Abstract

This research explores the spray-drying microencapsulation of polyphenols (PPs), quercetin and vanillin, using four different fibre polymers as encapsulants (sodium alginate, methyl β-cyclodextrin (MβCD), hydroxypropylmethyl cellulose (HPMC) and inulin). The microstructure, physico-chemical properties, PP content and reconstitution properties in water of the spray-dried powders were systematically evaluated and compared. Techniques used for powder characterisation were scanning electron microscopy, N2 physisorption, Fourier transform infrared (FT-IR) spectroscopy and water activity measurements. High-performance liquid chromatography and viscosity measurements were used to characterise the solutions obtained by reconstitution of the spray-dried powders in methanol or water, respectively. Results show that the type of encapsulant strongly influenced powder morphology, powder surface area and encapsulation efficiency of PPs. Powders prepared using sodium alginate and MβCD possessed more spherical particle shape, smaller average particle size and higher specific surface area than those using HPMC or inulin as encapsulants. For each encapsulant, higher encapsulation efficiencies were achieved for vanillin (37–53 %) than quercetin (9–19 %). Encapsulation efficiencies were inulin > MβCD > HPMC > sodium alginate for vanillin-containing powders. Inulin, MβCD and sodium alginate all gave similar encapsulation efficiencies for quercetin-containing powders. All powders possessed low water activity and excellent dissolution properties in water. Therefore, spray-drying microencapsulation using natural fibre encapsulants is a feasible approach for delivering the dual health benefits of PPs and dietary fibre to consumers. Spray-drying yields a product in a convenient powder form, which can be reconstituted in water or other beverages for direct consumption or used as a functional additive in solid food systems.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The importance of polyphenol (PP) antioxidants and dietary fibres (DFs) in human health and nutrition is now well understood (Bravo 1998; Arts and Hollman 2005; Slavin and Green 2007; Scott et al. 2008; Lauren et al. 2009) and justifies their incorporation in popular consumer food and beverage products. PPs are sensitive to environmental conditions such as pH, water activity, light exposure, oxygen and temperature (Bakowska et al. 2003; Wang et al. 2009; Bakowska-Barczak and Kolodziejczyk 2010). The bioactivity, polarity, hydrophobicity or hydrophilicity, solubility and stability of PPs depend on their chemical structure (Rice-Evans et al. 1996; Luthria 2006). A high concentration of some PPs in foods or beverages creates bitterness issues. Prevention of polyphenol degradation during food processing and amelioration of PP bitterness are significant technical challenges that need to be overcome when delivering high PP-content finished foods or beverages to consumers.

Encapsulation technologies offer solutions to the issues of PP stability, insolubility and bitterness. Spray-drying is a simple and low-cost microencapsulation technology that can circumvent many of the technical challenges associated with the use of PPs as food ingredients. Spray-drying microencapsulation can both protect bioactives from environmental pressures (e.g. oxygen or moisture) and mask the unpleasant taste of bioactives through the encapsulant physical barrier (Dzondo-Gadet et al. 2005; Ersus and Yurdagel 2007; Saenz et al. 2009; Favaro-Trindade et al. 2010; Malmo et al. 2011; Gharsallaoui et al. 2011). However, the high temperatures used in spray-drying may cause degradation of heat-sensitive compounds like PPs (Buchner et al. 2006; Sun-Waterhouse, Sivam et al. 2011), motivating the present study.

Using DF polymers as encapsulants for bioactives such as PPs is an effective approach to increase DF consumption. Fibre polymer materials such as plant gums, modified celluloses and dextrins can all be used as the components of an encapsulant matrix (Ashady 1993; Heidebach et al. 2009; Sun-Waterhouse, Zhou et al. 2011; Sun-Waterhouse, Penin-Peyta et al. 2011). A suitable encapsulant is the material that will form a protective shield surrounding the active core (Gharsallaoui et al. 2007). Maltodextrins are obtained by acid hydrolysis of several types of starch (corn, potato or others) and have good oxidative stability, but generally provide poor emulsifying capacity and emulsion stability (Gibbs et al. 1999). Alginate is a natural polysaccharide consisting of a linear 1,4-linked copolymer of β-d-mannuronic acid and α-l-guluronic acid. The addition of divalent cations such as Ca2+ allows the neutralisation of the repulsive charges of carboxylate groups and consequently leads to linking of alginate chains (Lencki et al. 1989). Hydroxypropylmethyl cellulose (HPMC) is made from cellulose through chemical modification (i.e. adding ether groups) and can rapidly form a viscous surface layer of hydrated polymer on contact with aqueous media. Combinations of various encapsulant polymers can be used to tailor the release of encapsulated bioactive substances. Both alginate and HPMC have been used to produce controlled-release delivery systems (Vazequez et al. 1996; Ishikawa et al. 2000; Liu et al. 2007; Deshmukh et al. 2009; Sun-Waterhouse, Penin-Peyta et al. 2011). Inulin is a fructooligosaccharide and composed of fructose units with β (2–1) links with glucose units at the end of the chains. Inulin shows prebiotic effects and is only partially hydrolyzed in the stomach and the large intestine without the formation of monosaccharides (Roberfroid and Slavin 2000). The relative suitability of these different natural fibre polymers for the spray-drying microencapsulation of polyphenols has yet to be ascertained.

In this study, sodium alginate, methyl-β-cyclodextrin, hydroxypropylmethycellulose and inulin were selected as wall materials for encapsulating two polyphenols, quercetin (bitter) or vanillin (sweet). Through detailed physico-chemical characterisation of all the spray-dried powders, quantification of their polyphenol contents and study of their reconstitution properties in water, this work aimed to identify the most suitable encapsulant for each of the polyphenol bioactives.

Materials and Methods

Chemicals and Materials

Sodium alginate was purchased from Danisco (Auckland, NZ). Benecel® HPMC was purchased from Ashland Aqualan Functional Ingredients (Wilmington, DE, 19894-0001, USA). Inulin (Frutafit® IQ) was obtained from Sensus Asia Pacific, Kuala Lumpur, Malaysia. PEG 400 (Carbowax™) was obtained from AMCD Australia Ltd (Mulgrave, Victoria, Australia). Soy lecithin was purchased from Yelkin® gold, Archer Daniels Midland Co., Decatur, IL, USA. Quercetin, vanillin and methyl β-cyclodextrin were purchased from Sigma-Aldrich Inc. (St Louis, MO, USA). High-performance liquid chromatography (HPLC)-grade acetonitrile was purchased from J. T. Baker (Phillipsburg, NJ, USA). Other chemicals were purchased from Ajax Finechem (Mt. Wellington, Auckland, NZ).

Encapsulation of Polyphenols by Spray-Drying

Encapsulant solutions containing sodium alginate (0.2 % w/w), methyl β-cyclodextrin (0.2 % w/w), HPMC (0.2 % w/w) or inulin (2 % w/w) were prepared by dissolving a required amount of each encapsulant in Milli-Q water at 60 °C. The resulting solutions were cooled and kept overnight at 4 ± 2 °C. Quercetin or vanillin (in purified form, 30 mg) was first mixed with PEG (0.73 g) and then added into the encapsulant solutions and prehomogenised in a shear homogeniser (3,000 rpm × 5 min, Silverson L4R, Buckinghamshire, UK). Soy lecithin was added as an additional emulsifier to improve the homogenisation process at a ratio of 0.1g/1g encapsulant (sodium alginate, methyl β-cyclodextrin, HPMC or inulin). A spray dryer (Büchi mini B-290, Büchi Labortechnik AG, Switzerland) equipped with a 0.7-mm standard diameter nozzle was used to prepare the spray-dried powders. The inlet and outlet temperature were 165 ± 2 °C and 89 ± 2 °C, respectively. The air flow rate, rate of liquid feed, atomisation pressure and pump speed were 600 L/h, 10 mL/min, 20 psi and 30 %, respectively. For all preparations, free-flowing powders were obtained. A portion of each powder was transferred to high-density polyethylene zip-lock plastic bags for temporary storage and immediate repeated use (due to the convenience of zip-lock feature). The remaining powders were kept in food-grade aluminium foil pouches for longer storage. A portion of each freshly prepared spray-dried powder was subjected to water activity, dissolution efficiency measurements and microscopic examination, with the remaining powder being stored in the dark at -20 °C for later analyses. All analyses reported here were completed within 1 week of spray-drying the powders.

Bulk Density, Water Activity and Dissolution Efficiency of the Spray-Dried Powders

The bulk density of the spray-dried powders was determined by accurately measuring the sample weight using an analytical balance (Mettler Toledo, XS205 dual range, Mettler-Toledo International Inc., Greifensee, Switzerland) and the bulk volume using a Stec Pycnometer (VM 100 STEC Volumeter, FL, USA). The water activity (a w) of the spray-dried powders was measured at room temperature using a water activity meter (AQUA LAB CX-2, Decagon Devices Inc., Pullman, WA, USA). Dissolution tests were carried out in triplicate by adding spray-dried powder (50 mg) to water (1 mL) at room temperature (20 °C). The obtained mixture was vortexed (MT19 vortex mixer, Chiltern International, Slough, UK; speed scale 1–8 with 1 the lowest and 8 the highest; ‘speed 4’ setting, 2 × 30 s). The time taken to fully reconstitute the powders was recorded.

N2 Physisorption Measurements

N2 physisorption measurements were carried out at liquid nitrogen temperature (−195 °C) using an analyzer (Tristar 3000 instrument, Micromeritics, GA, USA). Samples were degassed in a Heraeus vacuum chamber at 40 °C for 1 h prior to the N2 physisorption measurements. Brunauer–Emmett–Teller (BET)-specific surface areas, Langmuir-specific surface areas, Barrett–Joyner–Halenda (BJH) adsorption cumulative pore volumes and BJH average pore diameters were determined from N2 physisorption isotherms taken at −195 °C (Condon 2006).

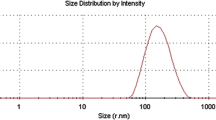

Microscopic Examination of Spray-Dried Powders

The shape, surface texture, particle size and size distribution of the spray-dried powders were determined by scanning electron microscopy (SEM) using a field-emission gun scanning electron microscope (Philips XL-30, FEGSEM, Eindhoven, The Netherlands). All micrographs were collected at an electron gun accelerating voltage of 5 kV. Specimens were mounted on black carbon adhesive tape and platinum sputter-coated for 5 min before analysis.

Fourier Transform Infrared (FT-IR) Spectroscopy

FT-IR spectra were obtained using a Perkin Elmer® Spectrum 100 FT-IR spectrometer equipped with a universal ATR attachment. Spectra were collected over the range of 4,000–650 cm−1 at a resolution of 4 cm−1, and 32 accumulated scans were used to produce a spectrum. Raw spectra were normalised using SigmaPlot (version 11.0).

Polyphenol Analyses

Extraction of Polyphenols from Spray-Dried Powders

Spray-dried powders (0.2 g) were mixed with methanol (95 %, 5 mL) and vortexed (‘speed 2’ setting, 1 min). The supernatant was collected. These steps were repeated twice and the obtained supernatants combined, dried using a RapidVap® concentrator (40 °C & 10 KPa for 50 min; model 79100-01, LabConco Corporation, Kansas City, MO), Labconco CentriVap® Concentrator (30 °C for 4 h; Model 78100-01, Ultra-Low Cold Trap, Kansas, USA), and then freeze-dried at −10 °C (Telstar Cryodos-80 Freeze Drier, Telstar Industrial, SL, Terrassa, Spain). The freeze-dried extracts were stored at −80 °C until HPLC analysis.

HPLC Analysis of Polyphenol Extracts

Polyphenol analyses were conducted by HPLC using the method proposed by Stevenson et al. (2006). A Shimadzu analytical HPLC equipped with a column oven (C40-10ASVP), auto-sampler (SIL-10AF), vacuum solvent degas module and diode-array detector (SPD-M10AVP), and a Synergi® Polar-RP ether-linked column (250 × 4.6 mm, 4 μm particle size, 80 Å ether-linked column, Phenomenex, Auckland, New Zealand) was used for HPLC analyses. The mobile phases comprising (A) acetonitrile + 0.1 % formic acid and (B) acetonitrile/water/formic acid (5:92:3) were pumped at a rate of 1.5 mL/min and at a temperature of 45 °C. The injection volume was 40 μL. Freeze-dried polyphenol extracts obtained from the spray-dried powders were dissolved in 25 % methanol at a concentration of 10 mg/mL, vortexed and then centrifuged at 3,000 rpm for 10 min (Eppendorf Centrifuge 5702, Hamburg, Germany). The resultant supernatant was then used for HPLC analyses. Quercetin or vanillin were detected at 370 and 280 nm, respectively, and quantified using rutin and caffeic acid as internal standards, respectively. The encapsulation efficiency was calculated: % w/w = [Retained polyphenol after encapsulation (milligrams catechin equivalent per gram powder)]/[Initially added polyphenol (milligrams catechin equivalent per gram powder)] × 100 %.

Viscosity of Reconstituted Aqueous Solutions of Spray-Dried Powders

The spray-dried powders were reconstituted in Milli-Q water with gentle stirring (10 cm3 powder (equivalent to two teaspoons) per 200 mL water). The viscosity of the obtained solutions was examined at 20 °C or 60 °C (the latter typical for hot drinks for human consumption), using a stress-controlled rheometer (Anton Parr Physica MCR301, Anton Parr GmbH, Graz, Austria) equipped with a Peltier temperature control device and flat plate geometry (diameter, 49.954 mm). A humidity chamber was used to prevent water loss during viscosity measurements. A 1-mm measurement gap was set. Shear rates in the range of 30–60 s−1 were used to simulate the effective shear rate range (40–50 s−1) in the mouth (Wood and Goff 1973). The viscosity of each sample was measured (30 measurements, in rotational mode) over the shear rate range of 0.001 to 100 s−1. Data were acquired and analysed with Rheoplus V3.4 software (Anton Paar GMBH, Graz, Austria). All tests were performed in triplicate; here, only the mean values are reported (standard deviations < 5 %).

Statistical Analysis

All data are expressed as the mean ± standard deviation from three replicates. Analyses were carried out using MINITAB 15 (Minitab Inc., Pennsylvania, USA) statistical software with one-way ANOVA followed by Tukey’s multiple comparison test at p < 0.05.

Results and Discussion

Shape, Size and Size Distribution of the Spray-Dried Powders

The colour of the spray-dried powders reflected the colour of the incorporated polyphenol. Powders containing quercetin were a pale yellow colour whereas those containing vanillin were white (quercetin and vanillin are yellow and white, respectively). SEM investigations (Fig. 1) revealed that the morphology and particle size of the spray-dried powder particles varied considerably with the type of encapsulant used. Powder morphology was largely independent of the polyphenol encapsulated. This result was not unexpected given the low nominal PP content of the spray-dried powders.

Under the same spray-drying conditions, including gas flow, pump speed, the rate of liquid feed, atomisation pressure and inlet temperature, the time required to spray dry the different encapsulation formulations were similar (~20 min for 200 mL feed solution). The spray-dried powders prepared using sodium alginate appeared as spheres of different sizes with wrinkled surfaces (size distribution ranged from 0.5–15 micron) (Fig. 1). Powders prepared using methyl β-cyclodextrin as the encapsulant were predominantly of smooth spherical shape, with individual powder particles co-joined to form larger aggregates. Powders prepared using HPMC as the encapsulant were of highly irregular shape and size and appeared in the form of fully collapsed hollow spheres. Powders prepared using inulin as the encapsulant generally had a smooth surface and an aggregated spherical habit. The final shape of the various spray-dried powders can be related to the spray-drying process and the rate of water removal from the encapsulant polymer network. The irregular shape (deviation from spherical) and wrinkled surfaces shown by a number of the powders in Fig. 1 can be rationalised in terms of rapid loss of water during the spray-drying process. The encapsulants used in this study are strongly hydrated in aqueous media and will exhibit different physicochemical characteristics, due to the differences in their chemical structure, charge and inter-molecular forces (e.g. van der Waals forces, hydrogen bonds, electrostatic forces, steric repulsive force and hydrophobic interactions) (Banerjee and Bhattacharya 2012). These differences between encapsulants, as well as the difference between quercetin and vanillin in chemical structure, hydrophobicity or hydrophilicity, solubility (Rice-Evans et al. 1996), influence the size of spray droplets, their cohesion or adhesion, agglomeration and hardening, hence the size, surface area, surface roughness and porosity of powder particles (Chew et al. 2000; Daniher and Zhu 2008). Reduced adhesion between solids is associated with high surface asperities (Tabor 1977).

Bulk Density, Water Activity and Dissolution Efficiency of the Spray-Dried Powders

The difference in bulk density of all the spray-dried powders was not significant (P < 0.05): Quercetin-containing powders had a bulk density 0.039 g/cm3 for sodium alginate and HPMC, 0.040 g/cm3 for MβCD and 0.042 g/cm3 for inulin. All the vanillin-containing powders had a bulk density of 0.040 g/cm3. The water activity of the spray-dried powders ranged from 0.24 to 0.43 (Table 1). This is consistent with visual observations that all the obtained spray-dried powders were free-flowing powders (water activity less than 0.5). Such values indicate a low risk of microbial spoilage and a good shelf life. The powders produced using HPMC had the highest water activity (0.37 for quercetin and 0.43 for vanillin, and significantly different at the P < 0.05 level), whilst the powders prepared using inulin had the lowest water activity (0.25 for quercetin and 0.24 for vanillin; no significant difference at the P < 0.05 level). The quercetin- and vanillin-containing powders had similar water activity when the same encapsulant was used (except in the case of HPMC): The water activity was the same (0.32) for the quercetin– and vanillin–alginate powders, and no significant difference at the P < 0.05 level was observed for the quercetin– and vanillin–MβCD powders (0.37 and 0.35, respectively). Thus, the type of encapsulant likely influences the water activity of the spray-dried powders more than the type of encapsulated polyphenol.

The time required for the quercetin- and vanillin-containing powders to be fully reconstituted in water followed the same trend: HPMC (166 s for quercetin, 68 s for vanillin) > sodium alginate (55 s for quercetin, 48 s for vanillin) > inulin (13 s for quercetin, 15 s for vanillin) > MβCD (9 s for quercetin, 14 s for vanillin). The required dissolution time for the quercetin-containing powders was generally longer (1.2–2.4 times) than the vanillin-containing powders, except for powders encapsulated using inulin. The quercetin–HPMC powder required the longest time (166 s) for reconstitution in water. This reconstitution time is not overly long, indicating the quercetin–HPMC spray-dried powder is still suitable for powdered beverage applications. Differences in chemical composition and porosity of the encapsulating networks may influence the water permeability, water diffusion, water holding capacity and ultimately solubility of the spray-dried powders (Lim et al. 2011). Furthermore, the type of encapsulant used will affect the release rate of encapsulated polyphenols on contact with aqueous media.

N2 Adsorption Isotherms

All of the quercetin-containing spray-dried powders had low specific surface areas and negligible pore volumes. This is not unexpected based on the particle sizes of the powders and also their chemical composition which would be expected to yield dense, non-porous powders. Table 2 summarises N2 physisorption results for the spray-dried quercetin-containing powders. The quercetin-alginate and quercetin-β-cyclodextrin powders had higher specific surface areas (either BET or Langmuir) than the quercetin–HPMC and quercetin–inulin powders. The opposite trend was observed for the BJH adsorption average pore diameters. The inulin-containing powder had the largest pore diameter (33.71 nm). These results are consistent with the SEM examinations of the same samples. The quercetin–alginate powder had the smallest average particle size and well-defined “spherical” powder morphology by SEM and accordingly gave the highest specific surface area. By comparison, the quercetin–HPMC and quercetin–inulin powders are strongly aggregated and as a result gave lower specific surface areas. For spherical particles, the diameter (D) of a particle (in microns) can be estimated from the surface area (SA, square meters per gram) and density (ρ, in grams per cubic meter) of the material accordingly to the equation D = 6/(SA × ρ). For the quercetin–alginate powder, this analysis yields an average particle size, D, of 2.86 μm (density of sodium alginate = 1.601 g/cm3), in excellent agreement with the SEM data of Fig. 1. N2 physisorption data was not collected for the spray-dried powders containing vanillin though is expected to be comparable to that of the quercetin-containing powders based on powder particle size considerations (Fig. 1).

FT-IR Analysis of Spray-Dried Powders

FT-IR spectroscopy is a powerful tool for chemical structure elucidation and qualitative compositional analysis and was used here to characterise the quercetin- and vanillin-containing spray-dried powders. Figure 2 shows FT-IR absorbance spectra for quercetin, vanillin and various other compounds used in the preparation of the spray-dried powders (excluding the encapsulants). All spectra are consistent with previous literature data for these compounds (Di Noto et al. 2002; Binoy et al. 2005; Gasperini et al. 2007; Wu et al. 2008; Sahoo et al. 2009). The spectral region between 1,800 and 650 cm−1 is especially useful for the “fingerprinting” of polysaccharides and polyphenols, as Fig. 2b demonstrates.

Normalised FT-IR absorbance spectra for quercetin, vanillin and the key compounds used in the preparation of the spray-dried powders (excluding the encapsulants). Spectra are shown over the range a 4,000–650 cm−1 and b the “spectral fingerprint region” of 1,800−650 cm−1. The spectra have been offset vertically for clarity

Figure 3a, b shows FT-IR absorbance spectra for spray-dried powders prepared using sodium alginate as the encapsulant. The FT-IR spectrum of pure sodium alginate contains intense bands at 1,616 and 1,415 cm−1, which are assigned to the asymmetric –COO− stretching mode and symmetric –COO− stretching mode of carboxylate groups (Caykara et al. 2005). Other bands in the range 1,200–800 cm−1 are assigned to the polysaccharide backbone and comprise C–O stretching, CH2 twisting, C–O–H bending and C–O–C bond stretching vibrations of the polysaccharide chains (Kacuráková and Mathlouthi 1996; Kacuráková et al. 2000; Wang and Somasundaran 2007). The carboxylate related peaks at 1,616 and 1,415 cm−1 were absent in the FT-IR spectra of the spray-dried powders prepared using sodium alginate (Fig. 3a, b), indicating that the carboxylate groups of sodium alginate are lost during the spray-drying process. This may be due to thermal decomposition or chemical reaction during powder preparation. The FT-IR absorption spectra for the quercetin- and vanillin-containing powders were dominated by polysaccharide chain signals and were indistinguishable from one another (Fig. 3a, b). No FT-IR signals due to quercetin or vanillin (cf. Fig. 2a, b) could be detected, which is explained by the low concentration of these polyphenols in the spray-dried powders.

Normalised FT-IR absorbance spectra for quercetin- and vanillin-containing spray-dried powders prepared using sodium alginate and methyl β-cyclodextrin (MβCD) as encapsulants. Spectra are shown over the range 4,000–650 cm–1 (a and c) and the “spectral fingerprint region” of 1,800–650 cm−1 (b and d). Reference spectra for sodium alginate and methyl β-cyclodextrin are provided for comparison purposes. The spectra have been offset vertically for clarity

The FT-IR absorbance spectra of quercetin and vanillin spray-dried powders prepared using methyl β-cyclodextrin (Fig. 3c, d), HPMC (Fig. 4a, b) and inulin (Fig. 4c, d) were near identical to FT-IR spectra collected for the corresponding encapsulant (methyl β-cyclodextrin, HPMC and inulin, respectively) and dominated by signals due to polysaccharides. Again, no signals characteristic for quercetin or vanillin are identifiable, due to their low concentration in the spray-dried powders. Reaction between the polyphenols and the encapsulating matrix during spray-drying could also contribute to the non-observation of FT-IR signals for quercetin or vanillin.

Normalised FT-IR absorbance spectra for quercetin- and vanillin-containing spray-dried powders prepared using hydroxypropylmethylcellulose (HPMC) and inlulin as encapsulants. Spectra are shown over the range 4000-650 cm-1 (a and c) and the “spectral fingerprint region” of 1800-650 cm-1 (b and d). Reference spectra for HPMC and inulin are provided for comparison purposes. The spectra have been offset vertically for clarity

HPLC Analysis of Polyphenol Extracts from Spray-Dried Powders

Table 1 shows that the concentration of vanillin retained in the spray-dried powders was approximately two to four times higher than that of quercetin in the quercetin-containing powders, when the same encapsulant and the same PP quantity were used. The encapsulation efficiency of HPMC for quercetin was very low (8.90 %), whilst the other encapsulants had significantly improved encapsulation efficiencies for quercetin (18.0–18.5 %). The encapsulation efficiency for vanillin was superior for all encapsulants. Vanillin has a higher thermal stability than quercetin, and the higher encapsulation efficiencies observed for vanillin are rationalised on this basis. Results demonstrate that the encapsulated PP and the encapsulant both influence the final PP concentration in the spray-dried powders.

HPLC provides evidence for quercetin and also quercetin-derived compounds in the spray-dried powders (Fig. 5). The main signals in the chromatograms taken at 370 nm are due to quercetin and rutin (internal standard). Additional weaker peaks are likely protocatechuic acid and 2-(3’,4’-dihydroxyphenyl)-3,3,5,7-tetrahydroxy-2-methoxy-2,3-dihydrochromen-4-one, products of quercetin oxidation/degradation during spray-drying. The loss of quercetin was likely due to the heat and pressure encountered during the high shear homogenisation and spray-drying steps. Differences in the particle size and surface area of the powders, and hence susceptibility to oxidation, can be excluded as a factor in the loss of quercetin since powders prepared using sodium alginate had the highest surface area and reasonable encapsulation efficiencies for quercetin (18.0 %). The chemical structure of quercetin and vanillin ultimately determines their stability during spray-drying (Rice-Evans et al. 1996; Lin et al. 2007) and susceptibility to oxidation/degradation. For quercetin, the hydroxyl group at C-3 on the C-ring, adjacent to the 2,3-double bond and the 4-carbonyl, is easily oxidised due to the electron donation of the ketone structure at C-4 (Hendrickson et al. 1994 and Hendrickson et al. 1994). Quercetin degradation in the presence of oxygen can be substantially reduced if quercetin is bound to an encapsulant polymer, which explains why the spray-dried powders produced in this work still possessed reasonable quercetin contents. Vanillin, due to its more robust polyphenolic structure, appears much less susceptible to chemical oxidative or thermal degradation during spray-drying. No products of vanillin oxidation or degradation were detected by HPLC (Fig. 5).

High-performance liquid chromatography (HPLC) chromatograms for a quercetin-containing powders (λ = 370 nm) and b vanillin-containing powders (λ = 280 nm) encapsulated using sodium alginate, methyl β-cyclodextrin, hydroxypropylmethycellulose (HPMC) or inulin. Peak 1, rutin (internal standard); peak 2, quercetin; peak 3, caffeic acid (internal standard); peak 4, vanillin

Viscosity of Aqueous Solutions of the Spray-Dried Powders

The viscosity of solutions or dispersions of carbohydrate polymers depends markedly on the measuring conditions. Here, the spray-dried powders were reconstituted in water and the viscosity of the resulting solutions measured. Viscosities were measured at 20 °C or 60 °C. Viscosities in the shear rate range of 30–60 s−1 correspond to actual sensory consistency (Wood and Goff 1973). Results are shown in Fig. 6. The data reveal that the viscosity of the reconstituted solutions varied with the type of encapsulant, the type of polyphenols encapsulated and the temperature of the solution.

At 20 °C (Fig. 6a, c), the highest viscosities were observed for solutions prepared using powders that had sodium alginate as the encapsulant. The quercetin–alginate and vanillin–alginate powders produced solutions of similar viscosity over the range of shear rates studied. Solutions of powders produced using methyl β-cyclodextrin, HPMC or inulin as encapsulants all yielded solutions of similar viscosity (Fig. 6), though these solutions were of significantly lower viscosity than those of quercetin–alginate and vanillin–alginate powders. Differences in viscosity among the inulin-, HPMC- and methyl β-cyclodextrin-based powders were greater for the quercetin-containing powders than for the vanillin-containing powders. For all solutions at 20 °C, the viscosity did not vary significantly with the shear rate.

At 60 °C (Fig. 6b, d), the viscosity of solutions prepared from the quercetin-containing powders changed markedly and decreased in the encapsulant order of inulin > HPMC > alginate > methyl β-cyclodextrin. The viscosity of solutions of inulin- and HPMC-encapsulated powders was much higher at 60 °C than at 20 °C, and the trend was opposite for solutions of the methyl β-cyclodextrin- and alginate-encapsulated powders. The viscosity of all the four solutions decreased with increasing shear rate at 60 °C. This was most evident for solutions containing the quercetin–inulin and quercetin–methyl β-cyclodextrin powders. For the vanillin-containing powders, the viscosity of all solutions did not show much of a dependence on shear rate at either 20 °C or 60 °C. Interestingly, the viscosity of all the solutions was lower at 60 °C than at 20 °C. The decrease in viscosity on raising the temperature from 20 °C to 60 °C was comparable for solutions of the inulin-, HPMC- and methyl β-cyclodextrin-based powders. A much larger viscosity decrease with temperature was observed for solutions of the vanillin–alginate powders.

The data of Fig. 6 indicate that each spray-dried powder affords different properties in solution because of the unique characteristics of the two polyphenols and their encapsulating polymer networks (Whistler and BeMiller 1997). Differences in pH, ionic strength and hydrogen bonding interactions between the encapsulated PP (quercetin or vanillin) and the carbohydrate polymers within the encapsulation matrix all likely influence the viscosity of solutions prepared by dissolving the spray-dried powders in water. Importantly, the spray-dried powders produced in this work appear suitable for both the delivery of polyphenol bioactives and dietary fibres in food and beverage systems, as well as viscosity-modifiers of beverages.

Conclusions

Polyphenol bioactives, such as quercetin and vanillin, can be successfully encapsulated by spray-drying using natural fibre polymers such as sodium alginate, methyl β-cyclodextrin, HPMC or inulin as encapsulants. The type of encapsulant has a significant impact on the encapsulation efficiency of the polyphenols. For vanillin, satisfactory encapsulation efficiencies are achievable using any of the aforementioned encapsulants. The same encapsulants were less effective for the spray-drying encapsulation of quercetin, due to the lower thermal stability of this polyphenol. Both the quercetin-containing and vanillin-containing spray-dried powders produced in this study possessed acceptable water activity and dissolution behaviour in water. Results demonstrate the feasibility of spray-drying encapsulation as an approach to deliver health-beneficial compounds (polyphenols and dietary fibres) to consumers. The spray-dried powders produced would be suitable for cold or hot drink applications.

References

Arts, I. C. W., & Hollman, P. C. H. (2005). Polyphenols and disease risk in epidemiologic studies. The American Journal of Clinical Nutrition, 81(1), 317S–325S.

Ashady, R. (1993). Microcapsules for food. Journal of Microencapsulation, 10, 413–435.

Bakowska, A. M., Kucharska, A. Z., & Oszmianski, J. (2003). The effects of heating, UV irradiation and storage on stability of anthocyanin-polyphenol copigment complex. Food Chemistry, 81, 349–355.

Bakowska-Barczak, A. M., & Kolodziejczyk, P. P. (2010). Black currant polyphenols: Their storage stability and microencapsulation. Industrial Crops and Products. doi:10.1016/j.indcrop. 2010.10.002.

Banerjee, S., & Bhattacharya, S. (2012). Food gels: Gelling process and new applications. Critical Reviews in Food Science and Nutrition, 52(4), 334–346.

Binoy, J., Joe, I. H., & Jayakumar, V. S. (2005). Changes in the vibrational spectral modes by the nonbonded interactions in the NLO crystal vanillin. Journal of Raman Spectroscopy, 36, 1091–1100.

Bravo, L. (1998). Polyphenols: Chemistry, dietary sources, metabolism, and nutritional significance. Nutrition Reviews, 56(11), 317–333.

Buchner, N., Krumbein, A., Rohn, S., & Kroh, L. W. (2006). Effect of thermal processing on the flavonols rutin and quercetin. Rapid Communications in Mass Spectrometry, 20, 3229–3235.

Caykara, T., Demirci, S., Eroglu, M. S., & Guven, O. (2005). Poly(ethylene oxide) and its blends with sodium alginate. Polymer, 46, 10750–10757.

Chew, N. Y., Bagster, D. F., & Chan, H. K. (2000). Effect of particle size, air flow and inhaler device on the aerosolisation of disodium cromoglycate powders. International Journal of Pharmaceutics, 206, 75–83.

Condon, J. B. (2006). Surface area and porosity determinations by physisorption: Measurements and theory (1st ed.). Boston: Elsevier.

Daniher, D. I., & Zhu, J. (2008). Dry powder platform for pulmonary drug delivery. Particuology, 6, 225–238.

Deshmukh, V. N., Sakarkar, D. M., & Wakade, R. B. (2009). Formulation and evaluation of controlled release alginate microspheres using locust bean gum. Journal of Pharmacy Research, 2(3), 458–461.

Di Noto, V., Munchow, V., Vittadello, M., Collet, J. C., & Lavina, S. (2002). Synthesis and characterization of lithium and magnesium complexes based on [EDTA][PEG400]2 and [EDTA]3[PEG400]7. Macromolecular Chemistry and Physics, 203, 1211–1227.

Dzondo-Gadet, M., Nzikou, J. M., Etoumongob, A., Linder, M., & Desobry, S. (2005). Encapsulation and storage of safou pulp oil in 6DE maltodextrins. Process Biochemistry, 40, 265–271.

Ersus, S., & Yurdagel, U. (2007). Microencapsulation of anthocyanin pigments of black carrot (Daucus carota L.) by spray drier. Journal of Food Engineering, 80, 805–812.

Favaro-Trindade, C. S., Santana, A. S., Monterrey-Quintero, E. S., Trindade, M. A., & Netto, F. M. (2010). The use of spray drying technology to reduce bitter taste of casein hydrolysate. Food Hydrocolloids, 24, 336–340.

Gasperini, G., Fusari, E., Bella, L. D., & Bondioli, P. (2007). Classification of feeding fats by FT-IR spectroscopy. European Journal of Lipid Science and Technology, 109, 673–681.

Gharsallaoui, A., Roudaut, G., Chambin, O., Voilley, A., & Saurel, R. (2007). Applications of spray-drying in microencapsulation of food ingredients: An overview. Food Research International, 40(9), 1107–1121.

Gharsallaoui, A., Saurel, R., Chambin, O., & Voilley, A. (2011). Pea (Pisum sativum, L.) protein isolate stabilized emulsions: A novel system for microencapsulation of lipophilic ingredients by spray drying. doi:10.1007/s11947-010-0497-z.

Gibbs, B. F., Kermasha, S., Alli, I., & Mulligan, C. N. (1999). Encapsulation in the food industry: A review. International Journal of Food Sciences and Nutrition, 50, 213–224.

Heidebach, T., Főrst, P., & Kulozik, U. (2009). Microencapsulation of probiotic cells by means of rennet-gelation of milk proteins. Food Hydrocolloids, 23, 1670–1677.

Hendrickson, H. P., Kaufman, A. D., & Lunte, C. E. (1994). Electrochemistry of catechol-containing flavonoids. Journal of Pharmaceutical and Biomedical Analysis, 12, 325–334.

Hendrickson, H. P., Sahafayen, M., Bell, M. A., Kaufman, A. D., Hadwiger, M. E., & Lunte, C. E. (1994). Relationship of flavonoid oxidation potential and effect on rat hepatic microsomal metabolism of benzene and phenol. Journal of Pharmaceutical and Biomedical Analysis, 12, 335–341.

Ishikawa, T., Watanabe, Y., Takayama, K., Endo, H., & Matsumoto, M. (2000). Effect of hydroxypropylmethylcellulose (HPMC) on the release profiles and bioavailability of a poorly water-soluble drug from tablets prepared using macrogol and HPMC. International Journal of Pharmaceutics, 202, 173–178.

Kacuráková, M., & Mathlouthi, M. (1996). FTIR and laser-Raman spectra of oligosaccharides in water: Characterization of the glycosidic bond. Carbohydrate Research, 284, 145–157.

Kacuráková, M., Capek, P., Sasinková, V., Wellner, N., & Ebringerová, A. (2000). FT-IR study of plant cell wall model compounds: Pectic polysaccharides and hemicelluloses. Carbohydrate Polymers, 43, 195–203.

Lauren, D. R., Smith, W. A., Adaim, A., Cooney, J. M., Wibisono, R., Jensen, D. J., et al. (2009). Chemical composition and in vitro anti-inflammatory activity of apple phenolic extracts and of their sub-fractions. International Journal of Food Sciences and Nutrition, 60(S7), 188–205.

Lencki, R., Neufeld, R., & Spinney, T (inventor). (1989). Method of producing microspheres. US patent 4 822 534. April 18.

Lim, L. H., Tan, A., Simovic, S., & Prestidge, C. A. (2011). Silica-lipid hybrid microcapsules: Influence of lipid and emulsifier type on in vitro performance. International Journal of Pharmaceutics, 409, 297–306.

Lin, Q. L., Wang, J., Qin, D., & Bergenståhl, B. (2007). Influence of amphiphilic structures on the stability of polyphenols with different hydrophobicity. Science in China Series B: Chemistry, 50(1), 121–126.

Liu, J., Liu, K., Zhao, L.-B., Zeng, Q., Guo, Z.-X., & Zhao, X.-Z. (2007). Controlled-release of materials in calcium alginate microbeads prepared by microfluidic device. Bioinformatics and Biomedical Engineering, 6–8, 1241–1243.

Luthria, D. L. (2006). Significance of sample preparation in developing analytical methodologies for accurate estimation of bioactive compounds in functional foods. Journal of the Science of Food and Agriculture, 86, 2266–2272.

Malmo, C., La Storia, A., & Mauriello, G. (2011). Microencapsulation of Lactobacillus reuteri DSM 17938 cells coated in alginate beads with chitosan by spray drying to use as a probiotic cell in a chocolate soufflé. doi:10.1007/s11947-011-0755-8.

Rice-Evans, C. A., Miller, N. J., & Paganga, G. (1996). Structure-antioxidant activity relationships of flavonoids and phenolic acids. Free Radical Biology & Medicine, 20, 933–956.

Roberfroid, M., & Slavin, J. (2000). Nondigestible oligosaccharides. Critical Reviews in Food Science and Nutrition, 40(6), 461–480.

Saenz, C., Tapia, S., Chavez, J., & Robert, P. (2009). Microencapsulation by spray drying of bioactive compounds from cactus pear (Opuntia ficus-indica). Food Chemistry, 114(2), 616–622.

Sahoo, N. G., Abbas, A., Judeh, Z., Li, C. M., & Yuen, K. H. (2009). Solubility enhancement of a poorly water-soluble anti-Malarial drug: Experimental design and use of a modified multifluid nozzle pilot spray drier. Journal of Pharmaceutical Sciences, 98(1), 281–296.

Scott, K. P., Duncan, S. H., & Flint, H. J. (2008). Dietary fibre and the gut microbiota. Nutrition Bulletin, 33, 201–211.

Slavin, J., & Green, H. (2007). Dietary fibre and satiety. Nutrition Bulletin, 32, S32–S42.

Stevenson, D., Wibisono, R., Jensen, D., Stanley, R., & Cooney, J. (2006). Direct acylation of flavonoid glycosides with phenolic acids catalysed by Candida antarctica lipase B (Novozym 435®). Enzyme and Microbial Technology, 39, 1236–1241.

Sun-Waterhouse, D., Sivam, A. S., Cooney, J., Zhou, J., Perera, C. O., & Waterhouse, G. I. N. (2011). Effects of added fruit polyphenols and pectin on the properties of finished breads revealed by HPLC/LC-MS and size-exclusion HPLC. Food Research International, 44(9), 3047–3056.

Sun-Waterhouse, D., Zhou, J., Miskelly, G. M., Wibisono, R., & Wadhwa, S. S. (2011). Stability of encapsulated olive oil in the presence of caffeic acid. Food Chemistry, 126(3), 1049–1056.

Sun-Waterhouse, D., Penin-Peyta, L., Wadhwa, S. S., & Waterhouse, G. I. N. (2011). Storage stability of phenolic-fortified avocado oil encapsulated using different polymer formulations and co-extrusion technology. Food and Bioprocess Technology. doi:10.1007/s11947-011-0591-x.

Tabor, D. (1977). Surface forces and surface interactions. Journal of Colloid and Interface Science, 58, 2–13.

Vazequez, M. J., Casalderrey, M., Duro, R., Gomez-Amoza, J.-L., Martinez-Pecheco, R., Souto, R., et al. (1996). Atenolol release from hydrophilic matrix tablets with hydroxypropylmethylcellulose (HPMC) mixtures as gelling agent: Effects of the viscosity of the HPMC mixture. European Journal of Pharmaceutical Sciences, 4, 39–48.

Wang, J., & Somasundaran, P. (2007). Study of galactomannose interaction with solids using AFM, IR and allied techniques. Journal of Colloid and Interface Science, 309, 373–383.

Wang, X., Wang, Y.-W., & Huang, Q. (2009). Enhancing stability and oral bioavailability of polyphenols using nanoemulsions. In Q. Huang, P. Given, & M. Qian (Eds.), Micro/nanoencapsulation of active food ingredients (pp. 198–212). Washington: US: American Chemical Society. ACS Symposium Series, Chapter 13, Vol. 1007.

Whistler, R. L., & BeMiller, J. N. (1997). Carbohydrate chemistry for food scientists (pp. 203–210). St. Paul: The American Association of Cereal Chemists.

Wood, F. W., & Goff, T. C. (1973). The determination of the effective shear rate in the Brabender Viscograph and in other systems of complex geometry. Starch, 25(3), 89–91.

Wu, T.-H., Yen, F.-H., Lin, L.-T., Tsai, T.-R., Lin, C.-C., & Cham, T.-M. (2008). Preparation, physicochemical characterization, and antioxidant effects of quercetin nanoparticles. International Journal of Pharmaceutics, 346, 160–168.

Acknowledgements

We acknowledge research funding from The University of Auckland and Plant and Food Research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun-Waterhouse, D., Wadhwa, S.S. & Waterhouse, G.I.N. Spray-Drying Microencapsulation of Polyphenol Bioactives: A Comparative Study Using Different Natural Fibre Polymers as Encapsulants. Food Bioprocess Technol 6, 2376–2388 (2013). https://doi.org/10.1007/s11947-012-0946-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-012-0946-y