedite acceptance of this technology.

Several studies have been conducted to improve the effectiveness of MFC-based biosensors; however, these efforts have primarily concentrated on one section of the reactor. It should be noted that MFC operates as a system, so partial performance may not be significantly affected by other components, and an overall strategy should be used to build an MFC-based biosensor. We believe that microbial biosensors will have a promising and bright future with current breakthroughs in microbial biosensors and progress in modern biotechnology.

Conclusion

Over the past two decades, the development of MFC as an analytical tool has been remarkably rapid. In addition to measuring BOD, it can now also detect toxicity, detect DO, analyze microbiological activity, and act as a power supply for other sensors. It has special benefits in various applications, including straightforward construction, low cost, and in-place monitoring. Commercially available MFC-based biosensors include some. MFC-based biosensors may someday be accepted as standard procedures due to advancements in materials and microbiology, particularly electrogenic bacteria. By electrochemically covering electrodes of BFCs with conducting polymers like PPy or PANI or blends of conducting polymers with chitosan or hydrogels, the biocompatibility problems of the implantable MFCs could be alleviated. By selecting the best chemical and electrochemical settings for efficient electrode modifications to stop inflammatory reactions when in contact with biological tissues, it is simple to manage the various properties of the layers formed.

Data Availability

Not applicable.

Abbreviations

- DO :

-

Dissolved oxygen

- BOD :

-

Biochemical oxygen demand

- COD :

-

Chemical oxygen demand

- AG :

-

Activated graphite

- CB :

-

Carbon brush

- CC :

-

Carbon cloth

- CF :

-

Carbon fiber

- CP :

-

Carbon paper

- CR :

-

Carbon rod

- GF :

-

Graphite felt

- GG :

-

Graphite gravel

- GP :

-

Graphite plate

- GR :

-

Graphite rod

- SPEEK :

-

Sulfonated poly ether ketone

- AC :

-

Activated carbon

- SCE :

-

Saturated calomel electrode

- Pt. :

-

Platinum

- TWWM :

-

Titanium woven wire mesh

- ENIG :

-

Electro less nickel immersion gold

- AEM :

-

Anion exchange membrane

- CEM :

-

Cation exchange membrane

- PEM :

-

Proton exchange membrane

- PF :

-

Porous filter

- SDS :

-

Sodium dodecyl sulfate

- VFA :

-

Volatile fatty acids

- MMFCs :

-

Microfluidic microbial fuel cells

- SAV :

-

Surface area-to-volume

- PDMS :

-

Polydimethylsiloxane

- PTFE :

-

Polytetrafluoroethylene

- GAL :

-

-D-galactosidase

- GUS :

-

B-d-glucuronidase

References

Abbas, S. Z., Wang, J.-Y., Wang, H., Wang, J.-X., Wang, Y.-T., & Yong, Y.-C. (2022). Recent advances in soil microbial fuel cells based self-powered biosensor. Chemosphere, 303, 135036. https://doi.org/10.1016/j.chemosphere.2022.135036

Ahmed, S. F., Mofijur, M., Islam, N., Parisa, T. A., Rafa, N., Bokhari, A., et al. (2022). Insights into the development of microbial fuel cells for generating biohydrogen, bioelectricity, and treating wastewater. Energy, 254, 124163. https://doi.org/10.1016/j.energy.2022.124163

Apollon, W., Luna-Maldonado, A. I., Vidales-Contreras, J. A., Rodríguez-Fuentes, H., Gómez-Leyva, J. F., & Kamaraj, S.-K. (2022). Application of microbial fuel cells and other bioelectrochemical systems: A comparative study. Microbial Fuel Cells: Emerging Trends in Electrochemical Applications. https://doi.org/10.1088/978-0-7503-4791-4ch14

Dwivedi, K. A., Huang, S.-J., Wang, C.-T., & Kumar, S. (2022). Fundamental understanding of microbial fuel cell technology: recent development and challenges. Chemosphere, 288, 132446. https://doi.org/10.1016/j.chemosphere.2021.132446

Imoro, A. Z., Acheampong, N. A., Oware, S., Okrah, H., Coulibaly, V. T., Ali, A. G., et al. (2022). The potential benefits of microbial fuel cells in the context of the sustainable development goals. In: Ahmad, A., Mohamad Ibrahim, M. N., Yaqoob, A. A., Mohd Setapar, S. H., (Eds.), Microbial fuel cells for environmental remediation (pp. 167–82). Springer Nature. https://doi.org/10.1007/978-981-19-2681-5_9.

Massaglia, G., & Quaglio, M. (2022). 3D composite PDMS/MWCNTs aerogel as high-performing anodes in microbial fuel cells. Nanomaterials, 12, 4335. https://doi.org/10.3390/nano12234335

Prathiba, S., Kumar, P. S., & Vo, D.-V.N. (2022). Recent advancements in microbial fuel cells: a review on its electron transfer mechanisms, microbial community, types of substrates and design for bio-electrochemical treatment. Chemosphere, 286, 131856. https://doi.org/10.1016/j.chemosphere.2021.131856

Suganya, P., Divya Navamani, J., Lavanya, A., Mrinal, R. (2022). Design and development of microbial fuel cells based low power energy harvesting mechanism for ecological monitoring and farming of agricultural applications. Journal of Circuits, Systems and Computers 2350112. https://doi.org/10.1142/S0218126623501128

Touqeer, T., Miran, W., Mumtaz, M. W., Mukhtar, H. (2022). Design and configuration of microbial fuel cells. In: Ahmad, A., Mohamad Ibrahim, M. N., Yaqoob, A. A., Mohd Setapar, S. H (Eds), Microbial fuel cells for environmental remediation (pp. 25–39). Springer Nature. https://doi.org/10.1007/978-981-19-2681-5_3

Dharmalingam, S., Kugarajah, V., Elumalai, V. (2022). Chapter 2 - Proton exchange membrane for microbial fuel cells. In: Kaur, G (Ed), PEM Fuel Cells (pp. 25–53). Elsevier. https://doi.org/10.1016/B978-0-12-823708-3.00011-0

Mahmoud, R. H., Gomaa, O. M., & Hassan, R. Y. A. (2022). Bio-electrochemical frameworks governing microbial fuel cell performance: technical bottlenecks and proposed solutions. RSC Advances, 12, 5749–64. https://doi.org/10.1039/D1RA08487A

Li, S., Zhao, Z., Li, B., Wei, T., Jiang, H., & Yan, Z. (2022). Supercapacitors accumulating energy harvesting from stacked sediment microbial fuel cells and boosting input power for power management systems. International Journal of Hydrogen Energy, 47, 10689–10700. https://doi.org/10.1016/j.ijhydene.2021.11.081

Ma, J., Zhang, J., Zhang, Y., Guo, Q., Hu, T., Xiao, H., et al. (2023). Progress on anodic modification materials and future development directions in microbial fuel cells. Journal of Power Sources., 556, 232486. https://doi.org/10.1016/j.jpowsour.2022.232486

Shabangu, K. P., Bakare, B. F., & Bwapwa, J. K. (2022). Microbial fuel cells for electrical energy: Outlook on scaling-up and application possibilities towards South African energy grid. Sustainability, 14, 14268. https://doi.org/10.3390/su142114268

Nishaa, V., Spoorthi, B. V., Soumya, T. B., Meda, U. S., & Desai, V. S. (2022). Powering implantable medical devices with biological fuel cells. ECS Transactions, 107, 19197. https://doi.org/10.1149/10701.19197ecst

Žalnėravičius, R., Paškevičius, A., Samukaitė-Bubnienė, U., Ramanavičius, S., Vilkienė, M., Mockevičienė, I., et al. (2022). Microbial fuel cell based on nitrogen-fixing Rhizobium anhuiense bacteria. Biosensors, 12, 113. https://doi.org/10.3390/bios12020113

Coy-Aceves, L. E., & Corona-Vasquez, B. (2022). Bibliometric analysis of artificial intelligence algorithms used for microbial fuel cell research. Water Practice and Technology, 17, 2071–2082. https://doi.org/10.2166/wpt.2022.116

Dwivedi, K. A., Huang, S.-J., & Wang, C.-T. (2022). Integration of various technology-based approaches for enhancing the performance of microbial fuel cell technology: a review. Chemosphere., 287, 132248. https://doi.org/10.1016/j.chemosphere.2021.132248

Kolajo, O. O., Pandit, C., Thapa, B. S., Pandit, S., Mathuriya, A. S., Gupta, P. K., et al. (2022). Impact of cathode biofouling in microbial fuel cells and mitigation techniques. Biocatalysis and Agricultural Biotechnology, 43, 102408. https://doi.org/10.1016/j.bcab.2022.102408

Moqsud, M. A. (2022). Introduction to microbial fuel cell technology. Microbial Fuel Cells: Emerging Trends in Electrochemical Applications. https://doi.org/10.1088/978-0-7503-4791-4ch1

Ren, Z., Ji, G., Liu, H., Yang, M., Xu, S., Ye, M., et al. (2022). Accelerated start-up and improved performance of wastewater microbial fuel cells in four circuit modes: role of anodic potential. Journal of Power Sources, 535, 231403. https://doi.org/10.1016/j.jpowsour.2022.231403

ul Haque, S., Nasar, A., Duteanu, N., Pandey, S., Inamuddin. (2023). Carbon based-nanomaterials used in biofuel cells – a review. Fuel, 331:125634. https://doi.org/10.1016/j.fuel.2022.125634

ul Haque S, Yasir M, Cosnier S. Recent advancements in the field of flexible/wearable enzyme fuel cells. Biosensors and Bioelectronics 2022;214:114545. https://doi.org/10.1016/j.bios.2022.114545.

Wang, J., He, N., Fei, J., Ma, Z., Ji, Z., Chen, Z., et al. (2022). Flexible and wearable fuel cells: a review of configurations and applications. Journal of Power Sources, 551, 232190. https://doi.org/10.1016/j.jpowsour.2022.232190

You, J., Gajda, I., Greenman, J., & Ieropoulos, I. A. (2022). Integration of cost-efficient carbon electrodes into the development of microbial fuel cells. In F. Borghi, F. Soavi, & P. Milani (Eds.), Nanoporous carbons for soft and flexible energy devices (pp. 43–57). Springer International Publishing. https://doi.org/10.1007/978-3-030-81827-2_3

Shao, Y., Wang, J., Wu, H., Liu, J., Aksay, I. A., & Lin, Y. (2010). Graphene based electrochemical sensors and biosensors: A review. Electroanalysis, 22, 1027–1036. https://doi.org/10.1002/elan.200900571

Chen, Z., Niu, Y., Zhao, S., Khan, A., Ling, Z., Chen, Y., et al. (2016). A novel biosensor for p-nitrophenol based on an aerobic anode microbial fuel cell. Biosensors & Bioelectronics, 85, 860–868. https://doi.org/10.1016/j.bios.2016.06.007

Biofuel cell based on bacteria of the genus - ProQuest n.d. https://www.proquest.com/docview/2158431855 (Accessed 4 Mar 2022).

Yang, G.-X., Sun, Y.-M., Kong, X.-Y., Zhen, F., Li, Y., Li, L.-H., et al. (2013). Factors affecting the performance of a single-chamber microbial fuel cell-type biological oxygen demand sensor. Water Science and Technology, 68, 1914–1919. https://doi.org/10.2166/wst.2013.415

Chang, I. S., Jang, J. K., Gil, G. C., Kim, M., Kim, H. J., Cho, B. W., et al. (2004). Continuous determination of biochemical oxygen demand using microbial fuel cell type biosensor. Biosensors & Bioelectronics, 19, 607–613. https://doi.org/10.1016/s0956-5663(03)00272-0

Ayyaru, S., & Dharmalingam, S. (2014). Enhanced response of microbial fuel cell using sulfonated poly ether ether ketone membrane as a biochemical oxygen demand sensor. Analytica Chimica Acta, 818, 15–22. https://doi.org/10.1016/j.aca.2014.01.059

Modin, O., & Wilén, B.-M. (2012). A novel bioelectrochemical BOD sensor operating with voltage input. Water Research, 46, 6113–6120. https://doi.org/10.1016/j.watres.2012.08.042

Pasternak, G., Greenman, J., & Ieropoulos, I. (2017). Self-powered, autonomous biological oxygen demand biosensor for online water quality monitoring. Sensors and Actuators B: Chemical, 244, 815–822. https://doi.org/10.1016/j.snb.2017.01.019

Di Lorenzo, M., Thomson, A. R., Schneider, K., Cameron, P. J., & Ieropoulos, I. (2014). A small-scale air-cathode microbial fuel cell for on-line monitoring of water quality. Biosensors & Bioelectronics, 62, 182–188. https://doi.org/10.1016/j.bios.2014.06.050

Xu, L., Zhao, Y., Fan, C., Fan, Z., & Zhao, F. (2017). First study to explore the feasibility of applying microbial fuel cells into constructed wetlands for COD monitoring. Bioresource Technology, 243, 846–854. https://doi.org/10.1016/j.biortech.2017.06.179

Kretzschmar, J., Koch, C., Liebetrau, J., Mertig, M., Harnisch, F. (2016). Electroactive biofilms as sensor for volatile fatty acids: cross sensitivity, response dynamics, latency and stability. Sensors and Actuators B: Chemical, 241. https://doi.org/10.1016/j.snb.2016.10.097

Jin, X., Li, X., Zhao, N., Angelidaki, I., & Zhang, Y. (2017). Bio-electrolytic sensor for rapid monitoring of volatile fatty acids in anaerobic digestion process. Water Research, 111, 74–80. https://doi.org/10.1016/j.watres.2016.12.045

Zhang, Y., & Angelidaki, I. (2012). A simple and rapid method for monitoring dissolved oxygen in water with a submersible microbial fuel cell (SBMFC). Biosensors & Bioelectronics, 38, 189–194. https://doi.org/10.1016/j.bios.2012.05.032

Song, N., Yan, Z., Xu, H., Yao, Z., Wang, C., Chen, M., et al. (2019). Development of a sediment microbial fuel cell-based biosensor for simultaneous online monitoring of dissolved oxygen concentrations along various depths in lake water. Science of the Total Environment, 673, 272–280. https://doi.org/10.1016/j.scitotenv.2019.04.032

Zhou, T., Han, H., Liu, P., Xiong, J., Tian, F., & Li, X. (2017). Microbial fuels cell-based biosensor for toxicity detection: A review. Sensors (Basel), 17, 2230. https://doi.org/10.3390/s17102230

Kim, M., Sik Hyun, M., Gadd, G. M., & Joo, K. H. (2007). A novel biomonitoring system using microbial fuel cells. Journal of Environmental Monitoring, 9, 1323–1328. https://doi.org/10.1039/b713114c

(PDF) Microbial Fuel Cell-Based Biosensors n.d. https://www.researchgate.net/publication/334653412_Microbial_Fuel_Cell-Based_Biosensors (Accessed 4 Mar 2022).

Schneider, G., Czeller, M., Rostás, V., & Kovács, T. (2015). Microbial fuel cell-based diagnostic platform to reveal antibacterial effect of beta-lactam antibiotics. Enyzme and Microbial Technology, 73–74, 59–64. https://doi.org/10.1016/j.enzmictec.2015.04.004

Jiang, Y., Liang, P., Liu, P., Wang, D., Miao, B., & Huang, X. (2017). A novel microbial fuel cell sensor with biocathode sensing element. Biosensors & Bioelectronics, 94, 344–350. https://doi.org/10.1016/j.bios.2017.02.052

Zhang, Y., & Angelidaki, I. (2011). Submersible microbial fuel cell sensor for monitoring microbial activity and BOD in groundwater: Focusing on impact of anodic biofilm on sensor applicability. Biotechnology and Bioengineering, 108, 2339–2347. https://doi.org/10.1002/bit.23204

Schmidt-Rohr, K. (2020). Oxygen is the high-energy molecule powering complex multicellular life: Fundamental corrections to traditional bioenergetics. ACS Omega, 5, 2221–2233. https://doi.org/10.1021/acsomega.9b03352

Rewatkar, P., & Goel, S. (2020). 3D printed bioelectrodes for enzymatic biofuel cell: Simple, rapid, optimized and enhanced approach. IEEE Transactions on Nanobioscience, 19, 4–10. https://doi.org/10.1109/TNB.2019.2941196

Khaled, F., Ondel, O., & Allard, B. (2016). Microbial fuel cells as power supply of a low-power temperature sensor. Journal of Power Sources, 306, 354–360. https://doi.org/10.1016/j.jpowsour.2015.12.040

Singh, A., & Yakhmi, J. (2014). Microbial fuel cells – applications for generation of electrical power and beyond. Critical Reviews in Microbiology, 42, 1–17. https://doi.org/10.3109/1040841X.2014.905513

Water quality monitoring in developing countries; can microbial fuel cells be the answer? - PubMed n.d. https://pubmed.ncbi.nlm.nih.gov/26193327/ (Accessed 9 Mar 2022)

Elmekawy, A., Sandipam, S., Vanbroekhoven, K., De Wever, H., & Pant, D. (2014). Bioelectro-catalytic valorization of dark fermentation effluents by acetate oxidizing bacteria in bioelectrochemical system (BES). Journal of Power Sources, 262, 183–191. https://doi.org/10.1016/j.jpowsour.2014.03.111

Di Lorenzo, M., Curtis, T. P., Head, I. M., & Scott, K. (2009). A single-chamber microbial fuel cell as a biosensor for wastewaters. Water Research, 43, 3145–3154. https://doi.org/10.1016/j.watres.2009.01.005

Rabaey, K., & Verstraete, W. (2005). Microbial fuel cells: Novel biotechnology for energy generation. Trends in Biotechnology, 23, 291–298. https://doi.org/10.1016/j.tibtech.2005.04.008

Du, Z., Li, H., & Gu, T. (2007). A state of the art review on microbial fuel cells: A promising technology for wastewater treatment and bioenergy. Biotechnology Advances, 25, 464–482. https://doi.org/10.1016/j.biotechadv.2007.05.004

Perumal, V., & Hashim, U. (2014). Advances in biosensors: Principle, architecture and applications. Journal of Applied Biomedicine, 12, 1–15. https://doi.org/10.1016/j.jab.2013.02.001

Clauwaert, P., Aelterman, P., Pham, T., Schamphelaire, L., Carballa, M., Rabaey, K., et al. (2008). Minimizing losses in bio-electrochemical systems: The road to applications. Applied Microbiology and Biotechnology, 79, 901–913. https://doi.org/10.1007/s00253-008-1522-2

Yaqoob, A. A., Khatoon, A., Mohd Setapar, S. H., Umar, K., Parveen, T., Mohamad Ibrahim, M. N., et al. (2020). Outlook on the role of microbial fuel cells in remediation of environmental pollutants with electricity generation. Catalysts, 10, 819. https://doi.org/10.3390/catal10080819

Kjeang, E., Djilali, N., & Sinton, D. (2009). Microfluidic fuel cells: A review. Journal of Power Sources, 186, 353–369. https://doi.org/10.1016/j.jpowsour.2008.10.011

Ho, B., & Kjeang, E. (2011). Microfluidic fuel cell systems. Open. Engineering, 1, 123–131. https://doi.org/10.2478/s13531-011-0012-y

Safdar, M., Jänis, J., & Sánchez, S. (2016). Microfluidic fuel cells for energy generation. Lab on a Chip, 16, 2754–2758. https://doi.org/10.1039/C6LC90070D

Ren, H., Lee, H. S., & Chae, J. (2012). Miniaturizing microbial fuel cells for potential portable power sources: Promises and challenges. Microfluidics and Nanofluidics, 13, 353–381. https://doi.org/10.1007/s10404-012-0986-7

Micro- and nanoscale fluid mechanics: transport in microfluidic devices. SiloPub 2018. https://silo.pub/micro-and-nanoscale-fluid-mechanics-transport-in-microfluidic-devices.html (Accessed 9 Mar 2022).

Alrifaiy, A., Lindahl, O. A., & Ramser, K. (2012). Polymer-based microfluidic devices for pharmacy, biology and tissue engineering. Polymers, 4, 1349–1398. https://doi.org/10.3390/polym4031349

Weibel, D. B., Diluzio, W. R., & Whitesides, G. M. (2007). Microfabrication meets microbiology. Nature Reviews Microbiology, 5, 209–218. https://doi.org/10.1038/nrmicro1616

Xia, Y., & Whitesides, G. M. (1998). Soft lithography. Angewandte Chemie (International Edition in English), 37, 550–575. https://doi.org/10.1002/(SICI)1521-3773(19980316)37:5%3c550::AID-ANIE550%3e3.0.CO;2-G

Jiang, H., Ali, M. A., Xu, Z., Halverson, L. J., & Dong, L. (2017). Integrated microfluidic flow-through microbial fuel cells. Science and Reports, 7, 41208. https://doi.org/10.1038/srep41208

Chiao, M., Lam, K. B., & Lin, L. (2006). Micromachined microbial and photosynthetic fuel cells. Journal of Micromechanics and Microengineering, 16, 2547–2553. https://doi.org/10.1088/0960-1317/16/12/005

Luo, X., Xie, W., Wang, R., Wu, X., Yu, L., & Qiao, Y. (2018). Fast start-up microfluidic microbial fuel cells with serpentine microchannel. Frontiers in Microbiology, 9, 2816. https://doi.org/10.3389/fmicb.2018.02816

Lim, K. G., & Palmore, G. T. R. (2007). Microfluidic biofuel cells: The influence of electrode diffusion layer on performance. Biosensors & Bioelectronics, 22, 941–947. https://doi.org/10.1016/j.bios.2006.04.019

Wu, R., Ye, D., Chen, R., Zhang, B., Zhu, X., Guo, H. et al. (2019). A membraneless microfluidic fuel cell with continuous multistream flow through cotton threads. International Journal of Energy Research, 44. https://doi.org/10.1002/er.5085

Fraiwan, A., Adusumilli, S. P., Han, D., Steckl, A. J., Call, D. F., Westgate, C. R., et al. (2014). Microbial power-generating capabilities on micro-/nano-structured anodes in micro-sized microbial fuel cells. Fuel Cells, 14, 801–809. https://doi.org/10.1002/fuce.201400041

Amirdehi, M. A., Khodaparastasgarabad, N., Landari, H., Zarabadi, M. P., Miled, A., & Greener, J. (2020). A high performance membraneless microfluidic microbial fuel cell for stable, long-term benchtop operation under strong flow. ChemElectroChem, 7, 2227–2235. https://doi.org/10.1002/celc.202000040

Saadi, M., Pezard, J., Haddour, N., Erouel, M., Vogel, T., Khirouni, K. (2020). Stainless steel coated with carbon nanofiber/PDMS composite as anodes in microbial fuel cells. Materials Research Express, 7. https://doi.org/10.1088/2053-1591/ab6c99.

Togo, M., Takamura, A., Asai, T., Kaji, H., & Nishizawa, M. (2007). An enzyme-based microfluidic biofuel cell using vitamin K3-mediated glucose oxidation. Electrochimica Acta, 52, 4669–4674. https://doi.org/10.1016/j.electacta.2007.01.067

Déctor, A., Dector, D., Moreno, A., On-Torres, S., An-Valencia, M., Arriaga, L. G., et al. (2016). Glucose microfluidic fuel cell using air as oxidant. International Journal of Hydrogen Energy, 41, 23394–23400. https://doi.org/10.1016/j.ijhydene.2016.04.238

Ammam, M., & Fransaer, J. (2012). Glucose/O2 biofuel cell based on enzymes, redox mediators, and multiple-walled carbon nanotubes deposited by AC-electrophoresis then stabilized by electropolymerized polypyrrole. Biotechnology and Bioengineering, 109, 1601–1609. https://doi.org/10.1002/bit.24438

Arjun, A. M., Vimal, M., & Sandhyarani, N. (2019). A hybrid hydrogel separated biofuel cell with a novel enzymatic anode and glucose tolerant cathode. International Journal of Hydrogen Energy, 44, 27056–27066. https://doi.org/10.1016/j.ijhydene.2019.08.131

Selloum, D., Tingry, S., Techer, V., Renaud, L., Innocent, C., & Zouaoui, A. (2014). Optimized electrode arrangement and activation of bioelectrodes activity by carbon nanoparticles for efficient ethanol microfluidic biofuel cells. Journal of Power Sources, 269, 834–840. https://doi.org/10.1016/j.jpowsour.2014.07.052

Tang, J., Yan, X., Engelbrekt, C., Ulstrup, J., Magner, E., Xiao, X., et al. (2020). Development of graphene-based enzymatic biofuel cells: a minireview. Bioelectrochemistry., 134, 107537. https://doi.org/10.1016/j.bioelechem.2020.107537

Li, X., Li, D., Zhang, Y., Lv, P., Feng, Q., & Wei, Q. (2020). Encapsulation of enzyme by metal-organic framework for single-enzymatic biofuel cell-based self-powered biosensor. Nano Energy, 68, 104308. https://doi.org/10.1016/j.nanoen.2019.104308

Desmaële, D., Nguyen-Boisse, T. T., Renaud, L., & Tingry, S. (2016). Integration of cantilevered porous electrodes into microfluidic co-laminar enzymatic biofuel cells: Toward higher enzyme loadings for enhanced performance. Microelectronic Engineering, 165, 23–26. https://doi.org/10.1016/j.mee.2016.08.008

Escalona-Villalpando, R. A., Reid, R. C., Milton, R. D., Arriaga, L. G., Minteer, S. D., & Ledesma-García, J. (2017). Improving the performance of lactate/oxygen biofuel cells using a microfluidic design. Journal of Power Sources, 342, 546–552. https://doi.org/10.1016/j.jpowsour.2016.12.082

Pramanik, H., & Rathoure, A. K. (2017). Electrooxidation study of NaBH4 in a membraneless microfluidic fuel cell with air breathing cathode for portable power application. International Journal of Hydrogen Energy, 8, 5340–5350. https://doi.org/10.1016/j.ijhydene.2016.11.143

Ji, J., Ro, S., & Kwon, Y. (2020). Membraneless biofuel cells using new cathodic catalyst including hemin bonded with amine functionalized carbon nanotube and glucose oxidase sandwiched by poly(dimethyl-diallylammonium chloride). Journal of Industrial and Engineering Chemistry, 87, 242–249. https://doi.org/10.1016/j.jiec.2020.04.010

Togo, M., Takamura, A., Asai, T., Kaji, H., & Nishizawa, M. (2008). Structural studies of enzyme-based microfluidic biofuel cells. Journal of Power Sources, 178, 53–58. https://doi.org/10.1016/j.jpowsour.2007.12.052

Siu, C.-P.-B., & Chiao, M. (2009). A microfabricated PDMS microbial fuel cell. Journal of Microelectromechanical Systems, 17, 1329–41. https://doi.org/10.1109/JMEMS.2008.2006816

Banerjee, R., Jeevan Kumar, P., Mehendale, N., Sevda, S., & Garlapati, V. K. (2019). Intervention of microfluidics in biofuel and bioenergy sectors: technological considerations and future prospects. Renewable and Sustainable Energy Reviews, 101, 548–58. https://doi.org/10.1016/j.rser.2018.11.040

Kulkarni, T., & Slaughter, G. (2015). Enzymatic glucose biofuel cell and its application. Journal of Biochips & Tissue Chips, 5, 1000111. https://doi.org/10.4172/21530777.1000111

Luz, R. A. S., Pereira, A. R., de Souza, J. C. P., Sales, F. C. P. F., & Crespilho, F. N. (2014). Enzyme biofuel cells: Thermodynamics, kinetics and challenges in applicability. ChemElectroChem, 1, 1751–1777. https://doi.org/10.1002/celc.201402141

Zebda, A., Innocent, C., Renaud, L., Cretin, M., Pichot, F., Ferrigno. R, et al. (2011). Enzyme-based microfluidic biofuel cell to generate micropower. IntechOpen. https://doi.org/10.5772/17190.

Miyake, T., Oike, M., Yoshino, S., Yatagawa, Y., Haneda, K., & Nishizawa, M. (2010). Automatic, sequential power generation for prolonging the net lifetime of a miniature biofuel cell stack. Lab on a Chip, 10, 2574–2578. https://doi.org/10.1039/C004322B

Zebda, A., Renaud, L., Cretin, M., Innocent, C., Ferrigno, R., & Tingry, S. (2010). Membraneless microchannel glucose biofuel cell with improved electrical performances. Sensors and Actuators B: Chemical, 149, 44–50. https://doi.org/10.1016/j.snb.2010.06.032

Kim, T., & Han, J.-I. (2013). Fast detection and quantification of Escherichia coli using the base principle of the microbial fuel cell. Journal of Environmental Management, 130, 267–275. https://doi.org/10.1016/j.jenvman.2013.08.051

Patel, A., Mahboubi, A., Horváth, I. S., Taherzadeh, M. J., Rova, U., Christakopoulos, P, et al. (2021). Volatile fatty acids (VFAs) generated by anaerobic digestion serve as feedstock for freshwater and marine oleaginous microorganisms to produce biodiesel and added-value compounds. Frontiers in Microbiology, 12.

Nieto-Taype, M. A., Garcia-Ortega, X., Albiol, J., Montesinos-Seguí, J. L., Valero, F. (2020). Continuous cultivation as a tool toward the rational bioprocess development with Pichia pastoris cell factory. Frontiers in Bioengineering and Biotechnology, 8.

Understanding Graphene Batteries. AZoNanoCom 2016. https://www.azonano.com/article.aspx?ArticleID=4326 (Accessed 10 Mar 2022).

Kaur, A., Ibrahim, S., Pickett, C., Michie, I., Dinsdale, R., Guwy, A., et al. (2014). Anode modification to improve the performance of a microbial fuel cell volatile fatty acid biosensor. Sensors and Actuators B: Chemical, 201, 266–273. https://doi.org/10.1016/j.snb.2014.04.062

Jiang, Y., Liang, P., Liu, P.-P., Miao, B., Bian, Y., Zhang, H. (2017). Enhancement of the sensitivity of microbial fuel cell sensor by transient-state operation. Environmental Science: Water Research & Technology, 3. https://doi.org/10.1039/C6EW00346J.

Nagel, B., Dellweg, H., & Gierasch, L. M. (1992). Glossary for chemists of terms used in biotechnology (IUPAC Recommendations 1992). Pure and Applied Chemistry, 64, 143–168. https://doi.org/10.1351/pac199264010143

Karube, I., Matsunaga, T., Mitsuda, S., & Suzuki, S. (1977). Microbial electrode BOD sensors. Biotechnology and Bioengineering, 19, 1535–1547. https://doi.org/10.1002/bit.260191010

Yang, Z., Suzuki, H., Sasaki, S., & Karube, I. (1996). Disposable sensor for biochemical oxygen demand. Applied Microbiology and Biotechnology, 46, 10–14. https://doi.org/10.1007/s002530050776

Tan, T. C., Li, F., Neoh, K. G., & Lee, Y. K. (1992). Microbial membrane-modified dissolved oxygen probe for rapid biochemical oxygen demand measurement. Sensors and Actuators B: Chemical, 8, 167–172. https://doi.org/10.1016/0925-4005(92)80175-W

Kim, B. H., Chang, I. S., Cheol Gil, G., Park, H. S., & Kim, H. J. (2003). Novel BOD (biological oxygen demand) sensor using mediator-less microbial fuel cell. Biotechnology Letters, 25, 541–545. https://doi.org/10.1023/A:1022891231369

Liu, J., & Mattiasson, B. (2002). Microbial BOD sensors for wastewater analysis. Water Research, 36, 3786–3802. https://doi.org/10.1016/s0043-1354(02)00101-x

Feng, Y., Barr, W., & Harper, W. F. (2013). Neural network processing of microbial fuel cell signals for the identification of chemicals present in water. Journal of Environmental Management, 120, 84–92. https://doi.org/10.1016/j.jenvman.2013.01.018

Melhuish, C., Ieropoulos, I., Greenman, J., & Horsfield, I. (2006). Energetically autonomous robots: Food for thought. Autonomous Robots, 21, 187–198. https://doi.org/10.1007/s10514-006-6574-5

Peixoto, L., Min, B., Martins, G., Brito, A. G., Kroff, P., Parpot, P., et al. (2011). In situ microbial fuel cell-based biosensor for organic carbon. Bioelectrochemistry, 81, 99–103. https://doi.org/10.1016/j.bioelechem.2011.02.002

Hsieh, M.-C., Cheng, C.-Y., Liu, M.-H., & Chung, Y.-C. (2015). Effects of operating parameters on measurements of biochemical oxygen demand using a mediatorless microbial fuel cell biosensor. Sensors (Basel), 16, 35. https://doi.org/10.3390/s16010035

Torres, C. I., Marcus, A. K., Parameswaran, P., & Rittmann, B. E. (2008). Kinetic experiments for evaluating the Nernst-Monod model for anode-respiring bacteria (ARB) in a biofilm anode. Environmental Science and Technology, 42, 6593–6597. https://doi.org/10.1021/es800970w

Tardy, G., Lóránt, B., Gyalai-Korpos, M., Bakos, V., Simpson, D., & Goryanin, I. (2021). Microbial fuel cell biosensor for the determination of biochemical oxygen demand of wastewater samples containing readily and slowly biodegradable organics. Biotechnology Letters, 43, 1–10. https://doi.org/10.1007/s10529-020-03050-5

Kim, B. H., Park, H. S., Kim, H. J., Kim, G. T., Chang, I. S., Lee, J., et al. (2004). Enrichment of microbial community generating electricity using a fuel-cell-type electrochemical cell. Applied Microbiology and Biotechnology, 63, 672–681. https://doi.org/10.1007/s00253-003-1412-6

Sun, J., Kingori, G., Si, R., Zhai, D.-D., Liao, Z.-H., Sun, D.-Z., et al. (2015). Microbial fuel cell-based biosensors for environmental monitoring: A review. Water Science and Technology, 71, 801–809. https://doi.org/10.2166/wst.2015.035

Bowler, M. W., Montgomery, M. G., Leslie, A. G. W., & Walker, J. E. (2006). How azide inhibits ATP hydrolysis by the F-ATPases. Proceedings of the National Academy of Sciences U.S.A, 103, 8646–8649. https://doi.org/10.1073/pnas.0602915103

Harvey, J., Hardy, S. C., & Ashford, M. L. (1999). Dual actions of the metabolic inhibitor, sodium azide on K(ATP) channel currents in the rat CRI-G1 insulinoma cell line. British Journal of Pharmacology, 126, 51–60. https://doi.org/10.1038/sj.bjp.0702267

Petrie, B., Barden, R., & Kasprzyk-Hordern, B. (2015). A review on emerging contaminants in wastewaters and the environment: Current knowledge, understudied areas and recommendations for future monitoring. Water Research, 72, 3–27. https://doi.org/10.1016/j.watres.2014.08.053

Choi, S. H., & Gu, M. B. (2003). Toxicity biomonitoring of degradation byproducts using freeze-dried recombinant bioluminescent bacteria. Analytica Chimica Acta, 481, 229–238. https://doi.org/10.1016/S0003-2670(03)00091-6

Yang, H., Zhou, M., Liu, M., Yang, W., & Gu, T. (2015). Microbial fuel cells for biosensor applications. Biotechnology Letters, 37, 2357–2364. https://doi.org/10.1007/s10529-015-1929-7

Tchounwou, P. B., Yedjou, C. G., Patlolla, A. K., & Sutton, D. J. (2012). Heavy metal toxicity and the environment. Experientia Supplementum, 101, 133–164. https://doi.org/10.1007/978-3-7643-8340-4_6

Giller, K. E., Witter, E., & Mcgrath, S. P. (1998). Toxicity of heavy metals to microorganisms and microbial processes in agricultural soils: A review. Soil Biology and Biochemistry, 30, 1389–1414. https://doi.org/10.1016/S0038-0717(97)00270-8

Yu, D., Bai, L., Zhai, J., Wang, Y., & Dong, S. (2017). Toxicity detection in water containing heavy metal ions with a self-powered microbial fuel cell-based biosensor. Talanta, 168, 210–216. https://doi.org/10.1016/j.talanta.2017.03.048

Xu, Z., Liu, B., Dong, Q., Lei, Y., Li, Y., Ren, J., et al. (2015). Flat microliter membrane-based microbial fuel cell as “on-line sticker sensor” for self-supported in situ monitoring of wastewater shocks. Bioresource Technology, 197, 244–251. https://doi.org/10.1016/j.biortech.2015.08.081

Cheung, K. H., & Gu, J.-D. (2007). Mechanism of hexavalent chromium detoxification by microorganisms and bioremediation application potential: A review. International Biodeterioration & Biodegradation, 59, 8–15. https://doi.org/10.1016/j.ibiod.2006.05.002

Wang, G.-H., Cheng, C.-Y., Liu, M.-H., Chen, T.-Y., Hsieh, M.-C., & Chung, Y.-C. (2016). Utility of Ochrobactrum anthropi YC152 in a microbial fuel cell as an early warning device for hexavalent chromium determination. Sensors (Basel), 16, E1272. https://doi.org/10.3390/s16081272

Wu, L.-C., Tsai, T.-H., Liu, M.-H., Kuo, J.-L., Chang, Y.-C., & Chung, Y.-C. (2017). A green microbial fuel cell-based biosensor for in situ chromium (VI) measurement in electroplating wastewater. Sensors (Basel), 17, E2461. https://doi.org/10.3390/s17112461

Tran, P. H. N., Luong, T. T. T., Nguyen, T. T. T., Nguyen, H. Q., Duong, H. V., Kim, B. H., et al. (2015). Possibility of using a lithotrophic iron-oxidizing microbial fuel cell as a biosensor for detecting iron and manganese in water samples. Environmental Science: Processes & Impacts, 17, 1806–1815. https://doi.org/10.1039/C5EM00099H

Zhao, S., Liu, P., Niu, Y., Chen, Z., Khan, A., Zhang, P., et al. (2018). A novel early warning system based on a sediment microbial fuel cell for in situ and real time hexavalent chromium detection in industrial wastewater. Sensors, 18, 642. https://doi.org/10.3390/s18020642

Wu, S., Han, C., Liu, L., Zhong, W. (2018). A novel sediment microbial fuel cell based sensor for on-line and in situ monitoring copper shock in water. Electroanalysis, 30. https://doi.org/10.1002/elan.201800424

Prévoteau, A., Clauwaert, P., Kerckhof, F.-M., & Rabaey, K. (2019). Oxygen-reducing microbial cathodes monitoring toxic shocks in tap water. Biosensors and Bioelectronics, 132, 115–121. https://doi.org/10.1016/j.bios.2019.02.037

Kraemer, S. A., Ramachandran, A., & Perron, G. G. (2019). Antibiotic pollution in the environment: From microbial ecology to public policy. Microorganisms, 7, 180. https://doi.org/10.3390/microorganisms7060180

Wu, W., Lesnik, K. L., Xu, S., Wang, L., & Liu, H. (2014). Impact of tobramycin on the performance of microbial fuel cell. Microbial Cell Factories, 13, 91. https://doi.org/10.1186/s12934-014-0091-6

Chouler, J., & Di Lorenzo, M. (2015). Water quality monitoring in developing countries; can microbial fuel cells be the answer? Biosensors (Basel), 5, 450–470. https://doi.org/10.3390/bios5030450