Abstract

Computational fluid dynamics (CFD) modeling of entire bread baking process is very complicated due to involvement of simultaneous physiochemical and biological transformations. Bread baking is a fickle process where composition, structure, and physical properties of bread change during the process. CFD finds its application in modeling of such complex processes. This paper provides the basics of CFD modeling, different radiation models used for modeling of heating in electrical heating ovens, modeling of bread baking process along with the predictions of bread temperature, starch gelatinization, and browning index. In addition, some recent approaches in numerical modeling of bread baking process are highlighted. Moreover, current limitations, recent developments, and future applications in CFD modeling of bread baking process are discussed in detail.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Bread is closely related to people’s daily life, and bread baking is a food processing technique in which series of complex physical, chemical, and biochemical changes take place simultaneously in the given product. During the baking process of cereal products, semi-fluid dough transforms into bread, cake, biscuits, or cookies. Under the influence of heat, raw dough piece is transformed into a light, porous, readily digestible, and flavorful bakery product. Although bread baking had been in practice for a very long time, comprehensive understanding of physical processes in baking is still lacking (Cauvain 2003).

Freshly baked bread has pleasant aroma, golden brown crust, and a white crumb with fine porous structure (Cauvain 2003). Bread quality depends mainly on four parameters, i.e., texture, moisture content, bread surface color, and structure (shape and size) of the bread. These four parameters vary during the baking process due to change in operating conditions. All these parameters were temperature-dependent and therefore can be controlled through oven temperature. Water content and temperature were responsible for physiochemical and biological transformations such as evaporation of water, gelatinization of starch, volume expansion, crust formation, denaturation of protein, browning reactions, etc., which make the bread baking a complex process (Therdthai and Zhou 2003). Decock and Cappelle (2005) reviewed various technologies and new market trends in bread baking process. Variations in bread quality can be minimized by proper design of the oven as well as maintaining proper processing conditions such as air temperature, heating power, baking time, and bread size (Therdthai and Zhou 2003; Zhou and Therdthai 2007; Wong et al. 2006b, 2007a, b).

It can be observed in the literature that most of the CFD modeling of baking process was published in the last decade. The increase in use of the CFD in food industry in that period was due to the increase in computational power as well as trained technical people besides the availability of user friendly and robust softwares such as Fluent, CFX, and COMSOL Multiphysics etc. (Williamson and Wilson 2009). Above reports clearly indicate that there is an increase in use of CFD in bread baking process. However, only a few review papers have been published on numerical modeling of baking process (Sablani et al. 1998; Therdthai and Zhou 2003; Mondal and Datta 2008). Wong et al. (2006b) published a review paper on use of CFD techniques for the enhancement of the efficiency of ovens. However, later, there was no comprehensive review article published on CFD applications for bread baking process to accommodate the recent progress. Therefore, the present review is aimed to recapitulate the recent work carried out in CFD modeling of entire bread baking process including baking oven, bread, and physico-chemical transformation inside the bread. This review mainly focuses on the CFD modeling approaches, their strengths, and limitations along with future trends.

Application of CFD in Food Processing

CFD is a numerical tool, which can predict fluid flow, heat and mass transfer, chemical reactions, and other phenomena by solving a set of governing mathematical equations (conservation of mass, momentum, and energy) for discretized cells over a defined space and time domain using high computational power (Anderson 1984).

Although, the origin of CFD can be found in the automotive, aerospace, and nuclear industries, only in the recent years, the CFD has been applied in the area of food processing. The general applications of CFD in the food industry were reviewed by many researchers (Scott and Richardson 1997; Xia and Sun 2002; Anandharamakrishnan 2003; Norton and Sun 2006; Sun 2007). All these reviews concluded that CFD is a powerful and pervasive tool for process and product improvement in food processing sector. Sun (2007) edited a book, which explores applications of CFD in food processing including thermal sterilization, spray drying, baking process, pasteurization of egg, mixing, refrigeration, cooling processes, refrigerated display cabinets, humidification of cold storage, etc. Recently, application of CFD in spray drying process (Kuriakose and Anandharamakrishnan 2010; Anandharamakrishnan et al. 2010b) and spray-freezing (Anandharamakrishnan et al. 2010a) was also reported.

Bread Making Process

Bread making process consists of (1) mixing of ingredients such as flour, water, yeast, and other minor ingredients, (2) dough fermentation, (3) rounding and moulding of dough, (4) proofing; followed by (5) baking of bread in oven, and finally (6) cooling operation. In the literature, most of studies focused only on CFD modeling of baking operation (5th-operation). Therefore, CFD modeling for mixing, fermentation, and proofing operation can be further explored for better understanding of entire bread making process.

Bread Baking Process

Bread baking is considered as an art, and it leads to quality changes in terms of texture, color, and flavor due to several thermal reactions such as non-enzymatic browning reaction, starch gelatinization, protein denaturation, etc. (Therdthai and Zhou 2003). Baking time, oven temperature, source of heat, oven air relative humidity (RH) are the prime factors that decide the quality of bread during baking process. Bread baking parameters are interdependent in affecting its quality; however, temperature is the most dominating parameter (Eliasson and Larsson 1993).

According to Wong et al. (2006a), an ideal baking process can be divided into three stages (Fig. 1). An increase in temperature initiates rapid evaporation of water and release of carbon dioxide that produces oven spring in the first stage of baking. The top crust is thus pushed up followed by crumb development, and finally, gradual color development occurs. The structural changes also occur during the bread baking process, which comprises of solidification and expansion. The network-like structure of bread crumb formation is mainly due to starch gelatinization and protein denaturation. Starch gelatinization is normally used as the baking index. The protein denaturation also occurs under the influence of temperature due to wheat gluten network, where the thermal effect changes gluten gel to coagel (Zhou and Therdthai 2007). The increase in temperature and lower moisture content induce non-enzymatic browning reaction, which results in the crust formation at the surface of the bread. Generally, moisture loss is common for any baked product due to evaporation of water, but it varies with the properties of dough and baking conditions. Maximum moisture loss occurs at the surface of the bread, while moisture at the core region of bread remains unchanged due to evaporation–condensation of water. However, the completion of baking results in two different zones in bread with unique texture, crumb, and crust.

Major events during bread baking process (Wong et al. 2006a)

Simultaneous heat and mass transfer during bread baking is governed by evaporation–condensation mechanism, as shown in Fig. 2. This mechanism occurs in the following steps: (1) water evaporates on the warmer side of the gas cell, absorbing latent heat of vaporization; (2) water vapor migrates through the gas phase, due to vapor concentration gradient inside the cell; (3) water vapor condenses on the colder side of the gas cell and becomes liquid, releasing its latent heat and (4) heat and water transport by conduction and diffusion, respectively, through a dough membrane to the warmer region of the next gas cell, where these processes occur similarly. When the gas phase becomes continuous, the fourth stage no longer exist. This evaporation–condensation mechanism takes place until temperature gradient exists and the temperature of the whole crumb reaches 100 °C (Thorvaldsson and Janestad 1999; Therdthdai and Zhou 2003; Wagner et al. 2007; Purlis and Salvadori 2009a).

Baking Ovens

Baking ovens play an important role in deciding the final product quality of any baking process. Ovens are the integral part of any baking process, which serve as energy source that leads to heat and mass transfer in the product. The success or failure of any baking venture is determined by the oven and its operating conditions. The ovens may be classified based upon scale (size and capacity), product being baked (bread or biscuit, etc.), physical arrangements (batch or continuous), heating source (electrical or hot air), and mode of heating (conductive or convective). In batch baking process, electrical heating ovens are widely used because of their adaptability for different bakery products. Most commonly used continuous bread baking ovens are travelling tray oven and rotary rack oven. Use of impingement oven for the baking was earlier explored by Walker (1987) and Walker and Sparman (1989). Combination of microwave and impingement oven for the bread baking was also explored (Walker and Li 1993). Factors affecting heat distribution in the oven chambers are the location of heating source, air flow, product load, vent position, placement of the bread, and baking time. The product quality varies during the initial period of baking process due to high temperature gradient between the hot oven and product. Initial rate of heat absorption leads to the temperature rise and initiates a number of physical mechanisms. The supply of higher heat resulting in high initial temperature can cause early crust formation, darkening of crust, higher water loss, and low volume expansion (Zhou and Therdthai 2007). However, occasionally, high temperature was applied to make a strong crust initially and later, low temperature, used to complete the baking process.

Sometimes, steam is added to the oven to delay the crust formation. Addition of steam increases the relative humidity of the oven air. As dough surface being cold compared with the surrounding air, moisture condenses onto it from the air, thus delaying crust formation. Once the bread surface reaches the dew point temperature, steam accelerates the temperature rise, thus increasing weight loss from the crust. Occasionally, a fan is used inside the baking oven to increase the convective heat transfer. This results in higher moisture loss from the bread surface, lower softness, and darker surface (Vanin et al. 2009).

During baking process, heat transfer occurs by different modes, namely, radiation, conduction, and convection. Radiation is the most dominant mode in an electrical heating oven. It occurs from red hot heating coils and hot metal surfaces in the form of electromagnetic waves to the surroundings. Radiation occurs by photons, which are emitted by the respective surface and travel in straight lines without attenuation. Heating by radiation depends on emissivity of surface and the higher the emissivity, the higher is the heating rate (Abraham and Sparrow 2002). Air inside the oven is heated when it comes in contact with the heat source (coils) as well as hot metal parts of oven walls. Heat transfer from hot air to the product surface occurs by convection, and heat from metal pan to the bread is transferred by conduction (Sablani et al. 1998). Abraham and Sparrow (2002, 2004), and Sparrow and Abraham (2003) studied extensively the heat transfer in an electrical heating oven with a variety of geometrical, radiative source, and operating conditions of oven besides placement of thermal load.

CFD Modeling of Baking Process

Pre-processing and Solving

The first step of modeling a flow problem is known as pre-processing, which consists of creating geometry of the system, meshing, and specifying the boundary conditions. Geometry can be created using standard drawing platforms linked to CFD software such as GAMBIT, Turbo Grid, CATIA, etc., and meshing into a finite number of cells. The geometry creation and mesh generation are the most time-consuming but very significant steps in the development of a CFD model. Generally, complex geometry needs simplification to make the CFD model solvable while maintaining final geometry reflective enough of the actual process. CFD numerical computation stability, accuracy, and time are significantly influenced by quality and quantity of mesh/grid. Therefore, knowledge of the flow field is required in advance for adjusting the mesh (Wong et al. 2006b; Norton and Sun 2006; Sun 2007). In the complex geometries, unstructured mesh such as triangular and tetrahedral mesh elements are used for the two-dimensional (2D) and three-dimensional (3D) geometry, respectively. Grid resolution studies of baking oven were carried out by Mistry et al. (2006) and Wong et al. (2007a). Mistry et al. (2006) compared difference in prediction between the normal mesh (0.97 million cells) and fine mesh (1.5 million cells). They found only 0.5% difference in thermal field prediction using these approaches for conventional electrical heating oven. Wong et al. (2007a) compared coarse (0.15 million cells), normal (0.19 million cells), and fine (0.27 million cells) meshes for 2D model of industrial continuous bread baking oven. Normal mesh predicts reasonably well the temperature and velocity distribution as that of the fine mesh. However, coarsest mesh fails to reproduce the same (Wong et al. 2007a). Therefore, it can be concluded that the normal mesh gives similar accuracy of fine mesh, but selection of the mesh size totally depends on the problem and geometry of the oven. Nevertheless, normal mesh saves computational time. Anishaparvin et al. (2010) used tetrahedral mesh element for volume meshing, and the density of mesh was higher near heating source, vents, and products, where large gradients of flow properties were expected. Solving turbulence model along the wall needs a high degree of mesh refinement in the boundary layer to appropriately represent flow regime which described by y + criterion. The low Reynolds-number turbulence model requires y + ≤ 1 and high Reynolds-number turbulence model 30 < y + < 500. Meshing should be carried out until the y + criteria are satisfied. There are two types of solvers used in CFD studies, i.e., pressure-based and density-based solvers. Depending on the applications, researchers can select the best suitable grid, solver, and discretization schemes. For more details, readers may refer to standard CFD books (Versteeg and Malalasekera 1995; Sun 2007).

Commercial CFD packages do not contain thermo-physical properties for food materials and codes for kinetic models (starch gelatinization or browning index). However, Open-FOAM (an open source CFD package) has database of some of the thermo-physical properties. Therefore, physical properties need to be externally incorporated. Thermo-physical properties such as specific heat, density, and thermal conductivity can be incorporated as a function of temperature as piecewise linear or polynomial in the material properties or using own user-defined function (UDF) codes to the respective properties. Starch gelatinization kinetic model can be added as integrating external equation during post-processing. However, UDFs have the advantages to solve the equation in each time step, whereas externally solved equations are only based on temperature predictions. Outflow boundary conditions can be used to model flow exits, where the details of the flow velocity and pressure are unknown prior to the solution of flow problem.

Governing Equations

The flow of any fluid can be described using the following transport equations (Fluent, 2006; Versteeg and Malalasekera 1995).

-

(a)

Conservation of mass equation

The continuity equation describes the rate of change of density at a fixed point resulting from the divergence in the mass velocity vector ρv. Eq. 1 is the unsteady, 3D, mass conservation or continuity equation for the simplified case of a constant density fluid (incompressible fluid).

-

(b)

Momentum equation

The principles of the conservation of momentum is an application of Newton’s Second Law of Motion to an element of fluid and states that a small volume of element moving with the fluid is accelerated because of the force acting upon it. The rate of change of velocity (v) per unit volume for a fluid particle is given by \( \frac{{D\underline v }}{{Dt}} \) and density of gas ρ g, hence,

In Eq. 2, the convection terms are on the left side, and the right-hand side are the pressure gradient (p), source terms of gravitational force (g), and stress tensor (\( \underline{\underline \tau } \)), which are responsible for diffusion of momentum.

-

(c)

Energy equation

The first law of thermodynamics states that the time rate of change of internal energy plus kinetic energy is equal to the rate of heat transfer less the rate of work done by system. Fluent solves the energy equation in the following form.

where E is the internal (thermal) energy, k eff is the effective conductivity (k eff = k ta + k t, where, k ta is thermal conductivity and k t is turbulent thermal conductivity), T is the temperature, \( \underline{\underline \tau } \) is stress tensor, and \( {\mathop{{\underline J }}\limits_j} \) is the diffusion flux of species j, h j is the enthalpy of species “j”, and v is the velocity vector. The three terms on the right-hand side of the equation represent energy transfer due to conduction, species diffusion, and viscous dissipation, respectively.

Selection of Laminar or Turbulence Modeling for Oven Simulation

Verboven et al. (2000a, b) developed a model for the electrical forced convection oven using standard and renormalization group, i.e., RNG κ-ε [k- turbulence kinetic energy and ε- turbulence dissipation rate, for a detailed description of turbulence models readers may refer to Versteeg and Malalasekera (1995)] turbulence models and studied the isothermal airflow as well as temperature profile inside the oven. They validated the velocity magnitude predictions with laser Doppler anemometer velocity measurements. The discrepancy in CFD prediction for air velocity was 22% due to the limit of turbulence modeling and numerical grid density. Accuracy of κ-ε turbulence model is limited due to turbulence and wall boundary effect and swirl flow created by fan. Furthermore, Mirade et al. (2004) developed a CFD model for baking tunnel oven to evaluate temperature and air profile during baking process using κ-ε turbulent model. Therdthai et al. (2003, 2004b) and Wong et al. (2006a, 2007a, b) used k-ε turbulence model for industrial continuous bread baking oven since the Reynolds number (N Re) value was high (approx 27,255). Later, Williamson and Wilson (2009) used shear stress transport (SST) k-ω-based turbulent model for fluid flow (natural convection) in combination with radiation heat transfer using a Monte-Carlo ray-tracing technique to develop a CFD model of gas-fired burner with baking oven chamber of industrial baking oven. SST k-ω-based turbulent model switches to a low k-ω Reynolds number treatment when the turbulence level is low, and thus, it does not over-predict the effective eddy viscosity due to turbulent transport. Recently, Boulet et al. (2010) studied flow field and heat transfer in a bakery oven using CFD modeling with realizable κ-ε turbulent model. Their study indicated, under low inlet air velocity, radiation to be the predominant heat transfer mechanism during baking process. Moreover, rate of convective heat transfer was strongly dependent on the turbulent boundary layer, which κ-ε models often fail to predict accurately (Verboven et al. 2000b). Hence, more sophisticated turbulence model is to be used for the better accuracy.

Mistry et al. (2006) used laminar flow to predict the temperature profile during broil and bake cycle for cooking oven (small electrical heating oven). They compared laminar and turbulence models for prediction of thermal field inside the oven cavity and found only 3% difference in the temperature data at thermocouple locations and also observed similar thermal field. Since, model with laminar flow is able to predict the thermal performance with reasonable accuracy with less computational time compared with the turbulent approach. Their model predictions show 2.7% discrepancy for bake cycle and 10% for broil cycle of baking oven. Rayleigh number was used to determine the flow inside the oven (laminar or turbulent), which depends on the oven height and temperature difference across the oven (Mistry et al. 2006). Similarly, Anishaparvin et al. (2010) and Chhanwal et al. (2010, 2011) also considered laminar approach in their electrical heating baking oven simulations.

There are some other computationally expensive but more accurate methodologies such as direct numerical simulation (DNS), detached eddy simulation (DES), and large eddy simulation (LES) for predicting complex turbulent flow and transport phenomena. However, these are not yet used for CFD baking studies, but, in the future, these may find applications due to evolution in computing power. DNS needs intensive computing power due to use of fine mesh and thereby limiting it as a research tool for studying turbulence and heat-transfer dynamics (Sun 2007). DNS offers comprehensive information regarding turbulent flows of solutions with effective control of turbulence and heat transfer and also accounts for buoyancy. On the other hand, LES is an expensive technique used for solving flow containing large turbulent eddies, but offers more accuracy than RANS turbulence model with special filtering for turbulent fluctuation (Turnbull and Thompson 2005). The DES method combines RANS with the quality of flow predictions by wall-resolving LES. In this method, high near-wall resolution can be avoided by applying RANS in the vicinity of the wall and employing a modification of the Spalart–Allmaras, turbulence model equation in the far field. Model blends automatically from a statistical turbulence model to a subgrid-scale model without the use of shape function in the overlap region. DES has the advantage of capturing unsteady flow regions such as wakes and recirculation zones, where the RANS calculation often fails (Schmidt and Thiele 2002). Hence, the DNS, LES, or DES method can be used to increase the accuracy of turbulence model predictions to overcome turbulence and boundary effects as well as to account for the swirl flow created due to fan inside the baking oven.

Selection of Radiation Models

In literature, different types of radiation models such as DTRM (discrete transfer radiation model), S2S (surface to surface), and DO (discrete ordinate) were used for analyzing radiative heat transfer inside baking oven. The main assumption of DTRM is that the radiation leaving the surface element in a certain range of solid angle can be approximated by a single ray. The energy source in the fluid due to the radiation is then computed by summing the change in intensity along the path of each ray that is traced through the fluid control volume. The equation for change of radiant intensity can be written as

where I is radiation intensity watt per steradian, α is gas absorption coefficient (1/meter), s is path length (meters), and σ is Stefan–Boltzmann constant (watts per square meter per Kelvin to the fourth power).

S2S radiation model’s main assumption lies in neglecting all absorption, emission, or scattering of radiation and considering only surface to surface radiation to be significant enough. The energy flux leaving a given surface is composed of directly emitted and reflected energy. The reflected energy flux is dependent on the incident energy flux from the surroundings, which can then be expressed in terms of the energy flux leaving all other surfaces. The energy reflected from surface ‘K’ is

where q out.K is energy flux leaving the surface K (watts per square meter), q in.K is energy flux incident on the surface K from surrounding (watts per square meter),ε K is emissivity of surface K, and ρ K is density (kilograms per cubic meter).

The DO radiation model solves the radiative transfer equation for a finite number of discrete solid angles, each associated with a vector direction fixed in the global Cartesian system. The DO model has following equation

Where \( \vec{r} \) is position vector, \( \vec{s} \) is direction vector, n is refractive index, and α s is absorption coefficient of surface.

The DO model takes into account of media participation (air) in addition to surface-to-surface radiation effect. It also allows the solution of radiation at semi-transparent walls. Hence, DO model may be best suited in problems with localized sources of heat. Computational cost is moderate for typical angular discretization, and memory requirements are also modest (Fluent 2006).

Mistry et al. (2006) studied CFD modeling of heat transfer in batch electric heating oven using S2S radiation model with bake and broil cycle without the product. Initially, they compared DO and S2S radiation models for prediction of the thermal field inside the oven. Authors found that similar thermal field with 0.2% difference in temperature predictions at the center of the oven. They selected S2S model for further study by considering air as non-participating media in radiation mode. However, it was observed that only half of the computational time was required for S2S model compared with DO model for an identical grid. They studied mainly the air flow pattern through vent openings and also comparisons of air temperature during bake and broil cycles. Wong et al. (2007a) used DO radiation model to simulate continuous baking oven involving U-turn movement with sliding mesh. Boulet et al. (2010) used S2S model to predict radiative heat transfer inside a pilot oven. Dhall et al. (2009) modeled a near-infrared oven using DO model to predict heating of cubical food sample. Recently, Chhanwal et al. (2010) compared all three radiation models (i.e., DO, S2S, and DTRM) for domestic electrical heating oven and concluded that predictions by all these radiation models were alike. However, DO model need more computational power and time as compared with the S2S and DTRM models. Combination of convective and radiative heat transfer was considered for both glass door and steel walls of the oven, and heating coils were modeled as volumetric heat source. They also studied temperature profile inside domestic electrical heating oven and found that low temperature zone exists near oven walls.

CFD Modeling of Baking Oven

In recent years, CFD has been applied more and more to the design and development of baking ovens and also to investigate the baking process (Wong et al. 2006b; Zhou and Therdthai 2007). The published research works on CFD simulation of bread baking process with their salient findings are summarized in Table 1. CFD simulation studies initiated for the improvement of oven design and optimizing the baking conditions. In an early study, De Vries et al. (1995) developed a CFD model by assuming laminar flow inside the baking oven and calculated the velocity distribution, pressure drop, temperature, and heat flux. The effect of a perforated plate on improving the homogeneity of the air velocity and pressure drop in the oven was also evaluated. Later, Therdthai et al. (2003) developed a 2D model for industrial continuous bread baking oven to study the temperature and airflow pattern throughout the baking chamber under different operating conditions, including energy source and fan volume. Due to complex geometry of industrial oven, Therdthai et al. (2003) selected 2D geometry instead of 3D and used structural grid system to simulate the oven in 2D by ignoring variations along the oven width. Although CFD results provided constructive information to place the controller sensors at the best possible position, dynamic responses could not be accounted by this 2D model due to its steady-state assumption. Subsequently, the model was extended to a 3D model with moving grid and transient state assumption (Therdthai et al. 2004b). This 3D CFD model described different temperature profiles for different moving trays by simulating the actual movement of dough traveling into the oven. Dynamic response of the traveling tin (bread-pan) temperature profile predicted in accordance with a change in the oven load and its effect on the heat and mass transfer in the oven chamber. However, due to the limitation of the software used, the oven configuration had to be simplified, particularly to ignore the U-turn movement in the oven. Optimum temperature profile inside the oven was also obtained by varying the airflow volume and heat source temperatures. There was 40% relative error in prediction of velocity inside the oven and minor difference in prediction of temperature at top, bottom, as well as side of bread. Wong et al. (2006a) analyzed the impact of physical properties of dough/bread on the accuracy of the predictions using combined experimental and CFD modeling approach. They concluded the physical properties to have a significant impact and mainly density as well as specific heat capacities to be more dominant factors. Wong et al. (2007a) developed a 2D CFD model, extending the earlier works of Therdthai et al. (2003, 2004b), for continuous movement of traveling tray using sliding mesh technique and employed the DO radiation model. In their study, industrial oven was divided into two parts, then flipping and aligning them along the traveling track to simplify the oven configuration besides the burners being treated as circular objects with fixed wall temperature. Change in the direction of the gravitational force in the two parts (caused by flipping) was handled by using a UDF to redefine the body force. Their model predictions for top and bottom bread temperature were in good agreement with experimental results, but bread center temperature showed very significant difference (Wong et al. 2007a). Wong et al. (2007b) incorporated a feedback controller for temperature in CFD model by using UDF for industrial baking oven and proposed elimination of preheating of oven before baking.

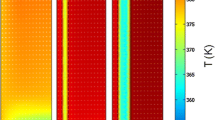

Anishaparvin et al. (2010) and Chhanwal et al. (2011) studied the temperature distribution inside pilot scale electrical heating oven consisting of two trays and nine heating elements placed in three layers, as shown in Fig. 3. Significant difference in temperature profile was observed between bottom and top tray due to the heating source, inlet vent, and product placement (Fig. 4). Anishaparvin et al. (2010) focused on modeling of stationary positioned bread. However, rotation of trays containing bread is normally used in the pilot ovens. Therefore, this study can be extended to evaluate the effect of tray rotation on velocity and temperature profile inside the pilot scale oven. However, modeling of moving mesh is a challenging task as interaction between the stationary (oven walls and heating coils) and moving parts (bread tray and bread) involved in the geometry. Hence, sliding mesh approach can be used to capture the transient behavior of the flow under rotating tray frame work. In this approach, oven needs to be split into the multiple cell zones, with well-defined interfaces between the zones. The use of laminar or turbulent flow needs to be suitably selected to account for the formation of swirl flow in the oven due to the rotation of trays.

A chamber of pilot-scale electrical heating oven geometry and meshed with bread (Chhanwal et al. 2011)

Temperature profiles (°C) inside the baking oven (Anishaparvin et al. 2010)

A common CFD model for baking oven is yet to be developed as the boundary conditions keep changing according to location of vent, fans, heating source, laminar or turbulent flow, batch or continuous, and electric or gas oven. More accurate turbulence models such as DNS, LES, or DES may be useful for studying turbulent flow inside the baking oven. DO radiation model is best suitable model for electrical heating baking ovens. Thus, according to oven types, different models need to be adapted.

CFD Modeling of Bread Baking Process

Producing high-quality bread is a great challenge in baking. Baking is an irreversible process, where unsatisfactory product has to be discarded which is economically unfavorable. Water content and temperature are mainly responsible for physiochemical and biological processes. Variation in bread color occurs due to the non-uniform temperature distribution inside the oven, which can be rectified using CFD modeling of entire baking process. For example, browning of bread surface was evaluated by using kinetic model based on the temperature predictions of the CFD (Chhanwal et al. 2011). However, very few works have been performed on CFD modeling of bread baking as discussed below.

Therdthai et al. (2004a) evaluated temperature profile within the bread and also studied the effect of positioning of bread on temperature. Variations in temperature were found in tins of the same tray, and the bread temperature increased as bread moves to different zones. Therdthai et al. (2004b) evaluated temperature profiles of bread with full load in a continuous bread baking oven. Effect of change in oven load on variation in bread quality was estimated by using this model. They reported that reducing heat supply and increasing air volume in oven can reduce weight loss of bread by 1.4%. The physical properties of dough/bread using CFD simulations were analyzed by Wong et al. (2006a). They considered bread as a solid with constant density as well as thermal conductivity, and specific heat values were given as functions of temperature. In their further study, Wong et al. (2007a) studied the transient simulation of bread travelling inside the oven chamber with main emphasis on heat transfer and air flow inside the oven. Better predictions of temperature at bread surface were obtained as compared with center of bread. Extending the work further, Wong et al. (2007b) proposed elimination of preheating of oven to a high temperature, incorporation of controller, and extracting surface temperature of bread across different zones of oven during baking process. Recently, Chhanwal et al. (2010) studied the change in temperature profile of bread during entire baking process with preheating of domestic electrical heating oven. Discrepancy in experimental and CFD simulated temperatures of bread center were observed in the above studies (Wong et al. 2007a; Anishaparvin et al. 2010; Chhanwal et al. 2010). The predictions of bread surface temperature were closer to experimental results as compared with that of the center temperature. Moreover, center temperature crosses 100 °C in the above studies. However, all these studies on CFD modeling predicted that crumb temperature crosses 100 °C, whereas in real process it never crosses 98–99 °C due to evaporation–condensation mechanism. Thus, these studies were unable to predict temperature profile over entire bread. However, recently Chhanwal et al. (2011) used evaporation–condensation mechanism to imitate the real bread baking process where bread crumb temperature remains below 100 °C for entire baking process. Evaporation–condensation mechanism was included by defining specific heat of bread as a function of temperature including enthalpy jump at the phase change and thermal conductivity of bread as a function of temperature, where thermal conductivity increases until bread reaches 100 °C, and it was made constant (0.2 W/m K) once condensation starts (Purlis and Salvadori 2009b). In this study, temperature predictions for crumb were identical to real bread baking process. This model prediction mimics the experimental bread center temperature, and the difference in predictions, with and without evaporation–condensation mechanism, is shown in Fig. 5. This model is very useful for predicting the bread temperature more accurately than the earlier CFD models published. Moreover, this model temperature prediction can also be used to predict physiochemical changes of bread during baking such as starch gelatinization and browning index.

Comparison of bread center temperature profile during bread baking process for the experiment, CFD modeling with and without evaporation–condensation (E–C) mechanism (Chhanwal et al. 2011)

Modeling of Starch Gelatinization

Degree of starch gelatinization can be used as minimum baking index in industrial baking process, which decides the baking time of bread. Gelatinization properties depend on the kind and origin of the starch. Gelatinization of starch causes disruption of the intermolecular hydrogen bonds, which maintain the structural integrity of the granules and an exudation of amylose. Differential scanning calorimetric (DSC) and X-ray diffraction methods are mainly used for the measurement of the degree of starch gelatinization during bread baking process. Starch gelatinization is a function of time/temperature and follows first-order kinetics (Lund 1984; Zanoni et al. 1995a, c). Zanoni et al. (1995a, c) studied starch gelatinization using DSC method and calculated the model parameters such as k 0 and E a as shown in the following equations.

where α gis degree of starch gelatinization, k, the reaction rate constant, and t, the time in seconds. The reaction rate constant (k) in turn can be calculated using Arrhenius-type equation,

where \( {k_{{0}}} = {2}.{8} \times {1}{0^{{18}}}\left( {{1}/{\text{s}}} \right) \) and E a = 138 kJ/mol (Zanoni et al. 1995c).

Change in temperature profile was correlated with the degree of starch gelatinization in bread, by integrating kinetics model for starch gelatinization with CFD simulation (Therdthai et al. 2004a; Chhanwal et al. 2010; Anishaparvin et al. 2010). It was reported that the starch gelatinization progressed faster at top and bottom parts of bread as compared with the left and right halves of the bread (Therdthai et al. 2004a). The top and bottom temperature of bread was found to be higher as compared with the center of the bread in the continuous bread baking oven. Chhanwal et al. (2010) reported the degree of starch gelatinization with respect to change in temperature profile for a bread slice as shown in Fig. 6. It can be observed from Fig. 6 that the starch gelatinization progressed from crust to the crumb with the formation of different gelatinization zones correspondingly. Extent of gelatinization at top and bottom was rapid as compared with the side portion of bread, which reflected in the temperature profile. Gelatinization was found to be complete within 300 s on outer surface as compared with 900 s at the center of the bread (Fig. 6). Starch gelatinization completes within 900 s of baking process as temperature at center of bread exceeds 80 °C. Formation of different starch gelatinization layers were observed identical to temperature layers inside the bread slice. Recently, Anishaparvin et al. (2010) developed CFD model for bread baking process in a pilot-scale baking oven to find out the effect of hot air distribution and placement of bread on temperature and starch gelatinization index of bread. Their study indicated that vent position and placement of bread are the most important factors in influencing the air temperature profile inside the oven cavity. Due to the air flow pattern, bread placed in top tray bake quickly as compared with those placed in bottom one. Thus, this study indicated that, apart from temperature and time, the placement of bread influences the final bread quality during batch baking process in an electrical heating oven.

Numerical Modeling of Bread Baking Process

Numerous articles have been published on modeling of bread baking process considering many aspects right from proofing to storage stability. However, only articles directly relevant to bread baking process are discussed in this paper. These approaches of bread baking modeling are summarized in Table 2. Therdthai and Zhou (2003) reviewed the heat and mass transfer mechanism during bread baking process along with physico-chemical changes such as starch gelatinization, expansion, protein denaturation, and flavor and color development. A quadratic equation was derived for specific heat of bread as a function of moisture content and temperature using experimental studies by Zanoni and Petronio (1991). Later, Zanoni et al. (1994) developed a phenomenological model for bread baking process, and they extended it further to model the starch gelatinization of bread, browning of bread crust, and also determined thermal diffusivity as a function of porosity (Zanoni et al. 1995b, c, d). Furthermore, Zhang et al. (2005) and Zhang and Datta (2006) developed a model for heat and moisture transport in porous matrix of bread and coupled with volume change. The following common heat and mass balance equations were used in most of the reported (Zanoni et al. 1994; Therdthai and Zhou 2003; Purlis and Salvadori 2009b) modeling work for bread baking process.

Heat Balance Equation

where k is the thermal conductivity (watts per meter Kelvin) and C P the specific heat (joules per kilogram Kelvin)

Mass Balance Equation

where W is the moisture content (kilograms per kilogram) and D the mass diffusivity (square meter per second).

Boundary Conditions for Heat and Mass Transfer

Conduction inside the bread balances heat arriving at the bread surface by convection and radiation (Purlis and Salvadori 2009a, b)

where h is heat transfer coefficient (watts per square meter Kelvin), ε is emissivity, and σ is Stefan–Boltzmann constant (5.672 × 10−8 W/m2 K4).

Moisture transport through bread surface was obtained by the following equation (Purlis and Salvadori 2009b):

where \( {P_{\text{S}}} = {a_{\text{w}}}{P_{\text{sat}}}\left( {{T_S}} \right) \) and \( {P_{\text{amb}}} = RH.{P_{\text{sat}}}\left( {{T_{\text{amb}}}} \right) \)

P S is partial pressure at bread surface, P sat saturated partial pressure, P amb ambient partial pressure, a w water activity, and RH relative humidity.

During baking, water evaporates at warmer side of gas cell and water vapor condenses at the colder side of the gas cell in simultaneous heat and mass transfer process as depicted in Fig. 2. These evaporation–condensation processes continue until the temperature of the whole crumb reaches 100 °C (Purlis and Salvadori 2009a). Purlis and Salvadori (2009b) studied bread baking as a moving boundary problem by accounting evaporation–condensation processes and latent heat of phase change. They proposed the following equation for specific heat of bread as a function of temperature and moisture. Moreover, they included enthalpy jump at the phase change in this Eq. 13.

where Cp is the specific heat (joules per kilogram Kelvin), λ v the heat of phase change (joules per cubic meter), T f is the temperature of phase change (Kelvin), and W the moisture content (kilograms per kilogram).

Effective thermal conductivity was also altered to account for evaporation–condensation mechanism (Purlis and Salvadori 2009b, 2010):

Purlis and Salvadori (2010) extended their work to study the volume expansion of bread using moving boundary by Arbitrary-Lagrangian-Eulerian approach. Purlis (2011) evaluated the baking time using kinetics models for starch gelatinization and browning of bread surface. Bollada (2008) modeled expansion of bread dough by using a set of linear second-order partial-differential equations corresponding to Hookean elastic model. Formation of crust and evaporation front was also discussed with this model. Vanin et al. (2009) extensively reviewed formation of crust with simultaneous heat and mass transfer occurring during the bread baking process. They found that the crumb water content remained unchanged, whereas crust water content dropped below 10%. Hadiyanto et al. (2007) studied the heat and mass transfer, starch, and color transformation in product and also investigated the change in quality attributes during storage.

Heat and mass transfer during freezing of par-baked bread was studied by Hamdami et al. (2004) considering effective thermal conductivity to include evaporation–condensation effect and ice formation rate in mass balance equation. Mondal and Datta (2008) reviewed experimental and mathematical studies on bread baking focusing on properties and structure of bread. Later, the same group (Mondal and Datta 2010) developed a model for the crust-less bread using finite element method. A model for dough movement due to a bubble collapse was developed by Jefferson et al. (2007) using vaporization boundary governed by Stefan condition. Ousegui et al. (2010) developed a porous multiphase model for bread baking using Fourier’s law for conductive heat transfer. Darcy’s and Fick’s laws were also used for convective as well as diffusive mass transfer of liquid and gas phases. Deshlahra et al. (2009) developed a model for the prediction of bubble size distribution and dynamic evolution of the foam structure in baked foods. These models consist of heat and mass transfer equations and reaction kinetics coupled with population balance equation for bubble growth during bread volume expansion due to gas bubbles. Readers may refer to Deshlahra et al. (2009) for detailed description of the equations. Fan et al. (1999) concluded that bubble growth rate, CO2 generation rate, nucleation frequency, and mass transfer coefficient decides bubble size distribution and rate of rise during baking. Increase in dough temperature above 60 °C showed significant effect on volume expansion as solubility of carbon dioxide in a liquid dough phase decreases with an increase in temperature.

Current Limitations and Future Trends of CFD Modeling

More realistic models need to be developed with the help of CFD, because modeling of complete baking process (i.e., including air flow, heating element, and bread) is possible using CFD. Though the predictions of CFD models are matching to some extent with the experimental observations, these models have some limitations due to some unrealistic assumptions such as exclusion of evaporation–condensation, moisture transfer, and volume expansion. Moisture transfer and volume expansion are critical phenomena in bread baking process, but due to limitation of commercial CFD software codes, these are not considered in any of the reports published so far. However, commercial COMSOL Multiphysics software can be used to model moisture transport and volume expansions during baking process. Inclusion of population balance equations in CFD model can open several opportunities to study the bubble growth (due to CO2 release) and expansion of dough during bread baking process. Inclusion of moisture transport equation using UDF or introducing another model to take into account the mass transport gives more realistic model for the bread baking process. CFD modeling of different heating modes such as infrared, microwave, with or without conventional heating needs to be studied for better understanding of effect of these heating methods on bread baking process for a possible synergy. Incredibly rapid growth in computation power and reduction in cost will allow researchers to use computational intensive turbulent models such as DNS, LES, and DES for the precise predictions of turbulent momentum and heat transfer dynamics. The coke deposition on the oven surface was neglected during the modeling of radiative heat transfer, which may be incorporated in future CFD modeling for better predictions.

Technical transfer of CFD approaches has increasingly yielded benefits to food processing industries by providing new insights into the performance of the baking process. For example, Therdthai et al. (2003) developed a CFD model for continuous industrial scale baking oven to optimize the air flow and placement of the controller to enhance quality of final product. Williamson and Wilson (2009) developed a CFD model for designing a burner for gas-heated industrial oven. However, its direct application could be difficult due to the complexity brought by the change from raw ingredients to final product. Baking is such a process, where the physical properties, structure, and even composition of the food changes during the course of the process. With recent scientific, technological, and instrumental breakthroughs, there are enough opportunities for researchers to take up the challenges of investigating the process of baking in depth coupled with CFD modeling to produce better quality product at reduced cost.

Conclusions

The aim of this review is to highlight the importance of CFD in the modeling of the bread baking process. There is considerable growth in the development and application of CFD simulation in the areas of baking ovens and bread baking process to predict the complex flow patterns in the ovens as well as bread temperatures. However, more modeling work needs to be undertaken including mass transport and volume expansion during bread baking process. Some of the problems during modeling of bread baking process have been highlighted, and even as some of these issues are addressed by different researchers, the objective purpose of this review can be considered to be fulfilled. Thus, this review clearly indicates the CFD to be a valuable tool for the designing of the baking oven and prediction of bread temperature along with various physiological changes such as browning index and starch gelatinization during bread baking process.

References

Abraham, J. P., & Sparrow, E. M. (2002). Heat transfer characteristics of vented/unvented enclosures for various radiation surface characteristics of the thermal load, enclosure temperature sensor, and enclosure walls. International Journal of Heat and Mass Transfer, 45, 2255–2263.

Abraham, J. P., & Sparrow, E. M. (2004). A simple model and validating experiments for predicting the heat transfer to a load situated in an electrically heated oven. Journal of Food Engineering, 62, 409–415.

Anandharamakrishnan, C. (2003). Computational fluid dynamics (CFD)—Applications for the food industry. Indian Food Industry, 22(6), 62–68.

Anandharamakrishnan, C., Gimbun, J., Stapley, A. G. F., & Rielly, C. D. (2010a). Application of computational fluid dynamic (CFD) simulations to spray-freezing operations. Drying Technology, 28, 94–102.

Anandharamakrishnan, C., Gimbun, J., Stapley, A. G. F., & Rielly, C. D. (2010b). A study of particle histories during spray drying using computational fluid dynamic simulations. Drying Technology, 28, 566–576.

Anderson, J. D. (1984). Computational fluid dynamics—The basics with applications. New York: McGraw-Hill Inc.

Anishaparvin, A., Chhanwal, N., Indrani, D., Raghavarao, K. S. M. S., & Anandharamakrishnan, C. (2010). An investigation of bread baking process in a pilot-scale electrical heating oven using computational fluid dynamics. Journal of Food Science, 75, E605–E611.

Bollada, P. C. (2008). Expansion of elastic bodies with application in the bread industry. Mathematical and Computer Modelling, 48, 1055–1067.

Boulet, M., Marcos, B., Dostie, M., & Moresoli, C. (2010). CFD modeling of heat transfer and flow field in a bakery pilot oven. Journal of Food Engineering, 97, 393–402.

Cauvain, S. P. (2003). Bread making—improving quality. New York: CRC Press.

Chhanwal, N., Anishaparvin, A., Indrani, D., Raghavarao, K. S. M. S., & Anandharamakrishnan, C. (2010). Computational fluid dynamics (CFD) modeling of an electrical heating oven for bread-baking process. Journal of Food Engineering, 100, 452–460.

Chhanwal, N., Indrani, D., Raghavarao, K. S. M. S., & Anandharamakrishnan, C. (2011). Computational fluid dynamics modeling of bread baking process. Food Research International, 44, 978–983.

De Vries, U., Velthuis, H., & Koster, K. (1995). Baking oven and product quality—A computer model. Food Science and Technology Today, 9, 232–234.

Decock, P., & Cappelle, S. (2005). Bread technology and sourdough technology. Trends in Food Science & Technology, 16, 113–120.

Deshlahra, P., Mehra, A., & Ghosal, D. (2009). Evolution of bubble size distribution in baked foods. Journal of Food Engineering, 93, 192–199.

Dhall, A., Datta, A. K., Torrance, K. E., & Almeida, M. F. (2009). Radiative heat exchange modeling inside an oven. AICHE Journal, 55, 2448–2460.

Eliasson, A. C., & Larsson, K. (1993). Cereals in bread making: A molecular colloidal approach. USA: Marcel Dekker Inc.

Fan, J., Mitchell, J. R., & Blanshard, J. M. V. (1999). A model for the oven rise of dough during. Journal of Food Engineering, 41, 69–77.

Fluent 6.3. (2006). Fluent user’s guide. USA: Ansys Inc.

Hadiyanto, Asselman, A., Straten, G., Boom, R. M., Esveld, D. C., & Boxtel, A. J. B. (2007). Quality prediction of bakery products in the initial phase of process design. Innovative Food Science and Emerging Technologies, 8, 285–298.

Hamdami, N., Monteau, J. Y., & Le Bail, A. (2004). Heat and mass transfer in par-baked bread during freezing. Food Research International, 37, 477–488.

Jefferson, D. R., Lacey, A. A., & Sadd, P. A. (2007). Crust density in bread baking: Mathematical modeling and numerical solutions. Applied Mathematical Modeling, 31, 209–225.

Kuriakose, R., & Anandharamakrishnan, C. (2010). Computational fluid dynamics (CFD) applications in spray drying of food products. Trends in Food Science & Technology, 21, 383–398.

Lund, D. B. (1984). Influence of time, moisture, ingredients, and processing conditions on starch gelatinization. Critical Reviews in Food Science and Nutrition, 20, 249–273.

Mirade, P. S., Daudin, J. D., Ducept, F., Trystram, G., & Clément, J. (2004). Characterization and CFD modeling of air temperature and velocity profiles in an industrial biscuit baking tunnel oven. Food Research International, 37, 1031–1039.

Mistry, H., Ganapathi-subbu, Dey, S., Bishnoi, P., & Castillo, J. L. (2006). Modeling of transient natural convection heat transfer in electric ovens. Applied Thermal Engineering, 26, 2448–2456.

Mondal, A., & Datta, A. K. (2008). Bread baking—A review. Journal of Food Engineering, 86, 465–474.

Mondal, A., & Datta, A. K. (2010). Two dimensional CFD modeling and simulation of crustless bread baking process. Journal of Food Engineering, 99, 166–174.

Norton, T., & Sun, D. W. (2006). Computational fluid dynamics (CFD)—An effective and efficient design and analysis tool for the food industry: A review. Trends in Food Science and Technology, 17, 600–620.

Ousegui, A., Moresoli, C., Dostie, M., & Marcos, B. (2010). Porous multiphase approach for baking process—explicit formulation of evaporation rate. Journal of Food Engineering, 100, 535–544.

Purlis, E. (2011). Bread baking: technological considerations based on process modeling and simulation. Journal of Food Engineering, 103, 92–102.

Purlis, E., & Salvadori, V. O. (2009a). Bread baking as a moving boundary problem. Part 1: Mathematical modeling. Journal of Food Engineering, 91, 428–433.

Purlis, E., & Salvadori, V. O. (2009b). Bread baking as a moving boundary problem. Part 2: Model validation and numerical simulation. Journal of Food Engineering, 91, 434–442.

Purlis, E., & Salvadori, V. O. (2010). A moving boundary problem in a food material undergoing volume change—simulation of bread baking. Food Research International, 43, 949–958.

Sablani, S. S., Marcotte, M., Baik, O. D., & Castaigne, F. (1998). Modeling of simultaneous heat and water transport in the baking process. LWT- Food Science and Technology, 31, 201–209.

Schmidt, S., & Thiele, F. (2002). Comparison of numerical methods applied to the flow over wall mounted cubes. International Journal of Heat and Fluid Flow, 23, 330–339.

Scott, G. M., & Richardson, P. (1997). The application of computational fluid dynamics in the food industry. Trends in Food Science and Technology, 8, 119–124.

Sparrow, E. M., & Abraham, J. P. (2003). A computational analysis of the radiative and convective process that take place in preheated and non-preheated ovens. Heat Transfer Engineering, 24, 25–37.

Sun, D. W. (2007). Computational fluid dynamics in food processing. Boca Raton: CRC Press.

Therdthai, N., & Zhou, W. (2003). Recent advances in the studies of bread baking process and their impact on the bread baking technology. Food Science and Technology Research, 9, 219–226.

Therdthai, N., Zhou, W., & Adamczak, T. (2003). Two dimensional CFD modeling and simulation of an industrial continuous bread baking oven. Journal of Food Engineering, 60, 211–217.

Therdthai, N., Zhou, W., & Adamczak, T. (2004a). Simulation of starch gelatinization during baking in a traveling-tray oven by integrating a three dimensional CFD model with a kinetic model. Journal of Food Engineering, 65, 543–550.

Therdthai, N., Zhou, W., & Adamezak, T. (2004b). Three-dimensional CFD modeling and simulation of the temperature profiles and airflow patterns during a continuous industrial baking process. Journal of Food Engineering, 65, 599–608.

Thorvaldsson, K., & Janestad, H. (1999). A model for simultaneous heat, water and vapour diffusion. Journal of Food Engineering, 40, 167–172.

Turnbull, J., & Thompson, C. P. (2005). Transient averaging to combine large eddy simulation with Reynolds-averaged Navier-Stokes simulations. Computers and Chemical Engineering, 29, 379–392.

Vanin, F. M., Lucas, T., & Trystram, G. (2009). Crust formation and its role in bread baking. Trends in Food Science & Technology, 20, 333–343.

Verboven, P., Scheerlinck, N., de Baerdemaeker, J., & Nicolai, B. M. (2000a). Computational fluid dynamics modelling and validation of the isothermal airflow in a forced convection oven. Journal of Food Engineering, 43, 41–53.

Verboven, P., Scheerlinck, N., de Baerdemaeker, J., & Nicolai, B. M. (2000b). Computational fluid dynamics modelling and validation of the temperature distribution in a forced convection oven. Journal of Food Engineering, 43, 61–73.

Versteeg, H. K., & Malalasekera, W. (1995). An introduction to computational fluid dynamics. Essex: Pearson Education Ltd.

Wagner, M. J., Lucas, T., Le Ray, D., & Trystram, G. (2007). Water transport in bread during baking. Journal of Food Engineering, 78, 1167–1173.

Walker, C. E. (1987). Impingement oven technology part I: Principles. American Institute of Baking Research Department Technology Bulletin, 9(11), 1.

Walker, C. E., & Li, A. (1993). Impingement oven technology part III: Combining impingement with microwave (hybrid oven). American Institute of Baking Research Department Technology Bulletin, 15(9), 1.

Walker, C. E., & Sparman, A. B. (1989). Impingement oven technology part II: Application and future. American Institute of Baking Research Department Technology Bulletin, 11(11), 1.

Williamson, M. E., & Wilson, D. I. (2009). Development of an improved heating system for industrial tunnel baking ovens. Journal of Food Engineering, 91, 64–71.

Wong, S. Y., Zhou, W., & Hua, J. (2006a). Robustness analysis of CFD model to the uncertainties in its physical properties for a bread baking process. Journal of Food Engineering, 77, 784–791.

Wong, S. Y., Zhou, W., & Hua, J. (2006b). Improving the efficiency of food processing ovens by CFD techniques. Food Manufacturing Efficiency, 1, 35–44.

Wong, S. Y., Zhou, W., & Hua, J. (2007a). CFD modeling of an industrial continuous bread-baking process involving U-movement. Journal of Food Engineering, 78, 888–896.

Wong, S. Y., Zhou, W., & Hua, J. (2007b). Designing process controller for a continuous bread baking process based on CFD modeling. Journal of Food Engineering, 81, 523–534.

Xia, B., & Sun, D. W. (2002). The application of computational fluid dynamics (CFD) in the food industry: A review. Computers and Electronics in Agriculture, 34, 5–24.

Zanoni, B., & Petronio, M. (1991). Effect of moisture and temperature on the specific heat of bread. International Journal of Food Science, 3, 239–242.

Zanoni, B., Pierucci, S., & Peri, C. (1994). Study of bread baking process-II. Mathematical modelling. Journal of Food Engineering, 23, 321–336.

Zanoni, B., Schiraldi, A., & Simonetta, R. (1995a). A naive model of starch gelatinization kinetics. Journal of Food Engineering, 24, 25–33.

Zanoni, B., Peri, C., & Gianotti, R. (1995b). Determination of the thermal diffusivity of bread as a function of porosity. Journal of Food Engineering, 26, 497–510 .

Zanoni, B., Peri, C., & Bruno, D. (1995a). Modeling of starch gelatinization kinetics of bread crumb during baking. LWT- Food Science and Technology, 28, 314–318.

Zanoni, B., Peri, C., & Bruno, D. (1995b). Modeling of browning kinetics of bread crust during baking. LWT- Food Science and Technology, 28, 604–609.

Zhang, J., & Datta, A. K. (2006). Mathematical modeling of bread baking process. Journal of Food Engineering, 75, 78–89.

Zhang, J., Datta, A. K., & Mukherjee, S. (2005). Transport processes and large deformation during baking of bread. AICHE Journal, 51, 2569–2580.

Zheleva, I., & Kambourova, V. (2005). Identification of heat and mass transfer processes in bread during baking. Thermal Science, 9, 73–86.

Zhou, W., & Therdthai, N. (2007). Three-dimensional modeling of a continuous industrial baking process. In D. W. Sun (Ed.), Computational fluid dynamics in food processing (pp. 287–312). Boca Raton: CRC Press.

Acknowledgments

We wish to acknowledge the Department of Science and Technology (DST), Government of India, and CSIR through Network project (NWP 02) for the financial support for this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chhanwal, N., Tank, A., Raghavarao, K.S.M.S. et al. Computational Fluid Dynamics (CFD) Modeling for Bread Baking Process—A Review. Food Bioprocess Technol 5, 1157–1172 (2012). https://doi.org/10.1007/s11947-012-0804-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-012-0804-y