Abstract

Lipid extract from shrimp cephalothorax is a potential food coloring owing to its intense red color. However, it presents some drawbacks, such as its characteristic odor, astaxanthin instability, and difficult dosage and manipulation. The present work is an attempt to overcome these problems by means of complex coacervation encapsulation using gelatin and gum arabic as wall materials. Round molecules in which the lipid extract was efficiently encapsulated in the form of multiple droplets were obtained. The resulting microcapsules stabilized by freeze-drying had good properties with a view to their application as food coloring, owing to their intense red color, improved astaxanthin stability, and low water activity, water solubility, and hygroscopicity. The coloring capacity and sensory properties were evaluated when added to yogurt and a gellified fish product. For yogurt, a trained sensory panel determined that encapsulation effectively reduced the characteristic odor, whereas the coloring capacity was improved, as compared to non-encapsulated lipid extract. For the gellified fish product, no sensory improvement was observed, but the encapsulated lipid extract provided an attractive, uniform color.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Consumer concern regarding the use of synthetic additives has driven research on natural additives in recent decades. This is true not only for food preservatives (mainly antioxidants and antimicrobials), which are the most studied ones (Negi 2012; Cleveland et al. 2001; Karre et al. 2013), but also for colorings and sweeteners (Rocha-Selmi et al. 2013a; Gómez-Estaca et al. 2015). However, natural compounds commonly present problems related to their instability, insolubility, or sensory properties, and encapsulation offers an effective means of improving these properties (Fathi et al. 2012; Gómez-Estaca et al. 2015; Comunian et al. 2017). The crustacean processing industry produces a large amount of waste annually, including cephalothorax and cuticles from peeling. This waste has been found to be a source of the carotenoid astaxanthin, as well as polyunsaturated fatty acids (PUFAs) and α-tocopherol (Gómez-Estaca et al. 2017). Owing to the intense red color of astaxanthin, it has uses as a food coloring. Furthermore, numerous studies have shown that astaxanthin has potential health-promoting effects in the prevention and treatment of various aging-related diseases (Yuan et al. 2011).

With regard to the use of fish or crustacean oils as food additives, the main problems that arise are those related to their intrinsic organoleptic properties (strong odor and flavor), as well as their instability. Not only astaxanthin but also PUFAs are susceptible to oxidative degradation (Takeungwongtrakul et al. 2015; Gómez-Estaca et al. 2017), limiting their uses. To date, the methods employed to encapsulate crustacean lipid extracts are spray-drying (Pu et al. 2011; Montero et al. 2016), complex coacervation (Aziz et al. 2014; Gomez-Estaca et al. 2016), and ultrasonic atomization (Taksima et al. 2015). Among them, those in which no thermal treatment is required seem to be more suitable for encapsulating thermolabile compounds such as PUFAs and astaxanthin. In this connection, Montero et al. (2016) found that lipid extract obtained from shrimp and encapsulated by spray-drying suffered some lipid oxidation, contrary to what happened when it was encapsulated by complex coacervation (Gomez-Estaca et al. 2016). Complex coacervation is a colloidal phenomenon in which a liquid–liquid phase separation is produced generally as a result of the combination of a positively charged protein and a negatively charged polysaccharide in aqueous solution (Xiao et al. 2014; Burey et al. 2008). The process is governed by parameters such as the type of polymers and the ratio between them, pH, and ionic strength, among others (Schmitt and Turgeon 2011). Although many polymer combinations have been described in the literature, gelatin–gum arabic is probably the one that has been most studied (Xiao et al. 2014). Complex coacervation is mainly used for encapsulation of lipophilic compounds (Matalanis et al. 2011), although the process has also been adapted for encapsulation of hydrophilic substances (Comunian et al. 2013). Oil-solubilized lycopene, lipid extracts from marine (fish, crustaceans) or vegetal origin, essential oils, and other flavors have been encapsulated by complex coacervation with good results (Wang et al. 2014; Rocha-Selmi et al. 2013b; Gomez-Estaca et al. 2016; Comunian et al. 2016).

With regard to reducing the sensory impact of lipid extracts from shrimp, studies are scarce and no conclusive results can be found in the literature. On the one hand, when incorporated in yogurt, a complex of gelatin and cashew gum formed by complex coacervation failed to mask the characteristic shrimp odor evaluated by a trained panel (Gomez-Estaca et al. 2016). On the other hand, Taksima et al. (2015) encapsulated a similar lipid extract by ultrasonic atomization, using chitosan and alginate as encapsulating matrices, and incorporated the encapsulated extract in yogurt, obtaining satisfactory acceptability and purchase intent. However, the potential of encapsulation to reduce the sensory impact of lipid extracts is evident, as demonstrated by Comunian et al. (2017), who achieved an improvement in the sensory acceptance of a functional yogurt with added encapsulated echium oil, as compared to its non-encapsulated counterpart. Similar results were obtained by Tamjidi et al. (2014) encapsulating tuna oil by complex coacervation and adding it to yogurt.

The objective of the present work was to encapsulate a lipid extract from shrimp waste by complex coacervation in order to improve its stability and sensory properties, widening its potential food applications.

Materials and Methods

Materials

Shrimp lipid extract was obtained from Litopenaeus vannamei cephalothorax as previous described (Gómez-Estaca et al. 2017). Type B gelatin from pig skin and gum arabic (≥ 99% purity for both) were purchased from Gelnex (Santa Catarina, Brazil) and Nexira (São Paulo, Brazil), respectively. All other reagents were of analytical grade and were acquired from Sigma-Aldrich.

Preparation of Microcapsules

The microcapsules were produced on the basis of the method described by Mendanha et al. (2009), with slight modifications. Gelatin and gum arabic were dissolved in distilled water (2.5 g/100 mL) at 45 ± 5 °C for 30 min under constant stirring. Oil-in-water emulsions in the gelatin solutions were prepared at 12,000 rpm for 3 min using a digital T-25 Ultra-Turrax blender (IKA-Werke GmbH & Co. KG, Staufen, Germany). Lipid extract was added to a final concentration of 25/100 g encapsulating agent (gelatin plus gum arabic). Gum arabic solution was then added under constant stirring, at a gelatin/gum arabic ratio of 1:1, and the pH was immediately adjusted to 4 with 5% (w/v) citric acid. The temperature was set to 45 ± 5 °C during the entire process up to this step. Afterwards, the solution was placed in an ice bath to gradually reduce the temperature to 10 ± 1 °C, under constant stirring, to promote complex coacervation. The coacervated material was stored at 7 ± 2 °C for 24 h to allow for precipitation prior to decantation, and the coacervates were then frozen at − 18 ± 1 °C and dehydrated by sublimation in a Terroni (São Carlos, Brazil) freeze dryer.

Encapsulation Efficiency

Encapsulation efficiency (EE) was calculated according to the total quantity of astaxanthin present in the capsules as compared to the quantity present on their surface. For surface astaxanthin determination, approximately 50 mg of freeze-dried powder was accurately weighed and washed twice with 2 mL of hexane; the two volumes of hexane were mixed, and the astaxanthin content was calculated as previously described (Montero et al. 2016). For determination of the total astaxanthin content, approximately 40 mg of freeze-dried powder was accurately weighed and dissolved in 5 mL of 10% (v/v) acetic acid at 35 °C for 10 min, with occasional stirring. Then, 5 mL of hexane was added, and the mixture was vigorously stirred in a vortex mixer and then centrifuged at 5000×g/15 min/22 °C. The astaxanthin contained in the upper hexane phase was determined (Montero et al. 2016), and EE calculated according to Eq. 1:

Morphological Characterization

The microcapsules were observed by optical microscopy both immediately after formation and after reconstitution of the freeze-dried powders in water, using a Bel Photonics BIO3 optical microscope (Italy). The morphology of the freeze-dried powder was evaluated by scanning electron microscopy using a Hitachi Tabletop TM 3000 microscope (Tokyo, Japan) equipped with the TM 3000 program.

Particle Size Analysis

The particle size and distribution of the microcapsules were determined in triplicate using a Malvern Mastersizer S laser diffraction particle size analyzer (Malvern Instruments Ltd., Worcestershire, UK) equipped with a He–Ne laser (λ = 633 nm). The measurement range was 0.05–900 μm, and obscuration was in the range of 8–15%. The mean diameter (d4,3) and volume diameters (d(0.1), d(0.5), d(0.9)) were calculated.

Water Solubility, Water Activity, and Hygroscopicity

The solubility of the microcapsules was determined in triplicate by a gravimetric method as described by Comunian et al. (2013) and expressed as %. The water activity was determined in duplicate using AQUALAB equipment (Decagon Devices, Pullman, WA, USA). Hygroscopicity was determined in triplicate as per Cai and Corke (2000), and results expressed as the mass of water absorbed per 100 g of sample after 7 days of storage.

Color

Powder color was measured in quintuplicate using a MiniScan MSEZ 1049 spectrophotometer (BrasEq, SP, Brazil) set to D65 illuminant/10° observer. A glass sample container was filled with 3 g of the powder, and the CIELAB color space was used to obtain the color coordinates L*, a*, and b*, in quintuplicate. The color was expressed as lightness (L*), chroma (C*), and hue angle (h°), using simple transformations (Montero et al. 2016).

Accelerated Stability Study

Aliquots of the non-encapsulated (NE sample) and encapsulated lipid extract (E sample) were accurately weighed, inserted in open glass vials in a desiccator containing Na2SO4 solution, and placed in an incubator at 36 ± 1 °C (≈ 80% RH) in darkness for 43 days. Total astaxanthin content during storage was determined, in triplicate, as follows: free lipid extract and microparticles were dissolved in absolute ethanol or 10% (v/v) acetic acid, respectively, at 35 °C for 10 min with occasional stirring. For the free oil, an aliquot was diluted with hexane. For the microparticles, a liquid–liquid extraction was performed with hexane, comprising vigorous shaking in a vortex mixer followed by centrifugation (5000×g/15 min/22 °C). The astaxanthin content in the hexane phase was determined as previously described (Montero et al. 2016).

The oxidative stability of the oil was determined in triplicate by a modified version of the thiobarbituric acid reactive substances (TBARS) method described by Gudipati et al. (2010). Aliquots (1 mL) of the free and encapsulated oils dissolved in absolute ethanol or 10% (v/v) acetic acid, respectively, were mixed with a reagent solution containing 15% trichloroacetic acid and 0.375% thiobarbituric acid (2 mL), and then incubated in a water bath for 15 min at 90 °C. The reaction was stopped in an ice bath, and the resulting colored complexes were extracted with 2 mL of 1-butanol by vigorous agitation in a vortex mixer. The mixture was centrifuged (5000×g/10 min/22 °C), and the absorbance of the upper phase was read at 532 nm. TBARS concentrations were calculated from a standard curve prepared with 1,1,3,3-tetraethoxypropane.

Application of the Microcapsules to Food Systems

To evaluate the coloring capacity and sensory properties of the encapsulated lipid extract, as compared to those of the non-encapsulated one, two food models were selected: plain yogurt and a gellified fish product. Their intrinsic whiteness made them suitable to evaluate the coloring capacity of the extract. Furthermore, their different textural characteristics (fluid vs. solid) and manufacture process (application of thermal treatment or not) allow a better screening of the potential coloring capacity on different products. Three batches of each product were prepared, in duplicate: control without addition (C batch), with added non-encapsulated lipid extract (NE batch), and with added encapsulated lipid extract (E batch). Lipid extract was added at 0.15/100 g product in all cases, according to a previous experiment in which different concentrations were tested (0.10, 0.15, and 0.20/100 g). For encapsulated lipid extract, the appropriate amount of freeze-dried product was accurately weighed and reconstituted in water in a proportion of 1:5 (powder/water) prior to mixing. The non-encapsulated lipid extract and the reconstituted capsules were homogenized with the yogurt using a digital T-25 Ultra-Turrax blender (IKA-Werke GmbH & Co. KG, Staufen, Germany) for 1 min at 3000 rpm. The gellified fish product was prepared from hake (Merluccius merluccius) that was headed, gutted, skinned, washed with tap water, and filleted. The chopped muscle was mixed with free or encapsulated lipid extract, sodium chloride (2/100 g mince), and water (final moisture 82/100 g), and homogenized in a Moulinex® mixer. The fish batters were placed in hermetic aluminum containers 3 cm in diameter and 6 cm in height, and heat-induced gels were obtained by heating at 90 °C for 45 min in a thermostatic bath.

The color of the products was measured in quintuplicate as described above, and results expressed as L*C*h° coordinates. Furthermore, the structure of the capsules in the yogurt matrix was observed by optical microscopy; for this purpose, an aliquot of the yogurt was diluted with distilled water (proportion 1:10) and observed in a Bel Photonics BIO3 optical microscope (Italy).

Sensory Analysis

The effect of shrimp lipid extract encapsulation on the relative intensity of the color and odor attributes was evaluated. For this purpose, a panel consisting of 14 trained panelists, who were selected from staff according to their ability to discriminate between samples supplemented with increasing concentrations of lipid extract (0.05, 0.1, and 0.15%), was employed. Two-sided paired comparison tests, according to Meilgaard et al. (2006), were performed. Two pairs of samples for each product type (yogurt or gellified fish product) were presented in two independent sessions: C/E and E/NE, where C are the control samples (no lipid extract addition), E are the encapsulated lipid extract-added samples, and NE the non-encapsulated lipid extract-added samples. For each pair, the panelists were asked to select the sample with the more intense odor and color, under red and white lights, respectively. The panelists were instructed to refresh their sense of smell with coffee beans between pairs. Results are expressed as the number of panelists that considered each sample as the more intense one for each pair evaluated.

Statistical Analysis

Statistical tests were performed using the SPSS® computer program (SPSS Statistical Software, Inc., Chicago, IL, USA). One-way and two way analyses of variance (ANOVA) were carried out. Differences between pairs of means were assessed on the basis of confidence intervals using the Tukey’s b test. The level of significance was p ≤ 0.05.

Results and Discussion

Characterization of the Microcapsules

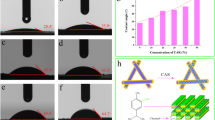

Multinuclear spherical microcapsules in which the shrimp lipid extract was efficiently encapsulated (93.5 ± 0.01% encapsulation efficiency) were obtained (Fig. 1a). Other authors encapsulating different lipid components such as oil-solubilized lycopene, krill oil, or flavored oil using the gelatin–gum arabic complex as encapsulating material also obtained similar structures with high encapsulation efficiency (Aziz et al. 2014; Yeo et al. 2005; Rocha-Selmi et al. 2013b). The composition and concentration of the wall polymer and environmental conditions such as pH and ionic strength, among others, are directly related to the efficiency of microcapsule production and to the variability in structure, size, and porosity, among other characteristics (Yeo et al. 2005). In this context, gelatin–gum arabic is one of the most common and most extensively used combinations in complex coacervation, thanks to its high yield and encapsulation efficiency, and its tunability in terms of wall thickness or loading capacity (Rocha-Selmi et al. 2013b). In this connection, Rocha-Selmi et al. (2013b) encapsulated lycopene and studied the effect of polymer concentration and core–shell ratios on microstructure, encapsulating efficiency, and lycopene stability. The formulation showing the highest encapsulating efficiency and lycopene stability was the one with 2.5 g polymer/100 g solution and 25 g core/100 g polymer, which was the one selected in the present work.

The measurement of the particle size distribution showed a well-defined monomodal distribution (Fig. 2) with a mean diameter (d4,3) of 119.6 ± 3.7 μm. The volume median diameter d(0.5) was 114.1 ± 1.4 μm, which suggests that 50% of the distribution was either higher or lower than this value. In addition, 10% of the microcapsules had a volume diameter d(0.1) < 62.5 ± 3.1 μm while 90% of them had a volume diameter d(0.9) < 184.4 ± 7.4 μm. These results indicate relatively good homogeneity. Microparticle size depends on several processing conditions, such as the emulsion preparation conditions, cooling rate, and characteristics of the wall and core materials (Alvim and Grosso 2010). Although high variability in particle size has been reported, the values in the present work are in line with previous works in which similar processing conditions were applied (Rocha-Selmi et al. 2013b; Aziz et al. 2014).

The microcapsules obtained were concentrated and stabilized by freeze-drying, and a powder with an intense red color was obtained (Fig. 1b). The objective measure of color revealed a hue angle in the second quadrant (49.1° ± 0.1), with a chromaticity value of 78.0 ± 0.8 and a lightness of 52.9 ± 0.05. These results are similar to those obtained when the lipid extract was encapsulated in a novel gelatin–cashew gum complex (Gomez-Estaca et al. 2016), confirming that it is the lipid extract that determines the color of the microcapsules. Although the freeze-drying process resulted in loss of the structure of the microcapsules, as observed by SEM (Fig. 1c), the structure completely resembled the original after rehydration of the powder (results not shown). With regard to application of the microparticles, water solubility is also an important factor to be considered, as it determines the release of the encapsulated material. The low water solubility (9.6 ± 1.5%) of the microcapsules found in the present work is in line with previous reports working with the same polymer pair (Comunian et al. 2013; Rocha-Selmi et al. 2013a), but it is lower than the value for microcapsules made from the gelatin–cashew gum pair (Gomez-Estaca et al. 2016). Gelatin–gum arabic coacervates present a characteristic low water solubility, which allows delayed or triggered release (Comunian et al. 2013).

The water activity of the freeze-dried microcapsules was low (0.593 ± 0.007), indicating high stability toward microbial growth (Roberts 1995), in line with results from other works (Comunian et al. 2013; Gomez-Estaca et al. 2016). With regard to hygroscopicity, a value of 2.33 ± 0.12 g water/100 g powder was obtained. Other authors obtained higher values, ranging from 4 to 10 g water/100 g powder, working with the same polymer combination (Rocha-Selmi et al. 2013a; Comunian et al. 2013), whereas even higher values (≈ 35 g/100 g) were obtained for other polymer pairs such as gelatin–pectin and soy protein isolate–pectin (Silva et al. 2012; Nori et al. 2011). Hygroscopicity is mostly related to the availability of polar groups of encapsulating agents to interact with environmental water. In this regard, Comunian et al. (2013) found that the individual polymers (gelatin, gum arabic) had high hygroscopicity, whereas the coacervated material was significantly less hygroscopic, owing to electrostatic interaction between the two polymers reducing free polar groups. The low hygroscopicity of the freeze-dried microcapsules obtained in the present work will ensure easy handling, packing, and application of the material.

Stability Study

To study the effect of microencapsulation on the stability of the lipid extract toward oxidation, the remaining astaxanthin content and TBARS were determined as a function of storage time. The astaxanthin content diminished in both non-encapsulated and encapsulated lipid extracts; however, encapsulation effectively reduced degradation, attaining higher values during the whole storage period (Fig. 3). Indeed, at the end of storage, the astaxanthin in the non-encapsulated lipid extract was almost fully degraded, whereas the encapsulated lipid extract retained ≈ 24% of the initial astaxanthin present. The gelatin–cashew gum complex also prevented astaxanthin degradation when used to encapsulate the same lipid extract as used in the present work, but in that case, ≈ 47% of the initial astaxanthin content was retained at the end of storage (Gomez-Estaca et al. 2016). The lower stability provided by gelatin–gum arabic can be attributed to the higher hygroscopicity, as compared to that of the gelatin–cashew gum microcapsules (2.33 ± 0.12 vs. 1.14 ± 0.01 g water/100 g powder, respectively). A progressive plasticization of the matrix as storage continues (the storage RH was ≈ 80%) would presumably produce an increase in the free volume among polymer chains and thus higher oxygen diffusion through the shell (Balaguer et al. 2013). Rocha-Selmi et al. (2013b) also found prevention of lycopene degradation when encapsulating it by complex coacervation in a gelatin–gum arabic matrix. Bustamante et al. (2016) solubilized an astaxanthin-containing extract from H. pluvialis in various oils and encapsulated it by spray-drying, resulting in a higher astaxanthin stability toward thermal treatment. With regard to the accumulation of TBARS, no differences were found as a function of either encapsulation or storage time (data not shown), revealing the high stability of the extract, which can be attributed to the antioxidant activity of astaxanthin and α-tocopherol (Gómez-Estaca et al. 2017; Takeungwongtrakul et al. 2015).

Application of the Microcapsules

In both food products (yogurt and gellified fish product), the lipid extract, either in free or encapsulated form, was efficiently distributed, providing an attractive reddish color (Fig. 4). The objective measure of color revealed some differences as a function of food product system and lipid incorporation method (Table 1). As expected, the hue angle was in the same range in all the samples (first quadrant), as the compound responsible for the products’ color, astaxanthin, was incorporated in comparable concentrations. In the case of yogurt, lipid extract encapsulation had a significant (p ≤ 0.05) effect on the product’s color, showing differences in lightness, hue, and chromaticity, as compared to the yogurt with the non-encapsulated extract. In contrast, no differences were observed in the gellified fish product as a function of encapsulation, probably owing to lipid extract release as consequence of thermal treatment. In this connection, gelatin–gum arabic microcapsules encapsulating echium oil have been found to disintegrate at temperatures ≥ 40 °C (Comunian et al. 2016).

The results of the sensory analysis are presented in Table 2. According to Meilgaard et al. (2006), with 14 panelists, at a 5% level of significance, at least 10 panelists should select one of the samples to confirm a significant difference between them. As expected, all the panelists rated a more intense reddish color in the encapsulated samples than in the control ones (without addition). With regard to odor evaluation of this pair, differences were found as a function of the food system. In the case of yogurt, no significant differences (p ≤ 0.05) were found between C and E samples, indicating that encapsulation of the shrimp lipid extract masked its characteristic odor when incorporated in yogurt. This was confirmed by the evaluation of the E/NE pair, as the NE sample was significantly (p ≤ 0.05) rated as having a more intense shrimp odor. The gelatin–cashew gum complex failed to mask the characteristic shrimp odor of the encapsulated lipid extract when the microcapsules were added to yogurt (Gomez-Estaca et al. 2016), in contrast with results from the present work. This is probably attributable to the lower solubility and the thicker wall of the gelatin–gum arabic microcapsules, resulting in a lower release of the lipid extract, as compared to the gelatin–cashew gum microcapsules. Indeed, the structure of the capsules was maintained in the yogurt matrix (Fig. 5), contrasting with the NE sample, in which free lipid droplets were found. With regard to color, it is worth noting that the E sample was rated as more intense in color than the NE one, indicating that encapsulation improved the coloring capacity of the lipid extract when added to yogurt, which is in agreement with the objective measure of color shown in Table 1. Encapsulation has been found to be an effective way of reducing undesirable sensory characteristics of lipid ingredients added to yogurt, as in the case of encapsulation of echium seed or tuna oils by complex coacervation to reduce the sensory impact when added to yogurt (Tamjidi et al. 2014; Comunian et al. 2017). Similar results were obtained by Taksima et al. (2015), who applied alginate–chitosan beads containing shrimp lipid extract rich in astaxanthin to yogurt.

In the case of the gellified fish product, a different behavior was observed, as the E sample was rated as more intense in odor than the C sample (p ≤ 0.05), whereas no differences (p ≤ 0.05) were detected between the E and NE samples. This means that encapsulation of the lipid extract did not mask the characteristic shrimp odor, which can be attributed to the intrinsic properties of the food system, in which thermal treatment is mandatory in order to gel. Despite this, the characteristic odor provided by the lipid extract would be appropriate with this kind of fish product. So in this case the benefit provided by encapsulation would be better dosage and manipulation. In the case of color, no differences were observed as a function of encapsulation, probably owing to lipid extract release too.

Conclusion

Encapsulation of a shrimp lipid extract by complex coacervation using the gelatin–gum arabic complex is a way of improving its stability, facilitating its manipulation and dosage, and masking its potentially undesirable sensory characteristics in food products in which no thermal treatment is applied, resulting in a widening of its techno-functionality and extending its use for food applications.

References

Alvim, I. D., & Grosso, C. R. F. (2010). Microparticles obtained by complex coacervation: infuence of the type of reticulation and the drying process on the release of the core material. Ciência e Tecnologia de Alimentos, 30(4), 1069–1076.

Aziz, S., Gill, J., Dutilleul, P., Neufeld, R., & Kermasha, S. (2014). Microencapsulation of krill oil using complex coacervation. Journal of Microencapsulation, 31(8), 774–784.

Balaguer, M. P., Cerisuelo, J. P., Gavara, R., & Hernandez-Muñoz, P. (2013). Mass transport properties of gliadin films: effect of cross-linking degree, relative humidity, and temperature. Journal of Membrane Science, 428, 380–392.

Burey, P., Bhandari, B. R., Howes, T., & Gidley, M. J. (2008). Hydrocolloid gel particles: formation, characterization, and application. Critical Reviews in Food Science and Nutrition, 48(5), 361–377.

Bustamante, A., Masson, L., Velasco, J., del Valle, J. M., & Robert, P. (2016). Microencapsulation of H. pluvialis oleoresins with different fatty acid composition: kinetic stability of astaxanthin and alpha-tocopherol. Food Chemistry, 190, 1013–1021.

Cai, Y. Z., & Corke, H. (2000). Production and properties of spray-dried Amaranthus betacyanin pigments. Journal of Food Science, 65(7), 1248–1252.

Cleveland, J., Montville, T. J., Nes, I. F., & Chikindas, M. L. (2001). Bacteriocins: safe, natural antimicrobials for food preservation. International Journal of Food Microbiology, 71(1), 1–20.

Comunian, T. A., Chaves, I. E., Thomazini, M., Moraes, I. C. F., Ferro-Furtado, R., de Castro, I. A., & Favaro-Trindade, C. S. (2017). Development of functional yogurt containing free and encapsulated echium oil, phytosterol and sinapic acid. Food Chemistry, 237, 948–956.

Comunian, T. A., Gomez-Estaca, J., Ferro-Furtado, R., Conceição, G. J. A., Moraes, I. C. F., De Castro, I. A., & Favaro-Trindade, C. S. (2016). Effect of different polysaccharides and crosslinkers on echium oil microcapsules. Carbohydrate Polymers, 150, 319–329.

Comunian, T. A., Thomazini, M., Alves, A. J. G., de Matos Junior, F. E., de Carvalho Balieiro, J. C., & Favaro-Trindade, C. S. (2013). Microencapsulation of ascorbic acid by complex coacervation: protection and controlled release. Food Research International, 52(1), 373–379.

Fathi, M., Mozafari, M. R., & Mohebbi, M. (2012). Nanoencapsulation of food ingredients using lipid based delivery systems. Trends in Food Science and Technology, 23(1), 13–27.

Gómez-Estaca, J., Calvo, M. M., Álvarez-Acero, I., Montero, P., & Gómez-Guillén, M. C. (2017). Characterization and storage stability of astaxanthin esters, fatty acid profile and α-tocopherol of lipid extract from shrimp (L. vannamei) waste with potential applications as food ingredient. Food Chemistry, 216, 37–44.

Gomez-Estaca, J., Comunian, T. A., Montero, P., Ferro-Furtado, R., & Favaro-Trindade, C. S. (2016). Encapsulation of an astaxanthin-containing lipid extract from shrimp waste by complex coacervation using a novel gelatin–cashew gum complex. Food Hydrocolloids, 61, 155–162.

Gómez-Estaca, J., Gavara, R., & Hernández-Muñoz, P. (2015). Encapsulation of curcumin in electrosprayed gelatin microspheres enhances its bioaccessibility and widens its uses in food applications. Innovative Food Science and Emerging Technologies, 29, 302–307.

Gudipati, V., Sandra, S., McClements, D. J., & Decker, E. A. (2010). Oxidative stability and in vitro digestibility of fish oil-in-water emulsions containing multilayered membranes. Journal of Agricultural and Food Chemistry, 58(13), 8093–8099.

Karre, L., Lopez, K., & Getty, K. J. K. (2013). Natural antioxidants in meat and poultry products. Meat Science, 94(2), 220–227.

Matalanis, A., Jones, O. G., & McClements, D. J. (2011). Structured biopolymer-based delivery systems for encapsulation, protection, and release of lipophilic compounds. Food Hydrocolloids, 25(8), 1865–1880.

Meilgaard M.C., Carr B.T. & Civille G.V. (2006) Sensory evaluation techniques. Boca Ratón: CRC PRESS.

Mendanha, D. V., Molina Ortiz, S. E., Favaro-Trindade, C. S., Mauri, A., Monterrey-Quintero, E. S., & Thomazini, M. (2009). Microencapsulation of casein hydrolysate by complex coacervation with SPI/pectin. Food Research International, 42(8), 1099–1104.

Montero, P., Calvo, M. M., Gómez-Guillén, M. C., & Gómez-Estaca, J. (2016). Microcapsules containing astaxanthin from shrimp waste as potential food coloring and functional ingredient: characterization, stability, and bioaccessibility. LWT - Food Science and Technology, 70, 229–236.

Negi, P. S. (2012). Plant extracts for the control of bacterial growth: efficacy, stability and safety issues for food application. International Journal of Food Microbiology, 156(1), 7–17.

Nori, M. P., Favaro-Trindade, C. S., Matias de Alencar, S., Thomazini, M., de Camargo Balieiro, J. C., & Contreras Castillo, C. J. (2011). Microencapsulation of propolis extract by complex coacervation. LWT - Food Science and Technology, 44(2), 429–435.

Pu, J., Bankston, J. D., & Sathivel, S. (2011). Developing microencapsulated flaxseed oil containing shrimp (Litopenaeus setiferus) astaxanthin using a pilot scale spray dryer. Biosystems Engineering, 108(2), 121–132.

Roberts, T. A. (1995). Microbial growth and survival: developments in predictive modelling. International Biodeterioration and Biodegradation, 36(3–4), 297–309.

Rocha-Selmi, G. A., Bozza, F. T., Thomazini, M., Bolini, H. M. A., & Fávaro-Trindade, C. S. (2013a). Microencapsulation of aspartame by double emulsion followed by complex coacervation to provide protection and prolong sweetness. Food Chemistry, 139(1–4), 72–78.

Rocha-Selmi, G. A., Favaro-Trindade, C. S., & Grosso, C. R. F. (2013b). Morphology, stability, and application of lycopene microcapsules produced by complex coacervation. Journal of Chemistry, 2013, 1–7.

Schmitt, C., & Turgeon, S. L. (2011). Protein/polysaccharide complexes and coacervates in food systems. Advances in Colloid and Interface Science, 167(1–2), 63–70.

Silva, D. F., Favaro-Trindade, C. S., Rocha, G. A., & Thomazini, M. (2012). Microencapsulation of lycopene by gelatin-pectin complex coacervation. Journal of Food Processing and Preservation, 36(2), 185–190.

Takeungwongtrakul S., Benjakul S., Santoso J., Trilaksani W. & Nurilmala M. (2015). Extraction and stability of carotenoid-containing lipids from Hepatopancreas of Pacific white shrimp (Litopenaeus vannamei). Journal of Food Processing and Preservation 39(1):10–18

Taksima, T., Limpawattana, M., & Klaypradit, W. (2015). Astaxanthin encapsulated in beads using ultrasonic atomizer and application in yogurt as evaluated by consumer sensory profile. LWT - Food Science and Technology, 62(1), 431–437.

Tamjidi, F., Nasirpour, A., & Shahedi, M. (2014). Rheological characteristics of yogurt enriched with microencapsulated fish oil. Journal of Agricultural Science and Technology, 16(5), 1073–1082.

Wang, B., Adhikari, B., & Barrow, C. J. (2014). Optimisation of the microencapsulation of tuna oil in gelatin-sodium hexametaphosphate using complex coacervation. Food Chemistry, 158, 358–365.

Xiao, Z., Liu, W., Zhu, G., Zhou, R., & Niu, Y. (2014). A review of the preparation and application of flavour and essential oils microcapsules based on complex coacervation technology. Journal of the Science of Food and Agriculture, 94(8), 1482–1494.

Yeo, Y., Bellas, E., Firestone, W., Langer, R., & Kohane, D. S. (2005). Complex coacervates for thermally sensitive controlled release of flavor compounds. Journal of Agricultural and Food Chemistry, 53(19), 7518–7525.

Yuan, J. P., Peng, J., Yin, K., & Wang, J. H. (2011). Potential health-promoting effects of astaxanthin: a high-value carotenoid mostly from microalgae. Molecular Nutrition and Food Research, 55(1), 150–165.

Acknowledgments

The authors wish to thank the Spanish Ministry of Economy and Competitiveness for financial support through projects AGL2011-27607 and AGL2014-52825, as well as for J. Gómez-Estaca’s “Juan de la Cierva” fellowship; the Spanish Ministry of Education, Culture and Sport for J. Gómez-Estaca’s “José Castillejo” fellowship; and the São Paulo Research Foundation (FAPESP) for T.A. Comunian’s fellowship (Process 2013/25862-5). Dr. Susana Cofrades is also acknowledged for particle size measurement assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gomez-Estaca, J., Comunian, T.A., Montero, P. et al. Physico-Chemical Properties, Stability, and Potential Food Applications of Shrimp Lipid Extract Encapsulated by Complex Coacervation. Food Bioprocess Technol 11, 1596–1604 (2018). https://doi.org/10.1007/s11947-018-2116-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-018-2116-3