Abstract

Nanoemulsions are small droplet-sized systems that have low surface tension and a small percentage of active material in their composition. In this study, low oil content nanoemulsion systems were developed for the use in enhanced oil recovery (EOR). The experiments were performed on a device capable of simulating petroleum reservoir conditions using sandstone rock cores. Nanoemulsions were obtained from a pre-selected microemulsion system composed of: RNX95 as surfactant, isopropyl alcohol as cosurfactant, kerosene as oil phase, and distilled water as aqueous phase. Different percentages of polyacrylamide were added to the systems obtained to evaluate the influence of viscosity in EOR results. The nanoemulsion droplet sizes ranged from 9.22 to 14.8 nm. Surface tension values were in the range of 33.6–39.7 dyn/cm. A nanoemulsion system with 2.5 wt% surfactant was used in EOR assays. The oil recovery was directly proportional to polymer percentage in the nanoemulsion, ranging from 39.6 to 76.8%. The total oil in the place recovery ranged from 74.5 to 90%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

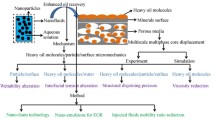

Enhanced oil recovery (EOR), or tertiary oil recovery, is a method used to recover additional oil remaining in reservoirs after primary and secondary recovery processes [1]. In the EOR technique, different types of surfactants alter interfacial properties and foam behaviors [2]. Polymers are also used in EOR to improve the water/oil mobility ratio by increasing the viscosity of the displacing fluid (water) [3].

The application of surfactant solutions and microemulsions in EOR methods leads to increased oil recoveries [4,5,6]. The addition of polymer to these surfactant systems can create a very stable displacement front, increasing sweep efficiency. The use of surface active agents enhances oil recovery due to the following mechanisms: (1) production of very low interfacial tension (<10−3 mN/m) between oil and flooding solution; (2) spontaneous emulsification or microemulsification of the trapped oil; (3) alternation of the interfacial rheological properties at the oil–flooding solution interface; and (4) control of the wettability of the rock pores, optimizing oil displacement [7].

The microemulsion systems generally use high amounts of surfactants for this kind of application. However, the use of nanoemulsion systems presents an alternative for this application.

Nanoemulsions, also referred to as miniemulsions or submicrometer emulsions, are transparent or translucent colloidal systems, with very small droplet size [8, 9]. Nanoemulsion droplets are kinetically stable against sedimentation or creaming. There are significant differences between nanoemulsions and microemulsions. The former are thermodynamically unstable systems and usually require energy input for their formation while the latter are thermodynamically stable and form spontaneously. The main advantage of nanoemulsions over microemulsions is the use of moderate to low surfactant concentration, considering that microemulsions require large amounts of surface active matter [10,11,12,13,14,15,16,17].

According to Anton et al. [18], the main advantage of nanoemulsions is their great droplet suspension stability. This kinetic stability against dilution and temperature changes, which can last for months, makes nanoemulsions prime candidates for nanoparticle engineering.

After conventional oil recovery, high amounts of oil remain retained in the reservoir rock. Enhanced oil recovery (EOR) methods act on the characteristics of the reservoir rock, as well as on its interaction with fluids, changing its wettability and fluid miscibility, aiming for the production of the retained oil [19]. According to Rebinder [20], solubilization is of great interest in oil recovery. Solubilization takes place, however, only in micellar solutions of surfactants, i.e., in two-phase colloidal solutions of surfactants, at a concentration greater than the critical micelle concentration (c.m.c.).

Overall, the current EOR studies applying chemical fluids seek to determine the influence of some parameters in oil displacement. Several references discuss and evaluate the action of different types of chemical systems, such as polymers [21, 22], surfactants [23, 24], and microemulsions [5, 25, 26]. For application of chemical systems in EOR, the most important parameters to be considered are: interfacial tension [27,28,29], surface tension [2, 30], droplet size [27, 31], viscosity [32–35], wettability [26, 36, 37], and characteristics of the associated porous media [38, 39].

Daghlian Sofla et al. [40] evaluated the action of three synthetic ionic surfactants (CTAB, SDS, AOS) and one natural surfactant (extracted from leaves of Zizyphus Spina-Christi trees) on the modification of interfacial tension (IFT) and wettability. The authors demonstrated that the natural surfactant can reduce the oil–water IFT, but the synthetic ones show better efficiency [40]. Shafiee Najafi et al. [41] demonstrated that the size and shape of microemulsion aggregates (CTAB) have a direct influence on viscosity. They observed that the transition of the aggregate shape from spherical to cylindrical leads to an increase in the system viscosity [41]. Sharma and Sangwai [42] developed SiO2 stable nanofluids of polyacrylamide, with and without addition of a surfactant (sodium dodecyl sulfate, SDS). They evaluated the droplet size (DLS), surface tension, and viscosity of the developed systems as well as their influence in IFT reduction of paraffinic oils. They concluded that the systems with surfactant were more effective in reducing IFT values [42].

The objective of this study is to develop new low oil content nanoemulsion systems (LONano), using small amounts of surfactants and low input of energy, to be used in EOR operations. Systems with and without polymer addition were developed aiming to evaluate the interaction effects between a micellar solution and a thickening agent. The micellar solution is capable of decreasing the interfacial tension, aiding in miscible displacement. The thickening agent acts to increase the viscosity and, consequently, the sweep efficiency.

Experimental

Materials

All chemicals used in the experiments were of analytical grade and were used without previous purification. The experiments used RNX95 (Fig. 1), a non-ionic surfactant with high hydrophilic-lipophilic balance (13 HLB value) [43]. According to Griffin [44], surfactants with this HLB value are used to produce oil-in-water (O/W) stable emulsified systems. Isopropyl alcohol (Dinâmica, 99.5%) was used as cosurfactant, sodium p-toluenesulfonate as hydrotrope (Aldrich, 99.5%), kerosene as oil phase (Petrobras), and polyacrylamide (SNF—Floerger; in granular form; pH 6–8; molecular weight 11 × 106 − 16 × 106 Da). Water was used to obtain all solutions and formed the aqueous phase of microemulsion and nanoemulsion systems.

The EOR experiments used sandstone cores (5 cm length by 4 cm diameter), from the Botucatu formation (Paraná—Brazil). Petrobras provided the crude oil samples (33° API gravity, Ubarana Oil Field, Rio Grande do Norte, Brazil). The brine used during the saturation of cores and in conventional oil recovery was a 20,000 ppm KCl solution (Êxodo, 99.0% purity).

Obtaining the LONano

The first step in the development of the LONano systems was obtaining a microemulsion system. Figure 2 shows the pseudoternary phase diagram developed in a previous work [45]. In Fig. 2, the microemulsion area (Winsor IV) without hydrotrope (sodium p-toluenesulfonate) formed is quite narrow, especially in the region of interest (high amount of water). Hydrotrope was added to enhance the Winsor IV formulation space. The function of the hydrotrope is to increase water-surfactant interaction, which can be seen in the phase diagram (Fig. 2). In this diagram, one can observe the microemulsion (Winsor IV—WIV) and the Winsor WI (WI—a microemulsion in equilibrium with an oil phase in excess) areas. The selected point was composed of: 12.5 wt% RNX95, 12.5 wt% cosurfactant (11.88 wt% isopropyl alcohol + 0.62 wt% sodium p-toluenesulfonate), 2 wt% kerosene, and 73 wt% water. This microemulsion system was selected because it comprises a great amount of aqueous phase and a small amount of active material (Cosurfactant (C)/Surfactant (S) ratio).

The microemulsion system was obtained in three steps. First, in a 150-mL beaker, the sodium p-toluenesulfonate (hydrotrope) was added to the aqueous phase and dissolved at constant stirring (500 rpm, 15 min). It was added to the water to increase surfactant solubility, increasing the microemulsion area (Winsor IV). In the second step, the remaining components of the microemulsion were mixed in another 150-mL beaker (500 rpm, 15 min). Next, the hydrotrope solution was poured into the second beaker to obtain a clear and stable system.

Prior to obtaining of the low oil content nanoemulsions (LONano), it was necessary to use a low-energy methodology to attain a stable system using a small amount of active material. Water was added slowly to the microemulsion system, under constant stirring (500 rpm). The choice of the nanoemulsion system was based on the relation between surface tension and surfactant concentration. To ensure the formation of the nanoemulsion system, the following tests were conducted: droplet size measurements, polydispersity index, and surface tension.

Addition of Polymer to the LONano

Different percentages of polyacrylamide (0.02 to 0.40 wt%) were added to the developed nanoemulsion system. However, to maintain the composition of the nanoemulsion, the mass fraction corresponding to the polymer addition was decreased from the mass of the aqueous phase.

Physicochemical Characterization of the LONano

Nanoemulsion droplet size and polydispersity index were obtained with the aid of a particle size analyzer (Zeta Plus Particle Sizing, Brookhaven Instruments), which uses a dynamic light scattering (DLS) technique. These parameters were assessed immediately after obtaining the nanoemulsions, and after 30 days of storage (120-mL umber storage bottles). Surface tension and viscosity were measured using a tensiometer (QC6000, SensaDyne Instruments) and a rheometer (Haake Mars, Thermo Electron GmbH, Thermo Scientific), respectively. All measurements were performed at 25 °C.

Interfacial Tension Measurement Between LONano and Crude Oil Phases

Interfacial tension measurements were made using the Spinning Drop tensiometer (SITE 100, Krüss). This equipment is based on the theory of Vonnegut [46]. To carry out the measurements, a drop of a fluid with lower density is inserted into a capillary filled with other denser fluid subject to high rotation so that the less dense fluid reaches the axis of rotation and assumes a cylindrical shape.

The nanoemulsion was used as bulk phase to fill the capillary, and approximately 10 µL of crude oil was injected as light phase. All the analyses were made at 5000 rpm and 25 °C.

Sandstone Core Flooding Tests

Oil recovery tests were performed using five sandstone cores. First, the cores were calcined at 700 °C for 6 h (10 °C/min) to ensure the removal of all water and organic materials. Later, core porosities were measured using a Boyle’s porosimeter. The Containment System for Hydrostatic Testing (Fig. 3) was used in enhanced oil recovery (EOR) experiments to determine the recovery efficiencies of conventional (brine—2 wt% KCl solution) and special (LONano) methods. All tests were performed at 25 °C and under 1500 psi (overburden pressure).

Core flooding experiments were made in five steps. First, the sandstone core was placed inside the core holder, and the injection line was connected. The overburden pressure was adjusted to the desired level. The second step was the flushing of the core with brine (8 pore volumes—PVs). After that, the crude oil (8 PVs) was injected. At this point, irreducible water saturation (S wi) and initial oil saturation (S oi) were determined. The fourth and fifth stages refer to the oil recovery: first injecting brine (conventional oil recovery—3 PVs) and, then, injecting the LONano (enhanced recovery—3 PVs) at a constant injection flow rate (0.5 mL/min). The residual oil saturation after conventional and enhanced oil recoveries were measured and named S or_b and S or_n, respectively. Samples of recovered fluids were collected and the separation of oil and water was performed using a centrifuge (Q222E, Quimis) for 3 min at 2000 rpm. Another way to determine the efficiency of oil recovery would then be considering the initial volume of oil in the porous media (oil in place—OIP) and the volume of oil recovered in each flooding step (OOIP).

Results and Discussion

LONano System

The minimum amount of surfactant required to obtain produced stable nanoemulsions was obtained by measurements of surface tension. Figure 4 shows that the surface tension tends to increase sharply for systems with less than 1 wt% (Log [RNX 95] = 0) surfactant. However, for surfactant concentrations below 2 wt% (Log [RNX 95] = 0.3), a slight turbidity was achieved by increasing dilution. Based on this result, the final composition of the nanoemulsion chosen in EOR experiments was: 2.50 wt% surfactant (RNX95), 94.60 wt% distilled water, 0.40 wt% kerosene, 2.38 wt% isopropyl alcohol, and 0.12 wt% sodium p-toluenesulfonate. This system had a clear appearance and low surface tension. However, the composition chosen for the dilution point corresponded to Winsor I, as shown in the pseudoternary diagram obtained (Fig. 2). The experiments were unable to obtain the composition chosen at Winsor IV just by slight mixing. It is important to point out that this nanoemulsion remained stable and transparent after 30 days of storage time.

To observe the effects of viscosity, different percentages of polyacrylamide (0.02–0.4 wt%) were added to this LONano system. The systems with polymer addition were named: I (0.00 wt%), II (0.02 wt%), III (0.10 wt%), IV (0.20 wt%), and V (0.40 wt%). The maximum concentration of polyacrylamide used was justified by the increase in apparent viscosity, considering the difficulty of injecting highly viscous fluids that could be attained by further increasing the polymer level.

LONano Characterization

The effective droplet size for nanoemulsion systems, immediately after formation and with 30 days storage time, is shown in Fig. 5. There is a slight difference between the two measurements, indicating the stability of systems. The droplet size ranged between 9.2 and 14.8 nm. Another parameter assessed was the polydispersity index (PDI). The PDI values for systems I to V were: 0.114, 0.215, 0.259, 0.227, and 0.183 for initial measurements and 0.098, 0.208, 0.240, 0.225, and 0.179 after 30 days of storage time. All systems had a PDI value lower than 0.5, which is typical of homogenous and monodisperse systems [47, 48].

Figure 5 shows that, by increasing the percentage of polyacrylamide in the LONano, the droplet diameter increases. However, for the polymer addition of 0.10 wt%, this increase was not significant. After the storage time, there was a decrease of polydispersity index. This result can indicate an agglutination of micellar aggregates, due to the slight increase of diameter after 30 days of storage of nanoemulsions obtained.

Table 1 shows the values of apparent viscosity for the obtained nanoemulsion systems. As expected, the apparent viscosity increases with the addition of polyacrylamide. The apparent viscosity of the crude oil used in EOR experiments is 14.799 cP. According to the values shown in Table 1, it is expected the improvement in EOR results is obtained with the injection of more viscous systems (IV and V) because they are less susceptible to flow through lower pressure zones, avoiding the formation of preferential paths [49].

There is usually some surfactant solubilized in the bulk water phase of the nanoemulsion [50]. It is assumed that, in increasing polymer concentration, a competition between polymer and surfactant molecules by water molecules will occur. This competition causes the surfactant to migrate to the micelles, leading to discrete micelle swelling. As a result, system viscosity increases with the reduction of water-free molecules (enhanced polymer solubilization), as illustrated in Fig. 6.

Figure 7 shows the variation of LONano viscosity with shear rate (0–200 s−1) and temperature (30–90 °C). One can observe that viscosity increases with polymer concentration and tends to remain constant with increasing shear rate, for any temperature. The increase in temperature has a slight influence on the viscosity values.

Figure 8 shows surface tension measurements for nanoemulsions and polymer solutions at the same concentration. One can observe a slight increase in surface tension with the increase in polyacrylamide concentration. The values of surface tension for nanoemulsions were significantly lower due to the presence of surfactant in its compositions. As explained, the addition of polymer contributes to an increase in viscosity values. However, low interference in surface tension results was observed, showing that polymer addition to the LONano system can improve the mobility ratio by increasing the viscosity of the injected fluid and by reducing interfacial tension.

Surface tension as a function of polymer concentration for nanoemulsion and polymer solution (T = 30 °C; nanoemulsion composition: 2.50% RNX95, 94.60% distilled water, 0.40% kerosene, 2.38% isopropyl alcohol, and 0.12% sodium p-toluenesulfonate; mass fraction corresponding to polymer addition was decreased from aqueous phase)

Interfacial Tension Between LONano Systems and Crude Oil Phases

Figure 9 presents the results for interfacial tension versus polymer concentration. It shows that the addition of polyacrylamide decreases the value of interfacial tension between crude oil and LONano. This behavior is associated with polymer solubilization in the aqueous phase, increasing system viscosity (with less free water) and intensifying micelle-crude oil interaction, resulting in increased miscibility. This action is very important for application in oil recovery due to the increase in miscibility between nanoemulsion and the reservoir fluids. Polymer solutions were not considered in this study because the equipment used in this research is designed only for fluids with very low interfacial tension. Interfacial tension results were similar to other studies [51–55] in advanced oil recovery tests.

Enhanced Oil Recovery Experiments

Table 2 presents the porous volume (PV) of the sandstone cores used in EOR experiments and shows the results for oil initial saturation (S oi), oil residual saturation after the use of brine (S or_b) and after the use of nanoemulsions (S or_n), and oil displacement efficiency in conventional (E dc), enhanced (E dn), and total (E dT) stages.

The results for conventional displacement efficiency (E dc) have slight differences, which are related to the pore volume variation among the used sandstone cores. For core A, the recovery percentile of the oil in place by the advanced method (OOIPnano) was 16.7%, increasing the recovery percentage from 57.8% in the conventional recovery (OOIPbrine) up to 74.5% of total recovery (OOIPTotal). This enhancement in oil recovery can be attributed to the reduction in interface tension between nanoemulsion systems and reservoir fluids and to nanoemulsion high miscibility power. It was observed in EOR tests that the enhanced oil recovery for C, D, and E cores, where nanoemulsions III, IV, and V were injected, were greater than for cores A and B. The efficiency in oil displacement (OOIPnano) was improved with increasing polymer concentration (I—16.7% ≤ II—16.3% < III—22.8% < IV—27.9% < V—33.0%), reaching twice the efficiency of the nanoemulsion without polymer addition. The apparent viscosity of nanoemulsions IV and V were higher than the one for the crude oil used (15.30 cP at 30 °C and 200 s−1). This is an important observation, considering that more viscous fluids can prevent the formation of preferential paths, increasing the fluid-oil contact, and, consequently, displacing the retained oil. Previous research involving microemulsion systems (using higher surfactant percentages) show oil displacement efficiencies similar to the ones presented in this work [5, 6, 33].

Figure 10 shows the behavior of oil recovery efficiency by conventional and enhanced methods as a function of pore volume injected for core E, where the best result was obtained. One can observe that cumulative oil production starts when pore volume values are higher than 0.4. After this point, the volume of oil produced decreases with the increase in volume of brine injected, having a tendency to remain constant. The following stage is the injection of the nanoemulsion, seeking to recover additional oil volume. In Fig. 10, one can also observe the fractional flow of injected fluids (F w) during the recovery steps. It is possible to note that this fraction increases initially and tends to become constant during conventional oil production. However, with the injection of the nanoemulsion, this flow tends to reduce, since the injection of this fluid works as an alternative to increase the volume of oil produced and, consequently, reduces the production of the injected fluid.

Conclusions

In this work, low oil content nanoemulsion systems (LONano) were developed, characterized, and used in enhanced oil recovery experiments. Based on the experimental results, the following conclusions can be drawn:

-

The methodology proposed for the obtaining of LONano systems was effective, with systems showing clear appearance and no visual changes over time;

-

The LONano systems were classified as monodisperse, with small particle size and low PDI;

-

The addition of polymer to the nanoemulsions resulted in more viscous systems;

-

The oil displacement efficiency is directly proportional to the increase in viscosity, with nanoemulsion V (0.4 wt% polymer) presenting the highest residual oil recovery (76.8%), resulting in the highest total oil in place recovery (90.0%).

References

Kamal MS. A review of gemini surfactants: potential application in enhanced oil recovery. J Surfactants Deterg. 2016;19:223–36. doi:10.1007/s11743-015-1776-5.

Bera A, Ojha K, Mandal A. Synergistic effect of mixed surfactant systems on foam behavior and surface tension. J Surfactants Deterg. 2013;16:621–30. doi:10.1007/s11743-012-1422-4.

Kamal MS, Hussain SMS, Sultan AS. Development of novel amidosulfobetaine surfactant-polymer systems for EOR applications. J Surfactants Deterg. 2016;19:989–97. doi:10.1007/s11743-016-1848-1.

Chen L, Zhang G, Ge J, et al. Research of the heavy oil displacement mechanism by using alkaline/surfactant flooding system. Colloids Surf A. 2013;434:63–71. doi:10.1016/j.colsurfa.2013.05.035.

Jeirani Z, Mohamed Jan B, Si Ali B, et al. Formulation, optimization and application of triglyceride microemulsion in enhanced oil recovery. Ind Crops Prod. 2013;43:6–14.

Santanna VC, Curbelo FDS, Castro Dantas TN, et al. Microemulsion flooding for enhanced oil recovery. J Petrol Sci Eng. 2009;66:117–20. doi:10.1016/j.petrol.2009.01.009.

Myers D. Surfactant science and technology, 3rd ed. New York: Wiley; 2005. doi:10.1002/047174607X.

Sadurní N, Solans C, Azemar N, García-Celma MJ. Studies on the formation of O/W nanoemulsions, by low-energy emulsification methods, suitable for pharmaceutical applications. Eur J Pharm Sci. 2005;26:438–45. doi:10.1016/j.ejps.2005.08.001.

Pathak M. Nanoemulsions and their stability for enhancing functional properties of food ingredients. In: Grumezescu A, editor. Nanotechnology applications in food. New York: Elsevier; 2017. p. 87–106.

Ee SL, Duan X, Liew J, Nguyen QD. Droplet size and stability of nano-emulsions produced by the temperature phase inversion method. Chem Eng J. 2008;140:626–31. doi:10.1016/j.cej.2007.12.016.

Floury J, Desrumaux A, Axelos MA, Legrand J. Effect of high pressure homogenisation on methylcellulose as food emulsifier. J Food Eng. 2003;58:227–38. doi:10.1016/S0260-8774(02)00372-2.

Klang V, Matsko NB, Valenta C, Hofer F. Electron microscopy of nanoemulsions: an essential tool for characterisation and stability assessment. Micron. 2012;43:85–103. doi:10.1016/j.micron.2011.07.014.

Landfester K, Eisenblätter J, Rothe R. Preparation of polymerizable miniemulsions by ultrasonication. J Coat Technol Res. 2004;1:65–8. doi:10.1007/s11998-004-0026-y.

Mittal KL, Shah DO. Adsorption and aggregation of surfactants in solution, vol. 109. Surfactant Science SeriesBoca Raton: CRC Press; 2003. doi:10.1201/9780203910573.

Mountain GA, Jelier BJ, Bagia C, Frieson CM, Janjic JM. Design and formulation of nanoemulsions using 2-(poly(hexafluoropropylene oxide)) perfluoropropyl benzene in combination with linear perfluoro(polyethylene glycol dimethyl ether). J Fluorine Chem. 2014;162:38–44. doi:10.1016/j.jfluchem.2014.03.007.

Solans C, Izquierdo P, Nolla J, et al. Nano-emulsions. Curr Opin Colloid Interface Sci. 2005;10:102–10. doi:10.1016/j.cocis.2005.06.004.

Tadros T, Izquierdo P, Esquena J, Solans C. Formation and stability of nano-emulsions. Adv Coll Interface Sci. 2004;108–109:303–18. doi:10.1016/j.cis.2003.10.023.

Anton N, Benoit JP, Saulnier P. Design and production of nanoparticles formulated from nanoemulsion templates—a review. J Control Release. 2008;128:185–99. doi:10.1016/j.jconrel.2008.02.007.

Chilingarian GV, Donaldson EC, Yen TF. Preface. Dev Pet Sci 1985;17:vii–viii. doi:10.1016/S0376-7361(08)70561-2.

Rebinder PA. Use of surfactant in the petroleum industry. Berlin: Kluwer Academic Publishers; 1965.

Wang Z, Le X, Feng Y, Zhang C. The role of matching relationship between polymer injection parameters and reservoirs in enhanced oil recovery. J Petrol Sci Eng. 2013;111:139–43. doi:10.1016/j.petrol.2013.07.011.

Pei H, Zhang G, Ge J, et al. Effect of polymer on the interaction of alkali with heavy oil and its use in improving oil recovery. Colloids Surf A. 2014;446:57–64. doi:10.1016/j.colsurfa.2014.01.031.

El-Batanoney M, Abdel-Moghny T, Ramzi M. The effect of mixed surfactants on enhancing oil recovery. J Surfactants Deterg. 1999;2:201–5. doi:10.1007/s11743-999-0074-7.

Hadji M, Al-Rubkhi A, Al-Maamari RS, Aoudia M. Surfactant (in situ)–surfactant (synthetic) interaction in Na2CO3/surfactant/acidic oil systems for enhanced oil recovery: its contribution to dynamic interfacial tension behavior. J Surfactants Deterg. 2015;18:761–71. doi:10.1007/s11743-015-1714-6.

Bera A, Kumar T, Ojha K, Mandal A. Screening of microemulsion properties for application in enhanced oil recovery. Fuel. 2014;121:198–207. doi:10.1016/j.fuel.2013.12.051.

Castro Dantas TN, Soares APJ, Wanderley Neto AO, et al. Implementing new microemulsion systems in wettability inversion and oil recovery from carbonate reservoirs. Energy Fuels. 2014;28:6749–59. doi:10.1021/ef501697x.

Zhu P, Zhu Y, Xu Z, et al. Effect of polymer on dynamic interfacial tensions of anionic–nonionic surfactant solutions. J Dispers Sci Technol. 2016;37:820–9. doi:10.1080/01932691.2015.1065502.

Nandwani SK, Malek NI, Lad VN, et al. Study on interfacial properties of Imidazolium ionic liquids as surfactant and their application in enhanced oil recovery. Colloids Surf A. 2017;516:383–93. doi:10.1016/j.colsurfa.2016.12.037.

Aoudia M, Al-Shibli MN, Al-Kasimi LH, et al. Novel surfactants for ultralow interfacial tension in a wide range of surfactant concentration and temperature. J Surfactants Deterg. 2006;9:287–93. doi:10.1007/s11743-006-5009-9.

Hosseini-nasab SM, Zitha PLJ, Mirhaj SA, Simjoo M. A new chemical-enhanced oil recovery method? Colloids Surf A. 2016;507:89–95.

Ahmadi M-A, Ahmad Z, Phung LTK, et al. Experimental investigation the effect of nanoparticles on micellization behavior of a surfactant: application to EOR. Petrol Sci Technol. 2016;34:1055–61. doi:10.1080/10916466.2016.1148051.

Sveistrup M, van Mastrigt F, Norrman J, et al. Viability of biopolymers for enhanced oil recovery. J Dispers Sci Technol. 2016;37:1160–9. doi:10.1080/01932691.2015.1088450.

Li K, Jing X, He S, et al. Laboratory study displacement efficiency of viscoelastic surfactant solution in enhanced oil recovery. Energy Fuels. 2016;30:4467–74. doi:10.1021/acs.energyfuels.5b02925.

Malik IA, Al-Mubaiyedh UA, Sultan AS, et al. Rheological and thermal properties of novel surfactant-polymer systems for EOR applications. Can J Chem Eng. 2016;94:1693–9. doi:10.1002/cjce.22541.

Mahdavi SZ, Aalaie J, Miri T, et al. Study of polyacrylamide-surfactant system on the water–oil interface properties and rheological properties for EOR. Arab J Chem. 2016. doi:10.1016/j.arabjc.2016.05.006.

Hou B, Wang Y, Cao X, et al. Mechanisms of enhanced oil recovery by surfactant-induced wettability alteration. J Dispers Sci Technol. 2016;37:1259–67. doi:10.1080/01932691.2015.1089778.

Sulaiman WRW, Lee ES. Simulation of surfactant based enhanced oil recovery. Open Petrol Eng J. 2012. doi:10.2174/1874834101205010078.

Zhou X, Dong M, Maini B. The dominant mechanism of enhanced heavy oil recovery by chemical flooding in a two-dimensional physical model. Fuel. 2013;108:261–8. doi:10.1016/j.fuel.2013.02.012.

Hendraningrat L, Li S, Torsæter O. A coreflood investigation of nanofluid enhanced oil recovery. J Petrol Sci Eng. 2013;111:128–38. doi:10.1016/j.petrol.2013.07.003.

Daghlian Sofla SJ, Sharifi M, Sarapardeh AH. Toward mechanistic understanding of natural surfactant flooding in enhanced oil recovery processes: the role of salinity, surfactant concentration and rock type. J Mol Liq. 2016;222:632–9. doi:10.1016/j.molliq.2016.07.086.

Shafiee Najafi SA, Kamranfar P, Madani M, et al. Experimental and theoretical investigation of CTAB microemulsion viscosity in the chemical enhanced oil recovery process. J Mol Liq. 2017;232:382–9. doi:10.1016/j.molliq.2017.02.092.

Sharma T, Sangwai JS. Silica nanofluids in polyacrylamide with and without surfactant: viscosity, surface tension, and interfacial tension with liquid paraffin. J Petrol Sci Eng. 2017. doi:10.1016/j.petrol.2017.01.039.

Oxiteno. Boletim técnico Ultranex® NP. 2014.

Griffin WC. Classification of surface-active agents by “HLB”. J Soc Cosmet Chem. 1949;1:311–26.

Dantas TNC, Neto AAD, Teixeira ERF, et al. Influence of polymer addition in a microemulsion system and its application in enhanced oil recovery. In: Intenational solvent extraction conference. 2011.

Vonnegut B. Rotating bubble method for the determination of surface and interfacial tensions. Rev Sci Instrum. 1942;13:6–9. doi:10.1063/1.1769937.

Barradas TN, de Campos VEB, Senna JP, et al. Development and characterization of promising o/w nanoemulsions containing sweet fennel essential oil and non-ionic sufactants. Colloids Surf A. 2014;480:214–21. doi:10.1016/j.colsurfa.2014.12.001.

Biruss B, Dietl R, Valenta C. The influence of selected steroid hormones on the physicochemical behaviour of DPPC liposomes. Chem Phys Lipids. 2007;148:84–90. doi:10.1016/j.chemphyslip.2007.04.009.

Muggeridge A, Cockin A, Webb K, et al. Recovery rates, enhanced oil recovery and technological limits. Philos Trans R Soc Lond A. 2013. doi:10.1098/rsta.2012.0320.

Langevin D. Micelles and microemulsions. In: Garrido L, editor. Complex Fluids: proceedings of the xii sitges conference sitges, Barcelona, Spain, 1–5 June 1992. Berlin: Springer; 1993. p. 327–49.

Ahmadi MA, Arabsahebi Y, Shadizadeh SR, Shokrollahzadeh Behbahani S. Preliminary evaluation of mulberry leaf-derived surfactant on interfacial tension in an oil-aqueous system: EOR application. Fuel. 2014;117:749–55. doi:10.1016/j.fuel.2013.08.081.

Babadagli T, Al-Bemani A, Boukadi F, Al-Maamari R. A laboratory feasibility study of dilute surfactant injection for the Yibal field, Oman. J Petrol Sci Eng. 2005;48:37–52. doi:10.1016/j.petrol.2005.04.005.

Babadagli T. Evaluation of the critical parameters in oil recovery from fractured chalks by surfactant injection. J Petrol Sci Eng. 2006;54:43–54. doi:10.1016/j.petrol.2006.07.006.

Bera A, Ojha K, Mandal A, Kumar T. Interfacial tension and phase behavior of surfactant-brine-oil system. Colloids Surf A. 2011;383:114–9. doi:10.1016/j.colsurfa.2011.03.035.

Xu J, Zhang Y, Chen H, et al. Effect of surfactant headgroups on the oil/water interface: an interfacial tension measurement and simulation study. J Mol Struct. 2013;1052:50–6. doi:10.1016/j.molstruc.2013.07.049.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

de Castro Dantas, T.N., de Souza, T.T.C., Dantas Neto, A.A. et al. Experimental Study of Nanofluids Applied in EOR Processes. J Surfact Deterg 20, 1095–1104 (2017). https://doi.org/10.1007/s11743-017-1992-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11743-017-1992-2