Abstract

The Blueberry cv. Biloxi is characterized by its high phenolic compounds content, mainly anthocyanins, which are relevant for their application in the prevention of chronic degenerative diseases. In this study, we have demonstrated that the encapsulation of blueberry extracts is feasible using as a matrix a combination of biopolymers through the electrohydrodynamic process from aqueous solutions. Corn prolamin zein, whey protein concentrate and high polymerization grade agave fructans were used as polymers. The properties of the solution and the capacity of atomization with high voltage were evaluated by adding glycerol as an adjuvant. The results of this investigation showed that most of the solutions were within the recommended ranges to be electrospun. However, not all exhibited stability when the blueberry polyphenolic extract was added. The morphology of structures was characterized and then related to the properties of the solution. The corn prolamin zein was able to obtain capsules loaded with encapsulation efficiency of 52.65% of polyphenolic extract by electrospraying process with homogeneous morphology and smooth, as well as continuous nanofibers by electrospinning process.

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The blueberry (Vaccinium corymbosum L.) is a fruit with a significant content of anthocyanins, representing the 75% of the total phenolic compounds. The anthocyanins are chemical compounds responsible for conferring red, blue and violet colors on leaves, flowers and fruits [1]. Anthocyanins are considered nutraceutical compounds that show a positive effect in the prevention of chronic-degenerative diseases through biological activities such as antioxidant function and the ability to alter enzymatic activities. Furthermore, the anthocyanins exhibit a protective effect against DNA damage caused by reactive oxygen species [2]. Different extraction methods for phenolic compounds have been used. However, many of them have disadvantages such as long processing times and application of temperatures. Recent studies have demonstrated the efficiency of the ultrasound-assisted extraction method to obtain high biological value compounds [3, 4]. Ultrasound is a technique that involves the application of sound waves transmitted through matter causing cycles of expansion and compression. The expansion cycles can create bubbles or cavities in the liquid, and when the bubbles implode, high temperatures and pressures are produced that induce the release of compounds from the plant matrix [5]. Then, compounds extracted are exposed to the environment.

The polyphenolic compounds, especially anthocyanins, in the fruit are stable. However, they are susceptible to degradation during transformation and storage processes. The degradation of the phenolic compounds is attributed to various environmental factors such as temperature, pH, exposure to oxygen, light, the presence of acids and extraction methods [6].

An alternative to avoid the degradation of polyphenolic compounds is the encapsulation, which is a process that involves the entrapment of an active ingredient through a polymeric matrix, that seeks to increase stability, improve bioavailability and the controlled release of bioactive agents [7, 8]. An emerging, innovative and environmentally friendly technique for encapsulation is electrospraying. This technique has been used to obtain nanocapsules by using electric fields, which exceed the surface tension of the polymer solution, favoring the atomization of the initial drop, the rearrangement of the charges and the cross-linking of the polymer [9].

The most widely used biopolymers in the encapsulation processes are polysaccharides and proteins [7, 10, 11]. Zein is a globular prolamin, partially hydrophobic due to the presence of apolar amino acids such as leucine, proline and alanine. It is extensively used in the food industry as a coating for sweets, rice and nuts. In addition, it is used as a thermoplastic and in the pharmaceutical industry for the capsule manufacturing, allowing the protection and controlled release, as well as masking of flavors and aromas [12]. Whey protein concentrate (WPC) is a high-quality protein source with many applications in the food industry. Milk proteins are widely valued as food ingredients, with excellent surface properties and stabilization characteristics of colloids, as well as coating materials [13]. Agave fructans are characterized by a mixture of linear and branched structures that contains β (2 → 1) and β (2 → 6) linkages with terminal glucose units. Among the agave fructans, the agavins highlight due to concentration and complex structure [14]. The agavins have a potential for association with other biopolymers because of the high concentration of OH groups [15]. The physicochemical properties that confer its use as an encapsulating material are determined by its degree of polymerization (DP) [16, 17]. Although its techno-functional application as an encapsulant is promising, few studies can be found regarding its use in the electrospraying encapsulation [18].

Based on the previously mentioned, the aim of this study was to evaluate the electrospray encapsulation capacity of various polymeric biomaterials in order to obtain encapsulated polyphenolic compounds extracted from blueberry cv. Biloxi by ultrasound.

Materials and methods

Raw material

Blueberry fruits cv. Biloxi were collected from an orchard at Tepic, Nayarit, Mexico (21° 28′ to 21° 18′ north latitude and 104° 45′ to 105° 04′ west longitude). The fruits were lyophilized and stored at 25 ºC and 30% RH until further use. The biopolymers used in this investigation were as follows: corn prolamin zein grade Z3625, (Sigma-Aldrich, Madrid, Spain), fructans of agave of a high degree of polymerization (Campos Azules Co., Mexico City, Mexico) and concentrate of whey protein (Davisco Foods, USA).

Extraction of polyphenolic compounds

The polyphenolic compounds were extracted based on the protocol reported by Ruíz-Montañez et al. [3] with some modifications. Methanol acidified with 1% citric acid was used as the extraction solvent, in a ratio of 1:10 (g sample: mL solvent). The samples were sonicated for 30 min in a Kendal CD-4820 (Pittsburgh, USA) with a constant frequency of 42 kHz at 25 °C. Then, the extract was filtered using Whatman No.1 filter paper and concentrated in a rotary evaporator IKA RV Basic S1 (Staufen, Germany) at 45 °C.

Determination of total soluble polyphenols

The concentration of total soluble phenols was determined by the Folin Ciocalteu method [19] with some modifications. The 10% Folin reagent and 7.5% sodium carbonate were prepared for this analysis. 2.5 mg of extract was diluted in 5 mL of methanol. 250 μL of the diluted extract was mixed with 1 mL of sodium carbonate and incubated in tubes for 5 min. 1.25 mL of the Folin solution was added, and the tubes were incubated in a water bath for 15 min at 55 °C. Finally, the absorbance was measured at 780 nm on a Varian Cary 50 UV–Vis spectrophotometer (Sydney, Australia). The results were expressed in mg equivalents of gallic acid (EAG) in 100 g of fresh fruit.

Determination of antioxidant capacity (ABTS)

The antioxidant capacity was determined according to the method proposed by Re et al. [20]. A 7 mM solution of the ABTS reagent with potassium persulfate at 2.45 Mm was prepared and allowed to stir for 16 h in the dark. The mixture was adjusted with 85% hydroalcoholic solution until reach an absorbance of 0.70 ± 0.02 at 734 nm. 50 μL of the extract diluted in ethanol was added to 950 μL of the ABTS solution and left to react for 1 min. Subsequently, the absorbance was measured at 734 nm on a Varian Cary 50 UV–Vis spectrophotometer (Sydney, Australia). The results were expressed as % ABTS inhibition according to Eq. (1).

where A = absorbance value of the ABTS control solution. B = absorbance value of the sample.

Identification of polyphenolic compounds in the extract (HPLC–MS)

The polyphenolic compounds were identified in high-resolution liquid chromatography (HPLC) Agilent Technologies 1200 (Santa Clara, CA, USA) coupled to a mass detector 6120 Quadrupole LC/MS. An Agilent Poroshell 120 C-18 column of 4.6 mm internal diameter, 2.7 μm particle size at 25 °C was used. Acetonitrile (solvent A) and acidified water with acetic acid at pH 2 (solvent B) were used as mobile phase, with a flow of 0.1 mL min−1. The extract was diluted in methanol and filtered with a 0.22 μm nylon membrane. The injection volume was 5 μL. The operating conditions of the mass spectrometer were set at a nebulizer pressure of 8 psi, a capillary voltage of 3000 V, gas flow of 9 L/min and a solvation temperature of 300 °C.

Solutions formulation

A 3 × 3 × 2 factorial design was used for this study, which corresponds to 3 polymers (zein, whey protein concentrates and agave fructans with a high degree of polymerization), 3 polymer concentrations (10, 20 and 30%) and 2 glycerol concentrations as adjuvant (1 and 2%). %). Agave fructans and whey protein were dissolved in distilled water, the zein was dissolved in 70% ethanol hydroalcoholic solution. The extract was added in a 1:10 ratio (polymer-extract). The polymer solutions were homogenized by magnetic stirring at 300 rpm for 5 min.

Characterization of polymer solutions

The physicochemical parameters evaluated were conductivity, pH, surface tension and viscosity. Conductivity and pH were measured in a Hanna Instruments multiparameter potentiometer HI 251 (Rhode Island, USA) at 25° C. The surface tension of the polymer solutions was determined using the Wilhemy plate method on an EasyDyne K20 tensiometer (Krüss GmbH, Hamburg, Germany). 25 mL of sample was placed in a container, then the Wilhemy plate was burned and suspended from the pendulum. Later, the equip performed 5 continuous measurements to determine the surface tension expressed in mN/m. The viscosity was determined in a TA Instruments rheometer model DISCOVERY HR-1 (Delaware, USA). A cone-plate geometry (diameter 60 mm, cone angle 2°, a gap of 0.064 mm) was used at 25 °C and a shear rate of 50 s−1 for 5 min.

Evaluation of the stability of polymer solutions

The stability of the solution was determined with the qualitative technique of accelerated aging [3]. The samples were placed in a microcentrifuge (Hettich model 200R) at 5000 rpm, 25 °C for 5 min, in order to observe the absence or presence of sedimentation phenomena.

Encapsulation by electrospraying

The polymer solutions added with the extract in a 10:1 ratio (polymer: extract) were subjected to electrospraying drying in a Fluidnatek® LE-10 Bioinicia S.L. (Valencia, Spain). A flux of 100 μL/h, a voltage of 10–20 kV and a distance to the collector of 18 cm was used to obtain nanocapsules (Fig. 1).

Scanning electron microscopy

The morphology of the capsules was analyzed in a scanning electron microscope Hitachi S-4100 (Tokyo, Japan) with an acceleration voltage of 5 kV. 1 mg of sample was fixed on a double-sided adhesive tape and placed on a metal slide, then the samples were coated with palladium-gold for 3 min [17].

Encapsulation efficiency

The encapsulation efficiency was determined using 10 mg of capsules that were washed with 5 mL of distilled water, in a cone of Whatman filter paper no. 1, adding 1% formic acid to the permeate to guarantee the stability of the phenolic compounds. After that concentration of these compounds was determined by the Folin–Cicalteu method explained in “Determination of total soluble polyphenols” section. The efficiency was calculated with the following equation:

where % EE: amount of polyphenols inside the capsules. CP: amount of polyphenols loaded in the sample. PL: amount of polyphenols outside the capsules. TP: total amount of polyphenols.

Statistical analysis

The data were analyzed by ANOVA with a 5% significant level. Tukey comparison test was carried out to examine the difference between means. STATISTICA v. 10 (StatSoft, Tulsa, OK, USA) was used for all statistical analysis. All determinations were performed in triplicate.

Results and discussion

Evaluation of the polyphenolic compounds content and antioxidant capacity

The content of polyphenolic compounds in the blueberry extract was 1496.07 mg EAG/100 g of fresh fruit, with a value of 45.8 ± 0.07 μmol ET/g sample for antioxidant capacity. These values are higher than those reported by Bunea et al. [21] who analyzed the content of phenolic compounds in blueberry extracts from the varieties Bluecrop, Elliot and Duke obtained by maceration. These authors reported values in a range of 424.84–819.12 mg EAG/100 g of fresh fruit, 36.26 ± 4.26 μmol ET/g sample in the antioxidant capacity. This result can be attributed to the fact that the blueberry cv. Biloxi is a genetically modified commercial variety generated to increase its concentration of solids and size. Ultrasound-assisted extraction has shown that maximizes the extraction of compounds of high biological value (CAVB) compared with conventional techniques such as Soxhlet extraction and maceration [3, 4, 6]. Several authors have reported that the synthesis of these secondary metabolites is closely related to plant stress, which is caused by environmental conditions. In addition, factors such as sample conditioning, type of solvent and extraction method are associated with the concentration of active compounds in the extracts, which explains the difference in this study with the previously reported in other studies [3, 22, 23].

The antioxidant capacity of the polyphenolic compounds is attributed to the presence of hydroxyl functional groups (–OH). Recent studies have reported that blueberries contain 75% of anthocyanins with respect to the total content of phenolic compounds [4, 23, 24] These compounds belong to the group of flavonoids and possess multiple hydroxyl groups in their structure, which have the ability to release electrons or donate hydrogen atoms, to neutralize free radicals. The antioxidant capacity and the content of polyphenolic compounds are correlated (higher concentration of phenolic compounds, greater is the antioxidant capacity), this correlation explains the obtaining of greater antioxidant capacity in the blueberry cv. Biloxi extract compared to the varieties Bluecrop, Elliot and Duke [25].

Identification of polyphenolic compounds

The identification was based on the comparison of retention times, mass spectral data (NIST) and reports of previous studies [21, 26, 27]. 18 anthocyanins were identified, including 4 phenolic acids in blueberry cv. Biloxi extract (Table 1). The anthocyanins identified in this study were also found in major proportion compared to phenolic acids, as it has been previously reported for Duke, Bluecrop and Elliot varieties. This is explained due to the high content of anthocyanins in cranberry [21, 26]. Likewise, 5 aglycones (malvidin, delphinidin, cyanidin, petunidin and peonidin) were identified. However, we did not identify the pelargonidin, one of the six most abundant aglycones in nature. This result coincides with the reported by Pataro et al. [4]. The presence or absence of an active compound in fruit extracts is mainly related to the variety of fruit, stages of maturation and environmental conditions, since these have a great influence on the synthesis of these compounds, and to a lesser extent to the type of solvent and extraction method [22]. Additionally, gallic, chlorogenic, ferulic and caffeic acid were identified in the blueberry cv. Biloxi extract. The presence of these phenolic acids is mainly associated with the stability of the anthocyanins in the fruit because they act by acylating them, which provides the structure of the anthocyanin with resistance to temperature, light, oxygen and pH [23]. It is important to note that these phenolic acids are found in a lesser proportion in the extract. Consequently, the monomeric anthocyanins are susceptible to structural modification due to the aforementioned factors, and therefore, their protection by encapsulation is necessary.

Evaluation of the physicochemical properties of the solutions

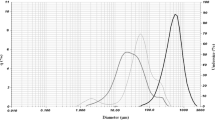

A polymeric solutions characterization prior to the drying process was carried out in order to determine if they were considered as electrospun (Table 2). The process of encapsulation by electrospraying is affected by factors such as the conductivity of the solutions, viscosity, surface tension and in some cases the pH [28]. These factors play an important role in the efficiency and reproducibility of the method [29]. In general terms, it is recommended for the process of encapsulation by electrospraying intermediate viscosities (1 to 10 cP), intermediate conductivities (100 to 5000 μS/cm), low surface tensions (20 to 80 mN/m) and application of moderate voltages (5 to 30 kV) [30, 31].

The ANOVA showed that the polymer concentration and glycerol concentration (interactions) had a significant effect on viscosity, conductivity and surface tension (p ≤ 0.05). The polymer with the highest viscosity was zein. Moreover, low conductivity and surface tension were recorded. These results can be associated with the solvent used to dissolve it (ethanol). Additionally, since it is a protein with surfactant character, facilitates its electrospun. The WPC showed the highest conductivity and surface tension (p ≤ 0.05). These characteristics are due to the concentration of salts, which promotes the conductivity of the solution, so greater voltage is required to achieve the stability of the Taylor cone [9, 13]. González-Tello et al. [32] analyzed the whey protein concentrate demonstrating that the rheological properties of this biopolymer are ruled by its composition, molecular mass, protein shape, the degree of hydration and intermolecular interaction. The HDPAF presented intermediate values in all the physicochemical properties analyzed, which differ with those reported by Ramos-Hernandez et al. [18]. This difference is related to the use of surfactant in its formulation, which decreases the surface tension of the solution. The degree of polymerization (GP ≥ 40) and the multiple hydroxyl groups on their branched structure are the main characteristic of agave fructans that makes them present intermediate values in the solution of their physicochemical properties [15]. Indeed, this provokes to remain in suspension, not increase their viscosity in low and intermediate concentrations, and decrease the surface tension at high concentrations. On the other hand, the glycerol used in the formulation had influences on all the solutions, increasing the viscosity (p ≤ 0.05) (Table 2).

Evaluation of the stability

The stability of the solutions was evaluated by the accelerated aging method, which is a qualitative test that indicates whether a material is capable of staying in suspension. For the electrospraying process, it is required that the solutions are stable for long periods of time since the separation of the solution causes Taylor cone instability, and consequently droplet projection in the collector, which causes that the encapsulation does not occur [30].

Based on the results obtained in this investigation, we verified that regardless of the combination (polymer concentration-glycerol concentration) all the solutions remain stable for a time longer than 24 h (Table 3). Nevertheless, it is important to mention that the stability of a solution does not guarantee that it is electrospun, and therefore, the physicochemical characteristics of the solution (viscosity, surface tension, pH and electrical conductivity) must be taken into account. Simultaneously, the evaluation of the stability and electrospraying drying of each of the solutions was carried out with the objective to verify which of them were electrospun once mixed with the extract.

The polymer solutions mixed with the extract showed (in general) a decrease in pH and an increase in surface tension, which produced instability in the Taylor cone for HDPAF and WPC. Nonetheless, the zein solution showed no change in its stability during the electrospraying process in any of its formulations. It is important to note that at concentrations higher than 10% zein, the limits of the physicochemical properties established for obtaining capsules are exceeded. Taking this into account, when the samples were subjected to the drying process by electrospraying, continuous structures called nanofibers were obtained. López-Rubio and Lagaron [13] encapsulated β-carotene, noting that the main problem to stabilize WPC solutions is the pH. This behavior is similar to the solutions analyzed in this study. The change in pH modifies the physicochemical properties, such as conductivity and surface tension, destabilizing the Taylor cone [31]. In the case of the HDPAF that were stabilized with WPC to reduce the hygroscopicity, the decrease in the pH by addition of the extract caused the precipitation of the protein, and consequently, clogging in the nozzle was observed. However, it is necessary to point out that the solutions of these polymers without extract were electrospun, so they could be used to encapsulate different non-acidified active ingredients.

In a solution rich in anthocyanins, color is an indicator of the stability of these compounds. In this regard, the stability of the extract in solution exhibited color changes in all the solutions related to the structural modification induced by the pH [1]. According to the identification of phenolic compounds of blueberry cv. Biloxi extracts and in comparison with the reported by other authors [33, 34] the anthocyanins content exceeds 70% of the total, thus, the color of it corresponds to the presence of these compounds classified as halochromic. In the WPC solutions, the red hue completely disappeared, this phenomenon is associated with the colorless pseudo-base carbinol structure of the anthocyanin. In the case of HDPAF with 6% WPC (w: w), no change in hue was observed, although the pH caused the precipitation of the protein. In the case of zein, the color change is attributed to the xanthophilic residues (yellow color), resulting in a reduction of the red to reddish–brown color. However, this change is not associated with structural modification of the anthocyanin, but with a decrease in the chromaticity of the solution.

Morphology of the capsules

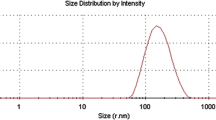

The micrographs (Fig. 2a–c) show the capacity of the HDPAF, WPC and zein biopolymers to form capsules, it should be noted that only those obtained with 10% polymer and 1% glycerol are shown, although all solutions were elestrosprayables without the extract. The HDPAF and WPC polymers with extract were unstable during the electrospraying process. This behavior was observed when the blueberry extract was added and the solution pH decreased (< 3.5), Then, it was not possible to obtain capsules.

The capsules obtained from HDPAF and WPC without extract have smooth surfaces, without cracks or dents, spherical, without agglomerations, with sizes ranging from 700 to 800 nm (Fig. 2b). These results are similar to those obtained by Ramos-Hernández et al. [18], who produced HDPAF capsules at different concentrations (10–50%). Fructans have branched structures and multiple hydroxyl groups that facilitate the formation of capsules, and recently, they demonstrated their ability to form fibers at high concentrations [35].

The capsules obtained from WPC without extract show smooth surfaces, without cracks or dents, spherical, without agglomerations, with sizes ranging from 1 to 2 µm (Fig. 2c). The structures obtained are similar to those reported by López-Rubio et al. [13]. The ability of proteins to form capsules is conditioned by concentration and their chemical structure.

The morphology of the nanocapsules obtained with the zein with and without extract (Fig. 2a, d) presented smooth surfaces, without cracks or dents, were not completely spherical and with a size ranging from 200 to 300 nm, they presented an encapsulation efficiency of 52.65%, however, this value is not the encapsulation limit presented by the polymer, so that the concentration of the extract to be encapsulated can be increased. Furthermore, the nanocapsules showed a tendency to form agglomerates, behavior that has been reported and associated with the addition of glycerol (Fig. 1a). Gomez-Estaca et al. [36] reported for zein, capsules with similar characteristics obtained by electrospraying with Curcumin as an active of interest.

Previous studies have shown that zein in concentrations of 20% in acid media, generated the formation of smooth flat fibers in form of tapes [12, 36]. However, the decrease in pH in the 20% zein solution caused by the addition of the extract does not weaken the structure of the polymer. This effect is reversed and overcome by the plasticizing action of glycerol, which favors the mechanical properties of the polymer, allowing it to be able to electrospun and obtain continuous tubular structures. In this sense, we obtained smooth, continuous, ultrafine fibers with cross sections of 300 to 400 nm, classified as nanofibers (Fig. 2e). Similar structures have been reported by Torres-Giner et al. [12] under conditions of pH 5.97, who obtained smooth and tubular fibers using zein as a polymer matrix with diameters of 450 nm in a percentage of 33%.

Conclusions

Blueberry cv. Biloxi has a high content of polyphenolic compounds with high antioxidant capacity, mainly anthocyanins followed by phenolic acids. 18 anthocyanins and 4 phenolic acids were identified in the methanolic extract. The characterization of the polymer solutions determined that the three polymers investigated here are capable of forming capsules, however, the HDPAF and WPC were not viable for the encapsulation process of the polyphenolic extract. The zein allowed the encapsulation of polyphenolic extract by electrospraying/ electrospinning, achieving the formation of nanocapsules of homogeneous morphology and smooth and continuous nanofibers. The Biloxi variety cultivated in the state of Nayarit presents similarity in the phenolic compounds profile compared to the varieties with export quality. In turn, gives an added value and potentizes its commercialization, as well as its application for the extraction of compounds of high biological value susceptible to being encapsulated.

Availability of data and material

Not applicable.

References

Diaconeasa Z, Leopold L, Rugină D et al (2015) Antiproliferative and antioxidant properties of anthocyanin rich extracts from blueberry and blackcurrant juice. Int J Mol Sci. https://doi.org/10.3390/ijms16022352

Spagnuolo C, Russo M, Bilotto S et al (2012) Dietary polyphenols in cancer prevention: the example of the flavonoid quercetin in leukemia. Ann NY Acad Sci. https://doi.org/10.1111/j.1749-6632.2012.06599.x

Ruiz-Montañez G, Ragazzo-Sánchez JA, Calderón-Santoyo M et al (2014) Evaluation of extraction methods for preparative scale obtention of mangiferin and lupeol from mango peels (Mangifera indica L.). Food Chem. https://doi.org/10.1016/j.foodchem.2014.03.009

Pataro G, Bobinaitė R, Bobinas Č et al (2017) Improving the extraction of juice and anthocyanins from blueberry fruits and their by-products by application of pulsed electric fields. Food Bioprocess Technol. https://doi.org/10.1007/s11947-017-1928-x

Jin J, Ma H, Qu W et al (2015) Effects of multi-frequency power ultrasound on the enzymolysis of corn gluten meal: kinetics and thermodynamics study. Ultrason Sonochem. https://doi.org/10.1016/j.ultsonch.2015.04.031

Aspé E, Fernández K (2011) Comparison of phenolic extracts obtained of Pinus radiata bark from pulp and paper industry and sawmill industry. Maderas Cienc y Tecnol. https://doi.org/10.4067/s0718-221x2011000300001

Fathi M, Martín Á, McClements DJ (2014) Nanoencapsulation of food ingredients using carbohydrate based delivery systems. Trends Food Sci Technol 39:18–39. https://doi.org/10.1016/j.tifs.2014.06.007

Pérez-Masiá R, Lagaron JM, Lopez-Rubio A (2015) Morphology and stability of edible lycopene-containing micro- and nanocapsules produced through electrospraying and spray drying. Food Bioprocess Technol. https://doi.org/10.1007/s11947-014-1422-7

Pérez-Masiá R, Lagaron JM, López-Rubio A (2014) Development and optimization of novel encapsulation structures of interest in functional foods through electrospraying. Food Bioprocess Technol. https://doi.org/10.1007/s11947-014-1304-z

Favaro-Trindade CS, Santana AS, Monterrey-Quintero ES et al (2010) The use of spray drying technology to reduce bitter taste of casein hydrolysate. Food Hydrocoll. https://doi.org/10.1016/j.foodhyd.2009.10.012

Torkamani AE, Syahariza ZA, Norziah MH et al (2018) Production and characterization of gelatin spherical particles formed via electrospraying and encapsulated with polyphenolic antioxidants from momordica charantia. Food Bioprocess Technol. https://doi.org/10.1007/s11947-018-2153-y

Torres-Giner S, Martinez-Abad A, Ocio MJ, Lagaron JM (2010) Stabilization of a nutraceutical omega-3 fatty acid by encapsulation in ultrathin electrosprayed zein prolamine. J Food Sci. https://doi.org/10.1111/j.1750-3841.2010.01678.x

López-Rubio A, Lagaron JM (2012) Whey protein capsules obtained through electrospraying for the encapsulation of bioactives. Innov Food Sci Emerg Technol. https://doi.org/10.1016/j.ifset.2011.10.012

Mellado-Mojica E, González de la Vara LE, López MG (2017) Fructan active enzymes (FAZY) activities and biosynthesis of fructooligosaccharides in the vacuoles of Agave tequilana Weber Blue variety plants of different age. Planta. https://doi.org/10.1007/s00425-016-2602-7

Sosa-Herrera MG, Martínez-Padilla LP, Delgado-Reyes VA, Torres-Robledo A (2016) Effect of agave fructans on bulk and surface properties of sodium caseinate in aqueous media. Food Hydrocoll. https://doi.org/10.1016/j.foodhyd.2016.03.033

Ortiz-Basurto RI, Rubio-Ibarra ME, Ragazzo-Sanchez JA et al (2017) Microencapsulation of Eugenia uniflora L. juice by spray drying using fructans with different degrees of polymerisation. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2017.08.030

Jimenez-Sánchez DE, Calderón-Santoyo M, Picart-Palmade L et al (2017) Effect of addition of native agave fructans on spray-dried chayote (Sechium edule) and Pineapple (Ananas comosus) juices: rheology, microstructure, and water sorption. Food Bioprocess Technol. https://doi.org/10.1007/s11947-017-1974-4

Ramos-Hernández J, Ragazzo-Sánchez J, Calderón-Santoyo M et al (2018) Use of electrosprayed agave fructans as nanoencapsulating hydrocolloids for bioactives. Nanomaterials. https://doi.org/10.3390/nano8110868

García E, Fernández I, Fuentes A (2015) Determinación de polifenoles totales por el método de Folin- Ciocalteu. Univ politécnica Val

Re R, Pellegrini N, Proteggente A et al (1999) Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic Biol Med. https://doi.org/10.1016/S0891-5849(98)00315-3

Bunea A, Ruginǎ DO, Pintea AM et al (2011) Comparative polyphenolic content and antioxidant activities of some wild and cultivated blueberries from Romania. Not Bot Horti Agrobot Cluj-Napoca 39:70–76

Castrejón ADR, Eichholz I, Rohn S et al (2008) Phenolic profile and antioxidant activity of highbush blueberry (Vaccinium corymbosum L.) during fruit maturation and ripening. Food Chem. https://doi.org/10.1016/j.foodchem.2008.01.007

Michalska A, Łysiak G (2015) Bioactive compounds of blueberries: Post-harvest factors influencing the nutritional value of products. Int J Mol Sci 16:18642–18663. https://doi.org/10.3390/ijms160818642

Khoo HE, Azlan A, Tang ST, Lim SM (2017) Anthocyanidins and anthocyanins: colored pigments as food, pharmaceutical ingredients, and the potential health benefits. Food Nutr Res. https://doi.org/10.1080/16546628.2017.1361779

Kalt W, Lawand C, Ryan DAJ et al (2003) Oxygen radical absorbing capacity, anthocyanin and phenolic content of highbush blueberries (Vaccinium corymbosum L.) during ripening and storage. J Am Soc Hortic Sci 128:917–923. https://doi.org/10.21273/JASHS.128.6.0917

Wang H, Guo X, Hu X et al (2017) Comparison of phytochemical profiles, antioxidant and cellular antioxidant activities of different varieties of blueberry (Vaccinium spp.). Food Chem. https://doi.org/10.1016/j.foodchem.2016.09.002

Serafini M, Testa MF, Villaño D et al (2009) Antioxidant activity of blueberry fruit is impaired by association with milk. Free Radic Biol Med. https://doi.org/10.1016/j.freeradbiomed.2008.11.023

Raghavan P, Lim DH, Ahn JH et al (2012) Electrospun polymer nanofibers: the booming cutting edge technology. React Funct Polym. https://doi.org/10.1016/j.reactfunctpolym.2012.08.018

Mendes AC, Stephansen K, Chronakis IS (2017) Electrospinning of food proteins and polysaccharides. Food Hydrocoll. https://doi.org/10.1016/j.foodhyd.2016.10.022

Bock N, Dargaville TR, Woodruff MA (2012) Electrospraying of polymers with therapeutic molecules: State of the art. Prog Polym Sci 37:1510–1551. https://doi.org/10.1016/j.progpolymsci.2012.03.002

Anu Bhushani J, Anandharamakrishnan C (2014) Electrospinning and electrospraying techniques: potential food based applications. Trends Food Sci Technol 38:21–23. https://doi.org/10.1016/j.tifs.2014.03.004

González-Tello P, Camacho F, Guadix EM et al (2009) Density, viscosity and surface tension of whey protein concentrate solutions. J Food Process Eng. https://doi.org/10.1111/j.1745-4530.2007.00213.x

Jiang T, Mao Y, Sui L et al (2019) Degradation of anthocyanins and polymeric color formation during heat treatment of purple sweet potato extract at different pH. Food Chem. https://doi.org/10.1016/j.foodchem.2018.07.141

Heinonen J, Farahmandazad H, Vuorinen A et al (2016) Extraction and purification of anthocyanins from purple-fleshed potato. Food Bioprod Process. https://doi.org/10.1016/j.fbp.2016.05.004

Cruz-Salas CN, Prieto C, Calderón-Santoyo M et al (2019) Micro-and nanostructures of agave fructans to stabilize compounds of high biological value via electrohydrodynamic processing. Nanomaterials. https://doi.org/10.3390/nano9121659

Gomez-Estaca J, Balaguer MP, Gavara R, Hernandez-Munoz P (2012) Formation of zein nanoparticles by electrohydrodynamic atomization: effect of the main processing variables and suitability for encapsulating the food coloring and active ingredient curcumin. Food Hydrocoll. https://doi.org/10.1016/j.foodhyd.2011.11.013

Acknowledgements

The authors thank Tecnológico Nacional de México (Project code 6810.18-P) for their support in conducting the work throughout this project, CONACYT (Mexico) for the scholarship granted (number 467459) to Elda Margarita González-Cruz and Dr. Darvin Ervey Jimenez-Sánchez for technical assistance, and Dr. Rosa Isela Ortiz-Basurto for providing the agave fructans with a high degree of polymerization.

Funding

Tecnológico Nacional de México (Project Code 6810.18-P) for their support in conducting the work throughout this project, CONACYT (Mexico) for the scholarship granted (Number 467459).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Code availability

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

González-Cruz, E.M., Calderón-Santoyo, M., Barros-Castillo, J.C. et al. Evaluation of biopolymers in the encapsulation by electrospraying of polyphenolic compounds extracted from blueberry (Vaccinium corymbosum L.) variety Biloxi. Polym. Bull. 78, 3561–3576 (2021). https://doi.org/10.1007/s00289-020-03292-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03292-3