Abstract

In this study a bottom-up approach of designing functional ingredients from green tea extract is proposed by a systematic investigation of 12 different natural biopolymers and their efficiency as carrier materials of green tea bioactive compounds by spray drying at low temperature (130 °C). Screening of carriers revealed that inulin and whey proteins provide the highest product yields (67.04 and 65.18 %, respectively) and, accompanied with pectin, also the highest total polyphenols (67.5–82.2 %) and flavan-3-ols (93.7–75.9 %) loading capacity. Up to 162 mg/g of (−)−epigallocatechin gallate (EGCG) was achieved, while low-caffeine contents (<5 mg/g) indicated the potential of obtaining low-caffeine functional ingredients. Employing alginate, carageenan and gums (acacia gum and xanthan) enabled the best colour preservation and highest chlorophyll content. Reconstituted green tea microencapsulates comprising modified starch, inulin or carageenan exhibited the lowest bitterness and astringency and the highest green tea flavour intensity as the most favourable sensory properties. An artificial neural network (ANN) designed based on the experimentally obtained results revealed hydrocolloid gums as the best encapsulants for achieving good physical properties, high EGCG contents and prolonged dissolution/release profiles while pectin, inulin and modified starch as the optimal ones in terms of the product yields, loading capacities and sensory properties. This indicates that a formulation comprising a combination of all of those biopolymers would provide potentially functional ingredients with encapsulated green tea phytochemicals, retained colour and improved sensory properties.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The market and consumption of green tea (Camellia sinensis L.) over the past 10 years have been tremendous and continue to expand, which is reflected by its predicted annual growth rate of ca. 7.2 % (FAO 2012) until 2021. Growing consumer awareness about various health benefits offered by tea bioactive compounds, primarily polyphenols and caffeine, and intensive marketing have been acting as the primary drivers of changing consumption patterns and the major factors driving their market. The global market for tea polyphenols, as one of the most popular and well-known nutraceuticals today, was estimated to be worth 209.3 million USD in 2012 and is expected to reach 367.7 million USD by 2020. Green tea polyphenols dominate the overall market owing to its high extractable polyphenol content (30 to 40 % of extractable polyphenols, in comparison to just 5 to 20 % of extractable polyphenols in oolong tea and black tea, respectively). Therefore, green tea polyphenols emerged as the leading type of tea polyphenols consumed worldwide and accounted for 72.5 % of total market volume in 2012 (Dufrene 2012).

However, due to the rapid absorption, a short half-life and low oral bioavailability of tea polyphenols, primarily catechins, resulting in plasma concentrations 5 to 50 times less than concentrations shown to exert biological activities in in vitro systems, their repeated intake is necessary to obtain an accumulation of metabolites in the plasma (Warden et al. 2001; Chow et al. 2003). Polyphenols are extensively altered during the first-pass metabolism resulting in markedly different molecular forms reaching the peripheral circulation and tissues, in comparison to those present in the original food (Zhang et al. 2003). Therefore, it is suggested that up to ten cups of green tea should be consumed daily for achieving the beneficial anticarcinogenic properties of green tea (Hirota, 2012). In that respect, formulating stable and efficient dosage forms of green tea polyphenols is required that would provide the possibility of their implementation to different food systems and exerting the biological activity in vivo that are suggested by in vitro studies.

Since the development of functional food products with tailored health benefits considers numerous requirements, a bottom-up approach by designing functional ingredients is necessary, which should enable their stabilization in the food matrix, increase bioavailability and reflect targeted physiological effects. The process of formulating novel nutraceuticals, especially phytochemicals, is constantly evolving in order to overcome the challenges associated with producing viable dosage forms to reach the target tissues. The encapsulation approach is an ideal solution for the protection of tea polyphenols and formulation of stable dosage forms for food purposes since it enables to (i) overcome the solubility incompatibilities between ingredients, (ii) protect sensitive ingredients such as polyphenols from degradation e.g. by oxidation, (iii) increase their bioavailability including the controlled release of encapsulated compounds and (iv) modify sensory or physical properties of food materials (Helgason et al. 2009; Dube et al. 2010; Zimet et al. 2011; Liao et al. 2010). Encapsulation of green tea polyphenols in carbohydrate nanoparticles (Hu et al. 2008; Kosaraju et al. 2006), liposomes (Fang et al. 2006), other preformed materials (Shi et al. 2008) or spray drying (Tang et al. 2011; Peres et al. 2011) has already been performed previously. However, often numerous different polymer materials and techniques and their potential of entrapping green tea polyphenols are evaluated, regardless of their feasibility, economic aspects or dosing size and sensory properties relevant to the food application and industry.

Very often, due to the incompatibility of produced encapsulates and food matrix, the easiest and preferred encapsulation form would be to obtain powdered materials by spray drying. Spray drying is a simple and low-cost microencapsulation technology that can circumvent many of the technical challenges associated with the use of polyphenols as food ingredients (Sun-Waterhouse et al. 2013). Numerous papers have been published about both the operational conditions and qualitative properties of spray-dried juice/extract powders (Chegini and Ghobadian 2007; Georgetti et al. 2008; Goula and Adamopoulos 2008). However, the high temperatures used for spray drying, most often above 160 °C, may cause degradation of heat-sensitive compounds like tea polyphenols (Buchner et al. 2006; Sun-Waterhouse et al. 2013). Almost all studies conducting encapsulation by spray drying evaluate the effect of different inlet and outlet temperatures on the encapsulation efficiency of a targeted compound; despite that, high inlet temperatures of ≥145 °C are used. Further, in the spray-drying applications, the most often applied carrier materials are maltodextrins, modified starches and gum arabic to obtain good product recovery and stability. There is a lack of studies reporting the use of other naturally derived biopolymers as carriers of phytochemicals which could serve as functional ingredients, enabling the formulation of products with improved nutritional, colour, textural and bioactive properties.

Therefore, to overcome demerits of green tea bioactives’ encapsulation by spray drying, the purpose of this study was to provide a comprehensive overview and evaluate the potential of using different natural biopolymers (dietary fibres, proteins, hydrocolloid gums) as carriers of green tea bioactive compounds by spray drying at lower-process temperature. A simple, water-based green tea extract preparation technique and spray drying of formulated encapsulating solutions were performed, and their potential to entrap and protect green tea polyphenols and caffeine was evaluated. The effect of input process parameters was examined on physical, bioactive, colour and sensory properties of spray-dried green tea extract, and the obtained results were used to design an artificial neural network for prediction of the optimal parameters.

Materials and Methods

Chemicals

All chemicals used for the experimental procedures were of analytical grade. Sodium alginate was purchased from Sigma-Aldrich (USA). Whey protein isolate (consisting of 95 % ß-lactoglobulin) was supplied by Davisco Foods International (Le Sueur, MN, USA). Inulin, oligofructose, modified corn starch, LE pectin, κ-carageenan, xanthan and locust bean gum (LBG) were supplied from Cargill. Acacia gum and guar gum were obtained from HiMedia Laboratories (India). Green tea Darjeeling (Müller, Abtswind, Germany) and pea proteins (flour) were purchased at a local organic market.

Preparation of Green Tea Extract

Green tea leaves were ground using a domestic grinder Braun KSM2 (Braun, Kronberg, Germany) and sieved through 0.45-mm pore-size sieve to obtain a homogenized fraction for the extraction. The extraction was carried out repeatedly (twofold), by pouring 100 mL of distilled water heated to 80 °C over 8 g of ground tea. The extraction was carried out on a magnetic stirrer at 80 °C for 15 min, where after the obtained extract was filtered through a tea strainer and the crude residue was extracted again with another 100 mL of distilled water. After the second extraction, the supernatants were collected, filtered through a 4-layer cotton gauze and filled up to 200 mL. Dry matter content of the prepared green tea extract amounted to 1.51 %.

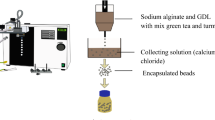

Encapsulation of Green Tea Bioactives by Spray Drying

The prepared green tea extract was spray-dried under the below-stated spray-drying conditions to serve as a reference (control) sample. For the microencapsulation of green tea bioactives by spray drying, encapsulant solutions containing different biopolymers: alginate (5 %, w/v), pectin (5 %, w/v), carageenan (2 %, w/v), modified corn starch (5 %, w/v), acacia gum (2 %, w/v), guar gum (1 %, w/v), xanthan (0.5 %, w/v), locust bean gum (0.5 %, w/v), whey proteins (10 %, w/v), pea flour (7 %, w/v), oligofructose (10 %, w/v) or inulin (10 %, w/v) were prepared by dissolving a required amount of each encapsulant in the previously prepared green tea extract at 40 °C. The resulting solutions were mixed overnight at 4 ± 2 °C, well homogenized and sonicated for 10 s prior to spray drying. A spray dryer (Büchi mini B-290, Büchi Labortechnik AG, Switzerland) equipped with a 0.7-mm standard diameter nozzle was used to prepare the spray-dried powders. The inlet and outlet temperatures were 130 ± 3 and 56 ± 2 °C, respectively. The spraying air flow rate, rate of liquid feed, atomisation pressure and pump speed were 536 L/h, 8 mL/min, 6 psi and 30 %, respectively. The spray dryer operating conditions and instrument settings were established by taking into account the design of lab-scale spray dryer and previously conducted experiments, as well as the infeed (encapsulant) solution viscosity (due to different carrier materials used with wide viscosity ranges). Therefore, one set of spray-drying operating conditions needed to be selected in order to enable comparison of the product yield for each sample. Thus, a relatively low-spraying air flow rate (536 L/h), liquid feed (8 mL/min rate) and atomisation pressure (6 psi) at low inlet temperature were chosen in order to ensure a good atomization along the liquid feed rate employed and obtaining a stable powder with high loading strength and low water content.

For all samples, free-flowing powders were obtained and immediately subjected to analysis, which was completed within 1 week of spray drying the powders. A portion of each powder was transferred to high-density polyethylene zip-lock plastic bags and stored in the dark at −20 °C for later analyses.

The product yield was calculated as the ratio between the amount of powders (g) obtained by spray drying (P) and the product of total amount of tea leaves (g) used in each extraction (R) and the amount of spray-dried extract (g) (E 2), divided by the total amount of extract (g) (E 1), according to the equation:

Rheological Measurements

The rheological behaviour of green tea encapsulant systems (solutions) was characterized using a rotational viscometer (RM180 Rheomat Rheometric Scientific, TA Instruments, Eschborn, Germany). The samples were incubated at ambient temperature (23 ± 2 °C) and the measurements performed at the same temperature as a function of increasing the shear rates from 100 to 1290 s−1, applied to the samples in an upwards and subsequently downwards sequence. The mean value and standard deviation of triplicate readings were recorded, and the apparent viscosity was calculated at the maximum shear rate applied for each sample.

Physical Properties of Spray-Dried Green Tea Extract

The moisture content of spray-dried powders was determined according to the procedure described by Şahin Nadeem et al. (2011) by drying in an oven at 70 ° C until constant weight.

The bulk density of the samples was determined following a modified method of Murakami et al. (2001). The sample was poured into a 100 mL measuring cylinder; the mass of empty and filled measuring cylinder and the volume occupied by the sample were recorded. Bulk density was determined by dividing the net weight of the sample with the volume occupied by the sample in the cylinder and calculated as an average value of 10 measurements.

Dissolution tests were carried out as described by Sun-Waterhouse et al. (2013) by adding spray-dried powder (50 mg) to water (1 mL) at room temperature (20 °C). The obtained mixture was vortexed and the time taken to fully reconstitute the powders was recorded. All analyses were conducted in triplicate.

Morphology and Particle Size Determination

Scanning electronic microscopy (SEM) analysis was performed using a TESCAN Mira3 microscope (Czech Republic). The samples were attached to stubs using a two-sided adhesive tape, then coated with a layer of gold (50 nm) and examined using an acceleration voltage of 4–5 kV. The particle size of the obtained spray-dried samples was determined using Mastersizer 2000 (Malvern Instruments, Worcestershire, UK) equipped with the Scirocco 2000 dispersion unit. The size distribution was quantified as relative volume of particles in size bands presented as size distribution curves using Mastersizer 2000 Software (Malvern Instruments, Worcestershire, UK). Particle size distribution (PSD) parameters obtained included surface weighted mean D[3,2], mean particle size d(0.5) and PSD width.

Microparticles Composition Analysis by FTIR Spectroscopy

For the Fourier transform infrared spectroscopy (FTIR) spectroscopic analysis of plain green tea extract, materials used as carriers (encapsulants) and obtained spray-dried powders were crushed using a mortar and pestle. The crushed material was mixed with potassium bromide, dried and compressed to pastilles. Infrared spectra over the wavelength range 4000 to 600 cm−1 were recorded as KBr pastilles with a IRAffinity-1 FTIR spectrophotometer (Schimadzu, Japan). The resolution was 4 cm−1.

UV-Vis Absorption Yield, Chlorophyll Content and Colour Properties

The UV-Vis absorbance strength of the reconstituted spray-dried powders was determined as described by Obón et al. (2009) with some modifications and defined as the absorbance at 360 nm of a 0.5 % (v/v) solution. The wavelength of 360 nm was defined as the maximum wavelength absorption by scanning the spectra of previously prepared green tea extract with an UV–visible spectrophotometer (Genesys 10S, Thermo Fisher Scientific Inc., Waltham, USA). Namely, since green tea extract is characterized by a very high content of polyphenolic compounds that exhibit absorption maxima at 250–360 nm in water (Atomssa and Gholap 2015), the absorption maximum of green tea extract, regardless of its green-yellowish colour, is at 360 nm and not in the visible part of the spectrum. Therefore, UV-Vis absorbance yield (comprising all light-absorbing substances and just the ones having colour properties) was calculated as absorbance strength of powder obtained × grammes obtained powder × 100 / absorbance strength of green tea extract × tea extract volume in millilitre used.

The chlorophyll pigments in the spray-dried powders were determined according to the method of Huang et al. (2007). The powdered samples were suspended with 80 % (v/v) acetone and vortexed for 2 min in a dark tube, followed by filtering through Whatman no. 4 and filling up to a defined volume. The absorbance of the filtrate was measured spectrophotometrically at 30 °C using a wavelength of 663 nm (chlorophyll a) and 645 nm (chlorophyll b), respectively. The content of chlorophylls a and b was calculated based on specific equations (Tea Institute of Chinese Academy of Agricultural Sciences, 1983), and the final results were expressed (mg/g DM). All measurements were performed in triplicate.

The instrumental colour of spray-dried samples was evaluated using a colorimeter (Konica Minolta, Sensing, CM–700d, CM–A177, Japan) and the readings of L* (lightness), a* (redness) and b* (yellowness) parameters were recorded. For the analysis, samples of dried spray-dried powders were filled into plastic Petri dishes (i.d. 50 mm) taking care to ensure a homogenous and representative sample. Five replicate measurements were performed, and the results were presented as mean values with corresponding standard deviations. In addition, total colour difference was calculated according to the equation: ∆E = √(L*0 − L*)2 + (a*0 − a*)2 + (b*0 − b*)2 (Tijskens et al. 2001), where subscript “0” refers to the colour value of spray-dried green tea extract.

Encapsulation Efficiency and Bioactive Compounds

The content of total polyphenols, flavan-3-ols and specific polyphenols entrapped in the obtained beads was estimated by dissolving a known amount of samples in distilled water, under vigorous shaking on a Vortex mixer (Tehtnica, Železniki, Slovenia) at ambient temperature. The content of the total polyphenols was determined using the Folin-Ciocalteu assay and the content of flavan-3-ols using the vanillin assay (Belščak-Cvitanović et al. 2015a, b) and the contents of (−)−epigallocatechin gallate (EGCG) and caffeine loaded in the microbeads by high-performance liquid chromatography (HPLC) analysis. The possible interactions of Folin-Ciocalteu reagent with plain carriers were neutralized by parallel readings of blank carrier solutions (not dissolved in green tea extract but just distilled water). For the HPLC analysis, all samples were filtered through a 0.45-μm filter (Nylon Membranes, Supelco, Bellefonte, USA) before HPLC analysis. Amount of 20 μL of the sample was injected for HPLC analysis using Agilent 1100/1200 Series HPLC device (Agilent, Santa Clara, USA) and a photodiode array detector (Agilent, Santa Clara, USA) with a reversed-phase column Zorbax extended C-18 column (Agilent, Santa Clara, USA) (250 × 4.6 mm, 5 μm i.d.). The solvents consisted of 2 % formic acid in water (solvent A) and methanol (solvent B) at a flow rate of 1 mL/min. The elution was performed with a gradient starting at 10 % A, rising to 40 % A after 25 min and then to 70 % A after 15 min. Chromatograms were recorded at 278 nm. Detection was performed with a photodiode array detector by scanning between 200 and 400 nm, with a resolution of 1.2 nm. Caffeine was identified by comparing the retention times and spectral data with those of standards. The data acquisition and treatment were conducted using Star Chromatography Workstation Version 5 software. All analyses were repeated three times.

The percentage of loading efficiency was calculated as the ratio between the total polyphenols or flavan-3-ols content in the aqueous solutions of dissolved spray-dried samples and their respective content in the initial infeed solutions.

In Vitro Dissolution Test in Simulated Gastric and Intestinal Fluids

The dissolution rate of total polyphenols and flavan-3-ols from the obtained spray-dried beads was determined in simulated gastric (simulated gastric fluid (pH = 1.2) containing pepsin) and intestinal (phosphate buffer, pH = 7.4) conditions. According to the literature data upon consumption, polyphenols are stable enough up to 2 h to accomplish their biological effects (Rusak et al. 2002; Matsuo et al., 2005) without the formation of secondary metabolites or spontaneous degradation products which could influence their activity (Plochmann et al., 2007). Since previous studies on microencapsulation of polyphenolic compounds indicated that a fast release of entrapped polyphenols from microencapsulates occurs in the first 60 min (Belščak-Cvitanović et al. 2015a, b) of release experiments, the majority of entrapped compounds should be released during the time in simulated gastric fluid (SGF) (2 h). Therefore, in vitro release study was limited to 2 h in SGF in the presence of pepsin, while the release in SIF served as a control to check whether additional release may still be occurring. The dissolution kinetics was performed by evaluating the total polyphenols content by the Folin-Ciocalteu assay and the flavan-3-ols content by the vanillin assay (as described in “Encapsulation efficiency and Bioactive Compounds” section). For the analysis a known amount of spray-dried samples (of about 3 g) was suspended in 50 mL of the media (SGF, SIF). The samples were submitted to continuous agitation on an orbital shaker (New Brunswick Scientific Co., Inc., Edison, NJ, USA) operating at 100 rpm. At defined time intervals, an aliquot of the supernatant was taken for analysis and centrifuged, and the clear supernatant was used for chemical analyses. The excerpt aliquot was replaced by the same amount of fresh medium which was used to transfer the crude particles remaining after the centrifugation step back to the initial sample.

Sensory Evaluation of Reconstituted Powders

The sensory evaluation of bitterness, astringency and green tea flavour intensity of the spray-dried green tea extract samples was conducted by quantitative descriptive analysis procedure according to Nilsang et al. (2005) and Normah et al. (2013) with some modifications. Ten panellists were trained for 2 weeks using caffeine solution as the standard for bitterness and tannic acid as the standard for astringency. Different concentrations of caffeine or tannic acid solutions (0–500 mg/L) were prepared and presented to the panellists. Plain spray-dried green tea extract was used as the reference to evaluate the green tea flavour intensity of different microencapsulated samples. A 10-point intensity scale ranging from none to strongly expressed bitterness; astringency or green tea flavour was defined and used for the evaluation. The spray-dried green tea extract samples were suspended in distilled water in the concentration of 0.5 % (w/v) (concentration adapted to approximate the caffeine and tannic acid contents that could be recognized by the sensory panel) and given to the trained panellist to be evaluated. A plain green tea brew, prepared according to the usual domestic preparation manner to simulate household preparation was also evaluated. For testing, 10-mL volume of individual samples were prepared, coded and presented in random order to each panel member. As bitterness is a persistent sensation, 3-min break was taken between the samples, during which the panellists were asked to eat unsalted biscuits as a neutraliser and rinse thoroughly their mouths with spring water. The assessments were carried out at a sensory laboratory room, fulfilling the requirements of the ISO standards (ISO 8589, 1998).

Statistical Analysis and Artificial Neural Network Design

The results were analyzed statistically using the Statistica 7.0 software to determine the average value and standard error. Variance analysis, with a significance level of α = 0.05 %, was performed to determine the influence of carrier system formulations on the encapsulation attributes of obtained microparticles. Correlation analysis was also run with the same statistical package.

Nonlinear neural multiple-layer perceptron (MLP) network was applied for prediction of the physical, bioactive, colour and sensory properties of spray-dried microencapsulated green tea extract. The type of encapsulant material and its concentration and the dry matter content of infeed solution, its viscosity and density served as the input parameters, while all the experimentally determined physical, bioactive, colour and sensory properties were the output parameters. Artificial neural network (ANN) training was performed with separation of experimental data into training and validation sets as 80:20 ratios. Back error propagation algorithm available in Statistica 10.0 (StatSoft, USA) was applied for model training. The selection of the optimal neural network architecture was performed by comparing the values of the root mean square error (RMSE) and the linear correlation coefficient (R 2). The number of neurons in the hidden layer varied from 3 to 10. Different activation functions were tested for in hidden and output neurons (Identity, Logistic, Tanh and Exponential). The final selected network was MLP 17-10-23 using BFGS 156 algorithm.

The statistical significance of the input parameters on the output parameters was evaluated by the general sensitivities as the ratio of variances of individual parameter relative to the total variance given by Eq. 2:

Results and Discussion

Taking into account the pronounced catechin sensitivity to high temperature and pH values, control of the temperature during heat processing is a key factor to maintain tea catechin stability (Kim et al. 2007). Heating conditions, especially temperature, have an impact on the epimerization of tea catechins, meaning that the main representative catechins (EGCG, EGC, EC, and ECG) undergo epimerization during heating which results with a decrease of total catechin concentrations after processing. In a study by Vuong et al. (2013), decaffeinated and high-caffeine green tea powders were produced by spray drying; however, pointing to the deteriorative effects that high temperatures may have on tea catechins, the authors used a very high temperature range for spray drying of green tea extract (170–220 °C). Therefore, in the present study a low-temperature approach of only 130 °C for spray drying of green tea extract was examined, using a range of different carrier materials to provide a more stable and protected microencapsulated end product with potential nutraceutical features.

Physical Properties of Spray-Dried Powders

The produced spray-dried powders exhibited low moisture content <2.35 %, which is in correspondence to the results of Vuong et al. (2013) and below the moisture level of 5 % required for good stability and effective packaging and storage of powders (Sinija et al. 2007; Şahin Nadeem et al. 2011). Significant differences were observed among the moisture content of powders encapsulated by different carrier materials, indicating that moisture content may be dependant not only on the type of carrier material but also that lower spray-drying temperatures (130 °C) ensure end products with adequate moisture content, similarly as applying higher temperatures for that purpose. As previously stated, the majority of studies producing spray-dried microencapsulated powders use maltodextrins or gum arabic as the wall/carrier materials and usually rheological properties (viscosity) of reconstituted powders are evaluated (Medina-Torres et al. 2013), while the effect of infeed encapsulant solution viscosity on the resulting powder's physical properties is often neglected. Since in this study 12 different carrier materials were evaluated as carriers of green tea bioactive compounds, the effect of the encapsulant solution viscosity on the physical properties of spray-dried powders was determined. The concentrations of carrier materials used in the present study were adjusted to provide adequate viscosity and enable flowability of encapsulant solutions into the spray drier. According to the obtained results, higher encapsulant concentration did not automatically account for a higher viscosity, while their viscosity had no direct effect on any of the examined physical properties. Viscosity was in an inversely proportional relation to the bulk density of spray-dried powders, since it can be seen that alginate, carageenan and pectin exhibiting the highest viscosity provide the lowest bulk density of samples (Table 1). Bulk densities of the produced powders ranged from 169.64 kg/m3 (alginate) to 671.63 kg/m3 (oligofructose), which is in range of the bulk density values of decaffeinated and high-caffeine spray-dried green tea powders (Vuong et al. 2013) or herbal extracts (Şahin Nadeem et al. 2011). Again, a significant effect of the type of carrier material was established on the bulk density of produced powders, which is in agreement to the study of Şahin Nadeem et al. (2011). The concentration of carrier material revealed no marked influence on the bulk density values, which is in accordance to the results of Tewa-Tagne et al. (2007) who also observed neither significant change nor even a certain amount of decrease (Goula and Adamopoulos 2008) in the bulk density of the spray-dried powders with an increase in the carrier concentration. According to our results, using polysaccharides such as alginate, carageenan and pectin provided powders with the lowest bulk densities, as opposed to oligofructose with the highest bulk density. Good linear correlation was observed between the bulk densities and mean particle size (d = 0.5) of produced powders (r = 0.733). Oligofructose exhibiting the highest bulk density was also characterized by the highest mean particle size (d = 0.5) and highest Sauter diameter (D = 3,2). Generally, the mean particle size of produced powders ranged from 2.88 μm for plain green tea extract to 52.95 μm for oligofructose-encapsulating green tea extract. Spray-drying microencapsulation of green tea extract increased the particle size of all formulated encapsulant solutions, with oligofructose and pea proteins exhibiting the largest particles. According to Medina-Torres et al. (2013), particles with the average particle diameter less than 5 μm can be regarded as fine. In the present study, only the use of acacia and guar gum (apart from the plain green tea extract) provided particles with the average diameter <5 μm, indicating that only these biopolymers provide fine powders. Interestingly, xanthan and guar gum, followed by pea proteins were characterized with the widest PSD width, revealing a very unhomogeneous particle size distribution. With the exception of inulin and oligofructose, using pectin as the carrier also provided favourable physical properties of the spray-dried powders, characterized by low bulk density and low dissolution time, which are important for potential food applications.

SEM Microscopy and FTIR

SEM micrographs of spray-dried powders (Fig. 1) depict polydispersed particles with pronounced structural differences. The SEM micrograph of free (nonencapsulated) spray-dried green tea extract (Fig. 1a) reveals the irregular (nonspherical) shape of obtained microparticles, with highly dented surfaces, which form large aggregates. The pronounced shape depression (collapse) of plain spray-dried green tea extract was markedly improved by the addition of carrier materials such as modified corn starch (Fig. 1d), alginate (Fig. 1e), pectin (Fig. 1f) and carageenan (Fig. 1g), which provide less aggregated particles with more expressed spherical shape. An improved morphology but larger aggregation was also observed in case of using hydrocolloid gums as the carriers of green tea bioactives (acacia gum (Fig. 1j), locust bean gum (Fig. 1k), xanthan (Fig. 1m) and guar gum (Fig. 1l)). Usage of acacia gum in the spray-drying processes is well established and provides spherical particles, smaller in comparison to protein-based carriers (e.g. whey protein) (Kim and Morr 1996), which was also observed in this study. However, in the present study, pronounced shape distortion of particles with protein-based carriers (Fig. 1h-pea proteins; Fig. 1i-whey proteins) was also noticed when compared to systems based on natural polysaccharides. The formation of particles is evidenced by the cracked (broken) particle visible on Fig. 1k formed using LBG as the encapsulants, which clearly displays that a spherical hollow particle has been formed by spray drying.

SEM micrographs of a spray-dried green tea extract and spray-dried microencapsulated extract with b oligofructose, c inulin, d modified corn starch, e alginate, f pectin, g carageenan, h pea proteins, i whey proteins, j acacia gum, k locust bean gum, l guar gum and m xanthan (all images depict the enhancements of ×3000)

The best morphological properties, suggested by the SEM microscopy, may be achieved using pectin or carageenan as the matrix materials since the most regular, spherical shape of obtained particles can be observed. Fu et al. (2011) determined that the drying temperature (in the range of 70–130 °C) of EGCG nanoparticles produced by spray drying has little effect on the particle morphology, indicating that the used lower temperature in the present study is justified. The extensively dented surface of oligofructose (Fig. 1b), inulin (Fig. 1c) and starch (Fig. 1d) encapsulated microparticles has also been observed in previous studies, such as in gum arabic-maltodextrin microparticles encapsulating EGCG (Peres et al. 2011), nopal mucilage (Opuntia ficus indica) microparticles encapsulating gallic acid (Medina-Torres et al. 2013) and ß-carotene using modified tapioca starch and maltodextrin as encapsulating agents (Loksuwan 2007). In case of using inulin, starch or hydrocolloid gums (acacia, guar, LBG, xanthan), corrugated surface of the particles can be especially observed, which may be attributed to uneven drying and shrinkage, as previously observed by Fu et al. (2011). According to the same authors, the shrinkage of particles occurs due to the slow diffusion rate of encapsulated compounds (in our case green tea polyphenols and caffeine) inside the particle. As water is removed from the particle surface, an increase in the bioactives concentration near the surface occurs and results in a solid crust being formed on the particle surface. The thickness of the crust continues to increase until a hollow particle is formed, while the crust eventually collapses into a convex-concave-shaped particle. It seems that oligofructose is less suitable as carrier for tea extract encapsulation by spray drying regarding morphological properties of samples. The reason for this might be the fact that oligofructose consisted of shorter molecular chain that cannot provide adequate formation of structure upon spray drying and water evaporation. This may also explain the largest particle size of oligofructose-encapsulating microparticles discusses previously (Table 1).

The FTIR spectra of free spray-dried green tea extract as well as spray-dried green tea encapsulates with different carrier materials are displayed on Fig. 2a–d. For comparison, FTIR spectrum of spray-dried (free) green tea extract is presented on Fig. 2b (g), d (g). As can been seen, the FTIR spectrum of free green tea extract exhibits several characteristic bands: the broad band around 3370 cm−1 corresponded to O–H stretching of hydroxyl groups; the peak at 2927 cm−1 is connected with C–H vibration; the band around 1630 cm−1 occurs due to C=O vibration in the structures of different chemicals extracted from plant material (Szymczycha-Madeja et al. 2013). Generally, the bands in the spectral region between 800 and 1200 cm−1 are assigned to presence of carbohydrates extracted from green tea (Zhou et al. 2009). The bands at 1452, 1517 and 1554 cm−1 were also observed, which are most probably related to the presence of catechins and their complexes with metal ions (Torreggiani et al. 2008). The spectrum of encapsulated green tea extract is primarily defined by the presences of the carrier material, especially in the case of carageenan, pectin, alginate, modified starch, inulin, oligofructose and proteins (i.e. whey proteins and pea proteins), where the spectrum of tea extract is overlapped by bands assigned to carrier materials. On the other hand, in the case of encapsulates based on xanthan, guar gum and locust bean gum, the bands of green tea extract are more pronounced.

The results of FTIR analysis presented in this study show that green tea extract in both free and encapsulated forms exhibits characteristic spectrum that is assigned to chemical structure of carriers, as well as compounds present in the green tea extract. These results confirm that green tea bioactive molecules are incorporated in the biopolymer (encapsulant) matrix by intermolecular interactions and reveal that the green tea extract integrity was preserved after the spray-drying process. Moreover, the presence of bands that most probably are related to catechins and their complexes with either encapsulant materials or metal ions might be useful for understanding of the higher flavan-3-ols loading capacity observed in case of some carrier materials (Table 3).

UV-Vis Absorption and Colour Properties of Spray-Dried Samples

Since the quality of all food products may be considered in terms of taste, texture, mouth feel and other sensory attributes, with regard to visual quality, colour acts as a very important indicator. Due to a high content of catechin polyphenols that exhibit absorption maxima at 250–360 nm, the absorption maximum of green tea extract, regardless of its green-yellowish colour, is at 360 nm and not in the visible part of the spectrum. Therefore, UV-Vis absorbance yield was defined as a parameter to encompass all UV-Vis absorbing substances (and just the ones having colour properties) after spray drying. In terms of the parameter in spray-dried powders encapsulating green tea bioactives produced in this study, Table 2 reveals that microencapsulation of green tea extract enabled the preservation of UV-Vis absorbing compounds using all employed carriers except guar gum, LBG, xanthan and pea proteins, since much lower yields were obtained in comparison to plain spray-dried extract. This indicates that using the three previously stated hydrocolloids and pea proteins as carrier materials for encapsulation of green tea extract is not efficient for the retention of all UV-Vis absorbing compounds. Correspondingly, using these materials also provided lower chlorophylls content than other employed carriers. Among all evaluated biopolymer materials, alginate provided the highest UV-Vis absorbance yield but not significantly different (p > 0.05) than acacia gum. Oligofructose can generally be regarded as the most efficient one to preserve the colour properties of green tea extract. Using oligofructose as the carrier of green tea bioactive compounds resulted with high UV-Vis absorbance yield (when compared to plain spray-dried green tea extract), the highest chlorophyll content and total colour difference of spray-dried powder.

The type of carrier material significantly influenced the experimental colour parameters, since an increase in lightness (L*) and varying effects on the a and b values were obtained by the addition of different wall materials. The increase in lightness (L*) of spray-dried powders is consistent with the augmentation of the used carrier concentration in the ranking: hydrocolloid gums < inulin, starch, oligofructose, which is in agreement with the results of Şahin Nadeem et al. (2011). However, marked fluctuations of a and b values within the samples imply on a more significant effect of the type of carrier material, rather than its concentration, since significant differences can be observed between a and b values of powders produced with equal concentration of the added carrier (for example, inulin and oligofructose). Further, the use of guar gum, modified starch or LBG provides even more greenish powders than plain spray-dried green tea extract, since lower a values of those samples in comparison to plain spray-dried green tea can be observed. Since no similar pattern or correspondence in the ranking of samples according to their UV-Vis absorbance yield, chlorophyll content and total colour difference was observed, correlation analysis between the absorbance yield and the content of bioactive pigments (chlorophylls and total polyphenols) was performed in order to verify which of the bioactive pigments contribute more to the colour of spray-dried microencapsulated green tea bioactives. The correlation analysis confirmed that chlorophylls contribute more to the colour of spray-dried powders than polyphenolic compounds (r absorbance yield/chlorophylls = 0.369; r absorbance yield/polyphenols = −0.595).

Product Yield, Loading Capacity and Bioactive Composition of Spray-Dried Green Tea Extract

In terms of the product yield, only microencapsulation in inulin (67.04 %), whey proteins (65.18 %), acacia gum (56.90 %) and oligofructose (56.48 %) enabled significantly (p < 0.05) higher product yield obtained by spray drying, when compared to plain spray-dried green tea extract (42.89 %). The yield of plain spray-dried green tea extract is generally in correspondence to the yields of decaffeinated and high-caffeine green tea powders (26.7–51.4 %) produced by spray drying in a study of Vuong et al. (2013). According to the obtained results, the type of carrier material had a significant effect on the product yield, which can also be observed in the group of hydrocolloid gums used as the carriers (gum arabic, guar gum, LBG, xanthan), where guar gum exhibits a very low product yield (8.64 %). Taking into account that the product yield is among the most important factors for the efficiency evaluation of spray drying, the results indicate that using materials such as inulin and whey proteins as carriers of green tea bioactives is justified from the feasibility and overall economic aspects related to food applications. The significant effect of the type of carrier on the yield is converse to the results of Şahin Nadeem et al. (2011), who determined that the product yield was significantly affected by the carrier concentration, whereas the type of carrier (ß-cyclodextrin, maltodextrins and gum arabic) showed no significant influence.

The loading capacity of green tea total polyphenols (TP) and flavan-3-ols exhibited the same trend, which was confirmed by a high linear correlation observed between the loading capacities of these compounds (r TP/Flavan-3-ols = 0.869). Similarly as in the case of colour preservation, hydrocolloid gums provided the lowest loading capacities of both total polyphenols and flavan-3-ols, indicating that these materials do not facilitate protection of polyphenolic compounds during spray drying. Moreover, significantly lower TP and flavan-3-ol loading capacities of microencapsulated green tea extract using these carriers in comparison to plain spray-dried extract can be observed.

The obtained results are in conversion to the results of Şahin-Nadeem et al. (2013) who determined that the loading capacity of TP in the maltodextrin or gum arabic microparticles encapsulating sage extract is significantly decreased by increasing the concentration of the carriers. The results of the present study revealed that lower carrier concentration, such as in the case of hydrocolloid gums, provides lower polyphenol entrapment, while higher concentrations of polysaccharides were more efficient to protect and entrap polyphenols, which may also be associated with the specific interactions of polyphenols with the employed carrier material. According to the obtained results, only the use of modified starch and inulin as the carriers of green tea bioactive compounds provided significantly higher (p < 0.05) loading capacities of both TP and flavan-3-ols, in comparison to plain spray-dried extract. The use of pectin and alginate also retained higher but insignificant TP and flavan-3-ols content in comparison to plain spray-dried extract. The beneficial, protective effect of inulin, modified starch, alginate and pectin on green tea polyphenolic compounds may be explained by the interactions of these polysaccharide materials and polyphenolic compounds. Namely, the interactions of flavonoid compounds and proteins are well known and examined; however, much less is known regarding the interaction between flavonoids and carbohydrates (Bordenave et al. 2014). Given the polymeric character of most carbohydrates and their versatile physicochemical properties (regarding hydrophilic/hydrophobic character, for example), interactions driven by similar factors governing flavonoid–protein interactions are anticipated. Guzar (2012) observed interactions of polyphenolic compounds with hydrophobic regions of leached amylose and with amylopectin side chains in the starch molecule through hydrogen bonds and van der Waals forces. These interactions and the presence of hydroxyl and carboxyl groups in polyphenolic compounds can affect functional properties of starch by competing for water. Interactions between green tea catechins and starch amylose have also been proposed by Liu et al. (2011). Apart from starch, in the present study, a high loading capacity of flavan-3-ols in the spray-dried microcapsules was achieved, amounting to even 91 % in case of using pectin as the encapsulant. Two studies modelling plant cell walls using cellulose and pectin showed how such composite materials were able to absorb and retain model phenolic acids and anthocyanins (Padayachee et al. 2012) via non-covalent interactions (ionic with pectin and hydrophobic with cellulose). Generally, nonspecific hydrogen bonding and ionic interactions seem to be the primary drivers for the association of non-starch polysaccharides with flavonoids. Gum arabic, cyclodextrins, pectins and other polygalacturonic acids, xanthan gum, dextrans, arabinogalactans and glucose have been assessed according to their ability to disrupt procyanidin–protein interactions (Carvalho et al. 2006; De Freitas et al. 2003; Soares et al. 2009). Similarly to gum arabic, ionic polysaccharides such as pectins or arabinogalactans can also bind to flavonoids without the presence of proteins (Bordenave et al. 2014). In case of catechins, it was determined that galloylation seemed to increase the binding capacity to ß-glucans, which is suggested to be mainly driven by hydrogen bonding interactions (Wang et al. 2013; Simonsen et al. 2009). Besides the study of these complexes, flavonoids were tried to be entrapped in polysaccharide particles by encapsulation such as the EGCG-loaded nanoparticles made from gum arabic and maltodextrin with improved EGCG stability (Qin et al. 2010), quercetin incorporation into a guar gum-based matrix (Peres et al. 2011) or pectin–hydroxypropyl methylcellulose tablets for specific delivery to the colon (Wang et al. 2013), quercetin complexation with pectin for enhanced bioavailability (Monteiro et al. 2007), etc. Nitta et al. (2004) revealed that thermoreversible gels can be formed from tamarind seed xyloglucan by addition of EGCG, suggesting that EGCG plays the role of a non-covalent cross-linker in the three-dimensional polysaccharide network. This is in accordance to the results of the present study (Table 3) since the highest contents of EGCG and caffeine in the microencapsulated spray-dried powders were also determined while using hydrocolloid gums (such as xanthan gum) or oligofructose as the carriers (cellulose-like chemical structure), confirming that indeed interactions between green tea polyphenolic compounds and polysaccharide materials may occur, which contribute to their higher loading efficiency during microencapsulation. By observing the contents of prevalent-specific bioactive compounds of green tea, EGCG and caffeine (Table 3), much lower caffeine contents loaded in the spray-dried powders were obtained. This was also confirmed by high EGCG-to-caffeine ratios, producing even up to 200-fold difference between the contents of these two compounds, which reveals that much higher EGCG contents were entrapped within the produced microparticles than caffeine contents, indicating that EGCG as a polyphenolic compound exhibits more potent interactions with the employed carriers than caffeine. Also, since significant differences were observed within the EGCG-caffeine ratios depending on the type of carrier material, it seems that selective interactions and entrapment of polyphenols and caffeine indeed occurred in dependence of the used biopolymer material. Nonsignificant differences among the EGCG contents of spray-dried microencapsulated green tea powders were observed only between plain spray-dried green tea extract and guar gum-encapsulated extract, indicating that guar gum contributes the most to preserving EGCG during spray drying. Using other biopolymer materials did not achieve protection of EGCG, since lower EGCG contents were observed in comparison to plain spray-dried green tea extract; however, even higher caffeine contents in the microencapsulated powders can be observed while using xanthan, LBG, pectin, modified starch or oligofructose as the carriers. This indicates a higher stability of caffeine to the spray-drying temperature (130 °C) employed in the present study but also reveals a great potential for stabilizing this psychoactive drug in the microencapsulated form.

Using 1 g of microencapsulated spray-dried green tea extract, up to almost 162 mg of EGCG (in case of using hydrocolloid gums such as guar gum as the carriers) and a very low caffeine content (<5 mg) are delivered. Since the content of caffeine in the obtained spray-dried green tea powders was below the maximum permitted level of 1 % (w/w), the powders can be classified as decaffeinated products (Ye et al. 2007), similarly as obtained in a study by Vuong et al. (2013). However, the results presented in Table 3 reveal much higher contents of EGCG obtained in this study in comparison to maximum 54.3 mg/g powder obtained by Vuong et al. (2013), implying that the extraction procedure of green tea and spray drying of the extract at 130 °C are more efficient for producing a high polyphenol-loaded microencapsulated green tea powder. Also, since due to the health concerns related to the psychoactive activities of caffeine, numerous decaffeinated and alternative caffeine-free products are developed; in this study an excellent nutraceutical for the delivery of green tea polyphenols is developed, additionally ensuring a low-caffeine content.

In Vitro Dissolution Tests in SGF and SIF

The dissolution/release profiles of total polyphenols and flavan-3-ols from the spray-dried powders are reported in Fig. 3a, b, respectively. The dissolution/release tests were performed and designed in the gastric and small intestine conditions as this should represent the places where polyphenolic compounds are metabolized and absorbed. According to the obtained results, in 10 min complete dissolution (up to 100 %) of the spray-dried powders in SGF evaluated as the release of total polyphenols and flavan-3-ols was obtained from the plain spray-dried green tea extract and polysaccharide- and protein-microencapsulated powders (inulin, oligofructose, modified starch, whey proteins, pea proteins), with respect to approximately 50 % from the hydrocolloid-encapsulated green tea extract bioactives (xanthan, LBG, guar gum). The hydrophilic nature of polysaccharide and protein biopolymers (inulin, oligofructose, modified starch, whey proteins, pea proteins) and their water sorption properties may justify the immediate and high dissolution rate and the fast release of bioactive compounds in SGF and SIF (Sriamornsak et al. 2008; Panchev et al. 2010; Humblet-Hua et al. 2011). This may be explained by an increase of the microparticle–water interaction due to both amorphous physical state of the powders, leading to an improvement of solubility (Hancock and Parks 2000). On the other hand, using acacia gum and carageenan enabled a prolonged release of TP in SGF, similarly as in case of using pectin and alginate as the carriers, and their dissolution was further continued in SIF. According to the displayed dissolution/release profiles of polyphenolic compounds and flavan-3-ols in simulated gastric and intestinal fluids, it can be observed that hydrocolloid gums as the encapsulants provide the most favourable dissolution/release pattern. Using xanthan, LBG and guar gum enabled the most retarded release during 2 h of dispersion in SGF and additional release in SIF. The same release profile was also observed for flavan-3-ols, with gums again exhibiting the best dissolution profile. At the end (2 h) of dispersion in SGF, about 90 % of both TP and flavan-3-ols was dissolved/released from the LBG and guar gum-encapsulated microparticles, while even less (76–83 %) was release at the same time from the xanthan-encapsulated powder. Interestingly, it can be pointed out that xanthan, after the plain green tea of course, released the highest contents of both polyphenols and flavan-3-ols. The obtained dissolution/release profiles indicate that an evident prolongation and improvement of the release of polyphenolic compounds in gastric and intestinal conditions can be achieved using xanthan, guar gum and LBG or even carageenan, alginate and pectin as carriers during spray drying, rather than using conventionally employed carrier such as maltodextrin, starch or acacia gum for that purpose. The slow water dissolution efficiency of hydrocolloid gums used in this study (Table 1) corresponded to the most retarded release of polyphenolic compounds in SGF and SIF from these microencapsulated particles.

Sensory Properties of Spray-Dried Green Tea Extract

The sensory properties of spray-dried microencapsulated substrates are very rarely evaluated, despite the fact that although there are many factors influencing consumers' preferences of food products, the final decision is most often affected entirely on the basis of sensory perception. By reviewing the available scientific literature, most often only the odour of spray-dried powders is evaluated by “sniffing tests” (Sansone et al. 2011; Seo and Hummel 2009). Sensory analysis of rehydrated spray-dried green tea extract powders performed in this study revealed that the evaluated sensory attributes differ significantly in dependence of the used encapsulant material. Generally, microencapsulation of green tea extract using different carrier materials enabled to reduce the bitterness intensity in comparison to tea infusion prepared by simple brewing technique to simulate household preparation conditions, and in comparison to plain spray-dried green tea, however, it had a varying effect on astringency and green tea aroma intensity(Fig. 4). According to the obtained results, xanthan, gum arabic and pectin provided powders with the most pronounced astringency intensity, while alginate, whey proteins and pea proteins generally were the lowest scored samples due to the low flavour intensity of green tea. The best ranked samples, with the highest green tea aroma intensity and lowest astringency were modified starch > inulin > carageenan, indicating that using these materials can contribute to preserving green tea aroma and lowering negative hedonic properties like bitterness and astringency. The best retention of odour by these matrixes with respect to other ones used is probably due to a fair absorption of volatile compounds. According to the literature data, matrix in the amorphous state (corresponding to the state that inulin, modified starch and carageenan are found at high temperatures during spray drying (Ronkart et al. 2009)) is more efficient in aroma retention than crystalline ones which release the encapsulated compounds in a larger amount (Goubet et al. 1998).

Artificial Neural Network

Since based on the obtained results for each of the evaluated aspects (physical, morphological, colour, bioactive and sensory properties) a different carrier material provided the end product with the best properties, it is very hard to deduce any general conclusions about the optimal encapsulant. Therefore, an artificial neural network was designed in this study, taking into account the type of carrier, its concentration, total solids content of encapsulant solution, and its density and viscosity as the input parameters and all the experimentally determined results as the output parameters. The most suitable network was selected based on training, test and validation preferences and errors, as previously stated by Carvalho et al. (2013) and Di Scala et al. (2013), and had a hidden activation functions identity and logistic output, with the maximum test error of 0.027 achieved in the test period, and was selected for analysis of the spray-drying process .

Bitterness, astringency and green tea flavour intensity of infusion, plain spray-dried extract and spray-dried microencapsulated green tea bioactives using different carrier materials (reconstituted solutions). The values superscripted with the same letter are not significant (p>0.05). LBG – locust bean gum

Global sensitivity coefficient, as an indicator of influence of the particular input parameter on the output variable, is defined as the ratio of variances of individual parameter relative to the total variance. Higher global sensitivity coefficient corresponds to the higher influence on the output variables. Using this network as a modelling tool, the global sensitivity analysis revealed the ranking of input parameters as the major factors that influence mostly the quality or the properties of the spray-dried powders: type of carrier material > carrier material concentration > dry matter content (%) of encapsulant solution > viscosity (Fig. 5). Also, a very high correlation R 2 > 0.967 between the experimentally obtained and ANN-predicted results were obtained for all output parameters, with specific groupings of samples depending on the evaluated output parameter. However, using the network also did not enable to deduce any general conclusion about the optimal type of encapsulant but rather indicated which carrier materials and in what concentration are the optimal ones for achieving the best bioactive, physical, sensory or colour properties. In that respect it was revealed that hydrocolloid gums are the best ones for providing the smallest particle size (LBG −0.46 %), high EGCG (guar gum −1.06 %) and chlorophylls content (xanthan −0.54 %), pectin enabled the lowest bitterness and astringency intensities and the highest flavan-3-ol loading capacity (5.06 %), while using inulin as the encapsulant material produced microparticles with the highest product yield and highest TP loading capacity (10.21 %). In terms of the UV-Vis absorbance yield and bulk density, alginate in the concentration of 5.03 % can also provide good properties to the spray-dried green tea powders. By comparing the experimentally obtained and ANN-predicted results for the best encapsulation performance by the employed encapsulant materials, some discrepancies can be observed; however, a general indication on the possibility of using nonconventional biopolymer materials as carriers for spray-drying purposes has been provided.

Conclusions

The results of the present study reveal the potential of using several natural biopolymers as carriers of green tea phytochemicals, especially flavan-3-ols and caffeine. A comprehensive overview of physical, morphological, bioactive, colour, release and sensory properties of spray-dried microencapsulated green tea extract is provided; and the obtained results are used for the design of an artificial neural network that reveals the optimal encapsulant material and its concentration for each of the evaluated powder properties. Based on the obtained results, using gums as the carrier materials provides the smallest particle size, a high EGCG and chlorophylls content and the most favourable release/dissolution kinetics. However, the use of pectin, inulin and alginate which are not that often employed as carriers for spray-drying purposes enables high loading capacities of bioactive compounds, masking of negative sensory properties such as bitterness and astringency and high product and UV-Vis absorbance yields. Based on the obtained results, it can be deduced that a formulation comprising a combination of those biopolymers would provide potentially functional ingredients with encapsulated green tea phytochemicals, retained colour and improved sensory properties. Thus, obtained microencapsulated powders may have a few potential food applications, such as using the pectin-encapsulated powder for production of jelly candies. In the same way, using inulin- or oligosaccharide-encapsulated green tea extract can be added as a functional ingredient to chocolates and cocoa drink powder mixtures as a bulking agent. Using these compounds may enable to enrich conventional products and achieve formulation of novel, functional food products.

References

Atomssa, T., & Gholap, A. V. (2015). Characterization and determination of catechins in green tea leaves using UV-visible spectrometer. Journal of Engineering and Technology Research, 7, 22–31.

Belščak-Cvitanović, A., Đorđević, V., Karlović, S., Pavlović, V., Komes, D., Ježek, D., Bugarski, B., & Nedović, V. (2015a). Protein-reinforced and chitosan-pectin coated alginate microparticles for delivery of flavan-3-ol antioxidants and caffeine from green tea extract. Food Hydrocolloids, 51, 361–374.

Belščak-Cvitanović, A., Komes, D., Dujmović, M., Karlović, S., Biškić, M., Brnčić, M., & Ježek, D. (2015b). Physical, bioactive and sensory quality parameters of reduced sugar chocolates formulated with natural sweeteners as sucrose alternatives. Food Chemistry, 167, 61–70.

Bordenave, N., Hamaker, B. R., & Ferruzzi, M. G. (2014). Nature and consequences of non-covalent interactions between flavonoids and macronutrients in foods. Food & Function, 5, 18–34.

Buchner, N., Krumbein, A., Rohn, S., & Kroh, L. W. (2006). Effect of thermal processing on the flavonols rutin and quercetin. Rapid Communications in Mass Spectrometry, 20, 3229–3235.

Carvalho, E., Povoas, M. J., Mateus, N., & De Freitas, V. (2006). Application of flow nephelometry to the analysis of the influence of carbohydrates on protein–tannin interactions. Journal of the Science of Food & Agriculture, 86, 891–896.

Carvalho, N. B., Minim, V. P. R., Silva, R., Della Lucia, S. M., & Minim, L. A. (2013). Artificial neural networks (ANN): prediction of sensory measurements from instrumental data. Food Science and Technology Campinas, 33(4), 722–729.

Chegini, G. R., & Ghobadian, B. (2007). Spray dryer parameters for fruit juice drying. World Journal of Agricultural Sciences, 3, 230–236.

Chow, H. H. S., Cai, Y., Hakim, I. A., Crowell, J. A., Shahi, F., Brooks, C. A., Dorr, R. T., Hara, Y., & Alberts, D. S. (2003). Pharmacokinetics and safety of green tea polyphenols after multiple-dose administration of epigallocatechin gallate and polyphenon E in healthy individuals. Clinical Cancer Research, 9, 3312–3319.

De Freitas, V., Carvalho, E., & Mateus, N. (2003). Study of carbohydrate influence on protein–tannin aggregation by nephelometry. Food Chemistry, 81, 503–509.

Di Scala, K., Meschino, G., Vega-Galvez, A., Lemus-Mondaca, R., Roura, S., & Mascheroni, R. (2013). An artificial neural network model for prediction of quality characteristics of apples during convective dehydration. Food Science and Technology Campinas, 33(3), 411–416.

Dube, A., Ng, K., Nicolazzo, J. A., & Larson, I. (2010). Effective use of reducing agents and nanoparticle encapsulation in stabilizing catechins in alkaline solution. Food Chemistry, 122, 662–667.

Dufrene B. Global tea consumption remains robust. Tea & Coffee Trade Journal. 2012;24–30.

Fang, J. Y., Lee, W. R., Shen, S. C., & Huang, Y. L. (2006). Effect of liposome encapsulation of tea catechins on their accumulation in basal cell carcinomas. Journal of Dermatological Science, 42(2), 101–109.

Food and Agriculture Organization (FAO) (2012). Firm tea prices set to continue. http://www.fao.org/news/story/en/item/124221/icode/. Accessed 15 November 2014.

Fu, N., Zhou, Z., Jones, T. B., Tan, T. T. Y., Wu, W. D., Lin, S. X., Chen, X. D., & Chan, P. P. Y. (2011). Production of monodisperse epigallocatechin gallate (EGCG) microparticles by spray drying for high antioxidant activity retention. International Journal of Pharmaceutics, 413, 155–166.

Georgetti, S. R., Casagrande, R., Souza, C. R. F., Oliveira, W. P., & Fonseca, M. J. V. (2008). Spray drying of the soybean extract: effects on chemical properties and antioxidant activity. Lebensmittel-Wissenschaft und Technologie, 41, 1521–1527.

Goubet, I., Le Quere, J. L., & Voilley, A. J. (1998). Retention of aroma compounds by carbohydrates: influence of their physicochemical characteristics and of their physical state. A review. Journal of Agricultural and Food Chemistry, 46, 1981–1990.

Goula, A. M., & Adamopoulos, K. G. (2008). Effect of maltodextrin addition during spray drying of tomato pulp in dehumidified air: II. Powder properties. Drying Technology, 26, 726–737.

Guzar, I. Effect of Starch-Polyphenol Interactions on Starch Hydrolysis. Thesis, University of Guelph, Ontario, Canada; 2012.

Hancock, B. C., & Parks, M. (2000). What is the true solubility advantage for amorphous pharmaceuticals? Pharmaceutical Research, 17(4), 397–404.

Helgason, T., Awad, T. S., Kristbergsson, K., Decker, E. A., McClements, D. J., & Weiss, J. (2009). Impact of surfactant properties on oxidative stability of β-carotene encapsulated within solid lipid nanoparticles. Journal of Agricultural and Food Chemistry, 57, 8033–8040.

Hirota, F. (2012). Green tea cancer prevention. In M. Schwab (Ed.), Encyclopedia of Cancer (pp. 1603–1607). Berlin: Springer.

Hu, B., Pan, C. L., Sun, Y., Hou, Z. Y., Ye, H., Hu, B., et al. (2008). Optimization of fabrication parameters to produce chitosan-tripolyphosphate nanoparticles for delivery of tea catechins. Journal of Agricultural and Food Chemistry, 56(16), 7451–7458.

Huang, Y., Sheng, J., Yang, F., & Hu, Q. (2007). Effect of enzyme inactivation by microwave and oven heating on preservation quality of green tea. Journal of Food Engineering, 78, 687–692.

Humblet-Hua, K. N. P., Scheltens, G., Van Der Linden, E., & Sagis, L. M. C. (2011). Encapsulation systems based on ovalbumin fibrils and high methoxyl pectin. Food Hydrocolloids, 25(3), 307–314.

ISO 8589 (1998). Sensory analysis–general guidance for the design of test rooms.

Kim, D. Y., & Morr, V. C. (1996). Microencapsulation properties of gum arabic and several food proteins: spray-dried orange oil emulsion particles. Journal of Agricultural and Food Chemistry, 44, 1314–1320.

Kim, E. S., Liang, Y. R., Jin, J., Sun, Q. F., Lu, J. L., & Du, Y. Y. (2007). Impact of heating on chemical compositions of green tea liquor. Food Chemistry, 103, 1263–1267.

Kosaraju, S. L., D’ath, L., & Lawrence, A. (2006). Preparation and characterisation of chitosan microspheres for antioxidant delivery. Carbohydrate Polymers, 64(2), 163–167.

Liao, J. W., Hong, L. Z., Wang, M. F., Tsai, S. C., Lin, Y. J., & Chan, Y. C. (2010). Mutagenic safety and fatty liver improvement of nanonized black soybeans in senescence-accelerated prone-8 mice. Journal of Food Science, 75, T82–T90.

Liu, J., Wang, M., Peng, S., & Zhang, G. (2011). Effect of tea catechins on the postprandial glycemic response to starches differing in amylose content. Journal of Agricultural and Food Chemistry, 59, 4582–4588.

Loksuwan, J. (2007). Characteristics of microencapsulated betacarotene formed by spray drying with modified tapioca starch, native tapioca starch and maltodextrin. Food Hydrocolloids, 21, 928–935.

Matsuo, M., Sasaki, N., Saga, K., & Kaneko, T. (2005). Cytotoxicity of flavonoids toward cultured normal human cells. Biological & Pharmaceutical Bulletin, 28, 253–259.

Medina-Torres, L., García-Cruz, E. E., Calderas, F., González Laredo, R. F., Sánchez-Olivares, G., Gallegos-Infante, J. A., Rocha-Guzmán, N. E., & Rodríguez-Ramírez, J. (2013). Microencapsulation by spray drying of gallic acid with nopal mucilage (Opuntia ficus indica). LWT-Food Science and Technology, 50, 642–650.

Monteiro, L.M., Souza, A.E., Gianotto, E.A.S., Nery, M.M.F., Duarte, J.C., De Freitas, O., Casagrande, R., & Baracat, M.M. Comprimidos matriciais preparados com hidroxipropilmetilcelulose e pectina contendo quercetina para liberaçao colon-especica. 2007; 26:179–184.

Murakami, H., Yoneyama, T., Nakajima, K., & Kobayashi, M. (2001). Correlation between loose density and compactibility of granules prepared by various granulation methods. International. Journal. Pharmaceutics, 216, 159–164.

Nitta, Y., Fang, Y., Takemasa, M., & Nishinari, K. (2004). Gelation of xyloglucan by addition of epigallocatechin gallate as studied by rheology and differential scanning calorimetry. Biomacromolecules, 5, 1206–1213.

Nilsang, S., Lertsiri, S., Suphantharika, M., & Assavanig, A. (2005). Optimization of enzymatic hydrolysis of fish soluble concentrate by commercial proteases. Journal of Food Engineering, 70, 571–578.

Normah, I., Siti Hafsah, M. S., & Nurul Izzaira, A. (2013). Bitterness of green mussel (Perna viridis) hydrolysate as influenced by the degree of hydrolysis. International Food Research Journal, 20(5), 2261–2268.

Obón, J. M., Castellar, M. R., Alacid, M., & Fernández-López, J. A. (2009). Production of a red–purple food colorant from Opuntia stricta fruits by spray drying and its application in food model systems. Journal of Food Engineering, 90, 471–479.

Padayachee, A., Netzel, G., Netzel, M., Day, L., Zabaras, D., Mikkelsen, D., & Gidley, M. J. (2012). Binding of polyphenols to plant cell wall analogues–part 2: phenolic acids. Food Chemistry, 135, 2287–2292.

Panchev, I. N., Slavov, A., Nikolov, K., & Kovacheva, D. (2010). On the water-sorption properties of pectin. Food Hydrocolloids, 24(8), 763–769.

Peres, I., Rocha, S., Gomes, J., Morais, S., Carmo Pereira, M., & Coelho, M. (2011). Preservation of catechin antioxidant properties loaded in carbohydrate nanoparticles. Carbohydrate Polymers, 86, 147–153.

Plochmann, K., Korte, G., Koutsilieri, E., Richling, E., Riederer, P., Rethwilm, A., Schreier, P., & Scheller, C. (2007). Structure-activity relationships of flavonoid-induced cytotoxicity on human leukemia cells. Archives of Biochemistry and Biophysics, 460, 1–9.

Ronkart, S.N., Paquot, M., Blecker, C. S., Fougnies, C., Doran, L., Lambrechts, J.C., Norberg, B., & Deroanne, C. (2009). Impact of the crystallinity on the physical properties of inulin during water sorption. Food Biophysics, 4, 49–58.

Rusak, G., Gutzeit, H. O., & Müller, J. L. (2002). Effects of structurally related flavonoids on hsp gene expression in human promyeloid leukaemia cells. Food Technology and Biotechnology, 40, 267–273.

Qin, Y., Wang, H. W., Karuppanapandian, T., & Kim, W. (2010). Chitosan green tea polyphenol complex as a released control compound for wound healing. Chinese Journal of Traumatology, 13, 91–95.

Şahin Nadeem, H., Torun, M., & Özdemir, F. (2011). Spray drying of the mountain tea (Sideritis stricta) water extract by using different hydrocolloid carriers. LWT-Food Science and Technology, 44, 1626–1635.

Şahin Nadeem, H., Dincer, C., Torun, M., Topus, A., & Özdemir, F. (2013). Influence of inlet air temperature and carrier material on the production of instant soluble sage (Salvia fruticosa Miller) by spray drying. LWT-Food Science and Technology, 52, 31--38.

Sansone, F., Mencherini, T., Picerno, P., d’Amore, M., Aquino, R. P., & Lauro, M. R. (2011). Maltodextrin/pectin microparticles by spray drying as carrier for nutraceutical extracts. Journal of Food Engineering, 105, 468–476.

Seo, H. S., & Hummel, T. (2009). Effects of olfactory dysfunction on sensory evaluation and preparation foods. Appetite, 53(3), 314–321.

Shi, G. R., Rao, L. Q., Yu, H. Z., Xiang, H., Yang, H., & Ji, R. (2008). Stabilization and encapsulation of photosensitive resveratrol within yeast cell. International Journal of Pharmaceutics, 349(1–2), 83–93.

Simonsen, H. T., Nielsen, M. S., Christensen, N. J., Christensen, U., Cour, T. V. L., Motawia, M. S., Jespersen, B. P. M., Engelsen, S. B., & Møller, B. L. (2009). Journal of Agricultural and Food Chemistry, 57, 2056–2064.

Sinija, V. R., Mishra, H. N., & Bal, S. (2007). Process technology for production of soluble tea powder. Journal of Food Engineering, 82, 276–283.

Soares, S. I., Gonçalves, R. M., Fernandes, I. V. A., Mateus, N., & De Freitas, V. (2009). Carbohydrates inhibit salivary proteins precipitation by condensed tannins. Journal of Agricultural and Food Chemistry, 57, 4352–4358.

Sriamornsak, P., Wattanakorn, N., Nunthanid, J., & Puttipipatkhachorn, S. (2008). Mucoadhesion of pectin as evidence by wettability and chain interpenetration. Carbohydrate Polymers, 74, 458–467.

Sun-Waterhouse, D., Wadhwa, S. S., & Waterhouse, G. I. N. (2013). Spray-Drying microencapsulation of polyphenol bioactives: a comparative study using different natural fibre polymers as encapsulants. Food and Bioprocess Technology, 6, 2376–2388.

Szymczycha-Madeja, A., Welna, M., & Zyrnicki, W. (2013). Multi-element analysis, bioavailability and fractionation of herbal tea products. Journal of the Brazilian Chemical Society, 24(5), 777–787.

Tang, W. Q., Li, D. C., Lv, Y. X., & Jiang, J. G. (2011). Concentration and drying of polyphenols extracted from green tea using molecular distillation and spray drying. Drying Technology, 29(5), 584–590.

Tea Institute of Chinese Academy of Agricultural Sciences. (1983). Experiment handbook of tea tree physiology and tea leaves biochemistry. Beijing: Press of Chinese Agriculture.

Tewa-Tagne, P., Briançon, S., & Fessi, H. (2007). Preparation of redispersible dry nanocapsules by means of spray-drying: development and characterisation. European Journal of Pharmaceutical Sciences, 30, 124–135.

Tijskens, L. M. M., Schijvens, E. P. H. M., & Biekman, E. S. A. (2001). Modelling the change in color broccoli and green beans during blanching. Innovative Food Science and Emerging Technologies, 2, 303–313.

Torreggiani, A., Jurasekova, Z., Sanchez-Cortes, S., & Tamba, M. (2008). Spectroscopic and pulse radiolysis studies of the antioxidant properties of (+)catechin: metal chelation and oxidizing radical scavenging. Journal of Raman Spectroscopy, 39, 265–275.

Vuong, Q. V., Golding, J. B., Nguyen, M. H., & Roach, P. D. (2013). Preparation of decaffeinated and high caffeine powders from green tea. Powder Technology, 233, 169–175.

Ye, J.-H., Liang, Y.-R., Jin, J., Liang, H.-L., Du, Y.-Y., Lu, J.-L., Ye, Q., & Lin, C. (2007). Preparation of partially decaffeinated instant green tea. Journal of Agricultural and Food Chemistry, 55, 3498–3502.

Wang, Y., Liu, J., Chen, F., & Zhao, G. (2013). Effects of molecular structure of polyphenols on their noncovalent interactions with oat ß-glucan. Journal of Agricultural and Food Chemistry, 61, 4533–4538.

Warden, B. A., Smith, L. S., Beecher, G. R., Balentine, D. A., & Clevidence, B. A. (2001). Catechins are bioavailable in men and women drinking black tea throughout the day. The Journal of Nutrition, 131, 1731–1737.

Zhang, Y., Hendrich, S., & Murphy, P. A. (2003). Glucuronides are the main isoflavone metabolites in women. Journal of Nutrition, 133, 399–404.

Zhou, L. X., Sun, N. P., Bucheli, P., Huang, H. T., & Wang, D. (2009). FT-IR methodology for quality control of arabinogalactan protein (AGP) extracted from green tea (Camellia sinensis). Journal of Agricultural and Food Chemistry, 57, 5121–5128.

Zimet, P., Rosenberg, D., & Livney, Y. D. (2011). Re-assembled casein micelles and casein nanoparticles as nano-vehicles for omega-3 polyunsaturated fatty acids. Food Hydrocolloids, 25, 1270–1276.

Acknowledgments

This work was supported by the COST action FA1001 The application of innovative fundamental food-structure-property relationships to the design of foods for health, wellness and pleasure, as well as the Ministry of Science, Education and Sports, Republic of Croatia (Project No. 058 3470) and the Ministry of Education, Science and Technological Development, Republic of Serbia (Project No. III46010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Belščak-Cvitanović, A., Lević, S., Kalušević, A. et al. Efficiency Assessment of Natural Biopolymers as Encapsulants of Green Tea (Camellia sinensis L.) Bioactive Compounds by Spray Drying. Food Bioprocess Technol 8, 2444–2460 (2015). https://doi.org/10.1007/s11947-015-1592-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-015-1592-y