Abstract

Herein, an efficient graphene oxide/Fe3O4@polythionine (GO/Fe3O4/PTh) nanocomposite sorbent was introduced for magnetic solid-phase extraction combined with high-performance liquid chromatography–ultraviolet detection of duloxetine (DLX) in human plasma. To prepare the sorbent, an oxidative polymerization of thionine on the surface of magnetic GO was utilized while PTh was simply used as a surface modifier to improve extraction efficiency. Transmission electron microscopy, scanning electron microscopy, X-ray diffraction, energy-dispersive X-ray analysis, vibrating sample magnetometry, Fourier transform-infrared spectroscopy and Brunauer–Emmett–Teller technique were applied to characterize the prepared nanoparticles. Firstly, effective parameters controlling the performance of the extraction process were evaluated in detail and optimized. Under the optimized conditions, calibration curve showed linearity in the range of 2–2500 ng mL−1 with regression coefficient corresponding to 0.998. Limits of detection (LOD, S/N = 3) and quantification (LOQ, S/N = 10) were 0.5 and 2 ng mL−1, respectively. Reasonable intra-assay (3.5–4.5%, n = 6) and inter-assay (3.8–6.7%, n = 9) precision represented acceptable performance of the procedure. The applicability of the method was successfully extended to the determination of DLX in human plasma after oral administration of 60 mg single dose of the drug and finally some pharmacokinetic data was achieved.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Duloxetine (DLX) is a selective serotonin–norepinephrine reuptake inhibitor (SNRI), originally developed as an antidepressant and is currently recommended for maintenance treatment of major depressive disorder (Hunziker et al. 2005; Zhao et al. 2009; Freeman et al. 2013). The drug is approved by the United States Food and Drug Administration (U.S. FDA) for the treatment of diabetic polyneuropathy and is recommended as a first line treatment for the purpose (Mallinckrodt et al. 2006; Sultan et al. 2008). Other indications include management of generalized anxiety (Ball et al. 2013), fibromyalgia (Bennett et al. 2012), and most recently, stress urinary incontinence (Leeuwen et al. 2008; Mihaylova et al. 2010).

According to literature survey, there have been several reports on the determination of DLX in pharmaceutical and biological media including ion-selective electrode (Ammar et al. 2012), high performance thin layer chromatography (Dhaneshwar et al. 2008), capillary electrophoresis (Rickard and Bopp 1994; Liu and Nussbaum 1999; Musenga et al. 2009) and chromatographic methods (Lantz et al. 2003; Anderson et al. 2006; Ma et al. 2007; Mercolini et al. 2007). Practical demands for the analysis in the field of pharmaceutical, environmental and life science are the main driving forces for the development in sample preparation (Moldoveanu 2004; Zeeb et al. 2016). The main objective of this challenge is to transfer the analyte into a form that is pre-purified, concentrated, and compatible with the analytical system (Pawliszyn 2002; D’Archivio et al. 2016; Huang et al. 2017). Recent trends in sample preparation have focused on miniaturization, automation, high-throughput, on-line coupling with analytical instruments and low-cost operations through extremely low or no solvent consumption (Moldoveanu and David 2002; Mitra 2003; Pavlović et al. 2007; Pastor-Belda et al. 2016). The common sample preparation techniques applying to monitor the drug are liquid–liquid extraction (LLE) and solid-phase extraction (SPE). LLE is time-consuming and needs large amounts of high purity organic solvents which are potentially hazardous and expensive (Zeeb et al. 2014). In contrast, SPE offers many merits including high extraction efficiency, low consumption of toxic solvents, and convenience of operation (Gołębiowski et al. 2017; Karpavičiūtė et al. 2017). However, when large volumes of samples pass through the SPE column, long extraction time is required and the SPE cartridge blockage is probable (Płotka-Wasylka et al. 2015). As a result, there is an increasing need to fabricate novel extraction sorbents with high extraction efficiency, good dispersible property and anti-interference ability.

Magnetic solid-phase extraction (MSPE) has lately received great attention due to its numerous advantages involving magnetic irretrievability, operational simplicity, high extraction yield and capability towards selective functionalization of materials (Yan et al. 2014). Moreover, magnetic nanocomposite materials affect extraction efficiency by providing a high surface area to volume ratio and their usage in sample preparation lead to easier and faster separation in the presence of an external magnetic field compared with common SPE methods (Asgharinezhad et al. 2014). The applications of MSPE in environmental and biological analysis have been described in several papers (Mehdinia et al. 2011; Wang et al. 2016). The type of sorbent is a key factor in MSPE because it influences the affinity, selectivity and extraction capacity. So, the explorations of new types of sorbents to ameliorate the extraction performance are considered an important research field in analytical chemistry (Herrero-Latorre et al. 2015).

Recently, grapheneoxide (GO) as a new class of carbon nanomaterial has become a new supermaterial due to its unique characteristics such as high electrical conductivity as well as exceptional mechanical and optical properties (Dimiev and Eigler 2016). The nanosheet of GO seems to be an efficient sorbent in MSPE because of its huge surface area along with superior chemical and thermal stability and large quantities of oxygen atoms on its surface including epoxy, hydroxyl, and carboxyl groups. Thus, this nanomaterial provides rich functional groups for the strong π–π interaction between GO and biological or organic materials. In addition, it is highly hydrophilic and can form stable colloidal suspensions in water. Accordingly, GO has been utilized as a practical sorbet for extraction and enrichment of various analytes in different media (Marcano et al. 2010; Liu et al. 2014). The conductive polymers (CPs) are significantly promising in sample preparation owing to their flexible and unique properties such as hydrophobicity, π-interaction, acid–base character, polar functional groups, ion exchange characteristics, hydrogen bonding, stability and simplicity of fabrication (Li et al. 2012). These kinds of polymers have been applied to increase the merits of magnetic materials as sorbents for extraction and preconcentration of some analytes in real samples (Bagheri et al. 2013).

In this work, polythionine (PTh) as a CP was coated on the surface of GO/Fe3O4 and the new designed nanocomposite sorbent was applied in MSPE for the extraction and preconcentration of DLX in human plasma. The parameters affecting the extraction performance were studied in detail and the optimum conditions were established. The developed method was validated for quantitative purposes after oral administration of the drug, and ultimately applied for achieving some pharmacokinetic parameters in combination with high-performance liquid chromatography–ultraviolet detection (HPLC–UV).

Experimental

Chemicals

All of chemicals were analytical grade and used without further purification. Thionine (Th) acetate (85%), sodium hydroxide (NaOH, 99%), nitric acid (HNO3, 65%), hydrochloric acid (HCl, 37%), iron (III) chloride hexahydrate (FeCl3·6H2O), iron (II) chloride tetrahydrate (FeCl2·4H2O), potassium permanganate (KMnO4), ammonia (NH3, 25%) were obtained from Merck Company (Darmstadt, Germany). Hydrogen peroxide (H2O2, 30%) and graphite powder (mesh of 100) were bought from Sigma-Aldrich (St. Louis, MO, USA). DLX and paroxetine (as internal standard, IS) were obtained from Daroupakhsh Company (Tehran, Iran). DLX tablets (60 mg) were purchased from commercial sources. HPLC-grade methanol, acetonitrile (Fisher Chemicals, Fair Lawn, NJ, USA) and ultrapure water (Millipore, Bedford, MA, USA) were used in all experiments.

Instrumentation

The chromatographic analysis was performed on an Agilent 1100 HPLC system (Agilent Technologies, Palo Alto, CA, USA) equipped with a isocratic pump (Santa Clara, USA), a UV detector (set at 230 nm) and a manual injector with 20 µL sample loop. The separations were carried out on an RP-C18 reversed-phase column (150 mm × 4.6 mm id, 5 µm particle size) from LiChrospher (Merck Millipore, Darmstadt, Germany) at the temperature of 30 ± 0.5 °C. The isocratic mobile phase consisting ammonium formate (10 m mol L−1) and acetonitrile (40:60) with pH of 3.8 was delivered through the column at a flow rate of 1.0 mL min−1. All of the pH measurements were performed with a WTW Inolab pH meter (Weilheim, Germany). Routine degassing of the mobile phase was carried out by passing it through a 0.2 μm membrane filter (Millipore, Bedford, MA, USA). The dispersion of GO/Fe3O4/PTh as the sorbent was performed into the aqueous media via Sonorex ultrasonic baths (Bandelin, Berlin, Germany). A Heraeus Sepatech Model Labofuge 1500 centrifuge (Osterode/Harz, West Germany) was used to separate the supernatant from protein precipitate in deproteinization of plasma samples. Scanning electron microscopy (SEM) images and Energy dispersive X-ray spectroscopy (EDX) spectra were recorded using a Hitachi S-4160 machine (Tokyo, Japan). Fourier transform-infrared (FT-IR) spectra were recorded using a Vector 22 FT-IR spectrometer (Bruker, Germany). The X-ray diffraction (XRD) spectra were recorded using Cu Kα radiation (λ = 1.5406 Å) on A D8 Advance X-ray diffractometer (Bruker, Germany). The magnetic properties of the prepared extraction sorbent were studied using a vibrating sample magnetometer (Kashan, Iran) at room temperature (22 ± 0.5 °C) by changing the applied field in the range of −10 to 10 kOe. The morphology of GO, GO/Fe3O4 and GO/Fe3O4/PTh were evaluated using JEOL-JEM 2010 transmission electron microscopy (TEM, Michigan, USA). A Quantachrome, USA, Brunauer–Emmet–Teller (BET) surface area analyzer was employed for surface area measurements by N2 adsorption–desorption analysis.

Preparation of standards and quality control samples

A stock solution (100.0 µg mL−1) of DLX was prepared in methanol. The working solutions of DLX were daily prepared by step-diluting the stock solution with the ultrapure water to yield final required concentrations. Standards for plotting calibration curve were prepared by spiking the working solutions into human plasma. Quality control (QC) samples of DLX at concentration levels of 5, 100, 500 and 2000 ng mL−1 were prepared by spiking appropriate amount of working solutions into human plasma. All the stocks and working solutions were stored at −20 °C.

Deproteinization of plasma and preparation of spiked samples

Spiked plasma samples were prepared by adding 100 µL of the working solutions with various concentrations into 1.9 mL drug-free matrixes to yield final desired concentrations. The samples were deproteinized by 2.0 mL of 2% (w/v) zinc sulfate-acetonitrile (60:40 v/v) and vortexed for 2 min. To settle the proteins, the samples were centrifuged for 12 min at 4000 rpm and then, the acetonitrile content of the solution was evaporated under a nitrogen stream at 50 °C. About 3 mL of the remained supernatant phase was transferred into a vial, diluted to 6.0 mL with water and centrifuged again for 2 min at 4000 rpm. Subsequently, the clear upper phase was placed into new test tubes and put through to MSPE.

Synthesis of GO/Fe3O4

GO was simply synthesized from expanded graphite according to a modified Hummer’s method (Marcano et al. 2010). In brief, graphite powder (3.0 g) was mixed with NaNO3 (1.5 g), followed by the addition of H2SO4 (69.0 mL). To start oxidation step, the mixture was cooled to 0 °C by an ice water bath, and then 9.0 g of KMnO4 was added to this solution. The temperature of the mixture was increased up to 20 °C via a thermostat and kept constant for 5 min. The solution was heated, and continuously stirred for 10 h at 35 °C. The temperature of the mixture was decreased to 25 °C afterwards and transferred into a baker containing 400 mL of ice and 3.0 mL of 30% H2O2. To separate the solid phase, it was centrifuged at rate of 4000 rpm for 3 min. The solid phase was washed with HCl 5% and water three times while ultrasonic irradiation was simultaneously applied for suspension. It was finally centrifuged and the settled phase was dried at 100 °C.

To prepare magnetic GO/Fe3O4, the fabricated GO (0.30 g) was dispersed in 150 mL water by applying ultrasonic irradiation. Then, 0.825 g FeCl3·6H2O and 0.322 g of FeCl2·4H2O were dissolved in 25 mL water. The solution of iron (II) and (III) was added dropwise to GO solution at room temperature (22 ± 0.5 °C) under a nitrogen flow and vigorous agitation while the pH was adjusted to 10 with ammonia (25% v/v). The temperature of the mixture was elevated to 80 °C and stirred for 50 min. The solution containing the black sedimented was centrifuged, the settled material was washed four times with ethanol and then, dried at 100 °C in an oven under vacuum.

Synthesis of GO/Fe3O4/PTh nanocomposite

To generate GO/Fe3O4/PTh, the fabricated GO/Fe3O4 (0.3 g) was suspended in 150 mL water and was placed in a shaker for 10 min. 0.1 g of FeCl3·6H2O as a catalyst (with purple color) and 0.20 g thionine (Th) was dissolved in 100 mL water and slowly added to the mentioned solution. Then, 2.0 mL of H2O2 as an oxidizing agent was added dropwise during vigorous shaking and temperature of the solution was increased and stirred at 50 °C for an hour. In this step, the purple color was removed and polythionine was synthesized. The sedimented black solid phase was separated using a strong magnet and it was washed four times with deionized water and dried at 25 °C in an oven under vacuum (Zhao et al. 2015).

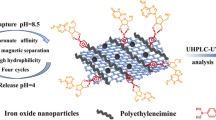

MSPE procedure

The experimental extraction setup is illustrated in Fig. 1. At first, 5.0 mL of the spiked plasma was transferred into a glass tube. The pH of the sample solution was adjusted at 9.0 using 10−2 M of NaOH. Then, 15 mg of the magnetic sorbent was added to the sample tube. The glass container was placed into an ultrasonic bath and sonicated for 6 min in order to disperse the magnetic GO/Fe3O4@PTh sorbent into the sample. The sorbent was separated from sample by exposing glass tube to a strong magnet (5 cm × 5 cm × 5 cm, 0.6 Tesla) and afterwards, the upper phase was discarded. To desorb the analyte, the collected magnetic extraction phase was eluted with 1.0 mL methanol containing 2% acetic acid. Elution was carried out twice and in every washing, 0.5 mL desorption solvent was utilized. The eluted solution was collected and dried under a stream of nitrogen gas at 60 °C. Subsequently, 100 µL of methanol was added to the remained phase and sonicated for 1 min. After all, the obtained mixture was again exposed to the strong magnet and 20 μL of the upper phase was injected into the HPLC.

Results and discussion

A one at a time approach was employed to optimize the main factors controlling the extraction efficiency. A fixed concentration (250.0 ng mL−1) of IS was added to all sample solutions and quantifications were performed by calculating peak areas relative to the IS from the average of three replicate measurements. Blank plasma samples were periodically run to confirm the absence of interference.

The sorbent composition

The composition of sorbent significantly controls the selectivity and efficiency of MSPE (Taghvimi and Hamishehkar 2017). GO has much more hydrophilic property, large surface area, high extraction ability and notable π-electron interaction with hydrocarbon ring structures. It is well-documented that GO sheets are extremely negative charged resulting undesirable dispersion into aqueous media (Yan et al. 2014). To solve the latest issue, the magnetic nanocomposite can be synthesized via electrostatic interaction between Fe3O4 with positively charged surface and GO. The fabricated magnetic nanocomposite can be meaningfully dispersed through the aqueous media due to the retained hydrophilic moieties. Because of the large surface area, considerable π–π interactions and excellent chemical, mechanical and thermal stabilities, CPs are classified as adequate additives for the sorbents in the extraction of many types of compounds. Herein, to study the merits of the sorbent and provide better extraction efficiency, the surface of GO/Fe3O4 was simply modified with PTh by chemical oxidative polymerization method.

The characterization of nanocomposite sorbent

Figure 2 presents FT-IR spectra, XRD patterns, BET surface area analysis and magnetic properties of GO/Fe3O4@PTh nanocomposite. As it can be seen in Fig. 2A (a), the presence of oxygen-containing functional groups in GO is demonstrated by the peak located at 1156 cm−1, which corresponds to the stretching vibrations of epoxy C–O and ester bonds. The C=O of carbonyl and carboxyl groups shows a highlight vibration at 1698 cm−1. Furthermore, the peak at 3452 cm−1 is related to stretching vibration of O–H bonds in GO structure. In Fig. 2A (b), the peak at 583 cm−1 is assigned to Fe–O vibration confirming the GO has been properly modified with Fe3O4. In addition, the peaks located at 1084 and 2941 cm−1 are probably assigned to C–N stretching vibrations and aromatic C–H stretching vibrations, respectively. These results demonstrate that GO has been well modified with Fe3O4 and PTh. Besides, the integration of Fe3O4 particles with extraction sorbent was approved by recording XRD spectra of Fe3O4, GO, and GO/Fe3O4@PTh. As it is clear in Fig. 2B (a), the GO presents a very sharp diffraction peak at 2θ = 11.281. The position and relative intensities of seven characteristic peaks for Fe3O4 at 2θ = 30.251°, 35.581°, 43.211°, 54.391°, 57.091°, 62.921° and 75.191° prove the pure cubic spinel crystal structure of Fe3O4 (reference: JCPDS card 03-065-3107) (Fig. 2B (b)) (Cao et al. 2014). Figure 2B (c) shows that after fabrication of GO/Fe3O4@PTh, the characteristic peak of Fe3O4 remained unchanged but the diffraction peak for graphene oxide increased to 2θ = 29.421, which these results indicate sorbent has good magnetic properties and can be used for the magnetic separation. In order to investigate the magnetic features of the sorbent, vibrating sample magnetometry (VSM) of GO/Fe3O4@PTh nanocomposite at temperature of 300 K was obtained by cycling the field in the range of −10 to 10 kOe. Figure 2C exhibits the S-like shape of magnetization hysteresis loop and reveals a relatively high saturation magnetization amount of 38.4 emu g−1 with no hysteresis and coercively. This amount is high enough for magnetic separation by applying an external magnet after extraction process. The morphologies of GO, GO/Fe3O4 and GO/Fe3O4@PTh nanostructures were evaluated using TEM and SEM images. As it is obvious in Fig. 3a–e, the Fe3O4 particles have grown on the surface of GO sheets and well distributed. Besides, a slight edge thickness of the sorbent is due to the presence of the oxygen-containing functional groups. It can also be noted that the GO sheets were thicker at the edges. The TEM image reveals the formation of a thin layer coating of PTh on the GO/Fe3O4 sheets. To demonstrate the modification of GO/Fe3O4 with the polymer, EDX spectra of GO and GO/Fe3O4@PTh were recorded and compared (Fig. 4a, b). The EDX spectrum of the modified sorbent reveals the existence of sulfur revealing the proper modification and the presence of PTh on the surface of GO/Fe3O4 sheet. The BET analysis recommends that GO/Fe3O4@PTh has an area of 325.7 m2 g−1 (Fig. 2D).

The effect of sorbent amount per volume

Figure 5 provides information about the effect of sorbent amount on the extraction efficiency. This factor was investigated in the range of 5–60 mg sorbent per 5.0 mL of sample. As it is apparent in Fig. 5, the relative peak area increases with raising the dosage of GO/Fe3O4@PTh from 5 to 15 and remains stable afterwards. Therefore, 15 mg of the sorbent is quite enough to extract DLX and obtain maximum analytical signals. This amount was chosen as the optimum value.

The effect of ultrasonic time

The time of ultrasound radiation, which defines as the extraction time, has important influence on dispersion of the sorbent and the extraction efficiency (Chen et al. 2015). This parameter was studied in the range of 0–9 min. As shown in Fig. 5, relative peak area reaches a maximum value at 6 min and remains constant, then. It is evident that the equilibrium between the sorbent and sample media was nearly reached at 6 min and was selected for the following experiments.

The effect of ionic strength

The addition of salt often increases the ionic strength, and thus increases the extraction efficiency due to the salting-out effect (Farahani et al. 2016). For this purpose, different concentrations of NaCl (0–10% w/v) were added to the sample solution to evaluate its effect on the extraction performance (Fig. 6). The results indicate that analytical responses rise up to 2%, followed by a steady fall. The decline of the extraction efficiency after 2% can be explained by occupying active sites on the surface of the sorbent by the salt ions. Thus, a fixed concentration of 2% w/v of NaCl was used as the optimum value.

The effect of sample pH

The pH of sample solution could change the state of the target analyte and the kind of its interaction with magnetic sorbent as well as the charges on the sorbent surface (Li et al. 2017). In an acidic media, due to the non-ionized characteristic of carboxylic acid groups of the fabricated sorbent, low extraction efficiency was achieved. This phenomenon causes an increase of sorbent aggregation and subsequently a decrease in surface area for interaction with the analyte. By growing the pH value up to 9.0, the ionization of the carboxylic groups become prevalent and provides better dispersion of sorbent into the sample media. The latest fact enhances the extraction efficiency. The effect of sample pH was investigated within the range of 2.0–12.0 using HCl and NaOH (10−2 mol L−1 of each, by a micropipette). Figure 6 denotes that the best results were obtained at pH 9.0 which was selected as the optimum.

The effect of desorption conditions

The type and volume of desorption solvent have important effects on the extraction efficiency and must be carefully evaluated to obtain the highest analytical signal (Shi et al. 2016). In order to evaluate the kind of desorption solvent, various organic solvents involving methanol (containing 2% acetic acid), acetonitrile (containing 2% acetic acid) and acetone (containing 2% acetic acid) were examined. The obtained results indicated that desorption of methanol containing 2% acetic acid was much stronger and more stable than the other tested ones. Therefore, it was selected as the optimum, which provided suitable eluting ability. Moreover, the volume of desorption solvent was evaluated in the range of 0.5–3.0 mL and the best elution condition was also achieved using 1.0 mL of desorption solvent. Consequently, it was indicated that applying 0.5 mL in two times washing provided more stable results. The impact of desorption time on the extraction efficiency was tested from 0.5 to 7 min and the results showed that 2 min was quite sufficient to elute and desorb the target analyte from the extraction sorbent.

Reusability of the magnetic sorbent

To assess the applicability and cost-effective advantages of the fabricated magnetic sorbent, the reusability must be taken into account (Ding et al. 2016). In order to study this factor, the sorbent was washed with 3.0 mL methanol and then 3.0 mL water, after the extraction of target analyte. Thereupon, the sorbent was dried at ambient temperature and utilized again for new measurements. These results demonstrated that the designed extraction phase could be reused at least 9 times and in the last usage it almost provided extraction recovery of 87%.

Method validation

Analytical performance

To evaluate the practical usage of the methodology, calibration curves were plotted using spiked levels of the analyte. Each standard sample was extracted by the proposed method at the optimum conditions. For each level, three replicate extractions were conducted. The limit of detection (LOD), based on the signal-to-noise ratio (S/N) of 3, the limit of quantification (LOQ) based on the S/N of 10 and the determination coefficients (r 2) were calculated. All the analytical features as well as system suitability were determined according to ICH guidelines. The calibration curve was drawn with the equation of Y = 0.0047 (±0.00019) X + 0.3031 (±0.016) where Y and X are DLX relative peak areas to the IS (three replicates) and DLX concentration (ng mL−1), respectively. The values in parenthesis give the standard deviations. The LR (2–2500 ng mL−1 with r 2 = 0.998) is practical to cover the possible concentration of DLX in human plasma while LOD (0.5 ng mL−1) and LOQ (2 ng mL−1) provide a high and desire sensitivity of the method.

Precision and accuracy

The intra-day and inter-day precisions at four concentration levels of DLX (5, 100, 500 and 2000 ng mL−1) as the QC samples were performed and the results are summarized in Table 1. As it can be seen, intra-assay precisions were studied by measuring the samples at 6 runs a day and provided RSD values within the range of 3.5–4.5%. In addition, the inter-assay precisions were determined on 3-day period at total run of 9 and RSD values were achieved in the range of 3.8–6.7%. In all experiments, the relative errors as the accuracy of the method were less than 9%. These results confirm that the developed method is repeatable and reliable.

The stability study

The stability assessment was performed by analyzing QC samples after three freeze–thaw cycles (Table 2). The cycle was repeated twice and the solutions were then analyzed. The samples were stored at −20 °C for 24 h and then thawed at 25 °C. Applying a newly constructed calibration plot and three replicate measurements for each concentration level of QC samples revealed that there was no significant difference between the freeze–thaw sample and the freshly spiked samples. Subsequent experiments showed that real samples are stable for 3 days at 2–10 °C.

Application

The developed protocol at optimum conditions was applied to determine DLX concentration in human plasma. All the studies were carried under the guidance and supervision of a professor (faculty member of Pharmacy and Pharmaceutical Sciences Research Center, Tehran University of Medical Sciences, expire date of permission in August 01, 2017). Oral administration of a 60 mg single dose was performed to three healthy male volunteers. The real samples were collected at 0, 1, 2, 3, 4, 5, 6, 8, 10, 12, 24 and 48 h after drug administration and the mean plasma concentration–time curve was obtained. The main pharmacokinetic parameters including T max, C max, AUC0–t , AUC0–∞, and T ½ are summarized in Table 3. The chromatograms of DLX in human plasma after the drug administration at different time periods in addition to blank are illustrated in Fig. 7.

Comparison with other methods

A comparison of the method with previously reported techniques for the determination of DLX is provided in Table 4. The LOQ of the MSPE-HPLC–UV was better than the other methods except protein precipitation-liquid chromatography–mass spectrometry (PP-LC–MS). Beside its simplicity, low cost and the widest LR, an extra advantage of MSPE-HPLC–UV is short extraction time. The data revealed a significant improvement in RSD excluding ultra-performance liquid chromatography (UPLC). These characteristics are of great interest for routine laboratories in the trace analysis of DLX in plasma samples.

Conclusion

A new magnetic nanocomposite of GO/Fe3O4@PTh was successfully fabricated and utilized as an efficient sorbent for MSPE. Applying PTh as a surface modifier, led to producing a sorbent with extra extraction properties of GO/Fe3O4. The results show that high surface area and fast mass transfer capacity of the fabricated sorbent in combination with HPLC–UV is a valid means of enrichment and quantification of DLX at trace level in human plasma. The satisfactory extraction efficiency, sufficient sensitivity and repeatability along with significant accuracy were achieved, almost independent of the complex matrix in the real samples. Furthermore, the entire analytical procedure presents a cost-effective and quick way for the screening purposes. Hence, putting all the advantages together, the method possesses great potential to be employed in the other applications.

References

Ammar RA, Otaif H, Al-Warthan A (2012) A novel ion-selective membrane electrode for the determination of duloxetine. Anal Methods 4:1427–1431. doi:10.1039/C2AY05884G

Anderson D, Reed S, Lintemoot J, Kegler S, DeQuintana S, Sandberg M, Muto J (2006) A first look at duloxetine (Cymbalta®) in a postmortem laboratory. J Anal Toxicol 30:576–580. doi:10.1093/jat/30.8.576

Asgharinezhad AA, Ebrahimzadeh H, Mirbabaei F, Mollazadeh N, Shekari N (2014) Dispersive micro-solid-phase extraction of benzodiazepines from biological fluids based on polyaniline/magnetic nanoparticles composite. Anal Chim Acta 844:80–89. doi:10.1016/j.aca.2014.06.007

Bagheri H, Ayazi Z, Naderi M (2013) Conductive polymer-based microextraction methods: a review. Anal Chim Acta 767:1–13. doi:10.1016/j.aca.2012.12.013

Ball S, Marangell LB, Lipsius S, Russell JM (2013) Brain-derived neurotrophic factor in generalized anxiety disorder: results from a duloxetine clinical trial. Prog Neuropsychopharmacol Biol Psychiatry 43:217–221. doi:10.1016/j.pnpbp.2013.01.002

Bennett R, Russell IJ, Choy E, Spaeth M, Mease P, Kajdasz D, Walker D, Wang F, Chappell A (2012) Evaluation of patient-rated stiffness associated with fibromyalgia: a post hoc analysis of 4 pooled, randomized clinical trials of duloxetine. Clin Ther 34:824–837. doi:10.1016/j.clinthera.2012.02.013

Cao X, Shen L, Ye X, Zhang F, Chen J, Mo W (2014) Ultrasound-assisted magnetic solid-phase extraction based ionic liquid-coated Fe3O4@graphene for the determination of nitrobenzene compounds in environmental water samples. Analyst 139:1938–1944. doi:10.1039/c3an01937c

Chaves AR, Júnior GC, Queiroz MEC (2009) Solid-phase microextraction using poly (pyrrole) film and liquid chromatography with UV detection for analysis of antidepressants in plasma samples. J Chromatogr B 877:587–893. doi:10.1016/j.jchromb.2008.12.070

Chen X, You X, Liu F, Hou F, Zhang X (2015) Ionic-liquid-based, manual-shaking-and ultrasound-assisted, surfactant-enhanced emulsification microextraction for the determination of three fungicide residues in juice samples. J Sep Sci 38:93–99. doi:10.1002/jssc.201400970

D’Archivio AA, Maggi MA, Ruggieri F, Carlucci M, Ferrone V, Carlucci G (2016) Optimisation by response surface methodology of microextraction by packed sorbent of non steroidal anti-inflammatory drugs and ultra-high performance liquid chromatography analysis of dialyzed samples. J Pharm Biomed Anal 125:114–121. doi:10.1016/j.jpba.2016.03.045

Dhaneshwar SS, Deshpande P, Patil M, Vadnerkar G, Dhaneshwar SR (2008) Development and validation of a HPTLC method for estimation of duloxetine hydrochloride in bulk drug and in tablet dosage form. Indian J Pharm Sci 70:233–236. doi:10.4103/0250-474X.41463

Dimiev AM, Eigler S (2016) Graphene oxide: fundamentals and applications. Wiley, New York. ISBN 978-1-119-06940-9

Ding J, Mao LJ, Guo N, Yu L, Feng YQ (2016) Determination of endogenous brassinosteroids using sequential magnetic solid phase extraction followed by in situ derivatization/desorption method coupled with liquid chromatography–tandem mass spectrometry. J Chromatogr A 1446:103–113. doi:10.1016/j.chroma.2016.04.012

Farahani H, Shokouhi M, Rahimi-Nasrabadi M, Zare-Dorabei R (2016) Green chemistry approach to analysis of formic acid and acetic acid in aquatic environment by headspace water-based liquid-phase microextraction and high-performance liquid chromatography. Toxicol Environ Chem 98:714–726. doi:10.1080/02772248.2015.1126283

Freeman MP, Hirschberg AM, Wang B, Petrillo LF, Connors S, Regan S, Joffe H, Cohen LS (2013) Duloxetine for major depressive disorder and daytime and nighttime hot flashes associated with the menopausal transition. Maturitas 75:170–174. doi:10.1016/j.maturitas.2013.03.007

Gołębiowski M, Stepnowski P, Leszczyńska D (2017) Application of carbon nanotubes as solid-phase extraction sorbent for analysis of chlorophenols in water samples. Chem Pap Chem Zvesti 71:831–839. doi:10.1007/s11696-016-0098-z

Herrero-Latorre C, Barciela-García J, García-Martín S, Peña-Crecente RM, Otárola-Jiménez J (2015) Magnetic solid-phase extraction using carbon nanotubes as sorbents: a review. Anal Chim Acta 892:10–26. doi:10.1016/j.aca.2015.07.046

Huang Y, Zheng Z, Huang L, Yao H, Wu X, Li S, Lin D (2017) Optimization of dispersive liquid-phase microextraction based on solidified floating organic drop combined with high-performance liquid chromatography for the analysis of glucocorticoid residues in food. J Pharm Biomed Anal 138:363–372. doi:10.1016/j.jpba.2017.02.026

Hunziker ME, Suehs BS, Bettinger TL, Crismon ML (2005) Duloxetine hydrochloride: a new dual-acting medication for the treatment of major depressive disorder. Clin Ther 27:1126–1143. doi:10.1016/j.jpba.2017.02.026

Karpavičiūtė D, Murkovic M, Vinauskienė R, Venskutonis R (2017) Determination of non-polar heterocyclic aromatic amines in roasted coffee by SPE-HPLC-FLD. Chem Pap Chem Zvesti 71:67–70. doi:10.1007/s11696-016-0039-x

Lantz RJ, Gillespie TA, Rash TJ, Kuo F, Skinner M, Kuan HY, Knadler MP (2003) Metabolism, excretion, and pharmacokinetics of duloxetine in healthy human subjects. Drug Metab Dispos 31:1142–1150. doi:10.1124/dmd.31.9.1142

Leeuwen JHS, Lange RR, Jonasson AF, Chen WJ, Viktrup L (2008) Efficacy and safety of duloxetine in elderly women with stress urinary incontinence or stress-predominant mixed urinary incontinence. Maturitas 60:138–147. doi:10.1016/j.maturitas.2008.04.012

Li N, Chen J, Shi YP (2017) Magnetic polyethyleneimine functionalized reduced graphene oxide as a novel magnetic solid-phase extraction adsorbent for the determination of polar acidic herbicides in rice. Anal Chim Acta 949:23–34

Li X, Wang Y, Yang X, Chen J, Fu H, Cheng T (2012) Conducting polymers in environmental analysis. TrAC Trends Anal Chem 39:163–179. doi:10.1016/j.trac.2012.06.003

Liu L, Nussbaum MA (1999) Systematic screening approach for chiral separations of basic compounds by capillary electrophoresis with modified cyclodextrins. J Pharm Biomed Anal 19:679–694. doi:10.1016/S0731-7085(98)00295-7

Liu L, Feng T, Wang C, Wu Q, Wang Z (2014) Magnetic three-dimensional graphene nanoparticles for the preconcentration of endocrine-disrupting phenols. Microchim Acta 181:1249–1255. doi:10.1007/s00604-014-1234-5

Ma N, Zhang BK, Chen BM, Xu P, Wang F, Zhu RH, Feng S, Xiang DX, Zhu Y-G (2007) Determination of duloxetine in human plasma via LC/MS and subsequent application to a pharmacokinetic study in healthy Chinese volunteers. Clin Chim Acta 380:100–105. doi:10.1016/j.cca.2007.01.018

Malfará WR, Bertucci C, Queiroz MEC, Carvalho SAD, Bianchi MLP, Cesarino EJ, Crippa JA, Queiroz RHC (2007) Reliable HPLC method for therapeutic drug monitoring of frequently prescribed tricyclic and nontricyclic antidepressants. J Pharm Biomed Anal 44:955–962. doi:10.1016/j.jpba.2007.04.005

Mallinckrodt CH, Prakash A, Andorn AC, Watkin JG, Wohlreich MM (2006) Duloxetine for the treatment of major depressive disorder: a closer look at efficacy and safety data across the approved dose range. J Psychiatr Res 40:337–348. doi:10.1016/j.jpsychires.2005.08.010

Marcano DC, Kosynkin DV, Berlin JM, Sinitskii A, Sun Z, Slesarev A, Alemany LB, Lu W, Tour JM (2010) Improved synthesis of graphene oxide. ACS Nano 4:4806–4814. doi:10.1021/nn1006368

Mehdinia A, Roohi F, Jabbari A (2011) Rapid magnetic solid phase extraction with in situ derivatization of methylmercury in seawater by Fe3O4/polyaniline nanoparticle. J Chromatogr A 1218:4269–4274. doi:10.1016/j.chroma.2011.04.070

Mercolini L, Mandrioli R, Cazzolla R, Amore M, Raggi MA (2007) HPLC analysis of the novel antidepressant duloxetine in human plasma after an original solid-phase extraction procedure. J Chromatogr B 856:81–87. doi:10.1016/j.jchromb.2007.05.031

Mihaylova B, Pitman R, Tincello D, Der Vaart HV, Tunn R, Timlin L, Quail D, Johns A, Sculpher M (2010) Cost-effectiveness of duloxetine: the Stress Urinary Incontinence Treatment (SUIT) study. Value Health 13:565–572. doi:10.1111/j.1524-4733.2010.00729.x

Mitra S (2003) Sample preparation techniques in analytical chemistry. Wiley, New York. ISBN 978-0-471-32845-2

Moldoveanu SC (2004) Solutions and challenges in sample preparation for chromatography. J Chromatogr Sci 42:1–14. doi:10.1093/chromsci/42.1.1

Moldoveanu SC, David D (2002) Sample preparation in chromatography, vol 65. Elsevier, Amsterdam. ISBN 9780080540702

Musenga A, Amore M, Mandrioli R, Kenndler E, Martino LD, Raggi MA (2009) Determination of duloxetine in human plasma by capillary electrophoresis with laser-induced fluorescence detection. J Chromatogr B 877:1126–1132. doi:10.1016/j.jchromb.2009.02.059

Pastor-Belda M, Bastida D, Campillo N, Pérez-Cárceles MD, Motas M, Viñas P (2016) A study of the influence on diabetes of free and conjugated bisphenol A concentrations in urine: development of a simple microextraction procedure using gas chromatography–mass spectrometry. J Pharm Biomed Anal 129:458–465. doi:10.1016/j.jpba.2016.07.042

Pavlović DM, Babić S, Horvat AJM, Kaštelan-Macan M (2007) Sample preparation in analysis of pharmaceuticals. TrAC Trends Anal Chem 26:1062–1075. doi:10.1016/j.trac.2007.09.010

Pawliszyn J (2002) Sampling and sample preparation for field and laboratory: fundamentals and new directions in sample preparation, vol 37. Elsevier, Amsterdam. ISBN 9780080929453

Płotka-Wasylka J, Szczepańska N, Guardia M, Namieśnik J (2015) Miniaturized solid-phase extraction techniques. TrAC Trends Anal Chem 73:19–38. doi:10.1016/bs.coac.2017.03.001

Rickard EC, Bopp RJ (1994) Optimization of a capillary electrophoresis method to determine the chiral purity of a drug. J Chromatogr A 680:609–621. doi:10.1016/0021-9673(94)85161-1

Shi Y, Wu H, Wang C, Guo X, Du J, Du L (2016) Determination of polycyclic aromatic hydrocarbons in coffee and tea samples by magnetic solid-phase extraction coupled with HPLC–FLD. Food Chem 199:75–80. doi:10.1016/j.foodchem.2015.11.137

Suh JH, Lee YY, Lee HJ, Kang M, Hur Y, Lee SN, Yang D-H, Han SB (2013) Dispersive liquid–liquid microextraction based on solidification of floating organic droplets followed by high performance liquid chromatography for the determination of duloxetine in human plasma. J Pharm Biomed Anal 75:214–219. doi:10.1016/j.jpba.2012.11.041

Sultan A, Gaskell H, Derry S, Moore RA (2008) Duloxetine for painful diabetic neuropathy and fibromyalgia pain: systematic review of randomised trials. BMC Neurol 8:29. doi:10.1186/1471-2377-8-29

Taghvimi A, Hamishehkar H (2017) Carbon coated magnetic nanoparticles as a novel magnetic solid phase extraction adsorbent for simultaneous extraction of methamphetamine and ephedrine from urine samples. J Chromatogr B 1041:113–119. doi:10.1016/j.jchromb.2016.11.039

Wang L, Zhang Z, Zhang J, Zhang L (2016) Magnetic solid-phase extraction using nanoporous three dimensional graphene hybrid materials for high-capacity enrichment and simultaneous detection of nine bisphenol analogs from water sample. J Chromatogr A 1463:1–10. doi:10.1016/j.chroma.2016.08.003

Yan S, Qi T-T, Chen D-W, Li Z, Li X-J, Pan S-Y (2014) Magnetic solid phase extraction based on magnetite/reduced graphene oxide nanoparticles for determination of trace isocarbophos residues in different matrices. J Chromatogr A 1347:30–38. doi:10.1016/j.chroma.2014.04.073

Zeeb M, Mirza B, Zare-Dorabei R, Farahani H (2014) Ionic liquid-based ultrasound-assisted in situ solvent formation microextraction combined with electrothermal atomic absorption spectrometry as a practical method for preconcentration and trace determination of vanadium in water and food samples. Food Anal Methods 7:1783–1790. doi:10.1007/s12161-014-9820-z

Zeeb M, Farahani H, Papan MK (2016) Determination of atenolol in human plasma using ionic-liquid-based ultrasound-assisted in situ solvent formation microextraction followed by high-performance liquid chromatography. J Sep Sci 39:2138–2145. doi:10.1002/jssc.201501365

Zhao R, Cheng G, Tang J, Song J, Peng W-X (2009) Pharmacokinetics of duloxetine hydrochloride enteric-coated tablets in healthy Chinese volunteers: a randomized, open-label, single-and multiple-dose study. Clin Ther 31:1022–1036. doi:10.1016/j.clinthera.2009.05.005

Zhao C, Jiang Z, Cai X, Lin L, Lin X, Weng S (2015) Ultrasensitive and reliable dopamine sensor based on polythionine/AuNPs composites. J Electroanal Chem 748:16–22. doi:10.1016/j.jelechem.2015.04.025

Acknowledgements

This work has been supported by grants from the Islamic Azad University South Tehran Branch which is hereby gratefully acknowledged. The authors greatly appreciate Miss Farnaz Bahman for cooperating to carry out the HPLC analysis, and also thank the volunteers for enrolling in this study and taking their valuable time.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared no conflict of interest.

Rights and permissions

About this article

Cite this article

Zeeb, M., Farahani, H. Graphene oxide/Fe3O4@polythionine nanocomposite as an efficient sorbent for magnetic solid-phase extraction followed by high-performance liquid chromatography for the determination of duloxetine in human plasma. Chem. Pap. 72, 15–27 (2018). https://doi.org/10.1007/s11696-017-0253-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-017-0253-1