Abstract

This study assesses the performance of untreated and resin-modified beech-wood (Fagus sylvatica L.) during outdoor weathering. Boards modified with thermosetting N-methylol melamine (NMM) and phenol–formaldehyde (PF) resins, which were partly dye stained, were coated solely with a waterborne acrylic binder and formulations containing the same binder with different types and contents of photo-protective additives. Most modifications of the wood substrate changed the original color of wood, except for sole NMM modification. Changes in mass and capillary water uptake during exposure of modified, uncoated and coated boards were less than those of respective controls. Surface defects and cracks were clearly fewer on modified wood than on the controls, but no clear difference was observed among the topcoats containing UV-protective agents (UV-PA). The color stability during outside weathering depended on the treatment and coating formulation. Untreated and NMM-modified boards became grayer, and the NMM-dye-modified boards turned to a lighter gray, while PF-modified boards adopted a darker, blackish color. The weathered coating on the modified boards, particularly with PF resin, showed less blistering, flaking, and cracking than that on the controls. UV-PA stabilized the color and adhesion on all boards compared to the sole binder formulation. We conclude that wood modification with NMM and PF resin improves the natural weathering performance of wood coated with acrylic coatings. Combination of modification with staining enables diversification of the optical appearance.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Today, modern designing which uses wood products of long service life is becoming increasingly popular. For exterior applications, enhanced wood resistance to weathering and fungal decay is necessary. The traditional methods to slow down outdoor degradation processes and to prolong the service life of wood focus on preventive preservative treatments and coating application. Environmental concerns associated with the use of conventional preservatives, however, have drawn the attention to wood modification approaches, which alter various material properties.1 A variety of modification methods (thermal, surface, chemical, impregnation) exist and have shown good potential in reducing water absorption, increasing biological resistance, and enhancing weathering performance of wood.2 Lignin strongly absorbs ultra-violet (UV) light due to the high susceptibility of the phenolic sides leading to photo-oxidation. UV light also photo-oxidizes cellulose and hemicelluloses and causes reductions in molecular weight but to a lower extent than in the case of lignin. The photo-degraded wood surface is a good substrate for bacteria and fungi, including staining fungi; the light color of the photo-degraded wood surface and the black color of fungal hyphae make up the majority of the gray surface of outdoor weathered wood.3,4

Chemical modification (e.g., with linear anhydrides and aldehydes) and impregnation modification (e.g., with furfuryl alcohol, 1,3-dimethylol-4,5-dihydroxyethylene urea (DMDHEU), phenolic or melamine resins) enhances the outdoor performance of wood during service life.2 Modification with N-methylol melamine (NMM) resins considerably improves the material properties of wood by reducing the water uptake and increasing dimensional stability, hardness, resistance to weathering, and color stability as well as decay resistance.5–10 Formulations of NMM resins penetrate and polymerize in the cell wall resulting in cell wall bulking,5 but a major proportion of the resin also remains located in the cell lumens after modification.11 The resin is fixed in the wood by formation of a 3-dimensional NMM network rather than by covalent bonding to the wood matrix.7 Impregnation modification with low molecular weight phenol–formaldehyde (PF) resin proceeds in a comparable way, but PF penetrates the cell wall to a greater extent and thus causes greater cell wall bulking than NMM resin.12 Modification with PF improves the hardness, dimensional stability, decay resistance, and weathering performance of wood.13,14 PF resins are considered to be strong absorbers of UV light; PF modification of pine wood has induced a better performance of transparent (clear) finishes during exposure to accelerated weathering than unmodified, coated controls.14 Recent studies reported the combined staining of wood with thermosetting resin and a metal-complex dye to enhance the esthetic quality of the whole beech substrate.11,15–18 UV-microspectrophotometry and X-ray microanalysis revealed that condensation of NMM causes fixation of the water-soluble dye in the wood cell wall.16 In many applications, wood surfaces are protected from weathering by transparent or translucent coatings which leave the natural texture of wood visible. These coatings themselves need to be protected against external factors summarized as weathering conditions.19 Light stabilizers, such as UV absorbers (UVA) and hindered amine light stabilizers (HALS), are state-of-the-art for the inherent protection of the coating, and their respective roles have been widely described.20–22 For exterior applications, there is a clear advantage to combining both UVA and HALS. UV absorbers in coating layers increase UV absorbance upon increasing coating thickness (Beer–Lambert’s law). HALS, which are effective in the whole film thickness, act as free radical scavengers that quench photo-induced radicals which occur within the binder matrix and help to maintain their original properties (i.e., flexibility, gloss, water repellency).23 In addition, special HALS products are applied as primers directly on the wood surface. These act as scavengers of lignin radicals (or other wood-derived radicals) and protect the interface between wood and coating.22 The aim of the present study is to investigate the effect of wood modification with thermosetting resins (NMM, PF) combined with an organic dye on natural weathering performances of uncoated and transparently coated beech-wood.

Materials and methods

Wood specimens and chemicals

Beech-wood boards (Fagus sylvatica L.) measuring 78 ± 3 × 20 ± 2 × 375 ± 2 (longitudinal) mm3 were quartersawn with approximately 45° annual ring orientation according to the standard EN 927-3.24 The mean density of the samples was 685 kg m−3 at 12% moisture content. The specimens were oven dried at 103 ± 2°C for 48 h and weighed. The heating was performed very carefully with a temperature regime of 20, 40, 60, 80, 100°C (24 h each), and 103°C (48 h) in a drying oven. Prior to chemical modification, the dried wood specimens were conditioned at 20 ± 1°C and 65 ± 5% relative humidity (RH). The NMM resin Madurit MW840/75WA (Ineos Melamines GmbH, Frankfurt, Germany) is an aqueous formulation with approx. 75% solid content, 1.245–1.260 g mL−1 density at 23°C, 430 mPa s dynamic viscosity, and pH of 9.3 (all values at 25°C). The low molecular weight phenol formaldehyde (PF) resin Phenoplastharz P554 (Surfactor GmbH, Schöppenstedt, Germany) is an aqueous formulation with approx. 59% solid content, 1.15–1.25 g cm−3 density, and pH of 8.4–8.8 (all values at 23°C). The metal-complex dye Basantol® Brown 269 liquid (BS) (BASF SE, Ludwigshafen, Germany) is an aqueous formulation with 30% solid content, 1.15 g cm−3 density, and pH of 7.0–7.5. The following coating components were obtained from BASF SE (Ludwigshafen, Germany). The waterborne binder formulation Acronal® LR 9014 (topcoat 1) is an aqueous anionic dispersion of a copolymer of 2-ethylhexyl acrylate and methyl methacrylate with approx. 33% solid content, 1.04 g cm−3 density at 23°C, 100–400 mPa s dynamic viscosity, and pH of 7.5–8.5. The topcoats 2 and 3 also contained the binder Acronal® LR 9014 and additional light stabilizer blends. Topcoat 2 was a mixture of Acronal® LR 9014 and Tinuvin® 5333-DW; the latter contains UV absorbers (UVA) and a hindered amine light stabilizer (HALS). Topcoat 3 was a mixture of Acronal® LR 9014, Tinuvin® 5333-DW and CGL 378-DW; this blend of light stabilizers contains UVA, HALS, and iron oxides.

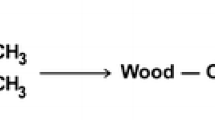

Modification of wood

The wood boards were modified with 25% (wt/wt) aqueous solutions of NMM and PF as well as with respective resins solutions containing 1.5% (final concentration) dye (BS) as described previously.25 The conditioned specimens were impregnated (20°C) using a vacuum pressure process at 5 kPa (1 h) and 1200 kPa (2 h). Drying and curing included 72 h air drying followed by continuous temperature increases 30, 40, 60, 80, 100°C (24 h each), 120°C (48 h), and 103°C (24 h). Solution uptakes (SU) after impregnation and the weight percent gain (WPG) after modification were related to the dry mass of untreated beech-wood (Table 2). Untreated wood boards served as control specimens.

Coating application

Prior to coating, all samples were conditioned at 20°C and 65% RH for 2 weeks and sanded with a 240 grid paper and subsequently a 400 grid paper. All specimens were coated on one side with Acronal® LR 9014 as primer on the sanded surfaces (all other sides were left uncoated) using a spay gun with a nozzle tip of 1.0 mm at 2 bar. Then, three topcoat formulations were, respectively, applied twice in the same manner. The amount of the freshly applied coating was calculated by weighing the sample before and after each spray application. After each coating step, the finishes were dried at 25 ± 1°C. The thickness of the cured coating was determined as described previously.25 The topcoat formulations are depicted in Table 1.

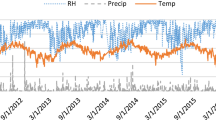

Natural weathering

Natural weathering was performed according to the European standard 927-3.24 Three specimens were exposed per treatment; one served as reference sample. The edges were sealed with a commercial sealant (Sikkens Rubbol Gold Plus, Akzo Nobel Decorative Paints, Köln, Germany) to reduce water uptake on side and end grain. Afterward, they were placed on weathering racks in the test field of the Georg-August University (latitude 51.559957°N, longitude 9.956736°E), Göttingen (Germany) for 32 months (January 2012 to August 2014); untreated specimens served as a control. The exposure area pointed to south-west and was tilted 45° horizontally.

Surface evaluation

About every 3 months, after each weathering cycle, the mass of the boards was determined, and these were conditioned (20°C and 65% relative humidity (RH) for 1 week) but the equilibrium moisture content (EMC) was not achieved. The mass change of the boards was calculated as the weight difference of the samples [%] before weathering and after each weathering cycle.

The degradation of the boards’ surfaces and coating formulations, respectively, was evaluated and ranked with regard to defects and cracking according to DIN ISO standards.26,27 The evaluation scale for cracks ranged from 0 to 5 (CR = 0: no cracks and CR = 5: dense pattern of cracks) and for defects from 0 to 5 (DR = 0: no damage and DR = 5: dense pattern of damage). Afterward, the boards were scanned to record their surface appearance.

After each weathering period, water uptake of the beech samples was determined according to a DIN standard,28 over a period of 24 h. Prior to and after the water uptake test, all specimens were conditioned at 20°C and 65% RH for 1 week.

Optical appearance

The surfaces were scanned (Epson Expression 11000XL with the program Silver Fast 8.2, LaserSoft Imaging AG, Kiel, Germany) and assessed by using the CIE-L*a*b system according to an ASTM standard.29 Non-weathered data served as reference. The parameters L*, a*, and b* represent the lightness, as well as the components of green/red, and blue/yellow. The color difference ∆E was calculated according to30

where ∆E is the color distance (difference), L represents lightness, a represents the red/green opponent colors, and b represents yellow/blue opponent colors.

Results and discussion

Weight percent gain and solution uptake

The beech-wood boards were easily treatable with the different resin formulations (Table 2) as described previously.25 All treatments resulted in similar solution uptake but the PF-modified specimens attained a higher weight percent gain (WPG) than those modified with NMM resin.

Coatability of wood

All acrylic coatings (topcoat 1–3) could be easily applied by spraying on the beech-wood boards. There were differences in coatability between the NMM and PF resins, respectively, dye treated, and untreated specimens as reported previously.25 The drying time of the three topcoat formulations based on binder (Acronal® LR 9014) and the different photo-protective additives was longer on the modified wood than on the untreated beech-wood.25

Natural weathering

Mass changes

All boards were exposed to outdoor weathering over 32 months and the mass changes due to water sorption were recorded (Fig. 1). It should be borne in mind that the specimens were not fully conditioned to EMC after the exposure and the subsequent water uptake test. Therefore, the mass changes are only indications for the water sorption due to weathering. Unmodified boards exhibited greater mass changes than the respective modified specimens. The coating formulations reduced the mass changes of unmodified and modified specimens compared to the uncoated boards. The PF-treated (with and without dye) boards (Fig. 1) exhibited lower amounts of water sorption and minor mass changes than NMM-treated specimens and the unmodified boards. This might be attributed to the lower level of vapor sorption and capillary water uptake of PF-treated wood.11,31 As resin modification enhances dimensional stability of the wood substrate, it might protect the wood and the coating from (micro) cracking. After cracking of the coating, resins in the wood reduce capillary water uptake and dimensional changes. Resins might maintain the adhesion between the wood surface and the binder in the coating.32 Reduction in moisture sorption due to modification can be attributed to the deposition of NMM and PF resins in the cell wall which occupy the available sorption sites. The mass change of untreated boards coated with the sole binder (topcoat 1, Fig. 1b) were slightly greater than those of boards coated with the binder and photo-protective additives (topcoat 2 and 3, Figs. 1c and 1d), especially after longer exposure. This might be attributed to the degradation of the sole binder through UV light resulting in increased penetration of liquid water and vapor into the wood substrate.33–35

Formation of defects and cracks

The surface of all weathered boards were optically evaluated and ranked from 1 (no defects/cracks) to 5 (complete failure) every 3 months over 32 months (Table 3). The degree of surface deterioration depended on the type of modification and on the coating formulation. None of the resin-modified and coated boards showed any obvious change in the surface appearance after outdoor weathering. In contrast, unmodified, sole binder-coated (topcoat 1) boards showed surface deterioration (cracking) to a certain extent. Wood surface cracking of uncoated boards was observed with the controls (Fig. 3f) and NMM-(dye)-modified boards (Figs. 3g and 3i), while PF-(dye)-modified specimens exhibited considerably less cracks (Figs. 3h and 3j); (Table 3). The same trends were found with solely binder-coated (topcoat 1) boards (Figs. 3k–3o), where the thermosetting resin-(dye)-modified specimens displayed the lowest degree of cracking and flaking of the coating. Specimens containing UV-protective agents in the coating formulations showed a very low degree of cracking and flaking for all wood substrates (Figs. 3p–3y).

Water uptake in course of weathering

All boards were subjected to water uptake tests (24 h) after each weathering cycle (every 3 months). The capillary water uptake of coated boards was clearly lower than that of the corresponding uncoated samples (Fig. 2); modified coated specimens showed lower water uptake than the coated controls (Figs. 2b–2d). In the case of the coated untreated boards, the water uptake ranged between approximately 10–40% compared to boards treated with NMM resin (4–10%) or with PF resin (2–6%). Control boards coated with the topcoats 2 and 3 (UVA/HALS) exhibited low water uptake which indicates formation of few cracks on the surface (Figs. 2c and 2d) and corresponds to the results of optical evaluation (Table 3). The water uptake of the controls coated with topcoat 1 (just binder, Fig. 2b) increased over time more than that of the uncoated controls (Fig. 2a). This is explained by a failure of topcoat 1 at early stage of exposure and may be attributed to degradation of the wood surface at the interface to the coating film by UV light.33–35 An additional explanation could be the presence of residual surfactants from the coating and consequently accelerated sorption of water. Degradation of the wood surface leads to reduced adhesion of the coating and enables accelerated capillary water uptake. As a consequence, the wood surface undergoes enhanced swelling, which results in the formation of cracks in the coating and on the wood surface. With respect to both coated and uncoated boards, the modifications with NMM and PF resin reduced the water uptake significantly. The reduction is attributed not only to the higher weight of the modified boards but also to a generally lower capillary water uptake, less surface erosion, and higher dimensional stability of the resin-treated specimens which results in the formation of less cracks in the wood and the coatings.25,36

Water uptake during natural weathering of untreated, resin-modified and resin-dye-modified beech-wood determined according to DIN 52617 (1987): (a) uncoated; (b) topcoat 1 (sole binder); (c) topcoat 2 (binder + 3% UV-PA, [protective agents]); (d) topcoat 3 (binder + 3% UV-PA + 1.5 UV-PA); mean values of 3 replicates ± SD

Color change

The coloration of the boards prior to weathering depended on the type of chemical modification and the applied binder formulation (Fig. 3). Only topcoat 3 (containing iron oxide) exhibited a minor brownish color compared to the transparent topcoats 1 and 2. NMM modification caused a slight color change compared to the beech controls, while PF modification made the boards more brownish. Dye-resin treatment changed the color toward dark brown with PF-dye being darker than NMM-dye. The color of the uncoated controls, NMM-modified and the NMM-dye-modified boards became grayish during natural weathering (Figs. 3f, 3g, and 3i). Graying of the wood surface during natural weathering is attributed to two processes. UV light causes degradation mainly of lignin resulting in whitening of the wood surface. The UV-bleached surface is colonized by surface fungi which specifically feed on UV-derived degradation products. The black color of the fungal hyphae on the bleached wood surface gives the impression of gray staining.3,4 The uncoated PF modified boards adopted a darker brown color, while the PF-dye-modified specimens became only slightly lighter brownish (Fig. 3j). The darker brown color of the PF-modified boards is attributed to the formation of more colorful chromophores due to the oxidation of PF, which offsets degradation and leaching of the phenolic compounds and,14 in addition, by fungal colonization. Among the boards, which were solely coated with an acrylic binder, the unmodified specimens showed a strong graying of the surface indicating intensive lignin removal and fungal colonization (Fig. 3k). Also the NMM-dye-modified board adopted a lighter color compared to the dark brown surface before weathering (Fig. 3n), but the discoloration was less than with the equally modified specimens without coating (Fig. 3i). Boards modified with NMM, PF, and PF-dye (Figs. 3g, 3h, and 3j) displayed a darker color after weathering; however, slightly grayish spots also appeared in areas where the coating failed (Figs. 3l, 3m, and 3o). It is assumed that in these cases, the wood surfaces and the resins and dye already underwent degradation, but leaching of the degradation product did not occur because the coating film remained mostly intact during weathering. Boards coated with topcoat 2 (Figs. 3p–3t) showed higher color stability than uncoated boards (Figs. 3f–3j) and those coated with topcoat 1 (Figs. 3k–3o). Prior to weathering, all boards coated with topcoat 3 were slightly darker due to the presence of iron oxide and therefore hardly changed the color during weathering (Figs. 3u–3y). This shows the potential of the UV absorbers, radical scavengers, and, in addition, iron oxide to protect the surfaces of all substrates and to prevent degradation and cracking of the coating film.

Appearance of beech-wood surfaces with and without coating: uncoated, unweathered (a–e); uncoated after natural weathering (32 months) (f–j); coated with topcoat 1 (sole binder) after weathering (k–o); coated with topcoat 2 (binder + 3% UV-PA [protective agents]) after weathering (p–t); coated with topcoat 3 (binder + 3% UV-PA + 1.5 UV-PA) after weathering (u–y). Controls (a, f, k, p, u); boards modified with NMM (b, g, l, q, v); with PF (c, h, m, r, w); with NMM-dye (d, i, n, s, x); with PF-dye (e, j, o, t, y)

During approximately 2.5 years of natural weathering, the greatest color differences (ΔE) mainly occurred during the first year (Fig. 4), particularly with uncoated or those specimens coated with topcoat 1 (solely binder). With respect to uncoated wood, the greatest ΔE occurred with unmodified, NMM-modified, and PF-modified boards, but these color changes are based on different mechanisms. While the unmodified and NMM treated surfaces turned gray, the PF-modified specimens adopted a black color (compare Figs. 3h and 3j).

Uncoated controls revealed the strongest color changes (∆E), which already started within the first 8 months (Fig. 4a) of weathering. This phenomenon is mainly caused by the change in lightness (∆L) due to colonization of the surface by staining fungi as well as by the change in chroma (∆C) due to degradation by the UV light of solar radiation and wash-out of chromophoric lignin.15,37,38 Control boards coated with topcoat 1 hardly changed color in the first months of weathering but underwent severe changes in the following months of exposure (Fig. 4b). In the case of uncoated boards and those coated with topcoat 1, resin modification reduced the color differences due to weathering compared to the controls (except for uncoated, melamine-treated boards, Figs. 3b and 3g). PF-dye-modified boards showed the lowest degree of color change (Figs. 3j, 3o, 3t, and 3y), because the surfaces were already very dark before weathering and due to the protective effect of PF toward lignin.14 The greatest differences between specimens coated with topcoat 1 (Fig. 4b) and those coated with topcoat 2 and 3 (Figs. 4c and 4d), however, were found for boards modified with NMM-dye. This result is mainly affected by UV light causing degradation of lignin and of the NMM-dye complex. The UV-bleached and cracked surface is colonized by surface fungi which specifically feed on UV-derived degradation products, resulting in whitening of the wood surface.3,4

Conclusion

Treatment of solid wood with NMM and PF resin, also combined with a dye, clearly improves the weathering performance and reduces the capillary water uptake compared to untreated wood. Higher dimensional stability imparted by the modification results in less formation of cracks in the wood and in the coating and thus reduces the failure of the coating. Modification with PF resin enhances the photo-stability of uncoated wood because it inhibits lignin degradation, while NMM does not impart photo-stability to lignin. In addition, higher dimensional stability caused by NMM and PF increases the stability of the coatings and reduces leaching of photo-degradation products, particularly of lignin (particularly when UV protectives are used) and the degree of surface colonization by fungi. UV-protective agents (UV absorbers, HALS, iron oxides) further improved the coating performance on all substrates. Thus, wood modified with thermosetting NMM and particularly PF resin reveals a good potential to improve the weathering performance and to prolong the service life of wood coated with acrylic coatings. Staining of the natural wood substrate combined with the thermosetting resin modification offers an additional way to diversify the optical appearance of wood coated with transparent and translucent (light brown) coatings.

References

Rowell, RM, Handbook of Wood Chemistry and Wood Composites. CRC Press, Boca Raton (2005)

Hill, CAS, Wood Modification: Chemical, Thermal and Other Processes. Wiley, Chichester (2006)

Duncan, C, “Role of Microorganisms in the Weathering of Wood and Degradation of Exterior Finishes.” Off. Dig., 35 (465) 1003–1012 (1963)

Sell, J, “Investigation of the Infestation of Untreated and Surface-Treated Wood by Blue-Stain Fungi.” Holz Roh- Werkst., 26 (6) 215–222 (1968)

Stamm, AJ, Wood and Cellulose Science. Ronald Press Company, New York (1964)

Inoue, M, Ogata, S, Nishikawa, M, Otsuka, Y, Kawai, S, Norimoto, M, “Dimensional Stability, Mechanical Properties and Colour Changes of a Low Molecular Weight Melamine Formaldehyde Resin Impregnated Wood.” Mokuzai Gakkaishi, 39 181–189 (1993)

Lukowsky, D, Holzschutz mit Melaminharzen. PhD Thesis, University of Hamburg (1999)

Rapp, AO, Peek, RD, “Melaminharzimprägniertes sowie mit Wetterschutzlasur oberflächenbehandeltes und unbehandeltes Vollholz während zweijähriger Freilandbewitterung.” Holz Roh- Werkst., 57 331–339 (1999)

Gindl, W, Hansmann, C, Bierlinger, N, Schwanninger, M, Hinterstoisser, B, Jeronimidis, G, “Using a Water-Soluble Melamine-Formaldehyde Resin to Improve the Hardness of Norway Spruce Wood.” J. Appl. Polym. Sci., 93 1900–1907 (2004)

Hansmann, C, Deka, M, Wimmer, R, Gindl, W, “Artificial Weathering of Wood Surfaces Modified by Melamine Formaldehyde Resins.” Holz Roh- Werkst., 64 198–203 (2006)

Kielmann, BC, Militz, H, Mai, C, “The Effect of Combined Melamine Resin Colouring Agent Modification on Water Related Properties of Beech Wood.” Wood Res., 61 (1) 1–12 (2016)

Furuno, T, Imamura, Y, Kajita, H, “The Modification of Wood by Treatment with Low Molecular Weight Phenol-Formaldehyde Resin Penetration into Wood Cell Walls.” Wood Sci. Technol., 37 (5) 349–361 (2004)

Ryu, JY, Imamura, Y, Takahashi, M, Kajita, H, “Effects of Molecular Weight and Some Other Properties of Resin on the Biological Resistance of Phenolic Resin Treated Wood.” Mokuzai Gakkaishi, 39 (4) 486–492 (1993)

Evans, PD, Kraushaar Gibson, S, Cullis, I, Liu, C, Sèbe, G, “Photostabilization of Wood Using Low Molecular Weight Phenol Formaldehyde Resin and Hindered Amine Light Stabilizer.” Polym. Degrad. Stab., 98 158–168 (2013)

Kielmann, BC, Militz, H, Adamopoulos, S, “Combined N-Methylol Melamine Colouring Agent Modification of Hardwoods to Improve Their Performance Under Use Class 3.” Proc. 6th European Conference on Wood Modification, Ljubljana, Slovenia, 2012

Kielmann, BC, Adamopoulos, S, Militz, H, Koch, G, Mai, C, “Modification of Three Hardwoods with an N-Methylol Melamine Compound and a Metal-Complex Dye.” Wood Sci. Technol., 48 (1) 123–136 (2013)

Kielmann, BC, Adamopoulos, S, Militz, H, Mai, C, “Strength Changes in Ash, Beech and Maple Wood Modified with a N-Methylol Melamine Compound and a Metal-Complex Dye.” Wood Res., 58 (3) 343–350 (2013)

Kielmann, BC, Adamopoulos, S, Militz, H, Mai, C, “Decay Resistance of Ash, Beech and Maple Wood Modified with N-methylol Melamine and a Metal Complex Dye.” Int. Biodeterior. Biodegrad., 89 110–114 (2014)

Valet, A, Light Stabilizers for Paints, pp. 45–128. C.R. Vincentz Verlag, Hannover (1997)

Decker, C, Biry, S, Zahouily, K, “Photostabilisation of Organic Coatings.” Polym. Degrad. Stab., 49 111–119 (1995)

Schaller, C, Rogez, D, “New Approaches in Wood Coating Stabilization.” J. Coat. Technol. Res., 4 (4) 401–409 (2007)

Schaller, C, Rogez, D, Braig, A, “Organic vs Inorganic Light Stabilizers for Waterborne Clear Coats: A Fair Comparison.” J. Coat. Technol. Res., 9 (4) 433–441 (2012)

Kimpel, D, “Novel Waterborne UVA/HALS Blend for High Performance Waterborne Coatings.” Proc. 8th International Woodcoatings Congress “Science and Technology for Sustainable Design”, Amsterdam, Netherland, 2012

EN 927-3, Paints and Varnishes—Coating Materials and Coating Systems for Exterior Wood—Part 3: Natural Weathering Test (2006)

Kielmann, BC, Mai, C, “Application and Artificial Weathering Performance of Translucent Coatings on Resin-Treated and Dye-Stained Beech-Wood.” Prog. Org. Coat., 95 54–63 (2016)

DIN ISO 4628-1, Paints and Varnishes—Evaluation of Degradation of Coatings—Designation of Quantity and Size of Defects and of Intensity of Changes—Part 1: General Principles and Designation System (1997)

DIN ISO 4628-4, Paints and varnishes—Evaluation of Degradation of Coatings—Designation of Quantity and Size of Defects, and of Intensity of Changes—Part 4: Assessment of Degree of Cracking (1997)

DIN 52617, Determination of the Water Absorption Coefficient of Construction Materials (1987)

ASTM D 2244-02, Standard Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates (2002)

Billmeyer, FW, Saltzman, M, Principles of Color Technology, 2nd ed. Wiley, New York, 1981

Hosseinpourpia, R, Adamopoulos, S, Mai, C, “Dynamic Vapour Sorption of Wood and Holocellulose Modified with Thermosetting Resins.” Wood Sci. Technol., 50 (1) 165–178 (2015)

Nienhuis, JG, van de Velde, B, Cobben, WNH, Beckers, EPJ, “Exterior Durability of Coatings on Modified Wood.” Proc. of First European Conference on Wood Modification, Ghent, Belgium, 2003

Williams, RS, Winandy, JE, Feist, WC, “Paints Adhesion to Weathered Wood.” J. Coat. Technol., 59 (749) 43–49 (1987)

de Meijer, M, “Review on the Durability of Exterior Wood Coatings with Reduced VOC-Content.” Prog. Org. Coat., 43 217–225 (2001)

de Meijer, M, Creemers, J, Cobben, W, “Relationship Between the Performance of Low-VOC Wood Coatings and the Dimensional Changes of the Wooden Substrate.” Surf. Coat. Int., 84 77–85 (2001)

Xie, Y, Krause, A, Militz, H, Mai, C, “Coating Performance of Finishes on Wood Modified with an N-methylol Compound.” Prog. Org. Coat., 57 291–300 (2006)

Hon, DNS, Chang, ST, Feist, WC, “Photodegradation and Photoprotection of Wood Surfaces.” Wood Fiber Sci., 14 (2) 104–117 (1982)

Donath, S, Militz, H, Mai, C, “Weathering of Silane Treated Wood.” Holz Roh- Werkst., 65 (1) 35–42 (2007)

Acknowledgments

The authors would like to thank Dr. Delphine Kimpel, BASF SE, Ludwigshafen, Germany for valuable discussions and for supplying coating material. We very much appreciate the support afforded us by Surfactor GmbH, Schöppenstedt, Germany and Ineos Melamines GmbH, Frankfurt, Germany.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kielmann, B.C., Mai, C. Natural weathering performance and the effect of light stabilizers in water-based coating formulations on resin-modified and dye-stained beech-wood. J Coat Technol Res 13, 1065–1074 (2016). https://doi.org/10.1007/s11998-016-9818-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-016-9818-0