Abstract

The effect of synthetic surfactant molecular structure on the dynamic interfacial tension (DIFT) behavior in Na2CO3/surfactant/crude oil was investigated. Three surfactants, a nonionic (iC17(EO)13), an alcohol propoxy sulfate (C14–15(PO)8SO4), and sodium dodecyl sulfate (SDS) were considered in this study. Sodium tripolyphosphate (STPP) was added to ensure complete compatibility between brine and Na2CO3. In Na2CO3/iC17(EO)13/oil and Na2CO3/C14–15(PO)8SO4/oil systems, a strong synergistic effect for lowering the dynamic interfacial tension was observed, in which the dynamic IFT are initially reduced to ultralow transient minima in the range 1.1 × 10−3–6.6 × 10−3 mNm−1 followed by an increment to a practically similar equilibrium value of 0.22 mNm−1 independent of Na2CO3 concentration (for iC17(EO)13) and to decreasing equilibrium values with increasing alkali concentrations (for C14–15(PO)8SO4). The observed difference in the equilibrium IFT for the two systems suggest that in both systems, the mixed interfacial film is efficient in reducing the dynamic interfacial tension to ultralow transient minima (~10−3 mNm−1) but the mixed film soap-iC17(EO)13 is much less efficient than the mixed film soap-C14–15(PO)8SO4 in resisting soap diffusion from the interface to the bulk phases. In both systems, the synergism was attributed, in part, to the intermolecular and intramolecular ion–dipole interactions between the soap molecules and the synthetic surfactant as well as to some shielding effect of the electrostatic repulsion between the carboxylate groups by the nearby ethylene oxide (13 EO) and propylene oxide (8 PO) groups in the mixed interfacial monolayer. SDS surfactant showed a much lower synergism relative to iC17(EO)13 and C14–15(PO)8SO4, probably due to the absence of ion–dipole interactions and shielding effect in the mixed interfacial layer at the oil–water interface.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The occurrence of ultralow transient interfacial tension in alkali/surfactant/acidic crude oil systems assumes that the oil contains a mixture of organic carboxylic acids (HA) that can form in situ surface active species by the reaction with alkaline [1–4]. Two reaction paths have been considered. The first path involves the extraction of the organic acid into the aqueous phase, where it reacts with OH− to form the active anion \({\text{A}}_{\text{w}}^{ - }\). In the presence of large amount of Na+, AwNa, is formed. The second reaction path involves the migration of the organic acid in the oil phase (HAo) to the interface, where it undergoes dissociative adsorption (\({\text{A}}_{\text{ads}}^{ - }\)) resulting in a decrease of the IFT at the oil–water interface [5].

The synergistic effect reflected in the reduction of the interfacial tension (IFT) at the oil–water interface has been mainly investigated in terms of the system’s physicochemical properties such as temperature, alkali concentration and type, surfactant type and concentration, sodium chloride, and crude oil acid number and composition. Thus, Sun et al. [6] showed that Na2CO3 reacts slowly and partly with the acid components in crude oil, while the reaction with NaOH was very fast and complete. In addition, Na2CO3 was found to be more effective than NaOH in lowering the oil–water interfacial tension. Synergism for lowering the dynamic interfacial tension (DIFT) between alkyl naphthalene sulfonates having different alkyl chain lengths and n-decane model oil and crude oil was found to be controlled by surfactant concentration, alkyl chain length, alkali concentration, alkali type, and oleic acid concentration [7]. Zhang et al. [8] reported that the acid fractions with lower average molecular weight (Mn < 500) have considerable aliphatics in the R side chain and show stronger interfacial activities and dynamic interfacial tension behavior with alkali solutions. On the other hand, the fractions with the higher average molecular weight (Mn > 500) have considerable aromaticity in the R side chain and show lower interfacial activities. Furthermore, the authors reported the following interesting observations: (i) the acidic fractions in the oil phase can influence the partition of added surfactants between the oil phase and the aqueous phase, which resulted in the change of interfacial tensions, (ii) the aromatic fractions, which have high polarity, influenced interfacial tensions more intensively, and (iii) the synergism for lowering the interfacial tension in acidic fraction model oil/petroleum sulfonate systems can be positive or negative according to the character of the oil phase and aqueous phase. Rudin et al. [9, 10] studied both equilibrium and dynamic interfacial tension in added surfactant/alkali/acidic oil systems. They suggested that the unionized acid species play a key role in affecting the DIFT and the leading mechanism by which added surfactant aids in the reduction of the DIFT is formation of a mixed film with the ionized acid at the oil–water interface. Touhami et al. [11] investigated the fundamental mechanisms for lowering the DIFT between acidic oil and surfactant-enhanced alkaline solutions. They found that the DIFT behavior was a function of acid concentration in the oil phase, alkali concentration, and added surfactant concentration in the aqueous phase. They also reported the existence of an optimum concentration with respect to both surfactant and alkali, at which the DIFT was the lowest (DIFTmin), and this optimum concentration depended on acid concentration. They suggested that the unionized acid contributed to the lowering of the DIFT through simultaneous adsorption of ionized acid and surfactant at the interface. In another study, Touhami et al. [12] investigated the dynamic IFT behavior in NaOH/SDS/model acidic oil (linoleic acid dissolved in paraffin oil) system using pendant drop measurements. A relationship between the critical micelle concentration and the DIFT behavior was proposed, stating that below the CMC the addition of synthetic surfactant can lead to IFT values significantly lower than those obtained from a chemical reaction alone, controversially above the CMC it can play significant role in damping the IFT behavior arising from a chemical reaction alone. An interesting study on the effect of surfactant concentration, NaOH and salt concentrations on interfacial tension and electrophoretic mobility was reported by Chan and Shah [13]. The transient minimum IFT (DIFTmin) corresponded to the maximum electrophoretic mobility, indicating that maximum adsorption of the surfactant at the oil/water interface led to the highest surface charge density, contributing to the lowering of the interfacial tension to a minimum value.

Thus, the totality of research work reported in the literature correlates the synergism for lowering dynamic interfacial tensions in alkaline/surfactant/acidic oil systems to the physicochemical properties of the system such as alkaline concentration and type (NaOH, Na2CO3), added surfactant concentration and type (anionic, nonionic,…), and crude oil acid number and composition. On the other hand, the contribution of surfactant–surfactant interactions between the in situ surfactant and the added (synthetic) surfactant, that form a mixed interfacial monolayer, to the overall synergism have rarely been addressed. Such surfactant–surfactant interactions in aqueous mixed micelles have been widely investigated and were found to play a dominant role in the observed synergism [14–18].

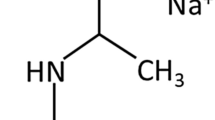

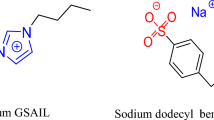

The aim of this work is therefore to investigate the contribution of surfactant (in situ)–surfactant (synthetic) interactions to the synergism for lowering the dynamic interfacial tensions in surfactant/alkali/acidic crude oil systems. Our hypothesis is that the synergism will be somehow influenced by the type of added synthetic surfactant via intermolecular attractive interactions between the in situ surfactant and the added synthetic surfactant in the mixed interfacial monolayer as well as by the interactions between the added surfactant with the two immiscible phases. Three surfactants having different molecular structures are considered in this investigation, namely a nonionic polyoxyethylenated type surfactant (iC17–O–(CH2CH2O)13–H, iC17(EO)13), one conventional anionic surfactant (sodium dodecyl sulfate, SDS), and a propoxylated anionic surfactant (C14–15–O–(CH2–CH(CH3)–O)8–SO3Na, C14–15(PO)8SO4).

In particular, pioneer work on propoxylated anionic surfactants for EOR revealed that by varying the carbon chain number of the alcohol hydrophobe and the number of propoxyl (PO) groups, together with shifting the hydrophobicity with increasing electrolyte concentration (i.e., optimum salinity), it should be possible to find the appropriate water:oil phase behavior for any oil [19–21]. However, unlike ethoxy (EO) groups, increasing the number of PO groups enhances the hydrophobicity and slightly the hydrophilicity. Hence, the propoxyl chain appears to be mostly in the oil phase with the first 2–3 PO groups attached to the anionic group on the water side of the interface [22, 23]. This can explain the ultralow interfacial tensions that can be achieved with these surfactants [24, 25]. Owing to their different molecular structures, the surfactants used in this investigation will probably display different intermolecular interactions with the in situ produced surfactant and with the oil and water phases, and consequently exhibit different dynamic interfacial tension behavior in surfactant/alkali/crude oil systems.

Experimental

Materials

Highly branched alkyl ether nonionic surfactant ((iC17–O–(CH2–CH2–O)13–H, 100 wt% active material) and anionic alcohol propoxy sulfate (C14–15–O–(CH2–CH(CH3)–O)8–SO3Na, 85.3 wt%, active material) were used in this study. These two surfactants were designed and tailored for the enhanced oil recovery process and kindly supplied by BASF (nonionic surfactant) and Sasol (anionic surfactant). Sodium dodecyl sulfate was purchased from Sigma-Aldrich (99+ % purity).

Sodium tripolyphosphate (Na5P3O10, Sigma-Aldrich, 85 % purity) and sodium carbonate (Na2CO3, Qualigens Fine Chemicals, 99.9 % purity) were used respectively as chelating and alkaline agents. The following salts were used to prepare the synthetic brine: NaCl (Fluka Analytical, assay >99.5 %), MgCl2.6H2O (Kanto Chemical, assay >99 %), CaCl2.2H2O, (Riedel-deHaën, >99 %), Na2O4S (Fluka, >99 %), and NaHCO3 (Sigma-Aldrich, assay >99.5 %).

Dead crude oil was provided by Petroleum Development Oman (PDO). The viscosity and the density of the crude oil are 173.5 mPa·s (cp) and 0.924 g/cm3 at 50 °C respectively. The crude’s total acid number (TAN) is 1.224 mg KOH/g of oil.

Methods

Dynamic interfacial tension measurements were performed using a spinning drop tensiometer (SVT 20 from Data Physics) in order to record the evolution of the interfacial tension more readily in a short period of time. In all measurements, the crude oil (~1–2 μL) was injected into 1 mL of the aqueous solution in a capillary tube. This tube was rotated at 2000–3000 rpm after preheating to 50 °C. The interfacial tension measurements were recorded using image acquisition and software analysis. Depending on the experiment type, the aqueous solution can be brine, brine/alkali solution, brine/surfactant solution, and brine/alkali/surfactant solution. In all experiments, sodium tripolyphosphate (STPP, 0.1 wt%) was added as a chelating agent to the brine, unless otherwise stated. Surfactants and Na2CO3 were added to the brine at the desired concentration.

Na2CO3–STPP compatibility in brine was tested by mixing the two chemicals at different weight fractions in glass tubes. The tubes were tightly closed with screw caps and placed in a temperature-controlled cabinet (50 °C) to equilibrate. They were visually observed for any precipitation of a gel-like formation. Translucent and stable one phase systems were considered as compatible.

In this work, all solutions were prepared with synthetic brine (Table 1) and the measurements were carried out at 50 °C. Such conditions prevail in many Omani petroleum reservoirs.

Results and Discussion

Brine/Na2CO3/STPP Compatibility

In alkaline chemical flood, the cations Ca2+ and Mg2+are known to easily precipitate their corresponding sparingly soluble salts CaCO3 (solubility limit in water 0.014 g/L at 25 °C) and MgCO3 (solubility limit in water 0.16–0.4 g/L at 100 °C) [26]. According to Table 1, Ca2+ concentration (0.54 g/L) is above the solubility limit of CaCO3, making the use of Na2CO3 as an alkali agent impracticable. Removing hardness to use softened injection water is generally done by a precipitation process using lime or caustic soda. However, chemical precipitation processes are not capable of producing water having a hardness value below 15–50 ppm (expressed as CaCO3). Hence, we added sodium tripolyphosphate (STPP, Na5P3O10) to the alkali/surfactant solution as an alternative approach in this study. This salt dissociates in water according to the following Na5P3O10 → 5Na+ + [O3POP(O2)OPO3]5−. The highly charged chelating agent, TPP5− binds to Ca2+ and Mg2+ tightly and prevents them from interfering with the alkali (Na2CO3). In Fig. 1, the phase diagram for Na2CO3–STPP system in brine shows chemical compatibility between the two compounds over a wide range of concentration. For instance, at 0.1 wt% STPP, a clear and stable one phase system is observed up to around 2.6 wt% Na2CO3. In fact, 0.1 wt% STPP is equivalent to 2.71 mM whereas Ca2+ and Mg2+ concentrations are 1.47 mM and 0.78 mM (Ca2+ + Mg2+: 2.25 mM), respectively, indicating that all divalent cations are chelated.

Another important issue is the effect of STPP on the pH of the alkaline–surfactant solution. Figure 2 shows such an effect in de-ionized water and in brine at different STPP concentrations in a wide range of Na2CO3 concentration (0.03–2.5 wt%). Clearly, no significant effect of STPP on the pH is observed, as reflected by the invariance of the pH with increasing STPP concentration from 0.05 to 0.2 wt%. In addition, at 0.5 wt% Na2CO3 concentration and above, the pH of the solution remains practically invariant with alkaline concentration (pH ~ 11.0), reflecting the excellent buffering ability of Na2CO3.

Effect of STPP on the IFT Between Oil and Brine

The IFT between oil and brine in the absence and in the presence of STPP (0.1 wt%) is displayed in Fig. 3. In deionized water, the interfacial tension decreases from an initial value of 28.5 mNm−1 to an equilibrium value of 25.5 mNm−1. In brine, both in the presence and absence of STPP, the IFT decreases from an initial value of about 18 mNm−1 to a similar value at equilibrium (~6 mNm−1). However, the decrease occurs in a relatively shorter time in the presence of TPPS. In addition, this relatively low value of the IFT (in the absence of added surfactant) is probably due to the combined basic pH of the brine (~7.9) and the acidity of the crude oil (TAN = 1.224 mg KOH/g) that results in the formation of in situ naphthenic carboxylate surfactant.

The effect of STPP (0.1 wt%) on the dynamic interfacial tension behavior was also investigated in brine/surfactant systems (Fig. 4). As shown in this Figure, no noticeable effect of STPP is observed with the nonionic surfactant. In both cases the IFT decreases from an initial value of 0.55 mNm−1 to an equilibrium of 0.29 mNm−1, suggesting no significant interaction between STPP and iC17(EO)13. Similar behavior is practically observed for SDS surfactant, in which the equilibrium IFT value is around 1.0 mNm−1. On the other hand, in C14–15(PO)8SO4/oil system, the IFT decreases from an initial value of 0.36 mNm−1 to an equilibrium value of 0.16 mNm−1 in the presence of STPP (0.1 wt%) and from an initial value of 0.13 mNm−1 to a significantly lower IFT at equilibrium (6.6 × 10−2 mNm−1) in the absence of STPP, suggesting a probable effect of Na+ and Ca2+ on the dynamic IFT behavior.

Dynamic interfacial tension behavior in surfactant (0.1 wt%)/oil systems at 50 °C: SDS (filled squares), iC17(EO)13 (filled stars), C14–15–(PO)8–SO4Na (filled lower triangles), SDS (0.1 wt% STPP) (filled upper triangles), iC17(EO)13–H (0.1 wt% STPP) (filled circles), and C14–15–(PO)8–SO4Na (0.1 wt% STPP) (filled diamonds)

Dynamic IFT in Na2CO3/Oil System

The dynamic IFT behavior in Na2CO3 aqueous solution (0.1 wt% STPP)/oil systems at different alkaline concentrations (0.3–2.5 wt%) is shown in Fig. 5. Similar trends in the variation of the DIFT are observed, in which the IFT reaches rapidly a transient minimum (DIFTmin) and then increases as time proceeds to reach equilibrium (IFTeq). Both IFT are extracted from Fig. 5 and reported in Table 2. As shown in this Table, with increasing alkalinity there is a decrease in IFTmin from 2.86 mNm−1 (0.3 wt% Na2CO3) to 1.4 × 10−1 mNm−1 (2.5 wt% Na2CO3), whereas equilibrium IFT decrease from 4.78 to 8.1 × 10−1 mNm−1 respectively. Transient IFT minima between crude oil and alkali-aqueous phase have been reported earlier in many studies [11, 12, 27–29]. This observation was attributed to the migration of organic species to the oil–water interface. The in situ produced surface-active species by the reaction of alkaline with acids and esters in oil adsorbed at the O/W interface reduce the IFT. Initially, the adsorption rate is higher than the desorption rate and the surface-active species accumulates at the interface. Ultimately, the surfactant concentration at the oil–water interface reaches the maximum, and the minimum of dynamic IFT is achieved accordingly. Subsequently, the rate of adsorption is slowed, whereas the desorption process is accelerated, leading to an increase in the IFT which eventually reaches an equilibrium value when both rates are equal. Furthermore, Fig. 5 shows that the IFT-time profile is shifted to lower IFT values as the concentration of Na2CO3 is increased.

At this juncture, it is important to realize that in IFT measurements using the spinning drop technique the water to oil ratio is extremely high [~1 mL/(1–2 μL = 1000–500)], suggesting that the equilibrium pHeq is very close to the initial pH i . Accordingly, we measured pH i and pHeq for Na2CO3 (0.3 wt%)/oil and Na2CO3 (1.0 wt%)//oil systems at water to oil ratio of 500. For Na2CO3 (0.3 wt%)/oil system, pH i = 10.52 and pHeq = 10.42 (ΔpH = 0.10) whereas for Na2CO3 (1.0 wt%)/oil pH i = 10.75 and pHeq = 10.66 (ΔpH = 0.09). Practically, a very small and similar ΔpH variation is observed, reflecting a similar amount of in situ produced surfactant in both systems. Thus, the decrease in the IFT with increasing Na2CO3 concentration is probably due to a salt effect in which the electrostatic repulsion between carboxylate head groups in the interfacial oil–water layer is reduced upon increasing salt concentration. In addition, IFT measurements were carried out in Na2CO3 (0.3 wt%)/oil and Na2CO3 (0.3 wt%)/NaCl (2.5 wt%)/oil systems. IFTmin and IFTeq were 1.37 mNm−1 and 2.05 mNm−1 for Na2CO3 (0.3 wt%)/oil and 0.89 mNm−1 and 1.54 mNm−1 for Na2CO3 (0.3 wt%)/NaCl (2.5 wt%)/oil system, reflecting a decrease in the IFT with salinity.

Finally, the transient IFT minima observed in the entire range of Na2CO3 concentration used (0.3–2.5 wt%) fall in the range 2.86–0.14 mNm−1, well above the ultralow IFT (<10−2 mNm−1) required in EOR applications. Ultralow interfacial tensions (~10−3 mNm−1) cannot therefore be achieved with the alkali alone and the addition of synthetic surfactant to the alkali solution is necessary.

Dynamic IFT in Na2CO3/Surfactant/Oil Systems

Na2CO3/iC17(EO)13/Oil System

In this set of experiments, we measured the IFT inNa2CO3/iC17(EO)13/oil at different alkaline concentrations (0–1.8 wt%) in the presence of STPP (0.1 wt%). The results are shown in Fig. 6. In the absence of alkaline, no minimum transient IFT between crude oil and surfactant solution is observed as reflected by the continuous decrease of the IFT from 4.5 × 10−1mNm−1to about 3.1 × 10−1mNm−1, suggesting that the nonionic surfactant alone cannot reduce the IFT below 10−2 mNm−1. When Na2CO3 (0.8 wt%) is added to the surfactant solution, the IFT is significantly reduced to about 4.2 × 10−2 mNm−1 at the beginning followed by an increment to 2.3 × 10−1 mNm−1 at equilibrium. With further increase in alkaline concentration (1.0–1.8 wt%), the IFT are reduced from about 1.82 × 10−2 mNm−1 at the beginning to ultralow transient minima in the range 1.1 × 10−3–6.3 × 10−3 mNm−1 followed by an increment to a practically similar value of 2.2 × 10−1 mNm−1 at equilibrium (Table 2). These results are clearly reflecting a strong synergistic effect between the in situ produced surfactant and the added surfactant in reducing the IFT more effectively than surfactant alone, and that the alkaline is playing a key role in this process. The dynamic interfacial tension behavior displayed in Fig. 6 is generally attributed to the rapid diffusion of crude oil surface-active species and the added surfactants initially dispersed in the aqueous phase into the oil–water interface forming a mixed surfactant layer responsible for the transient ultralow IFT. It is believed that the dynamic IFT reaches a minimum when the adsorbed surface-active species, including the added surfactant and the in situ produced surfactant, reach the optimum concentration and ratio [30–33]. In addition, it can be seen from Table 2 that the ultralow transient IFTmin values decrease from 6.3 × 10−3 to 1.1 × 10−3 mNm−1 upon increasing Na2CO3 concentration from 1.0 to 1.8 wt%. This IFTmin-alkaline concentration dependence may be attributed to an increase in in situ produced surfactant as Na2CO3 concentration is increased, leading to higher adsorption of soap molecules at the oil–water interface and consequently lower IFTmin. On the other hand, the equilibrium IFT are independent of Na2CO3 concentration, as reflected by the convergence of the dynamic IFT to similar values at equilibrium (~2.2 × 10−1 mNm−1), a value quite close to the equilibrium IFT for the surfactant alkali-free system (2.9 × 10−1 mNm−1). The significance of this observation is that the increase in the dynamic IFT in Na2CO3–iC17(EO)13 system is probably attributed to a selective diffusion of the in situ produced surfactant from the oil–water interface to the bulk aqueous and oil phases. In other words, the mixed interfacial soap-iC17(EO)13 is very efficient in reducing the dynamic IFT to ultralow transient values (~10−3 mNm−1) but less efficient in resisting the diffusion of soap molecules from the interface.

It is also worth noting that the lifetime (τ) of the ultralow transient interfacial tensions around the minima (time for which the IFT remains in the range 10−2 to 10−3 mNm−1 as required in EOR applications) increases with increasing alkaline concentration (Table 3). This observation was reported by Touhami et al. [11] by studying the dynamic IFT of acidified model oil/alkaline systems. Zhang et al. [8] reported a similar trend in the variation of the dynamic IFT and attributed this phenomenon to the influence of the increased Na2CO3 concentration on the in situ surfactant’s diffusion. As the alkaline concentration increases, more Na+ are present in the aqueous phase. The increased ionic strength reduces the diffusion of the in situ produced surface-active species from the interface to the bulk phases. In fact, this is consistent with the observations shown in Fig. 6, in which it can also be observed that the higher the alkaline concentration the more time is needed for the systems to reach the ultralow transient interfacial tension minima, confirming that diffusion of the in situ surfactant from the interface to the aqueous phase is somehow limited by the ionic strength of the solution [8]. Interestingly, the time needed to reach equilibrium values is practically independent of the alkali concentration.

As previously mentioned, the effect of synthetic surfactants on the interfacial tension behavior of acidic crude oil/alkali systems was generally associated with the physicochemical properties of the alkali/surfactant/oil system such as the nature and composition of the crude oil, type and concentration of the synthetic surfactant, and the type and concentration of the alkaline. However, irrespective of the nature of the system’s physicochemical properties mentioned above, the intermolecular (and intramolecular) attractive interactions between the in situ produced surfactant (soap) and the added synthetic surfactant iC17(EO)13 that form a mixed interfacial monolayer at the crude oil–water interface, may consequently contribute to the overall synergism in Na2CO3/iC17(EO)13/oil system (Fig. 6). Surfactant–surfactant interactions in aqueous anionic-nonionic mixed micelles have been extensively investigated in terms of the interaction parameter β M [14–18]. A negative β M means that the repulsive interactions between the two different surfactants in mixed micelles are weaker than the repulsive interactions of the individual surfactants with themselves in single micelles. At the molecular scale, the mixed soap/iC17(EO)13 interfacial monolayer between the crude oil and brine can be considered to be similar to mixed micelle-water interface. Accordingly, the synergism for lowering the DIFT in Na2CO13/C17(EO)13/Na2CO3/oil system may also be attributed, to some extent, to the fact that the repulsive interactions between the in situ carboxylate surfactant and iC17EO13 in the mixed interfacial film is weaker than the repulsive interactions of the individual surfactants with themselves in Na2CO3/oil (surfactant-free) and iC17(EO)13/oil (alkaline-free) systems. In alkaline surfactant-free solutions there will be a significant electrostatic self-repulsion between the anionic carboxylic groups of the in situ produced soap, whereas in iC17(EO)13 alkaline-free solution there will be a weak steric self-repulsion between the ethylene oxide (EO) groups. On the other hand, in Na2CO3/iC17(EO)13/oil system, the strong electrostatic self-repulsion between the polar head groups (–COO−) in Na2CO3/oil system can be significantly reduced by the formation of a mixed soap-iC17(EO)13 interfacial film at the oil–brine interface, as reflected by the synergism in Fig. 7. This is because in the mixed interfacial monolayer, the carboxylate groups of the naphthenic soap molecules are probably located at the brine–oil interface and surrounded by water molecules, whereas the nonionic bulky polyoxyethylene chain extends further into the aqueous phase and adopt a somehow coiled conformation surrounding the nearby –COO− groups. Consequently, some shielding of the carboxylate groups may occur (Scheme 1a), resulting in a decrease in –COO−–COO− electrostatic repulsion. Furthermore, the proximity of the ethylene oxide groups to the carboxylate groups may result in ion–dipole attractive interactions between –COO− and the nearby O → CH2 dipole as illustrated in Scheme 1a. It is therefore reasonable to assume that these intermolecular ion–dipole attractive interactions between the two surfactants will contribute to the observed synergism in Na2CO3/iC17(EO)13/oil system (Fig. 7). Recently, we reported such ion–dipole interactions in sodium lauryl ether sulfate (SLES)-Triton X-100 [14] and SLES-Brij35 [15] mixed micelles in aqueous media.

Na2CO3/C14–15(PO)8SO4/Oil System

Figure 8 shows the effect of Na2CO3 concentration (0.4–1.0 wt%) on the dynamic interfacial tension behavior in Na2CO3/C14–15(PO)8SO4/oil system. The IFT-time profile is essentially similar to that observed with iC17(EO)13, namely: (i) no minimum transient IFT between the oil and surfactant solution is observed in the absence of alkaline as reflected by the continuous decrease in the IFT from an initial value of 3.6 × 10−1 mNm−1 to an equilibrium IFT value around 1.6 × 10−1 mNm−1, (ii) when alkaline (0.4 wt%) is added to the surfactant solution (0.1 wt%), the IFT is significantly reduced to about 3.6 × 10−2 mNm−1 and remains practically invariant with time, (iii) increasing alkaline concentration to 0.6, 0.8, and 1.0 wt% resulted in a decrease of the IFT from 1.5 × 10−2 mNm−1 at the beginning to transient ultralow minima in the range 1.1 × 10−2–2.9 × 10−3 mNm−1 followed by an increment to IFT at equilibrium in the range 1.3 × 10−2–3.8 × 10−2 mNm−1 (Table 2), (iv) the IFT-time curve shifts to lower IFT as the alkaline concentration is increased, and (v) the lifetime of the transient ultralow IFT (10−2–10−3 mNm−1) increases with increasing Na2CO3 concentration. These results indicate that the repulsive interactions between the carboxylate and sulfate groups in Na2CO3/C14–15(PO)8SO4/oil are weaker than the strong repulsive interactions of the individual surfactants with themselves in Na2CO3/oil and C14–15(PO)8/oil systems, in which there will be strong electrostatic self-repulsion between the carboxylate groups in one hand and between the sulfate groups in the other hand, respectively. Unlike in Na2CO3/iC17(EO)13/oil system, only the 2–3 first PO groups attached to the sulfate group can participate in either intramolecular attractive ion dipole attractive interactions with the sulfate group or in intermolecular ion–dipole interaction with carboxylate moieties (Scheme 1b). It is also worth noting that the shielding effect by PO groups on carboxylate-sulfate electrostatic repulsion is probably negligible in Na2CO3/C14–15(PO)8SO4/oil system.

A final interesting observation is the dependence of the equilibrium IFT on Na2CO3 concentration (Table 3). Particularly, the equilibrium IFT in the presence of 1.0 wt% Na2CO3 (IFTeq = 1.3 × 10−2 mNm−1) is one order of magnitude lower that the corresponding IFT in surfactant–alkaline free system (1.4 × 10−1 mNm−1). This indicates that, contrary to what was observed in Na2CO3/iC17(EO)13/oil system, the mixed interfacial film in Na2CO3/C14–15(PO)8/oil is efficient in decreasing the IFT at equilibrium and in resisting mass transfer of the in situ surfactant across the oil–water interface.

Na2CO3/SDS/Oil System

In order to compare and corroborate our interpretations for the two surfactants investigated above, the same experiments were carried out with sodium dodecyl sulfate (SDS), a non ethoxylated/propoxylated conventional surfactant. The effect of Na2CO3 concentration on the dynamic IFT behavior is shown in Fig. 9. The trend is comparable to that observed with iC17(EO)13 and C14–15(PO)8SO4 in which (i) the IFT decreases rapidly to a low transient IFT value, followed by an increase to an equilibrium IFT value, and (ii) the IFT-time curve shifts to lower IFT values upon increasing alkaline concentration. The IFT at equilibrium are independent of alkaline concentration and converge to a similar value of about 5.6 × 10−1 mNm−1 in the alkali concentration range 0.8–1.8 wt%. In terms of ultralow transient IFT minima, the lowest value obtained at 1.6 wt% alkaline concentration was around 1.1 × 10−2 mNm−1, one order of magnitude higher that the ultralow transient minima obtained with the nonionic ethoxylated (iC17(EO)13) and the propoxylated sulfate anionic (C14–15(PO)8SO4) surfactants (IFTmin ~ 10−3 mNm−1). This may be explained by the relative strong electrostatic repulsion between the carboxylate and sulfate groups in Na2CO3/SDS/oil system due to the absence of (i) intermolecular and intramolecular ion–dipole attractive interactions and (ii) the shielding effect of the carboxylate groups in Na2CO3/SDS/oil system, as compared to Na2CO3/iC17(EO)13/oil and C14–15(PO)8SO4/oil systems.

Synergism and Synthetic Surfactant Molecular Structure

According to Figs. 7, 8, and 9, maximum synergism in terms of lowering the dynamic interfacial tension occurs at 1.8, 1.0, and 1.6 wt% Na2CO3 for iC17(EO)13, C14–15(PO)8SO4, and SDS respectively. In order to compare the effect of the synthetic surfactant molecular structure on the observed synergism, we plot the variation of the dynamic IFT versus time for the three surfactant solutions at the corresponding optimum alkaline concentration in Fig. 10. As seen in this Figure, iC17(EO)13 displays the strongest synergism for lowering dynamic IFT transient (DIFTmin = 1.1 × 10−3 mNm−1), against 2.9 × 10−3 mNm−1 and 1.1 × 10−2 mNm−1 for C14–15(PO)8SO4 and SDS, respectively. Hence, in addition to the strong effect of Na2CO3 on DIFTmin, surfactant–surfactant interactions at the mixed interfacial film may also contribute to the overall synergism as reflected by the increase in synergism in the order iC17(EO)13 > C14–15(PO)8SO4 > SDS. The stronger synergism observed with iC17(EO)13 relative to that observed with C14–15(PO)8SO4 can be attributed to the additional intramolecular ion–dipole attractive interaction between the sulfate group and the nearby propylene oxide group and to the possible carboxylate-sulfate repulsive interactions in Na2CO3/C14–15(PO)8SO4/oil system. The lowest synergism observed in Na2CO3/SDS/oil system is probably due to the absence of ion–dipole interactions, and shielding effect of the carboxylate group that occur in Na2CO3/iC17(EO)13/oil and Na2CO3/C14–15(PO)8SO4/oil systems.

Dynamic interfacial tension behavior at 50 °C for Na2CO3/surfactant (0.1 wt%)/oil systems at their corresponding optimum alkaline concentrations: Na2CO3 (1.6 wt%)/SDS/oil (filled circles), Na2CO3 (1.8 wt%)/iC17(EO)13/oil (filled squares), and Na2CO3 (1.0 wt%)/C14–15–(PO)8–SO4/oil (filled lower triangles)

In addition to surfactant–surfactant interaction in the mixed interfacial monolayer, the interaction of the synthetic surfactant polar and hydrophobic groups with the aqueous and the oil phases also may contribute to the overall observed synergism. The higher these interactions are, the higher is the reduction in the IFT between the two immiscible phases. Nonionic polyoxyethylenated type surfactants are known to derive their polarity from the polar ethylene oxide groups which interact strongly with water environment via hydrogen-bonding. This results in a strong water-iC17(EO)13 interaction. On the other hand, water interaction with the propylene oxide groups in Na2CO3/C14–15(PO)8SO4/oil system is probably weaker due to the known hydrophobicity character of propylene oxide groups. Likewise, added surfactant–oil hydrophobic attraction is expected to follow the order iC17(EO)13) > C14–15(PO)8SO4 > SDS, owing to the increase in alkyl chain hydrophobicity with an increasing number of carbon atoms.

An interesting feature is observed for the dynamic interfacial tension behavior in Na2CO3/iC17(EO)13/oil and Na2CO3/SDS/oil systems, in which the equilibrium IFT are independent of Na2CO3 concentration (2.2 × 10−1 mNm−1 and 5.6 × 10−1 mNm−1 for iC17(EO)13 and SDS, respectively). The equilibrium IFT value for Na2CO3/iC17(EO)13/oil is relatively close to the corresponding value in alkaline-free system iC17(EO)3/oil system (2.9 × 10−1 mNm−1). This can be explained by a selective diffusion of the in situ surfactant from the oil–water interface to the aqueous phase. Consequently, the mixed interfacial monolayer becomes gradually richer in synthetic surfactant. In other words, the mixed interfacial layer is efficient at lowering the dynamic interfacial tension (~10−3 mNm−1) but less efficient at resisting the diffusion of the carboxylate in situ surfactant diffusion from the interface to the bulk phases. On the contrary, the equilibrium IFT in Na2CO3/C14–15(PO)8SO4/oil system decrease with increasing alkaline concentration (Table 2). For instance, at the optimum alkaline concentration of 1.0 wt%, the equilibrium IFT is around 1.3 × 10−2 mNm−1, whereas the corresponding IFTeq in the absence of alkaline is about 1.6 × 10−1 mNm−1. This suggests that the synergistic effect between the in situ surfactant and Na2CO3/C14–15(PO)8SO4/oil that form the mixed interfacial film is efficient in (i) decreasing the transient IFT to ultralow values (10−3 mNm−1), and (ii) resisting the mass transfer of the in situ produced surfactant across the crude oil/brine interface.

Finally, it should be mentioned that the increase in IFT from ultralow transient values (~10−3 mNm−1) to equilibrium values higher than the required ones in EOR applications may appear problematic in actual reservoir flooding. However, Taylor and co-workers [29] reported that residual oil recovery through alkaline–surfactant flooding of linear Berea sandstone correlates better with the minimum transient IFT than with the equilibrium one. Understanding the factors affecting the occurrence of minimum transient ultralow IFT is therefore of paramount importance in actual reservoir alkaline–surfactant flooding.

References

Liu Q, Dong D, Yue X (2006) Synergy of alkali and surfactant in emulsification of heavy oil in brine. Colloids Surf A physicochem Eng Asp 273:219–228

Zhan L, Luo S, Zhao B, Yang H, Yu JY (2003) Studies of synergism/antagonism for lowering dynamic interfacial tension in surfactant/alkali/acidic model oil systems 3. Synergism/antagonism in surfactant/alkali/acidic model oil systems. J Colloid Interface Sci 260:398–403

Samanta A, Ojha K, Mandal A (2011) Interactions between crude acidic oil and alkali and their effects on enhanced oil recovery. Energy Fuels 25(4):1642–1649

Hirasaki G, Miller CA, Puerto M (2011) Recent advances in surfactant EOR. SPE J 16(4):889–907

Taylor KC, Nasr-El-Din HA (1996) The effect of synthetic surfactants on the interfacial behavior of crude oil/alkali/polymer systems. Colloids Surf A Physicochem Eng Aspects 108(1):49–72

Sun J, Sun L, Liu W, Liu X, Li X, Shen Q (2008) Alkaline consumption mechanism by crude oil: a comparison of sodium carbonate and sodium hydroxide. Colloids Surf A Physicochem Eng Aspects 315(3–1):38–43

Chu YP, Gong Y, Tan XL, Zhang L, Zhao S, An JY, Yu JY (2004) Studies of synergism for lowering dynamic interfacial tension in sodium α-(n-alkyl) naphthalene sulfonate/alkali/acidic crude oil systems. J Colloid interface Sci 276:182–187

Zhang L, Luo L, Zhao S, Xu ZC, An JY, Yu JY (2004) Effect of different acidic fractions in crude oil on dynamic interfacial tensions in surfactant/alkali/model oil systems. J Pet Sci Eng 41(1–3):189–198

Rudin J, Wasan DT (1992) Mechanism for lowering of interfacial tension in alkali/acidic oil systems: effect of added surfactant. Ind Eng Chem Res 31(8):1899–1906

Rudin R, Bernard C, Wasan DT (1994) Effect of added surfactant on interfacial tension and spontaneous emulsification in alkali/acidic oil systems. Ind Eng Chem Res 33(5):1150–1158

Touhami Y, Hornof V, Neale GH (1998) Dynamic interfacial tension behavior of acidified oil/surfactant-enhanced alkaline systems. 1. Experimental studies. Colloids Surf A Physicochem Eng Aspects 132(1):61–74

Touhami Y, Rana D, Hornof V, Neale GH (2001) Effects of added surfactant on the dynamic interfacial tension behavior of acidic oil/alkaline systems. J Colloid Interface Sci 239(1):226–229

Chan KS, Shah DO (1981) In: Shah DO (ed) Surface phenomena in enhanced oil recovery. Plenum Press, New York, pp 53–72

Aoudia M, Al-Maamari T, Al-Salmi F (2010) Intramolecular and intermolecular ion-dipole interactions in sodium lauryl ether sulfates (SLES) self-aggregation and mixed micellization with Triton X-100. Colloids Surf A Physicochem Eng Aspects 335(1–3):55–61

Al-Hadabi B, Aoudia M (2014) Surfactant–surfactant and surfactant–solute interactions in SLES–Brij35 mixed micelles: effect of the degree of ethoxylation on pyrene solubilization enhancement in water. Colloids Surf A physicochem Eng Aspects 459:82–89

Khimani M, Vora S (2011) Effect of inorganic additives on a conventional anionic–nonionic mixed surfactants system in aqueous solution. J Surfactant Deterg 14(4):545–554

Vora S, George A, Desai H, Bahadur P (1999) Mixed micelles of some anionic-anionic, cationic-cationic, and ionic–nonionic surfactants in aqueous media. J Surfactant Deterg 2(2):213–221

Al-Sabagh AM, Azzam EMS, Mahmoud SA, Saleh NEA (2007) Synthesis of ethoxylated alkyl sulfosuccinate surfactants and the investigation of mixed solutions. J Surfactants Deterg 10(1):3–8

Aoudia M, Wade WH, Weerasooriya V (1995) Optimum microemulsions formulated with propoxylated alcohol sulfates and propoxylated tridecyl alcohol sulfates. J Dispers Sci Technol 16(2):115–135

Miňana-Perez M, Gracia A, Lachaise J, Salager JL (1995) Solubilization of polar oils with extended surfactants. Colloids Surf A physicochem Eng Aspects 100:217–224

Miňana-Perez M, Gracia A, Lachaise J, Salager JL (1995) Solubilization of polar oils in microemulsion systems. Prog Colloid Polym Sci 98:177–179

Forgiarini AM, Scorzza C, Velásquez J, Vejar F, Zambrano E, Salager JL (2010) Influence of the mixed propoxy/ethoxy spacer arrangement order and of the ionic head group nature on the adsorption and aggregation of extended surfactants. J Surfact Deterg 13(1):451–458

Velásquez J, Scorzza C, Vejar F, Forgiarini AM, Raquel E, Salager JL (2010) Effect of temperature and other variables on the optimum formulation of anionic extended surfactant–alkane–brine systems. J Surfactants Deterg 13(1):69–73

Salager JL, Forgiarini AM, Bullón J (2013) How to attain ultralow interfacial tension and three-phase behavior with surfactant formulation for enhanced oil recovery: a review. Part 1. Optimum formulation for simple surfactant–oil–water ternary systems. J Surfactants Deterg 16(4):449–472

Salager JL, Forgiarini AM, Márquez L, Manchego L, Bullón J (2013) How to attain ultralow interfacial tension and three-phase behavior with surfactant formulation for enhanced oil recovery: a review. Part 2. Performance improvement trends from Winsor’s premise to currently proposed inter- and intra-molecular mixtures. J Surfactants Deterg 16(5):631–663

Green DRP (2007) Perry’s Chemical Engineers Handbook, 8th Edition

Trujillo EM (1983) The static and dynamic interfacial tension between crude oil and caustic solution. Soc Pet Eng J 23(4):645–657

Borwankear RP, Wasan DT (1986) Dynamic interfacial tension in acidic crude oil/caustic systems. Part I. A chemical diffusion-kinetic model. AIChE J 32(3):455–466

Taylor KC, Hawkins BF, Islam MR (1990) Dynamic interfacial tension in surfactant-enhanced alkaline flooding. J Can Pet Technol 29(1):50–57

Zhao Z, Li Z, Qiao W, Cheng L (2005) Dynamic interfacial tension between crude oil and octyl methylnaphthalene sulfonate surfactant flooding system. Colloids Surf A Physicochem Eng Aspects 259(1–3):71–80

Aoudia M, Al-Shibli MN, Al-Kasimi LH, Al-Maamari RS, Al-Bemani AS (2006) Novel surfactants for ultralow interfacial tension in a wide range of surfactant concentration and temperature. J Surfactants Deterg 9(3):287–293

Clint JH, Neustadter EI, Wheeler PA (1984) Interaction of enhanced oil recovery surfactants with model crude oil. Colloid Surf 11(1–2):129–136

Taylor KC, Schramm LL (1990) Measurements of short-lived dynamic interfacial tensions: application to surfactant enhanced alkaline flooding in enhanced oil recovery. Colloids Surf 47:245–253

Acknowledgments

We are very grateful to the Research Council (TRC, Sultanate of Oman) for supporting this research (Grant: ORG/SQU/EI/11/014).

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Hadji, M., Al-Rubkhi, A., Al-Maamari, R.S. et al. Surfactant (in situ)–Surfactant (Synthetic) Interaction in Na2CO3/Surfactant/Acidic Oil Systems for Enhanced Oil Recovery: Its Contribution to Dynamic Interfacial Tension Behavior. J Surfact Deterg 18, 761–771 (2015). https://doi.org/10.1007/s11743-015-1714-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11743-015-1714-6

) and intramolecular (

) and intramolecular ( ) ion–dipole interactions and electrostatic –COO−–SO4

− repulsion (

) ion–dipole interactions and electrostatic –COO−–SO4

− repulsion ( ) in Na2CO3/iC17(EO)13/oil (a), Na2CO3/C14–15(PO)8/oil (b), and Na2CO3/SDS/oil (c) systems

) in Na2CO3/iC17(EO)13/oil (a), Na2CO3/C14–15(PO)8/oil (b), and Na2CO3/SDS/oil (c) systems