Abstract

The object of the present study was to develop polycaprolactone (PCL)/casein (Cas) electrospun nanofibers incorporated with green tea essential oils (GTO) as an active food packaging to prevent spoilage and food loss. The obtained results show that increase in the weight concentration of Cas leads to increasing the viscosity and diameter of nanofibers up to the range of 237–298 nm, leading to enhance the mechanical strength owing to the creation of hydrogen bonds and increased surface wettability. However, increase of the PCL content led to the reduction of the fiber diameter (203 ± 108 nm), more porosity (around 80%), and high thermal stability. In addition, the nanofiber samples, with 5% (PC5), and 12% (PC6) concentrations of GTO exhibited a long-term sustained release with high antioxidant activity 39.85% and 58.56% for PC5 and PC6, respectively. These findings suggested the promising applications of the produced PCL/Cas/GTO electrospun fibers for active food packaging.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recently, more research has focused on the development of suitable alternative materials for active food packaging to eliminate non-degradable oil-based packaging materials and increase the shelf life, quality, and safety of food products (Aghaei et al., 2018; Amjadi et al., 2020a; Amjadi et al., 2020b; Liu et al., 2021; Maroufi et al., 2022). The addition of antibacterial compounds into the polymer matrix of food packaging is a useful strategy for this end (Babitha et al., 2017; Duan et al., 2021; Liu et al., 2021; Pirsa et al., 2020; Riahi et al., 2021; Shao et al., 2019). Moreover, nanotechnology is one of the successful strategies to provide the packaging materials to encapsulate and sustaine release of functional substances which provided a new solution to improve their bioavailability (Akrami-Hasan-Kohal et al., 2020; Aman Mohammadi et al., 2021; Qin et al., 2019; Raeisi et al., 2019). Electrospinning, a single-stage encapsulation technology, has attracted more attention in the fabrication of polymeric nanofibers containing bioactive compounds due to their high porosity, high surface-to-volume ratio, flexibility, and high loading capacity (Akrami et al., 2020; Aman Mohammadi et al., 2019; Kumar et al., 2019). Moreover, electrospinning is an easy, highly versatile, and cost-effective technology that produces nanofibers using an external electric field, and the continuous drawing of a polymer solution from a syringe needle to the ground collector (Ahmadian et al., 2020; Sameen et al., 2022).

Polycaprolactone (PCL) is a type of aliphatic polyester and it has been extensively studied in the field of drug delivery, tissue engineering, and food packaging due to its good properties such as biocompatibility, biodegradability, and non-toxicity (Hajikhani et al., 2020; Li & Tan, 2014; Suwantong, 2016). It also has been extensively used in food packaging owing to its excellent mechanical characteristics (Cesur et al., 2018). Casein is a desirable hydrocolloid for using in food packaging system due to the great nutritional value, solubility in water, and emulsification capacity (Li et al., 2021). Also, owing to the distribution of polar amino acids along the chain of this protein, casein-containing systems display an excellent barrier to oxygen and other non-polar molecules, which makes them beneficial for the conservation of food products to oxidation (Aslaner et al., 2021; Picchio et al., 2018).

Essential oils (EOs) are a type of natural compound with high antimicrobial activity against a variety of foodborne bacteria (Bhavaniramya et al., 2019; Maroufi et al., 2022). However, their high volatility, hydrophobicity and special flavor limit their application (Wen et al., 2016a, b). Encapsulation of EOs into electrospinning nanofibers (NFs) can overcome these drawbacks (Bodbodak et al., 2021; Lin et al., 2017; Mohammadi et al., 2020; Nazari et al., 2019). Additionally, the electrospinning technique can generate NFs at ambient temperature which prevented from deterioration and volatilization of the EOs (Cerqueira et al., 2016; Dierings et al., 2021). Green tea oil (GTO), which is derived from the leaves of the green tea plant (Camellia sinensis), is used as a natural antioxidant and antimicrobial in a variety of food industry applications (Perumal et al., 2021). As reported in previous literature, GTO is mainly composed of phenolic compounds especially catechins (Yavari Maroufi et al., 2020). Recent studies have shown that green tea compounds play an important role in antioxidant and antimicrobial characteristics (Borzi et al., 2019; López de Dicastillo et al., 2013; Siripatrawan & Harte, 2010; Wrona et al., 2017).

To the best of our knowledge, no published study was reported to fabricate NFs based on PCL and Cas containing GTO and its application as an active food packaging. Therefore, the present research fabricated the electrospun PCL/Cas nanofibers containing GTO, which is applicable for active food packaging. We assessed the properties and structure of the produced NFs through Fourier transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), thermogravimetric analysis (TGA), mechanical properties, and water vapor transmission rate (WVTR) analyses. The optimum NFs were selected based on the SEM analysis. Then, the GTO was added as a powerful antioxidant and antibacterial to the optimized NFs in two different percentages. The DPPH free radical scavenging, and antibacterial activity were finally tested in the optimized NFs.

Material and Methods

Material

Polycaprolactone (PCL, Mn = 80 kDa), technical grade casein from bovine milk, DPPH (1,1-diphenyl-2-picrylhydrazyl), thiazolyl blue tetrazolium bromide (MTT), fetal bovine serum (FBS), Phosphate buffered saline (PBS), trypsin–EDTA, RPMI 1640 medium, and Muller Hinton Agar were supplied from Sigma-Aldrich (St. Louis, USA). Stock cultures, Escherichia coli (E. coli) (PTCC-1270), Staphylococcus aureus (S. aureus) (PTCC-1112) were obtained from Institut Pasture (Iran). The mouse embryonic fibroblast cell line (NIH-3 T3) was obtained from the Pasteur Institute of Iran. GTO was obtained from Barij Essence Company (Mashhad, Iran) in air-impermeable glass.

Preparation of the Electrospinning Solutions

Polymer solutions (total polymer weight 15% w/v) were prepared with dissolving the polymers at the four-weight ratio of PCL/Cas in acetic acid 90% (v/v) with stirring overnight at 25 °C. Moreover, GTO at concentrations of 5 and 12 (versus total polymer weight) was added to the selected optimal polymer electrospinning solutions.

Electrospinning

Polymer solutions at the four-weight ratio of PCL/Cas (95:5, 90:10, 85:15, and 80:20) were taken into a 10 mL syringe fitted with an 18-gauge steel needle. Next, these solutions were pumped at a flow rate (1 mL/h) via syringe pump. Electrospinning was conducted by applying the voltage of 16 kV, a receiving distance of 15 cm, a constant rate of 1 mL/min, at the room temperature, and the humidity of 50 ± 5%. Fibers were accumulated on an aluminum foil which is effective to take out NFs. Table 1 represents different electrospun NFs that were produced in this study.

Characterizations and Measurements

Scanning Electron Microscopy (SEM)

To determine the diameter, and morphology of the produced NFs, the scanning electron microscope (SEM) was utilized (Philips XL 30 FEG, Amsterdam, Holland) at the voltage of 26 kV. Before SEM, all produced NFs was coated by a thin layer of gold with a sputter coater. All images derived from SEM technique were investigated with ImageJ software to obtain average diameter of NFs.

Fourier Transform Infrared Spectra (FTIR)

FTIR measurements were carried out with a spectrometer (Tensor27, Bruker Co., Ettlingen, Germany) to determine the functional groups present in the PCL, Cas, and prepared PC nanofibers without, and with 5%, and 12% of GTO. The spectra were documented in the range of 500 to 4000 cm−1 at a resolution of 4 cm−1. The pellets of samples were prepared with KBr powder, so all samples were measured using a KBr-pellet method.

Thermal Properties

The thermogravimetric analysis (TGA) of formulated NFs was performed using thermogravimetric Analyzer (LINSEIS SPA PT 1600 device, Germany). This measurement was accomplished under a nitrogen atmosphere, and the NFs were heated up to 600 °C at a constant heating rate of 10 °C/min.

Porosity Assessment

The porosity of the produced NFs was evaluated with the liquid displacement method and calculated as follow (Salehi et al., 2020):

where, V1 and V2 are the initial volume of ethanol (96%) and the volume after immersing the NF samples, respectively. In addition, V3 is the volume of the ethanol after the NFs removed (after 5 min).

Mechanical Properties

Tensile strength, elongation at break, and Young’s modulus of produced NFs were determined at 25 °C with a Tensile Analyzer (Instron 5566, USA), according to ASTM D-882 (Zhang et al., 2021). The specimens were cut into pieces with dimensions of 10 mm × 30 mm, and the tests were carried out at room temperature and a moving crosshead speed of 50 mm/min.

Measurements of Surface Wettability

The surface wettability of produced NFs was measured with water contact angle (WCA) method (Data physics, OCA ES 149 r, Filderstadt, Germany). A drop of deionized water (2 µL) was dropped on the surface of each produced NFs (20 mm × 60 mm), and photographed instantly within 5 s.

Water Vapor Transmission Rate (WVTR)

The WVTR of the produced nanofibers was measured by the following method (Dadras Chomachayi et al., 2018; Fahimirad et al., 2021). The WVTR was measured with fixing the piece of NF samples on the round opening of a vial. The vial was filled with 2 mg of calcium chloride anhydride (RH = 0%). The vials were located in a desiccator comprising oversaturated sodium chloride solution at 25 °C for 24 h, and the WVTR was determined as follows:

In the above formula, ΔW is the weight changes of NF samples (g), A is the exposure area (m2) of NF samples, and t is the exposure time (24 h).

GTO Release Behaviors

For measurement of the in vitro release of GTO from produced NFs, each sample (20 mg) was immersed in 5 mL of PBS (pH = 7.4, at 37 °C) and shaken at 150 × g for 36 h. After the specified times, 1 mL of the solution was removed and analyzed with UV–vis spectroscopy at the wavelength of 275 nm. After that, the 1 mL was returned to the vial until the next time point. Then, the amount of GTO encapsulated in the electrospun NFs was detected (Karami et al., 2021).

Antioxidant Activity

The antioxidant activity of GTO-loaded PC fibers was calculated with 2,2-diphenyl-1-picrylhydrazyl (DPPH) free radical. For this purpose, 2 mL of the NF samples extract was mixed with 3 mL of ethanolic DPPH solution (0.1 mM) and permitted to be kept in the dark condition for 30 min at 25 °C. At the end of the 30 min, the absorbance of the solution was evaluated at 517 nm by a UV–vis spectrophotometer (Spectrum SP-UV500DB) (Aytac et al., 2017; Borzi et al., 2019). The antioxidant activity (AA) of samples was calculated as follow:

Antimicrobial Activity

The antimicrobial properties of the produced PC/GTO nanofibers were assessed against two bacterial species (S. aureus and E. coli) through the agar diffusion assay. Initially, the suspensions of selected bacteria were prepared (1.5 × 106 CFU/mL). Then, the 100 µL of prepared bacteria suspension was spread onto solid media plates containing MHA for each selected bacterium. Next, the produced NFs were cut in circular shape, sterilized, and placed on inoculated petri dishes. These petri dishes were incubated for 24 h at 37 °C. The diameters of inhibition areas of the NF samples were calculated in millimeters (Ghorbani et al., 2020; Ngamakeue & Chitprasert, 2016; Zhang et al., 2020a, b).

Cytotoxicity Assessment

To investigate the cytotoxicity of the formulated NFs on NIH3T3 fibroblast cells, MTT test was performed (Ghorbani et al., 2016a, b; Golizadeh et al., 2019; Maroufi & Ghorbani, 2021). In short, after 1, 3, and 5 days, the NF samples with the attached NIH3T3 fibroblast cells were incubated in MTT solution (5 mg/mL) in RPMI-1640 at 37 °C under a 5% CO2 atmosphere (Sabzichi et al., 2017). Next, the specified amount of DMSO solution was added into each sample to dissolve the formed formazan crystals. Thereafter, the optical density (OD) of the supernatant solution was measured using a spectrophotometer at a wavelength of 570 nm (Shimadzu, Japan, UV-2550).

Statistical Analysis

All experiments were investigated in three replications, and were documented as mean ± standard deviation (SD). Statistical comparisons were carried out with ANOVA (Tukey’s test), and significance was defined at P < 0.05.

Result and Discussion

Fiber Morphology

The SEM results and the mean diameters of the electrospun NFs with different weight ratios of PCL/Cas, and PC containing different concentrations of GTO (5 and 12%) are shown in Fig. 1, and Fig. 2, respectively. Since the processing parameters and the environmental conditions were constant during electrospinning process, so the only parameter which was affected on the morphology and diameter distribution of the synthesized NFs was the different weight ratios of the PCL, Cas, and the GTO. First, the different weight ratios of PCL and Cas were investigated on the morphology of produced NFs. Four different weight ratios of PCL/Cas (95:5, 90:10, 85:15 and 80:20) were electrospun. All samples displayed a porous, free-beads, and uniformity structure. However, with increasing the weight ratio of Cas, the average fiber diameter increased (Fig. 1). So, the diameter of PCL/Cas fibers increased from 203 ± 108 nm with ratio of 95:5 to 298 ± 49 nm with ratio of 80:20. As known, the viscosity of the electrospinning solution is one of the most important factors that effects on the morphology of NFs (Panzavolta et al., 2011). Therefore, increasing the viscosity of polymer solution by enhancing the content of protein (Cas) leads to the formation of electrospun NFs with a high average diameter. As reported in previous studies, in the electrospinning process, increasing the viscosity of the solution owing to the creation of stronger resistance of the viscoelastic force to the electric field force leads to the production of thicker nanofibers with a high average diameter (Aydogdu et al., 2018; Colín-Orozco et al., 2015; Drosou et al., 2018). Besides, the encapsulation of GTO into the selected sample (PC1 95:5), significantly increased the average diameter of the fabricated NFs (Fig. 2). This result may be due to the effect of GTO in reducing the electrical conductivity of the electrospinning PCL/Cas solution, because EOs have low ionic conductivity (Wen et al., 2016a, b). Therefore, the lower electrical conductivity may result in lower elongation of a jet by the electrostatic force to form fibers of thick diameter (Bhagwan et al., 2019). A similar result based on the decrease in the electrical conductivity of electrospinning solutions by addition of EOs has been reported in other studies (Ardekani et al., 2019; Tavassoli-kafrani et al., 2018). These researchers reported that the encapsulation of orange essential oil, and zataria multiflora essential oil into the gelatin (Tavassoli-kafrani et al., 2018), and poly (vinyl alcohol) (Ardekani et al., 2019) nanofiber resulted in the formation of thicker nanofibers due to reducing the electrical conductivity of electrospinning solutions. Moreover, with increasing GTO concentration, the diameter of the fiber also increases. In addition to the reseason mentioned above, as reported by Hosseini et al. (2021), increase in the nanofiber diameter can be due to the greater resistance of the high concentration of GTO to be stretched toward the collector (Heydari-Majd et al., 2019; Miri et al., 2021).

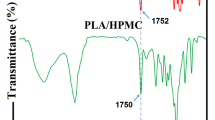

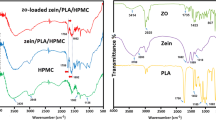

FTIR Spectroscopy

To study the molecular interactions between the compound and polymers, FTIR analysis was performed. The FTIR spectra of all samples are revealed in Fig. 3. The FTIR of PCL demonstrated the specific peaks at 2949 cm−1, 2865 cm−1, 1727 cm−1, 1293 cm−1, 1240 cm−1, 1190 cm−1, 1170 cm−1, and 1157 cm−1, which could be attributed to the asymmetric CH2 stretching, symmetric CH2 stretching, carbonyl stretching, C–O and C–C stretching in crystalline phase, asymmetric COC stretching, CC–O stretching, symmetric COC stretching, and C–O, C–C stretching in amorphous phase, respectively (Salehi et al., 2020). The main peaks at 1510–1580 cm−1, 1661 cm−1, 3100 cm−1, and 3455 cm−1 were seen in Cas spectrum, which are consistent with that previously reported by Singh et al., (2015a, b) that may be related to the amide II (N–H bending vibration), amide I (C = O stretching vibration), amide B, and amide A, respectively. The shifts of peak positions in the FTIR spectrum of produced PCL/Cas fibers indicate a successful interaction between the PCL, and Cas (hydrogen bonding). In the FTIR spectrum of produced PCL/Cas fibers containing 5 and 12% concentration of GTO, no new peaks were observed in these samples with and without GTO due to the similar chemical composition between PCL (C6H10O2)n and GTO catechins C15H4O6. However, a minor change in peak intensity was observed due to the formation of a new hydrogen bond between the compounds. In the previous study reported by Mohd Rashid et al. (2021), it was confirmed that the encapsulation of GTO in the polymer structure of PCL does not generate a novel peak in the IR spectrum of the final sample due to the similar structure.

Thermal Stability

The thermal stability of produced NFs with different weight ratio of PCL/Cas (95:5 (PC1), 90:10 (PC2), 85:15 (PC3), and PC4 (80:20)) was investigated with TGA analysis, and the detailed thermal data are summarized in Table 2. As can be seen, the first stage of weight loss occurred at around 25–150 °C, which was related to the volatilization of residual water. The second stage occurred at around 250–400 °C, which could be associated to the heating degradation. The last one happened at 400–600 °C that can be due to the progress in heating degradation of polymeric chains (Hadad & Goli, 2018). According to these results, the weight loss of the produced NFs increased slightly with increasing Cas content. In fact, the highest residual weight (6.54%) is related to PC1 sample with the high PCL (95%) content, presenting PCL has an effective role in increasing thermal stability. A similar result was observed in previous studies in which electrospun nanofibers with the highest content of PCL showed the lowest weight loss and the highest thermal stability (Aynali et al., 2021; Hivechi et al., 2019; Zou et al., 2020).

Porosity

The porosity of the formulated NFs was revealed in Fig. 4. The porosity value of the produced fibers was found as follow (Fig. 4): 82%, 74%, 70%, and 63% for PCL/Cas with weight ratios of 95:5, 90:10, 85:15, and 80:20, respectively. According to these findings, by increasing the content of Cas, the viscosity and the diameter of produced NFs increased, resulting in the reduction of the porosity of formulated NFs reduced. The highest porosity (82%) was related to PCL/Cas fibers with a weight ratio of 95:5 that could be associated to the geometry of their fibrous structure, and formed hydrogen bond between polymer chains. Previous studies have shown that thinner electrospun fibers formed as a result of low viscosity lead to higher porosity (Ahmadian et al., 2020; Ghorbani et al., 2020).

Mechanical Properties

Mechanical characteristics of the electrospun fibers are considered as a major factor in food packaging applications. The mechanical parameters (Tensile stress, Young’s modulus, and Elongation at break) are summarized in Table 3. As a general trend, increasing the weight ratio of Cas led to the increasing of tensile stress (TS) and Young’s modulus (YM), as well as reducing the value of elongation at break (EAB). Mechanical properties of the electrospun fibers can be affected by a series of parameters such as composition of fibers, average diameter of fibers, and morphology of fibers (Fadaie et al., 2018). Bölgen et al. (2005) demonstrated that thinner PCL fibers have lower TS, and YM than thicker fibers. Therefore, by increasing the weight ratio of Cas, the average diameter of NFs increased which caused the two parameters of YM and TS to improve. It can be related to the increase in intermolecular interactions of Cas and PCL molecular chains (Fadaie et al., 2018). For instance, the TS of the PC1 (95:5) sample was 46.31 ± 0.34 MPa, while the TS of the PC2 (90:10), PC3 (85:15), and PC4 (80:20) samples with increasing weight ratio of Cas, significantly enhanced to 53.4 ± 0.42, 56.11 ± 0.17, and 58.2 ± 0.11 MPa, respectively. In the case of the EAB parameter, as a general trend, this parameter showed a decreasing trend with increasing the weight ratio of Cas. Thus, the PC1 sample elongated around 136.14 ± 2.83% of its initial length while the elongation at break was reduced to 98.14 ± 11.21% upon increasing Cas weight ratio up to 20%. The decrease in EAB with increasing Cas content can be related to the interactions between PCL and Cas, which contribute to create a stiffer but brittle network within the electrospun nanofibers. As reported in previous literature, the intermolecular hydrogen bonds formed between polymer chains (PCL and Cas) may restrict the movement of the polymer chains and promoted rigidity (Zhang et al., 2020a, b). By adding the GTO to the selected sample (PC1 95:5), TS values were decreased from 46.31 ± 0.34 to 45.3 ± 0.14 MPa, and 40.7 ± 0.22 MPa, which were, respectively, related to fibers containing 5 and 12% GTO. On the other hand, EAB values were increased from 136.14 ± 2.83 to 140.45 ± 6.45%, and 145.14 ± 8.5%, which were respectively related to fibers containing 5 and 12% GTO. Previous studies have confirmed that mechanical properties (TS, and YM) of composite nanofibers/films were decreased by incorporating hydrophobic compounds such as EOs (Ardekani et al., 2019; Ge et al., 2019; Karami et al., 2021). On the other hand, EAB of composite nanofibers/films were increased by incorporating EOs due to their plasticizing effect, so the interaction between polymer chains and EOs caused the mobility of polymer chains to increase and improve the flexibility (Imran et al., 2012).

Surface Wettability

PCL has been identified as a biocompatible synthetic polymer for a number of food industry applications (Joseph et al., 2011; Lukic et al., 2020). However, its hydrophobic nature is a limited parameter for a design of active food packaging, because hydrophilicity is a required parameter to achieve the effective release of active compounds encapsulated in the polymeric matrix of active packaging (Choi et al., 2006). Accordingly, the synthesis of composite electrospun NFs consisting of PCL and Cas can be a reliable strategy to overcome this limitation. For this purpose, water contact angle (WCA) measurement was performed to determine the surface wettability of produced PCL/Cas electrospun NFs. The images of the WCA evaluation are shown in Fig. 5. The hydrophobic nature of PCL is related to the presence of CH2 groups along the main polymer chain (Qian et al., 2014). As shown in this figure, the average WCA values for PC1 (95:5), PC2 (90:10), PC3 (85:15), and PC4 (80:20) fiber samples were 95 ± 2.1°, 87 ± 1.3°, 80 ± 2°, and 76 ± 1.2°, respectively, that were in correlation with the weight ratio of PCL, and its hydrophobic property. In fact, increasing the weight ratio of Cas as the hydrophilic segment in the PCL/Cas electrospun NFs (due to the presence of carboxyl and amine groups along the main polymer chain), increased the surface wettability.

The water contact angle (WCA) of Polycaprolactone/Casein (PCL/Cas) nanofibers with different weight ratios of PCL/Cas (95:5 (PC1), 90:10 (PC2), 85:15 (PC3), and 80:20 (PC4)). The labels of NS (No Significance), *p, and **p, show significant difference (P < 0.05) between data of PC1, PC2, PC3, and PC4

Water Vapor Transmission Rate (WVTR)

The WVTR of the produced PCL/Cas fibers with different weight ratios of PCL and Cas is exposed in Fig. 6. It is known that WVTR is the one of main parameter for design of food packaging materials that is attributed to the moisture transfer between the environment and food product (Zou et al., 2020). From WVTR examinations, the average WVTR values for PC1 (95:5), PC2 (90:10), PC3 (85:15), and PC4 (80:20) fiber samples were about 4100 ± 10.12, 5980 ± 45.61, 6000 ± 46.21, and 6237 ± 85.46 g/m2.24 h, respectively. Regarding the results, the WVTR of produced fibers was significantly increased with increment of Cas weight ratio. The most important factors affecting WVTR are porosity and hydrophilicity of fibers (Martins et al., 2018). As explained in previous studies, the WVTR is inversely related to the porosity of fibers caused by fibers average diameter (Ahmadian et al., 2020; Lu et al., 2017; Rashidi et al., 2021). The incorporation of GTO at concentration of 5 and 12%, resulted in a decrease of the WVTR with respect to the fiber samples with high content of Cas (PC2, PC3, and PC4), but they did not show a significant difference with PC1. In consistence with the results of the present study, Nazari et al. (2019) (Nazari et al., 2019) found that the WVTR of poly(vinyl alcohol) nanofibers loaded with cinnamon EO decreased significantly. Reduced WVTR values of resulting nanofibers loaded with GTO can be a consequence of the reduction in the hydrophilic nature of the nanofibers and crosslinking interactions between hydrophobic constituents and biopolymers, which may lead to a scarcity of hydroxyl groups for interaction with water molecules (Ardekani et al., 2019; Nazari et al., 2019; Pourhojat et al., 2017).

The water vapor transmission rate (WVTR) of Polycaprolactone/Casein (PCL/Cas) nanofibers with different weight ratios of PCL/Cas (95:5 (PC1), 90:10 (PC2), 85:15 (PC3), PC4 (80:20)), and selected optimal (PC1) nanofibers containing 5 and 12% concentrations of green tea essential oils named PC5, and PC6, respectively. The label of **p shows significant difference (P < 0.05)

Release Studies

The in vitro release study of GTO from the optimal PCL/Cas fibers was performed for 36 h in PBS (pH = 7.4, at 37 °C). Experimental curves are demonstrated in Fig. 7. The degradation of the polymer matrix in an aqueous medium may occur for longer periods of exposure. During the 36-h analysis period, it can be confirmed that there is no degradation in the polymer matrix, and the diffusion process is solely responsible for the oil diffusion (da Costa et al., 2020). In the present study, all samples revealed a gradual release of the GTO. As shown in Fig. 7, the maximum release rate of GTO (around 68.21%) corresponds to a PC6 sample containing 12% GTO at 37 °C and an incubation time of 36 h. Thus, the release rate of GTO enhanced with the increment of GTO concentration up 12% in the samples, and over time. Moreover, these findings illustrated that the formulated PCL/Cas fibers with GTO had the long-term release behavior during 36 h for PC5 and PC6. Because during 36 h, the perfect release of GTO was not observed for both samples. These results agreed with the report of Shetta et al. (2019).

Antioxidant Activity

Green tea polyphenols such as catechins, tannins, and gallic acid, which are present in GTO, propose high activity in inhibiting DPPH free radicals owing to the presence of phenolic hydroxyl groups (Siripatrawan & Harte, 2010). Therefore, the encapsulation of GTO into polymeric matrix of food packaging could considerably improve the antioxidant activity of packaging to protect food product from an oxidative spoilage. In this regard, the antioxidant activity of the formulated NFs with different concentrations of GTO (5 and 12%) was investigated with free radical (DPPH) scavenging technique, and the findings are exposed in Fig. 8. As expected, the pure NFs (PC1) illustrated negligible activity against DPPH free radicals. On the other hand, the antioxidant properties of fibers containing GTO enhanced significantly (P < 0.05) due to the capability of phenolic groups of green tea to provide hydrogen to stabilize free radicals. Green tea is one of the most effect antioxidant compounds that has a high capability to inhibit free radicals and has been proven in many studies to have strong antioxidant function (Dou et al., 2018; Wen et al., 2020; Yavari Maroufi et al., 2020). The antioxidant activity for formulated PCL/Cas fibers without and with 5%, 12% concentration of GTO was estimated to be around 10.21%, 39.85%, and 58.46%, respectively.

Antimicrobial Activity

Antimicrobial activity of the optimal PCL/Cas fiber containing GTO with concentrations of 5 and 12 wt.% was examined against two pathogenic bacteria namely S. aureus (gram positive) and E. coli (gram negative). The obtained results are showing in Fig. 9 and Table 4. It is evident from the results that the formulated fiber without GTO did not prevent the growth of the mentioned bacteria. While, the fibers containing GTO exposed a notably (P < 0.05) inhibitory effect against both bacteria. Moreover, the formulated fibers with GTO illustrated the concentration-dependent antibacterial ability against bacteria. Many previous studies have confirmed that green tea catechins are responsible for the antimicrobial activity of green tea. These compounds attach to bacterial membranes and inhibit bacterial activity by affecting cellular processes such as apoptosis and mitochondrial function (Belščak-Cvitanović et al., 2015; Dou et al., 2018; Shetta et al., 2019; Singh et al., 2015a, b; Wang et al., 2020; Wrona et al., 2017; Yavari Maroufi et al., 2020). The findings of this study showed that although it has caused the inhibition of both types of bacteria, but its effect on gram-positive bacteria is more than gram-negative. It is noteworthy that the antimicrobial properties of pure GTO on gram-negative bacteria such as E. coli depend on the interaction of lipophilic oil and the phospholipid membrane which induce permeability of the GTO molecules (Singh et al., 2015a, b).

Cell Viability

The effects of the formulated PCL/Cas fibers without and with different concentrations of GTO on the viability of NIH3T3 fibroblast cells are exposed in Fig. 10. According to the MTT results, no significant reduction in the number of viable cells was observed in the presence of fiber samples with and without GTO, after 1, 3, and 5 days. As revealed in this figure, all the values of cell viability were higher than 90%. Moreover, these results illustrate that fiber samples have great biocompatibility and ability to support cell proliferation. Additionally, the presence of GTO improved the fiber hydrophilicity due to the presence of green tea polyphenols. As reported in previous studies, increasing the hydrophilicity of scaffolds improves adhesion and cell proliferation (Dziadek et al., 2021; Raja et al., 2021; Zadeh et al., 2019).

Conclusion

In the present study, the PCL/Cas nanofibers containing GTO were developed by electrospinning technique as a suitable material for active food packaging. Physico-chemical and biological characterization of produced nanofibers were assessed. Morphological study exposed that the average fiber diameter was enhanced with increment of Cas weight content. In addition, surface wettability, WVTR, and mechanical properties gradually enhanced with the increment of Cas weight content, notably, for the PC4 sample. Moreover, the antioxidant and antimicrobial activities of the fibers containing GTO were investigated and the results exposed that the fiber with high concentration of GTO revealed the good performance. In addition, the cell cytotoxicity studies presented excellent cell viability and proliferation of NIH3T3 fibroblast cells in the presence of fiber samples with and without GTO. In conclusion, the fabricated novel nanofiber with significant biocompatibility and antioxidant/microbial activity possesses promising potential for active food packaging.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Aghaei, Z., Emadzadeh, B., Ghorani, B., & Kadkhodaee, R. (2018). Cellulose acetate nanofibres containing alizarin as a halochromic sensor for the qualitative assessment of rainbow trout fish spoilage. Food and Bioprocess Technology, 11(5), 1087–1095.

Ahmadian, S., Ghorbani, M., & Mahmoodzadeh, F. (2020). Silver sulfadiazine-loaded electrospun ethyl cellulose/polylactic acid/collagen nanofibrous mats with antibacterial properties for wound healing. International Journal of Biological Macromolecules, 162, 1555–1565.

Akrami-Hasan-Kohal, M., Ghorbani, M., Mahmoodzadeh, F., & Nikzad, B. (2020). Development of reinforced aldehyde-modified kappa-carrageenan/gelatin film by incorporation of halloysite nanotubes for biomedical applications. International Journal of Biological Macromolecules, 160, 669–676.

Akrami, M., Tayebi, L., & Ghorbani, M. (2020). Curcumin-loaded naturally-based nanofibers as active wound dressing mats: Morphology, drug release, cell proliferation and cell adhesion studies. New Journal of Chemistry, 44(25), 10343–10351.

Aman mohammadi, M., Ramazani, S., Rostami, M., Raeisi, M., Tabibiazar, M., & Ghorbani, M. (2019). Fabrication of food-grade nanofibers of whey protein Isolate–Guar gum using the electrospinning method. Food Hydrocolloids, 90(December 2018), 99–104.

Aman Mohammadi, M., Ramezani, S., Hosseini, H., Mortazavian, A. M., Hosseini, S. M., & Ghorbani, M. (2021). Electrospun antibacterial and antioxidant zein/polylactic acid/hydroxypropyl methylcellulose nanofibers as an active food packaging system. Food and Bioprocess Technology, 14(8), 1529–1541.

Amjadi, S., Almasi, H., Ghorbani, M., & Ramazani, S. (2020a). Reinforced ZnONPs/rosemary essential oil-incorporated zein electrospun nanofibers by κ-carrageenan. Carbohydrate Polymers, 232, 115800.

Amjadi, S., Almasi, H., Ghorbani, M., & Ramazani, S. (2020b). Preparation and characterization of TiO2 NPs and betanin loaded zein/sodium alginate nanofibers. Food Packaging and Shelf Life, 24(March), 100504.

Ardekani, N. T., Khorram, M., Zomorodian, K., Yazdanpanah, S., Veisi, H., & Veisi, H. (2019). Evaluation of electrospun poly (vinyl alcohol)-based nanofiber mats incorporated with Zataria multiflora essential oil as potential wound dressing. International Journal of Biological Macromolecules, 125, 743–750.

Aslaner, G., Sumnu, G., & Sahin, S. (2021). Encapsulation of grape seed extract in rye flour and whey protein–based electrospun nanofibers. Food and Bioprocess Technology, 14(6), 1118–1131.

Aydogdu, A., Sumnu, G., & Sahin, S. (2018). A novel electrospun hydroxypropyl methylcellulose/polyethylene oxide blend nanofibers: Morphology and physicochemical properties. Carbohydrate Polymers, 181, 234–246.

Aynali, F., Balci, H., Doganci, E., & Bulus, E. (2021). Production and characterization of non-leaching antimicrobial and hydrophilic polycaprolactone based nanofiber mats. European Polymer Journal, 149(March), 110368.

Aytac, Z., Keskin, N. O. S., Tekinay, T., & Uyar, T. (2017). Antioxidant α-tocopherol/γ-cyclodextrin–inclusion complex encapsulated poly(lactic acid) electrospun nanofibrous web for food packaging. Journal of Applied Polymer Science, 134(21), 1–9.

Babitha, S., Rachita, L., Karthikeyan, K., Shoba, E., Janani, I., Poornima, B., & Purna Sai, K. (2017). Electrospun protein nanofibers in healthcare: A review. International Journal of Pharmaceutics, 523(1), 52–90.

Belščak-Cvitanović, A., Lević, S., Kalušević, A., Špoljarić, I., Đorđević, V., Komes, D., ... & Nedović, V. (2015). Efficiency assessment of natural biopolymers as encapsulants of green tea (Camellia sinensis L.) bioactive compounds by spray drying. Food and Bioprocess Technology, 8(12), 2444–2460.

Bhagwan, J., Kumar, N., & Sharma, Y. (2019). Fabrication, characterization, and optimization of MnxOy nanofibers for improved supercapacitive properties. In Nanomaterials Synthesis (pp. 451–481).

Bhavaniramya, S., Vishnupriya, S., Al-Aboody, M. S., Vijayakumar, R., & Baskaran, D. (2019). Role of essential oils in food safety: Antimicrobial and antioxidant applications. Grain & Oil Science and Technology, 2(2), 49–55.

Bodbodak, S., Shahabi, N., Mohammadi, M., Ghorbani, M., & Pezeshki, A. (2021). Development of a novel antimicrobial electrospun nanofiber based on polylactic acid/hydroxypropyl methylcellulose containing pomegranate peel extract for active food packaging. Food and Bioprocess Technology, 14(12), 2260–2272.

Bölgen, N., Menceloǧlu, Y. Z., Acatay, K., Vargel, I., & Pişkin, E. (2005). In vitro and in vivo degradation of non-woven materials made of poly(ε-caprolactone) nanofibers prepared by electrospinning under different conditions. Journal of Biomaterials Science, Polymer Edition, 16(12), 1537–1555.

Borzi, F., Torrieri, E., Wrona, M., & Nerín, C. (2019). Polyamide modified with green tea extract for fresh minced meat active packaging applications. Food Chemistry, 300(March), 125242.

Cerqueira, M. A., Fabra, M. J., Castro-Mayorga, J. L., Bourbon, A. I., Pastrana, L. M., Vicente, A. A., & Lagaron, J. M. (2016). Use of electrospinning to develop antimicrobial biodegradable multilayer systems: Encapsulation of cinnamaldehyde and their physicochemical characterization. Food and Bioprocess Technology, 9(11), 1874–1884.

Cesur, S., Köroğlu, C., & Yalçın, H. T. (2018). Antimicrobial and biodegradable food packaging applications of polycaprolactone/organo nanoclay/chitosan polymeric composite films. Journal of Vinyl and Additive Technology, 24(4), 376–387.

Choi, W. Y., Lee, C. M., & Park, H. J. (2006). Development of biodegradable hot-melt adhesive based on poly-ε-caprolactone and soy protein isolate for food packaging system. LWT - Food Science and Technology, 39(6), 591–597.

Colin-Orozco, J., Zapata-Torres, M., Rodriguez-Gattorno, G., & Pedroza-Islas, R. (2015). Properties of poly (ethylene oxide)/whey protein isolate nanofibers prepared by electrospinning. Food Biophysics, 10(2), 134–144.

da Costa, R. C., Daitx, T. S., Mauler, R. S., da Silva, N. M., Miotto, M., Crespo, J. S., & Carli, L. N. (2020). Poly (hydroxybutyrate-co-hydroxyvalerate)-based nanocomposites for antimicrobial active food packaging containing oregano essential oil. Food Packaging and Shelf Life, 26, 100602.

Dadras Chomachayi, M., Solouk, A., Akbari, S., Sadeghi, D., Mirahmadi, F., & Mirzadeh, H. (2018). Electrospun nanofibers comprising of silk fibroin/gelatin for drug delivery applications: Thyme essential oil and doxycycline monohydrate release study. Journal of Biomedical Materials Research - Part A, 106(4), 1092–1103.

Dierings de Souza, E. J., Kringel, D. H., Guerra Dias, A. R., & da Rosa Zavareze, E. (2021). Polysaccharides as wall material for the encapsulation of essential oils by electrospun technique. Carbohydrate Polymers, 265(December 2020), 118068.

Dou, L., Li, B., Zhang, K., Chu, X., & Hou, H. (2018). Physical properties and antioxidant activity of gelatin-sodium alginate edible films with tea polyphenols. International Journal of Biological Macromolecules, 118, 1377–1383.

Drosou, C., Krokida, M., & Biliaderis, C. G. (2018). Composite pullulan-whey protein nanofibers made by electrospinning: Impact of process parameters on fiber morphology and physical properties. Food Hydrocolloids, 77, 726–735.

Duan, M., Yu, S., Sun, J., Jiang, H., Zhao, J., & Tong, C. (2021). Development and characterization of electrospun nanofibers based on pullulan/chitin nanofibers containing curcumin and anthocyanins for active-intelligent food packaging. International Journal of Biological Macromolecules, 187(July), 332–340.

Dziadek, M., Dziadek, K., Checinska, K., Zagrajczuk, B., Golda-Cepa, M., Brzychczy-Wloch, M., et al. (2021). PCL and PCL/bioactive glass biomaterials as carriers for biologically active polyphenolic compounds: Comprehensive physicochemical and biological evaluation. Bioactive Materials, 6(6), 1811–1826.

Fadaie, M., Mirzaei, E., Geramizadeh, B., & Asvar, Z. (2018). Incorporation of nanofibrillated chitosan into electrospun PCL nanofibers makes scaffolds with enhanced mechanical and biological properties. Carbohydrate Polymers, 199, 628–640.

Fahimirad, S., Abtahi, H., Satei, P., Ghaznavi-Rad, E., Moslehi, M., & Ganji, A. (2021). Wound healing performance of PCL/chitosan based electrospun nanofiber electrosprayed with curcumin loaded chitosan nanoparticles. Carbohydrate Polymers, 259(January), 117640.

Ge, Y., Tang, J., Fu, H., Fu, Y., & Wu, Y. (2019). Characteristics, controlled-release and antimicrobial properties of tea tree oil liposomes-incorporated chitosan-based electrospun nanofiber mats. Fibers and Polymers, 20(4), 698–708.

Ghorbani, M., Hamishehkar, H., Arsalani, N., & Entezami, A. A. (2016a). Surface decoration of magnetic nanoparticles with folate-conjugated poly(N-isopropylacrylamide-co-itaconic acid): A facial synthesis of dual-responsive nanocarrier for targeted delivery of doxorubicin. International Journal of Polymeric Materials and Polymeric Biomaterials, 65(13), 683–694.

Ghorbani, M., Hamishehkar, H., Hajipour, H., Arsalani, N., & Entezami, A. A. (2016b). Ternary-responsive magnetic nanocarriers for targeted delivery of thiol-containing anticancer drugs. New Journal of Chemistry, 40(4), 3561–3570.

Ghorbani, M., Mahmoodzadeh, F., Yavari Maroufi, L., & Nezhad-Mokhtari, P. (2020). Electrospun tetracycline hydrochloride loaded zein/gum tragacanth/poly lactic acid nanofibers for biomedical application. International Journal of Biological Macromolecules, 165, 1312–1322.

Golizadeh, M., Karimi, A., Gandomi-Ravandi, S., Vossoughi, M., Khafaji, M., Joghataei, M. T., & Faghihi, F. (2019). Evaluation of cellular attachment and proliferation on different surface charged functional cellulose electrospun nanofibers. Carbohydrate Polymers, 207, 796–805.

Hadad, S., & Goli, S. A. H. (2018). Fabrication and characterization of electrospun nanofibers using flaxseed (Linum usitatissimum) mucilage. International Journal of Biological Macromolecules, 114, 408–414.

Hajikhani, M., Emam-Djomeh, Z., & Askari, G. (2020). Fabrication and characterization of gluten film reinforced by lycopene-loaded electrospun polylactic acid nano-fibers. Food and Bioprocess Technology, 13(12), 2217–2227.

Heydari-Majd, M., Ghanbarzadeh, B., Shahidi-Noghabi, M., Najafi, M. A., & Hosseini, M. (2019). A new active nanocomposite film based on PLA/ZnO nanoparticle/essential oils for the preservation of refrigerated Otolithes ruber fillets. Food Packaging and Shelf Life, 19(September 2018), 94–103.

Hivechi, A., Bahrami, S. H., & Siegel, R. A. (2019). Drug release and biodegradability of electrospun cellulose nanocrystal reinforced polycaprolactone. Materials Science and Engineering C, 94, 929–937.

Hosseini, F., Miri, M. A., Najafi, M., Soleimanifard, S., & Aran, M. (2021). Encapsulation of rosemary essential oil in zein by electrospinning technique. Journal of Food Science, 86(9), 4070–4086.

Imran, M., Revol-Junelles, A. M., René, N., Jamshidian, M., Akhtar, M. J., Arab-Tehrany, E., & Desobry, S. (2012). Microstructure and physico-chemical evaluation of nano-emulsion-based antimicrobial peptides embedded in bioactive packaging films. Food Hydrocolloids, 29(2), 407–419.

Joseph, C. S., Prashanth, K. V. H., Rastogi, N. K., Indiramma, A. R., Reddy, S. Y., & Raghavarao, K. S. M. S. (2011). Optimum blend of chitosan and poly-(ε-caprolactone) for fabrication of films for food packaging applications. Food and Bioprocess Technology, 4(7), 1179–1185.

Karami, N., Kamkar, A., Shahbazi, Y., & Misaghi, A. (2021). Electrospinning of double-layer chitosan-flaxseed mucilage nanofibers for sustained release of Ziziphora clinopodioides essential oil and sesame oil. LWT - Food Science and Technology, 140(December 2020), 110812.

Kumar, T. S. M., Kumar, K. S., Rajini, N., Siengchin, S., Ayrilmis, N., & Rajulu, A. V. (2019). A comprehensive review of electrospun nanofibers: Food and packaging perspective. Composites Part b: Engineering, 175, 107074.

Li, A., Guo, C., Li, X., Li, P., Yang, X., & Guo, Y. (2021). Gelation mechanism and physical properties of glucono-δ-lactone induced alginate sodium/casein composite gels. Food Hydrocolloids, 118, 106775.

Li, Z., & Tan, B. H. (2014). Towards the development of polycaprolactone based amphiphilic block copolymers: Molecular design, self-assembly and biomedical applications. Materials Science and Engineering: C, 45, 620–634.

Lin, L., Dai, Y., & Cui, H. (2017). Antibacterial poly (ethylene oxide) electrospun nanofibers containing cinnamon essential oil/beta-cyclodextrin proteoliposomes. Carbohydrate Polymers, 178, 131–140.

Liu, Y., Wang, D., Sun, Z., Liu, F., Du, L., & Wang, D. (2021). Preparation and characterization of gelatin/chitosan/3-phenylacetic acid food-packaging nanofiber antibacterial films by electrospinning. International Journal of Biological Macromolecules, 169, 161–170.

López de Dicastillo, C., del Castro-López, M., & M., López-Vilariño, J. M., & González-Rodríguez, M. V. (2013). Immobilization of green tea extract on polypropylene films to control the antioxidant activity in food packaging. Food Research International, 53(1), 522–528.

Lu, H., Wang, Q., Li, G., Qiu, Y., & Wei, Q. (2017). Electrospun water-stable zein/ethyl cellulose composite nanofiber and its drug release properties. Materials Science and Engineering C, 74, 86–93.

Lukic, I., Vulic, J., & Ivanovic, J. (2020). Antioxidant activity of PLA/PCL films loaded with thymol and/or carvacrol using scCO2 for active food packaging. Food Packaging and Shelf Life, 26(June), 100578.

Maroufi, L., Ghorbani, M., & Tabibiazar, M. (2020). A gelatin-based film reinforced by covalent interaction with oxidized guar gum containing green tea extract as an active food packaging system. Food and Bioprocess Technology, 13(9), 1633–1644.

Maroufi, L. Y., & Ghorbani, M. (2021). Injectable chitosan-quince seed gum hydrogels encapsulated with curcumin loaded-halloysite nanotubes designed for tissue engineering application. International Journal of Biological Macromolecules, 177, 485–494.

Maroufi, L. Y., Shahabi, N., & Ghorbani, M. (2022). Development of antimicrobial active Food packaging film based on gelatin/dialdehyde quince seed gum incorporated with apple peel polyphenols. Food and Bioprocess Technology, 15(3), 693–705.

Martins, D., Souza, I., Lacerda, A. D., Passos, R., Santos, D. O., Frollini, E., et al. (2018). Nanostructured electrospun nonwovens of poly ( ε -caprolactone )/ quaternized chitosan for potential biomedical applications. Carbohydrate Polymers, 186(January), 110–121.

Miri, M. A., Habibi Najafi, M. B., Movaffagh, J., & Ghorani, B. (2021). Encapsulation of ascorbyl palmitate in zein by electrospinning technique. Journal of Polymers and the Environment, 29(4), 1089–1098.

Mohammadi, M., Mirabzadeh, S., Shahvalizadeh, R., & Hamishehkar, H. (2020). Development of novel active packaging films based on whey protein isolate incorporated with chitosan nanofiber and nano-formulated cinnamon oil. International Journal of Biological Macromolecules, 149, 11–20.

Mohd Rashid, A. A. B., Jaganathan, S. K., Mohd Khudzari, A. Z., & Ismail, A. F. (2021). Fabrication and characterization of fibrous polycaprolactone blended with natural green tea extracts using dual solvent systems. Autex Research Journal, 1–7.

Nazari, M., Majdi, H., Milani, M., & Abbaspour-ravasjani, S. (2019). Cinnamon nanophytosomes embedded electrospun nanofiber: Its effects on microbial quality and shelf-life of shrimp as a novel packaging. Food Packaging and Shelf Life, 21(June), 100349.

Ngamakeue, N., & Chitprasert, P. (2016). Encapsulation of holy basil essential oil in gelatin: Effects of palmitic acid in carboxymethyl cellulose emulsion coating on antioxidant and antimicrobial activities. Food and Bioprocess Technology, 9(10), 1735–1745.

Panzavolta, S., Gioffrè, M., Focarete, M. L., Gualandi, C., Foroni, L., & Bigi, A. (2011). Electrospun gelatin nanofibers: Optimization of genipin cross-linking to preserve fiber morphology after exposure to water. Acta Biomaterialia, 7(4), 1702–1709.

Perumal, A. B., Li, X., Su, Z., & He, Y. (2021). Preparation and characterization of a novel green tea essential oil nanoemulsion and its antifungal mechanism of action against Magnaporthae oryzae. Ultrasonics Sonochemistry, 76, 105649.

Picchio, M. L., Linck, Y. G., Monti, G. A., Gugliotta, L. M., Minari, R. J., & Igarzabal, C. I. A. (2018). Casein films crosslinked by tannic acid for food packaging applications. Food Hydrocolloids, 84, 424–434.

Pirsa, S., Farshchi, E., & Roufegarinejad, L. (2020). Antioxidant/antimicrobial film based on carboxymethyl cellulose/gelatin/TiO2–Ag nano-composite. Journal of Polymers and the Environment, 28(12), 3154–3163.

Pourhojat, F., Sohrabi, M., Shariati, S., Mahdavi, H., & Asadpour, L. (2017). Evaluation of poly ε-caprolactone electrospun nanofibers loaded with Hypericum perforatum extract as a wound dressing. Research on Chemical Intermediates, 43(1), 297–320.

Qian, Y., Zhang, Z., Zheng, L., Song, R., & Zhao, Y. (2014). Fabrication and characterization of electrospun polycaprolactone blended with chitosan-gelatin complex nanofibrous mats. Journal of Nanomaterials, 2014.

Qin, Z., & yu, Jia, X. W., Liu, Q., Kong, B. hua, & Wang, H. (2019). Fast dissolving oral films for drug delivery prepared from chitosan/pullulan electrospinning nanofibers. International Journal of Biological Macromolecules, 137, 224–231.

Raeisi, S., Chavoshi, H., Mohammadi, M., Ghorbani, M., Sabzichi, M., & Ramezani, F. (2019). Naringenin-loaded nano-structured lipid carrier fortifies oxaliplatin-dependent apoptosis in HT-29 cell line. Process Biochemistry, 83(April), 168–175.

Raja, I. S., Preeth, D. R., Vedhanayagam, M., Hyon, S. H., Lim, D., Kim, B., et al. (2021). Polyphenols-loaded electrospun nanofibers in bone tissue engineering and regeneration. Biomaterials Research, 25(1), 1–16.

Rashidi, M., Seyyedi, S., Mostashari, P., & Ramezani, S. (2021). Electrospun nanofiber based on ethyl cellulose/soy protein isolated integrated with bitter orange peel extract for antimicrobial and antioxidant active food packaging. International Journal of Biological Macromolecules, 193, 1313–1323.

Riahi, Z., Priyadarshi, R., Rhim, J., & Bagheri, R. (2021). Gelatin-based functional films integrated with grapefruit seed extract and TiO2 for active food packaging applications. Food Hydrocolloids, 112(September 2020), 106314.

Sabzichi, M., Mohammadian, J., Ghorbani, M., Saghaei, S., Chavoshi, H., Ramezani, F., & Hamishehkar, H. (2017). Fabrication of all-trans-retinoic acid-loaded biocompatible precirol: A strategy for escaping dose-dependent side effects of doxorubicin. Colloids and Surfaces b: Biointerfaces, 159, 620–628.

Salehi, M., Niyakan, M., Ehterami, A., Haghi-Daredeh, S., Nazarnezhad, S., Abbaszadeh-Goudarzi, G., et al. (2020). Porous electrospun poly(ε-caprolactone)/gelatin nanofibrous mat containing cinnamon for wound healing application: In vitro and in vivo study. Biomedical Engineering Letters, 10(1), 149–161.

Sameen, S., & D. E., Ahmed, S., Lu, R., Li, R., Dai, J., Qin, W., & Liu, Y. (2022). Electrospun nanofibers food packaging: Trends and applications in food systems. Critical Reviews in Food Science and Nutrition, 62(22), 6238–6251.

Shao, P., Liu, Y., Ritzoulis, C., & Niu, B. (2019). Preparation of zein nanofibers with cinnamaldehyde encapsulated in surfactants at critical micelle concentration for active food packaging. Food Packaging and Shelf Life, 22(August), 100385.

Shetta, A., Kegere, J., & Mamdouh, W. (2019). Comparative study of encapsulated peppermint and green tea essential oils in chitosan nanoparticles: Encapsulation, thermal stability, in-vitro release, antioxidant and antibacterial activities. International Journal of Biological Macromolecules, 126, 731–742.

Singh, A., Bajpai, J., Tiwari, A., & Bajpai, A. K. (2015a). Designing casein-coated iron oxide nanostructures (CCIONPs) as superparamagnetic core-shell carriers for magnetic drug targeting. Progress in Biomaterials, 4(1), 39–53.

Singh, R., Shushni, M. A. M., & Belkheir, A. (2015b). Antibacterial and antioxidant activities of Mentha piperita L. Arabian Journal of Chemistry, 8(3), 322–328.

Siripatrawan, U., & Harte, B. R. (2010). Physical properties and antioxidant activity of an active film from chitosan incorporated with green tea extract. Food Hydrocolloids, 24(8), 770–775.

Suwantong, O. (2016). Biomedical applications of electrospun polycaprolactone fiber mats. Polymers for Advanced Technologies, 27(10), 1264–1273.

Tavassoli-Kafrani, E., Goli, S. A. H., & Fathi, M. (2018). Encapsulation of orange essential oil using cross-linked electrospun gelatin nanofibers. Food and Bioprocess Technology, 11(2), 427–434.

Wang, T., Zhang, F., Zhao, R., Wang, C., Hu, K., Sun, Y., & Nie, L. (2020). Polyvinyl alcohol/sodium alginate hydrogels incorporated with silver nanoclusters via green tea extract for antibacterial applications. Designed Monomers and Polymers, 23(1), 118–133.

Wen, H., Hsu, Y. I., Asoh, T. A., & Uyama, H. (2020). Antioxidant activity and physical properties of pH-sensitive biocomposite using poly (vinyl alcohol) incorporated with green tea extract. Polymer Degradation and Stability, 178, 109215.

Wen, P., Zhu, D. H., Feng, K., Liu, F. J., Lou, W. Y., Li, N., & Wu, H. (2016a). Fabrication of electrospun polylactic acid nanofilm incorporating cinnamon essential oil/β-cyclodextrin inclusion complex for antimicrobial packaging. Food Chemistry, 196, 996–1004.

Wen, P., Zhu, D. H., Wu, H., Zong, M. H., Jing, Y. R., & Han, S. Y. (2016b). Encapsulation of cinnamon essential oil in electrospun nanofibrous film for active food packaging. Food Control, 59, 366–376.

Wrona, M., Cran, M. J., Nerín, C., & Bigger, S. W. (2017). Development and characterisation of HPMC films containing PLA nanoparticles loaded with green tea extract for food packaging applications. Carbohydrate Polymers, 156, 108–117.

Zadeh, K. M., Luyt, A. S., Zarif, L., Augustine, R., Hasan, A., Messori, M., & Yalcin, H. C. (2019). Electrospun polylactic acid/date palm polyphenol extract nanofibres for tissue engineering applications. Emergent Materials, 2(2), 141–151.

Zhang, R., Lan, W., Ji, T., Sameen, D. E., Ahmed, S., Qin, W., & Liu, Y. (2021). Development of polylactic acid/ZnO composite membranes prepared by ultrasonication and electrospinning for food packaging. LWT - Food Science and Technology, 135, 110072.

Zhang, W., Li, X., & Jiang, W. (2020a). Development of antioxidant chitosan film with banana peels extract and its application as coating in maintaining the storage quality of apple. International Journal of Biological Macromolecules, 154, 1205–1214.

Zhang, Y., Deng, L., Zhong, H., Pan, J., Li, Y., & Zhang, H. (2020b). Superior water stability and antimicrobial activity of electrospun gluten nanofibrous films incorporated with glycerol monolaurate. Food Hydrocolloids, 109, 106116.

Zou, Y., Zhang, C., Wang, P., Zhang, Y., & Zhang, H. (2020). Electrospun chitosan/polycaprolactone nanofibers containing chlorogenic acid-loaded halloysite nanotube for active food packaging. Carbohydrate Polymers, 247, 116711.

Acknowledgements

The authors gratefully acknowledge the Nutrition Research Center, Tabriz University of Medical Sciences, Tabriz, Iran.

Funding

This research has received financial support from the Nutrition Research Center, Tabriz University of Medical Sciences, Tabriz, Iran (69797).

Author information

Authors and Affiliations

Contributions

Leila Yavari Maroufi: Investigation; Formal analysis; Methodology; Data curation; Writing—Original draft. Sepideh PourvatanDoust: Formal analysis; Methodology; Writing—Original draft. Fatemeh Naeijian: Formal analysis; Data curation. Marjan Ghorbani: Project administration; Conceptualization; Methodology; Investigation; Data curation; Supervision; Funding acquisition; Review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yavari Maroufi, L., PourvatanDoust, S., Naeijian, F. et al. Fabrication of Electrospun Polycaprolactone/Casein Nanofibers Containing Green Tea Essential Oils: Applicable for Active Food Packaging. Food Bioprocess Technol 15, 2601–2615 (2022). https://doi.org/10.1007/s11947-022-02905-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-022-02905-1