Abstract

This study evaluated the combined modification and staining of ash, beech and maple wood with a low molecular weight N-methylol melamine compound (NMM) and a metal-complex dye. Wood samples were treated with aqueous solutions of 10, 20 and 30 wt% NMM and 5 wt% of the dye. The treatment caused the fixation of the water-soluble dye by the NMM resin. Vacuum pressure impregnation of unsealed wood blocks did not result in different solution uptake and weight percent gain after curing among the three species, but sealing of the surfaces of the wood blocks to allow penetration only into one direction revealed easiest penetrability of beech followed by maple and ash. UV micro-spectrophotometry and light microscopy indicated that NMM was partly deposited in the cell wall and partly in the lumens. Penetration of the metal-complex dye was shown by means of X-ray micro-analysis (SEM–EDX). The study shows that a combined resin modification and staining of the three wood species tested is possible and that NMM causes fixation of the water-soluble dye.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Wood as a renewable and biodegradable resource is an exceptional material for construction, or furniture because of its favourable properties such as high strength to mass ratio. Many wood species, however, exhibit low durability and require protection to prolong their service life when exposed outdoors. Traditional methods to enhance resistance to decay organisms involve superficial or full treatment of wood with biocidal preservatives. Thermal, chemical and impregnation modification of wood has received considerable attention in recent years as an alternative to conventional wood preservation. Enhanced durability of modified wood is attributed to alteration in material properties such as reduced pore size in the cell wall matrix and/or lower cell wall moisture content rather than to biocidal effects. As a consequence, additional wood properties are improved, which encompass dimensional stability, water uptake, hardness and resistance to weathering (Rowell 2005; Hill 2006). These improvements were also shown to be caused by low molecular weight melamine formaldehyde (N-methylol melamine, NMM) resins (Stamm 1964; Inoue et al. 1993; Pittman et al. 1994; Lukowsky 1999; Rapp and Peek 1999; Gindl et al. 2003a; Krause et al. 2004; Hansmann et al. 2006). NMM treatment is considered as passive impregnation modification, in which simple deposition of chemicals in the wood cell wall brings about changes in material properties without further alteration in the cell wall chemistry (Norimoto and Gril 1993). It is not a primary requirement that the impregnant is covalently bonded to the cell wall polymers although it can occur in some cases. Cell wall penetration of NMM was evidenced as cell wall bulking, which is assessed as an increase in the volume of wood after the modification. Cell wall bulking is the major reason for the enhanced dimensional stability of NMM-treated wood (Stamm 1964). Fixation of condensed NMM resin is attributed to the formation of a three-dimensional network within the cell wall rather than to covalent bonding with the cell wall polymers (Lukowsky 1999). It has been shown previously that melamine resins penetrate into the lignified cell wall (Rapp et al. 1999).

In the modern society, wood cannot only be appreciated for its functional properties, but also for its aesthetic qualities, i.e. texture, figure and colour (Janin et al. 2001). Various paints, varnishes and other coatings are available on the market to enhance or maintain the aesthetic appearance of wood surfaces, and contribute to better performance and prolong the service life of wood. Painting problems due to deficiencies in coating materials and their application, as well as deterioration of the wood substrate at the wood-coating interface (e.g. through photo-degradation, colonisation by staining fungi, high moisture content), however, bring about additional maintenance costs during service life (Miller and Boxall 1984). Permanent staining of the wood substrate through impregnation combined with impregnation modification with NMM provides an alternative option to surface coatings. The combined treatment is expected not only to improve the performance of wooden items exposed outdoors but also to increase the value of wood by enhancing its aesthetic quality.

In this study, three hardwood species (ash, beech and maple), which are extensively used in wooden structures, were treated with aqueous NMM solution combined with a metal-complex dye. Macroscopic (depth) and microscopic (cell wall) penetration were assessed by determining the solution uptake, nitrogen and colour gradient, as well as by light microscopy, UV micro-spectrophotometry and X-ray mapping (EDX) of the combined solution.

Materials and methods

Wood and chemicals

Defect-free specimens with dimensions 40 × 40 × 100 mm3 (R × T × L) of ash (Fraxinus excelsior L.), beech (Fagus sylvatica L.) and maple (Acer platanoides L.) were prepared from air-dried boards. The specimens were oven-dried at 103 ± 2 °C for 48 h and weighed. Prior to NMM-dye (BS) treatment, the dried wood specimens were conditioned at 20 °C and 65 % RH to a constant weight.

The N-methylol melamine (NMM) resin Madurit MW840/75WA (Ineos Melamines GmbH, Frankfurt, Germany) was supplied as an aqueous stock solution with a solid content of approx. 75 %, density of 1.245–1.260 g ml−1 at 23 °C, dynamic viscosity of the formulation was 430 mPa s and pH value of 9.3 (all values at 25 °C). NMM is partly methylolated (with residual amino groups of the melamine) and partly methylated.

The aqueous metal-complex dye Basantol® Red 311 liquid (BS) was provided by BASF SE (Ludwigshafen, Germany) with 30 % solid content, density of 1.12 g cm−3, pH 5 and fastness 6–7. NMM-dye (BS) solutions were prepared consisting of 10, 20 and 30 % Madurit MW840/75WA (solid content) and 5 % BS (of stock solution) by diluting with tap water. Ethanolamine (1 %) was added, and the pH of the final solution was adjusted to 10 by adding sodium hydroxide.

NMM-dye treatment

The conditioned wood specimens were impregnated in a stainless steel vessel using a full cell process, which included an initial vacuum phase of 50 mbar (1 h) and a pressure phase of 12 bar (72 h). After impregnation, the excess solution from the specimens’ surface was dabbed off with paper and the specimens were weighed. In a drying oven, the impregnated specimens were exposed to the following temperature cycle: 20, 40, 60, 80, 100 °C (24 h each), 120 °C (8 h), 103 °C (24 h). Solution uptake (SU) after impregnation and weight percent gain (WPG) after drying (and resin curing) were related to the dry mass of untreated wood. All further tests were conducted with specimens treated with a solution containing 30 % NMM and 5 % metal-complex dye (BS).

Fixation of the dye

The fixation of the dye in wood was evaluated through water submersion of the treated specimens at room temperature. The content of the dye in the water was determined spectrophotometrically at 493 nm after 7 and 35 days using the spectrophotometer Specord 205 (Analytik Jena AG, Jena, Germany). The amount of extracted metal-complex dye was determined using a calibration curve of the same dye.

Colour measurements and nitrogen analysis

Five sides of wood blocks measuring 40 × 40 × 40 mm3 (R × T × L, lateral penetration) and 40 × 40 × 80 mm3 (R × T × L, longitudinal penetration) were sealed with the coating Pyrotect Schutzlack 2 K (Rütgers Organics GmbH, Mannheim, Germany), in order to allow penetration only in one particular direction. After impregnation and curing as described above, the blocks were sliced at 10- or 20-mm interval (axial, radial penetration) and at 20- or 40-mm interval (longitudinal penetration) to expose inner surfaces.

Depth profiling by colour measurement and carbon/nitrogen analysis were performed on the same wood blocks using three replicates. Colour measurements were recorded with a colorimeter (BYK-Gardner—Colour Guide 45/0, Columbia, USA) working with the CIE L*a*b system according to the American standard ASTM D 2244-02 (2005). The parameter “a*” representing the green/red components was used to estimate the colour change. Two measurements were taken on each exposed surface. When no marked difference was observed between the measurements, their average was used for analysis. Colour data from untreated specimens served as reference.

Carbon–nitrogen analyses were performed to profile NMM penetration. Slices of treated blocks for the various depths were ground in a ball mill; subsequently, 6 mg of dry powder was used for C–N analysis in a LECO CHN 2000-Analyzer (LECO Instrumente GmbH, Mönchengladbach, Germany).

Light microscopy and SEM–EDX analysis

Transverse sections (15–20 μm thick) of treated specimens were prepared using a sliding microtome (Reichert-Jung, Nussloch, Germany) by lightly wetting the wood surfaces. Unstained sections were embedded with Euparal (Merck KGaA, Darmstadt, Germany) mounting medium for normal light microscopy and examined under the microscope AX 70 (Olympus, Hamburg, Germany).

The elemental distribution of the dye within the cell walls of treated wood was studied by means of the scanning electron microscope (SEM) Supra 45 (Leo Elektronenmikroskopie GmbH, Oberkochen, Germany) equipped with an energy-dispersive X-ray detector (EDX, Thermo Fisher Scientific GmbH, Waltham, USA). Wood blocks 5 × 5 × 5 mm3 (R × T × L) were smoothed at their transverse surfaces, mounted on aluminium stubs, dried overnight at 25 °C and carbon-coated. EDX analysis of coated specimens was performed at a working distance of 13 mm with an operating voltage of 15 kV. The distribution of the metal-complex dye in the cell wall was assessed by recording a line scan of sulphur (K 15 keV) and chromium (K 15 keV).

UV micro-spectrophotometry (UMSP)

The subcellular distribution of NMM resin was topochemically studied using scanning UV micro-spectrophotometry (UMSP) as described by Koch and Kleist (2001) and Koch and Grünwald (2004). Treated specimens of 1 × 1 × 5 mm3 (R × T × L) dimensions were embedded in Spurr’s epoxy resin (Spurr 1969) under mild vacuum and several cycles of evacuation and ventilation (Kleist and Schmitt 1999). Transverse sections (1 μm thickness) of the embedded specimens were cut with a diamond knife and transferred to non-reflective quartz slides, and after immersion in glycerine, the sections were covered with a quartz cover slip. The samples were scanned with a Zeiss UMSP 80 micro-spectrophotometer (Carl Zeiss Jena GmbH, Jena, Germany) at a wavelength of 240 nm (absorbance maximum of melamine compounds according to Gindl et al. 2002). Image profiles were acquired with the software APAMOS® (Carl Zeiss Jena GmbH, Jena, Germany), which digitises the rectangular field of the examined tissue at a geometrical resolution of 0.25 × 0.25 μm². The photometrical resolution amounted to 4,096 grey scale levels, which were converted to 14 colours for visualisation of UV absorbance intensities. Moreover, photometric point measurements were taken from individual cell wall layers at a spot size of 1 μm2 in the range of 230–350 nm by using a MSP 800 micro-spectrometer (J&M Spectralytics GmbH, Esslingen, Germany), and the data evaluation was done by the software TIDAS-DAQ (J&M Spectralytics GmbH, Essingen, Germany) and PANORAMA ProColorSearch (Labcognition, Analytical Software GmbH&Co KG, Cologne, Germany). Ten spectra were taken from each individual cell type and cell wall layer, respectively, for the semi-quantitative statistic studies.

Results and discussion

Solution uptake and weight percent gain

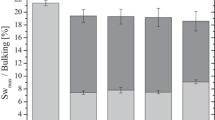

For all selected species, the WPG increased linearly with increasing solid content of the NMM-dye (BS) solution (Fig. 1). As wood of ash, beech and maple exhibit only minor differences in density and consequently in their void volume, WPG results were rather similar among the species for each NMM-dye (BS) concentration. Assuming similar densities of the untreated wood specimens, density of the treated specimens was used as a measure for WPG. The average density at 12 % moisture content was 690 kg m−3 for ash, 680 kg m−3 for beech and 660 kg m−3 for maple. The weight-based solution uptake (SU) tended to increase with the amount of dissolved NMM, because the density of the solutions increased with increasing NMM content, while the volumetric solution uptake kept constant (Fig. 1). This finding is in accordance with previous results on the NMM modification of Bombax species (Sint et al. 2013) and confirms that penetration of NMM into wood does not depend on the concentration of the impregnating solution within the range used.

Penetration of NMM-dye (BS) into the wood

For all species tested, the content of the metal-complex dye in the leaching water after 7 days submersion was below 0.002 mg and did not increase within 35 days, implying good fixation in wood. The surfaces displayed a uniform colour distribution. Some irregularities appeared on the transverse surfaces of beech and ash due to the distinct rays of beech and the ring-porous character of ash, respectively, but these surfaces are the least exposed in wooden items. The dye stained the wood substrate at least 20 mm from the surface in the lateral directions (radial, tangential) and up to 40 mm longitudinally (Table 1). Based on the red/green component values (a*), modified specimens were approximately 2–5 times redder in ash and maple, and 2–3 times in beech than the respective untreated ones. For each direction, visible red staining was more or less uniform in depth, while variations in a* values among the directions were minor. A slightly reduced redness was only observed in maple, especially in the centre (20 mm) of the lateral penetration specimens. Deviations in colour, however, might also be attributed to the natural variability in anatomical features and density.

The nitrogen content varied much among the species at penetration in defined anatomical directions (Table 1). A quite significant reduction of nitrogen ranging, however, was detected between the surface of the specimens and the inner parts for the lateral directions on 10 mm and 20 mm approximately 70–97 % for ash, 14–67 % for beech and 30–95 % for maple. A similar reduction of 26–35 % in nitrogen content was observed longitudinally at 20 and 40 mm for beech and maple, while for ash the reduction was higher (39–49 %).

Distribution of the dye in the cell wall

The results from the SEM–EDX line scans (signal minus background) reveal the deposition of the dye in the cell wall matrix (Fig. 2). Similar count levels, which are proportional to the amount of S and Cr atoms, were observed in the fibre walls of all treated species. The count rate of Cr was relatively even across the cell wall (Fig. 2). The line scan curve for S indicates more distinct areas for the distribution of the dye in the different cell wall layers. The count rate curve seems to increase from the lumen towards the inside of S2 layer, while there is also a high concentration of the dye near or in the middle lamella. The presence of micro-cracks in the cell wall from the lumen formed during wood drying (Thuvander et al. 2002) might provide fast diffusion paths for the solution.

SEM–EDX linescans for ash (a), beech (b) and maple (c) fibre walls impregnated with 30 % NMM-5 % dye (BS). The linescan signal (counts) of S (upper line) and Cr (lower line) is the peak counts minus the background counts. Note for untreated samples, equivalent counts for S and Cr are at zero levels; vertical lines indicate the highest peak of the S scan

Topochemistry of NMM-dye-treated wood

Like with other bulking chemicals, equal distribution of the NMM resin in the wood cell wall is of crucial importance in order to achieve dimensional stability, hardness and resistance to weathering (Lukowsky 1999; Hansmann et al. 2006). The UV absorbance of cell walls treated with NMM-dye (BS) was considerably higher, especially at wavelengths between 230 and 260 nm, than that of untreated wood (Fig. 3). In detail, the absorbance values of the S2 layers of fibres, parenchyma and vessels reveal a distinct increase in the UV absorbance from 0.2 to 0.4 (controls) up to 0.8–1.0 (30 % NMM-dye (BS) treatment), respectively. Melamine resins have been reported to contribute to a specific UV absorbance (Gindl et al. 2003b; Devallencourt et al. 2000); thus, significant portions of NMM resin penetrated secondary cell wall layers. The S2 layers of fibres, axial and ray parenchyma and vessel tissues of all NMM-dye-treated species were characterised by two distinct peaks (Fig. 3). The distinct peak at approximately 240 nm is attributed to NMM (Gindl et al. 2002; Sint et al. 2013) and cell wall constituents, while the peak at approximately 278 nm is assigned to phenolic groups in hardwood lignin (Fergus and Goring 1970; Koch and Kleist 2001).

Light micrographs revealed NMM-dye (BS) deposits in the cell lumens of treated wood (Fig. 4). UV point measurements of NMM deposits with resolution of 1 μm² (e.g. Fig. 5 for beech) showed a distinct absorbance maximum at 240 nm assigned to NMM resin and another peak at 510 nm to metal-complex dye. These deposits, thus, represent stained NMM resin, which did not diffuse into the cell wall due to saturation effects (Lukowsky 1999). The topochemical characterisation of untreated wood at the selected scanning wavelength of 240 nm (absorbance maximum of NMM) revealed the distribution of aromatic compounds of the lignified cell walls and constituents of extractives (Fig. 6a–c). As reported previously (Koch and Kleist 2001), the compound middle lamella and cell corners of the individual fibres can be distinguished on account of significantly higher UV absorbance as compared to the S2 of fibres (Fig. 6a–c). The UV scanning two-dimensional (2D) profiles of NMM-dye-treated wood (Fig. 6d–f) showed a significantly increased UV absorbance at 240 nm as compared to untreated wood representing the deposition of NMM in various morphological regions of wood tissue including the cell lumens. Statistical evaluation of the detected absorbance values (up to 15,000 measuring points of one individual scan) indicated an increase in the mean absorbance. The UV absorbance of treated wood was higher in the compound middle lamella indicating higher amounts of NMM than in the S2 layers, as previously reported (Rapp et al. 1999). The (topochemically) detected higher UV absorbance of individual cell types in treated wood was distinctively observed in beech and maple, while the cell walls of vessel and parenchyma cells of ash did not show significant increase. Treated fibres of ash, however, also revealed pronounced increase in the UV absorbance at 240 nm (compare Table 2). Theses individual deviations are attributed to differences in wood anatomical characteristics and chemical composition of the species affecting the accessibility for NMM of different molar mass into the cell walls. In general, the UV micro-spectrophotometry is suited to study the topochemistry of NMM-dye-treated cell walls as NMM causes absorbance at 240 nm, which can be subtracted from that of the cell wall polymers (especially lignin and extractives). In particular, the scanning technique provides fundamental information on both the distribution of NMM and the metal-complex dye.

Representative UV microscopic scanning 2D profiles of transversal surfaces showing an increased UV absorption of 30 % NMM-dye (BS)-treated wood (d–f) as compared to untreated wood (a–c) The colour pixels represent different UV absorption values of the cell wall layers measured at 240 nm. Species and size of UV pictures: a ash, 141 × 107 pixel; b beech, 156 × 123 pixel; c maple, 111 × 119 pixel; d ash, 240 × 160 pixel; e beech, 174 × 133 pixel; f maple, 142 × 161 pixel, pixel size: (0.25 × 0.25) μm²

Conclusion

This study shows that larger dimensions of ash, beech and maple wood can be fully modified with a combined solution of N-methylol melamine (NMM) pre-condensates and a metal-complex dye. The combined treatment causes the fixation of the water-soluble dye. Penetration of impregnation solution in the radial, tangential and longitudinal direction depends on the wood species. Beech is the easiest wood species to impregnate followed by maple and ash. When lager dimensions are treated, the latter species require longer impregnation times at high pressure to achieve solution uptake above 100 %.

Cell wall penetration of metal-complex dyes can be assessed by X-ray micro-analysis and of NMM by UMSP at the wavelength of 240 nm. NMM and metal-complex dye are able to penetrate the cell wall but major parts are deposited in the lumens. With regard to the distribution of the NMM in the cell wall, the absorbance of the wood tissue at 240 nm increased from the lumens towards the middle lamella.

References

Devallencourt C, Saiter JM, Capitaine D (2000) Reactions between melamine formaldehyde resin and cellulose: influence of pH. J Appl Polym Sci 78:1884–1896

Fergus BJ, Goring DAI (1970) The location of guaiacyl and syringyl lignins in birch xylem tissue. Holzforschung 24:113–117

Gindl W, Dessipri E, Wimmer R (2002) Using UV-microscopy to study diffusion of melamine-ureaformaldehyde resin in cell walls of spruce wood. Holzforschung 56:103–107

Gindl W, Mueller U, Teischinger A (2003a) Transverse compression strength and fracture of spruce wood modified by melamine formaldehyde impregnation of cell walls. Wood Fiber Sci 35:239–246

Gindl W, Zargar-Yaghubi F, Wimmer R (2003b) Impregnation of softwood cell walls with melamine-formaldehyde resin. Bioresour Techn 87:325–330

Hansmann C, Deka M, Wimmer R, Gindl W (2006) Artificial weathering of wood surfaces modified by melamine formaldehyde resins. Holz Roh Werkst 64:198–203

Hill CAS (2006) Wood modification, chemical, thermal and other processes. Wiley, Chichester

Inoue M, Ogata S, Nishikawa M, Otsuka Y, Kawai S, Norimoto M (1993) Dimensional stability, mechanical properties and color changes of a low molecular weight melamine formaldehyde resin impregnated wood. Mokuzai Gakkaishi 39:181–189

Janin G, Goncalez J, Ananías R, Charrier B, da Silva FG, Dilem A (2001) Aesthetics appreciation of wood colour and patterns by colorimetry. Part 1. Colorimetry theory for the CIELAB system. Maderas Cienc Technol 3(1–2):3–13

Kleist G, Schmitt U (1999) Evidence of accessory compounds in vessel walls of Sapelli heartwood (Entandrophragma cylindricum) obtained by transmission electron microscopy. Holz Roh Werkst 57:93–95

Koch G, Grünwald C (2004) Application of UV microspectrophotometry for the topochemical detection of lignin and phenolic extractives in wood fibre cell walls. In: Schmitt U et al (eds) Wood fibre cell walls: methods to study their formation, structure and properties. Swedish University of Agricultural Sciences, Uppsala, pp 119–130

Koch G, Kleist G (2001) Application of scanning UV microspectrophotometry to localise lignins and phenolic extractives in plant cell walls. Holzforschung 55:563–567

Krause A, Hof C, Militz H (2004) Novel wood modification processes for windows and cladding products. Proceedings of 35th annual meeting on the international research group on wood preservation. Slovenia. IRG/WP 04-40285

Lukowsky D (1999) Holzschutz mit Melaminharzen. PhD thesis, University of Hamburg

Miller ER, Boxall J (1984) The effectiveness of end-grain sealers in improving paint performance in softwood joinery. Holz Roh Werkst 42:27–34

Norimoto M, Gril J (1993) Structure and properties of chemically treated woods. In: Shiraishi N, Kajita H, Norimoto M (eds) Recent research on wood and wood-based materials. Elsevier, Barking, pp 135–154

Pittman CU, Kim MG, Nicholas DD, Wang L, Kabir FRA, Schultz TP, Ingram LL (1994) Wood enhancement treatments I. Impregnation of southern yellow pine with melamine formaldehyde and melamine-ammeline-formaldehyde resins. J Wood Chem Technol 14(4):577–603

Rapp AO, Peek RD (1999) Melaminharzimprägniertes so wie mit Wetterschutzlasur oberflächenbehandeltes und unbehandeltes Vollholz während zweijähriger Freilandbewitterung. Holz Roh Werkst 57:331–339

Rapp AO, Bestgen H, Adam W, Peek RD (1999) Electron energy loss spectroscopy (EELS) for quantification of cell-wall Penetration of a melamine resin. Holzforschung 53:111–117

Rowell RM (2005) Moisture properties. In: Rowell RM (ed) Handbook of wood chemistry and wood composites. CRC Press, USA

Sint KM, Adamopoulos S, Koch G, Hapla F, Militz H (2013) Impregnation of Bombax ceiba and Bombax insigne wood with a N-methylol melamine compound. Wood Sci Technol 47:43–58

Spurr AR (1969) A low-viscosity epoxy resin embedding medium for electron microscopy. J Ultrastruct Res 26(1–2):31–43

Stamm AJ (1964) Wood and cellulose science. Ronald Press Company, New York

Thuvander F, Kifetew G, Berglund LA (2002) Modeling of cell wall drying stresses in wood. Wood Sci Technol 36(3):241–254

Acknowledgments

The authors express their appreciation to Tanja Potsch and Karin Brandt for their valuable help during the sample preparation and the actual measurements conducted at the Institute for Wood Technology and Wood Biology, Federal Research Institute of Rural Areas, Forestry and Fisheries (vTI), Hamburg, Germany.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kielmann, B.C., Adamopoulos, S., Militz, H. et al. Modification of three hardwoods with an N-methylol melamine compound and a metal-complex dye. Wood Sci Technol 48, 123–136 (2014). https://doi.org/10.1007/s00226-013-0595-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-013-0595-y