Abstract

The food packaging industry has shown increasing attention toward biodegradable active packaging because of consumer demand for the extended shelf life of food products, as well as environmental concerns. In this study, the gelatin-based nanocomposite containing chitosan nanofiber (CHINF) and ZnO nanoparticles (ZnONPs) were fabricated and characterized by SEM analysis. The fabricated nanocomposite film revealed high antibacterial activity against foodborne pathogenic bacteria. To assess the efficiency of this bionanocomposite film for food packaging, chicken fillet and cheese was selected as food models. The results showed that the wrapping with nanocomposite film significantly (p < 0.05) decreased the growth of inoculation bacteria in chicken fillet and cheese samples. The changes in pH values and color parameters in chicken fillet and cheese samples were controlled by wrapping with nanocomposite film during storage time. At the end of 12-day storage, the weight loss of the wrapped chicken fillet and cheese samples with nanocomposite were 18.91 ± 1.96 and 36.11 ± 3.74%, respectively. In addition, the organoleptic characteristics of wrapped chicken fillet and cheese samples with nanocomposite film were acceptable until the end of storage. In conclusion, the fabricated nanocomposite can be suggested as a suitable packaging material for poultry meat and cheese to improve their shelf life and quality.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microbial contamination is one of the most common drawbacks in the food industry especially in meat and dairy products because of quality deterioration and reduced shelf life of these products (Clarke et al. 2016). Among the meat products, poultry meat is the most favorite one because of its high nutritional value, low-fat content, and low cost (Azlin-hasim et al. 2016). Despite all the mentioned benefits, the poultry meat is a susceptible product for growth of spoilage and pathogenic microorganisms because of its inherent properties such as protein and moisture content and high pH value (Giteru et al. 2017; Konuk Takma and Korel 2018). In addition, cheese is a nutritious and popular dairy product that is favored by different groups of consumers (Youssef et al. 2016). However, cheese is prone to microbial spoilage during storage that limits the shelf life of this dairy product (Tsiraki and Savvaidis 2013). In this regard, several attempts have been made to develop various physical and chemical preservation methods to reduce microbial contamination and improve the shelf life of these food products (Medeiros et al. 2014). Antimicrobial active packaging is an alternative new technology for preserving the quality and safety of food products, which is often achieved by incorporation of antimicrobial agents into the packaging system (Arfat et al. 2015). The application of organic antibacterial agents is limited for active packaging due to their low heat stability. In contrast, inorganic metallic nanoparticles (NPs) as antibacterial agents are suitable for application in active packaging because of their properties such as high heat stability, high surface to volume ratio, and high surface reactivity (Amna et al. 2013). Zinc oxide nanoparticles (ZnONPs) are interesting antibacterial agents in food and medical fields and reveal high antimicrobial activity in a board spectrum of microorganisms (Espitia et al. 2012). Moreover, these NPs are approved by the Food and Drug Administration (FDA) and generally recognized as safe (GRAS) (Noshirvani et al. 2017). In the previous studies, the use of ZnONPs in active packaging films and its effect on the physical and antimicrobial properties of these films have been investigated (Arfat et al. 2015; Meng et al. 2014; Sahraee et al. 2017a). In response to consumers’ demand for nutritive, healthy food products, and environmental concerns, the food packaging industry has shown growing attention to biodegradable packaging prepared from a variety of biopolymers such as polysaccharides, lipids, and proteins or their combinations (Enrione et al. 2012; Feng et al. 2016). Among the biopolymers, gelatin is widely used in the biodegradable packaging because of its high film-forming ability, biodegradability, low gelling and melting point, and low cost (Amjadi et al. 2019a; Crizel et al. 2018). However, gelatin has some drawbacks for application in food packaging such as poor water barrier and mechanical properties (Sahraee et al. 2017a). To overcome these restrictions, the use of nanoreinforcements and preparation of nanocomposites are offered (Voon et al. 2012; Farshchi et al. 2019). Chitosan nanofiber (CHINF) is a suitable nanoreinforcement for combination with the most of biopolymers by homogeneously dispersing in their matrices (Almasi et al. 2018). Additionally, CHINF provides a good barrier and transparency properties, high specific surface areas, low thermal expansion coefficient, and controlled release of additives in biodegradable films (Arkoun et al. 2018). The previous studies have fabricated the nanocomposite films such as gelatin nanocomposite films containing chitin and ZnONPs (Sahraee et al. 2017a), fish protein isolate/fish skin gelatin-ZnONPs nanocomposite (Arfat et al. 2015), silver nanoparticles/polyvinyl chloride nanocomposite (Azlin-hasim et al. 2016), and alginate/lysozyme nanolaminate film (Medeiros et al. 2014) for packaging of food productions such as poultry meat and cheese. To the best of our knowledge, no study has been conducted on the use of CHNF and ZnONPs in the fabrication of gelatin-based nanocomposite and this nanocomposite has not been considered for packaging of food products. The present study was conducted because of the following three reasons: (1) ZnONPs have the antimicrobial effect leading improved physical properties and barrier properties. (2) They enhance the physical properties of nanocomposite and synergistic effects on antimicrobial properties. (3) Gelatine has the film-forming ability and the biocompatibility of gelatin. Hence, this research was conducted to prepare gelatin-based nanocomposite containing CHNF and ZnONPs and assess the efficacy of this nanocomposite for improving the shelf life of chicken fillet and evaluate the physicochemical and sensory properties of white cheese during storage based on some microbial tests.

Materials and Methods

Materials

Gelatin (99.9% purity), glycerol (99.5% ≤ purity), and ethanol (97% purity) were obtained from Merck Chemicals Co, Germany. ZnONP powder (average particle diameter of about 30 nm, 99.8% purity) were purchased from Iranian Nanomaterials Pioneers Co, Iran. CHINF (average diameter about 28 nm, average length about 2–3 m, 99% purity) was procured from Nano Novin Polymer Co, Iran. For antibacterial tests, Baird-Parker agar, eosin methylene blue agar (EMB), cetrimide fusidin cephaloridine agar, and Mueller-Hinton agar were obtained from Sigma-Aldrich, USA. Staphylococcus aureus (ATCC® 12600™), Escherichia coli (ATCC® 11775™), and Pseudomonas aeruginosa (ATCC® 10145™) were procured from the Iranian Biological Resource Center (IBRC). The transparent plastic polyethylene bag for the wrapping of control sample was purchased from market.

Preparation of Nanocomposite Films

The casting method used for preparation of films. First, gelatin at a ratio of 4% (w/v) was dissolved in distilled water and then stirred for 30 min at 45 °C. CHINF (10% of dry gelatin) and ZnONPs (5% of dry gelatin) were dispersed in distilled water for 20 min at 50 °C in 1000 rpm and sonicated for 15 min with nominal frequency of 20 kHz at 70% of full power before annealing. Optimum concentrations of CHINF and ZnONPs were determined according to our pre-tests to achieving the highest film properties without obvious aggregation of nanoparticles. Then, the prepared CHINF and ZnONPs solutions were added into the previously prepared gelatin solution and stirred at 25 °C for 30 min in 1000 rpm. Next, glycerol as plasticizer was added as a 25% weight of gelatin into prepared mixture and stirred for 1 h at room temperature in 1000 rpm. In order to remove dissolved air bubbles, the film solution was degassed by ultrasound for 30 min with nominal frequency of 28 kHz. Finally, film solutions were cast onto polystyrene plate and dried at room temperature for 72 h. The dried films were conditioned at 50% relative humidity and 25 °C in desiccator for 72 h before testing (Sahraee et al. 2017b; Shahmohammadi Jebel and Almasi 2016). The fabricated film samples were coded as follows:

-

G: gelatin film

-

G/CHINF: gelatin-based nanocomposite containing CHINF

-

G/ZnONPs: gelatin-based nanocomposite containing ZnONPs

-

G/CHINF/ZnONPs: gelatin-based nanocomposite containing CHINF and ZnONPs

Characterization of Films

Scanning Electron Microscopy (SEM)

The morphology of the surface of the films were shown using the SEM (Quanta 200, FEI Co., USA). The accelerating voltage applied was 5.0 kV. The film samples were coated under vacuum with gold in an argon atmosphere prior to observation using a direct current sputtering technique (DST1, Nanostructured Coating Co., Tehran, Iran).

Antimicrobial Activity

The antibacterial activity of the film samples was assessed by the agar disc diffusion method. Three foodborne pathogenic bacteria, E. coli, S. aureus, and P. aeruginosa were used for evaluation. Suspensions containing (1.5 × 108 CFU/mL) colonies of E. coli, S. aureus, and P. aeruginosa were prepared and cultured on surface of prepared Mueller-Hinton agar plate. The film samples were prepared in the form of a round disc with 12 mm diameter and were placed on the surface of Mueller-Hinton agar plates and then subsequently incubated at 37 °C for 24 h. After incubation time, the diameter of the inhibition zone around the film samples was measured in triplicate by the caliper and the means were reported (Jahed et al. 2017).

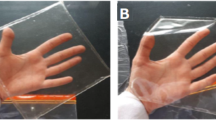

Treatment of Food Models

The chicken fillet and white cheese were obtained from a local market, directly transferred to the laboratory and were sliced into 10-g square pieces under aseptic conditions. The samples were divided into two groups (treatment and control): the treatment group packaged with prepared films (70 × 70 mm) and the control group wrapped with sterile transparent plastic polyethylene bag. It has to be noted that the thickness of the assayed films and as a result the contact surface of the active ingredients was similar in food models. Finally, all the packaged samples were stored for 12 days at 4 °C and 80 ± 5% RH. The samples were harvested after 1, 3, 6, 9, and 12 days for total count of bacteria, pH, texture, color, and sensory analyses (Fig. 1).

Microbiological Analyses

Total Bacterial Count (TBC)

For assay the TBC in the food samples, the wrapped food samples (2 g) were brought with 20 ml of 0.1% sterile peptone water solution and homogenized using a stomacher (Seward, London, UK) for 2 min. The 100 μl of diluted homogenates solution (1:10) were spread for the total bacterial counts by plate count agar and incubated at 37 °C for 24–48 h (Alizadeh Sani et al. 2017).

Inoculation of Food Samples with Common Foodborne Pathogenic Bacteria

The chicken fillet and white cheese pieces were sprayed with ethanol solution (95% v/v) and dried under UV for 20 min. The samples were immersed to bacterial suspension containing 1.5 × 106 CFU/mL of S. aureus (for the chicken fillet samples), P. aeruginosa (for the cheese samples), and E. coli (for the chicken fillet and cheese samples) and homogenized for 2 min. Then, the inoculated samples were packed with prepared films as treatment group and plastic bags as control group. All packaged samples were kept under sterile condition during 12 days of storage at 4 ± 1 °C. The S. aureus (in the chicken fillet samples), P. aeruginosa (in the cheese samples), and E. coli (in the chicken fillet and cheese samples) counts were carried out at 1, 3, 6, 9, and 12 days on Baird-Parker, cetrimide fusidin cephaloridine, and EMB agar plates, respectively, and incubated at 37 °C for 24 h (Alizadeh Sani et al. 2017).

pH Measurement

Five grams of the chicken fillet and white cheese samples were blended with 95 ml of distilled water and homogenized and then filtered. The pH values of filtrates were measured directly using a calibrated digital pH meter (Metrohm, Switzerland) at room temperature and three replicates were carried out for each measurement (Gomes et al. 2019).

Weight Loss Measurement

The weight loss of chicken and cheese samples was investigated during storage time. The results were expressed as percentages of weight lost relative to the initial weight.

Color Measurement

Image processing method was used to determine color parameters; i.e., L* (lightness/brightness), a* (redness/greenness), and b* (yellowness/blueness) of chicken fillet and white cheese samples during storage time. The samples and RAL standard color sheets (RAL-K7 Classic) were put in the standard box and photographed using a digital camera (Canon Power shot SX720 HS, Japan). Then, the L*, a*, and b* factors were shown by the Adobe Photoshop software and the calibration curves were found by drawing the L*, a*, and b* factors of the standard sheets obtained from software and actual values of the standard sheets (obtained from the EasyRGB color calculator: www.easyrgb.com/en/convert.php). Finally, the values of L*, a*, and b* factors of samples were calculated via the replacement of obtained factors in the equation of calibration curves (Amjadi et al. 2018).

Sensory Analysis

The sensory evaluation was assessed by 30 semi-trained panelists (15 males and 15 females, 25–35 years old), which were not awarded of the experimental procedure. The panelists scored sensory properties of samples such as color, odor and overall acceptability using a five-point hedonic scale (5 = like much, 4 =like, 3 = neither like or nor dislike, 2 = dislike, 1 = dislike much) during storage time. The samples were blind encoded with three-digit random numbers and sensory properties were explained beforehand to the panelists (Alizadeh et al. 2018).

Statistical Analysis

Effect of packaging type and storage time on microbial, pH, color, and sensory properties was assessed based on one-way analysis of variance (ANOVA) and Duncan’s mean comparison tests at 5% significant level using IBM SPSS Statistics 22 (IBM Corporation, Armonk, NY, USA).

Results and Discussion

Characterization of Films

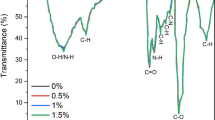

The prepared film samples were characterized successfully by FTIR and DSC analyses, and their physicochemical and mechanical properties were assessed. The results were reported in our recently published study (Amjadi et al. 2019b).

Scanning Electron Microscopy

The SEM image of a neat gelatin film (Fig. 2a) exhibited a rough surface with a few cracks, pores, and wrinkles. These wrinkles could be attributed to the effects of drying on the surface of film samples due to water evaporation. As shown in Fig. 2b, incorporation of ZnONPs enhanced the compactness and density of film because of the reduction in the number of pores and cracks in the film, indicating a strong affinity between ZnONPs and gelatin. However, the ZnONPs aggregation was observed because of phase separation and weak interaction between matrix and nanoparticles due to the high concentration of ZnONPs; this result is consistent with the previous studies (Sahraee et al. 2017a; Shahmohammadi Jebel and Almasi 2016). In addition, an interconnective porous structure was observed for G/CHINF sample, which was due to the filamentary structure of CHINF (Fig. 2c). The highly porous structure of composite could provide the loading of NPs in its inner space. G/CHINF/ZnONPs nanocomposite (Fig. 2d) revealed a good interconnective porous structure and the ZnONPs were observed in the inner structure of the gelatin and CHINF. These results can be explained by the appropriate interactions occur between gelatin matrix, CHINF and ZnONPs, and their good compatibility because of their anionic and cationic nature (Sahraee et al. 2017b). In accordance with these results, we showed that the chitin and ZnO nanoparticles were compatible with gelatin matrix and dispersed well in it (Sahraee et al. 2017a). In addition, Almasi et al. (2018) showed that CHINF had a filamentary structure and copper oxide NPs were distributed in CHINF more uniformly than bacterial cellulose nanofibers.

Antimicrobial Activity

Table 1 and Fig. 3 presents the inhibition zone diameters of the film samples against gram-positive (S. aureus) and gram-negative (E. coli and P. aeruginosa) bacteria. The neat gelatin and G/CHINF films did not show antibacterial activity. The G/ZnONPs film showed inhibition zones against bacteria, which were 30.62 ± 0.56, 15.06 ± 0.17, and 10.7 ± 0.72 mm against S. aureus, E. coli, and P. aeruginosa bacteria, respectively. The antibacterial activity levels of G/CHINF/ZnONPs nanocomposite were 8.19, 66.40, and 21.02% higher than those of G/ZnONPs sample against S. aureus, E. coli, and P. aeruginosa, respectively. Therefore, the CHINF had a synergistic effect on the antimicrobial activity of ZnONPs, which was in line with the results of previous studies (Almasi et al. 2018). This synergistic effect of CHNF on the antimicrobial activity of ZnONPs might be due to the electrostatic interaction of positively charged amine groups of CHNF with anionic groups of microbial cell membranes and their distribution in the cell membrane, which enhance the penetrate of Zn2+ ions and reactive oxygen species (ROS) produced by ZnONPs through the cell wall of bacteria and kill bacteria by reacting with cytoplasmic content (Jahed et al. 2017). As a result, the antibacterial activity of G/ZnONPs and G/CHINF/ZnONPs nanocomposites against Gram-positive bacteria was higher than Gram-negative bacteria. These results can be explained by the structural differences in the outer membrane of these bacteria. So, the cell wall of Gram-positive bacteria is thick and composed of multilayer peptidoglycan (Shahmohammadi Jebel and Almasi 2016). However, the cell wall of Gram-negative bacteria is more complex because of the presence of an outer membrane that is composed mainly of lipopolysaccharide, in addition to a thin peptidoglycan layer (Shankar et al. 2015). The outer membrane of Gram-negative bacteria limits the antibacterial potential of ZnONPs due to its barrier properties against Zn2+ ions and reactive oxygen species (ROS) produced by ZnONPs (Espitia et al. 2012). Similar results reported that the antibacterial activity of ZnO nanoparticle-loaded bacterial cellulose (Shahmohammadi Jebel and Almasi 2016) and gelatin (Shankar et al. 2015) composites against Gram-positive bacteria was higher than that of Gram-negative bacteria.

Microbiological Analyses

Total Bacterial Count

The efficiency of the film samples on TBC in the wrapped chicken fillet samples during storage time is shown in Fig. 4a. The initial TBC values were 3.1–3.3 log CFU/g, indicating that the chicken breast fillets were of good microbiological quality. So, previous studies reported that the chicken breast fillets with TBC values < 4 log CFU/g as good quality samples (Azlin-hasim et al. 2015). The TBC in chicken fillet samples increased significantly (p < 0.05) during storage time. The highest and lowest increases in these values are attributed to the samples wrapped with pure gelatin and G/CHINF/ZnONPs films, respectively. At the end of storage time, the TBC in the wrapped chicken fillet samples with pure gelatin and G/CHINF/ZnONPs films were 7.03 ± 0.35 and 5.26 ± 0.30 log CFU/g, respectively. The acceptable limit for TBC of chicken meat products is 6–7 log CFU/g (Azlin-hasim et al. 2015). Thus, the wrapped samples with G/ZnONPs and G/CHNF/ZnONPs films were acceptable after 12-day storage from the microbiological point of view. This result approved the antibacterial activity of prepared nanocomposite films especially G/CHNF/ZnONPs nanocomposite and their potential for improving the shelf life of chicken meat. The results of TBC analyses for wrapped chicken fillet samples are quite appropriate and more satisfactory than those reported in the previous studies. In this regard, the TBC value for wrapped chicken fillet samples with silver nanoparticles/polyvinyl chloride (Azlin-hasim et al. 2016), carboxymethyl cellulose/polyvinyl alcohol/clove oil (Muppalla et al. 2014), and silver nanoparticles/low-density polyethylene (Azlin-hasim et al. 2015) nanocomposite films were more than 6 log CFU/g, at the end of storage time. Figure 4b shows the TBC values in the wrapped cheese samples with film samples during storage time. The initial TBC values in cheese samples were 2.4 log CFU/g. All the cheese samples revealed a statistically significant (p < 0.05) increase trend in TBC value during storage time, except the samples wrapped with G/ZnONPs and G/CHNF/ZnONPs nanocomposite film. Therefore, TBC value of samples wrapped with G/ZnONPs and G/CHNF/ZnONPs film were significantly (p < 0.05) reduced during storage time, where the TBC value of this sample were 1.93 ± 0.15 and 1.66 ± 0.15 log CFU/g, respectively, at the end of storage time. In general, based on the obtained results, the most effective inhibition of bacteria was obtained for cheese wrapped by G/CHINF/ZnONPs nanocomposite. In accordance with these results, other studies reported the TBC value of skimmed milk acid coagulated cheese (Youssef et al. 2018) and soft white cheese (Youssef et al. 2015b) showed increasing trend during storage time, while the wrapping of these cheese samples with chitosan/poly(vinyl alcohol)/titanium nanoparticles nanocomposite films inhibited this the growth of bacteria and the TBC value of these samples decreased.

The total bacterial counts in wrapped chicken fillet (a) and cheese (b) samples with fabricated films during storage time at 4 °C. Data are presented as mean ± standard deviation (n = 3) and the means followed by different lowercase letters within the same Packaging type were significantly different at difference at the 5% level; means forerun by different capital letters within the same storage time were significantly different at difference at the 5% level in Duncan’s test (p < 0.05). G, gelatin; CHINF, chitosan nanofiber; ZnONPs, zinc oxide nanoparticles

Inoculation of Food Samples with Common Foodborne Pathogenic Bacteria

Figure 5a presents the growth rate of S. aureus in chicken fillets packaged with film samples. S. aureus is a foodborne pathogen and an important source of foodborne diseases. Among the foods related to staphylococcal food poisoning, poultry, egg, red meat, and seafood have been most commonly reported (Yuan and Yuk 2018). One day after inoculation, the highest (4 ± 0.3 log CFU/g) and the lowest (3 ± 0.2 log CFU/g) S. aureus count were attributed to the samples wrapped with neat gelatin and G/CHINF/ZnONPs films, respectively. The count of S. aureus significantly (p < 0.05) increased in all samples during storage time, with the highest (6 ± 0.1 log CFU/g) and the lowest (4 ± 0.1 log CFU/g) levels being related to neat gelatin and G/CHINF/ZnONPs, respectively, at the end of the storage. The interesting point in this regard is that the S. aureus count of G/ZnONPs sample exhibited no statistically significant (p ≥ 0.05) difference with G/CHINF/ZnONPs sample after 1 day, but the S. aureus count of G/ZnONPs sample was significantly (p < 0.05) higher than G/CHINF/ZnONPs at the end of the storage. These observations can be explained by the synergistic effect of CHINF on the antimicrobial activity of ZnONPs and controlled the release of ZnONPs during storage time (Almasi et al. 2018). The growth rates of E. coli in chicken fillets packaged with film samples are shown in Fig. 4b. E. coli and coliforms are usually considered by food manufacturers as hygiene indicators of sanitary quality of foods such as poultry meat (Soysal et al. 2015). Here, the highest E. coli count of chicken fillets was related to the control sample (4.6 ± 0.2 log CFU/g) while the lowest E. coli count associated with G/ZnONPs sample (2.6 ± 0.1 log CFU/g) after 1 day. The E. coli count exhibited an increasing trend in chicken fillet samples during storage time. At the end of the storage, the sample wrapped with neat gelatin film had the highest E. coli count (5.5 ± 0.3 log CFU/g) while the sample wrapped with G/CHINF/ZnONPs nanocomposite had the lowest content (3.4 ± 0.2 log CFU/g). Moreover, the chicken fillets wrapped with neat gelatin film showed the highest counts of both of inoculated bacteria at the end of storage time, probably due to the increased availability of protein (gelatin) or carbohydrate (glycerol) sources for bacteria growth (Noori et al. 2018). In general, based on the obtained results, the most effective inhibition of S. aureus and E. coli bacteria was obtained for chicken fillets wrapped by G/CHINF/ZnONPs nanocomposite. In this connection, Panea et al. (2014) showed that the low-density polyethylene-based nanocomposite containing ZnO and Ag nanoparticles improved the shelf life of chicken breast fillet. Alizadeh Sani et al. (2017) also reported that the whey protein isolate/cellulose nanofiber/TiO2 nanoparticle/rosemary essential oil nanocomposite film exhibited strong antibacterial activity against Listeria monocytogenes, E. coli, and S. aureus inoculated in lamb meat during the storage time.

The counts of inoculated S. aureus (a) and E. coli (b) bacteria in wrapped chicken fillet samples with fabricated films during storage time at 4 °C. Data are presented as mean ± standard deviation (n = 3) and the means followed by different lowercase letters within the same packaging type were significantly different at difference at the 5% level; means forerun by different capital letters within the same storage time were significantly different at difference at the 5% level in Duncan’s test (p < 0.05). G, gelatin; CHINF, chitosan nanofiber; ZnONPs, zinc oxide nanoparticles

The efficiency of the film samples in inhibiting the growth of P. aeruginosa and E. coli inoculated on cheese during storage time is presented in Fig. 6a, b, respectively. After 1 day of inoculation, the counts of P. aeruginosa and E. coli in cheese samples wrapped with G/CHINF/ZnONPs nanocomposite was significantly (p < 0.05) lower than other samples, but did not show a significant difference with cheese samples wrapped with G/ZnONPs film (p ≥ 0.05). Additionally, no significant difference (p ≥ 0.05) was identified between the G/CHINF/ZnONPs and G/ZnONPs at each storage time. So, a lower count of both bacteria was observed in cheese samples wrapped with G/CHINF/ZnONPs and G/ZnONPs films at the end of storage. This finding can be related to the controlled release of ZnONPs by CHNF that led to the increasing trend for antibacterial activity of G/CHINF/ZnONPs nanocomposite during the storage time. Besides, the CHINF had a synergistic effect on the antimicrobial activity of ZnONPs that compensated the low release of ZnONPs in the first days. Thus, the wrapping of some food products such as cheese with G/CHINF/ZnONPs nanocomposite can show no significant difference with the wrapping them with G/ZnONPs in the bacteria count for short storage time. Moreover, the sample wrapped with neat gelatin film revealed the highest counts of P. aeruginosa (5.6 ± 0.1 log CFU/g) and E. coli (5.6 ± 0.3 log CFU/g) after 12 days of storage, which was 1.4-fold higher than G/CHINF/ZnONPs and G/ZnONPs samples. These results showed the inhibition potential of G/CHINF/ZnONPs bionanocomposite against common foodborne pathogen bacteria. It has to be noted that this potential is due to the antibacterial activity of ZnONPs and synergistic effect of CHINF on the antimicrobial activity of ZnONPs. In accordance with these results, Youssef et al. (2016) reported that the novel chitosan/carboxymethyl cellulose/ZnONPs bionanocomposite film exhibited high antibacterial activity against S. aureus, P. aeruginosa, and E. coli bacteria and improved the shelf life of white soft cheese. In another study, the wrapping with polyethylene oxide nanofibers containing nisin-loaded poly-g-glutamic acid/chitosan nanoparticles decreased the numbers of Listeria monocytogenes from 3.19 to 1.43 log CFU/g in cheese samples during 7 days (Cui et al. 2017).

The counts of inoculated P. aeruginosa (a) and E. coli (b) bacteria in wrapped cheese samples with fabricated films during storage time at 4 °C. Data are presented as mean ± standard deviation (n = 3) and the means followed by different lowercase letters within the same packaging type were significantly different at difference at the 5% level; means forerun by different capital letters within the same storage time were significantly different at difference at the 5% level in Duncan’s test (p < 0.05). G, gelatin; CHINF, chitosan nanofiber; ZnONPs, zinc oxide nanoparticles

pH Measurement

The pH values of chicken fillet samples during the storage time are presented in Fig. 7a. The pH values of samples were significantly (p < 0.05) decreased until day 3, except for the sample wrapped with G/CHINF/ZnONPs bionanocomposite. In this regard, previous studies reported that a reduction in pH values may be related to the production of lactic acid by lactic acid bacteria (Azlin-hasim et al. 2015). After day 3, the pH values of samples were increased significantly (p < 0.05) until the end of storage. The highest (6.91 ± 0.15) and lowest (6.30 ± 0.04) levels of pH were attributed to control and G/CHINF/ZnONPs samples, respectively. The pH increase can be associated with the production of volatile basic components due to microbial growth, i.e., their endogenous proteolytic activity that results in the production of the basic component (Gomes et al. 2019). Therefore, the G/CHINF/ZnONPs nanocomposite limited the pH increase by inhibition of the growth of bacteria and protein denaturation. There are several studies on relationships between increasing pH of chicken meat and the growth of bacteria, especially psychotropic bacteria. Most of these works reported that the increase in pH may be attributed to the protein denaturation and accumulation of amines and ammonia by psychotropic bacteria during storage that were common microbial population in chicken meat (Cortez-Vega et al. 2012; Ghollasi-Mood et al. 2017; Melo et al. 2012). Similarly, Giteru et al. (2017) reported that the final pH of chicken fillets wrapped with kafirin-based films containing citral and quercetin was significantly higher than the initial values of the fresh chicken fillets. The pH change is an important parameter for determination of the acceptability and shelf life of cheese (Youssef et al. 2015a, b). Figure 7b presents the pH of cheese samples during the storage time. The pH values of samples revealed a significantly (p < 0.05) decreasing trend during storage time except for the samples wrapped with G/ZnONPs and G/CHINF/ZnONPs films. The pH reduction might be attributed to the production of CO2 by microorganisms due to degradation of lactate and decarboxylation of amino acids at the cheese surface (Youssef et al. 2015a, b). Moreover, reduction of the cheese pH reveals the presence of lipolysis, which is unfit for consumers (Singh et al. 2018). The pH values of the samples wrapped with G/ZnONPs and G/CHINF/ZnONPs films showed no significant (p ≥ 0.05) differences at the end of storage, which can be explained by the result of microbiological analyses. Youssef et al. (2015a, b) reported that the pH values of soft white cheese samples decreased during storage time, while the pH of the wrapped sample with chitosan/poly(vinyl alcohol)/titanium nanoparticles nanocomposite showed no significant difference with other samples.

The pH values of wrapped chicken fillet (a) and cheese (b) samples with fabricated films during storage time at 4 °C. Data are presented as mean ± standard deviation (n = 3) and the means followed by different lowercase letters within the same packaging type were significantly different at difference at the 5% level; means forerun by different capital letters within the same storage time were significantly different at difference at the 5% level in Duncan’s test (p < 0.05). G, gelatin; CHINF, chitosan nanofiber; ZnONPs, zinc oxide nanoparticles

Weight Loss Measurement

The weight loss of some food products such as chicken meat and cheese during storage time is an important parameter to express the quality and profitability of products (Amato et al. 2015). The weight loss percentages of the chicken fillet and cheese samples during storage time are summarized in Table 2. As can be seen, the weight loss of all chicken fillet and cheese samples significantly (p < 0.05) increased during storage time. The lowest weight loss levels are attributed to the control samples of chicken fillet and cheese at the end of storage, which are 8.63 ± 0.95 and 16.79 ± 1.47%, respectively. The highest weight loss levels are related to the chicken fillet and cheese samples wrapped with G/CHINF film, which are 38.03 ± 2.11 and 51.19 ± 4.26%, respectively. This result, which is confirmed by SEM results, could be attributed to the high moisture absorption by G/CHINF film sample because of its highly porous structure due to the filamentary structure of CHINF. The weight loss of the chicken fillet (18.91 ± 1.96%) and cheese (36.11 ± 3.74%) samples wrapped with G/CHINF/ZnONPs nanocomposite was (p < 0.05) lower than that of the samples wrapped with other films. The weight loss of food samples can be affected by the RH conditions in the storage time, which was 80 ± 5% in this study. Thus, the observed results can be described by the high water barrier properties (low moisture absorption and water vapor permeability) of the G/CHINF/ZnONPs nanocomposite compared to the other film samples. So, the presence of the ZnONPs decreased the moisture absorption by increasing the interactions between polymer chains and reduced mobility of chains due to filling free spaces in the gelatin matrix. Thus, the low absorption of moisture of food samples by G/CHINF/ZnONPs nanocomposite and the environment resulted in a low weight loss of the samples wrapped with G/CHINF/ZnONPs nanocomposite compared to samples wrapped with other films. In this regard, Shahmohammadi Jebel and Almasi (2016) reported that incorporation of ZnONPs reduced the moisture uptake in bacterial cellulose-based film because of forming new interactions and the creation of a strong structure. There are several studies on relationships between weight loss of wrapped food samples and water barrier properties of the wrapping films. For example, some studies reported that the major part of weight loss of the chicken fillet (Noori et al. 2018) and cheese (Amato et al. 2015) samples is due to the moisture extraction by pure biopolymeric films.

Color Measurement

Color properties of food products have a major influence on the general appearance and consumer acceptance (Soysal et al. 2015). Table 3 presents the color factors (L*, a*, and b*) of chicken fillet samples. The L* value of control sample significantly (p < 0.05) increased during storage time such that the highest L* value (70.45 ± 1.35) was related to this sample at the end of storage time. The L* values of fillet chicken samples wrapped with fabricated films showed no significant (p ≥ 0.05) differences during storage time, except the L* value of the wrapped sample with neat gelatin film that significantly (p < 0.05) decreased during storage time. Previous studies described that the chicken fillets with L* values of up to 50 were scored as “light” and those with lower value were scored as “dark” (Panea et al. 2014). Therefore, all the chicken fillet samples can be considered “light,” because the L* values of all samples were higher than 50 during storage time. The a* values of all chicken fillet samples showed a significant (p < 0.05) increasing trend during storage time. The highest and lowest a* values were associated with the samples wrapped with neat gelatin (24.46 ± 1.75) and G/CHINF/ZnONPs (16.19 ± 0.66), respectively. According to the previous literature (Giteru et al. 2017), the increasing redness (a*) in fillet samples may be related to the lipid oxidation, which could have caused oxidation of meat pigments. Therefore, the lower a* value in the wrapped sample with G/CHINF/ZnONPs composite film could be due to the reduction-oxidation of lipid and meat pigments. Moreover, the b* values of all chicken fillet samples exhibited a significantly (p < 0.05) increasing trend during storage time, but the b* values of samples wrapped with composite films showed no significant (p ≥ 0.05) difference with the control sample at the end of storage.

The color parameters of cheese samples are presented in Table 4. As a result, the L* values of control sample and sample wrapped with neat gelatin film revealed no significantly (p ≥ 0.05) difference during storage time, while the L* values of samples wrapped with composite films significantly (p < 0.05) increased during storage time. In addition, no significant difference (p ≥ 0.05) was observed in a* values of cheese samples during storage time except the sample wrapped with G/CHINF film, for which a* values significantly (p < 0.05) reduced during storage time. The b* values of all cheese samples significantly (p < 0.05) increased during storage, with the highest (13.06 ± 2.11) and lowest (5.66 ± 0.91) levels observed for the samples wrapped with G/CHINF and G/CHINF/ZnONPs films. The increase in the b* value (yellowness) is a sign of rancidity (Singh et al. 2018); thus, the lower b* value of the sample wrapped with G/CHINF/ZnONPs nanocomposite could be related to the potential of this nanocomposite film in the preservation of rancidity. Similarly, this result was reported by Singh et al. (2018), according to whom the yellowish coloration in unpacked cheese samples increased rapidly than those of packed cheese samples with silver nanoparticles-immobilized chitosan-coated poly (ethylene terephthalate) film. Youssef et al. (2015a, b) also reported similar findings that the yellow color for all cheese samples increased at the end of the storage period, for which the highest and lowest yellow values were related to the control sample and sample wrapped with chitosan/poly (vinyl alcohol)/titanium nanoparticles nanocomposite film, respectively.

Sensory Analysis

The measured sensory evaluation parameters of chicken fillet samples are presented in Fig. 8. The color acceptability of the samples wrapped with G/CHINF/ZnONPs showed no significant (p ≥ 0.05) difference during storage (Fig. 8a). At the end of storage, the lowest and highest amounts of color acceptability of chicken fillet samples were associated with samples wrapped with neat gelatin and G/CHINF/ZnONPs films, which were 2 ± 0.81 and 3.7 ± 0.67, respectively. Moreover, the odor acceptability of the all chicken fillet samples significantly (p < 0.05) decreased during storage time (Fig. 8b). The highest odor acceptability (3 ± 0.27) of chicken fillet samples was related to the sample wrapped with G/CHINF/ZnONPs nanocomposite and the lowest odor acceptability (1.7 ± 0.86) was associated with the control sample. In addition, the results of overall acceptance values revealed that the lowest (2.3 ± 0.62) and the highest (3.5 ± 0.16) values of chicken fillet were determined for the samples wrapped with neat gelatin and G/CHINF/ZnONPs films, respectively (Fig. 8c). Generally, based on the obtained result, the packaging of chicken fillet with G/CHINF/ZnONPs nanocomposite film protected the sensory parameters of samples during storage time due to the controlling of microbial spoilage. In this regard, Noori et al. (2018) reported the nanoemulsion-based edible sodium caseinate coating containing ginger essential oil limited the reduction of the sensory acceptance of chicken fillet during storage time because of its antimicrobial activity.

The color (a), odor (b), and overall (c) acceptance scores of wrapped chicken fillet samples with fabricated films during storage time at 4 °C. Data are presented as mean ± standard deviation (n = 3) and the means followed by different lowercase letters within the same packaging type were significantly different at difference at the 5% level; means forerun by different capital letters within the same storage time were significantly different at difference at the 5% level in Duncan’s test (p < 0.05). G, gelatin; CHINF, chitosan nanofiber; ZnONPs, zinc oxide nanoparticles

The results of sensory evaluation of cheese samples are shown in Fig. 9. As can be seen, the color acceptability of all the cheese sample significantly (p < 0.05) decreased during storage time such that the highest (4.4 ± 0.78) and the lowest (2.8 ± 0.63) amounts were determined for the control sample and sample wrapped with G/ZnONPs film, respectively, at the end of storage. The results of odor and overall acceptance values revealed that this sensory parameter significantly (p < 0.05) reduced during storage time, but there were no significant (p ≥ 0.05) differences between the odor and overall acceptance of cheese samples, at the end of storage. Therefore, the packaging with G/CHINF/ZnONPs nanocomposite film exhibited no considerable effects on the overall acceptance of the cheese sample. In accordance with these results, Cui et al. (2017) showed that the polyethylene oxide nanofibers containing nisin-loaded poly-g-glutamic acid/chitosan nanoparticles could maintain the sensory quality of the cheese during storage. In another study, similar findings reported that the sensory properties of all cheese samples decreased during storage time and the wrapping with chitosan/polyvinyl alcohol/titanium dioxide nanoparticles nanocomposite film revealed no considerable effects on sensory properties of cheese sample (Youssef et al. 2018).

The color (a), odor (b), and overall (c) acceptance scores of wrapped cheese samples with fabricated films during storage time at 4 °C. Data are presented as mean ± standard deviation (n = 3) and the means followed by different lowercase letters within the same packaging type were significantly different at difference at the 5% level; means forerun by different capital letters within the same storage time were significantly different at difference at the 5% level in Duncan’s test (p < 0.05). G, gelatin; CHINF, chitosan nanofiber; ZnONPs, zinc oxide nanoparticles

Conclusion

G/CHINF/ZnONPs nanocomposite and other film samples were prepared by casting method and were characterized by SEM analysis. The SEM images showed the incorporation of CHINF and ZnONPs changed the morphology of the gelatin matrix and G/CHINF/ZnONPs nanocomposite had a good interconnective porous structure. Moreover, the evaluation of the antibacterial activity of fabricated film samples revealed that the synergistic effect between CHNF and ZnONPs improved the antibacterial activity of nanocomposite. The potential of G/CHINF/ZnONPs nanocomposite was assayed for packaging of chicken fillet and cheese. The microbial analyses of food samples during storage revealed that the most effective inhibition of inoculation bacteria was obtained for chicken fillet and cheese samples wrapped by G/CHINF/ZnONPs nanocomposite film. The use of G/CHINF/ZnONPs film protected the physical and chemical quality of chicken fillet and cheese samples during storage time. Here, the weight loss of the chicken fillet and cheese samples wrapped with G/CHINF/ZnONPs nanocomposite were lower than the samples wrapped with other film samples. Furthermore, the organoleptic characteristics of chicken fillet and cheese samples wrapped with G/CHINF/ZnONPs nanocomposite film were acceptable. Consequently, G/CHINF/ZnONPs antibacterial nanocomposite film is appropriate for the packaging of poultry meat and cheese, representing a great promise for improving quality and shelf life of these food products.

References

Alizadeh Sani, M., Ehsani, A., & Hashemi, M. (2017). Whey protein isolate/cellulose nanofibre/TiO2 nanoparticle/rosemary essential oil nanocomposite film: its effect on microbial and sensory quality of lamb meat and growth of common foodborne pathogenic bacteria during refrigeration. International Journal of Food Microbiology, 251, 8–14.

Alizadeh, A., Oskuyi, A. S., & Amjadi, S. (2018). The optimization of prebiotic sucrose-free mango nectar by response surface methodology: the effect of stevia and inulin on physicochemical and rheological properties. Food Science and Technology International, 25(3), 243–251.

Almasi, H., Jafarzadeh, P., & Mehryar, L. (2018). Fabrication of novel nanohybrids by impregnation of CuO nanoparticles into bacterial cellulose and chitosan nanofibers: characterization, antimicrobial and release properties. Carbohydrate Polymers, 186, 273–281.

Amato, L., Ritschard, J. S., Sprecher, I., Lacroix, C., Schuppler, M., & Meile, L. (2015). Effect of packaging materials, environmental factors and rRNA transcriptional activity of surface microflora on red-smear cheese defect development. International Dairy Journal, 41, 50–57.

Amjadi, S., Ghorbani, M., Hamishehkar, H., & Roufegarinejad, L. (2018). Improvement in the stability of betanin by liposomal nanocarriers: its application in gummy candy as a food model. Food Chemistry, 256, 156–162.

Amjadi, S., Hamishehkar, H., & Ghorbani, M. (2019a). A novel smart PEGylated gelatin nanoparticle for co-delivery of doxorubicin and betanin: a strategy for enhancing the therapeutic efficacy of chemotherapy. Materials Science and Engineering C, 97(June 2018), 833–841.

Amjadi, S., Emaminia, S., Davudian, S. H., Pourmohammad, S., Hamishehkar, H., & Roufegarinejad, L. (2019b). Preparation and characterization of gelatin-based nanocomposite containing chitosan nanofiber and ZnO nanoparticles. Carbohydrate Polymers, 216, 376–384.

Amna, T., Hassan, M. S., Yousef, A., Mishra, A., Barakat, N., Khil, M.-S., & Kim, H. Y. (2013). Inactivation of foodborne pathogens by NiO/TiO 2 composite nanofibers : a novel biomaterial system. Food and Bioprocess Technology, 6(4), 988–996.

Arfat, Y. A., Benjakul, S., Prodpran, T., Sumpavapol, P., & Songtipya, P. (2015). Physico-mechanical characterization and antimicrobial properties of fish protein isolate/fish skin gelatin-zinc oxide (ZnO) nanocomposite films. Food and Bioprocess Technology, 9, 101–112.

Arkoun, M., Daigle, F., Holley, R. A., Heuzey, M. C., & Ajji, A. (2018). Chitosan-based nanofibers as bioactive meat packaging materials. Packaging Technology and Science, 31(4), 185–195.

Azlin-Hasim, S., Cruz-romero, M. C., Morris, M. A., Cummins, E., & Kerry, J. P. (2015). Effects of a combination of antimicrobial silver low density polyethylene nanocomposite films and modified atmosphere packaging on the shelf life of chicken breast fillets. Food Packaging and Shelf Life, 1–10.

Azlin-hasim, S., Cruz-romero, M. C., Morris, M. A., Padmanabhan, S. C., Cummins, E., & Kerry, J. P. (2016). The potential application of antimicrobial silver polyvinyl chloride nanocomposite films to extend the shelf-life of chicken breast fillets. Food and Bioprocess Technology, 9(10), 1661–1673.

Clarke, D., Molinaro, S., Tyuftin, A., Bolton, D., Fanning, S., & Joe, P. (2016). Incorporation of commercially-derived antimicrobials into gelatin-based films and assessment of their antimicrobial activity and impact on physical film properties. Food Control, 64, 202–211.

Cortez-Vega, W. R., Pizato, S., & Prentice, C. (2012). Quality of raw chicken breast stored at 5C and packaged under different modified atmospheres. Journal of Food Safety, 32(3), 360–368.

Crizel, T. D. M., Rios, A. D. O., Alves, V. D., Bandarra, N., Moldão-Martins, M., & Flôres, S. H. (2018). Biodegradable films based on gelatin and papaya peel microparticles with antioxidant properties. Food and Bioprocess Technology, 11(3), 536–550.

Cui, H., Wu, J., Li, C., & Lin, L. (2017). LWT—food science and technology improving anti-listeria activity of cheese packaging via nanofiber containing nisin-loaded nanoparticles. LWT - Food Science and Technology, 81, 233–242.

Enrione, J. I., Sáez, C., López, D., Skurtys, O., Acevedo, C., Osorio, F., & Hill, S. (2012). Structural relaxation of salmon gelatin films in the glassy state. Food and Bioprocess Technology, 5(6), 2446–2453.

Espitia, P., Soares, N., Coimbra, J., Andrade, N., Cruz, R., & Medeiros, E. (2012). Zinc oxide nanoparticles: synthesis, antimicrobial activity and food packaging applications. Food and Bioprocess Technology, 5(5), 1447–1464.

Farshchi, E., Pirsa, S., Roufegarinejad, L., Alizadeh, M., & Rezazad, M. (2019). Photocatalytic/biodegradable film based on carboxymethyl cellulose, modified by gelatin and TiO2-Ag nanoparticles. Carbohydrate Polymers, 216, 189–196.

Feng, X., Ng, V. K., Mik, M., & Yang, H. (2016). Effects of fish gelatin and tea polyphenol coating on the spoilage and degradation of myofibril in fish fillet during cold storage. Food and Bioprocess Technology, 10, 89–102.

Ghollasi-Mood, F., Mohsenzadeh, M., Housaindokht, M. R., & Varidi, M. (2017). Microbial and chemical spoilage of chicken meat during storage at isothermal and fluctuation temperature under aerobic conditions. Iranian Journal of Veterinary Science and Technology, 8(1), 38–46.

Giteru, S. G., Oey, I., Ali, M. A., Johnson, S. K., & Fang, Z. (2017). Effect of kafirin-based films incorporating citral and quercetin on storage of fresh chicken fillets. Food Control, 80, 37–44.

Gomes, V., Souza, L., Pires, J. R. A., Torrico, É., Coelhoso, I. M., Paula, M., & Luisa, A. (2019). Activity of chitosan-montmorillonite bionanocomposites incorporated with rosemary essential oil: from in vitro assays to application in fresh poultry meat. Food Hydrocolloids, 89(2018), 241–252.

Jahed, E., Khaledabad, M. A., Almasi, H., & Hasanzadeh, R. (2017). Physicochemical properties of Carum copticum essential oil loaded chitosan films containing organic nanoreinforcements. Carbohydrate Polymers, 164, 325–338.

Konuk Takma, D., & Korel, F. (2018). Active packaging films as a carrier of black cumin essential oil: development and effect on quality and shelf-life of chicken breast meat. Food Packaging and Shelf Life, (September), 0–1.

Medeiros, B. G. D. S., Souza, M. P., & Carneiro-da-cunha, M. G. (2014). Physical characterisation of an alginate/lysozyme nano-laminate coating and its evaluation on “Coalho” cheese shelf life. Food and Bioprocess Technology, 7(4), 1088–1098.

Melo, A. A. M. D., Geraldine, R. M., Silveira, M. F. A., Torres, M. C. L., Fernandes, T. H., & Oliveira, A. N. D. (2012). Microbiological quality and other characteristics of refrigerated chicken meat in contact with cellulose acetate-based film incorporated with rosemary essential oil. Brazilian Journal of Microbiology, 43(4), 1419–1427.

Meng, X., Zhang, M., & Adhikari, B. (2014). The effects of ultrasound treatment and nano-zinc oxide coating on the physiological activities of fresh-cut kiwifruit. Food and Bioprocess Technology, 7(1), 126–132.

Muppalla, S. R., Kanatt, S. R., Chawla, S. P., & Sharma, A. (2014). Carboxymethyl cellulose–polyvinyl alcohol films with clove oil for active packaging of ground chicken meat. Food Packaging and Shelf Life, 2(2), 51–58.

Noori, S., Zeynali, F., & Almasi, H. (2018). Antimicrobial and antioxidant efficiency of nanoemulsion-based edible coating containing ginger (Zingiber officinale) essential oil and its effect on safety and quality attributes of chicken breast fillets. Food Control, 84, 312–320.

Noshirvani, N., Ghanbarzadeh, B., Rezaei Mokarram, R., & Hashemi, M. (2017). Novel active packaging based on carboxymethyl cellulose-chitosan-ZnO NPs nanocomposite for increasing the shelf life of bread. Food Packaging and Shelf Life, 11, 106–114.

Panea, B., Ripoll, G., González, J., Fernández-cuello, Á., & Albertí, P. (2014). Effect of nanocomposite packaging containing different proportions of ZnO and Ag on chicken breast meat quality. 123, 104–112.

Sahraee, S., Ghanbarzadeh, B., Milani, J. M., & Hamishehkar, H. (2017a). Development of gelatin bionanocomposite films containing chitin and ZnO nanoparticles. Food and Bioprocess Technology, 10(8), 1441–1453.

Sahraee, S., Milani, J. M., Ghanbarzadeh, B., & Hamishehkar, H. (2017b). Physicochemical and antifungal properties of bio-nanocomposite film based on gelatin-chitin nanoparticles. International Journal of Biological Macromolecules, 97, 373–381.

Shahmohammadi Jebel, F., & Almasi, H. (2016). Morphological, physical, antimicrobial and release properties of ZnO nanoparticles-loaded bacterial cellulose films. Carbohydrate Polymers, 149, 8–19.

Shankar, S., Teng, X., Li, G., & Rhim, J. W. (2015). Preparation, characterization, and antimicrobial activity of gelatin/ZnO nanocomposite films. Food Hydrocolloids, 45, 264–271.

Singh, A., Khamrai, M., Samanta, S., Kumari, K., & Kundu, P. P. (2018). Microbial, physicochemical, and sensory analyses-based shelf life appraisal of white fresh cheese packaged into PET waste-based active packaging film. Journal of Packaging Technology and Research, 2(2), 125–147.

Soysal, Ç., Bozkurt, H., Dirican, E., Güçlü, M., Deniz Bozhüyük, E., Erdal, A., & Kaya, S. (2015). Effect of antimicrobial packaging on physicochemical and microbial quality of chicken drumsticks. Food Control, 54, 294–299.

Tsiraki, M. I., & Savvaidis, I. N. (2013). Effect of packaging and basil essential oil on the quality characteristics of whey cheese “Anthotyros”. Food and Bioprocess Technology, 6(1), 124–132.

Voon, H. C., Bhat, R., & Easa, A. M. (2012). Effect of addition of Halloysite nanoclay and SiO 2 nanoparticles on barrier and mechanical properties of bovine gelatin films. Food and Bioprocess Technology, 5(5), 1766–1774.

Youssef, A. M., El-Sayed, S. M., El-Sayed, H. S., Salama, H. H., Assem, F. M., Abd El-Salam, M. H., & Lin, L. (2015a). Novel bionanocomposite materials used for packaging skimmed milk acid coagulated cheese (Karish). LWT - Food Science and Technology, 81(2017), 233–242.

Youssef, A. M., El-Sayed, S. M., Salama, H. H., El-Sayed, H. S., & Dufresne, A. (2015b). Evaluation of bionanocomposites as packaging material on properties of soft white cheese during storage period. Carbohydrate Polymers, 132, 274–285.

Youssef, A. M., El-sayed, S. M., El-sayed, H. S., Salama, H. H., & Dufresne, A. (2016). Enhancement of Egyptian soft white cheese shelf life using a novel chitosan/carboxymethyl cellulose/zinc oxide bionanocomposite film. Carbohydrate Polymers, 151, 9–19.

Youssef, A. M., El-Sayed, S. M., El-Sayed, H. S., Salama, H. H., Assem, F. M., & Abd El-Salam, M. H. (2018). Novel bionanocomposite materials used for packaging skimmed milk acid coagulated cheese (Karish). International Journal of Biological Macromolecules, 115(2017), 1002–1011.

Yuan, W., & Yuk, H. (2018). Antimicrobial ef fi cacy of Syzygium antisepticum plant extract against Staphylococcus aureus and methicillin-resistant S. aureus and its application potential with cooked chicken. Food Microbiology, 72, 176–184.

Acknowledgments

The authors gratefully acknowledge the support of the Islamic Azad University (Tabriz Branch) and Drug Applied Research Center, Tabriz University of Medical Sciences.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Amjadi, S., Emaminia, S., Nazari, M. et al. Application of Reinforced ZnO Nanoparticle-Incorporated Gelatin Bionanocomposite Film with Chitosan Nanofiber for Packaging of Chicken Fillet and Cheese as Food Models. Food Bioprocess Technol 12, 1205–1219 (2019). https://doi.org/10.1007/s11947-019-02286-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-019-02286-y