Abstract

Marine-capture shrimp is a general term for a type of shrimp that is different from marine-aquaculture shrimp. It is rich in protein, trace elements, and essential amino acids. It is an aquatic product with delicious meat and high nutritional and economic value. Most marine-capture shrimp are consumed fresh, with a small proportion subjected to processing. However, marine-capture shrimp is a highly perishable aquatic product, and hence, extensive preservation and processing methods have been developed to extend its shelf life. This review presents the current status of marine-capture shrimp in the world and the key issues (spoilage and melanization inhibition) regarding marine-capture shrimp preservation. Low-temperature preservation remains the predominant strategy for preserving marine-capture shrimp. Different preservation strategies combined with low temperature would maintain the quality of marine-capture shrimp more effectively, thereby extending the shelf life of the shrimp. The advantages and disadvantages of various preservation technologies are comprehensively considered and compared, as well as their scope of application. New processing technologies should be introduced, and various preservation technologies with complementary advantages should be organically combined to achieve the best preservation effect on marine-capture shrimp. This review provides a useful theoretical reference and a practical basis for future research on the shelf life extension of marine-capture shrimp.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Shrimp is one of the most popular aquatic products in the world due to its rich taste (Rusanova et al., 2022) and high nutritional content (Lv et al., 2020; Yu et al., 2022a). In terms of species classification, shrimp belong to different families in the suborder Dendrobranchiata of Decapoda, and being different from the aquaculture shrimp species, the marine-capture shrimp (Fig. 1) have unique species, such as Trachypenaeus curvirostris (Stimpson, 1860), and Parapenaeus longirostris (Lucas, 1846) in the family Penaeidae, Solenocera crassicornis (Milne Edwards, 1837) and Solenocera melantho (de Man, 1907) in the family Solenoceridae, and Acetes chinensis (Hansen, 1919) in the family Sergestidae. According to different production sources, shrimp can be divided into two types: marine shrimp and freshwater shrimp (Li et al., 2011). Based on whether they are produced by aquaculture or not, marine shrimp and freshwater shrimp can be further divided into marine capture shrimp and marine aquaculture shrimp and into freshwater capture shrimp and freshwater aquaculture shrimp, respectively. Shrimps that are mostly aquacultured and only partly caught in the ocean, such as the Pacific white shrimp (Penaeus vannamei, Boone, 1931), are not discussed in this review.

Species classification of shrimps (from order to family) (adapted from Lifemap, 2023)

As one of the most important products among fishery trading commodities (Hou et al., 2018), shrimps have been widely integrated into consumer diets due to its high quality protein and have become an indispensable delicacy worldwide. According to the Yearbooks published by FAO (2021), shrimp accounts for 3.36−3.78% of all capture production and occupy a relatively important position by statistics by weight (ton). However, overfishing of offshore fishery resources has led to the beginning of a decline in the production of marine-capture shrimp. Therefore, fishing moratoriums were established as a sustainable conservation measure (Ding et al., 2021). China is the leading producer and exporter of shrimp in the world. Indeed, the marine-capture shrimp production in China in 2020 was nearly 1.21 million tons (Fishery Knowledge Service System, 2022). Similarly, consumption and international trade demand are increasing annually, providing an advantageous market environment for the rapid development of shrimp foods and thus allowing the industry to have broad development prospects.

Shrimps are rich in water, protein, and highly active polyphenoloxidase (PPO) (Yu et al., 2022a); consequently, dead shrimps are easily degraded and spoiled during fishing, transportation, processing, and storage (Fan et al., 2022). The main causes of degradation include enzymatic autolysis (Huang et al., 2014), microbial spoilage (Broekaert et al., 2013), and lipid oxidation (Garcia-Soto et al., 2015). Lin et al. (2022) have conducted a detailed review of shrimp spoilage mechanisms. Shrimps will die soon after being caught due to being removed from their environment (Xu et al., 2017). At room temperature (25 °C), the shelf life of shrimp is approximately 1 day (Buyukcan et al., 2009), which can be extended to 4−6 days if placed at 4 °C. The shrimp will turn black over time, especially the head. Although the occurrence of blackening does not affect human health, it does greatly dissuade buyers. In order to solve these problems, researchers worldwide have conducted extensive research on how to preserve the freshness of marine-capture shrimp and how to minimize shrimp melanosis.

Based on the general concern about the preservation of marine-capture shrimp, this review aims to summarize the basic information about marine-capture shrimp in the world in recent years, analyze the production and species of marine-capture shrimp in China, the country with the highest consumption and production, and comprehensively present the current research trends (physical, chemical, and biological perspectives) on postharvest preservation of marine-capture shrimp. The characteristics and limitations of various preservation technologies used for marine-capture shrimp are objectively analyzed, and the direction of future technological development in marine-capture shrimp preservation is discussed. A theoretical reference and a practical basis are provided for future research on the shelf life extension of marine-capture shrimp.

Spoilage Mechanisms in Marine-Capture Shrimp

As with aquaculture shrimps, the mechanisms of spoilage in marine-capture shrimps include mainly biochemical reactions prior to stiffening, carcass lysis, and autolysis, and these were reviewed in detail by Peng et al. (2022). It is worth noting that marine-capture shrimps should focus on bacterial spoilage effects and blackening among these two most basic spoilage mechanisms.

Bacteria Spoilage Effects

Bacteria can cause spoilage of shrimps and also produce unpleasant odors. The main species associated with the spoilage of shrimps in sea catches include the genera Shewanella and Pseudomonas (Yu et al., 2022b). During shrimp spoilage, bacteria play a major role in the lysis phase of the carcass, including the production of various biogenic amines (which may cause allergies and other symptoms), the metabolisation of shrimp nutrients, and the production of unpleasant flavours (mainly trimethylamine and dimethylamine) (Peng et al., 2022).

Bacteria play a decisive role in the spoilage process, but often the shrimp muscle contains very few bacteria and more bacteria are enriched on the surface of the shell, so environmental and geographical factors are also key factors in determining the bacterial species contained in shrimp. Odeyemi et al. (2021) found that different environments and species determined the composition of the microbiota in shrimps. While excluding vacuum-packed shrimps, the storage environment also had an effect on the shrimp flora, and during this process, different bacterial populations underwent different changes at different stages of storage, which is considered a dynamic process.

Melanization

The bad appearance of fresh food will affect consumers’ desire to buy, and the blackening of shrimp is one of the main reasons for affecting the desire to buy. The current blackening phenomenon is explained as follows (Sharifian et al., 2019): (1) prophenoloxidase (proPO) is activated, and phenoloxidase (PO) catalyzes the conversion of monophenolic substrates to bisphenols in vivo and then forms highly reactive quinones that can spontaneously polymerize to produce browning, and (2) these quinones react with amino acids and proteins to form melanin (Jiang & Kanost, 2000; Nirmal & Benjakul, 2011; Sritunyalucksana & Soderhall, 2000; Terwilliger & Ryan, 2006) (Fig. 2). These chemical reactions lead to spontaneous oxidation and blackening of shrimp after death.

The mechanism of shrimp melanization. A Melanin production pathway. B The mechanism of PPO activation. PPO, Polyphenoloxidase; DHI, 5,6-dihydtoxyindole; IQ, indole 5,6-quinone; proPO, prophenoloxidase; LPS, lipopolysaccharide; p-APMSF, 4-amidino phenyl methane sulfonyl fluoride (Jiang & Kanost, 2000; Nirmal & Benjakul, 2011; Sritunyalucksana & Soderhall, 2000; Terwilliger & Ryan, 2006)

Even if there are no reports to prove that black substances can cause harm to the human body, the production of melanin does cause great difficulties in the actual consumption process. Therefore, more and more scholars have begun to focus on how to solve the production of melanin or inhibit melanin.

Preservation Strategies for Marine-Capture Shrimp

Traditional Preservation Technology

Low-Temperature Preservation

Low-temperature preservation is mainly aimed at preserving and keeping fresh shrimp alive during transportation and storage. The principle is to keep shrimp at a low temperature such that shrimp corporal temperature becomes stabilized within a lower range, thereby reducing the activity, stress responses, oxygen consumption, and metabolic rate of the live shrimps (Guo et al., 2010; Qiu et al., 2011; Ren et al., 2020), furthermore, inhibiting microbial metabolism and enzyme activity in dead shrimp (George, 1993; Pineiro et al., 2004). At present, low-temperature preservation is mainly divided into refrigerated preservation (0 to 4 °C), ice-temperature preservation (−2 to 0 °C), super-chilling preservation (−4 to −2 °C), and freezing preservation (−18 to −40 °C) (Leng et al., 2022; Pan et al., 2019). Ice-temperature and super-chilling preservation schemes are currently less used for economical shrimp, such as marine-capture shrimp because they have higher temperature control requirements, which results in excessively high costs. To our knowledge, some fishing vessels are now equipped with ultra-low-temperature equipment (< −60 °C); however, temperatures of −60 °C and below are more commonly used for laboratory preservation of precious biological samples, and the potential marginal gain in quality due to storage at −60 °C may be small for marine-capture shrimp (Ji et al., 2021). Nevertheless, most current research on freezing marine-capture shrimp for storage is mainly concentrated on the temperature range from −20 to −40 °C.

Parlapani et al. (2020) found that the shelf life of P. longirostris was extended from 2 days at 4 °C to 5 days at 0 °C, both temperatures at which the predominant microbes were Psychrobacter and Carnobacterium. Broekaert et al. (2013) found that Psychrobacter and Pseudoalteromonas were the predominant microbiota of Crangon crangon (Linnaeus, 1758) at 0 °C. The main volatile substances of P. longirostris at 0 °C were acetone and dimethyl sulfide, and at 4 °C, ethanol, 3-methyl-1-butanol, 2-ethyl-1-hexanol, 3-hydroxy-2-butanone, and indole (Parlapani et al., 2020). Compared with the S. melantho stored at 0, 3, and 6 °C, storing shrimp at −3 °C significantly inhibited spoilage (Xu et al., 2016). Furthermore, storage at −28 °C was more beneficial in slowing the deterioration of S. melantho than that at −20 °C or −12 °C (Xu et al., 2017). Overall, the lower the temperature, the less lipid oxidation was exhibited by S. melantho (Shi et al., 2017), which was also confirmed in S. crassicornis (Jin et al., 2018). At the same time, low temperature can effectively control the number of aerobic bacteria in marine-capture shrimp (Jin et al., 2018).

Among the preservation strategies of marine-capture shrimp, research on low-temperature preservation is the most in-depth; however, the actual effects achieved have not reached the ideal state. PPO in shrimp remains active at low refrigeration temperatures, even 0 to −20 °C (Montero et al., 2004; Nirmal & Benjakul, 2012), and can react slowly. Hence, this type of low-temperature storage cannot meet the requirements of shrimp storage during transportation and marketing, thereby affecting shrimp flavor and appearance. During freezing storage, moisture inside the shrimp is easily condensed into ice crystals that disrupt tissue structure, resulting in dry consumption, freezing denaturation, and other phenomena that strongly impact shrimp appearance, quality, and market value. Table 1 summarizes current preservation methods of marine-capture shrimp at low temperature combined with other methods (described in the following sections), aiming to provide more ideas for preserving marine-capture shrimp in the future.

Slurry Ice Preservation

Slurry ice, also known as liquid ice, is a natural and efficient cooling medium with a temperature of −1.5 to −0.5 °C (Liu et al., 2021). It is a homogeneous and stable two-phase mixture composed of an aqueous solution and ice crystals. Slurry ice shows the characteristics of small crystals and a large surface area (Huidobro et al., 2002). Aquatic products can be completely covered by slurry ice, and the temperature can be effectively lowered through its strong cooling capacity, inhibiting the reproduction of microorganisms and inactivating enzymes (Annamalai et al., 2018). In addition, slurry ice does not cause any mechanical damage to aquatic products during the preservation period (Lin et al., 2016) and can maintain the quality of aquatic products to the greatest extent (Annamalai et al., 2018). Currently, slurry ice is only suitable for pretreating fresh marine-capture shrimp on board. Generally, other preservation technologies, such as low-temperature preservation and MAP preservation, are more conducive to preserving marine-capture shrimp during transportation, processing, storage, and marketing. Huidobro et al. (2002) compared the effects of onboard slurry ice cooling and traditional flake-ice cooling on shrimp quality. Slurry ice can effectively inhibit the formation of nitrogen compounds and slow down the increase of pH and the growth of microorganisms. Slurry ice at −1.5 °C significantly extended the shelf life of P. borealis (Zeng et al., 2005).

In recent years, slurry ice has received much attention as a fast-cooling preservation technology. However, because it melts quickly, slurry ice may dissolve microorganisms and cause problems such as cross-contamination with shrimp meat. Therefore, special attention should be paid to draining the melted ice water as frequently as needed and replacing the slurry ice during the process of fresh shrimp preservation to achieve the best preservation results.

Chemical Preservation

Chemical preservation refers to a kind of preservation technology that uses the antibacterial and bactericidal effects of one or more drugs to be quantitatively added to the product according to the standard to achieve quality preservation and extension of the shelf life of the product. The mechanism underlying chemical preservation entails inhibiting the proliferation of harmful bacteria or their destruction with chemical substances, which can react with oxidase in the organism to achieve an antioxidant effect (Torres-Arreola et al., 2007). In marine-capture shrimp, chemical preservation is mainly used to prevent melanization. The traditional chemical preservative is sodium metabisulfite, which can effectively delay the melanization of fresh shrimp and inhibit microbial reproduction and the physiological oxidation process. Zhu et al. (2020) found that sodium metabisulfite can significantly inhibit the blackening of S. crassicornis. However, the excessive use of sodium metabisulfite leads to excessive SO2 residues, causing diseases such as gastrointestinal disorders, mucosal inflammation, and organ lesions (Rencuzogullari et al., 2001). Previous studies showed that 4-hexylresorcinol is an effective melanin inhibitor in marine-capture shrimp (Martinez-Alvarez et al., 2008; Montero et al., 2004) and that it tends to play a stronger role when combined with organic acids (citric, ascorbic, or acetic) and chelating agents (ethylenediaminetetraacetic acid and di-sodium di-hydrogen pyrophosphate) (Lopez-Caballero et al., 2019; Martinez-Alvarez et al., 2020); furthermore, the residual amount is relatively low (Montero et al., 2006). Other chemical preservatives can also act on marine-capture shrimp; for example, α-tocopherol maintained the muscle mass of Litopenaeus stylirostris (Stimpson, 1871) (Zulema Valencia-Perez et al., 2015), and phosphate treatment preserved the senses of Pleoticus muelleri (Spence Bate, 1888; Goncalves & Duarte Ribeiro, 2008).

Chemical preservation is advantageous due to its simplicity, efficiency, and low cost, although its application has certain limitations owing to the problems of SO2, excessive antibiotic residues, and bacterial resistance in marine-capture shrimps. From the perspective of food hygiene and public health, the future chemical preservation technology for marine-capture shrimp should be developed in a natural, safe, and non-toxic direction. For example, chemicals can be combined with biological preservation technology to reduce the dosage of chemical reagents, effectively preserving the freshness of marine-capture shrimp and reducing harmful residues.

Novel Preservation Technology

High-Pressure Preservation

High-pressure processing (HPP), also known as high hydrostatic pressure (HHP) (Campus, 2010), is a common non-thermal food processing technology (Oliveira et al., 2017). The underlying principle is to place flexible packaged food in a pressure vessel containing a pressure-transmitting liquid (usually water or an aqueous solution) that can withstand 100 to 1000 MPa (Zhang et al., 2019). The pressure is usually called ultra-high pressure (UHP) when it is greater than 600 MPa. Sterilization using high pressure is achieved due to the destruction of bacterial cell walls and membrane structure, change in the permeability of the cell membrane, and inhibition of the replication and enzymatic activity of DNA (Wang et al., 2016). However, UHP treatment acts only on non-covalent bonds (e.g., hydrogen bonds, hydrophobic bonds, ionic bonds) in biological macromolecules, while covalent bonds are not affected (Campus, 2010). Therefore, the original quality, color, taste, and nutritional value of the food can be better maintained while arresting all microbial activity (Linton & Patterson, 2000).

At present, HHP has been widely used in fruits and vegetables. Reports of HHP-treated shrimp basically focus on the quality (Kaur et al., 2013, 2015) and PPO (Huang et al., 2014) of aquaculture shrimp, but reports on marine-capture shrimp are scarce. The study by Lv et al. (2020) showed that HHP treatment at 100−200 MPa was optimal for S. melantho preservation. The solubility of the myofibrillar protein in shrimp treated with 300 MPa was reduced, and the surface hydrophobicity was increased, whereby the structure of the myofibrillar protein was partially converted from α-helical structure to α-sheet structure, thereby exposing tryptophan residues.

HHP preservation technology is a fresh shrimp preservation technology that can maintain the nutrition and quality of fresh shrimp without producing adverse reactions caused by thermal processing (Kaur et al., 2013). However, at pressures less than 600 MPa, the relative activity of PPO remains greater than 88% (Huang et al., 2014), but switching to higher pressures is challenging for large-scale applications due to the high cost of UHP processing equipment. Moreover, since the HHP preservation technology does not produce a significant lethal effect on bacterial spores, other auxiliary factors, such as acidity, temperature, and bacteriostatic agents, should be supplemented with this technology to achieve a maximal lethal effect.

Irradiation Preservation

Irradiation is a physical cold sterilization method (Yu et al., 2020), and the main irradiation sources currently used for shrimp preservation include γ-rays, X-rays, and the electron beam (EB) (Huang et al., 2019). Some of the properties of the three types of radiation are listed in Table 2. Food irradiation can effectively inactivate bacteria and pathogens with little impact on food nutrition or quality (Yu et al., 2020). Currently, doses of 0−10 kGy are widely accepted for food processing purposes (EFSA, 2011; Kontominas et al., 2021; WHO, 1999).

Irradiation has also been used for the preservation of marine-capture shrimp. Yu et al. (2022a) treated S. melantho by irradiating with different doses of EB and screened for the optimal dose based on physiological and biochemical indicators and microbial diversity. Further, by comparing the protein changes before and after irradiation, the effect of EB irradiation on S. melantho proteins was revealed (Yu et al., 2022c). Additionally, changes in shrimp metabolites after irradiation were observed by refrigeration (Yu et al., 2022b). The results of the study by Sharma et al. (2007) indicated that γ-irradiation at 2 kGy did not alter the sensory value of Solenocera chopri (Nataraj, 1945) muscles.

However, there are also some limitations of irradiation preservation; most countries currently only allow doses below 10 kGy for food processing (Kontominas et al., 2021), as high-dose irradiation treatments may produce off-flavors and reduce the nutritional quality of foods (Rodrigues et al., 2021). Presently, the acceptance of irradiated food by consumers is not high, resulting in limited research on the preservation of marine-capture shrimp using this technology in recent years. Therefore, it is still necessary to strengthen public understanding of irradiation preservation technology so that this emerging food preservation technology can play a more important role in shrimp preservation. Irradiated food and food-containing irradiated ingredients are required to be affixed with a label declaring them as irradiated food (Kontominas et al., 2021). Because consumers are wary of irradiated food, some businesses do not use labels or make declarations for economic benefit. Hence, Xiong et al. (2016) developed the multispectral imaging (MSI) system to identify whether marine-capture shrimp were irradiated or not.

Modified-Atmosphere Packaging (MAP) Preservation

Commonly used gases for MAP preservation include CO2, N2, and O2 (Sivertsvik et al., 2002). The general principle is to change the gas composition in the storage environment. For example, reducing O2 content (the factor that accelerates melanization of shrimp) and increasing CO2 and N2 contents can reduce the respiration rate of microorganisms in fresh shrimp, inhibit the reproduction and metabolism of microorganisms (Bouletis et al., 2017), and reduce PPO activity in the body (Qian et al., 2014), thereby maintaining the quality of shrimp products and prolonging the shelf life (Bouletis et al., 2017).

Bono et al. (2012) found that under freezing preservation (−35 °C) and MAP (100% N2) completely inhibited lipid oxidation in P. longirostris (better than 50%:50% N2: CO2) and inhibited melanosis for 6 months. This result was confirmed for Aristaeomorpha foliacea (Risso, 1827; Bono et al., 2016). Two MAPs (40%:30%:30% CO2:O2:N2 and 45%:5%:50% CO2:O2:N2) delayed microbial growth and production of trimethylamine and the total volatile nitrogen in P. longirostris (Lopez-Caballero et al., 2002); MAP involving 45%:5%:50% CO2:O2:N2 was better (Goncalves et al., 2003). After F. chinensis were soaked in compound fungicides and processed by MAP, their shelf life was extended to 13 days under 40%:30%:30% CO2:O2:N2 and 17 days under 100% CO2 at 2 °C (Lu, 2009). All microbial growth in Melicertus kerathurus (Forskål, 1775) was effectively inhibited under MAP 60%:40% CO2:N2 (Arvanitoyannis et al., 2011). MAP preservation was considered to be effective in C. crangon (Noseda et al., 2010), and different gas ratios (CO2:O2:N2) can inhibit microbial growth and reduce the metabolic effect of microorganisms, but the inhibitory effect will not be strong if the oxygen concentration is increased (Noseda et al., 2012). Under MAP involving 40%:60% CO2:N2, the predominant microorganisms in C. crangon at 4 °C were mainly Carnobacterium, Shewanella, and Psychrobacter (Calliauw et al., 2016). Nitrogen-filled packaging can effectively prolong the shelf life of P. borealis (Bak et al., 1999), and MAP treatment (50%:20%:30% CO2:O2:N2) of P. borealis effectively inhibits the growth of Listeria monocytogenes (Mejlholm et al., 2005).

As one of the most effective aquatic-preservation technologies in the world, MAP has been widely used in marine-capture shrimp preservation. Currently, MAP is mostly based on research conducted on pathogenic bacteria and the inhibitory effect of bacteria in marine-capture shrimp, while research on the influence of pathogenic bacteria and spores is relatively insufficient. This may explain why, although this method maintains the sensory quality of marine-capture shrimp, the safety of the method cannot be guaranteed. Furthermore, due to the high technical requirements and complexity of operation of this preservation method, it has neither become very popular nor widely adopted.

Acidic Electrolyzed Water (AEW) Preservation

As a new type of preservation technology, AEW shows efficient sterilization effects, no pollution, and no residues due to its low pH, high effective chlorine concentration, and high redox potential (Esua et al., 2021). These observations account for the increase in its use for sterilization and preservation of aquatic products in recent years (Gao et al., 2021; Lan et al., 2022).

Although AEW has rarely been reported to be applied to marine-capture shrimp, it is reported to significantly inhibit the proliferation of Vibrio parahaemolyticus, thereby maintaining the quality of fresh aquaculture shrimp and reducing the health threat of the pathogen during storage and transportation (Wang et al., 2014; Xie et al., 2012). AEW ice reportedly inhibits the growth of bacteria in aquaculture shrimp (Lin et al., 2013), destroys the conformation of PPO, slows down browning (Sun et al., 2018), and does not cause any adverse effects on shrimp (Wang et al., 2015).

AEW is easy to prepare and inexpensive (Esua et al., 2021) and will not cause the loss of shrimp color, flavor, or nutritional components during use, thus effectively overcoming the negative impact of traditional preservation technology on food quality. AEW ice can be better used to preserve fresh shrimp during summer. More research on AEW preservation technology will enable a more effective reduction of the potential harm caused by pathogenic bacteria in shrimp tissues and, thus, better ensure shrimp quality and safety.

Chemical Preservation

As a new chemical preservation method, ozone (O3) has been used to preserve the freshness of aquaculture shrimp (Goncalves & Lira Santos, 2019; Guo et al., 2013). Ozone destroys the bacterial cell wall, decomposes the membrane structure, and then diffuses into the interior of the cell, causing metabolic disorder and inhibiting growth (Kim et al., 2003). Ozone treatment is advantageous over traditional chemical preservatives for preserving marine-capture shrimp since the final product of ozone preservation is oxygen (Kim et al., 2003), which can effectively reduce the use of chemical preservatives, thereby improving food safety. At the same time, ozone sterilization is a non-thermal sterilization technology (Okpala, 2014), which can achieve the purpose of sterilization and anticorrosion without heating and thus save energy. However, it is vital to avoid high ozone concentrations to prevent its strong oxidizing power from adversely affecting shrimp quality (Okpala et al., 2016). There is currently little research on the application of ozone in preserving marine-capture shrimp despite ozone being able to prolong the shelf life of fresh shrimp effectively. Future preservation technology for marine-capture shrimp may possibly combine ozone preservation with low temperature, MAP preservation technology, and other technologies to enhance the preservation effect on fresh shrimp.

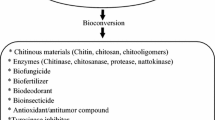

Biological Preservation

Biological preservation is an emerging research field derived from the theoretical study of biological sciences through integrating multiple disciplines. Its mechanism roughly includes (1) using related technologies to remove the air and inhibit enzyme activity so that oxidation is delayed and discoloration is prevented; (2) using substances with antibacterial, antioxidative, natural, and non-toxic properties to control the quality changes during food storage and transportation and to achieve anticorrosion and preservation effects; and (3) generating a protective film to prevent spoilage bacteria from breeding and contamination, slow down water loss, and maintain product quality. Recent research on biological preservatives mainly focuses on polyphenols, chitosan, and various biological extracts. Table 3 lists the relevant biological preservation methods currently used in marine-capture shrimp.

Although biological preservation has the potential to replace chemical preservation, the research and development of new biological preservation agents are not yet mature, and the research on the mechanism of biological preservation has not been studied in depth. Given the complex structure and composition of most biological preservatives, the low extraction rate, and the high technical requirements for the separation and purification process, the input cost is exceedingly high, greatly limiting its application in the actual storage and preservation process. In the future, it will still be necessary to strengthen further research on biotechnology and the development of new biological preservatives.

Other Preservation Technology

So far, there are also new preservation methods applied to various aquatic foods, including ultrasound, electrostatic fields, and magnetic fields (Abie et al., 2021). It is worth mentioning that Liu et al. (2022) applied a high-voltage electrostatic field to marine-capture shrimp, and the simulation diagram is shown in Fig. 3. Under the action of high-voltage electrostatic field, the ice crystal structure in the freezing process of red shrimp was improved, the freezing speed was increased, and the freezing quality of S. melantho was further improved, and the dose of the best electric field in the experiment was 15 kV/m.

Simulation diagram of high-voltage electrostatic field processing of marine-capture shrimp (Liu et al., 2022 with Elsevier permission)

Conclusions and Future Perspectives

Many of the preservation technologies for marine-capture shrimp described in this review can effectively prolong shrimp shelf life. However, each preservation technology shows its advantages and disadvantages. Therefore, in terms of the future practical application, the development of preservation technologies should comprehensively consider and compare the advantages and disadvantages of various preservation technologies and their applicability scope, and make reasonable use of the complementary advantages of various preservation technologies to combine different preservation technologies and achieve the best preservation effect on marine-capture shrimp.

In the future, the development of marine-capture shrimp preservation technology cannot be separated from preservatives. Presently, the main problem of preservatives is safety, followed by preservation efficacy and cost of use. Therefore, developing natural and efficient new preservatives is key to developing preservation technology. Due to the high cost and complexity of operation of many advanced preservation technologies, their development has been limited, and they are still in the research stage and have not yet been industrialized. At the same time, new processing and preservation technologies, such as voltage electrostatic fields and magnetic fields, have been applied to pork and fish, but no research has been reported on their application on marine-capture shrimp.

Therefore, future development of preservation technology for marine-capture shrimp should focus on safety, simplicity of operation, economy, and practicality to broaden the scope of application, thereby improving the economic and social benefits of shrimp preservation.

Data Availability

The data are available from the corresponding author upon suitable request.

References

Abie, S. M., Muench, D., Egelandsdal, B., Bjerke, F., Wergeland, I., & Martinsen, O. G. (2021). Combined 0.2 T static magnetic field and 20 kHz, 2 V/cm square wave electric field do not affect supercooling and freezing time of saline solution and meat samples. Journal of Food Engineering, 311, 110710. https://doi.org/10.1016/j.jfoodeng.2021.110710

Alparslan, Y., & Baygar, T. (2017). Effect of chitosan film coating combined with orange peel essential oil on the shelf life of deepwater pink shrimp. Food and Bioprocess Technology, 10(5), 842–853. https://doi.org/10.1007/s11947-017-1862-y

Alparslan, Y., Metin, C., Yapici, H. H., Baygar, T., Gunlu, A., & Baygar, T. (2017). Combined effect of orange peel essential oil and gelatin coating on the quality and shelf life of shrimps. Journal of Food Safety and Food Quality-Archiv Fur Lebensmittelhygiene, 68(3), 69–78. https://doi.org/10.2376/0003-925x-68-69

Annamalai, J., Lakshmi, N. M., Sivam, V., & Rao, R. C. N. (2018). A comparative study on the quality changes of croaker (Johnius dussumieri) fish stored in slurry ice and flake ice. Journal of Aquatic Food Product Technology, 27(4), 508–517. https://doi.org/10.1080/10498850.2018.1449152

Arvanitoyannis, I. S., Vasiliki, K., Bouletis, A. D., & Papaloucas, C. (2011). Study of changes in physicochemical and microbiological characteristics of shrimps (Melicertus kerathurus) stored under modified atmosphere packaging. Anaerobe, 17(6), 292–294. https://doi.org/10.1016/j.anaerobe.2011.04.006

Asik, E., & Candogan, K. (2014). Effects of chitosan coatings incorporated with garlic oil on quality characteristics of shrimp. Journal of Food Quality, 37(4), 237–246. https://doi.org/10.1111/jfq.12088

Avola, C., Licciardello, F., Mazzaglia, A., Giannone, V., Zanti, C., & Muratore, G. (2011). Quality evaluation of shrimps (Parapenaeus longirostris) as affected by edible films. Italian Journal of Food Science, 23, 99–102.

Bak, L. S., Andersen, A. B., Andersen, E. M., & Bertelsen, G. (1999). Effect of modified atmosphere packaging on oxidative changes in frozen stored cold water shrimp (Pandalus borealis). Food Chemistry, 64(2), 169–175. https://doi.org/10.1016/s0308-8146(98)00152-6

Bingol, E. B., Bostan, K., Varlik, C., Uran, H., Alakavuk, D. U., & Sivri, N. (2015). Effects of chitosan treatment on the quality parameters of shrimp (Parapenaeus longirostris) during chilled storage. Turkish Journal of Fisheries and Aquatic Sciences, 15(4), 821–831. https://doi.org/10.4194/1303-2712-v15_4_05

Bingol, E. B., Uran, H., Bostan, K., Varlik, C., Sivri, N., & Alakavuk, D. U. (2013). Effects of treatment with chitosan on sensory and chemical quality parameters of frozen shrimp. Kafkas Universitesi Veteriner Fakultesi Dergisi, 19(3), 399–405. https://doi.org/10.9775/kvfd.2012.7902

Bono, G., Badalucco, C. V., Cusumano, S., & Palmegiano, G. B. (2012). Toward shrimp without chemical additives: a combined freezing-MAP approach. Lwt-Food Science and Technology, 46(1), 274–279. https://doi.org/10.1016/j.lwt.2011.09.020

Bono, G., Okpala, C. O. R., Alberio, G. R. A., Messina, C. M., Santulli, A., Giacalone, G., & Spagna, G. (2016). Toward shrimp consumption without chemicals: combined effects of freezing and modified atmosphere packaging (MAP) on some quality characteristics of Giant Red Shrimp (i) during storage. Food Chemistry, 197, 581–588. https://doi.org/10.1016/j.foodchem.2015.10.146

Bouletis, A. D., Arvanitoyannis, I. S., & Hadjichristodoulou, C. (2017). Application of modified atmosphere packaging on aquacultured fish and fish products: a review. Critical Reviews in Food Science and Nutrition, 57(11), 2263–2285. https://doi.org/10.1080/10408398.2013.862202

Broekaert, K., Heyndrickx, M., Herman, L., Devlieghere, F., & Vlaemynck, G. (2013). Molecular identification of the microbiota of peeled and unpeeled brown shrimp (Crangon crangon) during storage on ice and at 7.5 degrees C. Food Microbiology, 36(2), 123–134. https://doi.org/10.1016/j.fm.2013.04.009

Buyukcan, M., Bozoglu, F., & Alpas, H. (2009). Preservation and shelf-life extension of shrimps and clams by high hydrostatic pressure. International Journal of Food Science and Technology, 44(8), 1495–1502. https://doi.org/10.1111/j.1365-2621.2007.01628.x

Calliauw, F., De Mulder, T., Broekaert, K., Vlaemynck, G., Michiels, C., & Heyndrickx, M. (2016). Assessment throughout a whole fishing year of the dominant microbiota of peeled brown shrimp (Crangon crangon) stored for 7 days under modified atmosphere packaging at 4 degrees C without preservatives. Food Microbiology, 54, 60–71. https://doi.org/10.1016/j.fm.2015.10.016

Campus, M. (2010). High pressure processing of meat, meat products and seafood. Food Engineering Reviews, 2(4), 256–273. https://doi.org/10.1007/s12393-010-9028-y

Ding, L., Lu, M., & Xue, Y. (2021). Driving factors on implementation of seasonal marine fishing moratorium system in China using evolutionary game. Marine Policy, 133, 104707. https://doi.org/10.1016/j.marpol.2021.104707

EFSA. (2011). Scientific opinion on the chemical safety of irradiation of food. EFSA Journal, 9(4), 1930. https://doi.org/10.2903/j.efsa.2011.1930

Elvira Lopez-Caballero, M., Martinez-Alvarez, O., del Carmea, G. -G., & Montero, P. (2007). Quality of thawed deepwater pink shrimp (Parapenaeus longirostris) treated with melanosis-inhibiting formulations during chilled storage. International Journal of Food Science and Technology, 42(9), 1029–1038. https://doi.org/10.1111/j.1365-2621.2006.01328.x

Esua, O. J., Cheng, J. H., & Sun, D. W. (2021). Functionalization of water as a nonthermal approach for ensuring safety and quality of meat and seafood products. Critical Reviews in Food Science and Nutrition, 61(3), 431–449. https://doi.org/10.1080/10408398.2020.1735297

Faisal, M., Vasiljevic, T., & Donkor, O. N. (2019). Effects of selected processing treatments on antigenicity of banana prawn (Fenneropenaeus merguiensis) tropomyosin. International Journal of Food Science and Technology, 54(1), 183–193. https://doi.org/10.1111/ijfs.13922

Fan, Y., Schneider, K. R., & Sarnoski, P. J. (2022). Determining spoilage of whiteleg shrimp (Litopanaeus vannemei) during refrigerated storage using colorimetric strips. Food Chemistry X, 14, 100263. https://doi.org/10.1016/j.fochx.2022.100263

FAO. (2021). FAO Yearbook. Fishery and Aquaculture Statistics 2019/FAO annuaire. Retrieved January 22,2022. https://www.fao.org/fishery/en/publications/287024

Fishery Knowledge Service System. (2022). Chinese Academy of Fishery Sciences (CAFS). Retrieved January 22, 2022, from http://fishery.ckcest.cn/featureYearbook.html

Gao, Y., Jiang, H., Lv, D., Benjakul, S., & Zhang, B. (2021). Shelf-life of half-shell mussel (Mytilus edulis) as affected by pullulan, acidic electrolyzed water, and stable chlorine dioxide combined ice-glazing during frozen storage. Foods, 10(8), 1896.

Garcia-Soto, B., Miranda, J. M., Barros-Velazquez, J., & Aubourg, S. P. (2015). Quality changes during the frozen storage of the crustacean lobster krill (Munida spp.). European Journal of Lipid Science and Technology, 117(4), 431–439. https://doi.org/10.1002/ejlt.201400309

Ge, Y., Li, Y., Wu, T., Bai, Y., Yuan, C., Chen, S., & Hu, Y. (2020). The preservation effect of CGA-Gel combined with partial freezing on sword prawn (Parapenaeopsis hardwickii). Food Chemistry, 313, 126078. https://doi.org/10.1016/j.foodchem.2019.126078

George, R. M. (1993). Freezing proceseses used in the food industry. Trends in Food Science & Technology, 4(5), 134–138. https://doi.org/10.1016/0924-2244(93)90032-6

Goncalves, A. A., & Duarte Ribeiro, J. L. (2008). Optimization of the freezing process of red shrimp (Pleoticus muelleri) previously treated with phosphates. International Journal of Refrigeration-Revue Internationale Du Froid, 31(7), 1134–1144. https://doi.org/10.1016/j.ijrefrig.2008.03.005

Goncalves, A. A., & Duarte Ribeiro, J. L. (2009). Effects of phosphate treatment on quality of red shrimp (Pleoticus muelleri) processed with cryomechanical freezing. Lwt-Food Science and Technology, 42(8), 1435–1438. https://doi.org/10.1016/j.lwt.2009.03.016

Goncalves, A. A., & Guidobono Gindri Junior, C. S. (2009). The effect of glaze uptake on storage quality of frozen shrimp. Journal of Food Engineering, 90(2), 285–290. https://doi.org/10.1016/j.jfoodeng.2008.06.038

Goncalves, A. A., & Lira Santos, T. C. (2019). Improving quality and shelf-life of whole chilled Pacific white shrimp (Litopenaeus vannamei) by ozone technology combined with modified atmosphere packaging. Lwt-Food Science and Technology, 99, 568–575. https://doi.org/10.1016/j.lwt.2018.09.083

Goncalves, A. C., Lopez-Caballero, M. E., & Nunes, M. L. (2003). Quality changes of deepwater pink shrimp (Parapenaeus longirostris) packed in modified atmosphere. Journal of Food Science, 68(8), 2586–2590. https://doi.org/10.1111/j.1365-2621.2003.tb07065.x

Gringer, N., Skytte, J. L., Tem Thi, D., Orlien, V., Olsen, K., Schlippe-Steffensen, K., & Jessen, F. (2020). Effect of ice maturation, freezing and heat treatment on the peelability and quality of cold water shrimps (Pandalus borealis). Lwt-Food Science and Technology, 134, 110139. https://doi.org/10.1016/j.lwt.2020.110139

Guo, B., Wang, F., Dong, S., Dong, Y., & Tian, X. (2010). The effects of cyclical temperature changes on growth and physiological status of Litopenaeus vannamei. Aquaculture International, 18(5), 921–932. https://doi.org/10.1007/s10499-009-9314-y

Guo, M., Jin, T. Z., Yang, R., Antenucci, R., Mills, B., Cassidy, J., & Sommers, C. H. (2013). Inactivation of natural microflora and inoculated Listeria innocua on whole raw shrimp by ozonated water, antimicrobial coatings, and cryogenic freezing. Food Control, 34(1), 24–30. https://doi.org/10.1016/j.foodcont.2013.04.009

Hocaoglu, A., Demirci, A. S., Gumus, T., & Demirci, M. (2012). Effects of gamma irradiation on chemical, microbial quality and shelf life of shrimp. Radiation Physics and Chemistry, 81(12), 1923–1929. https://doi.org/10.1016/j.radphyschem.2012.07.017

Hou, D., Huang, Z., Zeng, S., Liu, J., Wei, D., Deng, X., & He, J. (2018). Intestinal bacterial signatures of white feces syndrome in shrimp. Applied Microbiology and Biotechnology, 102(8), 3701–3709. https://doi.org/10.1007/s00253-018-8855-2

Huang, M., Zhang, M., & Bhandari, B. (2019). Recent development in the application of alternative sterilization technologies to prepared dishes: a review. Critical Reviews in Food Science and Nutrition, 59(7), 1188–1196. https://doi.org/10.1080/10408398.2017.1421140

Huang, W., Ji, H., Liu, S., Zhang, C., Chen, Y., Guo, M., & Hao, J. (2014). Inactivation effects and kinetics of polyphenol oxidase from Litopenaeus vannamei by ultra-high pressure and heat. Innovative Food Science & Emerging Technologies, 26, 108–115. https://doi.org/10.1016/j.ifset.2014.10.005

Huidobro, A., Lopez-Caballero, M. E., & Mendes, R. (2002). Onboard processing of deepwater pink shrimp (Parapenaeus longirostris) with liquid ice: effect on quality. European Food Research and Technology, 214(6), 469–475. https://doi.org/10.1007/s00217-002-0490-5

Ji, W., Bao, Y., Wang, K., Yin, L., & Zhou, P. (2021). Protein changes in shrimp (Metapenaeus ensis) frozen stored at different temperatures and the relation to water-holding capacity. International Journal of Food Science and Technology, 56(8), 3924–3937. https://doi.org/10.1111/ijfs.15009

Jiang, H. B., & Kanost, M. R. (2000). The clip-domain family of serine proteinases in arthropods. Insect Biochemistry and Molecular Biology, 30(2), 95–105. https://doi.org/10.1016/s0965-1748(99)00113-7

Jin, L., Ding, G., Li, P., Gu, J., & Zhang, X. (2018). Changes in quality attributes of marine-trawling shrimp (Solenocera crassicornis) during storage under different deep-frozen temperatures. Journal of Food Science and Technology-Mysore, 55(8), 2890–2898. https://doi.org/10.1007/s13197-018-3207-x

Kaur, B. P., Kaushik, N., Rao, P. S., & Chauhan, O. P. (2013). Effect of high-pressure processing on physical, biochemical, and microbiological characteristics of black tiger shrimp (Penaeus monodon). Food and Bioprocess Technology, 6(6), 1390–1400. https://doi.org/10.1007/s11947-012-0870-1

Kaur, B. P., Kaushik, N., Rao, P. S., & Mishra, H. N. (2015). Chilled storage of high pressure processed black tiger shrimp (Penaeus monodon). Journal of Aquatic Food Product Technology, 24(3), 283–299. https://doi.org/10.1080/10498850.2013.772271

Kim, J. G., Yousef, A. E., & Khadre, M. A. (2003). Ozone and its current and future application in the food industry. Advances in Food and Nutrition Research, 45, 167–218.

Kontominas, M. G., Badeka, A. V., Kosma, I. S., & Nathanailides, C. I. (2021). Innovative seafood preservation technologies: recent developments. Animals, 11(1), 92. https://doi.org/10.3390/ani11010092

Lan, W., Sun, Y., Feng, H., & Xie, J. (2022). Effects of slightly acidic electrolyzed water pretreatment combined with compound bio-preservatives on quality and microbiota changes of refrigerated obscure pufferfish (Takifugu obscurus). Journal of Food Processing and Preservation, 46(2), e16287. https://doi.org/10.1111/jfpp.16287

Leng, D., Zhang, H., Tian, C., & Xu, H. (2022). Low temperature preservation developed for special foods in East Asia: a review. Journal of Food Processing and Preservation, 46(1), e16176. https://doi.org/10.1111/jfpp.16176

Lin, D. Q., Sun, L. C., Chen, Y. L., Liu, G. M., Miao, S., & Cao, M. J. (2022). Shrimp spoilage mechanisms and functional films/coatings used to maintain and monitor its quality during storage. Trends in Food Science and Technology, 129, 25–27. https://doi.org/10.1016/j.tifs.2022.08.020

Li, G., Sinclair, A. J., & Li, D. (2011). Comparison of lipid content and fatty acid composition in the edible meat of wild and cultured freshwater and marine fish and shrimps from China. Journal of Agricultural and Food Chemistry, 59(5), 1871–1881. https://doi.org/10.1021/jf104154q

Lifemap. National Center of Biotechnology Information (NCBI). Retrieved January 25, 2023, from http://lifemap-ncbi.univ-lyon1.fr

Lin, H. M., Deng, S. G., Huang, S. B., & Guo, H. (2016). Effects of precooling with slurry ice on the quality and microstructure of anglerfish (Lophius americanus) liver. Journal of Food Process Engineering, 39(1), 3–10. https://doi.org/10.1111/jfpe.12193

Lin, T., Wang, J. J., Li, J. B., Liao, C., Pan, Y. J., & Zhao, Y. (2013). Use of acidic electrolyzed water ice for preserving the quality of shrimp. Journal of Agricultural and Food Chemistry, 61(36), 8695–8702. https://doi.org/10.1021/jf4019933

Linton, M., & Patterson, M. F. (2000). High pressure processing of foods for microbiological safety and quality (a short review). Acta Microbiologica Et Immunologica Hungarica, 47(2−3), 175–182. https://doi.org/10.1556/AMicr.47.2000.2-3.3

Liu, B., & Pan, S. (2020). Effect of chitosan coatings incorporated sodium phytate on the shelf-life of Antarctic krill (Euphausia superba). International Journal of Biological Macromolecules, 151, 62–65. https://doi.org/10.1016/j.ijbiomac.2020.02.148

Liu, J., Wang, Y., Zhu, F. X., Yang, J., Ma, X. H., Lou, Y. J., & Li, Y. Y. (2022). The effects of freezing under a high-voltage electrostatic field on ice crystals formation, physicochemical indices, and bacterial communities of shrimp (Solenocera melantho). Food Control, 142, 109238. https://doi.org/10.1016/j.foodcont.2022.109238

Liu, L., Lan, W., Pu, T., Zhou, Y., & Xie, J. (2021). Combining slightly acidic electrolyzed water and slurry ice to prolong the shelf-life of mackerel (Pneumatophorus japonicus). Journal of Food Processing and Preservation, 45(9), e15762. https://doi.org/10.1111/jfpp.15762

Lopez-Caballero, M. E., Goncalves, A., & Nunes, M. L. (2002). Effect of CO2/O-2-containing deepwater pink shrimp modified atmospheres on packed (Parapenaeus longirostris). European Food Research and Technology, 214(3), 192–197. https://doi.org/10.1007/s00217-001-0472-z

Lopez-Caballero, M. E., Martinez-Alvarez, O., Gomez-Guillen, M. C., & Montero, P. (2019). Several melanosis-inhibiting formulas to enhance the quality of deepwater pink shrimp (Parapenaeus longirostris). Innovative Food Science & Emerging Technologies, 51, 91–99. https://doi.org/10.1016/j.ifset.2018.07.008

Lu, S. (2009). Effects of bactericides and modified atmosphere packaging on shelf-life of Chinese shrimp (Fenneropenaeus chinensis). Lwt-Food Science and Technology, 42(1), 286–291. https://doi.org/10.1016/j.lwt.2008.03.004

Lv, M. C., Zhang, H., Mei, K. L., Yang, W. G., & Wang, Z. Y. (2020). Effects of High Pressure on Myofibrillar Protein and Moisture Distribution of Shrimp (Solenocera melantho) Muscle. Journal of Aquatic Food Product Technology, 29(3), 220–228. https://doi.org/10.1080/10498850.2020.1718818

Martinez- Alvarez, O., Montero, P., & del Gomez-Guillen, M. (2005). Controlled atmosphere as coadjuvant to chilled storage for prevention of melanosis in shrimps (Parapenaeus longirostris). European Food Research and Technology, 220(2), 125–130. https://doi.org/10.1007/s00217-004-1015-1

Martinez-Alvarez, O., Gomez-Guillen, C., & Montero, P. (2008). Effect of different chemical compounds as coadjutants of 4-hexylresorcinol on the appearance of deepwater pink shrimp (Parapenaeus longirostris) during chilled storage. International Journal of Food Science and Technology, 43(11), 2010–2018. https://doi.org/10.1111/j.1365-2621.2008.01810.x

Martinez-Alvarez, O., Lopez-Caballero, M. E., Montero, P., & del Carmen Gomez-Guillen, M. (2020). The effect of different melanosis-inhibiting blends on the quality of frozen deep-water rose shrimp (Parapenaeus longirostris). Food Control, 109, 106889. https://doi.org/10.1016/j.foodcont.2019.106889

Mejlholm, O., Boknaes, N., & Dalgaard, P. (2005). Shelf life and safety aspects of chilled cooked and peeled shrimps (Pandalus borealis) in modified atmosphere packaging. Journal of Applied Microbiology, 99(1), 66–76. https://doi.org/10.1111/j.1365-2672.2005.02582.x

Miraglia, D., Castrica, M., Menchetti, L., Esposto, S., Branciari, R., Ranucci, D., & Servili, M. (2020). Effect of an olive vegetation water phenolic extract on the physico-chemical, microbiological and sensory traits of shrimp (Parapenaeus longirostris) during the Shelf-Life. Foods, 9(11), 1647. https://doi.org/10.3390/foods9111647

Montero, P., Martinez-Alvarez, O., & Gomez-Guillen, M. C. (2004). Effectiveness of onboard application of 4-hexylresorcinol in inhibiting melanosis in shrimp (Parapenaeus longirostris). Journal of Food Science, 69(8), C643–C647. https://doi.org/10.1111/j.1365-2621.2004.tb09913.x

Montero, P., Martinez-Alvarez, O., Zamorano, J. P., Alique, R., & Gomez-Guillen, M. C. (2006). Melanosis inhibition and 4-hexylresorcinol residual levels in deepwater pink shrimp (Parapenaeus longirostris) following various treatments. European Food Research and Technology, 223(1), 16–21. https://doi.org/10.1007/s00217-005-0080-4

Nirmal, N. P., & Benjakul, S. (2011). Use of tea extracts for inhibition of polyphenoloxidase and retardation of quality loss of Pacific white shrimp during iced storage. Lwt-Food Science and Technology, 44(4), 924–932. https://doi.org/10.1016/j.lwt.2010.12.007

Nirmal, N. P., & Benjakul, S. (2012). Effect of green tea extract in combination with ascorbicacid on the retardation of melanosis and quality changes of pacific white shrimp during iced storage. Food and Bioprocess Technology, 5, 2941–2951. https://doi.org/10.1007/s11947-010-0483-5

Noseda, B., Dewulf, J., Goethals, J., Ragaert, P., Van Bree, I., Pauwels, D., & Devlieghere, F. (2010). Effect of food matrix and ph on the volatilization of bases (TVB) in packed north Atlantic gray shrimp (Crangon crangon): volatile bases in MAP fishery products. Journal of Agricultural and Food Chemistry, 58(22), 11864–11869. https://doi.org/10.1021/jf1025218

Noseda, B., Goethals, J., De Smedt, L., Dewulf, J., Samapundo, S., Van Langenhove, H., & Devlieghere, F. (2012). Effect of O-2 - CO2 enriched atmospheres on microbiological growth and volatile metabolite production in packaged cooked peeled gray shrimp (Crangon crangon). International Journal of Food Microbiology, 160(1), 65–75. https://doi.org/10.1016/j.ijfoodmicro.2012.09.018

Odeyemi, A. O., Dabade, S. D., Amin, M., Dewi, F., Waiho, K., & Kasan, A. N. (2021). Microbial diversity and ecology of crustaceans: influencing factors and future perspectives. Current Opinion in Food Science, 39, 140–143. https://doi.org/10.1016/j.cofs.2021.01.001

Okpala, C. O. R. (2014). Investigation of quality attributes of ice-stored Pacific white shrimp (Litopenaeus vannamei) as affected by sequential minimal ozone treatment. Lwt-Food Science and Technology, 57(2), 538–547. https://doi.org/10.1016/j.lwt.2014.02.007

Okpala, C. O. R., Bono, G., Cannizzaro, L., & Jereb, P. (2016). Changes in lipid oxidation and related flesh qualities of white shrimp (Litopenaeus vannamei) during iced storage: effects on the use of increasing ozone exposures. European Journal of Lipid Science and Technology, 118(12), 1942–1951. https://doi.org/10.1002/ejlt.201500347

Oliveira, F. A. d., Neto, O. C., Santos, L. M. R. d., Ferreira, E. H. R., & Rosenthal, A. (2017). Effect of high pressure on fish meat quality − a review. Trends in Food Science & Technology, 66, 1–19. https://doi.org/10.1016/j.tifs.2017.04.014

Orlowska, M., Havet, M., & Le-Bail, A. (2009). Controlled ice nucleation under high voltage DC electrostatic field conditions. Food Research International, 42(7), 879-884. https://doi.org/10.1016/j.foodres.2009.03.015

Pan, C., Chen, S., Hao, S., & Yang, X. (2019). Effect of low-temperature preservation on quality changes in Pacific white shrimp, Litopenaeus vannamei: a review. Journal of the Science of Food and Agriculture, 99(14), 6121–6128. https://doi.org/10.1002/jsfa.9905

Parlapani, F. F., Ferrocino, I., Michailidou, S., Argiriou, A., Haroutounian, S. A., Kokokiris, L., & Boziaris, I. S. (2020). Microbiota and volatilome profile of fresh and chill-stored deepwater rose shrimp (Parapenaeus longirostris). Food Research International, 132, 109057. https://doi.org/10.1016/j.foodres.2020.109057

Pati, S., Sarkar, T., Sheikh, H. I., Bharadwaj, K. K., Mohapatra, P. K. A., Chatterji, A., & Nelson, B. R. (2021). Gamma-irradiated chitosan from Carcinoscorpius rotundicauda (Latreille, 1802) improves the shelf life of refrigerated aquatic products. Frontiers in Marine Science, 8, 664961. https://doi.org/10.3389/fmars.2021.664961

Peng, S., Wei, H., Zhan, S., Yang, W., Lou, Q., Deng, S., Yu, X., & Huang, T. (2022). Spoilage mechanism and preservation technologies on the quality of shrimp: an overview. Trends in Food Science & Technology, 129, 233–243. https://doi.org/10.1016/j.tifs.2022.09.024

Pi, X., Yang, Y., Sun, Y., Wang, X., Wan, Y., Fu, G., & Cheng, J. (2021). Food irradiation: a promising technology to produce hypoallergenic food with high quality. Critical Reviews in Food Science and Nutrition. https://doi.org/10.1080/10408398.2021.1904822

Pineiro, C., Barros-Velazquez, J., & Aubourg, S. P. (2004). Effects of newer slurry ice systems on the quality of aquatic food products: a comparative review versus flake-ice chilling methods. Trends in Food Science & Technology, 15(12), 575–582. https://doi.org/10.1016/j.tifs.2004.09.005

Qian, Y. F., Xie, J., Yang, S. P., Wu, W. H., Xiong, Q., & Gao, Z. L. (2014). In vivo study of spoilage bacteria on polyphenoloxidase activity and melanosis of modified atmosphere packaged Pacific white shrimp. Food Chemistry, 155, 126–131. https://doi.org/10.1016/j.foodchem.2014.01.031

Qiu, J., Wang, W. N., Lj, W., Liu, Y. F., & Wang, A. L. (2011). Oxidative stress, DNA damage and osmolality in the Pacific white shrimp, Litopenaeus vannamei exposed to acute low temperature stress. Comparative Biochemistry and Physiology C-Toxicology & Pharmacology, 154(1), 36–41. https://doi.org/10.1016/j.cbpc.2011.02.007

Qiu, X., Wu, Y., Chen, S., Sun, L., Liu, G., & Lin, H. (2020). Oxidative stability and browning development of semi-dried shrimp (Acetes chinensis) with different salt contents and packaging methods stored at refrigerated temperature. Food Science and Technology Research, 26(2), 239–245. https://doi.org/10.3136/fstr.26.239

Ren, X., Yu, Z., Xu, Y., Zhang, Y., Mu, C., Liu, P., & Li, J. (2020). Integrated transcriptomic and metabolomic responses in the hepatopancreas of kuruma shrimp (Marsupenaeus japonicus) under cold stress. Ecotoxicology and Environmental Safety, 206, 111360. https://doi.org/10.1016/j.ecoenv.2020.111360

Rencuzogullari, E., Ila, H. B., Kayraldiz, A., & Topaktas, M. (2001). Chromosome aberrations and sister chromatid exchanges in cultured human lymphocytes treated with sodium metabisulfite, a food preservative. Mutation Research-Genetic Toxicology and Environmental Mutagenesis, 490(2), 107–112. https://doi.org/10.1016/s1383-5718(00)00142-x

Rusanova, P., Bono, G., Dara, M., Falco, F., Gancitano, V., Lo Brutto, S., Okpala, C. O. R., Nirmal, N. P., Quattrocchi, F., Sardo, G., & Hassoun, A. (2022). Effect of different packaging methods on the free amino acid profiles of the deep-water rose shrimp (Parapenaeus longirostris) during frozen storage. Frontiers in Nutrition, 9, 955216. https://doi.org/10.3389/fnut.2022.955216

Rodrigues, I., Baldini, A., Pires, M., Barros, J. C., Fregonesi, R., de Lima, C. G., & Trindade, M. A. (2021). Gamma ray irradiation: a new strategy to increase the shelf life of salt-reduced hot dog wieners. Lwt-Food Science and Technology, 135, 110265. https://doi.org/10.1016/j.lwt.2020.110265

Sadok, S., Abdelmoulah, A., & El Abed, A. (2004). Combined effect of sepia soaking and temperature on the shelf life of peeled shrimp Penaeus kerathurus. Food Chemistry, 88(1), 115–122. https://doi.org/10.1016/j.foodchem.2003.12.031

Sharifian, S., Shabanpour, B., Taheri, A., & Kordjazi, M. (2019). Effect of phlorotannins on melanosis and quality changes of Pacific white shrimp (Litopenaeus vannamei) during iced storage. Food Chemistry, 298, 124980. https://doi.org/10.1016/j.foodchem.2019.124980

Sharma, S. K., Basu, S., & Gholap, A. S. (2007). Effect of irradiation on the volatile compounds of shrimp (Solenocera choprii). Journal of Food Science and Technology, 44, 267–271.

Shi, J., Lei, Y., Shen, H., Hong, H., Yu, X., Zhu, B., & Luo, Y. (2019). Effect of glazing and rosemary (Rosmarinus officinalis) extract on preservation of mud shrimp (Solenocera melantho) during frozen storage. Food Chemistry, 272, 604–612. https://doi.org/10.1016/j.foodchem.2018.08.056

Shi, J., Zhang, L., Lu, H., Shen, H., Yu, X., & Luo, Y. (2017). Protein and lipid changes of mud shrimp (Solenocera melantho) during frozen storage: chemical properties and their prediction. International Journal of Food Properties, 20, 2043–2056. https://doi.org/10.1080/10942912.2017.1361973

Sivertsvik, M., Jeksrud, W. K., & Rosnes, J. T. (2002). A review of modified atmosphere packaging of fish and fishery products - significance of microbial growth, activities and safety. International Journal of Food Science and Technology, 37(2), 107–127. https://doi.org/10.1046/j.1365-2621.2002.00548.x

Soltanizadeh, N., & Mousavinejad, M. S. (2015). The effects of Aloe vera (Aloe barbadensis) coating on the quality of shrimp during cold storage. Journal of Food Science and Technology-Mysore, 52(10), 6647–6654. https://doi.org/10.1007/s13197-015-1747-x

Sritunyalucksana, K., & Soderhall, K. (2000). The proPO and clotting system in crustaceans. Aquaculture, 191(1−3), 53–69. https://doi.org/10.1016/s0044-8486(00)00411-7

Sun, J., Wang, M., Liu, H., Xie, J., Pan, Y., Xu, C., & Zhao, Y. (2018). Acidic electrolysed water delays browning by destroying conformation of polyphenoloxidase. Journal of the Science of Food and Agriculture, 98(1), 147–153. https://doi.org/10.1002/jsfa.8449

Terwilliger, N. B., & Ryan, M. C. (2006). Functional and phylogenetic analyses of phenoloxidases from brachyuran (Cancer magister) and branchiopod (Artemia franciscana, Triops longicaudatus) crustaceans. Biological Bulletin, 210(1), 38–50. https://doi.org/10.2307/4134535

Torres-Arreola, W., Soto-Valdez, H., Peralta, E., Cardenas-Lopez, J. L., & Ezquerra-Brauer, J. M. (2007). Effect of a low-density polyethylene film containing butylated hydroxytoluene on lipid oxidation and protein quality of sierra fish (Scomberomorus sierra) muscle during frozen storage. Journal of Agricultural and Food Chemistry, 55(15), 6140–6146. https://doi.org/10.1021/jf070418h

Varlik, C., Bostan, K., & Bingol, E. B. (2014). Effects of treatment with chitosan and antimelanogenesis agents on discoloration of chilled and frozen stored shrimp. Medycyna Weterynaryjna-Veterinary Medicine-Science and Practice, 70(6), 362–368.

Wang, C. Y., Huang, H. W., Hsu, C. P., & Yang, B. B. (2016). Recent advances in food processing using high hydrostatic pressure technology. Critical Reviews in Food Science and Nutrition, 56(4), 527–540. https://doi.org/10.1080/10408398.2012.745479

Wang, J. J., Sun, W. S., Jin, M. T., Liu, H. Q., Zhang, W., Sun, X. H., & Zhao, Y. (2014). Fate of Vibrio parahaemolyticus on shrimp after acidic electrolyzed water treatment. International Journal of Food Microbiology, 179, 50–56. https://doi.org/10.1016/j.ijfoodmicro.2014.03.016

Wang, M., Wang, J. J., Sun, X. H., Pan, Y. J., & Zhao, Y. (2015). Preliminary mechanism of acidic electrolyzed water ice on improving the quality and safety of shrimp. Food Chemistry, 176, 333–341. https://doi.org/10.1016/j.foodchem.2014.12.089

WHO. (1999). High dose irradiation: wholesomeness of food irradiated with doses above 10kGy. WHO. Technical Report Series No. 890.

Xie, J., Sun, X., Pan, Y., & Zhao, Y. (2012). Combining basic electrolyzed water pretreatment and mild heat greatly enhanced the efficacy of acidic electrolyzed water against Vibrio parahaemolyticus on shrimp. Food Control, 23(2), 320–324. https://doi.org/10.1016/j.foodcont.2011.07.019

Xiong, C., Liu, C., Liu, W., Pan, W., Ma, F., Chen, W., & Zheng, L. (2016). Noninvasive discrimination and textural properties of E-beam irradiated shrimp. Journal of Food Engineering, 175, 85–92. https://doi.org/10.1016/j.jfoodeng.2015.12.008

Xu, Z., Liu, X., Wang, H., Hong, H., & Luo, Y. (2017). Comparison between the Arrhenius model and the radial basis function neural network (RBFNN) model for predicting quality changes of frozen shrimp (Solenocera melantho). International Journal of Food Properties, 20(11), 2711–2723. https://doi.org/10.1080/10942912.2016.1248292

Xu, Z., Liu, X., Wang, H., Hong, H., Yu, X., & Luo, Y. (2016). Establishment of the Arrhenius model and the radial basis function neural network (RBFNN) model to predict quality of thawed shrimp (Solenocera melantho) stored at different temperatures. Journal of Food Processing and Preservation, 40(5), 882–892. https://doi.org/10.1111/jfpp.12666

Yu, D., Wu, L., Regenstein, J. M., Jiang, Q., Yang, F., Xu, Y., & Xia, W. (2020). Recent advances in quality retention of non-frozen fish and fishery products: a review. Critical Reviews in Food Science and Nutrition, 60(10), 1747–1759. https://doi.org/10.1080/10408398.2019.1596067

Yu, Q., Pan, H., Qian, C., Shao, H., Han, J., Li, Y., & Lou, Y. (2022a). Determination of the optimal electron beam irradiation dose for treating shrimp (Solenocera melantho) by means of physical and chemical properties and bacterial communities. Lwt-Food Science and Technology, 153, 112539. https://doi.org/10.1016/j.lwt.2021.112539

Yu, Q., Pan, H., Qian, C., Shao, H., Han, J., Li, Y., & Lou, Y. (2022b). UPLC/MS-based untargeted metabolomics reveals the changes in muscle metabolism of electron beam irradiated Solenocera melantho during refrigerated storage. Food Chemistry, 367, 130713. https://doi.org/10.1016/j.foodchem.2021.130713

Yu, Q., Pan, H., Qian, C., Shao, H., Li, Y., & Lou, Y. (2022c). Tandem mass tag-based proteomics reveals the effect of electron beam irradiation on metabolism-related differentially expressed proteins in Solenocera melantho postmortem. Journal of Aquatic Food Product Technology, 31(1), 60–70. https://doi.org/10.1080/10498850.2021.2010852

Zeng, Q. Z., Thorarinsdottir, K. A., & Olafsdottir, G. (2005). Quality changes of shrimp (Pandalus borealis) stored under different cooling conditions. Journal of Food Science, 70(7), S459–S466. https://doi.org/10.1111/j.1365-2621.2005.tb11493.x

Zhang, Y., Ren, Y., Bi, Y., Wang, Q., Cheng, K. W., & Chen, F. (2019). Review: seafood allergy and potential application of high hydrostatic pressure to reduce seafood allergenicity. International Journal of Food Engineering, 15(8), 20180392. https://doi.org/10.1515/ijfe-2018-0392

Zhang, Z., Huang, Y., Guo, X., Meng, X., Wu, H., Guo, F., & Li, D. (2020). Effects of chitosan combined with epsilon-polylysine coating on flavor and texture quality of Chinese shrimp during refrigerated storage. Foodmarine shrimp and freshwater shrimp Science & Nutrition, 8(3), 1480–1488. https://doi.org/10.1002/fsn3.1432

Zhu, J., Chen, Y., Jin, L., & Zhu, J. (2020). Quality assessment of frozen Solenocera crassicornis treated with sodium metabisulphite bysoaking or spraying. Journal of Ocean University of China, 19(1), 199–208. https://doi.org/10.1007/s11802-020-4219-5

Zulema Valencia-Perez, A., Soto-Valdez, H., Marina Ezquerra-Brauer, J., Marquez-Rios, E., & Torres-Arreola, W. (2015). Quality changes during frozen storage of blue shrimp (Litopenaeus stylirostris) with antioxidant, alpha-tocopherol, under different conditions. Food Science and Technology, 35(2), 368–374. https://doi.org/10.1590/1678-457x.6666

Funding

This work was supported by National Key R&D Programs of China (2020YFD0900903, 2022YFD2100603) and research on the key technology of fresh agricultural products storage and transportation logistics−the research and industrialization demonstration of the first-line fresh-keeping and cold chain logistics technology of marine-capture shrimp (2019C02086).

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yu, Q., Liu, J., Yang, J. et al. Postharvest Preservation Technologies for Marine-Capture Shrimp: A Review. Food Bioprocess Technol 16, 2343–2358 (2023). https://doi.org/10.1007/s11947-023-03049-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-023-03049-6