Abstract

Performance of coatings on wood surfaces is adversely affected by swelling and shrinkage of wood due to moisture absorption and degradation of wood polymers by UV radiation. Chemical modification of cell wall polymers improves the dimensional stability of wood considerably. This work was undertaken with the aim to minimize weathering deteriorations by chemically modifying wood substrate prior to application of coating thereby improving weathering performance of coatings. UV resistance and weathering performance of rubberwood (Hevea brasiliensis) modified with acetic anhydride or benzoyl chloride and subsequently coated with polyurethane based wood coating has been evaluated. UV resistance of modified wood was assessed by exposing unmodified and modified wood specimens to a 1,000-Watt xenon arc light source in a weatherometer. Modified and unmodified wood specimens coated with commercially available polyurethane based transparent and opaque finishes were exposed to natural weathering for a period of 2 years. Analysis of colour changes and chemical deteriorations of weathered specimens showed rapid discolouration and lignin degradation of unmodified wood surfaces. Modified wood showed resistance to weathering as compared to unmodified wood. Results indicate that performance of coatings can be significantly improved by chemically modifying wood substrate with benzoyl chloride and acetic anhydride. The performance of opaque coating was better than transparent coating, presumably due to photodegradation of wood substrate in transparent coating.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The wood surfaces exposed outdoors degrade due to weathering. The process is primarily initiated by absorption of UV light by wood constituents, mainly lignin, resulting in its degradation. UV light induced degradation, termed photodegradation, results in characteristic colour changes due to formation of coloured structures as a result of lignin breakdown (Feist and Hon 1984; Evans et al. 1992, 1996; Hon 2001; Williams 2005; Evans 2012). These solubilised lignin degradation products are washed out by rain. Weathered wood surfaces are high in carbohydrate content and are further subjected to colonization by micro-organisms leading to further discolouration.

Wood being a biopolymer suffers from dimensional changes (swelling and shrinkage) due to absorption/desorption of moisture. Protective finishes are usually applied to improve the appearance and moisture barrier for wood. A wide range of protective surface coverings or finishes such as paints, varnishes, stains, or water repellents are commercially available (Evans 2012). Dimensional changes in wood substrate due to moisture absorption by hydroxyl groups associated with wood polymers are one of the major reasons for coating failure. UV induced degradation of coating polymers and wood substrate is another important reason for coating failure. A pigmented coating does not allow solar radiation to reach wood surface and protect wood surfaces from photo-degradation. However, wood beneath transparent finishes is severely affected by photo-degradation. Transparent coatings that are not UV stabilized are not effective in controlling light-induced damage (Vollmer and Evans 2013). In such finishes, the interface (between wood and the coating) is degraded by transmitted UV through the coating. This influences the coating performance. For improved performance of coatings, wood surfaces must be stabilized against photodegradation and dimensional variation.

To protect the wood surface and coating polymers, UV absorbers (UVA) and hindered amine light stabiliser (HALS) are generally added in the coatings (Schaller et al. 2008; Forsthuber and Grüll 2010; Evans et al. 2013). UVAs have high absorption coefficients in the UV part and hence effectively filter out the harmful UV wavelengths of the light spectrum. The UVAs based on 2-(2-hydroxyphenyl)-benzotriazoles and 2-hydroxyphenyl-s-triazine are found to be very effective (Schaller et al. 2008). Chou et al. (2008) found that incorporation of light stabilizer (containing 2 % Tinuvin-1,130 i.e., hydroxyphenyl benzotriazole) in PU film reduced lignin degradation and generation of carbonyl derivatives in the underlying wood.

The performance of clear coatings can also be increased by photo-stabilizing wood substrates prior to coating application (Dawson et al. 2008, Vollmer and Evans 2013). Several approaches have been used to stabilize wood surfaces. These include pre-treatment of wood surfaces with solutions of inorganic chemicals (Williams and Feist 1985; Evans et al. 1992, Pandey and Khali 1998; Schmalzl and Evans 2003; Schmalzl et al. 2003) and grafting UV absorbers to wood surfaces (Williams 1983; Kiguchi and Evans 1998; Kiguchi et al. 2001). Dawson et al. (2008) suggested controlled surface delignification as an approach to photostabilize wood surfaces. Chemical modification of cell wall polymers is one of the effective methods for inducing dimensional stability and protecting wood against weathering and biological decay (Rowell 1984, 2006; Matsuda 1996; Plackett et al. 1996; Takahashi 1996). Wood properties can be improved considerably by converting hydrophilic OH-groups into larger more hydrophobic groups. Modified wood has high dimensional stability, lower equilibrium moisture content and improved decay resistance. Esterification of wood with some of the reagents also imparts photostability to wood surfaces (Chang and Chang 2001; Evans et al. 2002; Pandey and Chandrashekar 2006; Jebrane et al. 2009). Chemical modification of wood has also been found to be effective in enhancing the weathering performance of coated wood (Beckers et al. 1998; Xie et al. 2006; Meijer et al. 2012; Vollmer and Evans 2013).

In the present study, the weathering performance of commercially available polyurethane (PU) based transparent and opaque wood coatings on modified wood were evaluated. Specimens of rubberwood (Hevea brasiliensis) were chemically modified with benzoyl chloride and acetic anhydride and were coated with PU based coatings. UV resistance of modified wood was evaluated by exposing modified wood specimens to a xenon light source in a weatherometer. Chemical modification of wood substrate is expected to induce some resistance against UV degradation, e.g., benzoylated wood has been found to provide good photostability (Evans et al. 2002; Pandey and Chandrashekar 2006; Yuan et al. 2013). Increased hydrophobic nature and dimensional stability of chemically modified wood is expected to enhance the performance of coatings considerably. The performance of clear coating is expected to be better on chemically modified wood, particularly in benzoylated wood. The deterioration of modified wood was monitored by measuring colour changes and lignin degradation by using FTIR spectroscopy. The coating performance under natural weathering was assessed by visual inspection.

2 Materials and methods

2.1 Wood specimens

Rubberwood (H. brasiliensis) logs were purchased from a local sawmill. Defect free logs were selected from same lot. These logs were air dried for 3 months and converted to specimens of size 100 × 40 × 5 mm3. Specimens were then oven-dried and extracted in a Soxhlet apparatus using toluene: acetone: alcohol (in the ratio 4:1:1) mixture and were then chemically modified using benzoyl chloride (99 % AR grade; M/s Central Drug House, New Delhi) and acetic anhydride (99 %, AR grade; M/s Fischer Scientific, Mumbai).

2.2 Chemical modification of wood

Reaction scheme between wood and acetic anhydride and benzoyl chloride is as follows.

Reaction between wood and acetic anhydride

Reaction between wood and benzoyl chloride

Acetylation of wood specimens was carried out with acetic anhydride in a constant temperature oil bath at reaction temperatures of 120 °C for 6 h. The benzoylation of wood was carried out as per the published procedure (Pandey and Chandrashekar 2006). After the reaction, wood samples were first washed with acetone and later extracted in a Soxhlet apparatus with acetone: toluene (1:1) mixture to remove un-reacted chemicals. Chemically modified samples were then oven dried and weight gain (WPG) was calculated using Eq. 1,

where W0 and Wm are oven dried weight of unmodified and chemically modified wood, respectively. Six replicates were used for each case and average weight gain was calculated. Average weight gain for acetylated wood and benzoylated wood were 10.46 ± 0.84 and 16.39 ± 0.97, respectively.

2.3 Application of coating on modified wood with polyurethane paint

Wood surfaces were prepared before applying the paint by application of sealant followed by fine sanding with 350 grit sandpaper. Unmodified and chemically modified wood samples were spray coated with commercially available transparent and opaque polyurethane finishes (PU Luxury wood finish for exteriors and PU Palette M/s Asian Paints, Mumbai) using a low pressure pilot spray gun (M/s Manik Machinery manufacturer Pvt. Ltd. Mumbai) at an air pressure of 1 × 105 N/m2. Two layers of coats were applied with a drying time of two hours between coats. The coated specimens were allowed to air dry for two weeks before weathering exposure.

2.4 Evaluation of UV resistance of modified wood

The UV resistance of modified wood surfaces was assessed under artificial weathering conditions. The modified and unmodified wood specimens were exposed to a 1,000-Watt xenon arc light source at 50 % relative humidity and chamber temperature of 30 °C in a weatherometer (Xenotest 150 S, M/s Atlas Instruments) for different periods ranging from 0 to 250 h. The samples were removed from the weatherometer at regular intervals of 50 h and analyzed for colour changes and chemical changes.

2.5 Natural weathering of modified wood

Modified and unmodified rubberwood samples with or without coatings were placed on weathering racks facing South-East direction, inclined at an angle of 15° for 2 years (January 2010–January 2012) on the roof top of Institute of Wood Science and Technology, Bangalore. Ten samples per treatment were used for each test. Samples were periodically taken out for visual inspection; colour and chemical changes occurring due to outdoor exposure.

2.6 Analysis of weathered wood

Colour changes on modified and unmodified wood surface before and after weathering were measured using Hunter LabScan XE colorimeter. CIELAB L*, a*, b* and ΔE* parameters were measured at six locations on each specimen and average value was calculated. In the CIELAB system, the L* represents the lightness (L* varies from 100 (for white) to zero (for black)), and a* and b* are the chromaticity coordinates. (+a* is for red, −a* for green, +b* for yellow, −b* for blue).

FTIR spectra were obtained using a FTIR spectrometer (Bruker, Tensor 27). Spectra were measured directly from wood surfaces using attenuated total reflectance (ATR) method at a spectral resolution of 4 cm−1 and at a rate of 64 scans/measurement.

3 Results and discussion

3.1 UV resistance and weathering of modified uncoated wood

Effects of xenon light irradiation on colour parameters of unmodified and modified wood surfaces are shown in Fig. 1. Colour of unmodified wood surfaces changed rapidly upon irradiation. The colour of unmodified specimens deepened/darkened after irradiation. The value of L* (lightness) decreased whereas values of a* and b* increased upon irradiation in unmodified wood. Contrary to unmodified wood, L* values increased in modified wood particularly during initial period of exposure. The parameter a* and b* increased upon irradiation in unmodified wood while its value decreased in modified wood. This shows that chemically modified wood restricts darkening/yellowing of wood due to light irradiation. Increase in L* values accompanied by decrease in b* values indicates photo-bleaching of modified wood (Mitsui 2010; Salla et al. 2012). Modified wood retained original colour longer compared to unmodified wood.

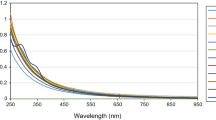

Changes in chemical composition of wood surfaces during light irradiation in unmodified wood are evident from IR spectra (Fig. 2). Relative intensities of lignin associated bands at 1,505 and 1,596 cm−1 (due to aromatic C=C stretching vibration in lignin), 1,465 and 1,245 cm−1 decreased, accompanied by successive increase in the intensity of bands at 1,740 and 1,660 cm−1. Significant changes occur within few hours of irradiation and almost complete degradation of lignin on top layer of wood surfaces is evident from disappearance of band at 1,505 cm−1. The increase in absorption at 1,740 and 1,660 cm−1 indicates generation of structures containing carbonyl groups as a result of degradation of wood polymers.

FTIR spectra of rubberwood modified by acetic anhydride and benzoyl chloride and irradiated up to 250 h are shown in Fig. 3. It can be seen that esterified wood is effective in photo-stabilizing wood surfaces to some extent. The increase of absorption at 1,720–1,740 cm−1 upon irradiation in benzoylated wood was insignificant, whereas the decrease at 1,506 cm−1 was smaller than the unmodified specimen. Similarly, the changes in the C–O group at 1,230 and 710 cm−1 were small. Though modified samples show delignification upon irradiation, the effect is less pronounced than that of unmodified samples. Comparison of FTIR spectra of acetylated and benzoylated wood indicates that the extent of photo-protection is more in benzoylated wood than in acetylated wood. These findings are in agreement with earlier studies on UV resistance of benzoylated wood and surfaces treated with aromatic structure containing compounds (Evans et al. 2002; Pandey and Chandrashekar 2006; Jebrane et al. 2009).

3.2 Natural weathering of chemically modified wood

The effect of natural weathering on the physical appearance of acetylated and benzoylated rubberwood after about 6 months of exposure are also shown in Fig. 4. Unmodified wood exposed to natural sunlight showed large changes in colour. The colour change in unmodified wood surface is indicated by decreasing value of lightness (L*) and increase in the chromaticity parameters a* and b*. The variation of lightness (L*) and yellowness index (b*) with exposure time is shown in Fig. 5. The decrease in L* parameter indicates severe darkening of the wood sample. The b* values of unmodified wood increased during initial exposure but b* values decreased upon extended exposure. The initial increase in value is due to the formation of quinone like structure from lignin degradation (Feist and Hon 1984). Decrease in b* values upon longer exposure can be attributed to leaching/removal of degradative products by moisture/rain water. Fungal growth also contributes to further darkening of wood surfaces under outdoor exposure (Feist and Hon 1984).

In contrast to unmodified wood, acetylated and benzoylated wood exhibited less yellowing/graying due to weathering, particularly during first few months of exposure (Fig. 5). Contrary to unmodified wood, L* of modified wood increased initially followed by decrease upon longer durations. Similarly, contrary to unmodified wood, b* values decreased during early period of exposure. In modified wood, the b* values decreased in the beginning followed by increase upon longer exposure. Modified wood retained its original colour for longer duration as compared to unmodified wood.

Above results indicate that colour darkening of modified wood due to weathering can be restricted for longer duration than unmodified wood. Benzoylation was more effective than acetylation in reducing discoloration of wood due to weathering. Benzoylated wood has been found to induce photostability (Evans et al. 2002; Pandey and Chandrashekar 2006; Yuan et al. 2013). However, modified wood (both acetylated and benzoylated) showed colour darkening/graying upon extended exposure. This supports the findings of earlier workers that esterification only restricts the photodegradation to some extent rather than blocking it completely.

FTIR spectra of unmodified rubberwood exposed to natural weathering reveal decrease in absorption peaks at ~1,730, 1,598, 1,505 and 1,240 cm−1 indicating degradation of wood polymers (Fig. 6). Decrease in 1,730 cm−1 in natural weathering indicates degradation of polysaccharides (mainly hemicelluloses) in wood. Most significant changes can be seen in the intensity of aromatic lignin C=C band (1,505 cm−1), which almost disappears within 4–6 days of exposure. Rapid reduction in the intensity of C=C band at 1,505 cm−1 indicates degradation of lignin (Hon 2001; Evans et al. 1996; Muller et al. 2003; Pandey 2005). This is accompanied by formation of new carbonyl absorption at 1,640 cm−1 region. The colour change in unmodified wood is attributed to formation of chromophoric structures due to degradation of wood polymers, which is indicated by increased intensity of carbonyl band in unmodified wood upon UV light irradiation. However, no increase in the carbonyl peak around 1,730 cm−1, as observed in xenon light exposure (Fig. 2), was observed in natural weathering. Decrease in intensity of 1,730 cm−1 peak in natural weathering can be attributed to degradation of hemicelluloses (Evans et al. 2002) and also leaching of photodegraded fragments due to moisture/rain.

The effect of natural weathering on FTIR spectra of rubberwood modified by acetic anhydride and benzoyl chloride is also shown in Fig. 7. It was observed that esterification of wood is effective in restricting weathering deterioration on wood surface during initial periods of exposure. Lignin aromatic peak at 1,505 cm−1 in unmodified wood completely disappeared within 4–6 days of exposure. The extent of decrease in modified wood during similar duration was less. Similarly, the change in carbonyl absorption at 1,720–1,740 cm−1 upon weathering in modified wood was much less as compared to unmodified wood. Esterified groups are more stable to weathering which is indicated by less change in the intensity of 1,720–1,740 cm−1 band upon irradiation. The intensity of peak at 1,505 and 1,225 cm−1 decreases upon extended exposure to natural weathering indicating that the lignin of modified wood also deteriorated upon longer exposure. These results revealed that degradation of esterified wood occurred upon extended exposure. FTIR spectra indicate that extent of photo-protection of lignin is more in benzoylated wood as compared to acetylated wood. However, the weathering protection also depends upon degree of modification (resistance increases with WPG). Therefore, in order to compare results of acetylated and benzoylated wood, further study based on equivalent WPG is necessary.

3.3 Natural weathering of coated wood

The comparison of performance of transparent and opaque coatings on unmodified, acetylated and benzoylated wood after 1 and 2 years natural weathering are shown in Figs. 8 and 9.

a Performance of transparent PU coating on benzoylated and acetylated wood after 1 year of natural weathering. Left specimen is unmodified wood and right specimen is modified wood. b Performance of transparent PU coating on unmodified (centre sample), acetylated (left sample) and benzoylated (right sample) rubberwood after 2 years of natural weathering

a Performance of opaque PU coating on benzoylated and acetylated wood after 1 year of natural weathering. Left specimen is unmodified wood and right specimen is modified wood. b Performance of opaque PU coating on unmodified (centre sample), acetylated (left side sample) and benzoylated (right sample) rubberwood after 2 years of natural weathering

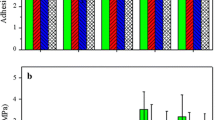

The significant enhancement in the performance of coating on modified wood as compared with unmodified wood can be clearly observed. Noticeable degradation within 6 months of exposure with complete failure of coating within 1 year of exposure was observed in unmodified wood. The performance of coatings on modified wood was significantly increased by chemical modification.

The failure/degradation of transparent coating was more than that of opaque coatings possibly due to photo-degradation of wood substrate. High dimensional stability and improved UV stability makes modified wood weather resistant. Opaque coating performed very well on modified wood. Significant failure within 6 months and almost complete degradation of opaque coating was observed in unmodified wood. However, in modified wood (both benzoylated and acetylated wood) the coating was still performing very well after 2 years of exposure. This indicates the positive influence of chemical modification of wood substrate on the performance of coatings. Vollmer and Evans (2013) recently studied performance of transparent acrylic, alkyd and polyurethane coatings on wood modified with a number of reagents including benzoyl chloride and compared results with chromic acid treatment. They found that performance of coating was best in wood treated with chromic acid, vinyl benzoyate or PF resin containing a hindered amine light stabiliser.

The findings here are in accordance with several earlier findings in that the performance of coatings can be improved by photostabilising wood surfaces (Williams and Feist 1985; Kiguchi et al. 2001; Vollmer and Evans 2013). Apart from level and type of photostabiliser, performance of coating also depends upon the type of coating (Vollmer and Evans 2013). Chemical modification has additional advantage in that it improves dimension stability of wood to a great extent. This is clearly indicated by much superior performance of opaque coating on modified wood as compared to transparent coatings observed in this work. Generally, light does not penetrate pigmented opaque coatings and the main cause of coating failure in this type of coating is dimensional variation due to moisture absorption by wood. Chemically modified wood (in the present case benzoylated and acetylated) has excellent dimensional stability because of reduction in number of available hydroxyl groups for moisture absorption. This explains the very good performance of opaque coating on both acetylated and benzoylated wood.

In case of clear coating both photo-stability and dimensional stability of wood substrate are important. Chemical modification of wood, though not completely effective, imparts UV resistance to some extent. Some of the systems like benzoyl benzoate and benzoyl chloride are found to be more effective than other systems. The superior photostabilising nature of benzoylated wood makes it a better choice for transparent coatings. However, while making such comparisons, the level of chemical modification has to be taken into account. Generally, there is a positive correlation between WPG and photostabilisation effect. Therefore, performance at equivalent WPGs of different systems (equal number of hydroxyl removal) should be studied for making such comparisons between two treatments. Incorporation of UV stabilisers (UVAs and HALS) in transparent coatings may further improve the performance of clear coatings (Vollmer and Evans 2013).

4 Conclusion

Chemically modified (benzoylated and acetylated) wood specimens coated with a transparent and opaque polyurethane exterior paint along with uncoated specimens were exposed to outdoor weathering and were periodically examined for weathering deteriorations. Analysis of colour changes and FTIR spectra reveal that esterification of wood with acetic anhydride and benzoyl chloride slows down weathering deterioration. However, modified wood exhibited colour darkening/graying upon extended exposure. Results indicate that performance of coating can be remarkably improved by chemical modification of wood substrate prior to coating. Chemical modification of wood enhanced performance of paints significantly. The performance of opaque coating is better than transparent coatings presumably due to photodegradation of wood substrate in transparent coatings. Results revealed that the extent of photo-protection is more in benzoylated wood as compared to acetylated wood. This results in better performance of clear coatings in benzoylated wood. Superior performance of opaque coating on both acetylated and benzoylated wood occurs because both methods of esterification improve dimensional stability of wood. However, in order to compare results of acetylated and benzoylated wood, further study based on equivalent WPG is required.

References

Beckers EPJ, Meijer M, Militz H, Stevens M (1998) Performance of finishes on wood that is chemically modified by acetylation. J Coat Technol 70:59–67

Chang S-T, Chang H-T (2001) Inhibition of the photodiscoloration of wood by butyrylation. Holzforschung 55:255–259

Chou PL, Chang JT, Yeh TF, Chang ST (2008) Characterizing the conservation effect of clear coatings on photodegradation of wood. Bioresour Technol l99:1073–1079

Dawson BSW, Singh AP, Kroese HW, Schwitzer MA, Gallagher S, Riddiough SJ, Wu S (2008) Enhancing exterior performance of clear coatings through photostabilisation of wooden surfaces. Part 2: Coating and weathering performance. J Coat Technol Res 5:207–219

Evans PD (2012) Weathering of wood and wood composites. In: Rowell RM (ed) Handboook of wood chemistry and wood composite, 2nd edn. Taylor and Francis, CRC Press, Boca Raton, pp 151–213

Evans PD, Michell AJ, Schmalzl KJ (1992) Studies of the degradation and protection of wood surfaces. Wood Sci Technol 26:151–163

Evans PD, Thay PD, Schmalzl KJ (1996) Degradation of wood surfaces during natural weathering. Effects on lignin and cellulose and on the adhesion of acrylic latex primers. Wood Sci Technol 30:411–422

Evans PD, Owen NL, Schmid S, Webster RD (2002) Weathering and photostability of benzoylated wood. Polym Degrad Stab 76:291–303

Evans PD, Kraushaar S, Cullis GI, Liu C, Sèbe G (2013) Photostabilization of wood using low molecular weight phenol formaldehyde resin and hindered amine light stabilizer. Polym Degrad Stab 98:158–168

Feist WC, Hon DNS (1984) Chemistry of weathering and protection. In: Rowell R (ed) The Chemistry of Solid Wood. American Chemical Society, Washington, pp 401–451

Forsthuber B, Grüll G (2010) The effects of HALS in the prevention of photo-degradation of acrylic clear topcoats and wooden surfaces. Polym Degrad Stab 95:746–755

Hon DNS (2001) Weathering and photochemistry of wood. In: Hon DNS, Shiraishi N (eds) Wood and cellulosic chemistry, 2nd edn. Marcel Dekker, NY, pp 512–546

Jebrane M, Sèbe G, Cullis I, Evans PD (2009) Photostabilization of wood using aromatic vinyl esters. Polym Degrad Stab 94:151–157

Kiguchi M, Evans PD (1998) Photostabilisation of wood surfaces using a grafted benzophenone UV absorber. Polym Degrad Stab 61:33–45

Kiguchi M, Evans PD, Ekstedt J, Williams RS, Kataoka Y (2001) Improvement of the durability of clear coatings by grafting of UV-absorbers on to wood. Surf Coat Int Part B Coat Trans 84:263–270

Matsuda H (1996) Chemical modification of solid wood. In: Hon DNS (ed) Chemical modification of lignocellulosic materials. Marcel Dekker, NY, pp 159–183

Meijer M, Bongers HPM, Riel S (2012) Outdoor weathering performance of acetylated wood. Proceedings of 8th International Wood coatings Congress “Science and Technology for Sustainable Design” The Netherlands

Mitsui K (2010) Acetylation of wood causes photobleaching. J Photochem Photobio B: Biol 101:210–214

Muller U, Ratzsch M, Schwanninger M, Steiner M, Zobi M (2003) Yellowing and IR changes of spruce wood as a result of UV irradiation. J Photochem Photobio B: Biol 69:97–105

Pandey KK (2005) Study of effect of photo-irradiation on surface chemistry of wood. Polym Degrad Stab 90:9–20

Pandey KK, Chandrashekar N (2006) Photostability of wood surfaces esterified by benzoyl chloride. J Appl Polym Sci 99:2367–2374

Pandey KK, Khali DP (1998) Accelerated weathering of wood modified by chromium trioxide. Holzforschung 52:467–471

Plackett DV, Dunningham EA, Singh AP (1996) Weathering of chemically modified wood. In: Hon DNS (ed) Chemical Modification of Lignocellulosic Materials. Marcel Dekker, NY, pp 277–294

Rowell RM (1984) Penetration and reactivity of cell wall components. In: Rowell RM (ed) The chemistry of solid wood. American Chemical Society, Washington, pp 175–210

Rowell RM (2006) Chemical modification of wood: A short review. Wood Mat Sci Eng 1:29–33

Salla J, Pandey KK, Prakash GK, Mahadevan KM (2012) Photobleaching and dimensional stability of rubberwood esterified by fatty acid chlorides. J Wood Chem Technol 32:121–136

Schaller C, Rogez D, Braig A (2008) Hydroxyphenyl-s-triazines: advanced multipurpose UV-absorbers for coatings. J Coat Technol Res 5:25–31

Schmalzl KJ, Evans PD (2003) Wood surface protection with some titanium, zirconium and manganese compounds. Polym Degrad Stab 82:409–419

Schmalzl KJ, Forsyth CM, Evans PD (2003) Evidence for the formation of chromium (III) diphenoquinone complexes during oxidation of guaiacol and 2,6-dimethoxyphenol with chromic acid. Polym Degrad Stab 82:399–407

Takahashi M (1996) Biological properties of chemically modified wood. In: Hon DNS (ed) Chemical modification of lignocellulosic materials. Marcel Dekker, NY, pp 331–361

Vollmer S, Evans PD (2013) Performance of clear coatings on modified wood exposed to the weather for 2 years in Australia. Int Wood Prod J 4:177–182

Williams RS (1983) Effect of grafted UV stabilizers on wood surface erosion and clear coating performance. J Appl Polym Sci 28:2093–2103

Williams RS (2005) Weathering of Wood. In: Rowell RM (ed) Handbook of Wood Chemistry and Wood Composites, vol 7. CRC Press, Boca Raton, pp 139–185

Williams RS, Feist WC (1985) Wood modified by inorganic salts: mechanism and properties. I. Weathering rate, water repellency, and dimensional stability of wood modified with chromium (III) nitrate versus chromic acid. Wood Fiber Sci 17:184–198

Xie Y, Krause A, Militz H, Mai C (2006) Coating performance of finishes on wood modified with an N-methylol compound. Prog Org Coat 57:291–300

Yuan T, Zhang L-M, Xu F, Sun R-C (2013) Enhanced photostability and thermal stability of wood by benzoylation in an ionic liquid system. Ind Crops Prod 45:36–43

Acknowledgments

This paper was presented at 44th IRG Annual Meeting held in Stockholm, Sweden 16–20 June 2013.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pandey, K.K., Srinivas, K. Performance of polyurethane coatings on acetylated and benzoylated rubberwood. Eur. J. Wood Prod. 73, 111–120 (2015). https://doi.org/10.1007/s00107-014-0860-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-014-0860-2