Abstract

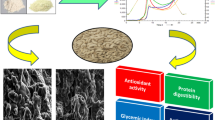

This study intended to explore the possibility of utilizing maize and different varieties of quality protein maize (QPM) for the enrichment of pasta. The blends (10, 20 and 30%) were prepared and assessed for their functional properties. The cooking quality, antioxidative properties, color values and in vitro digestibility were extensively assessed. Also, the effect of enrichment on the morphological attributes as well as on the secondary protein structure were analyzed. Enrichment improved the water absorption capacity (145.35 g/100–142.58 g/100 g) and swelling power (6.26–6.59 g/g) of the blends. The enriched pasta had significantly (p < 0.05) higher protein and crude fibre content, total phenolic content and flavonoids and remarkably better antioxidant activity (24.16–29.57%) than control. In vitro protein digestibility of QPM enriched pasta was found significantly (p < 0.05) higher (80.12%) than the maize (72.34%) and control pasta (71.91%). However, with the increase in the enrichment levels, an increase in the cooking time and gruel loss (5.78 to 8.4% for HQPM 1 and 6.85 to 9.12% for HQPM 1708) was observed. The acceptability index of pasta enriched with 20% HQPM1 flour was found the highest (96.99). Scanning electron microscopy and Fourier transform infrared spectroscopy confirmed the presence of higher protein and phenolic groups in QPM enriched pasta. Thus, QPM enrichment in a versatile food like pasta can be an excellent source of high-quality and cost-efficient protein along with several antioxidative properties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Maize is the third important cereal crop utilized as a staple food across the world after wheat and rice. India is one of the top maize-producing countries with an annual production of about 1147 million metric tonnes during the year 2020 (FAOSTAT 2020). Maize is an excellent source of starch, folic acid, pro-vitamin A, bioactive compounds, essential oils, valuable proteins and dietary fibres. Maize, being an inexpensive gluten-free cereal is highly preferred for the development of food products for celiac patients. Conventional maize contains approximately 7–13% protein (dry matter basis) but the protein quality is inferior as it lacks essential amino acids like tryptophan and lysine [1]. Lysine content in normal maize protein is quite low than that recommended by FAO (12 mg/kg/day). These amino acid inadequacies have been addressed through the development of nutritionally superior hybrid maize variety by researchers of the International Maize and Wheat Improvement Center (CIMMYT). The newly developed maize variety is known as quality protein maize (QPM) and had properties similar to maize in terms of organoleptic properties with the added advantage of higher tryptophan 0.33–0.54 g/100 g lysine which is 46% higher than normal maize and better yield [2, 3].

QPM has two times better essential amino acid profile in comparison with conventional maize and not only the quantity but the bioavailability is also comparable to casein protein [3]. Lysine accounts 1.3–4.4% of total endosperm protein in the case of traditional maize while 3.3–4% in QPM. Even though QPM and maize have equal content of niacin, the lower amount of leucine in QPM aids in liberating more tryptophan for the biosynthesis of niacin [4]. Also, it has a better tryptophan level (0.08%) than maize and the amalgamation of these essential amino acids permit the body to produce a total protein that reduces instances of protein-energy malnutrition in infants and children [5].

In today’s dynamic lifestyle, we require food products that are instant, versatile and ready-to-cook/eat/drink and pasta is one of those products which has gained popularity in the past two decades because of its versatility, nutritive value, low cost, ease of preparation, longer shelf-life and palatability [6]. Pasta is generally prepared from durum wheat semolina which is rich in complex carbohydrates, protein, fat and vitamin. But it lacks essential fatty acids and amino acids, vitamins, dietary fiber iron, vitamins, threonine [7] lysine, minerals and antioxidative properties [8]. It was reported that the phenolic content of maize and QPM lies within the range of 1.04–3.02 mg GAE/g and 0.64–2.76 mg GAE/g respectively. Similarly, a higher flavonoid content was reported in QPM (2.957/100 g naringin equivalents) than the normal maize (1.5205/100 g naringin equivalents) [9]. A significantly (p < 0.05) higher protein digestibility and lower starch digestibility was reported for opaque 2 maize in comparison to normal maize [10, 11]. In the past few years, the prospect of enrichment of pasta to contribute towards the recommended nutrient intake per day has triggered up. Both World Health Organization (WHO) as well as Food Agriculture Organization (FAO) have recommended pasta as one of the most effective enrichment media for various nutrients such as minerals, lipids, proteins, vitamins, etc. [12]. Therefore, there is a need to improve its nutritional quality and thus, to match the increasing demand for raw materials for pasta products, maize can be excellent alternative raw material and utilization of QPM in form of flour may help to combat protein and essential amino acid deficiencies [13].

In developing countries, due to unhealthy diet patterns and lack of quality proteins in the diet composition, severe protein energy malnutrition (PEM) has become one of the major problems in countries like India, where 20% of the children are suffering from PEM [14]. Thus, the appropriate use of widely available and low-cost protein sources for the purpose of fortification have turned out to be a significant (p < 0.05) field of study in the present scenario [15]. Therefore, present study aimed to develop QPM supplemented pasta and study the effect of enrichment/supplementation on physical, nutritional, techno-functional and bioactive profile on it based on the morphological attributes and multivariate analysis.

Materials and methods

Raw materials

Maize (PMH1) with protein content (9.73%), ash (1.02%), crude fat (1.30%), crude fiber (1.21%), carbohydrate (72.71%) and QPM (HQPM1 with protein content (11.46%), ash (2.30%), crude fat (4.02%), crude fiber (1.95%), carbohydrate (62.21%) with and HQPM1708 with protein content (10.70%), ash (1.78%), crude fat (4.24%), crude fiber (1.44%), carbohydrate (67.72%) were procured from the Indian Institute of Maize Research, Punjab Agricultural University, Ludhiana, Punjab, India. Semolina with protein content (10.70%), ash (1.78%), crude fat (4.24%), crude fiber (1.44%), carbohydrate (67.72%) was purchased from the local store, Ludhiana, Punjab.

Milling and preparation of blends

The grains were dried in Hot Air Cabinet Tray Drier at 45 ℃ for 6–7 h till it reaches optimum moisture content (6%) and milled using Domestic Mill (Perten Company, setting 1). The three compositions with 10%, 20% and 30% for each variety of maize and QPM were prepared. The blends were then passed through a sieve (mesh size 20.0 or 840 μm) thrice to ensure proper mixing and uniform particle size.

Pasta preparation

Half kilogram of each blend was mixed with the calculated amount of water (35%)-based on hydration capacity of the blends followed by thorough mixing at 10–15 min in the mixing chamber of the pasta extruder (La Monferrrina, Masoero Arturo and C.S.N.C., Italy). Hydrated blends were extruded at 37–40 °C temperature through the spiral-shaped die (No. 469) to produce pasta. The rotatory cutter speed was adjusted to obtain a uniform pasta length of 2.5 cm [14]. The pasta was dried in an oven drier (Naarang Scientifics, New Delhi, India) at 50–55 °C for 4 to 5 h. The dried pasta samples were packed in low density polyethylene (LDPE) pouches and stored at 4 ℃ for subsequent analysis.

Functional properties of the maize and QPM enriched blends

Water absorption capacity and water solubility index

Sample (2.0 g) was taken in a pre-weighed centrifuge tube, added with 20 mL distilled water. The contents in the tube were mixed properly and incubated for 30 min with shaking after every 5 min interval followed by centrifugation at 3000×g for 15 min. The supernatant was transferred to a pre-weighed petri dish and dried in a hot air oven at 100 ± 5 °C for 5 h [16]. The weight of the sediment gel and dry solids was observed. Water absorption capacity (WAC) and water solubility index (WSI) were calculated by using the following equations.

Oil absorption capacity

Oil absorption capacity (OAC) of samples was determined by the procedure suggested by [14]. Take 10.0 mL of refined vegetable oil mixed with 1.0 g of sample in the pre-weighed 50.0 mL centrifuge tubes. It was then incubated for 30 min with shaking after every 5 min followed by centrifugation at 3000×g for 15 min. The OAC of blends was calculated by using the following formula.

Swelling power (SP)

Weighed sample (1.0 g) was taken in a pre-weighed 50.0 mL centrifuge tube, to this 20 mL of distilled water was added and heated in the water bath (Labquest, Borosil, Model no. WBC012) for 30 min at 85 ℃. It was then centrifuged for 15 min at 3000×g. Weight of swollen pellet after removal of supernatant was taken and expressed in g/g of the sample taken [17].

Nutritional composition of pasta

Moisture, ash, crude protein, crude fat and crude fibre were estimated using the standard method [10] Carbohydrate (g/100 g) and energy content of the samples were calculated using the formula below:

Bioactive constituents and antioxidant activity

Extraction of samples was done by using the method described by Dini et al. [18]. Weighed sample (1.0 g) was mixed with 20.0 mL of acidified (0.1%) aqueous methanol (80% v/v). It was further refluxed twice for 2 h each. The extract was collected and volume makeup was done to 50.0 mL using acidified methanol.

Total phenolic content (TPC)

The TPC was estimated by the colorimetric method using Gallic acid as standard [19], using 0.5 mL sample extract, 0.5 mL of aqueous methanol and 5.0 mL of freshly diluted (1:10) Folin–Ciocalteu reagent (FC) reagent. Further, 4 mL saturated sodium bicarbonate (7.5%) was added and incubated for 2 h at 37 °C and the absorption was read at 765 nm. The results were expressed in terms of mg of gallic acid equivalents (GAE)/g of the dried sample weight.

Total flavonoid content (TFC)

Total flavonoid content was calculated corresponding to mg of quercetin equivalent/100 g using the colorimetric method [20]. 0.5 mL of methanolic extract, 0.15 mL NaNO2 (5% aqueous solution) and 2.0 mL of distilled water were mixed. After 5 min, 0.15 mL AlCl3 (10% aqueous solution) was added to it and incubated for 6 min. Finally, 1.0 mL of NaOH solution (1 M) and 1.2 mL of distilled water were added and the absorbance was read at 510 nm.

DPPH radical scavenging activity

Antioxidant activity was expressed in terms of DPPH (1,1-diphenyl-2-picrylhydrazyl) radical scavenging activity. It involves a colorimetric reduction reaction between methanolic extracts and DPPH dye solution. Methanolic extract (0.1 mL) and 3.9 mL of freshly prepared DPPH dye solution (0.1 mM) were added followed by incubation in dark for 45 min and absorbance was recorded at 515 nm at 0 min [21]. The results were calculated using the following equation [22]:

where AbsT is the absorbance of the sample after 30 min, Abso is the absorbance of control at 0 min.

In vitro nutrient digestibility

In vitro starch digestibility

In vitro starch digestibility of both raw and cooked pasta samples was assessed enzymatically by estimating the amount of free maltose formed after starch digestion [23]. A finely ground sample (100 mg) was added with 100 mg of pancreatic-α-amylase. Further, 20.0 mL phosphate buffer (pH 6.9) was added and incubated at 37 °C for 2 h. Digested filtrate (1.0 mL) and dinitro salicylic acid (2.0 mL) was added to inhibit the reaction. The test tubes were kept for 5 min in a boiling water bath followed by cooling. The volume was made up to 50.0 mL and the absorbance corresponding to mg of maltose present was taken at 540 nm.

In vitro protein digestibility

In vitro protein digestibility of pasta samples were determined as per the two‐step protein hydrolysis method [24]. Finely (500.0 mg) ground pasta sample was mixed with pepsin solution prepared in 0.1 N HCl (pH 1.9) and incubated for 2 h at 37 °C in the water bath. The solution was neutralized using 0.2 N NaOH. To maintain the aseptic environment, 0.25 mL of toluene was added. For the second stage enzymatic proteolysis, the pancreatin solution (pH 8) was added to the solution and incubated again under similar conditions. At the end of protein digestion, the samples were centrifuged for 15 min at 1693×g. The supernatant was removed and sediments were dried for further nitrogen estimation of the samples using the Macrokjedahl method. The digestibility was calculated using below equation:

Cooking quality of pasta

Minimum cooking time (MCT), volume expansion, water absorption and percent gruel solid loss were determined as per the method described by Sharma et al. [10]. The MCT was the time required for the complete disappearance of the raw white core, thereby indicating complete gelatinization of starch. 10.0 g samples were cooked in 100 mL boiling distilled water and MCT was determined by withdrawing pasta intermittently and pressing them between the glass slides to observe the extent of gelatinization. Volume expansion (mL/g) of pasta was determined by using the water displacement method before and after cooking the samples. 10.0 g sample was submerged in 200.0 mL distilled water contained in a 250.0 mL measuring cylinder. The initial volume of the product was noted. The sample was then cooked in distilled water (100.0 mL) for optimum cooking time, rinsed and excess water was removed. It was again submerged in 200.0 mL of water and the increase in the volume was recorded and expressed as mL/g.

Water absorption was estimated by calculating the increase in weight during cooking. Pasta (10.0 g) was cooked in 100 mL deionized water for MCT. The pasta was withdrawn and excess water from the cooked pasta was removed using blotting paper and the final weight of the cooked pasta was recorded, and the percent water absorption was obtained. The left-over cooking water was used to determine the gruel solid loss. The aliquot (10 mL) was collected in a pre-weighed petri dish and dried at 105 °C until no difference in the weight of petri plates was found. Water absorption and gruel solid loss were estimated by using the following formula.

Colour analysis

Hunter Lab Colorimeter (Color Flex EZ Hunter Associates Inc., USA) was used to perform the color analysis of the QPM pasta. The reflectance values and color parameters were recorded by measuring L*, a*, and b* values [14] where + L*, − L* denotes whiteness and blackness respectively. The values for + a*, − a*, + b*, and − b* represents redness, greenness, yellowness, and blueness respectively. The value of ΔE will be calculated using the following equation.

Texture analysis

The pasta (10 g) was cooked in 100 mL of deionized water for optimum cooking time. The firmness of the pasta was determined using the Texture Analyzer (Model: TA-XT plus, Stable Micro Systems, USA). The analysis was conducted in shear mode using knife blade probe (75 mm) moving at a speed of 1 mm/s and cutting the sample (2 g) to 10 mm distance. Trigger force used was 10.0 g with pre-test and post-test speeds fixed at 2.0 mm/s and 10.0 mm/s, respectively and 50 kg load cell was used. The maximum force required to cut the pasta was taken as firmness from the force–time graph [25].

Sensory evaluation

Sensory evaluation of the cooked pasta was done by 20 semi-trained panelists in the Department of Food Science and Technology, PAU, Ludhiana, Punjab, India. Cooked pasta samples were analyzed by a semi-trained panel of judges on a 9-point hedonic scale for different sensory attributes viz texture/mouthfeel, appearance, flavor, and overall acceptability [10].

Scanning electron microscopy (SEM)

The microstructure morphology of raw and steamed pasta was studied using the scanning electron microscopy. A holding pan was employed to hold the dried pasta samples and were sputter-coated with gold with the help of a vacuum evaporator for about 2 min. Gold-coated pasta sample was then shifted into microscope stage to examine the samples at 9.75 × 10−5 Pa vacuum and an accelerating voltage of about 15 kV [26]. The higher the atomic number, the brighter the macromolecule appears in the image.

Fourier transform infrared spectroscopy (FTIR)

The infrared spectra of the pasta samples were studied with FTIR spectrophotometer (Thermo Scientific, Nicolet 67,000). Samples were finely ground and placed into the FTIR sample holder and the spectrum was noted in 600–4000 cm−1 wavenumber ranges using ATR crystal. The peaks and bands were compared with the standard tables, denoting molecular similarities and differences.

Statistical analysis

All the analysis were conducted in triplicate unless stated differently. The data obtained from aforesaid experiments were subjected to statistical analysis using Statistical Package for Social Science (SPSS) software (Version 22.0, IBM Corporation, New York) to determine the statistical significance between the treatments. One-way analysis of variance (ANOVA) was performed and Tukey’s posthoc test was conducted to compare the means. The p value smaller than 0.05 was considered to be significant. Principal component analysis (PCA) and dendrogram were utilized to conduct multivariate analysis and validate the differences and relationship between various techno-functional and physico-chemical properties.

Results and discussion

Functional properties of raw materials, maize and QPM enriched blends

Water absorption capacity

The capacity of the flour to hold water, known as water absorption capacity (WAC) is primarily affected by starch and fiber content along with the strength of the network formed by protein moieties present in the sample [26]. WAC for control pasta was about 115.13 g/100 g which increased from 120.25 to 134.15 g/100 g, 139.78 to 145.35 g/100 g and 128.84 to 142.58 g/100 g on enrichment with PMH 1, HQPM 1 and HQPM 1708 respectively. Values for WAC increased significantly (p < 0.05) with an increase in enrichment levels of maize/QPM flour from 10 to 30% as presented in Table 1. Thus, high WAC of the enriched blends may be ascribed to better availability of polar amino acids and water-binding polysaccharides in the protein chain, constituting the QPM protein that acts as the primary regions for hydrophilic bonding. QPM had higher polar amino acids, globulins and albumins compared to the normal variety [27] imparting high WAC making it quite suitable for bakery and dough-based food items. The increase of the albumins and globulins of the QPM is associated with the higher germ proportion in the kernel and the lower synthesis of zein protein.

Water Solubility Index

Water Solubility Index (WSI) is a measure of the soluble components in a food system and mainly relates to the carbohydrate composition and their interactions in the food. WSI for control pasta was found to be 3.62 g/100 g. A significant (p < 0.05) difference in the water solubility index of control pasta and maize/QPM pasta was obtained (Table. 1). With an increase in the level of incorporation from 10 to 30%, WSI increased for all three varieties as denoted in Table 1. Higher values for HQPM 1 pasta and HQPM 1708 pasta in comparison to PMH 1 can be attributed to the leaching of higher soluble protein fractions present in QPM varieties. Similar results were obtained by Gupta et al. [26] and Ocheme et al. [28] where a high concentration of soluble protein led to high WSI. High WSI also depicted the ease of digestion in maize-based complementary foods prepared for infants [13, 29].

Oil absorption capacity

Oil absorption capacity (OAC) is an index representing the capacity to entrap and hold oil in the capillaries of the food particles. Moreover, it enhances the flavor profile and mouthfeel of the product [10]. Control pasta had significantly (p < 0.05) high oil absorption capacity (120.51 g/100 g) compared to maize enriched blends prepared from either variety of maize. It was observed that OAC declined with an increase in the incorporation levels of maize/QPM flour ranging between 116.23 to 112.23 g/100 g for PMH 1, 113.25 to 109.54 g/100 g for HQPM 1 and 113.88 to 108.9 g/100 g for HQPM 1708 as depicted in the Table. 1. Ikujenlola [30] reported the QPM had OAC of about 106%. The lower value of OAC for QPM incorporated blends can be attributed to the presence of polar side chains contributed by high albumin and globulin in the protein structure of QPM varieties. Similar results were obtained where the presence of polar side chains reduced the OAC in the pasta samples [14].

Swelling power

The SP of pasta signifies the amount of water absorbed by the proteins and starch during moist cooking to be utilized for protein hydration and starch gelatinization [31]. It determines whether the pasta is elastic and firm due to the development of a strong protein network or soft and sticky as a result of excess starch swelling when cooked. SP increased significantly (p < 0.05) with an increase in enrichment level of maize/QPM flour (6.10 to 6.31 g/g for PMH 1, 6.26 to 6.59 g/g for HQPM 1 and 6.10 to 6.26 g/g for HQPM 1708 flour, respectively) as denoted in Table. 1. Similar increase in SP on supplementation of pasta with sweet potato starch and panga protein isolate was reported by Kolaric [32] and Singh et al. [33]. Starch with large granules swells rapidly when heated in water and water molecules are bonded to the free hydroxyl groups of amylose and amylopectin by hydrogen bonds. In addition, the difference in the SP of the three varieties may be due to variable fat content, the low fat content may have an increasing effect on the SP [34].

Compositional analysis

The nutritional composition of QPM enriched pasta is depicted in Table. 2. The protein content of QPM enriched pasta was enhanced from 9.9 to 10.33% for HQPM 1 and 9.82 to 10.13% for HQPM 1708) which were higher than the maize pasta (9.75 to 9.86%). The values were slightly higher than the values reported by Ikujenlola [30], where the protein content of QPM pasta was found to be 9.46%. The higher ash content of QPM enriched pasta compared to control pasta can be attributed to the higher amount of minerals present in QPM. Also, the amount of calcium (85.61 mg/100 g), potassium (79.24 mg/100 g) and zinc (14.45 mg/100 g) were found considerably higher in the QPM than the maize [35]. With an increase in percent of maize/QPM flour from 10 to 30%, crude fibre content increased. A similar increase was reported, where the crude fibre content varied from 0.88 to 1% in QPM-based cakes with an increase in the level of QPM incorporation from 40 to 80% [36]. A decline in the carbohydrate content followed by an increase in energy content on QPM enrichment may be attributed to the higher fat content in maize and QPM than semolina.

Bioactive composition

The bioactive composition of the pasta samples has been denoted in Table. 2. The phenolic compounds possess antioxidative properties and help to prevent cardiovascular diseases and degenerative disorders like atherosclerosis, obesity and blood pressure [19]. Control pasta had total phenol content about 1.42 mg GAE/g. Total phenol content increased significantly (p < 0.05) (1.65 to 1.75 mg Gallic Acid Equivalents (GAE) /100 g) with an increase in the incorporation of PMH 1. Similar results were obtained for HQPM 1 and HQPM 1708 based blends where the concentration of total phenols increased from 1.84 to 1.98 mg GAE/100 g for HQPM 1 and 1.32 to 1.57 mg GAE/100 g HQPM 1708 pasta. Similarly, high free phenolic compounds (13.1–19.8 mg GAE/100 g) in tortillas prepared from extruded pigmented Mexican maize flour were obtained [37]. QPM tortilla had 0.96 mg GAE/g extractable polyphenols and 5.70 mg GAE/g hydrolysable polyphenols [38].

Significant (p < 0.05) differences (p < 0.05) in the flavonoid content of control as maize/QPM enriched blends were found. With an increase in the concentration of maize/QPM flour, an increasing trend in the TFC was obtained. Flavonoid content ranging between 20.76 to 29.73 mg quercetin/100 g for PMH 1, 18.79 to 27.81 mg quercetin/100 g for HQPM 1 and 22.19 to 34.12 mg quercetin/100 g for HQPM 1708 with 10 to 30% enrichment levels was observed.

A significant (p < 0.05) difference in the total antioxidant activity of control and maize and QPM enriched blends was observed. Antioxidant activity of maize and QPM enriched blends was found higher than the control. Control pasta had an antioxidant activity of about 23.32%. Antioxidant activity for PMH 1, HQPM 1 and HQPM 1708 pasta with 10 to 30% enrichment level ranged from 26.55 to 29.57%, 25.07 to 27.06% and 24.16 to 25.98% respectively. Also, the antioxidant activity of protein fractions and hydrolysates from QPM kernels was found quite higher than maize [27]. A similar trend had been observed, where the incorporation of blue maize flour led to improvement in the antioxidant activity of spaghetti [39].

In vitro nutrient digestibility

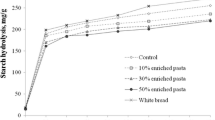

In vitro starch digestibility

A declining trend in starch digestibility was observed when the concentration of maize/QPM flour was increased from 10 to 30% (for both cooked and raw samples) however, the cooked samples had higher starch digestibility than the raw samples as denoted in Table 2. This decline may be attributed to the higher protein and fiber content of QPM and maize varieties respectively. Starch digestion was found negatively correlated with the protein content of the product since it reduces the availability of substrate for enzymatic reaction due to the development of barriers around starch granules [10, 40]. Dietary fibers are known to decrease the transit time of food in the GIT. Thus, the starch granules are available for enzymatic action for an only a short duration [41, 42]. In vitro digestibility of cooked samples was found significantly (p < 0.05) higher than their raw counterparts. In raw samples, the crystalline nature of the starch, shields the glycosidic bonds from the enzymatic action. It was observed that rapidly digestible starch and slowly digestible starch of cooked yellow maize flour was 56.66% and 11.7% respectively [39].

When cooked, gelatinization occurs and exposes the (1 → 4)-glycosidic linkages for digestion and therefore, improves the digestibility. A similar increase in starch digestibility on the cooking of maize was reported by [43].

In vitro protein digestibility

The physicochemical nature of proteins is highly influenced by differences in their association behavior and structural composition. Many new peptide and covalent bonds are formed due to cross-linkage occurring between protein molecules and other molecules during pasta development.

A significant (p < 0.05) difference in the in vitro protein digestibility of control and maize/QPM enriched pasta was observed from Table 2. An increase in the protein digestibility of enriched pasta was observed when the concentration of QPM flour was increased from 10 to 30%. Similar results were reported where in vitro protein digestibility increased drastically when wheat flour was replaced by QPM flour. However, no significant (p < 0.05) difference between control and PMH 1 enriched pasta was observed [44]. This may be attributed to very high content of flavonoids and dietary fibers in PMH 1 variety. Dietary fibres reduce the transit time of food, limiting the access of the enzymatic action in the intestine. The protein digestibility declined profoundly in the presence of flavonoids due to their ability to bind at active sites of the enzyme, inhibiting protease activity. Similar trend of reduced protein digestibility with phenol-flavonoids content had been reported [10]. The inhibitory action of phenolic acids and flavonoids on calorie-rich food components like carbohydrates and lipid may be beneficial to human health; however, quality of protein is influenced by their limited amino acid utilization [45]. Also, cooked samples had higher protein digestibility in comparison to uncooked counterparts. The results were found in line with Duodo et al. [43] where cooking treatment improved the protein digestibility. Also, the breakdown of starch structure allowed the pepsin better access to the protein bodies in the cooked maize. This might be due to protein denaturation, which may increase the exposure of sites susceptible to proteolytic activity.

Cooking quality

Water absorption

The water absorption percent of pasta can be described as the percent increase in its weight on cooking. Control pasta had minimum 115.14% water absorption (Table 3). The water absorption increased significantly (p < 0.05) with increasing incorporation levels of all three maize varieties. The results were in full agreement with Shobha et al. [46] where the water uptake ratio for QPM and maize-based noodles was significantly (p < 0.05) higher than refined wheat noodles. Significantly (p < 0.05) higher values for QPM pasta (154.56 to 160.06% for HQPM 1 and 149.41.84 to 156.12% for HQPM 1708) were observed. This can be correlated to higher protein content, presence of polar amino acids, gelling ability and water holding capacity of the proteins [47, 48]. QPM has exceptionally higher soluble albumin/globulin (rich in essential amino acids) and lower prolamines as compared to normal maize [27]. The positive effect of albumin protein on water absorption had been reported where the addition of albumin protein to rice starch led to the formation of the albumin–starch mixture on cooking that had higher water adsorption levels than pure starch [49]. The results were found in compliance with Surasani et al. [14] where water uptake increased with fish protein isolate supplementation that is supposed to have a high amount of hydrophilic polar amino acids.

Minimum cooking time

Minimum cooking time/optimum cooking time is described as the minimum time upto which the sample should be cooked so that the no central white core is visible when the pasta is squeezed between two glass plates. Control pasta had a cooking time of 5.20 min. There was a significant (p < 0.05) difference in the MCT of control as QPM/Maize pasta (Table 3). Higher values for MCT in case of HQPM 1 and HQPM 1708 pasta can be attributed to high protein content of these varieties. Increase in the cooking time of pasta (6.05 to 6.35 min for PMH 1, 6.25 to 7.05 min for HQPM 1 and 6.12 to 6.45 for HQPM 1708 pasta) on inclusion of maize/QPM flour at 10 to 30% was observed. The results were found in compliance with Kaur et al. [50] who reported that protein impedes the swelling as well as hydration capacity of starch granules by forming a matrix around them. Also, the high fiber content may disrupt of the gluten matrix and create a pathway for water to get absorbed by the starch granules easily, hence reducing the cooking time. They reported when protein-rich pasta gets cooked, it becomes firmer and stronger than pasta with low protein content.

Volume expansion

From Table 3, it can be concluded that the volume expansion of maize/QPM pasta and control pasta differed significantly (p < 0.05). Control pasta had a volume expansion of 1.05 mL/g while a significant (p < 0.05) increase in the values for QPM pasta on enrichment (1.06 to 1.12 mL/g for HQPM 1 and 1.13 to 1.57 mL/g for HQPM 1708) were observed. The higher water absorption can be attributed to the high WAC that caused higher volume expansion. A significant (p < 0.05) correlation (r = 0.96, p ≤ 0.05) was found between water absorption and volume expansion of pasta [50]. The results were in agreement with the findings of Kaur et al. [47] which demonstrated that the high protein content in the pasta resulted in better expansion during cooking. A similar phenomenon in the protein-enriched pasta supplemented with milk, egg protein and legumes [9, 51].

Gruel solid loss

The cooking loss is one of the most important factors to determine the quality of pasta and reflects the surface characteristics of the noodles/pasta [52]. Significantly (p < 0.05) higher gruel loss in maize (PMH 1) incorporated pasta compared to control pasta (5.25%) was observed. This may be attributed to the higher fibre content in PMH 1 maize variety that disrupts the gluten network formed by semolina. Shobha et al. [46] reported cooking loss in control and QPM noodles as 6.3 and 7.76% respectively. The gruel solid loss was found more for QPM varieties and much more for 30% incorporation levels (Table 3). It may be due to the disrupted protein and starch interaction as well as dilution of gluten protein on the addition of maize flour. The results were in good agreement with the results of Kaur et al. [47] and Arora et al. [48]. The values for gruel solid loss reported in the present study were found well within the range (5.6 to 9.1%) [53].

Color analysis

The L* value declined and a significant (p < 0.05) increase in the a* values denoting slight redness in the product was observed with an increase in the maize and QPM flour concentration from 10 to 30% as denoted in Table 3. Similar results were reported where a significant (p < 0.05) decline in L* value on the addition of 20% QPM flour (78.3 to 76.9) was observed [54]. Also, a drastic increase in b* values was observed that may be ascribed to high flavonoids, phenol content [55] and beta-carotene concentration in maize and QPM flour. Generally, consumers prefer pasta with a bright yellow color and the high value of the b* value is a desirable trait for pasta color [56]. Enrichment by maize and QPM flour improved the color of pasta and at 20 g/100 g enrichment level, HQPM 1 pasta had the most desirable color values (L* 53.65, a* 1.36 and b* 10.71). The differences in color of pasta (ΔE) denoted that all pasta samples had a different color compared to control pasta. The color difference was more prominent in PMH 1 and HQPM 1 enriched pasta that can be explained by the high phenolic, flavonoid and carotenoid content in PMH 1 and HQPM 1. Cooking led to an increase in the brightness values, a slight reduction in yellowness that accompanied by a reduction in the redness of pasta. A similar effect of increase in the brightness on cooking was reported by Surasani et al. [14].

Texture analysis

A significant (p < 0.05) decline in the firmness of cooked with an increase in enrichment level from 10 to 30% was observed. However, pasta with 20% of maize/QPM flour retained good firmness. The declined firmness on cooking may be due to the loss of continuity of gluten matrix on the incorporation of QPM/Maize flour. Similar results of gluten dilution and loss of the functional properties of dough and pasta firmness on the addition of chickpea flour were reported by Sabanis et al. [57]. Also, freeze-dried berries caused around 50% reduction in pasta firmness at 7.5 g/100 g supplementation [58]. A similar decline in firmness of pasta when added with bean flour and moringa powder [59, 60].

Sensory evaluation

Pasta prepared by incorporation of QPM/Maize flour varied significantly (p < 0.05) based on sensory evaluation as denoted in Table 4. Among all the compositions, enrichment at the rate of 20% for all the three maize varieties had the highest overall acceptability. Additionally, pasta formulated by incorporation of flour obtained from HQPM 1 variety at 20% level was most acceptable with highest acceptability index (96.99%), followed by HQPM 1708 (20%) and PMH 1 (20%). A significant (p < 0.05) difference in the appearance of the product was observed. The light yellow-golden hue in PMH 1 and HQPM 1 enriched pasta was profoundly visible. With an increase in the concentration of maize/QPM flour, a decline in compact texture and density of pasta was observed. The texture of HQPM 1 pasta at 20% incorporation levels was found more acceptable than HQPM 1708 pasta 20%. The flavor of pasta at all the enrichment levels was highly acceptable. Similar results were found by Shobha et al. [46], which denoted higher flavor scores for QPM in comparison to maize and control noodles. At levels above 20% the overall acceptability of the product declined owing to its loose texture, friability and sticky mouthfeel. It was reported that the addition of high fibre raw materials (cornmeal and brown rice) adversely affects the texture and appearance of pasta [61]. HQPM 1 pasta (20%) had an overall acceptability score of 8.7, similar to control pasta was widely accepted by panelists. A higher overall acceptability scores for QPM noodles in comparison to maize noodles [46]. Panel analysis was employed for sensory evaluation of developed pasta samples targeting the individual parameters and construction of multiple factor analysis plots on all the descriptors. PCA correlation circles for individual variables and sensory attributes of pasta prepared with various proportions of QPM/Maize and semolina were constructed. The descriptors have been mentioned as individual titles and a strong agreement between assessors was inferred from Fig. 1. Descriptors proximity map (mentioned in supplementary Table 1) defined sensory data variance with dimensional factor F1 (81.36%) and F2 (6.26%), clearly explaining the relation between individual descriptors. Also, overall acceptability, appearance and texture were found in close proximity, representing high correlation.

Scanning electron microscopy

SEM showed that the QPM had distinct polyhedral-shaped corn starch granules (Fig. 2). Similar irregular-shaped starch granules, larger than starch granules of other maize were reported in QPM [11]. Flat lens-shaped wheat starch granules in addition to polyhedral corn starch granules were observed. The results were justified by the microstructure studies that depicted the angular and polyhedral shape of corn starch, yellow and white QPM with an axial diameter of about 5–20 μm [34, 62]. Minor cracks and holes in the matrix were visible. Similar results were reported by Kim et al. [63] in rice-based, protein-enriched noodles due to the shrinkage and fluctuation in the surface tension caused due to extrusion and subsequent drying [64]. Control pasta had a smooth and even surface that may be attributed to the development of a continuous gluten network with starch granules embedded in it. On the contrary, pasta enriched with 20% of maize/QPM has a non-uniform surface and loose structure than control, which can be linked with higher gruel solid loss during cooking [65]. This might be due to the additional protein in QPM that disrupted the continuity of the gluten network resulting in the rough and uneven surface of the pasta. Findings denoted by Gupta et al. [26] in quinoa protein isolate supplemented pasta and [66] in bran enriched pasta have shown similar pieces of evidence of gluten disruption.

Scanning electron microscopic images of raw and cooked pasta at × 2000 magnification. a, e Raw and cooked durum wheat semolina pasta respectively; b–d raw pasta enriched with 20 g/100 g level of PMH 1, HQPM 1, HQPM 1708 flour respectively; f–h cooked pasta supplemented at 20 g/100 g level of PMH 1, HQPM 1 and HQPM 1708 flour respectively

Fourier transform infrared spectroscopy (FTIR)

Representative spectra of pasta samples over the wavelength of 4000 to 650 cm−1 have been illustrated in Fig. 3. The vibration type as well as the functional groups identified from the FTIR spectra of the pasta samples are summarized in Table 5. The presence of peaks at 1647.66 to 1648.7 signifying amide groups (N–H bending) and single peaks between 3500 to 3200 cm−1 corresponding to primary amines (N–H stretching) can be correlated with the protein content of pasta. Amide I (N–H bending and C–N stretching) and amide II (C=O stretching) bands related to peak 1580–1480 cm−1 and 1600–1700 cm−1 can be associated with the secondary configuration of the protein [67]. Medium peaks at 2994.4–2926.3 cm−1 were obtained denoting CH stretching related to the alkane group. Variations in peak intensity signify higher phenol content in the maize/QPM enriched pasta as compared to control pasta. Also, the peaks lying in the range 706.4 to 704.1 cm−1 representing benzene-derived aromatic rings justify the presence of the phenol group. The intensity of these peaks signifying OH stretching and benzene group was found higher denoting the presence of higher phenols and flavonoids in HQPM 1 and PMH1 enriched pasta in comparison to control and HQPM 1708 enriched pasta. Peaks at 1740.26–1742.10 cm−1 signifies C=O stretching that may be related to the presence of esters/carbonyl groups. The presence of the amine group with C–N stretching in the samples can be justified by the various peaks at 1218.99–1225.63 cm−1 wavenumber. Various bands and peaks ranging between 1006.8 and 1003.4 cm−1 denote C=C bending corresponding to the alkene group. Similar results were reported by Awolu et al. [68] where peaks at 3396.00, 2926.30, 1651.00 denoting O–H stretch, C–H stretch and C=C stretch in native QPM starch were obtained.

Transitions between various secondary structure of protein in the amide I band (1600–1700 cm−1) were observed using second derivative Gaussian deconvolution. The frequency range for β-sheet, random coils, α-helix and β-turn for were (1600–1640, 1670–1680 cm−1), (1640–1650 cm−1), (1650–1660 cm−1) and (1660–1670, 1680–1700 cm−1), respectively. The major protein fractions were characterized by β-sheet and β-turn that accounted for about 76–91% whereas the proportion of β-turns declined on incorporation of QPM flour when compared to control. The alpha helix structure was quite prominent in the pasta developed from normal maize when compared to the QPM varieties. This signifies the higher protein digestibility of the QPM based pasta in comparison to the maize pasta. Low α-helix proportion has been found strongly related with better protein digestibility [69].

Principal component analysis and dendrogram cluster analysis

Data variance (85.42%) from multivariate principal component analysis (PCA) was expressed with two dimensional factors, F1 (72.22%) and F2 (13.20%) as depicted in PCA plot (Fig. 4a). Active observations include different parameters based on which the active variables (different concentrations of QPM) were analyzed. Majority of the active observations including control were characterized by F1 factor. All the active variables were characterized by F1dimensional factor. The observations lying opposite to each other showed strong negative correlation whereas the ones in close proximity exhibited a positive correlation. All the three varietal pastas were at a significant (p < 0.05) distance from each other denoting clear differences in their techno-functional attributes. The DPPH-RSA, TFC, TPC were closely linked with the PMH1 and HQPM1 based pasta, showing clear resemblance with the above mentioned results for bioactive profile. Moreover, the decline in starch digestibility with increase in phenolic content was clearly justified by distance between their plots. The TFC and crude fiber lied exactly opposite to the in vitro starch and protein digestibility indicating the negative relationship between them.

The dendrogram was utilized for cluster analysis signifying dissimilarities between tested samples (Fig. 4b). The samples were divided into two groups/clusters and the cut-off was obtained at 120. The blue cluster included majority of the QPM based pasta formulations which possessed higher protein content and better in vitro digestibility. whereas the red clusters owned both QPM and PMH1 maize pasta samples which associated with each other due to higher bioactive profile. The control is found to be significantly (p < 0.05) associated with the pasta samples containing lower HQPM1708 concentration. Lastly, the red and blue clusters were segregated on the basis of cooking quality, blue samples showed lower gruel solid loss than the samples in red clusters.

Conclusion

Recent years have already indicated a drastic upswing in the consumption of minimally processed and enriched cold extruded products, indicating the excellent market utility of the QPM based pasta developed in this study. The pasta enriched with 20% QPM flour was found most desirable. The product has higher protein, excellent antioxidative properties, in vitro digestibility of protein and carbohydrates and a great overall acceptance among consumers. The microstructure characters studied through SEM and FTIR and correlation between several parameters using principal component analysis have clearly justified the research findings. Owing to the dynamic life style and longing need of the cheaper proteins in the world, QPM and its related convenience products including extruded products like QPM pasta came out as the one of the most ideal products for the upgrowing food processing and valorisation industry.

As concluded from this study, the enrichment of such highly consumed pasta using inexpensive protein source like QPM can serve as a piece of evidence for further researches associated with the non-conventional enrichment sources, functional foods and global nutritional security. The study reveals the techno-functional behaviour of the QPM as an ingredient in the conventional food products. Apart from the exploitation of QPM for the pasta development, the findings indicate the future potentiality of QPM for other extruded food, weaning products and fabricated grains.

References

B.M. Prasanna, S.K. Vasal, B. Kassahun, N.N. Singh, Curr. Sci. 81, 1308 (2001)

J. Ruiz-Ruiz, A. Martínez-Ayala, S. Drago, R. González, D. Betancur-Ancona, L. Chel-Guerrero, LWT Food Sci. Technol. 41, 1799 (2008)

C.S. Nyakurwa, E. Gasura, S. Mabasa, Afr. Crop Sci. J. 25, 521 (2017)

F. Hossain, K. Sarika, V. Muthusamy, R.U. Zunjare, H.S. Gupta, Quality Breeding in Field Crops (Springer, Cham, 2019), pp.217–237

M. R. Tiwari, P. B. Chapagain, M. K. Shah, and Y. K. Shrestha, Academia.Edu (2013).

A.S. Hager, E. Zannini, E.K. Arendt, Cereal Foods World 57, 225 (2012)

T. Liu, N. Hamid, K. Kantono, L. Pereira, M.M. Farouk, S.O. Knowles, Food Chem. 213, 108 (2016)

A. I.-I. J. of Technology and undefined 2016, Ijt.Oauife.Edu.Ng (2016).

N. Kaur, B. Singh, S. Sharma, J. Pharmacogn. Phytochem. 7, 38 (2018)

R. Sharma, B.N. Dar, S. Sharma, B. Singh, Int. J. Gastron. Food Sci. 23, 100300 (2021)

J. Hasjim, S. Srichuwong, M.P. Scott, J.L. Jane, J. Agric. Food Chem. 57, 2049 (2009)

S. Chillo, J.A. Monro, S. Mishra, C.J. Henry, Int. J. Food Sci. Nutr. 61, 149 (2010)

D. Shobha, U.K. Veena, P. Mahadevu, Pharma Innov. 10, 1067 (2021)

V.K. Reddy Surasani, A. Singh, A. Gupta, S. Sharma, LWT 111, 443 (2019)

W.A. Plahar, B. Onuma Okezie, C.K. Gyato, Plant Foods Hum. Nutr. 58, 1 (2003)

A.E.O. Elkhalifa, R. Bernhardt, Food Chem. 121, 387 (2010)

E.O. Elkhalifa, R. Bernhardt, J. Food Sci. Technol. 50, 186 (2013)

Dini, G.C. Tenore, A. Dini, LWT 43, 447 (2010)

P. Sharma, H.S. Gujral, Food Chem. 120, 673 (2010)

S. Žilić, A. Serpen, G. Akillioǧlu, V. Gökmen, J. Vančetović, J. Agric. Food Chem. 60, 1224 (2012)

R. Sharma, S. Sharma, B. Singh, G. Kaur, J. Nutr. Food Sci. (2018). https://doi.org/10.4172/2155-9600.1000706

S. Oladeji, C.T. Akanbi, S.O. Gbadamosi, J. Food Meas. Charact. 11, 1148 (2017)

P. Bernfeld, Methods Enzymol. 1, 149 (1955)

S. Sharma, A. Singh, B. Singh, J. Food Biochem. 43, 1 (2019)

S. Joshi, S. Sharma, R. Sharma, A. Gupta, R. Kumar, Int. J. Food Sci. (2023). https://doi.org/10.1111/ijfs.16378

A. Gupta, S. Sharma, V.K. Reddy Surasani, LWT 135, 110045 (2021)

M. Ortiz-Martinez, J.T. Otero-Pappatheodorou, S.O. Serna-Saldívar, S. García-Lara, J. Cereal Sci. 76, 85 (2017)

O.B. Ocheme, O.E. Adedeji, C.E. Chinma, C.M. Yakubu, U.H. Ajibo, Food Sci. Nutr. 6, 1173 (2018)

F.K. Amagloh, A.N. Mutukumira, L. Brough, J.L. Weber, A. Hardacre, J. Coad, SNF Swed. Nutr. Found. 57, 18717 (2013)

A. Adurotoye, J. Food Process. Technol. (2013). https://doi.org/10.4172/2157-7110.1000291

P.D. Shere, P. Sahni, A.N. Devkatte, V.N. Pawar, Nutr. Food Sci. 50, 1267 (2020)

L. Kolarič, L. Minarovičová, M. Lauková, J. Karovičová, Z. Kohajdová, J. Texture Stud. 51, 464 (2020)

A. Singh, A. Gupta, V.K.R. Surasani, S. Sharma, J. Food Meas. Charact. 15, 1317 (2021)

M. Cisse, L. Zoue, Y. Soro, R. Meganaou, S. Miamke, J. Appl. Biosci. 66, 5130 (2013)

A. Sumbo, I.A. Victor, Afr. J. Food Sci. Technol. (2014). https://doi.org/10.14303/ajfst.2014.024

Singh, O.J. McCarthy, H. Singh, Carbohydr. Polym. 64, 569 (2006)

Aguayo-Rojas, S. Mora-Rochín, E.O. Cuevas-Rodríguez, S.O. Serna-Saldivar, J.A. Gutierrez-Uribe, C. Reyes-Moreno, J. Milán-Carrillo, Plant Foods Hum. Nutr. 67, 178 (2012)

E.M. Grajales-García, P. Osorio-Díaz, I. Goñi, D. Hervert-Hernández, S.H. Guzmán-Maldonado, L.A. Bello-Pérez, Int. J. Mol. Sci. 13, 286 (2011)

G.A. Camelo-Méndez, E. Agama-Acevedo, M.M. Sanchez-Rivera, L.A. Bello-Pérez, Food Chem. 211, 281 (2016)

Singh, A. Dartois, L. Kaur, Trends Food Sci. Technol. 21, 168 (2010)

P.J. Harris, C. Tasman-Jones, L.R. Ferguson, J. Sci. Food Agric. 80, 2089 (2000)

S. Brennan, E. Samyue, Int. J. Food Prop. 7, 647 (2004)

G. Duodu, A. Nunes, I. Delgadillo, M.L. Parker, E.N.C. Mills, P.S. Belton, J.R.N. Taylor, J. Cereal Sci. 35, 161 (2002)

A. Ikujeunlola, Ijt.Oauife.Edu.Ng (2016).

T.D.C. Velickovic, D.J. Stanic-Vucinic, Compr. Rev. Food Sci. Food Saf. 17, 82 (2018)

Shobha, D. Vijayalakshmi, Puttaramnaik, K.J. Asha, J. Food Sci. Technol. 52, 8032 (2015)

G. Kaur, S. Sharma, H.P.S. Nagi, P.S. Ranote, J. Food Sci. Technol. 50, 1000 (2013)

B. Arora, S. Kamal, V.P. Sharma, J. Food Process. Preserv. 42, 1 (2018)

G. Baxter, J. Zhao, C. Blanchard, Cereal Chem. 87, 250 (2010)

G. Kaur, S. Sharma, H.P.S. Nagi, P.S. Ranote, J. Food Sci. Technol. 50, 1000 (2011)

S. Savita, K. Arshwinder, K. Gurkirat, N. Vikas, Int. J. Eng. 3, 1757 (2013)

S.Y. Shiau, A.I. Yeh, J. Cereal Sci. 33, 27 (2001)

C. Purnima, P.R. Ramasarma, P. Prabhasankar, J. Food Sci. Technol. 49, 50 (2012)

Ž Ugarčić-Hardi, M. Jukić, D.K. Komlenić, M. Sabo, J. Hardi, Czech J. Food Sci. 25, 151 (2007)

N. Kaur, B. Singh, S. Sharma, LWT 99, 291 (2019)

A. Pongpichaiudom, S. Songsermpong, J. Food Sci. Technol. 55, 2610 (2018)

Sabanis, E. Makri, G. Doxastakis, J. Sci. Food Agric. 86, 1938 (2006)

C. Bustos, C. Paesani, F. Quiroga, A.E. León, Cereal Chem. 96, 967 (2019)

J.A. Gallegos-Infante, N.E. Rocha-Guzman, R.F. Gonzalez-Laredo, L.A. Ochoa-Martínez, N. Corzo, L.A. Bello-Perez, L. Medina-Torres, L.E. Peralta-Alvarez, Food Chem. 119, 1544 (2010)

B. Simonato, R. Tolve, G. Rainero, C. Rizzi, D. Sega, G. Rocchetti, L. Lucini, G. Giuberti, J. Sci. Food Agric. 101, 1920 (2021)

M.M. da Silva, J.L.R. Ascheri, D.P.R. Ascheri, LWT 68, 698 (2016)

A.E. McPherson, T.B. Bailey, J. Jane, Cereal Chem. 77, 320 (2000)

Y. Kim, J.I. Kee, S. Lee, S.H. Yoo, Food Chem. 145, 409 (2014)

S. D’Amico, J. Mäschle, M. Jekle, S. Tömösközi, B. Langó, R. Schoenlechner, LWT 63, 391 (2015)

S. Phongthai, S. D’Amico, R. Schoenlechner, W. Homthawornchoo, S. Rawdkuen, LWT Food Sci. Technol. 80, 378 (2017)

Kaur, S. Sharma, H.P.S. Nagi, B.N. Dar, J. Food Sci. Technol. 49, 467 (2012)

J. Kong, S. Yu, Acta Biochim. Biophys. Sin. (Shanghai). 39, 549 (2007)

O.O. Awolu, J.W. Odoro, J.B. Adeloye, O.M. Lawal, J. Food Sci. 85, 3052 (2020)

S. Yasar, R. Tosun, Z. Sonmez, Meas. J. Int. Meas. Confed. 161, 107895 (2020)

Acknowledgements

Authors are thankful to ICAR, New Delhi, India for the award for Junior Research Fellowship and Punjab Agricultural University, India for necessary support. Analytical support from SAIF and CIL Labs is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that they have no conflicts of interest with respect to the work described in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sharma, S., Joshi, S., Gupta, A. et al. Influence of quality protein maize enrichment on the antioxidant, protein profile, in vitro digestibility and quality characteristics of pasta. Food Measure 17, 6236–6252 (2023). https://doi.org/10.1007/s11694-023-02063-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-023-02063-8