Abstract

Cold plasma (CP) treatment for enhancing functional and cooking properties has been investigated on less rice varieties and delays the industrial adoption of this technology. This study treated three types (short-, medium-, and long-kernel) of milled rice from six Chinese varieties with helium plasma (Radio frequency, 13.56 MHz, 140 Pa) at a combination of watt and time, and evaluated the cooking properties, cooked rice texture, kernel appearance quality, and surface morphology, as well as flour thermal and thermomechanical properties. CP treatment at 120 W for 20 s significantly decreased the cooking time and the hardness of cooked rice while increasing adhesiveness, elasticity, and gruel solid loss. CP did not significantly change the appearance of milled rice, except for chalky rice rate, and kept the peak temperature and enthalpy of gelatinization in rice flour. 120W–20s CP significantly increased rice dough development and stability time, starch gelatinization maximum torque, and starch breakdown, but decreased the stability of protein network and starch retrogradation. As CP power strength increased from 120 to 520 W; the surface rupture of a rice kernel became more severe, and small particles aggregated on the rough surface. Compared with the 0 h sample of 120W–20s CP treatment, the repeating CP treatments at 24 h, 48 h, and 30 d significantly decreased water contact angle and free fatty acid content, but increased water absorption rate and chalky rice rate. These results suggest that 120W–20s helium CP improved the cooking properties of milled rice via leading to the rough kernel surface, higher water absorption rate, weak protein network, and a higher speed of starch gelatinization.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recently, a demand for food products containing fewer preservatives and other chemical contents by consumers has increased. Physical nonthermal technologies, such as irradiation, ultraviolet light, pulsed light, high pressure processing, and ultrasound, are considered promising alternatives for treatment of products in food industries. Among these, non-thermal plasma has drawn a great deal of attention as a minimal processing technology (Deshmukh and Shetty 2007; Ziuzina et al. 2014; Mir et al. 2016; Ekezie et al. 2017). Nonthermal plasma is generated by the input of energy and transformation of gas into plasma containing neutral molecules, electrons, positive and negative ions, and excited species (Niemira 2012). Different antimicrobial substances, including UV photons, reactive oxygen species (e.g., hydrogen peroxide, hydroxyl radical, superoxide singlet oxygen, atomic oxygen, and ozone), and reactive nitrogen species (e.g., peroxynitrite, nitric oxide, and nitrite) are generated as a result (Rod et al. 2012). Recent advance in plasma physics engineering and emerged technologies gives a cheaper production of atmospheric pressure cold plasma. Atmospheric cold plasma has been used to reduce corn aflatoxin (Shi et al. 2017), produce antibacterial coatings (Múgica-Vidal et al. 2019), and to improve microbiological safety and quality characteristics of wheat (Los et al. 2018), seeds (Mitra et al. 2014; Puligundla et al. 2017), fruits (Dasan and Boyaci 2018; Dong and Yang 2019) and juices (Xu et al. 2017). Among the different plasma sources, plasma jet and dielectric barrier discharge (DBD) are widely used in food research and commercially available due to simple in construction and easy to adopt (Misra et al. 2016). The DBD plasma treated starch samples of tapioca, maize and cassava showed an increase in glycosidic linkage due to cross-linking (Deeyai et al. 2013; Bie et al. 2016). The DBD plasma treatment was also reported to increase the peak integral, elastic modulus, viscous modulus and dough strength in wheat flour (Misra et al. 2015), but decrease the pH and hardness in brown rice (Lee et al. 2016). Cold plasma activated water was tested to control microbial growth and maintain the quality of fresh-cut pear (Chen et al. 2019a) and Tiger nut (Muhammad et al. 2019).

As a novel and innovative food technology, plasma technology has been recently used in studies to induce the depolymerization of starch and carboxylic starch formed by partial oxidization (Lii et al. 2002; Thirumdas et al. 2017a), alter activities of the enzymes, including peroxidases and polyphenoloxidase (Pankaj et al. 2013; Surowsky et al. 2013; Paixão et al. 2019), and improve the spreadability of oil on biscuits (Misra et al. 2014), and increase water hydrophilicity in zein powder (Dong et al. 2017a) and peanut protein (Ji et al. 2018) . In addition, the cross-linking of starch by glow discharge plasma (air, 700 V for 45 min) has also been reported on soluble starch (Zou et al. 2004). Chen et al. (2012) used a treatment of direct current glow discharge plasma (1–3 kV) for 30 min to improve the cooking properties of brown rice. They observed that the water adsorption of rice was increased after plasma treatment, which resulted in the reduced cooking time. Thirumdas et al. (2016a) inferred that the etching and increased surface energy (enhanced hydrophilicity) of basmati rice could be useful to reduce the cooking time. The microbial safety and quality changes in brown rice (Lee et al. 2016), white rice (Lee et al. 2019), and brown/white cooked rice (Lee et al. 2018) after CP treatment were evaluated at different watt-time combination. However, the mechanism for cold plasma reducing rice cooking time should be further studied on more rice varieties. Moreover, the appearance quality of rice kernels and their dough thermomechanical properties need to be evaluated in different varieties of rice after CP treatment.

China is the world’s largest producer of rice, with an annual production over 200 million tons. About 40% of its production is stored for around 2 years in a form of paddy, such that the maintenance of rice quality is an important research topic. With the economy increase in China, the physical, chemical, or distinctive properties of plenty rice varieties harvested each year are increasingly paid much attention to. The present study was carried out to determine the cooking and thermal properties, kernel appearance quality and surface morphology, and dough thermomechanical properties for three types of six Chinese varieties of milled rice after helium CP treatment, with an aim to elucidate the response mechanism of different types of milled rice after plasma treatment and to develop a processing technology for improving their quality.

Materials and Methods

Milled Rice Samples

Samples of six varieties of milled rice used in this study were as follows: four japonica rice (Longjiang, Daohua Xiang, Changli Xiang, and Yuanli) and two indica rice (Sharuan Nian, and Tianlong). Longjiang (LJ) and Changli Xiang (CLX) were produced in Heilong Jiang province, China in 2016 and in 2017, respectively. Both Daohua Xiang (DHX) and Yuanli (YL) were produced in Jilin province, China in 2017. Sharuan Nian (SRN) and Tianlong (TL) were produced in Guangdong province, China in 2017. The paddy of LJ, SRN, and TL was milled into rice using a miller (LJJM 5588; Taizhou Grain Instrument Company, China) by milling 150 g of rough rice for 30 s. The milled rice varieties of CLX, DHX, and YL were gotten from a rice processing enterprise in Changzhou, Jiangsu Province, China in March 2018. Table 1 shows the ratio of kernel length to width, and contents of protein and amylose in six varieties of milled rice.

The moisture content of samples was determined by the oven-drying method (AOAC 1980). Ten grams of milled rice was crushed on a pulverizer with an 80-mesh screen (JFSD-100, Jiading Grain and Oils Instrument Co. Ltd., Shanghai, China). The powder (3.0000 g) was weighed in triplicate on a balance (0.0001 g, AL204-IC, Mettler Toledo, Shanghai, China) and dried at 103°C for 3 h.

Amylose content in milled rice was determined according to ISO 6647–1 (2007) and GB/T 15683-2008 (National Criterion of China GB/T 15683–2008 2008), with some revision. Two grams of the powder was defatted for 3 h with 85% methanol aqueous solution, then 100 mg defatted sample was weighed into 100 mL conical flask, and successively added 1 mL of 95% ethanol and 9 mL of 1 M NaOH solution. After shaking, the flask was heated in the boiling water for 10 min. After cooled to room temperature, the sample solution was transferred into 100 mL of volumetric flask using distilled water for cooling capacity. The reaction solution included 5 mL sample solution, 1 mL of 1 M acetate solution, 2 mL of 2% KI−0.2% I2 solution in 100 mL of volumetric flask. After using distilled water for cooling capacity, the absorption value in 720 nm was determined on an ultraviolet visible spectrophotometer (UV1700PC, Shanghai Aoxi Instrument Co. Ltd., China). The potato amylose was used for making the standard curve.

Content of protein in milled rice was determined according to ISO 14891 (2002). A rapid N cube nitrogen analyzer (Elementar Rapid, Germany) was used.

Plasma Apparatus

The cold plasma seed processor HD-3 N from Changzhou Zhongke Changtai Plasma Technology Co. Ltd., Jiangsu province, China was used to treat milled rice. The schematic diagram of this plasma apparatus was shown in our recent article given by Chen et al. (2019b). A plasma reactor comprised a quart-sized glass tube with a thickness of 10 mm, height of 300 mm, and internal diameter of 300 mm (Dong et al. 2017b). The top and base plates of the reactor were made of stainless steel. The electrodes were connected through Wilson seals on the plates. The base plate had ports through which the gas/monomer reservoir, Pirani gauge, vacuum pump, and air admittance valve were connected. The area of the two parallel electrodes was 280×250 mm and the distance between the electrodes was kept constant (30 mm) in all the experiments. The electrodes were capacitively coupled to a radio frequency (RF) power supply with a frequency of 13.56 MHz. The RF belongs to PSG-II type, and the working watt range is 0 to 1000 W. The working vacuum is 80 to 180 Pa. The helium, air, and oxygen can be used gas for plasma generation.

Milled rice samples were uniformly spread on the mesh, which was kept on a glass stand between the two electrodes. Initially, the system was evacuated to 20 Pa using three rotary vacuum pumps to remove any adsorbed gases or water vapors from the surface of the rice grains. The untreated sample was also kept in vacuum before characterization. Helium was used as gas for plasma generation and the working pressure was then adjusted to 140 Pa using a mass flow controller. The matching network was adjusted to obtain a stable glow discharge.

The samples of LJ, SRN, and TL milled rice were subjected to helium plasma treatment at a power of 80 W and 120 W for 20, 40, 60, 80, and 120 s, respectively, but samples of DHX, CLX and YL were only treated by 120 W CP for 20 s. In addition, for scanning electron microscopy (SEM) observation, the samples of TL and CLX were treated by different power intensity (0, 120, 220, 320, 420, and 520W) of helium CP for 60 s, respectively.

After CP treatments, a portion of milled rice was stored at a refrigerator, and about 200 g of untreated and CP treated milled rice were respectively milled into rice flour at a Gaosu universal pulverizer (Kewei Yongxing Instrument Co. Ltd., Beijing, China). The pulverizer has a power of 1000 W and 26,000 rpm/min of rotation rate with 100–120-mesh degree of grinding. The rice flour was kept at −20°C until to use.

Effect of Plasma Treatment on Cooking Properties

Cooking Time

Milled rice sample (2 g) was weighed into a glass test tube with the diameter of 2.5 cm and the length of 20 cm, and cooked in 20 mL of distilled water in a boiling water bath. The minimum cooking time was determined by extracting single rice kernels at different time intervals during cooking, placing them on a glass plate, and pressing them between two glass plates. The rice was cooked until no white core was observed in any kernels after pressing, as reported by Chen et al. (2012).

Water Uptake Ratio

Milled rice samples (2 g) were cooked in 20 mL of distilled water for a minimum cooking time in a boiling water bath. After cooking, the excess water was drained off and the contents were transferred onto filter paper to remove the surface water. The cooked samples were weighed on a balance (0.0001 g, AL204-IC, Mettler Toledo), and the water uptake ratio was calculated using the procedure described by Singh et al. (2005).

Gruel Solid Loss

The rice samples (2 g) were cooked in 20 mL of distilled water for minimum cooking time in a boiling water bath. The resulting gruel was transferred to petri dishes with a diameter of 15.5 cm and a height of 2.3 cm. The cooked rice was subjected to repeated washings with distilled water to extract the solids adhering to the surface of the rice grains. The pooled extracts were then evaporated at 110°C in an electro-thermostatic blast oven (DHG 9070A, Blue Sky Laboratory Instrument, Hangzhou, China) until completely dry. The dried solids were weighed on a balance (0.0001 g, AL204-IC, Mettler Toledo), and the percentage of gruel solids was calculated according to the procedure described by Singh et al. (2005).

Appearance Quality

The appearance quality of the milled rice was determined by using an Appearance Quality Instrument of Rice JMWT 12 (Beijing Dongfu Jiuheng Instrument Technology Co. Ltd and Satake, Beijing, China) as per procedure given by Chen et al. (2019b). The instrument comprises arrangement device, image acquisition device, and image processing system. The arrangement device consists of a scan plate and a series of different type of pore plates, and is used for rapid arranging rice kernels before image acquisition. Image acquisition device is a scanner (Canoscan 9000F Mark II, Cannon), which collects image information of rice sample. Image processing system handles the image information of rice sample with a software (Version 2.19) in a computer and gets appearance feature parameters of rice image, then discriminates processing according to the National Standard of P.R.C, GB/T 1354 Milled Rice, and finally outputs the corresponding quality indexes. The time from image acquisition to displaying result was below 40 s. About 500 kernels of milled rice were scanned each time. Each sample was run in triplicate. The quality attributes were as follows: broken kernel percentage (%), unsound kernel percentage (%), yellow kernel percentage (%), and chalky rice rate (%), as well as chalkiness degree (%), length-to-width ratio, and head rice percentage (%). Unsound kernels include worm-eaten, spotted, moldy, and damage kernels as well as sprouted, heat damage, frosted, and immature kernels.

Texture Profile Analysis of Cooked Rice

The texture of the cooked rice after plasma treatment was analyzed by using a Hardness and Adhesiveness analyzer RHS-1A from Japanese Satake Manufacturing Co. Ltd (Suzhou, China) according to the instrumental manual. A cylindrical probe P/36 R with a diameter of 30 mm was used to measure the texture. The force was measured in terms of compression (kg). The instrument was calibrated with a 50-kg load cell. The test speed was 1 mm s−1 and the probe was allowed to compress 0.5 m min1 to the sample. Each measuring ring with an inner diameter of 32.0 mm and the thickness of 9.1 mm contained (8.0±0.1) g of cooked japonica rice or (7.0±0.1) g of cooked indica rice. Five replicate aliquots were tested on each sample and the recorded values from the resulting compression cycle for each test were used for texture profile analysis, which included the attributes of hardness, adhesiveness, elasticity, and balance. The balance is the ratio of adhesiveness to hardness.

Gelatinization Properties of Rice Flour

The thermal properties of the flour obtained from the CP-treated milled rice were determined using a differential scanning calorimeter (DSC) 200F3 (Netzsch, Selb, Germany), as per procedure given by Han et al. (2017). One gram of each rice flour sample was ground in a pestle and mortal. Each ground sample (5.0–5.2 mg) was weighed into an aluminum crucible on a balance (1 mg, XS105, Mettler Toledo). Distilled water was added to obtain a water/sample weight ratio of 2:1. The aluminum crucible was sealed and equilibrated at 4°C overnight. The DSC temperature was raised from 20 to 110°C at a rate of 10°C min−1. Each sample was run in triplicate. The resulting data, including onset temperature (To), peak temperature (Tp), and conclusion temperature (Tc) of flour gelatinization, as well as peak width (PW), peak enthalpy, and the enthalpy of gelatinization (△H), were recorded.

Mixolab Measurement

The Mixolab is an instrument used for analysis of the thermomechanical properties of wheat dough. As such, the mixing and pasting behavior of rice flour dough was measured using a Mixolab (Chopin Technologies, Tripette et Renaud, Paris, France), as described by Rosell et al. (2007). The mixing and pasting behavior of the flour under mechanical and thermal constraints was determined. For an assay at a constant hydration, 55–60 g of rice flour was placed into the Mixolab bowl. A dough weighing 90 g with a 60% water level (14% moisture basis) was evaluated. Both the initial mixing temperature and the water tank temperature were 30°C. The mixing speed during the entire analysis was 80 rpm min−1. The initial mixing was performed at 30°C for 8 min. Then, the temperature was increased to 90°C within 15 min at a rate of 4°C min−1. After 7 min at 90°C, the temperature was decreased to 50°C within 10 min at a rate of 4°C min−1, and held for 5 min. The total time of the procedure was 45 min. The parameters of interest, including protein weakness at constant temperature phase (C1–Cs), amylase activity (C3/C4), starch breakdown (C3–C4) and starch setback (C5–C4), as well as dough development time (DDT) and stability time (DST), were recorded and calculated. Protein weakening (Nm) is the torque difference between the maximum torque (C1) at 30°C and the torque (Cs) at the end of the holding time at 30°C. Amylase activity is the ratio of the maximum gelatinization torque (C3) during the heating period and a torque (C4) after holding at 90°C. Starch breakdown is the difference between C3 and C4. Starch setback (Nm) is the difference between the torque (C5) produced after cooling at 50°C and the torque (C4) after the heating period. The maximum gelatinization torque (C3), heating speed (α, −Nm min−1), gelatinization rate (β, Nm min-1), and enzymatic degradation speed (γ, −Nm min−1) were also given.

Scanning Electron Microscopy

The milled rice of an indica variety TL and a japonica variety CLX was treated by different power intensity of helium CP, and used for scanning electron microscopy (SEM) observation. The surface morphology of kernel samples was examined using a tabletop scanning electron microscope (TM-1000, Hitachi, Tokyo, Japan). Before SEM observation, samples were fixed on a specimen holder using double-face tape and sputter coated with gold (at 2 mbar 3 min).

The Delay Between Cold Plasma Treatment and the Tests

A short-kernel variety of YL milled rice was repeatedly treated at 120 W for 20 s by the above helium CP apparatus according to the procedure in Fig. 1. The untreated (CK) sample was packed into a No.9 valve bag (280×200×0.04 mm of length × width × thickness, Apple Brand, Shanghai China Manufacturing). The CP treated rice (0 h CP) was packaged into a No.9 valve bag and No. 11 valve bag (400×280×0.04 mm of length × width × thickness), and kept at room temperature (RT). After CP treatment at the 48th hour, all the samples were kept at a 4°C refrigerator for 30 days. During the analysis, all the samples were kept in a carton box (21×17.5×8 cm) with 3 mm thickness in a 4°C refrigerator. The measured parameters include moisture content, water drop contact angle, water adsorption rate, and free fatty acid (FFA) content, as well as kernel broken index, cooking properties, and appearance quality.

The effect of the cold plasma on the hydrophilicity of milled rice was evaluated by water contact angle measurements with a Rame–Hart goniometer (Mountain Lakes, USA) as per procedure given by Deshmukh and Bhat (2003). A 2.5 μL droplet of deionized water was put on the surface of rice kernel and the contact angle was measured using sessile drop method. Analysis of performed immediately after deposition of a single droplet of deionized water on the grain surface. Further the dynamics of the droplet shape was recorded at every 10 s by a video camera.

The water adsorption rate of milled rice was determined in a 50 mL plastic centrifugal tube. The 4 g of rice (m1) was weighed into a tube, and 40 mL distilled water was added using a glass pod to remove bubbles. The tubes were stood still at room temperature for 4 h. After taking out the distilled water, the rice kernels were put on filter paper and drawn the water on kernel surface. Finally the rice kernels were weighed as m2. The water adsorption rate of milled rice was calculated as,

The content of free fatty acid (FFA) on rice flour was determined according to the procedure described by GB/T 5510–2011 (National Criterion of China GB/T 5510–2011 2011). Five grams of rice flour was weighed into a 50 mL plastic centrifugal tube, 25 mL anhydrous ethyl alcohol was added, and a lid was covered. The tube was turned upside down three times, and shaken at a table concentrator for 30 min. After stood still for 1 min, and the tubes were centrifuged at 2000 rpm for 5 min. The supernatant was used for titration. The 5 mL sample extract was added 5 mL 0.04% phenolphthalein ethanol solution, and titrated with 1.786 mM KOH ethanol solution.

The broken index of milled rice was defined as the difference between absorption value in 610 nm and in 690 nm, according to the method previously reported by Chen et al. (2019a, b). The sample (2.000 g) of milled rice was dyed by 0.005% fast green FCF (MW 808.85 g/mol, Sigma, USA) solution for 10 min, and then the sample was washed till the washing water shows no blue color. The dyed sample was eluted by 1 mM NaOH for 15 min. The elution was determined absorption value in 610 nm and 690 nm on an ultraviolet visible spectrophotometer (UV1700PC, Shanghai Aoxi Instrument Co. Ltd.).

Data Analysis

The results were statistically analyzed using SPSS (Version 17.0, SPSS In. 2006). For the untreated (CK) and eight CP treated samples within each variety, one–way ANOVA method was used to compare means. For CK and 120W–20s CP treated samples within each variety, independent-sample t test was used to compare means. For observing the effect of rice variety and CP treatment, General Linear Model–Univariate method was used to compare the means by the LSD test. Statistical significance was declared at p < 0.05 level.

Results

Effect of Cold Plasma Treatment on Cooking Properties

The methods for reducing the cooking time are explored for the preparation of instant rice and designing of rice cookers (Prasert and Suwannaporn 2009). Table 2 shows the effect of plasma treatment on the cooking properties of six varieties of milled rice with varying power and time treatments. In comparison to the untreated sample of each variety of milled rice, the CP treatment significantly (p < 0.05) reduced the cooking time. With an increased plasma power at the same treatment time, the cooking time of milled rice was reduced accordingly for SNR and TL varieties (p < 0.05). The cooking time of the milled rice treated at 80 W for 120 s was similar to that of milled rice treated at 120 W for 20 s for the SNR and TL varieties, while LJ milled rice had similar cooking time between 120W-20s CP and 80W-60s CP.

CP treatment increased water uptake ratio of the rice kernels of six varieties. For LJ milled rice, the water uptake ratio of CP treated rice increased with an increase in treatment time at the same plasma power; however, 80 W CP led to a greater water uptake ratio than treatment at 120 W for the same amount of time. For SRN, the milled rice treated with 80 W CP showed a close water uptake ratio for different treatment time intervals from 20 to 120 s, while 120 W CP treatment at 20, 40, 60, and 120 s produced a significantly greater water uptake ratio than 80 W CP at the corresponding treatment times. For TL, the milled rice treated at 80 W CP showed an increased water uptake ratio with an increase in treatment time from 20 to 120 s, while 120 W CP at 20 s and 40 s showed a higher water uptake compared to the same treatment at 60 s and 120 s. Both 120 W and 80 W CP at 20 s produced a significantly greater water uptake ratio than the untreated milled rice for LJ, SNR and TL varieties. For DHX, CLX, and YL milled rice, 120W-20s CP treatment resulted in a significantly (p < 0.05) greater water uptake ratio than the untreated milled rice.

CP treatment induced the gruel solid loss in all six varieties of milled rice. For LJ milled rice, the gruel solid loss increased with CP treatment time for the same watt, whereas the gruel solid loss of rice treated by 120 W was similar to that of 80 W CP at the same treatment time. For SNR, CP treatment at 120 W for 20, 40, and 60 s resulted in an accordingly greater gruel solid loss than CP treatment at 80 W for 20, 40, and 60 s, respectively. TL milled rice treated with CP 80 W and 120 W induced a similar loss of gruel solid at different treatment times; all CP treatments significantly (p < 0.05) increased the gruel solid loss than the untreatment. For DHX, CLX, and YL milled rice, 120 W-20s CP treatment significantly (p < 0.05) increased the gruel solid loss than the untreatment.

Considering the overall effect of rice variety (LJ, SRN and TL) and CP treatments (80 W and 120 W from 20 to 120 s) on cooking properties of milled rice (Table 3), SRN and TL milled rice had lower cooking time than LJ milled rice, and the water uptake ratio and gruel solid loss were different among these three rice varieties. All the CP treatments significantly (p < 0.05) reduced cooking time, and increased the water uptake ratio and gruel solid loss in these three varieties of milled rice. The 120 W CP for 20 s had similar cooking time to 80 W CP for 60 s and 120 W CP for 40 s. The 80 W CP for 120 s had the lowest cooking time than 80 W CP from 20 to 60 s, and the 120 W CP for 40 s had the higher cooking time than 120 W CP from 60 to 120 s. With increase in CP treated time and power, the water uptake ratio and gruel solid loss did not show a regularly significant increase. Taking into account the shorter treatment time of higher power CP, we selected 120 W CP for 20 s to milled rice.

For the six varieties of milled rice, the analysis of General Linear Model–Univariate method shows, compared to the untreatment, CP treatment at 120 W for 20 s significantly reduced cooking time, and increased the water uptake ratio and gruel solid loss (Table 4).

Textural Properties of Cooked Rice

The hardness and adhesiveness are two important parameters for evaluating cooked rice texture and consumer acceptability (Chen et al. 2012). Table 5 shows that CP treatment affected the textural properties of all six varieties of milled rice. The standard values of hardness, adhesiveness, balance, and elasticity of cooked rice are 4–5 kgf, 0.5–0.6 kgf, 0.16–0.18, and 0.70–0.72 kgf, respectively, as suggested by the manufacturing company of Hardness and Adhesiveness analyzer RHS-1A. In the present study, the hardness, adhesiveness, balance, and elasticity of cooked rice for the six Chinese varieties were 3.9–4.7 and 3.9–5.2 kgf, 0.9–1.0 and 0.8–0.9 kgf, 0.19–0.24 and 0.16–0.22, and 0.72–0.78 and 0.72–0.74 kgf in 120W–20s CP treated rice and untreated milled rice, respectively.

For LJ variety, compared to the hardness and adhesiveness of the untreated rice, 80 W CP from 20 to 40 s and 120W CP for 20 and 60 s significantly reduced the hardness, but other CP treatments kept the hardness, the adhesiveness of CP treated rice insignificantly increased with the watt and treatment time. For SRN variety, 80W–20s, 80W–40s, 80W–120s and 120W–20s CP treatments kept the same hardness with the untreatment, other CP treatments significantly increased the hardness. All the CP treatments did not significantly increase the adhesiveness in the SRN cooked rice. For TL variety, 80W–20s and 120W–20s CP treatments had the same hardness with the untreatment, but other CP treatments significantly increased the hardness. All the CP treatments kept the same adhesiveness with the untreated TL sample.

For SRN and TL varieties, CP treatments tended to increase the hardness and adhesiveness of cooked rice, wherein the efficacy of 120 W CP was slightly greater than that of 80 W CP at the same treatment time. In comparison to the untreatment, 120 W CP for 20 s induced a significant (p > 0.05) decrease in hardness for DHX and YL varieties, but not for CLX variety, this treatment did not significantly increase the adhesiveness of cooked rice in these three varieties.

For three varieties of LJ, SRN, and TL milled rice, most of 80 W and 120 W CP at 20–120 s did not significantly change the balance or elasticity in cooked rice. In comparison to the untreatment, 120 W CP for 20 s induced a significant increase in the elasticity for SNR, DHX, CLX, and YL, but not for LJ and TL. This treatment kept the balance of cooked rice in the six varieties.

Considering the overall effect of rice variety (LJ, SRN and TL) and CP treatments (80 W and 120 W from 20 to 120 s) on the texture of cooked rice (Table 6), three rice varieties had different hardness, balance and elasticity. For three varieties, the combination of CP power and treatment time changed the hardness and adhesiveness of cooked rice, but remained the elasticity. Compared with the untreated sample, the CP treatments of 80W–20s, 80W–40s, and 120W–20s kept or reduced hardness, other CP treatments significantly increased the hardness. The 120W–20s CP, as well as 80W–20s, 80W–60s and 80W–120s CP, insignificantly increased adhesiveness of cooked rice, but 120w CP from 40 to 120 s significantly increased the adhesiveness. The 120W–20s CP, as well as 80W–40s, 120W–40s and 120W–120s CP, significantly increased the balance.

Using an independent-sample t test to further analyze the effect of six rice varieties and 120W–20s CP on the texture of cooked rice, the six varieties such as DHX, CLX, and YL, as well as LJ, SRN and TL, had different hardness, balance and elasticity. Compared to the untreatment, CP treatment at 120 W for 20 s significantly reduced hardness, but increase adhesiveness, balance, and elasticity (Table 7).

Appearance Quality of Milled Rice

The appearance quality of milled rice decides its sale price. Table 8 shows the effect of CP treatment on the appearance quality of milled rice. In comparison to the untreated sample, CP treatment significantly decreased the moisture content in LJ milled rice, however, the moisture did not significantly reduce with increase in CP power and treatment time. For SNR, CP treatments at 80W–40s and 120W–20s maintained the moisture of milled rice, other CP treatments significantly reduced the moisture content when comparing with the untreatment. For TL, most of the CP treatments maintained the moisture content.

Except for CP treatments of 80W–60s and 80W–120s, the other CP treatments did not significantly (p > 0.05) increase the broken kernel percentage of LJ milled rice. Eight CP treatments did not significantly alter the percentage of broken kernels in SRN and TL milled rice.

Eight CP treatments also did not significantly (p>0.05) increase the unsound kernel percentage of LJ, SNR and TL milled rice. The CP treatments of 80W at 20 to 60s and 120W at 60 to 120s significantly increased yellow kernel percentage in LJ milled rice, 120W–20s CP also significantly increased yellow kernel percentage in TL milled rice.

The CP treatments of 80W–120s, 120W–60s and 120W–120s for LJ, 80W–120s and 120W–120s for SNR and TL significantly increased the chalky rice rate. As for the chalkiness degree, the CP treatments of 80W–120s and 120W–120s for LJ and 80W–120s, 120W–60s and 120W–120s for SNR induced a significant increase. The kernel length-to-width ratio and head rice percentage in LJ, SNR and TL milled rice were not significantly changed by most of CP treatments.

For DHX, CLX and YL milled rice, CP treatment at 120W–20s led to the significant lower moisture content in milled rice than the untreated sample. This treatment significantly increased the chalky rice rate and chalkiness degree in CLX and YL milled rice.

Considering the overall effect of rice variety (LJ, SRN and TL) and CP treatments (80 W and 120 W from 20 to 120 s) on the appearance quality of milled rice (Table 9), three rice varieties had difference in the percentage in broken kernel, unsound kernel, yellow kernel, and chalky rice rate, as well as chalkiness degree, length-to-width ratio and head rice percentage. The combination of CP power and treatment time mainly had an influence on the chalky rice rate and chalkiness degree. With increase in CP power and treatment time, the chalky rice rate and chalkiness degree increased. Compared with the untreated sample, the CP treatments of 80 W from 20 to 40 s and 120 W at 20s kept chalky rice rate and chalkiness degree.

Further comparing the effect of six rice varieties and 120W–20s CP on the appearance quality of milled rice (Table 10), 120W–20s CP induced significantly higher percentage of chalky rice rate and yellow kernel.

Thermal Properties of Milled Rice Flour

The gelatinization temperature is used for indicating the required energy for initiating starch gelatinization (Wang et al. 2010). Table 11 shows the effect of plasma treatment on thermal properties of milled rice. For LJ, SRN, and TL milled rice, CP 120 W for 20 s did not significantly change neither the onset temperature (To), peak temperature (Tp), or final temperature (Tc) of rice flour gelatinization, nor the enthalpy (∆H) of gelatinization. In contrast to the untreatment, this CP treatment kept the peak width of SRN and TL, and peak enthalpy of LJ and TL. For DHX milled rice, the same treatment (120W–20s CP) for significantly decreased To and Tc, but did not change any of thermal parameters of the rice flour.

Consider the overall effect of rice variety and CP treatment on thermal properties of milled rice (Table 12), SRN and TL milled rice had similar peak temperature and enthalpy of gelatinization, which is different from those of LJ and DHX. Compared with the untreatment, the 120 W CP for 20 s kept the average Tp, peak enthalpy and ∆H of these four varieties of milled rice while significantly decreased To and Tc with a significant increase in peak width of gelatinization.

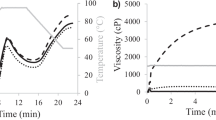

Thermomechanical Properties of Rice Flour Dough

Gel hydration properties are used to assess the starch gelatinization and protein denaturation during thermal treatment (de la Hera et al. 2013). Figure 2 shows curves representing the changes in the rice dough behavior during mixing, heating, and cooling. From the plot obtained for two varieties of milled rice, such as CLX and DHX, the difference between the CP-treated sample and the untreated sample was bigger during the mixing step (first part of the curve), where the proteins play the main role, as the dough is affected by a mechanical constraint. However, during the heating and cooling cycles, these differences decreased.

Table 13 shows the effect of plasma treatment on the thermal and mechanical properties of rice flour dough at a constant hydration. In comparison to the untreated samples, CP treatment at 120 W for 20 s significantly increased dough development time (DDT) of the flour from six varieties of milled rice, namely LJ, SRN, TL, DHX, CLX, and YL, as well as significantly increased the dough stability time (DST) of LJ, TL, DHX, and CLX rice flours.

C1–Cs shows the protein weakening degree of rice flour dough. For five varieties, namely LJ, SRN, TL, DHX and CLX milled rice, 120W–20s plasma treatment significantly reduced the C1–Cs of rice dough.

For LJ, SRN, and CLX milled rice, 120W–20s plasma treatment significantly increased the maximum gelatinization torque (C3) of rice dough, and kept the C3 of DHX and YL rice dough, but decreased the C3 of TL rice dough.

120W–20s CP treatment significantly increased the amylase activity (C3/C4) and starch breakdown (C3–C4) of LJ and DHX rice dough, but maintained the starch retrogradation (C5–C4) of all six varieties of rice dough.

CP treatment significantly increased the heating speed (α) of SRN, TL, and DHX rice dough, and also significantly increasing the starch gelatinization speed (β) of TL, CLX and YL rice dough. However, CP treatment significantly decreased the enzymatic degradation speed (γ) of TL rice dough.

The Mixolab parameters of interest in rice dough were affected by rice varieties (Table 14). For the six rice varieties, compared with the untreated samples, 120W–20s plasma treatment significantly increased the average values in DDT, DST, and C3, as well as C3–C4, α and β, but significantly decreased the average C1–Cs, C5–C4 and γ.

Scanning Electron Microscopy of Milled Rice

The SEM micrographs were used to reveal the etching effect of cold plasma (Thirumdas et al. 2016a). The SEM micrographs of untreated and helium CP-treated rice kernels of TL and CLX varieties are shown in Figs. 3 and 4, respectively. The indica milled rice of TL was processed into milled rice in the laboratory by milling 150 g of rough rice for 30 s. The japonica rice of CLX was gotten from a rice processing enterprise. The results in Figs. 3a and 4a indicate that the surface morphology of untreated rice kernel was smooth and regular. After the CP treatment at 120 W for 60 s, some scraggly structures appeared on the kernel surface (Figs. 3b and 4b). After being treated at 220 W CP for 60 s, cavities and cracks appeared, meanwhile some small particles aggregated together to form bigger piles on the surface (Figs. 3c and 4c). At the higher intensities of 320 W, 420 W and 520 W CP for 60 s, the kernel surface was found to be distorted apparently, as shown in Figs. 3d and 4d, 3e and 4e, and 3f and 4f, respectively. These results demonstrated that the surface structure of an intact kernel would be altered by different power strengths of helium plasma, and the aggregation of small particles led to the rough surface of rice kernel.

The CP Repeating Treatments on Milled Rice

The contact angle formed between a water drop placed on the surface of a material and its variation with time is related to the wettability of the material (Andrade et al. 2005). As shown in Table 15, the YL milled rice treated repeatedly with helium 120W–20s CP at 24 h (twice), 48 h (three times) and 30 days (four times) showed a steadily significant decrease in water drop contact angle and FFA, despite that a reduction in moisture content and an increase in water adsorption rate were changed accordingly to treatment times. In contrast to the once treatment, the CP repetition treatments did not significantly alter kernel broken index. Compared to the untreated sample, 120W–20s CP and its repeating treatments significantly decreased rice cooking time by 4.5-5.5 min (Table 16), but the repeating CP treatments did not decrease the cooking time. The cooking time was set at 15.5 min, the water uptake ratio and gruel solids loss were increased significantly with the treatment times. Compared with the 0 h sample of once CP treatment, the repeating CP treatments at 24 h (twice), 48 h (three times) and 30 d (four times) tended to decrease the full length and full width of rice kernel, but significantly increased chalky rice rate and chalkiness degree, maintaining the ratio of full length/width, head rice percent, unsound kernel and yellow kernel (Table 17).

Discussion

Different rice varieties and types may have differential response to cold plasma treatment. Plasma treatment reduced the cooking time to 13.15 min from 20.1 min for basmati rice (Thirumdas et al. 2016a) and 11.0–14.2 min from 24.7 min for Taichung Sen (TCS 10) brown rice (Chen 2014). In our study, after plasma treatment, the cooking time of three types of milled rice, short-kernel (LJ and YL, L/W 1.7–1.8), medium-kernel (CLX and DHX, L/W 2.1–2.5), and long-kernel (SRN and TL, L/W 2.8–2.9), was reduced from 19.0–19.5 min to 13.5–15.3 min, 18.0–18.5 min to 12.0–14.0 min, and 16.2–16.5 min to 12.3–13.0 min, respectively. It seems that the Chinese medium- and short- kernel milled rice clearly shorten cooking time than long-kernel milled rice after CP treatment. We chose 120W–20s CP to treat the six varieties of milled rice, in that its treated rice in LJ, SRN and TL varieties had similar cooking properties to 80W–60s CP, kept the similar cooked texture to 80W–40s CP, and also had similar chalky rice rate and chalkiness degree to 80W–60s CP.

120W–20s CP treatment increased the water uptake ratio of rice kernels for the six varieties of milled rice studied. This could be attributed to the easy penetration of water into the rice grain compared to the untreated sample. Similar observations have been previously reported in plasma-treated basmati rice (Thirumdas et al. 2016a) and brown rice (Chen et al. 2012). CP treatment also induced loss in gruel solids after cooking in the six varieties of milled rice, possibly due to the amount and molecular weight of the amylose leaching from the starch granules and the gelatinization of the starch remnants (Loh 1992).

In the present study, the cooked rice from 120W–20s CP treatment had significantly higher adhesiveness, balance, and elasticity and significantly lower hardness than the untreated sample, which is indicative of a higher score of cooked rice with sensory evaluation. Zhou et al. (2007) reported that the parameters of hardness and adhesiveness are related to the hydration process of starch granules. CP treatment increased the adhesiveness of cooked rice while decreasing the hardness, maybe due to increase in the hydrophilicity of milled rice.

Low pressure plasma treatment has been conducted to the modification of parboiled rice and its flour (Sarangapani et al. 2015, 2016), and basmati rice flour (Thirumdas et al. 2016b). Few studies have investigated the flour pasting behavior of CP-treated milled rice. A rapid visco analysis (RVA) is usually used to investigate the pasting characteristics of rice flour suspensions, however, the present study used the Mixolab (Chopin, Paris, France) to study the mixing and pasting behavior of the rice flour dough and blends (Rosell et al. 2007). In present study, CP treatment at 120 W for 20 s was found to significantly decrease the stability of the protein network (C1–Cs) and the starch retrogradation (C5–C4) of the rice dough while increasing maximum gelatinization torque (C3) and starch breakdown (C3–C4). This was reflected by the higher speeds of heating (α) and starch gelatinization (β) and the lower speed of enzymatic degradation (γ). CP treatment also significantly increased the dough development time (DDT) and stability time (DST) of rice dough. Thirumdas et al. (2017b) observed that the peak viscosity of rice starch increased after Radio frequency air plasma treatment. Pal et al. (2016) suggested that the cross-linking of starch molecules induced by plasma oxidation resulted in a higher peak viscosity compared to the untreated sample. Our results suggest that the increased C3 of the rice dough may easily leach out of the amylose molecules due to a weakening of the bonds or the breakdown of bonds caused by plasma reactive species.

The enthalpy values obtained by differential scanning calorimetry (DSC) are indictive of the degree of the starch damage occurring during grinding. Lower enthalpy values are correlated with a greater damage of the starch (Rosell and Marco 2008). In this study, for the samples of four varieties of milled rice, 120 W helium CP treatment for 20 s did not significantly increase the average peak gelatinization temperature (Tp) and enthalpy values of gelatinization (∆H). Thirumdas et al. (2017b) used 40 W and 60 W air Radio frequency plasma (13.56 MHz, 0.15 mbar) to treat rice starch for 5 and 10 min, respectively. Their results showed that the peak temperature (Tp) of gelatinization and gelatinization enthalpy (∆H) were not significantly changed. Wongsagonsup et al. (2014) found that, at lower plasma power levels, the plasma species initiated the cross-linking of starch chains and increased Tp, while, at higher plasma power levels, plasma species induced the depolymerization of starch chains and decreased Tp. These differences indicate that the penetration power of plasma into food is limited.

We also explore the effect of helium CP repeating treatments on milled rice. Compared to the untreated sample, 120W–20s CP and its repeating treatments significantly decreased rice cooking time and water drop contact angle, but the repeating CP treatments did not decrease the cooking time. At the same cooking time, the water uptake ratio and gruel solids loss were increased significantly with the treatment times. Compared with the 0 h sample of once CP treatment, the repeating CP treatments at 24 h (twice), 48 h (three times) and 30 d (four times) tended to decrease the full length and full width of rice kernel, but significantly increased chalky rice rate and chalkiness degree, maintaining the ratio of full length/width, head rice percent and yellow kernel. The increase in chalky rice rate and chalkiness degree after CP treatment should be further studied.

In the present study, as the helium CP power strength increased from 120 to 520 W, the surface rupture of rice kernel becomes more severe and gradually they lose their original shapes. Superficial damage was caused by plasma etching to different extents at various power levels. We infer that the aggregation of small surface particles at the surface of starch granules could be due to the Van der Waal’s force and electrostatic force during plasma reaction. Han et al. (2009) reported that a use of pulsed electric fields treatment on corn starch could cause damage on the protective envelope of starch granules, thus assisting further penetrative damage and leading to a better water-absorbing and swelling ability. Based on the results presented in this study, further study is needed in order to clarify how helium CP changes the fine structure of starch and physicochemical properties in milled rice.

Conclusion

In comparison to the untreated sample, 120W–20s helium plasma significantly reduced the cooking time of six Chinese varieties of milled rice while increasing their water uptake and gruel solid loss. This treatment also significantly reduced the overall hardness while increasing the adhesiveness, balance, and elasticity in the texture of cooked rice. CP treatment significantly increased the heating speed (α) and starch gelatinization speed (β), and significantly decreased enzymatic degradation speed (γ) in a rice dough behavior during mixing, heating, and cooling, thus significantly lowered stability in protein network (C1–Cs) and starch retrogradation (C5–C4), but increased the maximum gelatinization torque (C3) and starch breakdown (C3–C4). Except for chalky rice rate, 120W–20s helium plasma did not change any of the appearance quality parameters of the milled rice, including the unsound kernel and broken kernel percentage. Helium CP treatment kept the peak gelatinization temperature (Tp) and enthalpy of gelatinization (∆H) in rice flour, according to differential scanning calorimetry (DSC). As helium CP power strength increased from 120 to 520 W, the surface rupture of rice kernel becomes more severe and gradually they lose their original shapes. Superficial damage was caused by plasma etching to different extents at various powers. The CP repetition treatments on milled rice significantly decreased in water drop contact angle and FFA, but increased in water adsorption rate. The reason for an increase in chalky rice rate and chalkiness degree after CP treatment should be further studied.

References

Andrade, C. T., Sima, R. A., Rossana, M. S., & Achete, C. A. (2005). Surface modification of maize starch films by low-pressure glow 1-butene plasma. Carbohydrate Polymers, 61(4), 407–413.

AOAC. (1980). Official methods of analysis (13th ed.). Washington DC: Association of Official Analytical Chemists.

Bie, P., Pu, H., Zhang, B., Su, J., Chen, L., & Li, X. (2016). Innovative food science and emerging technologies, 34, 194–204.

Chen, H. H. (2014). Investigation of properties of long-grain brown rice treated by low-pressure plasma. Food and Bioprocess Technology, 7(9), 2484–2491.

Chen, H. H., Chen, Y., & Chang, C. H. (2012). Evaluation of physicochemical properties of plasma treated brown rice. Food Chemistry, 135(1), 74–79.

Chen, C., Liu, C. H., Jiang, A. L., Guan, Q. X., Sun, X. Y., Liu, S. S., Hao, K. X., & Hu, W. Z. (2019a). The effects of cold plasma-activated water treatment on the microbial growth and antioxidant properties of fresh-cut pears. Food and Bioprocess Technology, 12(11), 1842–1851.

Chen, Z. T., Wang, R. L., Li, X. J., Zhu, J., Xu, Y. N., & Liu, J. J. (2019b). Sorption equilibrium moisture and isosteric heat of cold plasma treated milled rice. Innovative Food Science and Emerging Technologies, 55, 35–47.

Dasan, B. G., & Boyaci, I. H. (2018). Effect of cold atmospheric plasma on inactivation of Escherichia coli and physicochemical properties of apple, orange, tomato juices, and sour cherry nectar. Food and Bioprocess Technology, 11(2), 334–343.

de la Hera, E., Gomez, M., & Rosell, C. M. (2013). Particle size distribution of rice flour affecting the starch enzymatic hydrolysis and hydration properties. Carbohydrate Polymers, 98(1), 421–427.

Deeyai, P., Suphantharika, M., Wongsagonsup, R., & Dangtip, S. (2013). Characterization of modified tapioca starch in atmospheric argon plasma under diverse humidity by FTIR spectroscopy. Chinese Physics Letters, 30(1), 018103.

Deshmukh, R. R., & Bhat, N. V. (2003). The mechanism of adhesion and printability of plasma processed PET films. Materials Research Innovations, 7(5), 283–290.

Deshmukh, R. R., & Shetty, A. R. (2007). Surface characterization of polyethylene films modified by gaseous plasma. Journal of Applied Polymer Science, 104(1), 449–457.

Dong, X. Y., & Yang, Y. L. (2019). A novel approach to enhance blueberry quality during storage using cold plasma at atmospheric air pressure. Food and Bioprocess Technology, 12(8), 1409–1421.

Dong, S., Gao, A., Xu, H., & Chen, Y. (2017a). Effects of dielectric barrier discharges (DBD) cold plasma treatment on physicochemical and structural properties of Zein powders. Food and Bioprocess Technology, 10(3), 434–444.

Dong, Y. H., Shao, H. L., Li, J. G., & Miao, Q. (2017b). Control system of full-automatic cold plasma seed processor. (United State Patent US 9782740B2).

Ekezie, F. C., Sun, D. W., & Cheng, J. H. (2017). A review on recent advances in cold plasma technology for the food industry: Current applications and future trends. Trends in Food Science & Technology, 69, 46–58.

Han, Z., Zeng, X. A., Zhang, B. S., & Yu, S. J. (2009). Effects of pulsed electric fields (PEF) treatment on the properties of corn starch. Journal of Food Engineering, 93(3), 318–323.

Han, X., Wang, X., Li, X. J., & Jiang, P. (2017). Sorption equilibrium moisture and isosteric heat of Chinese wheat flours. Quality Assurance and Safety of Crops & Foods, 9(4), 435–449.

ISO 14891 (2002). Milk and milk products—Determination of nitrogen content—Routine method using combustion according to the Dumas principle.

ISO 6647-1 (2007). Rice—Determination of amylose content—Part 1. Reference method, IDT.

Ji, H., Dong, S., Han, F., Li, Y. T., Chen, G. Y., Li, L., & Chen, Y. (2018). Effects of dielectric barrier discharge (DBD) cold plasma treatment on physicochemical and functional properties of peanut protein. Food and Bioprocess Technology, 11(2), 344–354.

Lee, K. H., Kim, H. J., Woo, K. S., Jo, C., Kim, J. K., Kim, S. H., Park, H. Y., Oh, S. K., & Kim, W. H. (2016). Evaluation of cold plasma treatments for improved microbial and physicochemical qualities of brown rice. LWT- Food Science and Technology, 73, 442–447.

Lee, K. H., Woo, K. S., Yong, H. I., Jo, C., Lee, S. K., Lee, B. W., Oh, S. K., Lee, Y. Y., Lee, B., & Kim, H. Y. (2018). Assessment of microbial safety and quality changes of brown and white cooked rice treated with atmospheric pressure plasma. Food Science and Biotechnology, 2018, 27(3), 661–667.

Lee, J. H., Woo, K. S., Jo, C., Jeong, H. S., Lee, S. K., Lee, B. W., Lee, Y. Y., Lee, B., & Kim, H. J. (2019). Quality evaluation of rice treated by high hydrostatic pressure and atmospheric pressure plasma. Journal of Food Quality, 4253701.

Lii, C. Y., Liao, C. D., Stobinski, L., & Tomasik, P. (2002). Behaviour of granular starches in low-pressure glow plasma. Carbohydrate Polymers, 49(4), 499–507.

Loh, J. (1992). The effect of shear rate and strain on the pasting behaviour of food starches. Journal of Food Engineering, 16(1-2), 75–89.

Los, A., Ziuzina, D., Akkermans, S., Boehm, D., Cullen, P. J., Impe, J. V., & Bourke, P. (2018). Improving microbiological safety and quality characteristics of wheat and barley by high voltage atmospheric cold plasma closed processing. Food Research International, 106, 509–521.

Mir, S. A., Shah, M. A., & Mir, M. M. (2016). Understanding the role of plasma technology in food industry. Food and Bioprocess Technology, 9(5), 734–750.

Misra, N. N., Sullivan, C., Pankaj, S. K., Alvarez-Jube, L., Cama, R., Jacoby, F., & Cullen, P. J. (2014). Enhancement of oil spreadability of biscuit surface by non-thermal barrier discharge plasma. Innovative Food Science & Emerging Technologies, 26, 456–461.

Misra, N., Kaur, S., Tiwari, B. K., Kaur, A., Singh, N., & Cullen, P. (2015). Atmospheric pressure cold plasma treatment of wheat flour. Food Hydrocolloids, 44, 115–121.

Misra, N. N., Pankaj, S. K., & Segat, A.,& Ishikawa, K. (2016). Cold plasma interactions with enzymes in foods and model systems. Trends in Food Science & Technology, 55, 39–47.

Mitra, A., Li, Y. F., Klämpfl, T. G., Shimizu, T., Jeon, J., Morfill, G. E., & Zimmermann, J. L. (2014). Inactivation of surface-borne microorganisms and increased germination of seed specimen by cold atmospheric plasma. Food and Bioprocess Technology, 7(3), 645–653.

Múgica-Vidal, R., Sainz-García, E., Álvarez-Ordóñez, A., Prieto, M., González-Raurich, M., López, M., López, M., Rojo-Bezares, B., Sáenz, Y., & Alba-Elías, F. (2019). Production of antibacterial coatings through atmospheric pressure plasma: a promising alternative for combatting biofilms in the food industry. Food and Bioprocess Technology, 12(5), 1251–1263.

Muhammad, A. I., Chen, W. J., Liao, X. Y., Xiang, Q. S., Liu, D. H., Ye, X. Q., & Ding, T. (2019). Effects of plasma-activated water and blanching on microbial and physicochemical properties of tiger nuts. Food and Bioprocess Technology, 12(10), 1721–1732.

National Criterion of China. (2008). Rice-Determination of amylose content. GB/T 15683-2008.

National Criterion of China. (2011). Inspection of grain and oils—Determination of fat acidity value of grain and oilseed. GB/T5510-2011.

Niemira, B. A. (2012). Cold plasma decontamination of foods. Annual Review of Food Science and Technology, 3(1), 125–142.

Paixão, L. M. N., Fonteles, T. V., Oliveira, V. S., Fernandes, F. A. N., & Rodrigues, S. (2019). Cold plasma effects on functional compounds of Siriguela Juice. Food and Bioprocess Technology, 12(1), 110–121.

Pal, P., Kaur, P., Singh, N., Kaur, A. P., Misra, N. N., Tiwari, B. K., Cullen, P. J., & Virdi, A. S. (2016). Effect of nonthermal plasma on physic-chemical, amino acid composition: Pasting and protein characteristics of short and long grain rice flour. Food Research International, 81, 50–57.

Pankaj, S. K., Misra, N. N., & Cullen, P. J. (2013). Kinetics of tomato peroxidase inactivation by atmospheric pressure cold plasma based on dielectric barrier discharge. Innovative Food Science & Emerging Technologies, 19, 153–157.

Prasert, W., & Suwannaporn, P. (2009). Optimization of instant jasmine rice process and its physicochemical properties. Journal of Food Engineering, 95(1), 54–61.

Puligundla, P., Kim, J. W., & Mok, C. (2017). Effects of nonthermal plasma treatment on decontamination and sprouting of radish (Raphanus sativus L.) seeds. Food and Bioprocess Technology, 10(6), 1093–1102.

Rod, S. K., Hansen, F., Leipold, F., & Knochel, S. (2012). Cold atmospheric pressure plasma treatment of ready-to-eat meat: inactivation of Listeria innocua and changes in product quality. Food Microbiology, 30(1), 233–238.

Rosell, C.M., & Marco, M. (2008). Rice, gluten-free cereal products and beverages, 10.1016/B978-012373739-7.50006-X, (81-III).

Rosell, C. M., Collar, C., & Haros, M. (2007). Assessment of hydrocolloid effects on the thermo-mechanical properties of wheat using the mixolab. Food Hydrocolloids, 21(3), 452–462.

Sarangapani, C., Devi, Y., Thirumdas, R., Annapure, U. S., & Deshmukh, R. R. (2015). Effect of low-pressure plasma on physico-chemical properties of parboiled rice. LWT- Food Science and Technology, 63(1), 1–9.

Sarangapani, C., Thirumdas, R., Devi, Y., Trimukhe, A., Deshmukh, R. R., & Annapure, U. S. (2016). Effect of low-pressure plasma on physico-chemical and functional properties of parboiled rice flour. LWT- Food Science and Technology, 69, 482–489.

Shi, H., Ileleji, K., Stroshine, R. L., Keener, K., & Jensen, J. L. (2017). Reduction of aflatoxin in corn by high voltage atmospheric cold plasma. Food and Bioprocess Technology, 10(6), 1042–1052.

Singh, N., Kaur, L., Singh, S., & Singh, S. K. (2005). Physicochemical, cooking and textural properties of milled rice from different Indian rice cultivars. Food Chemistry, 89(2), 253–259.

SPSS Inc. (2006). SPSS for Windows, Release 17.0.1. Chicago: SPSS Inc.

Surowsky, B., Fischer, A., Schlueter, O., & Knorr, D. (2013). Cold plasma effects on enzyme activity in a model food system. Innovative Food Science & Emerging Technologies, 19, 146–153.

Thirumdas, R., Deshmukh, R. R., & Annapure, U. S. (2016a). Effect of low temperature plasma processing on physicochemical properties and cooking quality of basmati rice. Innovative Food Science and Emerging Technologies, 37, 53–60.

Thirumdas, R., Deshmukh, R. R., & Annapure, U. S. (2016b). Effect of low temperature plasma on the functional properties of basmati rice flour. Journal of Food Science and Technology –Mysore, 53(6), 2742–2751.

Thirumdas, R., Kadam, D. S., & Annapure, U. S. (2017a). Cold Plasma: an alternative technology for the starch modification. Food Biophysics, 12(1), 129–139.

Thirumdas, R., Trimukhe, A., Deshmukh, R. R., & Annapure, U. S. (2017b). Functional and rheological properties of cold plasma treated rice starch. Carbohydrate Polymers, 157, 1723–1731.

Wang, L., Xie, B., Shi, J., Xue, S., Deng, Q., Wei, Y., & Tian, B. (2010). Physicochemical properties and structure of starches from Chinese rice cultivars. Food Hydrocolloids, 24(2), 208–216.

Wongsagonsup, R., Deeyai, P., Chaiwat, W., Horrungsiwat, S., Leejariensuk, K., Suphantharika, M., Fuongfuchat, A., & Dangtip, S. (2014). Modification of tapioca starch by non-chemical route using jet atmospheric argon plasma. Carbohydrate Polymers, 102, 790–798.

Xu, L., Garner, A.L., Tao, B., & Keener, K.M. (2017) Microbial inactivation and quality changes in orange juice treated by high voltage atmosphere cold plasma. Food and Bioprocess Techology, 10, 1–14

Zhou, Z. K., Robards, K., Helliwell, S., & Blanchard, C. (2007). Effect of storage temperature on cooking behaviour of rice. Food Chemistry, 105(2), 491–497.

Ziuzina, D., Petil, S., Cullen, P. J., Keener, K. M., & Bourke, P. (2014). Atmospheric cold plasma inactivation of Escherichia coli, Salmonella enterica serovar, Typhimurium and Listeria monocytogenes inoculated on fresh produce. Food Microbiology, 42, 109–116.

Zou, J. J., Liu, C. J., & Eliasson, B. (2004). Modification of starch by glow discharge plasma. Carbohydrate Polymers, 55(1), 23–26.

Acknowledgements

The authors would like to acknowledge the Operating Expenses of Basic Scientific Research Project of Central Public-interest Scientific Institution, China (JY2007) and the Major Application Technology Innovative Project for the Shandong Provincial Agriculture (SD2019ZZ012-4). We appreciate Mr. Hanliang Shao for giving invaluable suggestion and helps. We also thank Dr. Jie Zhu in School of Pharmaceutical Engineering and Life Science, Changzhou University, China for helping us to determine water drop contact angle. We also appreciate Dr. Sun D.W., Dr. McNulty P., Dr. Barros-Velazquez J., Dr. Belay Z.A., and four anonymous reviewers reviewing our paper and giving invaluable suggestion.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

1. The cooking properties of six Chinese varieties of milled rice were changed by 120 W helium cold plasma (CP) treatment for 20 s.

2. CP treated milled rice had higher adhesive, balance, and elasticity texture with less hardness.

3. CP treatment resulted in a higher speed of heating and starch gelatinization and a lower speed of enzymatic degradation in the thermomechanical properties of rice dough.

4. CP treatment did not change the appearance quality of milled rice except for chalky rice rate, and led to an aggregation of small particles at rough surface of rice kernel.

Rights and permissions

About this article

Cite this article

Liu, J., Wang, R., Chen, Z. et al. Effect of Cold Plasma Treatment on Cooking, Thermomechanical and Surface Structural Properties of Chinese Milled Rice. Food Bioprocess Technol 14, 866–886 (2021). https://doi.org/10.1007/s11947-021-02614-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-021-02614-1