Abstract

Silver (Ag) nanoparticles (NPs) were synthesised and characterised, and their antimicrobial activity against Escherichia coli, Staphylococcus aureus, Bacillus cereus, Pseudomonas fluorescens and microflora derived from raw chicken, beef or cooked ham was determined. Polyvinyl chloride (PVC) films or antimicrobial Ag/PVC nanocomposite films were manufactured via a solvent casting method and the mechanical and thermal properties of these materials determined. Manufactured antimicrobial Ag/PVC nanocomposite films were used to wrap chicken breast fillets, followed by modified atmosphere packaging (using conventional laminates and employing a gas mix of 60 % N2/40 % CO2), and compared against PVC control films. In general, Gram-negative bacteria were more sensitive to Ag NPs than Gram-positive bacteria and microflora isolated from meat products were more resistant than pure culture bacteria. However, the most sensitive bacteria to Ag NPs were Pseudomonas fluorescens. No significant differences (p > 0.05) in tensile strength and elongation at break were observed, but glass transition temperatures (T g) of Ag/PVC nanocomposite films were lower (p < 0.05) when compared to PVC control films. Results also indicated that antimicrobial Ag/PVC nanocomposite films significantly (p < 0.05) extended the shelf-life of chicken breast fillets and reduced lipid oxidation of chicken breast fillets compared to PVC-wrapped equivalents. Overall, results indicated that antimicrobial Ag/PVC nanocomposite films can potentially be used as antimicrobial packaging for food packaging applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The main approaches for the synthesis of metal nanoparticles (NPs) are ‘top down’ and ‘bottom up’. However, the bottom up approach has attracted more attention as a strategy to manufacture inorganic nanomaterials because of the wide variety of nanomaterials that can be produced. The chemical reduction of metal salts is the simplest, most cost-effective and commonly used technique to synthesise metal NPs at large scale (Cushen et al. 2012; Hannon et al. 2015; Sharma et al. 2009).

Metal NPs possess unique chemical, mechanical, optical and electrical properties compared to their bulk material counterparts largely due to their high ratio of surface area over volume (Altan and Yildirim 2012; Anyaogu et al. 2008). The novel properties of metal NPs lead to potential application in areas, such as catalysis, biosensor, wastewater treatment, medical products and food packaging (Badiou et al. 2011; Emamifar et al. 2011; Kaegi et al. 2011; Peterson et al. 2014; Shang et al. 2014).

In recent years, active and intelligent packaging technologies have been developed for food packaging applications as a means of providing information and stabilising mildly preserved, convenient foods (Restuccia et al. 2010). Future Market Insight (FMI 2015) reported that active packaging and intelligent packaging accounted for over 75 % market value share, and it is expected that the market value of these packaging technologies will reach US$58 billion by 2025, while the market value for antimicrobial active packaging has been forecasted to reach $3.6 billion by 2020.

Many metal NPs with antimicrobial activity have been reported; however, silver (Ag) NPs have been shown to have good antimicrobial activity against a wide range of microorganisms, including bacteria, fungi, viruses, algae, parasites, etc., and have been widely used to develop antimicrobial active packaging or nanocomposite films (Egger et al. 2009; Espinosa-Cristóbal et al. 2009; Kim et al. 2009; Lara et al. 2010; Navarro et al. 2008). Several mechanisms have been proposed to explain the antimicrobial activity effect of Ag NPs, and the major mechanisms include the following: reaction with sulphur-containing amino acids inside or outside the cell membrane, leading to the disruption of ATP production and DNA replication, which in turn affects bacterial cell viability. It was also suggested that silver ions (particularly Ag+) released from Ag NPs can interact with phosphorus moieties in DNA, resulting in inactivation of DNA replication, or interaction with proteins, particularly at thiol groups (sulfhydryl, −SH) leading to the inhibition of enzymatic functions. There is also evidence that Ag NPs generate large quantities of reactive oxygen species (ROS), which can have an antimicrobioal effect. Silver NPs can also get attached to the abundant sulphur-containing proteins on bacterial cell membrane leading to greater membrane permeability which can result in leakage of cell components and interference with the bacterial respiratory chain eventually causing the death of the bacteria (Marambio-Jones and Hoek 2010; Palza 2015; Park et al. 2009; Pelgrift and Friedman 2013; Sondi and Salopek-Sondi 2004).

Commonly, most of the contamination of food products occurs on the surface of the food due to the post-process handling; therefore, the use of antimicrobial nanocomposite films to package food products could delay or inactivate the microorganisms present on food surfaces, thereby leading to prolonged product shelf-life and reduced food waste (Appendini and Hotchkiss 2002). Previous studies demonstrated that incorporation of Ag NPs on food carrier containers or absorbent pads or embedded into packaging films significantly extended the shelf-life of beef meat, chicken meat, fruit juice, asparagus, fresh cut fruits and cheese (An et al. 2008; Azlin-Hasim et al. 2015; Costa et al. 2011; Emamifar et al. 2010; Fernández-Pan et al. 2014; Incoronato et al. 2011; Zhou et al. 2011).

Poly(vinyl) chloride (PVC) is one of the most commonly used polymer materials for packaging fresh food products, due to its low cost, good transparency, chemical resistance, good mechanical performance and flexibility (Becerra et al. 2012). Moreover, PVC has been used to manufacture antimicrobial PVC nanocomposite films containing ZnO, Cu and TiO2/Ag ion (Ag+) (Becerra et al. 2012; Cheng et al. 2006; Liu et al. 2012; Seil and Webster 2011). Cushen et al. (2013) reported that Ag NPs embedded in a PVC polymer matrix were unlikely to migrate from Ag nanocomposite films into chicken meat and that the exposure result was 8.85 mg/kg or 0.84 mg/dm2, which fell well below than the European Union (EU) legislation limits for Ag intended to come into contact with foodstuffs, no more than 60 mg/kg or 10 mg/dm2 (EC 2002).

Chicken meat is a popular food around the world due to its high nutritional value (Mexis et al. 2012). However, chicken meat is highly perishable and provides an ideal medium for the growth of pathogenic microorganisms. It was reported that the shelf-life of chicken breast fillets were less than 5 days under aerobic and chilled conditions (4 °C) (Bolton et al. 2013). Hence, any systems that could extend the shelf-life of the chicken products would be of significant interest to poultry processors, retailers and consumers (Azlin-Hasim et al. 2015).

To the best of our knowledge, there is little information on the development of antimicrobial Ag/PVC nanocomposite films manufactured via solvent casting and the application of the developed antimicrobial nanocomposites to extend the shelf-life of fresh chicken breast fillets. Therefore, the objectives of this study were to synthesise, characterise and assess the antimicrobial activity of Ag NPs against a wide range of microorganisms; manufacture antimicrobial PVC nanocomposite films containing Ag NPs (0.5 wt.%) via a solvent casting method; characterise the manufactured packaging films and investigate the effects of wrapping chicken breast fillets with Ag/PVC nanocomposite films followed by MAP (using conventional laminates and employing a gas mix of volume ratio of 60:40 N2/CO2) on the physicochemical and microbiological quality of chicken breast fillets during storage at 4 °C.

Materials and Method

Materials

PVC pellets, silver nitrate (AgNO3, 99 % min), polyvinylpyrrolidone (PVP, Mw = 40,000), ethanol (99 %), acetone, tetrahydrofuran (THF) and 2-bis-ethylhexyl adipate (DEHA) were purchased from Sigma-Aldrich, Ireland. All chemicals were used as received. Milli-Q water (MQW) (18.2 MΩcm) was obtained with a PURELAB Option-Q (Elga, UK).

Metal Nanoparticles

Synthesis of Metal Nanoparticles

Silver NPs of 20 nm diameter were synthesised using a method adapted from Chen et al. (2009). Briefly, an ethanolic solution of AgNO3 (0.1 M) was heated to 30 °C and an equal amount of 0.1 M PVP solution in ethanol was added at a rate of 0.667 mL min−1 using a programmable peristaltic pump (Dose It P910, Integra Biosciences AG Switzerland). The solution was stirred at a rate of 800 rpm for 2 h on a hot plate magnetic stirrer device (MSH-20D, Wise Stir, Korea), and the solution had turned a stable orange-brown colour. Ag NPs were separated by addition of acetone at a volume ratio of approximately 1:4, respectively. The solution was then sonicated using an ultrasonicator (Cole-Palmer 8891) for 10 min and centrifuged at 6000 rpm for 15 min in a Beckman J2-21 centrifuge (Beckman Instruments Inc., USA). The supernatant was discarded and the pellet was redispersed in ethanol. The separation step was repeated once again, and the pellet was dried in an oven overnight at 60 °C and finally crushed into a powder.

Characterisation of Metal Nanoparticles

Transmission electron microscopy (TEM) image of the Ag NPs was obtained using a JEOL 2000 FX at an accelerating voltage of 200 kV. The Ag NPs were dispersed into absolute ethanol, and one or two drops of the ethanolic solution was placed on a holey carbon film on copper grids under dry ambient atmosphere at room temperature and left overnight. The average size of the Ag NP is reported as the average of ten measurements of different NPs. The crystallinity and purity of the Ag NPs in the powder form were examined by X-ray diffractometer (XRD, PANalytical MPD) using an Xcelerator detector and a Cu Kα radiation (45 kV/40 mA). The scans were performed with a step size of 0.0084° from a 2θ of 10° to 70°. Energy-dispersive X-ray analysis (EDS) was carried out using a built-in Oxford INCA x-sight detection spectrometer combined with a scanning electron microscope (SEM). Before use, Ag NPs in powder form were mounted on a carbon tape and sputter-coated with gold under vacuum in an argon atmosphere to determine the elemental composition on a selected area. The formation and stability of Ag NPs in ethanolic solution was confirmed by UV–Vis spectroscopy (UV–Visible spectrophotometer Cary 60, Agilent Technology, Santa Clara, USA).

Antimicrobial Test

Bacteria Strain

In this study, antimicrobial activity of Ag NPs against Gram-positive bacteria (Staphylococcus aureus (S. aureus) (NCIMB 13062) and Bacillus cereus (B. cereus) (NCIMB 9373)) and Gram-negative bacteria (Escherichia coli (E. coli) (NCIMB 11943) and Pseudomonas fluorescens (P. fluorescens) (NCIMB 9046)) or microflora isolated from raw chicken breast fillets, beef or cooked ham was assessed. Before use, all pure culture bacteria were grown for 18 h at 30 °C (P. fluorescens and B. cereus) or 37 °C (S. aureus and E. coli) in 10 mL Mueller Hinton broth (MHB) (Oxoid, UK) under constant agitation at 170 rpm on an orbital shaker (Innova 2300, New Brunswick™, Germany).

For the isolation of microflora from raw chicken breast fillets, beef or cooked ham, 10 g of chicken, beef or cooked ham was placed aseptically in a filter stomacher bag and 90 mL of sterile MHB was added. After homogenising this mixture in a stomacher (Colworth Stomacher 400, Seward Ltd., England) for 3 min, 10 mL of the resulting homogenate was transferred into a sterile tube (Sterilin, UK) and incubated for 18 h at 37 °C under constant agitation at 170 rpm on an orbital shaker. The microbial load of pure culture or microflora was determined using the spread plate method.

Antimicrobial Activity Test

The antimicrobial activity of Ag NPs against pure culture bacteria and meat-derived microflora was qualitatively assessed by the disk diffusion method as recommended by the Clinical and Laboratory Standards Institute (CLSI 2007). Serial dilution of an overnight grown culture was carried out using maximum recovery diluent (MRD) (Oxoid, UK) to obtain ∼log 6 CFU mL−1 of the target microorganism and swabbed on Mueller Hinton agar (MHA) (Oxoid, UK) using a sterile swab (Starstedt, Italy). Before the disk-like diffusion antimicrobial activity test, Ag NPs (0.5 wt. %) were dissolved in sterilized MQW, sonicated for 10 min and filtered through a sterile membrane filter (0.2 μm, Whatman). Ten microlitres of the filtered Ag NP solution was loaded on 6-mm-diameter sterile Whatman No. 40 paper discs (Whatman International Ltd, UK) and subsequently placed aseptically onto the inoculated MHA plates using sterile forceps and incubated for 24 h at the temperatures mentioned above. A 10-μg standard antimicrobial streptomycin susceptibility disk (Oxoid, UK) was used as a positive control. The sensitivity of the microorganisms to the antimicrobial was classified according to the diameter of the inhibition zone (DIZ) as outlined by Azevedo et al. (2014): DIZ ≤9 mm, not sensitive; DIZ ≥9 to <15 mm, sensitive; DIZ ≥15 to <20 mm, very sensitive and DIZ ≥20 mm, extremely sensitive. The DIZ was measured using an electronic calliper (Model ECA 015D, Moore & Wright, Paintain tools Ltd., UK), and the results are the average of six replicates (two independent experiments × three measurements). The DIZ of Ag NPs are presented as percentage (%) of control (streptomycin) samples.

The antimicrobial activity of Ag NPs was measured by determining minimum inhibitory concentration (MIC) against the target microorganisms in 96 flat bottom well tissue culture microplates (Sarstedt Inc., NC, USA) according to the NCCLS (2000) broth microdilution method as described by Cruz-Romero et al. (2013). Bacterial strains were cultured overnight at the appropriate temperature on double-strength MHB (2XMHB) and adjusted to a final density of 105 CFU/mL and used as an inoculum within 15 min of preparation. Briefly, 100 μL of 2XMHB was added to each well in rows A to F, 150 μL of the adjusted culture suspension was added to each well in row H, columns 1–11 and the same amount of sterile 2XMHB was added to column 12. In each well of row G, 150 μL of Ag NP solutions (0.25 wt. %) was dispensed and a threefold serial dilution was performed by transferring 50 μL of Ag NP solution from row G into the corresponding wells of row F through to row B. After mixing, 50 μL of the resultant mixture on row B was discarded. Finally, using a 12-channel electronic pipette (Model EDP3-Plus, Rainin, USA) 15 μL of the tested microorganisms was pipetted from each well in row H into the corresponding wells in row A followed by rows B to G. Positive and negative growth controls were included in each assay plate. The inoculated plates were incubated in a wet chamber for 24 h at 30 °C (P. fluorescens and B. cereus) or 37 °C (E. coli, S. aureus, chicken microflora). The lowest concentration showing inhibition of growth was considered to be the MIC for the target microorganisms. The test was repeated in triplicate in two independent experiments (two independent experiments × three samples).

PVC Films or PVC Nanocomposite Films

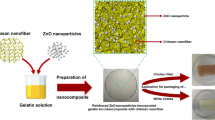

Preparation of PVC Films or PVC Nanocomposite Films

PVC nanocomposite films were manufactured using a casting method. The concentration of Ag NPs added to the polymer matrix was chosen based on preliminary results stating that films with good antimicrobial activity were obtained when a minimum concentration of Ag NPs (0.5 %) was used to manufacture the Ag/PVC nanocomposite films (data not shown). It was also found that concentrations higher than 0.5 % of Ag NPs affected the mechanical properties of the PVC nanocomposite films (Moloney et al. 2012). PVC (5 wt.%) was dissolved in THF and Ag NPs at a concentration of 0.5 wt.% of dry matter dissolved in minimum amount of ethanol which was added drop-wise into the PVC/THF solutions under stirring condition, and then DEHA was added as plasticiser at a level of 30 wt.% of PVC. The cloudy solution was stirred at a rate of 800 rpm on a magnetic stirrer device (MSH-20D, Wise Stir, Korea) until the solution had turned into a stable transparent solution. At this stage, the thick solution was poured onto a glass pane and cast to a thickness of approximately 500 μm using a 17.8-cm hand-held film applicator (AP-99500703, Gardco, Florida, USA). The cast PVC nanocomposite films were dried overnight under the fume hood and then removed from the glass pane. The obtained films were stored between A4 sheets of paper in an environmental chamber at 25 °C and 75 % relative humidity until further analysis. PVC control films were prepared as above except that no Ag NPs were added into the solution of PVC/THF/DEHA.

Characterisation of PVC Films or PVC Nanocomposite Films

The thermal analysis of the PVC or Ag/PVC nanocomposite films were determined using differential scanning calorimetry (DSC) 200F3 (Netzsch Group, Selb, Germany) with liquid N2 used as coolant. PVC or Ag/PVC nanocomposite samples (∼5 mg) were weighed into an aluminium pan and hermetically sealed. Samples were scanned at 10 °C min−1 in the temperature range of −130–100 °C. An empty pan was used as reference. In order to cancel the effect of the thermal history, samples were rescanned after cooling and T g (glass transition) was evaluated from the DSC thermogram obtained from the second scanning.

The mechanical properties of the PVC control or Ag/PVC nanocomposite films (tensile strength (TS) and elongation at break (EAB)) were determined according to the ASTM-D882-02 (ASTM 2002) using a Mecmesin force and Torque software (Imperial 2500 instruments, Mecmesin Ltd., Slinfold, West Sussex, England). PVC films were cut using a standard template (size 10 cm × 2 cm). The initial grip separation was set at 50 mm and was pulled at the speed of 50 mm min−1. Each value represents the average of 12 readings (two independent experiments × six samples).

The changes in colour of PVC control films or Ag/PVC nanocomposite films were measured using a Minolta chroma meter (CR-300, Minolta Camera Co., and Osaka, Japan) as outlined in Chen et al. (2010). Before any measurement, the instrument was calibrated using a white calibration plate provided by the manufacturer (Y = 86.0, x = 0.3166 and y = 0.3237). The PVC control or Ag/PVC nanocomposite films were then placed on the white calibration plate before the colour of the films was measured. Five random films from two independent experiments were measured three times (n = 30), and the average values of CIE L-value (lightness), a-value (redness) and b-value (yellowness) were reported. Total colour difference (ΔE*) is a parameter that quantifies the overall colour difference of a given sample compared to a reference sample, and ΔE* between PVC control films and PVC nanocomposite films containing Ag NPs was calculated as follows:

The smaller the value of ΔE*, the closer the samples are in colour. Values of ΔE* between 0 and 0.2 indicate undetectable colour difference, 0.2–0.5 for a very small difference, 0.5–1.5 for a small difference, 1.5–3.0 for distinct, 3.0–6.0 for very distinct, 6.0–12.0 for great and >12 for a very great difference (Cruz-Romero et al. 2007).

Preparation and MAP Packaging of Chicken Breast Fillets

To avoid cross-contamination, all utensils used, including PVC control or Ag nanocomposite films, were disinfected using ethanol 70 %. Excess fat and cartilage of the chicken breast fillets were trimmed, and then chicken breast fillets were wrapped with sterilised PVC control or Ag/PVC nanocomposite films. The wrapped chicken breast fillets were placed individually onto low-O2-permeable (8–12 cm3 m−2 day−1 at standard temperature & pressure (STP)) polystyrene/ethylene vinyl alcohol (EVOH)/PE trays and heat sealed using a low-O2-permeable (3 cm3 m−2 day−1 at STP) lidding material comprising a laminate of 20-μm oriented polypropylene (OPP) and a 50-μm co-extruded tri-layer construction of PE/EVOH/PE (Cryovac/WR Grace Europe Inc., Lausanne, Switzerland). A packaging system type VS 100 BS (Gustav Muller and Co., Bad Homburg 6, and Germany) was used for MAP-packed samples using a gas ratio of 60 % N2/40 % CO2. The MAP-packed samples were stored at 4 °C up to 9 days. Sampling was carried out every 3 days, and for each sampling day, two trays were randomly selected for microbiological and physicochemical analysis. The whole experiment was repeated twice in replicates (two independent experiments × two samples).

Shelf-Life Stability During Chilled Storage of Chicken Breast Fillets

Microbiological Analysis

For the microbiological analysis, 10 g of sample was taken aseptically from the surface of the chicken breast and placed into a sterile stomacher filter bag, and 90 mL of sterile MRD was added aseptically and homogenised for 3 min using BA6021 stomacher 400 (Colworth, Bury St. Edmunds, UK). The homogenate was then tenfold diluted and used for enumeration of total viable counts (TVCs), Pseudomonas spp., lactic acid bacteria (LAB), and total coliforms. TVCs were enumerated on plate count agar (PCA, Merck) plates after incubation for 48 h at 30 °C. Pseudomonas spp. were enumerated after a 48-h incubation at 30 °C on a Pseudomonas agar base (Oxoid, UK) to which CFC supplement was added (SR0103E, Oxoid, UK). For LAB count, overlaid MRS agar (Oxoid, UK) plates were incubated at 30 °C for 72 h. For the enumeration of total coliforms, appropriate dilution was placed on coliform agar (Oxoid, UK) plates and incubated at 37 °C for 24 h. The bacterial counts were converted to log10 colony-forming units per gram (CFU g−1) prior to statistical analysis.

Colour Changes

The colour changes on the surface of the chicken breast fillets during storage at 4 °C were monitored using the same colorimeter as described before. On each measurement day, ten random areas of the chicken breast fillets were measured per sample. Each value of the CIE L-values, a-values , b-values and ΔE* represents the average of 40 readings (two independent experiments × two samples × ten readings). The ΔE* between chicken breast fillets wrapped with PVC control films and chicken breast fillets wrapped with Ag/PVC nanocomposite was calculated as outlined above.

Lipid Oxidation of Chicken Fillets as Measured by TBARS Number

The level of lipid oxidation of chicken breast fillets wrapped with PVC control or Ag/PVC nanocomposite films and MAP packed were assessed by the thiobarbituric-acid-reacting substances (TBARS) assay as outlined by Siu and Draper (1978). The results were expressed as milligrams of malondialdehyde (MDA) per kilogram of chicken breast fillets, and each value represents the average of eight readings (two independent experiments × two samples × two readings).

Statistical Analysis

All data was analysed for means, standard deviations and analysis of variance. A t test of variance of data was carried out using SPSS 22 for Windows (SPSS Statistical software, IBM Corp., Armonk, NY, USA) software package. A difference between pairs of means was resolved by means of confidence intervals using Tukey’s test. The level of significance was set at p < 0.05.

Results and Discussion

Characterisation of Silver Nanoparticles

TEM Image

The TEM image indicated that the primary size of the synthesised Ag NPs was in the nanometer size range (see Supplementary S1). The synthesised Ag NPs had a spherical shape with an average particle size of 19.79 ± 5.51 nm.

XRD and EDS

The XRD pattern of Ag NPs (Fig. 1) was compared to standard data from the International Centre of Diffraction Data (ICDD). Four peaks for Ag NPs appeared at 37.44°, 44.43°, 50.43° and 61.30° and can be attributed to the (1 1 1), (2 0 0), (2 2 0) and (3 1 1) reflections of elemental Ag (JCPDS number 04-0783). XRD results for synthesised Ag NPs are in agreement with data presented by Shameli et al. (2012). Ruparelia et al. (2008) reported that high atom density facets of (1 1 1) were highly reactive compared to other face-centred cubic planes.

The elemental composition of synthesised Ag NPs determined using EDS (Fig. 2) indicated the presence of carbon peaks in the Ag NPs profile, and these may derive from the PVP nanoparticle stabiliser (Silva et al. 2014). The same author also suggested that the peaks can arise from the carbon tape that was used to attach Ag NPs or through the exposure of metals to atmospheric conditions. Existence of an oxygen peak in the Ag NP profile suggested the presence of an oxide layer (Ren et al. 2009). No other peak was detected in the EDS profile which indicated that the Ag NPs utilised in this study were of a high purity (data not shown).

UV–Vis Spectroscopy

The presence of Ag NPs in ethanolic solutions was confirmed by the absorption peak of the spectra obtained using UV–Vis spectrometer (Fig. 3). An absorbance peak at 420 nm in the ethanolic solution spectrum indicated the formation of Ag NPs. Similar results were reported by Ajitha et al. (2015) who synthesised Ag NPs using sodium borohydride as a reducing agent.

Antimicrobial Activity

Antimicrobial activity for Ag NPs indicated that all bacteria tested were susceptible to Ag NPs. The results of DIZ (Fig. 4a) showed that Gram-negative bacteria (P. fluorescens and E. coli) were more susceptible than were Gram-positive bacteria (S. aureus and B. cereus) and that microflora isolated from food products (chicken, beef and cooked ham) were less sensitive against Ag NPs compared to pure culture bacteria. However, antimicrobial activity of Ag NPs against microflora from raw beef was 35.1 % higher than streptomycin, indicating that antimicrobial activity of Ag NPs depended on the background microflora isolated from the meat product. Jay et al. (2005) reported that higher number of Gram-negative bacteria such as Moraxella, Psychrobacter, and Aeromonas are found on red meat than in poultry meat, and this may explain why microflora isolated from raw beef was more susceptible to Ag NPs compared to microflora isolated from raw chicken breast fillets. The DIZ values for S. aureus, B. cereus, chicken, beef or ham microflora were in the range of 9–15 mm, indicating that they were sensitive to Ag NPs according to the classification outlined by Azevedo et al. (2014). However, DIZ for P. fluorescens was 16.84 mm, indicating that this microorganism was very sensitive to Ag NPs. Similar results were reported by Kamrupi et al. (2011) on Ag-polystyrene nanocomposites with a higher DIZ for P. fluorescens compared to S. aureus and E. coli.

a Diameter of inhibition zone (DIZ) and b minimum inhibition concentration of silver nanoparticles (red bars) against Escherichia coli, Staphylococcus aureus, Bacillus cereus, Pseudomonas fluorescens or microflora derived from raw chicken, raw beef and cooked ham with streptomycin (white bars) as a control. The results are the average of six replicates (two independent experiments × three measurements). The DIZ of silver nanoparticles are presented as percentage (%) of control (streptomycin) samples

The MIC for Ag NPs against pure culture bacteria and microflora isolated from meat products is shown in Fig. 4b. In general, Gram-positive bacteria were more resistant than Gram-negative bacteria. Of all the bacteria tested in this study, the most sensitive bacteria were P. fluorescens (MIC = 0.004 %), while the most resistant to Ag NPs were S. aureus (MIC = 0.029 %). Among the three meat microflora tested, beef-derived microflora showed the least susceptibility against Ag NPs which had an MIC value =0.016 %. Similar MIC values were obtained for E. coli, B. cereus, chicken-derived microflora and cooked ham-derived microflora (MIC = 0.0113 %).

Overall, the data showed that all pure culture bacteria were more susceptible to Ag NPs compared to the microflora isolated from raw chicken, raw beef or cooked ham. This may be due to the fact that microflora from meat products are more complex systems with heterogeneous populations of Gram-positive and Gram-negative bacteria and which could have different resistances to the antimicrobial compared to pure cultures of the homogeneous population of each Gram-positive or Gram-negative bacterial strain (Lianou and Koutsoumanis 2013; Pin and Baranyi 1998). This critical difference can lead to lower susceptibility of food microflora against Ag NPs compared to pure culture bacteria. Lower susceptibility rate of meat microflora against food grade nano-sized solubilisates compared to pure culture bacteria was also reported by Cruz-Romero et al. (2013).

The difference in antimicrobial resistances can be explained by the properties of the bacterial cell membrane which are highly specific to the respective bacterial strain; for example, Gram-negative cell membranes are chemically and structurally more complex but possess a thinner layer of peptidoglycans compared to Gram-positive bacterial equivalents (Hajipour et al. 2012). Since the antibacterial effects of Ag NPs involve the penetration of the Ag NPs into the cell, therefore Gram-negative bacteria may be more susceptible than Gram-positive bacteria, owing to the influence of the cell membrane structure (Pelgrift and Friedman 2013).

Characterisation of PVC Films or PVC Nanocomposite Films

Thermal and Mechanical Properties

Thermal analysis indicated that the glass transition temperature (T g) of PVC films were 95 °C and that the addition of 0.5 wt.% of Ag NPs into the PVC polymer matrix significantly (p < 0.05) decreased the T g value to 72 °C. This noticeable decrease on T g values may be due to van der Waals interactions between Ag NPs and the PVC polymer chains (Olad et al. 2013). Hanemann and Szabó (2010) have suggested that the repulsive force between NPs and the interfacial layer may lead to polymer chain mobility, thus yielding plasticizing effects by decreasing the T g value. Conversely, Elashmawi et al. (2010) showed that T g values increased for PVC films containing ZnO (2.5–15 wt.%). These differences may be due to the concentration or type of nanomaterial used in the manufacture of PVC nanocomposite films.

TS and EAB values for PVC films or Ag/PVC nanocomposite films are shown in Table 1. No significant difference (p > 0.05) was observed in TS and EAB values for Ag/PVC nanocomposite films compared to PVC control films. The small differences in the mechanical properties may be due to the lower concentration of Ag NPs added to the polymer matrix. Moloney et al. (2012) reported that concentrations of Ag NPs higher than 2.5 % negatively affected the mechanical properties of the PVC nanocomposite films. These results are in agreement with data reported by Chinkamonthong et al. (2012) who showed no significant changes (p > 0.05) in TS and Young Modulus values when nano-Ag colloids were inserted into the PVC matrix compared to control films; however, a significant reduction (p < 0.05) in EAB values was observed.

Colour Changes

The colour changes produced after insertion of Ag NPs into the PVC matrix is shown in Table 1. L-values for the films indicated that Ag/PVC nanocomposite films were darker (p < 0.05) than PVC control films. Regarding a-value and b-values, incorporation of Ag NPs into the PVC matrix increased (p < 0.05) the blueness and yellowness of the Ag/PVC nanocomposite films compared to PVC control films. Similar results were obtained by Rhim et al. (2013) where Ag nanocomposite films had significantly (p < 0.05) lower L-values and higher b-values of compared to control films. The total colour difference (ΔE*) classification indicated that Ag/PVC nanocomposite films were very distinctive compared to PVC control films. Similarly, Kanmani and Rhim (2014) reported significant changes on the ΔE* on gelatin nanocomposite films when compared to control films .

Shelf-Life Study

The poultry industry uses TVC, Pseudomonas spp., LAB and total coliform counts as indicators of processing hygiene and microbiological quality (Bolton et al. 2013). Chicken products are not only considered spoiled due to the presence of high bacterial counts (>log 7 CFU g−1) but also when discoloration, off-smelling odors and/or slime appear due to development of psychrotrophic bacteria, especially Pseudomonas spp. (Bolton et al. 2013). The recommended microbiological limits of acceptability for raw chicken is 5–7 log CFU g−1 (ICMFS 1990). Thus, in this study, a marginal value of 6 log CFU g−1 for TVC was set as the maximum limit of acceptability. Changes in TVC, Pseudomonas spp. and LAB of MAP-packed chicken breast fillets during chilled storage are shown in Fig. 5.

Microbiological count of a total viable count, b Pseudomonas spp. and c lactic acid bacteria of chicken breast fillets during chilled storage under MAP condition using (circle) PVC control films or (black triangle) Ag/PVC nanocomposite films. Error bars represent standard deviation of analysis from eight readings

The initial microbiological quality of a food product significantly impacts upon the antimicrobial performance of Ag NPs. To obtain a longer shelf-life for a food product, the initial quality of the foodstuff has to be of a superior nature because the active packaging containing NPs and used for the same said foodstuff can only maintain the existing quality of the food product or delay the onset of spoilage by controlling the factors that contribute to microbiological spoilage. The initial TVC value of the chicken breast fillets was 3.8 log CFU g−1, thereby indicating good chicken meat quality.

Regardless of the packaging system used to pack the chicken breast fillets, TVC increased over time. Throughout the storage period, the TVCs of chicken breast fillets were higher for chicken breast fillets wrapped with PVC control films and which reached the upper limit of 6 log CFU g−1 by day 5 of storage. However, for chicken breast fillets wrapped with antimicrobial Ag/PVC nanocomposite films, the set limit of acceptability was reached by day 6 of storage. The antimicrobial Ag/PVC nanocomposite packaging films effectively prolonged the TVC lag phase on chicken breast fillets compared to control films (Fig. 5a) and therefore extended the shelf-life of chicken meat. Panea et al. (2014) reported that the use of LDPE nanocomposite films containing Ag and ZnO NPs increased (p < 0.05) the shelf-life of chicken breast fillets for more than 2 days compared to control films, even though the concentration of Ag antimicrobial was tenfold higher than the concentration of Ag NPs used in the present study (0.5 %).

Conversely, the initial value of Pseudomonas spp. was 3.6 log CFU g−1, but this value increased throughout storage (Fig. 5b). It was also noticed that Pseudomonas spp. was one of the dominant spoilage microorganisms at the end of the shelf-life (∼6 days), with a value of 5.0 log CFU g−1. Slower growth (p < 0.05) of Pseudomonas spp. was observed in chicken breast fillets wrapped with Ag/PVC nanocomposite films from the beginning of storage until day 6 of storage time compared to PVC control films. Similar results were also reported by Latou et al. (2014) who found that Pseudomonas spp. were the main spoilage microorganisms present on fresh meat.

The initial count for LAB on chicken breast fillets was 3.3 log CFU g−1, but counts increased significantly (p < 0.05) during chilled storage (Fig. 5c). However, the LAB count did not exceed the log 6 CFU g−1 after 9 days of storage, regardless of the PVC film treatment used. However, in a previous study, Azlin-Hasim et al. (2015) found that LAB on chicken breast fillets stored at 4 °C under MAP exceeded the log 6 CFU g−1 after 6 days of storage. The differences may be due to that in the present study, the main spoilage microorganism of chicken breast fillets was Pseudomonas spp. (Figure 5b). No significant differences (p > 0.05) were observed in relation to total coliform counts during chicken breast storage, regardless of the type of packaging film used to wrap the chicken fillets (data not shown).

The results of the antimicrobial activity study (see “Antimicrobial Activity” section) show that microflora from raw or cooked meat products showed higher resistance to Ag NPs compared to pure culture bacteria. Apart from that, Ilg and Kreyenschmidt (2011) reported that antimicrobial activity of Ag NPs can be affected by food components and low antimicrobial activity of Ag NPs may be due to the presence of protein functional groups in the chicken breast fillets that can potentially bind with Ag+ and reduce the potency of antimicrobial activity of Ag NPs. Direct insertion of Ag NPs into PVC can be ineffective since the dispersion of the Ag NPs can be non-homogeneous and the majority of them are not in direct contact with the food product, and, further, the antimicrobial effects become highly mass transport limited (Kumar et al. 2005). This may explain the low activity of Ag/PVC nanocomposite films when tested on the shelf-life of chicken breast fillets.

Physicochemical Changes During Chilled Storage of the Chicken Breast Fillets

Colour Changes During Storage of the Chicken Meat

The effects of PVC control or Ag/PVC nanocomposite films on the colour of chicken breast fillets are shown in Fig. 6. During storage, the L-values (lightness) of chicken meat wrapped with PVC control or Ag/PVC nanocomposite films increased (p < 0.05) up to day 3; however, a gradual decrease (p < 0.05) was noticed throughout the remaining storage period (Fig. 6a). This indicated that the colour of the chicken meat darkened during storage time, and this may relate to protein decomposition within the muscle amongst other processes (Latou et al. 2014). The results are in agreement with the results reported by Petrou et al. (2012), who found that lightness of chicken meat stored at 4 °C increased significantly during storage for up to 6 days, followed by a gradual decrease to the end of the shelf-life (12 days). The a-values (redness) of chicken meat increased (p < 0.05) during the storage period independent of the film used (PVC control or Ag/PVC nanocomposite films) as a wrapping material (Fig. 6b). Conversely, the b-values (yellowness) of chicken breast fillets packaged using PVC control films decreased (p < 0.05) while the b-values of chicken wrapped with Ag/PVC nanocomposite films increased (p < 0.05) compared to control films at the end of storage (Fig. 6c). In a previous study, Azlin-Hasim et al. (2015) reported that there were no significant changes in a- or b-values during storage of chicken breast fillets wrapped with Ag/LDPE nanocomposite films, and this may be due to the material used as a polymer matrix to insert Ag NPs. Using the classification scale for ∆E* reported by Cruz-Romero et al. (2007), it can generally be concluded that during storage regardless of the type of PVC films used to wrap chicken breast fillets, it resulted in very distinct colour differences. Taking as a reference the initial colour of unwrapped chicken at day 0, the ∆E* increased significantly (p < 0.05) during storage and the highest colour difference was obtained at day 3, resulting in very distinct significant differences (Fig. 6d).

Changes in a L-values, b a-values, c b-values and d ∆E* of chicken breast fillets wrapped with PVC control films (white bars) or Ag/PVC nanocomposite films (red bars) during storage time under MAP conditions. Error bars represent standard deviation of analysis from forty readings. Values with different letters are statistically different (p < 0.05) amongst treatments in the same storage day (a, b) or during storage (A, B, C).

Lipid Oxidation

Generally, chicken meat contains high levels of unsaturated fatty acids and low levels of natural antioxidants such as vitamin E which make this product susceptible to lipid oxidation (Gatellier et al. 2007). The effects of the packaging systems employed in this study on the lipid oxidation stability of chicken breast fillets are shown in Fig. 7. The mean initial TBARS value for fresh chicken breast fillets was 0.12 mg MDA kg−1. Similar values were reported by Azlin-Hasim et al. (2015). Irrespective of the packaging system used to pack chicken breast fillets, TBARS values increased (p < 0.05) during chilled storage. The TBARS values for chicken breast fillets packed using Ag/PVC were lower (p < 0.05) from day 6 to the end of storage compared to samples packed using PVC control films. Results indicated that the presence of Ag NPs in the polymer matrix can delay or lower lipid oxidation in chicken breast fillets. Similar results were reported by Panea et al. (2014) who obtained lower TBARS values for chicken meat when wrapped with LDPE films containing Ag and ZnO NPs.

Effects on TBARS values (mg MDA kg−1) of chicken breast fillets using PVC control films (white bars) or PVC nanocomposite films containing Ag NPs (0.5 %) (red bars) during storage time under MAP conditions. Error bars represent standard deviation of analysis from eight readings. Values with different letters are statistically different (p < 0.05) amongst treatments in the same storage day (a, b) or during storage (A, B, C, D)

Conclusions

Antimicrobial activity indicated that all bacteria tested (pure culture and microflora isolated from meat products) were sensitive to Ag NPs and that Gram-negative bacteria were more susceptible to Ag NPs than Gram-positive bacteria. The addition of Ag NPs significantly reduced the thermal properties of PVC films, while no changes were observed in relation to mechanical properties. PVC nanocomposite films containing Ag NPs significantly (p < 0.05) extended the product shelf-life and reduced the lipid oxidation of packed chicken breast fillets. Results also indicated that the initial microbiological quality of the chicken fillets used in this study significantly affected the performance of the Ag NPs. Therefore, in order to obtain an increased shelf-life for a food product, the initial quality of the foodstuff has to be of the highest quality such that the active packaging material employed can impact positively on microbial control and shelf-life extension. As evidenced by these results, the use of Ag/PVC nanocomposite films has the potential to be used as antimicrobial packaging, especially in food packaging applications.

References

Ajitha, B., Ashok Kumar Reddy, Y., & Sreedhara Reddy, P. (2015). Enhanced antimicrobial activity of silver nanoparticles with controlled particle size by pH variation. Powder Technology, 269, 77110–117.

Altan, M., & Yildirim, H. (2012). Mechanical and antibacterial properties of injection molded Polypropylene/TiO2 nano-composites: effects of surface modification. Journal of Materials Science & Technology, 28(8), 686–692.

An, J., Zhang, M., Wang, S., & Tang, J. (2008). Physical, chemical and microbiological changes in stored green asparagus spears as affected by coating of silver nanoparticles-PVP. LWT Food Science and Technology, 41(6), 1100–1107.

Anyaogu, K. C., Fedorov, A. V., & Neckers, D. C. (2008). Synthesis, characterization, and antifouling potential of functionalized copper nanoparticles. Langmuir : The ACS Journal of Surfaces and Colloids, 24(8), 4340–6.

Appendini, P., & Hotchkiss, J. H. (2002). Review of antimicrobial food packaging. Innovative Food Science & Emerging Technologies, 3, 113–126.

ASTM. (2002). Standard test method for tensile properties of thin plastic sheeting. Designation: D882-02. In Annual book of American standards testing methods standard (pp. 168–177). Philadelphia.

Azevedo, A. N., Buarque, P. R., Cruz, E. M. O., Blank, A. F., Alves, P. B., Nunes, M. L., & Santana, L. C. L. D. A. (2014). Response surface methodology for optimisation of edible chitosan coating formulations incorporating essential oil against several foodborne pathogenic bacteria. Food Control, 43, 1–9.

Azlin-Hasim, S., Cruz-Romero, M. C., Morris, M. A., Cummins, E., & Kerry, J. P. (2015). Effects of a combination of antimicrobial silver low density polyethylene nanocomposite films and modified atmosphere packaging on the shelf life of chicken breast fillets. Food Packaging and Shelf Life, 1–10.

Badiou, W., Lavigne, J.-P., Bousquet, P.-J., O’Callaghan, D., Marès, P., & de Tayrac, R. (2011). In vitro and in vivo assessment of silver-coated polypropylene mesh to prevent infection in a rat model. International Urogynecology Journal, 22(3), 265–272.

Becerra, A., Rodriguez-Llamazares, S., Carrasco, C., Diaz-Visurraga, J., Riffo, C., & Mondaca, M. (2012). Preparation of poly(vinyl chloride)/copper nanocomposite films with reduced bacterial adhesion. High Performance Polymers, 25(1), 51–60.

Bolton, D. J., Meredith, H., Walsh, D., & McDowell, D. A. (2013). The effect of chemical treatments in laboratory and broiler plant studies on the microbial status and shelf-life of poultry. Food Control, 36(1), 230–237.

Chen, D., Qiao, X., Qiu, X., & Chen, J. (2009). Synthesis and electrical properties of uniform silver nanoparticles for electronic applications. Journal of Materials Science, 44(4), 1076–1081.

Chen, Z., Zhu, C., Zhang, Y., Niu, D., & Du, J. (2010). Effects of aqueous chlorine dioxide treatment on enzymatic browning and shelf-life of fresh-cut asparagus lettuce (Lactuca sativa L.). Postharvest Biology and Technology, 58(3), 232–238.

Cheng, Q., Li, C., Pavlinek, V., Saha, P., & Wang, H. (2006). Surface-modified antibacterial TiO2/Ag+ nanoparticles: preparation and properties. Applied Surface Science, 252(12), 4154–4160.

Chinkamonthong, R., Kositchaiyong, A., & Sombatsompop, N. (2012). Effects of thermal and UV aging on antibacterial properties of linear low-density polyethylene and poly(vinyl chloride) films containing nano-silver colloid. Journal of Plastic Film and Sheeting, 29(2), 144–162.

CLSI. (2007). Performance standards for antimicrobial disk susceptibility tests. Approved standard M2-A9 (9th ed.). Clinical and Laboratory Standards Institute, Wayne, PA, USA: CLSI publication.

Costa, C., Conte, A., Buonocore, G. G., & Del Nobile, M. A. (2011). Antimicrobial silver-montmorillonite nanoparticles to prolong the shelf life of fresh fruit salad. International Journal of Food Microbiology, 148(3), 164–7.

Cruz-Romero, M., Kelly, A. L., & Kerry, J. P. (2007). Effects of high-pressure and heat treatments on physical and biochemical characteristics of oysters (Crassostrea gigas). Innovative Food Science & Emerging Technologies, 8(1), 30–38.

Cruz-Romero, M. C., Murphy, T., Morris, M., Cummins, E., & Kerry, J. P. (2013). Antimicrobial activity of chitosan, organic acids and nano-sized solubilisates for potential use in smart antimicrobially-active packaging for potential food applications. Food Control, 34(2), 393–397.

Cushen, M., Kerry, J., Morris, M., Cruz-Romero, M., & Cummins, E. (2012). Nanotechnologies in the food industry—recent developments, risks and regulation. Trends in Food Science & Technology, 24(1), 30–46.

Cushen, M., Kerry, J., Morris, M., Cruz-Romero, M., & Cummins, E. (2013). Migration and exposure assessment of silver from a PVC nanocomposite. Food Chemistry, 139(1–4), 389–397.

EC. (2002). Commission Directive 2002/72/EC of 6 August 2002 relating to plastic materials and articles intended to come into contact with foodstuffs. Official Journal of the European Communities, 18–58.

Egger, S., Lehmann, R. P., Height, M. J., Loessner, M. J., & Schuppler, M. (2009). Antimicrobial properties of a novel silver-silica nanocomposite material. Applied and Environmental Microbiology, 75(9), 2973–6.

Elashmawi, I. S., Hakeem, N. A., Marei, L. K., & Hanna, F. F. (2010). Structure and performance of ZnO/PVC nanocomposites. Physica B: Condensed Matter, 405(19), 4163–4169.

Emamifar, A., Kadivar, M., Shahedi, M., & Soleimanian-Zad, S. (2010). Evaluation of nanocomposite packaging containing Ag and ZnO on shelf life of fresh orange juice. Innovative Food Science & Emerging Technologies, 11(4), 742–748.

Emamifar, A., Kadivar, M., Shahedi, M., & Soleimanian-Zad, S. (2011). Effect of nanocomposite packaging containing Ag and ZnO on inactivation of Lactobacillus plantarum in orange juice. Food Control, 22(3–4), 408–413.

Espinosa-Cristóbal, L. F., Martínez-Castañón, G. A., Martínez-Martínez, R. E., Loyola-Rodríguez, J. P., Patiño-Marín, N., Reyes-Macías, J. F., & Ruiz, F. (2009). Antibacterial effect of silver nanoparticles against Streptococcus mutans. Materials Letters, 63(29), 2603–2606.

Fernández-Pan, I., Carrión-Granda, X., & Maté, J. I. (2014). Antimicrobial efficiency of edible coatings on the preservation of chicken breast fillets. Food Control, 36(1), 69–75.

FMI (2015). Next Generation Packaging Market: Global Industry Analysis and Opportunity Assessment 2015–2025. Retrieved October 6, 2015, from http://www.reuters.com/article/2015/09/09/ny-fmi-idUSnBw096260a+100+BSW20150909

Gatellier, P., Gomez, S., Gigaud, V., Berri, C., Bihan-Duval, E. L., & Santé-Lhoutellier, V. (2007). Use of a fluorescence front face technique for measurement of lipid oxidation during refrigerated storage of chicken meat. Meat Science, 76(3), 543–547.

Hajipour, M. J., Fromm, K. M., Ashkarran, A. A., Jimenez de Aberasturi, D., de Larramendi, I. R., Rojo, T., & Mahmoudi, M. (2012). Antibacterial properties of nanoparticles. Trends in Biotechnology, 30(10), 499–511.

Hanemann, T., & Szabó, D. V. (2010). Polymer-nanoparticle composites: from synthesis to modern applications. Materials, 3(6), 3468–3517.

Hannon, J. C., Cummins, E., Kerry, J., Cruz-Romero, M., & Morris, M. (2015). Advances and challenges for the use of engineered nanoparticles in food contact materials. Trends in Food Science & Technology, 43(1), 43–62.

ICMFS. (1990). Microorganisms in foods 2. Sampling for microbiological analysis: Principles and specific applications. In International Commission on Microbiological Specifications for Foods (2nd ed., pp. 148–156). Blackwell Scientific Publications.

Ilg, Y., & Kreyenschmidt, J. (2011). Effects of food components on the antimicrobial activity of polypropylene surfaces containing silver ions (Ag+). International Journal of Food Science & Technology, 46(7), 1469–1476.

Incoronato, A. L., Conte, A., Buonocore, G. G., & Del Nobile, M. A. (2011). Agar hydrogel with silver nanoparticles to prolong the shelf life of Fior di Latte cheese. Journal of Dairy Science, 94(4), 1697–704.

Jay, J. M., Loessner, M. J., & Golden, D. A. (2005). Fresh Meats and Poultry. In J. M. Jay, M. J. Loessner, & D. A. Golden (Eds.), Modern Food Microbiology (7th edn., pp. 63–100). US: Springer.

Kaegi, R., Voegelin, A., Sinnet, B., Zuleeg, S., Hagendorfer, H., Burkhardt, M., & Siegrist, H. (2011). Behavior of metallic silver nanoparticles in a pilot wastewater treatment plant. Environmental Science and Technology, 45(9), 3902–3908.

Kamrupi, I. R., Phukon, P., Konwer, B. K., & Dolui, S. K. (2011). Synthesis of silver-polystyrene nanocomposite particles using water in supercritical carbon dioxide medium and its antimicrobial activity. Journal of Supercritical Fluids, 55(3), 1089–1094.

Kanmani, P., & Rhim, J.-W. (2014). Physicochemical properties of gelatin/silver nanoparticle antimicrobial composite films. Food Chemistry, 148, 162–9.

Kim, K.-J., Sung, W. S., Suh, B. K., Moon, S.-K., Choi, J.-S., Kim, J. G., & Lee, D. G. (2009). Antifungal activity and mode of action of silver nano-particles on Candida albicans. BioMetals, 22(2), 235–242.

Kumar, R., Howdle, S., & Münstedt, H. (2005). Polyamide/silver antimicrobials: effect of filler types on the silver ion release. Journal of Biomedical Materials Research. Part B, Applied Biomaterials, 75(2), 311–9.

Lara, H. H., Ayala-Nuñez, N. V., Ixtepan-Turrent, L., & Rodriguez-Padilla, C. (2010). Mode of antiviral action of silver nanoparticles against HIV-1. Journal of Nanobiotechnology, 8, 1.

Latou, E., Mexis, S. F., Badeka, A. V., Kontakos, S., & Kontominas, M. G. (2014). Combined effect of chitosan and modified atmosphere packaging for shelf life extension of chicken breast fillets. LWT - Food Science and Technology, 55(1), 263–268.

Lianou, A., & Koutsoumanis, K. P. (2013). Strain variability of the behavior of foodborne bacterial pathogens: a review. International Journal of Food Microbiology, 167(3), 310–321.

Liu, F., Liu, H., Li, X., Zhao, H., Zhu, D., Zheng, Y., & Li, C. (2012). Nano-TiO2@Ag/PVC film with enhanced antibacterial activities and photocatalytic properties. Applied Surface Science, 258(10), 4667–4671.

Marambio-Jones, C., & Hoek, E. M. V. (2010). A review of the antibacterial effects of silver nanomaterials and potential implications for human health and the environment. Journal of Nanoparticle Research, 12(5), 1531–1551.

Mexis, S. F., Chouliara, E., & Kontominas, M. G. (2012). Shelf life extension of ground chicken meat using an oxygen absorber and a citrus extract. LWT - Food Science and Technology, 49(1), 21–27.

Moloney, C., Cruz-Romero, M., Morris, M., Cummins, E., & Kerry, J. P. (2012). Effect of metal nanoparticles on the mechanical properties of low-density polyethylene-based and polyvinylchloride-based nanocomposite films. In 2 nd international meeting on materials/bioproduct interactions (MATBIM). France: Dijon.

Navarro, E., Piccapietra, F., Wagner, B., Marconi, F., Kaegi, R., Odzak, N., & Behra, R. (2008). Toxicity of silver nanoparticles to Chlamydomonas reinhardtii. Environmental Science and Technology, 42(23), 8959–8964.

NCCLS. (2000). Methods for dilution antimicrobial susceptibility tests for bacteria that grow aerobically—Fifth edition: Approved standard M7-A5. (NCCLS, Ed.). Wayne, PA, USA.

Olad, A., Behboudi, S., & Entezami, A. A. (2013). Effect of polyaniline as a surface modifier of TiO2 nanoparticles on the properties of polyvinyl chloride/TiO2 nanocomposites. Chinese Journal of Polymer Science, 31(3), 481–494.

Palza, H. (2015). Antimicrobial polymers with metal nanoparticles. International Journal of Molecular Sciences, 16(1), 2099–2116.

Panea, B., Ripoll, G., González, J., Fernández-Cuello, Á., & Albertí, P. (2014). Effect of nanocomposite packaging containing different proportions of ZnO and Ag on chicken breast meat quality. Journal of Food Engineering, 123, 104–112.

Park, H.-J., Kim, J. Y., Kim, J., Lee, J.-H., Hahn, J.-S., Gu, M. B., & Yoon, J. (2009). Silver-ion-mediated reactive oxygen species generation affecting bactericidal activity. Water Research, 43(4), 1027–32.

Pelgrift, R. Y., & Friedman, A. J. (2013). Nanotechnology as a therapeutic tool to combat microbial resistance. Advanced Drug Delivery Reviews, 65(13–14), 1803–1815.

Peterson, R. D., Cunningham, B. T., & Andrade, J. E. (2014). A photonic crystal biosensor assay for ferritin utilizing iron-oxide nanoparticles. Biosensors and Bioelectronics, 56, 320–327.

Petrou, S., Tsiraki, M., Giatrakou, V., & Savvaidis, I. N. (2012). Chitosan dipping or oregano oil treatments, singly or combined on modified atmosphere packaged chicken breast meat. International Journal of Food Microbiology, 156(3), 264–271.

Pin, C., & Baranyi, J. (1998). Predictive models as means to quantify the interactions of spoilage organisms. International Journal of Food Microbiology, 41(1), 59–72.

Ren, G., Hu, D., Cheng, E. W. C., Vargas-Reus, M. A., Reip, P., & Allaker, R. P. (2009). Characterisation of copper oxide nanoparticles for antimicrobial applications. International Journal of Antimicrobial Agents, 33(6), 587–90.

Restuccia, D., Spizzirri, U. G., Parisi, O. I., Cirillo, G., Curcio, M., Iemma, F., & Picci, N. (2010). New EU regulation aspects and global market of active and intelligent packaging for food industry applications. Food Control, 21(11), 1425–1435.

Rhim, J. W., Wang, L. F., & Hong, S. I. (2013). Preparation and characterization of agar/silver nanoparticles composite films with antimicrobial activity. Food Hydrocolloids, 33(2), 327–335.

Ruparelia, J. P., Chatterjee, A. K., Duttagupta, S. P., & Mukherji, S. (2008). Strain specificity in antimicrobial activity of silver and copper nanoparticles. Acta Biomaterialia, 4(3), 707–16.

Seil, J. T., & Webster, T. J. (2011). Reduced Staphylococcus aureus proliferation and biofilm formation on zinc oxide nanoparticle PVC composite surfaces. Acta Biomaterialia, 7(6), 2579–84.

Shameli, K., Ahmad, M. B., Jazayeri, S. D., Shabanzadeh, P., Sangpour, P., Jahangirian, H., & Gharayebi, Y. (2012). Investigation of antibacterial properties silver nanoparticles prepared via green method. Chemistry Central Journal, 6(1), 73.

Shang, L., Bian, T., Zhang, B., Zhang, D., Wu, L.-Z., Tung, C.-H., & Zhang, T. (2014). Graphene-supported ultrafine metal nanoparticles encapsulated by mesoporous silica: robust catalysts for oxidation and reduction reactions. Angewandte Chemie, 126(1), 254–258.

Sharma, V. K., Yngard, R. A., & Lin, Y. (2009). Silver nanoparticles: green synthesis and their antimicrobial activities. Advances in Colloid and Interface Science, 145(1–2), 83–96.

Silva, E., M. Saraiva, S., P. Miguel, S., & Correia, I. J. (2014). PVP-coated silver nanoparticles showing antifungal improved activity against dermatophytes. Journal of Nanoparticle Research, 16(11).

Siu, G. M., & Draper, H. H. (1978). A survey of malonaldehyde content of retail meats and fish. Journal of Food Science, 43, 1147–1149.

Sondi, I., & Salopek-Sondi, B. (2004). Silver nanoparticles as antimicrobial agent: a case study on E. coli as a model for Gram-negative bacteria. Journal of Colloid and Interface Science, 275(1), 177–82.

Zhou, L., Lv, S., He, G., He, Q., & Shi, B. (2011). Effect of PE/Ag2O nano-packaging on the quality of apple slices. Journal of Food Quality, 34(3), 171–176.

Acknowledgments

The author, Azlin-Hasim, would like to thank the Ministry of Education of Malaysia (MOE) for the PhD scholarship. The funding for this research was provided under the National Development, through the Food Institutional Research Measure (FIRM) administered by the Department of Agriculture, Fisheries and Food.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 94 kb)

Rights and permissions

About this article

Cite this article

Azlin-Hasim, S., Cruz-Romero, M.C., Morris, M.A. et al. The Potential Application of Antimicrobial Silver Polyvinyl Chloride Nanocomposite Films to Extend the Shelf-Life of Chicken Breast Fillets. Food Bioprocess Technol 9, 1661–1673 (2016). https://doi.org/10.1007/s11947-016-1745-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-016-1745-7