Abstract

Effects of presoaking-high hydrostatic pressure (PHHP) on cooking time, hardness, gumminess, springiness, and microstructure of brown rice were evaluated. Compared with traditional soaking treatment, PHHP significantly shorten the cooking time of brown rice from 34 to 14 min. The hardness of brown rice treated by PHHP reduced remarkably, which is lower than that treated by soaking process and similar to that of white rice. The gumminess and springiness of brown rice dramatically decreased under pressure above 500 MPa. However, the water uptake capacity of brown rice treated by PHHP was not obviously affected, whose moisture contents were much lower than that of soaked samples. The analysis of thermal properties revealed that the enthalpy of brown rice was influenced by PHHP, and the denaturation of brown rice components generated. These results and microstructure analysis revealed that the structures of pericarp and aleurone layer of brown rice were damaged by PHHP, which allows water to be easily absorbed by the rice kernel during cooking process. PHHP treatment could be a potentially applicable pretreatment for improving cooking properties of brown rice.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Brown rice is dehulled directly from rough rice, which is one of the commonly consumed cereals for more than half of the world’s population. The brown rice provides more nutrients than white rice, including lipids, protein, vitamins, mineral elements, dietary fibers and essential amino acids from bran and embryo (Bhatnagar et al. 2014; Sastry et al. 1977). However, the sensory properties and cooking properties of brown rice are undesirable and unacceptable, due to the high hardness for eating and long cooking time for people. Numerous methods have been raised to modify the texture, shape, color after cooking and cooking time of brown rice, including partial milling heating and cooling (Mohapatra and Bal 2006), pre-gelatinization (Thakur and Gupta 2006), germination (Toyoshima et al. 2004), and hydrothermal treatment (Zhang et al. 2014). These methods have a variety of problems such as loss of nutrients, integrity, low quality appearance, off odours or complicated processes (Tian et al. 2014). Therefore, the brown rice processing industry is in urgent need of new processing methods of producing quick cooking brown rice with high quality.

With the rhythm of people’s living is speeding up, the fast cooking food become necessary. Long time soaking is an essential process to improve the palatability of cooked rice. But long-time soaking is not suitable for the brown rice pretreatment, due to time consumes and nutrients outflow. Many researchers applied the combination methods to improve the properties of cooked rice, for example, soaking has been tried to be improved in combination with non-thermal processing technology including ultrasound (Cui et al. 2010), plasma (Chen et al. 2012), puffing (Mir et al. 2014) on the brown rice and high pressure (Yamakura et al. 2005) on the white rice. However, few studies have attempted to investigate the effect on the cooking time and properties of the brown rice by soaking and high pressure treatment. High hydrostatic pressure (HHP) technology has become an alternative non-thermal food processing method to the traditional thermal process in the past 20 years, avoiding high temperature and long treatment time, to maximum retain the nutritional value, color, flavor and aroma (Oey et al. 2008).

In this paper, the effects on the cooking properties of brown rice by presoaking-HHP (PHHP) were studied, including hardness, gumminess, springiness, chewiness and viscosity. Furthermore, the water uptake, gelatinization properties and microstructure changes of brown rice were evaluated to discuss the mechanism of PHHP treatment on the brown rice.

Materials and methods

Materials

Rice was Feng-liang-you-xiang No.1, which is an indica hybrid rice, supplied by the farmer in Zhejiang, China. Brown rice samples were obtained after dehulling by paddy husker (6 L-152B3, Hupen, Chongqing, China) twice. All samples were kept refrigerated at 4 °C in desiccator chambers containing three layers of 200*280 mm ziplock bags and desiccants between these layers.

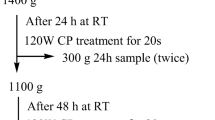

Sample preparation

The brown rice was presoaked in the redistilled water at 25 °C for 1 h. 100 g presoaked brown rice and 160 mL redistilled water were added in the 170*120 mm ziplock bags, with the residual gas removed before HHP treatment. Samples were treated under different pressures (200, 300, 400, 500, 600 MPa) for 0, 5, 10 and 20 min, where 0 min represents immediate pressure releasing after target was reached. At specific times, the samples were drained off, and dried the surface by the two-layer filter paper twice. The samples were stored in 4 °C until further tests.

As comparison, the second group of samples was treated under different soaking treatments at 20, 30, 35, 40, 45 °C for 1, 2, 3, 4 and 5 h, respectively. The samples were also stored in 4 °C until further tests.

Determination of cooking time changes

According to the national standard ISO 14864 (ISO 1998), which is entitled that rice – evaluation of gelatinization time of kernels during cooking, we evaluated the cooking time of the native brown rice and the PHHP and soaked brown rice. The method details are as following, put the samples after dealing with the different treatments in boiling water, boil out after a certain period of time, select interval and then squash with the two pieces of glass. The time at no white spots leaching was considered the cooking time.

Texture profile analysis of cooked brown rice

The fresh cooked brown rice was directly performed texture analysis by a texture analyzer (CT3, Brookfield Engineering Labs Inc., Middleboro, MA, USA) equipped with TA41 (6 mm diameter) cylinder probe with a two-cycle compression. The measurements were conducted as follows: the test speed was 0.5 mm/s, the deformation was 10 %, and the trigger was 50 g. The measurements were repeated 5 times using different grains, and the mean value was collected for statistical analysis. The attributes of texture of cooked brown rice were identified as the maximum force to compress the sample down to 70 % strain before the sample failed. Hardness, gumminess, and springiness were determined from the two-cycle curves (Szczesniak 2002). All the process and the detection samples were on the water bath at 35 °C to keep the moisture content.

The samples for the texture analysis were cooked as following: the brown rice dispersions at 15 g/24 g of distilled water were put into the 9*3*2.5 mm lunch-box, and boiled in the rice cooker (JBA-S18C, Tiger Co., Japan) for 40 min, and allowed to stand 20 min in the cooker. After cooking, the samples were tempered at an ambient temperature (−25 °C) for 1 h. The grains without touching the inner wall of lunch box were chosen to be tested by texture analyzer.

Water uptake capacity analysis

The moisture content changes on brown rice treated by different methods were investigated described by Akil et al. (2009) with little modification. For the water uptake capacity measurements, the samples in section 2.2 were withdrawn from the waters, wiped dry to remove the surface moisture, and then weighted using an electronic balance (Sartorius BSA224S) accurate to 10−4 g to monitor the mass during the process. The weighing was done within 30 s, in order to avoid the error due to water evaporation.

During soaking experiments, the samples were removed at predetermined time intervals (1 h) and the soaked samples were quickly wiped dry to remove residual surface moisture and then reweighed. All measurements were made in triplicate.

The water uptake capacity (WUC) was calculated according to the formulation

where WUC is the water uptake capacity of the sample, m 0 is the initial moisture content of the sample before treatment, and m t is the weight of the sample after treatment.

Differential scanning calorimetry (DSC) analysis

The thermal analyses of different treated brown rice were conducted using a Q2000-DSC (TA Instruments, New Castle, DE, USA), according to Zhong et al. (2013) with minor modification. The slurries were prepared by mixing 20 mg each of sample and 80 mg distilled water in aluminum pans and keeping for 1 h at 4 °C. An empty pan was used as a reference. The pans were hermetically sealed and heated at 5 °C/min from 25 to 95 °C under N2 atmosphere. The onset temperature (To), peak temperature (Tp), conclusion temperature (Tc) and the enthalpy (ΔH, J/g) were calculated by a curve of heat flux versus temperature using thermal analysis System. The degree of denaturation (DD) of samples was calculated according to the following equation:

where ΔH 0 is the enthalpy change of native brown rice, ΔH t is the enthalpy change of PHHP treated brown rice.

Scanning electron microscopy (SEM) analysis

The microstructure of cooked brown rice were estimated by the method of Cui et al. (2010) with minor modifications. The cooked brown rice samples treated by PHHP and untreated were immediately dried using an oven dryer at 35 °C. After drying, samples are divided into two groups: one was cut off for the cross-sectional observation; another was sputter-coated with a thin film of gold for the kernel microstructure observations. The resultant specimens picked from the central endosperm of rice kernel were observed and photographed using a scanning electron microscope (XL30, ESEM-FEG, Philips, Netherlands).

Statistical analysis

The data were expressed as mean standard deviation (SD). The significant differences between the means were calculated by one-way analysis of variance (ANOVA) with subsequent Tukey’s b-test at a significance level of 0.05 using SPSS 17.

Results and discussion

Cooking time of brown rice

The cooking time changes of brown rice only treated by soaking treatments at 25, 30, 35 and 40 °C with different durations are shown in Fig. 1a. In the first hour, the cooking time of brown rice under different soaking temperatures were remarkably different. Moreover, the higher soaking temperature could more seriously decrease the cooking time of brown rice. With the soaking duration increasing, the cooking time of brown rice were significantly reduced at 25 °C and 30 °C. At the higher temperature, the decrease of cooking time turned to be gently. The reduced cooking time by soaking might have been due to improved moisture content indicated by the higher water uptake ratio (Cui et al. 2010). When the brown rice was soaked at 40 °C for 1 h, the shortest optimal cooking time of brown rice (19 min) as a drop of at 44 % off the initial cooking time (34 min) was obtained, which is the same as that soaked at 25 °C for 5 h. These results suggested that the increment of presoaking temperature or soaking duration could shorten the cooking time of brown rice.

Figure 1b shows the effect of PHHP with various pressures and holding time on the cooking time of brown rice, compared with white rice. High pressure treatments at 200, 400 and 500 MPa for 5 and 20 min significantly decreased the optimal cooking time of brown rice to 25, 16 and 14 min, respectively, as compared with 34 min for presoaked brown rice. However, when extended the holding time at the same pressure, the cooking time of brown rice did not show the great difference, except 200 MPa. Brown rice after 500 MPa PHHP treatment got the shortest cooking time, 13.0 min, with a drop of 60 % off the without HHP treated brown rice, which is close to the cooking time of native white rice (10 min). However, the cooking time of brown rice after 600 MPa didn’t show significant differences with 500 MPa (Data not shown). From these results, we concluded that PHHP treatment could shorten the cooking time of brown rice. In addition, we also investigated the effects of PHHP on the white rice. After 200 and 400 MPa treatments for 20 min, the cooking time of white rice reduced from 10 to 7.5 and 3.5 min, respectively, by a drop of 35 and 75 %. This result is in agreement with the previous research by Boluda-Aguilar et al. (2013), indicating the high pressure treatment could reduce the cooking time of white rice. Different from the white rice, native brown rice due to the presence of outer bran layers, has a long cooking time. Several methods have been used in the process of brown rice processing, such as ultrasound and plasma. Cui et al. (2010) used ultrasound treatment on the brown rice, and they showed that the optimal cooking times of brown rice were 37, 35, and 33 min after ultrasonic treatment at 25, 40, and 55 °C, respectively, compared to the control of 39.6 min. Chen et al. (2012) found that the optimal cooking time of brown rice could be decreased by plasma to 17.2 min, as compared with 24.8 min of native brown rice. The difference of optimal cooking time of nature brown rice between different studies might be attributed to the type, composition and cooking method of brown rice. Through comparative analysis of the cooking time reduction of brown rice induced by soaking, ultrasound, plasma and PHHP, we found that PHHP treatment in this study is the most influential method to shorten the cooking time of brown rice. Therefore, the PHHP could be an emerging way to parboil the brown rice.

Effects on the texture of brown rice by PHHP

Hardness

Hardness is an important texture factor in the rice cooking, because it is related to a number of other performances. In Fig. 2a, it is evident that the hardness of brown rice with soaking declined with the temperature and duration increasing. There is no obvious variation in hardness of brown rice when soaked at 25 and 30 °C. However, the differences begin to emerge when the temperature reach to a relative high temperature (35 or 40 °C). The hardness of brown rice at 40 °C for 1 h is much lower than that of other temperatures with the same processing period. The smallest hardness (674 g) of soaked brown rice occurred at 40 °C for 5 h. We observed that the soaking temperature played a very important role in the brown rice cooking process. Han and Lim (2009) revealed that the brown rice attained 20 % moisture content during soaking was harder than that of the rice which attained 30 % moisture content when cooked, which is consistent with our results.

The effects of PHHP at various pressures and holding time on the hardness of brown rice are shown in Fig. 2b. The hardness of the brown rice dropped up to 29–47 % with the pressure increasing from 200 to 600 MPa with different holding time. The big changes of hardness started at 500 MPa, and the lowest hardness (481 g) of the brown rice treated by PHHP was obtained at 500 or 600 MPa for 20 min, which is lower than the lowest hardness of soaked samples by 192 g. The hardness of control brown rice and white rice measured by the same method was 923 and 369 g, respectively. The lowest hardness of the brown rice with presoaking at 25 °C for 1 h, soaking, and PHHP treatment, were 2.5, 1.8 and 1.3 times more than that of white rice, respectively. The hardness of the bran layers increased from outer to inner bran layers, while the different endosperm fractions were of comparable hardness (Lamberts et al. 2007). Among these treatments, the PHHP treatment could extremely decrease the hardness of the brown rice. Considering with the time consumption, PHHP treatment is a better preprocessing to improve the texture of the brown rice. Similarly, Tian et al. (2014) adopted different pressure-soaking treatments on the white rice, they showed that the HHP soaking could decrease the hardness of white rice by 8.5 %. Similarly, the plasma treatment was also used to modify the brown rice by Chen et al. (2012), and the results showed that the lowest hardness values of brown rice with plasma treatment were much lower than for untreated samples by 36.7 %. In this study, the hardness reduction of brown rice induced by PHHP was by 47.8 %, suggesting that PHHP is the most effective means to reduce the hardness of brown rice.

Gumminess and springiness

Springiness is a rate at which a deformed material goes back to its undeformed condition after deforming force removed (Szczesniak 2002). Figure 2c and d exhibit the gumminess and springiness of brown rice with various holding time and HHP pressures, respectively. When the pressure in around 200–400 MPa, the holding time and pressure played no obvious effect on the gumminess of brown rice. However, the gumminess did not show the significant decrement until the pressure increased to 500 MPa. The gumminess of native brown rice is 170.9 g. The lowest gumminess was 64.7 g at 500 MPa for 20 min, which is closed to that of regular white rice (73.3 g). Interestingly, the gumminess represents some kind of decrease with holding time and pressure increasing, but without a regular rule. The springiness of brown rice treated by HHP treatments shows the similar tendency with the gumminess (Fig. 2d). When the pressure is above 500 MPa, the springiness of brown rice was in the range of 0.32–0.37 mm. The springiness and gumminess of brown rice after PHHP were decreased. However, the mechanism affecting these properties has not been clearly explained. Some researchers have shown that the sensory gumminess could be related with amylose and protein content (Singh et al. 2005). Some other studies revealed that the property changes of brown rice might due to the structural changes of amylose and protein (Hu et al. 2011; Vallons et al. 2011). Above all these speculations might be associated with the super-high pressure, and the water which played very important role in high pressure process. Whether the moisture content of brown rice affected the springiness and gumminess would be discussed in the study.

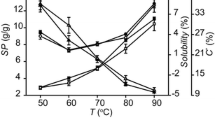

Water uptake capacity of brown rice

The changes of water uptake capacity (WUC) of brown rice treated by various soaking and PHHP treatments are displayed in Fig. 3. Obviously, the values of water uptake capacity were increased with the soaking temperature and soaking duration increasing (Fig. 3a). The WUC increase of brown rice was more pronounced during the initial stage of soaking at different temperatures, which was 0.117, 0.143, 0.154, 0.198 and 0.203, respectively. When the soaking time added to two or more hours, the increments of moisture content were much smaller than the first hour, which also could be concluded from soaking temperature. As for soaking temperature changes, the water holding capacities of brown rice were increasing as temperature increased, but there was not significant differences between 40 and 45 °C. The highest WUC of brown rice at different soaking durations were obtained at 40 or 45 °C, which is around 0.27. When soaking duration was 4 or 5 h, the water uptake capacity decreased slightly. The results were consistent with the previous study, which revealed that during the first soaking stage, the water could get into the rice by the capillary tube, so the water uptake proceeded rapidly (Miah et al. 2002). Thakur and Gupta (2006) got the model equation of moisture absorption of different rice samples, and reported that the rate of moisture migration was dependent on the soaking temperature. At the beginning of the soaking period, a higher rate of absorption was observed in the case of brown rice and husk compared to paddy over the entire temperature range. In addition, the higher the soaking temperature was, the higher the water uptake capacity was, and the shorter soaking time was needed.

The water uptake capacities of brown rice with various PHHP treatments are shown in Fig. 3b. The initial moisture content of HHP treated brown rice was the same as that of the sample with 1 h soaking at 25 °C, which is around 0.11. In Fig. 3b, the WUC of brown rice increased a little with the pressure increasing, but not significantly like the soaking treatment. When the pressure was at 600 MPa with 20 min, the highest WUC of 0.146 was achieved. Concerning the soaking treatment, the longer soaking time and higher temperature are contributed to the high water uptake (Bello et al. 2004). According to Ahromrit et al. (2006), using the high pressure treatment on the glutinous rice, the overall rates of water uptake and the equilibrium moisture content increased with pressure and time. Ahromrit et al. (2007) reported that the moisture content was not significantly influenced by pressure up to 300 MPa, and when its value exceeded 300 MPa at room temperature, gelatinization of glutinous rice initiated. Watanabe et al. (1991) noted that aged rice grains absorb large amounts of water at pressures greater than 400 MPa. In this work, however, the water uptake of brown rice did not increase significantly even at the pressure of 600 MPa, as shown in Fig. 3b. The conflict might be due to the different pattern of rice with/without the bran layer. Brown rice is dehulled directly from rough rice, consisting of bran layers (6–7 % of its total weight), embryo (2–3 %) and endosperm (about 90 %), which is much different from the white rice (starchy endosperm). The bran layer, consisting of high content of fibers, lipids and proteins, covered tightly around the endosperm, and limiting the permeability of water into the inner. However, in white rice, the starch could react with water directly. In addition, the moisture content of rice is an important factor of storage. The low-moisture-content storage system of brown rice could significantly improve the storability, like the low-temperature systems (Genkawa et al. 2008). In other words, the PHHP treatment could improve the shelf-life of brown rice by decreasing moisture content, where the metabolisms depressed and the growth of microorganism is inhibited.

Gelatinization changes of brown rice by PHHP treatment

The transition temperatures (To, Tp, and Tc) of brown rice were not significantly influenced by HHP, which are listed in the Table 1. This shows that PHHP treatment did barely effect on the crystal structure of brown rice starch. However, the gelatinization enthalpy (ΔH) of brown rice decreased from 8.0 J/g to 6.3, 6.3, 5.8, 6.0, 5.7 and 5.6 J/g with different PHHP treatments. ΔH of brown rice decreased significantly with the pressure increase and processing time. The degrees of denaturation of PHHP samples are presented in the range of 21.6–30.5 %, and higher pressure and longer duration could induce increased denaturation among the various PHHP treatments. This result is in agreement with the findings of HHP treatment could promote the gelatinization of potato starch (Błaszczak et al. 2005) and white rice (Ahmed et al. 2007). The high pressure treatment of 600 MPa decreased the T O, T C and T P of the starch, by changing starch granule structure. As known, the major components of brown rice are starch, protein, fiber, lipid, etc. The residual denaturation enthalpy is a net value from a combination of endothermic and exothermic reactions, like the disruption of hydrogen bonds, break-up of hydrophobic interactions and protein aggregation. The decrease of ΔH for brown rice after PHHP can not only be attributed to starch gelatinization, but also resulted from the denaturation of proteins and combination of these components The decrease of ΔH with pressure increasing has been reported in the literature for various starches (Ahmed et al. 2007; Kawai et al. 2007). The partial structure changes of protein and the gelatinization of starch induced decrease of ΔH. From these observations, it could be concluded that ΔH of brown rice was apparently influenced by PHHP, and the denaturation of brown rice components generated.

Morphologic changes of brown rice by PHHP

The moisture content of brown rice could significantly affect the texture and properties during the cooking process. The water uptake of brown rice treated by PHHP treatment wasn’t significantly improved, however, the cooking properties of brown rice including cooking time, hardness and gumminess improved by PHHP. To gain a deeper insight on the effect of PHHP on the brown rice, scanning electron microscopy (SEM) was used for morphologic analysis by investigating the cross section and endosperm cell of specimens. The cross section SEM images of brown rice after different PHHP treatments are shown in Fig. 4a to g. The brown rice is mainly composed with bran layer (consisted of pericarp, pericarp, aleurone layer, and germ) and starchy endosperm (Bhatnagar et al. 2014). The cross section SEM image of native brown rice displayed in Fig. 4a, shows the natural morphological structure that the combination of pericarp, aleurone layer and germ is compact. Compared with the microstructure of cross section of native specimen, the main difference was found in the pericarp and aleurone layers of brown rice after PHHP treatments. With PHHP of 200 MPa, pericarp and aleurone layer turned to be thinner (Fig. 4b and c). The cracks between aleurone layer and brown rice kernel appeared after treated by 400 MPa. When pressure increased to 500 MPa, the cracks were produced and propagated along the edges of the brown rice kernel. As the holding time increasing, the pericarp and aleurone layer of brown rice were destroyed.

The SEM micrographs of endosperm cells of brown rice before and after PHHP are shown in Fig. 5. The polyhedral starch granules of the native brown rice were clearly revealed in Fig. 5a, where the intact starch granules embedded in the protein can be observed. After treatment with 200 MPa, the starch granules in endosperm cell become fuzzy and smooth. This performance was highlighted under the pressure increasing to 400 MPa, with depressions on the granules added. When treated by 500 MPa, small cavities and gaps occurred in the starch granule. The phenomenon might be attributed to the starch gelatinization and protein denaturation during the PHHP treatment (Bárcenas et al. 2010).

Based on the results of water uptake, thermal property and morphologic changes, the major influence of cooking property improvement was attributed to a fact that the cracks between the pericarp, aleurone layer and endosperm kernel, and the damage of the bran layer. The PHHP treatment resulted in a loss in natural morphology of brown rice, allowing water to be easily absorbed by the rice kernel during the cooking process. The second influence was the denaturation of starch, protein and other components by the PHHP, which reduced the energy of cooking process needed.

Conclusions

Effects of PHHP on water uptake, thermal properties and microstructure of brown rice were evaluated. These results suggested that PHHP treatment change the morphological character of bran layer and partially denatured the components of brown rice. Through comparative analysis of the cooking of brown rice using as pre-treatment soaking, ultrasound, plasma and PHHP, we have found that PHHP treatment was the most effective method to shorten the cooking time and therefore, could be considered as a very promising technique for pre-treating the brown rice.

References

Ahmed J, Ramaswamy HS, Ayad A, Alli I, Alvarez P (2007) Effect of high-pressure treatment on rheological, thermal and structural changes in basmati rice flour slurry. J Cereal Sci 46:148–156. doi:10.1016/j.jcs.2007.01.006

Ahromrit A, Ledward DA, Niranjan K (2006) High pressure induced water uptake characteristics of Thai glutinous rice. J Food Eng 72:225–233. doi:10.1016/j.jfoodeng.2004.11.013

Ahromrit A, Ledward DA, Niranjan K (2007) Kinetics of high pressure facilitated starch gelatinisation in Thai glutinous rice. J Food Eng 79:834–841. doi:10.1016/j.jfoodeng.2006.03.003

Akil HM, Cheng LW, Mohd Ishak ZA, Abu Bakar A, Abd Rahman MA (2009) Water absorption study on pultruded jute fibre reinforced unsaturated polyester composites. Compos Sci Technol 69:1942–1948

Bárcenas ME, Altamirano-Fortoul R, Rosell CM (2010) Effect of high pressure processing on wheat dough and bread characteristics. LWT Food Sci Technol 43:12–19

Bello M, Tolaba MP, Suarez C (2004) Factors affecting water uptake of rice grain during soaking. LWT Food Sci Technol 37:811–816

Bhatnagar A, Prabhakar D, Prasanth Kumar P, Raja Rajan R, Gopala Krishna A (2014) Processing of commercial rice bran for the production of fat and nutraceutical rich rice brokens, rice germ and pure bran. LWT Food Sci Technol 58:306–311

Błaszczak W, Valverde S, Fornal J (2005) Effect of high pressure on the structure of potato starch. Carbohydr Polym 59:377–383

Boluda-Aguilar M, Taboada-Rodríguez A, López-Gómez A, Marín-Iniesta F, Barbosa-Cánovas GV (2013) Quick cooking rice by high hydrostatic pressure processing. LWT Food Sci Technol 51:196–204

Chen HH, Chen YK, Chang HC (2012) Evaluation of physicochemical properties of plasma treated brown rice. Food Chem 135:74–79

Cui L, Pan Z, Yue T, Atungulu GG, Berrios J (2010) Effect of ultrasonic treatment of brown rice at different temperatures on cooking properties and quality. Cereal Chem 87:403–408

Genkawa T, Uchino T, Inoue A, Tanaka F, Hamanaka D (2008) Development of a low-moisture-content storage system for brown rice: storability at decreased moisture contents. Biosyst Eng 99:515–522

Han J-A, Lim S-T (2009) Effect of presoaking on textural, thermal, and digestive properties of cooked brown rice. Cereal Chem 86:100–105

Hu X, Xu X, Jin Z, Tian Y, Bai Y, Xie Z (2011) Retrogradation properties of rice starch gelatinized by heat and high hydrostatic pressure (HHP). J Food Eng 106:262–266. doi:10.1016/j.jfoodeng.2011.05.021

ISO 14864 (1998) Rice—evaluation of gelatinization time of kernels during cooking. ISO, Geneva, Switzerland

Kawai K, Fukami K, Yamamoto K (2007) State diagram of potato starch–water mixtures treated with high hydrostatic pressure. Carbohydr Polym 67:530–535

Lamberts L, De Bie E, Vandeputte GE, Veraverbeke WS, Derycke V, De Man W, Delcour JA (2007) Effect of milling on colour and nutritional properties of rice. Food Chem 100:1496–1503. doi:10.1016/j.foodchem.2005.11.042

Miah M, Haque A, Douglass MP, Clarke B (2002) Parboiling of rice. Part II: effect of hot soaking time on the degree of starch gelatinization. Int J Food Sci Technol 37:539–545

Mir SA, Bosco SJD, Shah MA, Mir MM (2014) Effect of puffing on physical and antioxidant properties of brown rice. Food Chem. doi:10.1016/j.foodchem.2014.11.025

Mohapatra D, Bal S (2006) Cooking quality and instrumental textural attributes of cooked rice for different milling fractions. J Food Eng 73:253–259

Oey I, Lille M, Van Loey A, Hendrickx M (2008) Effect of high-pressure processing on colour, texture and flavour of fruit- and vegetable-based food products: a review. Trends Food Sci Technol 19:320–328. doi:10.1016/j.tifs.2008.04.001

Sastry B, Ramakrishna M, Raghavendra-Rao M (1977) Histochemical localization of lipase in the rice grain. J Food Sci Technol 14:273–274

Singh N, Kaur L, Sodhi NS, Sekhon KS (2005) Physicochemical, cooking and textural properties of milled rice from different Indian rice cultivars. Food Chem 89:253–259

Szczesniak AS (2002) Texture is a sensory property. Food Qual Prefer 13:215–225

Thakur AK, Gupta A (2006) Water absorption characteristics of paddy, brown rice and husk during soaking. J Food Eng 75:252–257

Tian Y, Zhao J, Xie Z, Wang J, Xu X, Jin Z (2014) Effect of different pressure-soaking treatments on color, texture, morphology and retrogradation properties of cooked rice. LWT Food Sci Technol 55:368–373

Toyoshima H, Ohtsubo Ki, Okadome H, Tsukahara K, Komatsuzaki N, Kohno T (2004) Germinated brown rice with good safety and cooking property, process for producing the same, and processed food therefrom. U.S. Patent No. 6685979, 2004

Vallons KJR, Ryan LAM, Arendt EK (2011) Promoting structure formation by high pressure in gluten-free flours. LWT Food Sci Technol 44:1672–1680

Watanabe M, Arai E, Honma K, Fuke S (1991) Improving the cooking properties of aged rice grains by pressurization and enzymatic treatment (food and nutrition). Agric Biol Chem 55:2725–2731

Yamakura M, Haraguchi K, Okadome H, Suzuki K, UT Tran, Horigane AK, Yoshida M, Homma S, Sasagawa A, Yamazaki A, Ohtsubo K (2005) Effects of soaking and high-pressure treatment on the qualities of cooked rice. J Appl Glycosci 52:85–93

Zhang Q, Tu Z, Wang H, Huang X, Shi Y, Sha X, Xiao H (2014) Improved glycation after ultrasonic pretreatment revealed by high-performance liquid chromatography–linear Ion trap/orbitrap high-resolution mass spectrometry. J Agric Food Chem 62:2522–2530

Zhong Y et al (2013) Effect of microwave irradiation on composition, structure and properties of rice (Oryza sativa L.) with different milling degrees. J Cereal Sci 58:228–233

Acknowledgments

This study was supported by the 863 Plan of National High-Tech Research and Development (2011AA100801) and the Natural Science Foundation of Zhejiang province (LZ14C200002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, Y., Ge, L., Zhu, S. et al. Effect of presoaking high hydrostatic pressure on the cooking properties of brown rice. J Food Sci Technol 52, 7904–7913 (2015). https://doi.org/10.1007/s13197-015-1901-5

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-1901-5