Abstract

The purpose of this study was to develop edible films based on chitosan that also incorporate natural extracts of tomato (T) and moringa (M). The formulated films were evaluated for their physical, optical, mechanical, barrier, and bioactive properties. The incorporation of extracts into the biopolymeric matrix with 40% glycerol significantly decreased light transmission in the UV range (especially at 400 nm) from 30 to 0%, with respect uncoated films. Moreover, the antioxidant activity of the films was increased to 41.92 mg ET/100 g film (DPPH) and 34.67 mg ET/100 g film (ABTS). The formulation 60/40-TM was applied to the fresh pork loin, and the physical, microbiological, and sensory properties of coated and uncoated samples were evaluated during storage at 4 °C for 14 days. Compared with coated films (0.892 g), uncoated films showed higher water loss on day 14 (1.132 g). The results of microbiological analyses showed no changes in the coated samples that is, there was no microbial growth on the subsequent days of storage (days 5 and 10). However, the uncoated samples showed bacterial growth of fecal coliforms (11 MPN/g) and E. coli (3 log10 CFU/g) on day 10. Sensory analysis of the samples with the treatments showed good overall acceptability with no significant difference (p ≥ 0.05). The coatings formulated with both extracts and higher concentrations of glycerol presented good material properties, making them suitable for application in pork loin; these results are promising for food preservation.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Meat is a vital component of the modern diet due to its protein, mineral, vitamin, and essential amino acids, and as a source of essential fatty acids. According to projections from the Organization for Economic Co-operation and Development (OECD) and the Food and Agriculture Organization of the United Nations (FAO), it is expected that the global supply of meat will increase to 374 million tons in 2030. Meat and meat products are perishable foods that must be handled properly to extend their shelf life [1]. Meats and meat-based foods have very low oxidative and microbial stability, which, along with other factors such as, temperature, atmospheric oxygen (O2), humidity, light, chemical factors (oxidation of lipids and pigments), and microorganisms influence the quality and shelf life of meat [2,3,4].

Consumers are now interested in purchasing preserved products made from natural materials instead of synthetic ingredients. Moreover, they are avoiding buying food packed in non-biodegradable materials. In this sense, the use of edible films and coatings is an alternative to food packaging. Edible coatings are a thin layer over the food product with properties capable of satisfying consumer demand, such as biodegradability and the incorporation of food additives (vitamins, dyes, antioxidants, and microbial agents) [5].

Edible material is developed from various types of biopolymer matrices such as polysaccharides (chitosan, pullulan, starch, alginate, cellulose, pectin, xanthan gum), proteins (collagen gelatin, gluten, casein), lipids (bee wax, paraffin wax, candelilla wax) and composite materials [6]. Chitosan is a linear polysaccharide composed of randomly distributed units of β-(1–4)-2 amino-2D-glucosamine and β-(1–4)-2-acetamido-2-D-glucosamine. Chitosan is obtained from the deacetylation of chitin, which is commonly found in the shells of invertebrates, such as crustaceans or insects, and some mushroom envelopes, green algae cell walls, and yeasts [7]. One of the applications of chitosan is its incorporation into edible films and coatings, which have potential uses in perishable foods, extending their shelf life [8]. The advantages of chitosan when in edible films and coatings are due to its film-forming, antimicrobial, and non-toxic properties, aesthetic appearance; good mechanical properties; ability to biodegrade; moreover, it is considered GRAS (Generally Recognized As Safe) by the Food and Drug Administration (FDA) [8,9,10].

The primary function of edible films and coatings is to control the transfer of O2, CO2, moisture, flavor, and aroma between food components and the external environment. They can also be used as a vehicle for many additives, such as flavors, colors, preservatives, plasticizers, surfactants, antioxidants, and antimicrobial agents [11]. The additives affect the mechanical, functional, organoleptic, and nutritional characteristics and stabilize the different components of edible films and coatings, improving the functionality, quality, and safety of packaged foods [12]. The use of antimicrobial agents can inhibit or delay the growth of pathogenic microorganisms. These components remain on the surface of the food during storage, to be released by evaporation or diffusion. The incorporation of natural antioxidants in packaging materials improves the stability of food products by reducing the levels of reactive oxygen species, which act as initiators of oxidation processes such as the deterioration of lipids [12, 13]. Several studies have evaluated the incorporation of natural active compounds in the film-forming and packaging matrices. Ones such study using Rheum ribes L. extract [11], found significant decreases in elongation at break and water vapor permeability values. In a study on propolis extract [14], microbial analysis showed that the coating had a significant inhibitory effect on bacterial growth in chicken fillets. Zein coating impregnated with ginger extract and Pimpinella anisum [3], resulted in the greatest reduction of the microbial load, as compared to the control, in bovine meat. Cinnamon, guarana, boldo-do-chile, and rosemary extract [15], presented good antioxidant properties and excellent growth inhibition of Escherichia coli and Staphylococcus aureus.

Due to its ease of use, low cost, and higher extraction efficiency due to greater diffusion, maceration extraction has risen in importance. However, for this approach, it is important to select the correct solvent. The most common solvents for extracting phenolic compounds are methanol, ethanol, or propanol and their combinations in water, acetone, and ethyl acetate. Successive extractions are also employed to obtain a greater yield of the recovered phenolic compounds from vegetable products. [16].

The tomato (Solanum lycopersicum L.) is one of the most important vegetable plants in the world. It originated in western South America and is believed to have been domesticated in Central America. Moreover, it is an important source of vitamin C, potassium, folic acid, and carotenoids, such as lycopene and β-carotene, which are responsible for the antioxidant properties of this fruit. The conjugated double bonds in their structures allow them to function as photo-protectors [17]. Total phenolic compounds (TPC), total flavonoids, and antioxidant activity in tomato fruits using ethanol as an extraction solvent have all shown significant results, representing the main water-soluble antioxidants in the fruit [18]. Zanfini’s study also demonstrated the presence of other antioxidant compounds in different tomato varieties such as lycopene and α-tocopherol [19]. Moringa (Moringa oleifera) is a plant native to India, but it is cultivated in Africa and some countries in Central and South America. The moringa´s leaves are a source of vitamin C, proteins, iron, and potassium [20]. It is rich in phenolic compounds, such as flavonoids, gallic acid, quercetin, and tannins. Some phytochemical compounds influence its antimicrobial properties, against bacteria such as Enterobacter spp, Pseudomonas aeruginosa, S. aureus, and E. coli [21].

The aim of this work was to prepare chitosan films with tomato (Solanum lycopersicum) (T) and moringa (Moringa oleifera) (M) extracts using glycerol as a plasticizer and Tween 20 as an emulsifier. The plasticized films were characterized by their physicochemical properties, and the best formulation was selected for application as a coating on fresh pork loin. The pork loin meat pieces, coated and uncoated, were evaluated for color, water loss, and microbiological properties and subjected to sensory analysis.

Materials and methods

Materials

Medium-molecular-weight chitosan (degree of deacetylation = 75–85%), glycerol, Tween®-20, Folin-Ciocalteu’s phenol reagent, 2,2-diphenyl-1-picrylhydrazyl (DPPH), 2,2’-azino-bis (3-ethylbenzothiozoline-6-sulphonic acid) (ABTS), and Trolox, were purchased from Sigma-Aldrich Chem. Comp. (St. Louis, MO, USA). Sodium carbonate, methanol, ethanol, and acetic acid were of analytical grade and purchased from FagaLab, S.A. (Hermosillo, Mexico).

Preparation of ethanolic extracts

Extracts of Moringa oleifera were obtained from leaves collected by hand in April 2019 in Merida Yucatan, Mexico. The collection and preparation procedure was reported previously by Chan-Matú et al. [10]. M. oleifera leaves were dried at 50 °C for 24 h in an air convection oven (Yamato Scientific Ltd., model DNF-411, Santa Clara, CA) and then crushed to obtain a fine powder. To prepare the tomato extract, 100 tomatoes (Solanum lycopersicum) var. “Saladette” were purchased at a local supermarket in Merida, Yucatan, Mexico; these were selected at stage 6 of ripening (red ripe). The tomatoes were selected for homogeneous size (length 6.7 ± 0.54 cm and width 5.2 ± 0.41 cm), disinfected with a solution of sodium hypochlorite (200 ppm), and crushed in a commercial blender to obtain a juice, which was filtered through a strainer. The filtered juice was dried in a convection oven at 50 °C for 36 h; then, the dried sample was manually milled to obtain flour.

Ethanolic extract of M. oleifera and tomato was obtained by the methodology proposed by Jodaini-Jafari et al. [14] with modifications. A 5 g amount of tomato flour was macerated by stirring in 100 ml ethanol–water (80:20 v/v) for 7 h under dark conditions. The extract was then stored at 4 °C for 16 h, and later vacuum filtered using Whatman™ No. 4 filter paper. The supernatant was concentrated using a rotary evaporator Büchi model R-100 (Flawil, Switzerland) at reduced pressure and 50 °C.

Film preparation

The films were prepared according to the method proposed by Chan-Matú et al. [10] with some modifications. A 1.5 g amount of chitosan was dissolved in 150 ml of acetic acid (1% v/v), and the natural extracts were added to the solution (Table 1). The concentrations of the tomato and moringa extracts were selected in a preliminary study. The solution was mixed by stirring at 300 rpm for 24 h and subsequently for 10 min at 8000 rpm, using a T25 ULTRA-TURRAX® from IKA-Works, Inc. (Wilmington, NC, USA). Then, 100 ml of the final solution was poured into square plastic containers (10 × 10 × 5 cm) and dried at 45 °C and reduced pressure (75 mm Hg) in a vacuum oven, LUZEREN® model DZF-6050 (Guadalajara, Mexico). To avoid moisture buildup, the produced films were removed from the casting surface and placed in a dark paper envelope, which were then kept in a desiccator at room temperature and 50% relative humidity.

Physical properties of films

Thickness

A digital micrometer model H-2780 (Mitutoyo America Corp., Aurora, IL) with an accuracy of 0.001 mm was used to measure the thickness of each film. At least six points on the film were measured and the analysis was performed in triplicate. Finally, the average was calculated and interpreted as the thickness of the film.

Color

The color of the films was determined according to the methodology reported by Chan-Matú et al. [10] using a Konica Minolta Corp. colorimeter model CR-400 (Osaka, Japan). The colorimeter was calibrated using a standard white plate (L = 94.1, a = 0.3155, and b = 0.3319). Color measurements were performed in duplicate in six different zones on the film surface. The color parameters measured in the CIE-Lab system were L* (lightness), a* (red-green), and b* (yellow-blue). The color difference was calculated using the following equation:

where L*, a*, and b* are the values obtained from the films with extracts, while L0, a0, and b0 are the values of the control films (films without extracts).

Light transmission and opacity

The optical properties were determined according to the methodology of Nouraddini et al. [22]. The films were cut into rectangles (1 × 4 cm), and a rectangle of each film was placed on the spectrophotometric cell. Four replicates were performed for each formulation. Light transmission through the films was measured from 200 to 800 nm, between the UV region and the visible wavelength region, using a UV–Vis spectrophotometer (Santa Clara, CA, USA). Light transmission was expressed as percent transmittance (%T).

The opacity values were determined by measuring the absorbance at 600 nm using a UV–Vis spectrophotometer and calculated by using the following equation:

where O is the opacity, Abs600 is the absorbance value at 600 nm and δ is the film thickness (mm).

Water vapor permeability (WVP)

The WVP of the films was evaluated using a modified version of ASTM reported by Chan-Matú et al. [10]. Each film was kept in a desiccator at 25 °C (with dry silica gel). A 30 ml volume of distilled water was added to the container, leaving a tiny air space between the sample and the water, to maintain the relative humidity (RH) gradient across the films. The container placed in the desiccator, and the weight was measured every 2 h until it reached 36 h. The WVTR was calculated by dividing the slope of the line by the film transfer area (0.000285 m2), and the analysis was performed in triplicate. The WVTR and WVP were calculated using the following equations:

where m is the slope (g/h), A is the transfer area of the film (0.000285 m2), Pi and Pa are the pressure values (Pa) of saturated air and at % of relative humidity, respectively. L is the thickness of the film (m).

Mechanical properties

According to the ASTM D882-18 procedure, tensile strength (TS), elongation at break (Eb), and tensile modulus (TM) were calculated using a Stable Micro System texture analyzer model TA.XT plusC (Surrey, UK). At least six rectangular (10 × 60 mm) samples were used. The samples were placed between the grips of the tensile unit; the initial grip separation was 30 mm, and the crosshead speed was set at 50 mm/s. The TM was obtained from the linear slope of the stress vs. strain graph.

The tear test was also determined according to procedure ASTM D1938. Rectangular strips of 60 × 10 mm with a 30 mm longitudinal slit were cut using a razor blade. The sample was placed between the grips of the texturometer unit; the initial grip separation was 30 mm, and the crosshead speed was set at 100 mm/min. The measurements represent an average of at least six samples.

Total phenolic content and antioxidant activity

Extracts were obtained following the methodology of Genskowsky et al. [23] with modifications. One gram of each film formulation was placed in a glass tube with a lid and 5 ml of methanol was added; subsequently, the samples were transferred to an ultrasonic bath UP200st sonicator (Hielscher USA, Inc., Wanaque, NJ) for 30 min and stored at 4 °C for 24 h. After this period, the supernatant was removed. The total phenolic content (TPC) of the extracted substances was measured, and the results were reported as milligrams of gallic acid equivalent per 100 g of the film (GAE/100 g film). Antioxidant activity was determined using the DPPH and ABTS assays according to Brand-Williams et al. [24], Müller et al. [25], and Hashemi [26].

DPPH antioxidant activity was determined using a solution of 2.5 mg of DPPH radical in 100 ml of methanol. Then, 10 μl of film extract and 140 μl of DPPH radical were mixed and allowed to stand for 30 min at room temperature in microplates. The absorbance of the DPPH assay solution at 515 nm was then measured using a UV–Vis spectrophotometer. The results were expressed as mg of Trolox equivalents per 100 g of the film (mg TE/100 g films). This assay was performed in triplicate.

ABTS antioxidant activity was determined using the ABTS radical method as follows: ABTS solution (7 mM) was mixed with 2.45 mM aqueous potassium persulfate solution at room temperature for 12 h in the dark. The resulting mixture was then diluted with ethanol to obtain an ABTS radical reaction solution with an absorbance of 0.70 ± 0.02 at 754 nm. For each sample measurement, 245 μl of ABTS radical and 5 μl of extract were mixed and allowed to stand for 5 min at room temperature in microplates, and then the absorbance of the solution was determined. The results were expressed in mg of Trolox equivalents per 100 g of films (mg TE/100 g films), this assay was performed in triplicate.

Application of edible coating on pork loin

The films with the best results for active, optical, and mechanical properties are candidates for application on pork loin, since their purpose is to delay the chemical reactions of deterioration and protect the meat from elements of the environment to which it is exposed, such as light. For the application of the coating on the meat, the methodology of Zhang et al. [27] was followed, with slight modifications. The selected edible coatings were 60/40-C (positive control) and 60/40-TM. These were applied by immersing 2 × 2 cm pieces of pork loin weighing 10 g for 10 s. The coated pieces were dried at room temperature on aluminum trays for 15 min before being covered with wax paper; the coating procedure was repeated twice. Finally, the coated samples were covered with low-density polyethylene plastic film and stored at 4 ± 1 °C until subsequent analyses on days 0, 5, 10, and 14. Four replicates per coating were performed and uncoated (UC) pieces of pork loin were also used as a negative control.

Evaluation of meat coated with edible coating

Color

Five pieces of each treatment performed on the meat were sampled, and the color parameter were measured in three different zones for each piece at 0, 5, 10, and 14 days of refrigerated storage (4 °C), using a colorimeter. The parameters measured in the CIE-Lab system have been described in Sect. “Color”.

Water loss

Water holding capacity refers to the amount of water lost, expressed in weight. At 5, 10, and 14 days of refrigerated storage, five pieces of each coated meat were removed from the trays and weighed on an analytical balance. For each sample, the results were expressed as grams of weight loss concerning its initial weight (day 0).

Microbiological analysis

Tests were performed to acquire the microbiological profiles of the meat for some microorganisms involved in meat deterioration and gastrointestinal diseases, such as E. coli 0157:H7, Salmonella, and fecal coliforms. The test method performed was NOM-210-SSA1-2014, at 0, 5, and 10 days of storage. These analyses were performed in triplicate.

Sensory analysis

Sensory evaluation was performed with 20 untrained panelists aged from 22 to 37 years, 60% men and 40% women, on samples of raw and cooked pork loin meat for each treatment. Each panelist evaluated three samples, each corresponding to a different treatment (UC, 60/40-C, and 60/40-TM) and identified by a random three-digit code. The evaluation of raw meat involves four variables (color, odor, appearance, and overall acceptability). These variables were evaluated on samples after three days of refrigerated storage using a 9-point hedonic scale (1 = extremely dislike and 9 = extremely like). The evaluation of cooked meat was performed after five days of storage. The raw meat was removed from the storage trays and cooked on a commercial George Foreman brand grill (Beachwood, OH, USA) preheated at 150 °C and until an internal meat temperature of 70 °C was reached. The evaluation of cooked meat involved five attributes (color, odor, appearance, texture, and overall acceptability), using a nine-point scale ranging from (1 = extremely dislike to 9 = extremely like).

Statistical analysis

A completely randomized experimental design was used. The parameters determined in mechanical, optical, transport, and antioxidant activity properties were subjected to a one-way analysis of variance (ANOVA). The comparison of means was performed by the Duncan test at a confidence level of 95%. The statistical calculations were performed using the statistical software STATGRAPHICS Centurion (The Plains, VA, USA). The results are presented as mean ± standard deviation.

Results and discussion

Physical characterization of films

Figure 1 shows images of the films formulated in this study. These films are homogeneous, without bubbles, and with a distinctive color due to the extracts added. The 24 h agitation period and the addition of emulsifier and plasticizer allowed homogeneous incorporation of the components. There was likely a synergistic interaction between the glycerol and the surfactant: because both compounds are of low molecular weight, they can linger between the biopolymer chains, increasing the mobility of the chitosan chains and improving the initial plastic effect [9].

Film thickness

The thickness of the films ranged from 0.048 mm to 0.105 mm (Table 2). The incorporation of tomato extract into the polymeric matrix led to a greater thickness (0.10 mm and 0.09 mm), compared to that of their respective controls (0.10 mm and 0.08 mm); this can be attributed to the higher content of solids added to the matrix. However, with the incorporation of both extracts, the opposite behavior was observed. The thickness decreased, which may be due to a lower uniformity when drying the films or to less molecular contact between the chitosan and the extracts, which may be weakening the aggregation forces of the polymer, thus making the matrix more compact [28]. Several works agree with the increase in thickness; for example, Assis et al. [29] presented similar behavior, using lycopene nanocapsules in cassava starch films.

Color

The color and appearance of food and packaging are important factors that determine consumer acceptability of a product. The incorporation of extracts decreased the L* values for all the formulations, in comparison to the films without extract (Table 2). The decrease in L* values in the films may be due to the addition of lycopene in the tomato extract, which gives it a darker appearance; likewise, the predominantly green color of the moringa extract, which directly affects the visual appearances of the films.

In the 60/40 formulations, the addition of tomato extract enhanced the parameter a* (11.26), which was significantly higher in 80/20 (20.56), indicating a shade of red in the films. When tomato and moringa extracts were incorporated, the films with 40% G exhibited an increase in a* (22.60). These results indicate that the lycopene content added through the tomato extract contributed to the reddish color of the films; this carotenoid is responsible for the red color observed in tomatoes. The values reported in this work were higher than those reported by Lopez-Palestina et al. [13] in gelatin-based films with tomato oil extract and by Assis et al. [29] in cassava starch films with lycopene nanocapsules added; such variations could be due to differences in extracts concentrations between studies. The values of the parameter b* (yellow-blue) showed an increase in the two extract formulations was higher in the films without moringa extract. This could be because there is no interference from the green extract, that is, only the presence of lycopene coming from the tomato extract contributes to the effect of such tonality since it is also responsible for the yellow and orange color. According to de Carvalho et al. [30], the presence of tomato extract (lycopene) causes an increase in this color parameter in gelatin films.

Chitosan films without extract (60/40-C and 80/20-C) were used as control films for comparison with the films with the tomato and moringa extracts added. The addition of the extracts to the chitosan films increased the color difference. The formulation with the highest ΔE was that of 60/40-TM (48.60). This behavior was observed in films of wheat starch with moringa leaf extract. The ΔE increased when a higher concentration of moringa leaf extract was added. The changes in color and ΔE were mainly due to the nature of the components mixed into the polymeric matrix, as well as the concentrations used in the formulations.

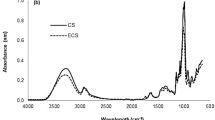

Optical properties: light transmission and opacity

Light and UV rays induce a series of chemical reactions in foods caused by free radicals; to reduce these effects, pigments can be added to the film-forming solution to protect the product from the effects of light, thus improving its optical properties. Figure 2 shows the results of spectroscopic analysis at wavelengths between 200 and 800 nm. Films without extracts allowed the highest light transmission of the analyzed samples. The incorporation of both extracts decreased the percent transmittance in the UV range (especially 400 nm); in general, all films with extracts were good barriers to light, especially those containing both extracts. These results can be attributed to the presence of natural pigments and to the fact that their components are available to act as protection, for example, the presence of large amounts of –OH groups and benzene rings in phenolic compounds and C = O groups in flavonoids [8, 10].

Due to the presence of natural pigments, the addition of the extracts increased the opacity of the films (Table 4). Moreover, this property is related to the concentration of the extracts, their interaction with the polymer, and the thickness of the film [31]. Films with a high amount of plasticizer showed lower opacity values. This is related to the properties of glycerol, as its low molecular weight can occupy the intermolecular free-volume between biopolymer chains and reduce the secondary forces between chains [32]. These results coincide with those reported by Martins et al. [33], who added α-tocopherol to chitosan films, and Assis et al. [29] who added it to cassava starch films and lycopene nanocapsules.

Transport properties

Due to the importance of water in spoilage reactions in food, knowing the barrier property, i.e., the ability of the material to be penetrated and passed through water vapor molecules through the polymeric membrane of the packaging, is key. Table 3 shows two alternative water vapor permeability (WVP) behaviors based on the amounts of chitosan and glycerol. In the films with 60% chitosan and 40% glycerol, an increase occurs with the addition of the extracts (3.41 × 10–6 and 8.70 × 10–6 g/m h Pa), possibly due to the lycopene present in the tomato extract, which could affect the hydrophilic-hydrophobic behavior of the film. It could influence the cohesive forces of the chitosan network, improving the transport of water vapor. This behavior was found in chitosan films treated with α-tocopherol (lipophilic compound), which resulted in crystalline films; normally, polymers with high crystallinity are less permeable due to their ordered structure [33]. The second behavior indicates that the addition of the extracts causes a reduction in the WVP; in this case, the tomato extract could be producing discontinuities in the hydrophilic phase that enhance the tortuosity factor for mass transfer. It reduces the WVP and the presence of covalent bonds and hydrogen interactions between the chitosan network and the polyphenolic compounds primarily found in the moringa extract, which may reduce the availability of the hydrophilic groups to form bonds and maintain interactions with water, resulting in a more water-resistant film. The addition of the extracts to chitosan films revealed that the WVP shows a similar behavior to that reported by Shen & Kandem [34] in chitosan films with essential oil of citronella, cedar, and Tween 80.

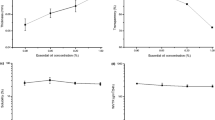

Mechanical properties of films

The mechanical behavior of a polymer is a function of its microstructure or morphology. Its morphology depends on several factors, both structural and environmental. Table 3 shows the mechanical parameters (TS, Eb, EM, and tear force) determined for the films. Like transport properties, they displayed two different behaviors. The first was an increase in the TS and EM in the 60/40 formulation with T and TM extracts, where the high content of plasticizer interacts with the emulsifier present (Tween 20) and possibly improves compatibility. Bonilla et al. [28] reported that the EM of starch and chitosan increased in the presence of α-tocopherol. The second was the maximization of TS and EM values in 80/20-C film, although the 80/20-T and 80/20-TM films showed a significant decrease (p < 0.05) in these parameters. This observation might be explained by the hydrophobic nature of lycopene, which modifies the interaction between the polymeric matrix chains, causing a decrease in the polymer–polymer interaction, i.e., weak bonds and cohesive forces, which allows the formation of discontinuities in the structure [29, 33].

The weak bonds caused by substituting the polymer with a hydrophobic compound, such as lycopene, resulted in a decrease in stiffness owing to the loss of continuity and cohesiveness of the polymeric network [13]. Bonilla & Sobral [15] reported that adding various extracts (guarana, cinnamon, rosemary, and boldo) to a biopolymeric matrix based on gelatin and chitosan decreased the EM. However, chitosan films with essential oils (basil and thyme) showed a contrary effect, the higher the amount of oil [28]. The Eb values are significantly reduced (p < 0.05) when the T and TM extracts are added to the films. The 80/20 films with and without extracts showed the lowest Eb values. Assis et al. [29] observed a similar behavior in cassava starch films with free lycopene, as did Martins et al. [33] in chitosan-based films with α-tocopherol. The addition of extracts such as T and TM to a hydrophilic chitosan matrix can modify the interaction between chains in the matrix. It reduces the polymer–polymer interaction and encourages the development of structural discontinuities, lowering the film’s TS and Eb [29, 34].

A tear test is a measure of the energy necessary to propagate of the tear, the energy absorbed by the sample to propagate a rupture that has already started. Table 3 shows a decrease in tear resistance when the extracts are added to the films, showing significant differences concerning the control films, but not among other formulations. The ranges of values were from 0.022 to 0.058 N. The films without extract presented the highest tear strength values. However, when the extracts were incorporated, a decrease in these values was observed. Chan-Matú et al. [10] observed a different behavior when different concentrations of Moringa oleifera extract was added to chitosan films with 20% and 40% glycerol, in that the tear strength values increased significantly compared to those of neat chitosan films. Anderson and Simsek [35] observed that, in films with 50% glycerol, the tear force values decreased compared to those of films with a lower concentration of plasticizer.

Active properties of films

The addition of antioxidants to the packaging prolongs the shelf life of food products by delaying or preventing oxidation caused by external agents [31]. The results of the TPC and antioxidant activity assays are shown in Table 4. The presence of both extracts increased the TPC and antioxidant activity according to the DPPH and ABTS assays; for this reason, the antioxidant properties of DPPH and ABTS also showed improvements, which was also proportional to the antioxidants added to the films. However, the film with the highest concentration of both extracts and 40% glycerol showed the highest TPC concentration. Hari et al. [36] reported the same behavior in chitosan films with starch nanocrystals loaded with β-carotene, corroborating previous studies. Chan-Matú et al. [10] observed in chitosan films with moringa extract that the concentration of glycerol increased the TPC and the antioxidant activity of the films. It is probable that the concentrations of TPC and the antioxidant activity of M. oleifera and tomato films are due to the presence of phytochemicals obtained in extractions prepared by maceration. Five flavonoids (rutin, quercetin, 3-O-glucoside, quercetin-acetyl-glycoside, kaempferol 3-O-glucoside, and kaempferol-acetyl-glycoside), compounds with antioxidant activity, have been found in the leaves of M. oleifera [37]. Regarding the tomato, several studies have shown the presence of various antioxidant compounds, including β-carotene, ascorbic acid, lycopene, tocopherols, phenolic acids, and anthocyanins, among others. Phenolic compounds in tomato are considered primary antioxidants due to their ability to donate hydrogen atoms to free radicals [38].

Evaluation of edible coatings in pork loin

According to the results of film characterization, 60/40-TM possessed the best active and mechanical properties, as they presented greater antioxidant activity and elasticity, as well as lower rigidity, and fragility. Therefore, this formulation and the 60/40-C formulation were tested on pork loin, and uncoated meat was used as the control. Both formulations used to coat the pork loin pieces were applied by immersion. The performance of coated samples was compared to that of UC samples.

Color

Pork meat is composed mainly of fatty acids, a composition that makes it a highly perishable food. For this reason, it is susceptible to physical alterations caused by chemical and biological factors, among which color is an important indicator of visual quality in fresh meat and a key determinant of consumer choice. Color is defined by the heme groups, pigments present in meat groups, especially myoglobin, which is key to meat color and is closely related to the a* value [39]. Table 5 shows the results obtained in the color analysis of meat with and without edible coatings. L* and a* values were affected from day 10, while b* values increased on day 14 and ∆E* and decreased as the days passed. In the 60/40-C coated slices, lightness was not affected during the four days of storage; however, on days 10 and 14, there was a decrease in the a* value, and an increase in the b* value; they also presented a smaller color difference. Uncoated pork tenderloin had lower L* values than the other treatments; the coating may have given the samples a shiny look. In this work, uncoated pork loin pieces showed a redder color. According to the literature, various variables influence meat color, including pH and temperature [40]. Protein denaturation and pale, soft, exudative meat (PSE) result from abnormally higher temperatures as fast pH decreases [39]. As mentioned above, chitosan was dissolved in an acidic solution, which could have been the cause of a color change in the flesh in the other treatments; however, this hue was affected earlier in uncoated samples (from day 5) than in samples coated with extracts. Zhang et al. [27] reported similar results in pork chops coated with chitosan and bamboo vinegar coatings, as did Noshad et al. [41] in buffalo meat treated with edible coatings based on Plantago major seed mucilage and Citrus limon essential oil. Likewise, the meat showed a significant increase in yellow color from day 14 onwards. In the three treatments, a decrease in a* and an increase in b* was observed during the four days of storage, due to the deterioration process, where deoxymyoglobin (purple color) and oxymyoglobin (red color) are oxidized to metmyoglobin (brown color) and, therefore, the meat takes on a less red and more yellowish color. The ΔE* was higher in the presence of the extracts, probably due to the yellowish color of the coating (Fig. 5). The ΔE* decreased significantly in the treatments as the days elapsed; possibly the darkening of the samples demonstrates a barely perceptible difference from the control (Fig. 3). Meanwhile, the addition of extracts increases the opacity of the films.

Water loss

Another of the objectives when studying edible coatings and films is to avoid surface dehydration of fresh meats, i.e., to avoid a deficient water retention capacity. The UC samples presented higher water loss on days 5 and 14, especially on day 14 (1.132 g), compared to the samples treated with the coatings (Fig. 4). The barrier characteristics of the chitosan-glycerol-based coatings (60/40-C) could be contributing to reduced water evaporation from the meat, although the WVP results of both coatings (60/40-C and 60/40-TM) showed significant differences (being higher for 60/40-C film). This was reflected in the water loss in the samples coated with the extracts, since they did not have the lowest values of water loss and did not show significant differences from the control sample. However, they contain bioactive compounds that contribute to the improvement of meat quality. Similar behavior was reported in edible coatings based on alginate and natural antioxidants (rosemary and oregano essential oils), which greatly reduced water loss in meat samples throughout all monitoring days [42]. Cardoso et al. [43] also observed a reduction in water loss for five days of storage of beef steaks with a chitosan and gelatin-based coating, proving the efficiency of the biopolymeric mixture in preserving the moisture content of the meat.

Microbiological analysis

Various microorganisms are responsible for food spoilage, especially that of perishable foods, causing organoleptic changes in the product and affecting its quality and consumption. The results of microbiological analyses indicated no changes in the coated samples during the three days of the study (0, 5, and 10 days), but the samples without the coating did show growth of fecal coliforms (11 MPN/g) and E. coli (3 CFU/g) on day 10 (Table 6). The 60/40-TM coating could be acting positively as a barrier against spoilage-causing microorganisms and increasing the shelf life of pork loin. According to the literature, chitosan and moringa have antimicrobial properties; chitosan can inhibit Gram-negative (E. coli and Pseudomonas spp.) and Gram-positive (Listeria monocytogenes) [9, 21] bacteria. Several studies demonstrate the capacity of coatings in the preservation of meat products from different biopolymeric matrices. Heydari et al. [44] found a promising effect of coatings based on Alyssum homolocarpum seed mucilage and lavender essential oil, which prolonged the shelf life of ostrich meat. On the other hand, Xiong et al. [45] reported a rapid increase in microbial growth (CFU/g) from day 5 in uncoated fresh pork samples, compared to that in pork with different coating formulations based on chitosan, gelatin, nisin, and grape seed extract.

Compounds responsible for the antimicrobial properties of moringa, such as pterygospermine, benzyl glucosinolate, and benzyl isothiocyanate, have been identified, as well as phytochemicals such as flavonoids, saponins, tannins, and other phenolic compounds [46]. Their mechanism of action is through disturbances that occur on the cell membrane, together with the action of β-lactams on cell transpeptidation; bacteria are thought to be killed by leakage of cytoplasmic contents, loss of membrane potential, changes in membrane permeability, lipid redistribution, peptide entry, and blockage of anionic cellular components or autolytic enzyme activation [47].

Sensory analysis

A summary of the sensory results (color, odor, appearance, texture, and acceptability) is shown in Figs. 5 and 6. In the raw meat, the panelists observed a significant difference between treatments in color and appearance, but not in odor. The lowest color score can be observed for treatment (60/40-TM), perhaps because the green hue of moringa is predominant (Fig. 5). These results differ from those reported by Zhang et al. [27] on pork chops coated with edible chitosan coatings with bamboo vinegar, where the score was lower in the untreated sample. All treatments presented good overall acceptability and no significant difference (p > 0.05).

In cooked meat, it was more difficult to identify the differences between samples, as shown in Fig. 6. The only significant difference was between the appearance of 60/40-TM coated samples and the UC (p < 0.05); this may be due to the presence of the extracts of T and M. Chitosan in low concentrations in extracts does not have an adverse impact on sensory characteristics. This was observed when chicken fillets were treated with chitosan films containing propolis extract: there was no significant effect on color or texture in treated samples compared to the control group [14]. Another study showed that the presence of tomato extract in coatings of chitosan applied to pork meat does not affect the sensory characteristics of the treatments; however, from day 12 these characteristics decreased significantly during refrigerated storage [48].

Conclusions

Coatings with adequate microbiological, light barrier, mechanical, optical, active, and water vapor permeability properties were obtained and formulated. Those formulated with both extracts (moringa and tomato) and higher glycerol content (60/40) were particularly effective. The results showed that when applied on pork loin, the edible coating with tomato and moringa extract allowed the qualities of this perishable food to be retained for a longer time by lowering weight loss and microbiological development. Furthermore, the meat was highly acceptable to the panelists and did not show any significant differences from the control. The results presented in this work represent a promising advance in food preservation. Additional studies could be conducted using supermarket tomatoes that are no longer acceptable to the consumer due to their high degree of ripeness. This normally wasted food could be used in the formulations of edible coatings.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

D.H. Song, V.B. Hoa, H.W. Kim, S.M. Khang, S.H. Cho, J.S. Ham, K.H. Seol, Coatings 11, 11 (2021). https://doi.org/10.3390/coatings11111344

G.H. Zhou, X.L. Xu, Y. Liu, Meat Sci. 86, 1 (2010). https://doi.org/10.1016/j.meatsci.2010.04.033

M. Sayadi, A. Mojaddar Langroodi, D. Jafarpour, J. Food Meas. Charact. 15, 5231 (2021). https://doi.org/10.1007/s11694-021-01096-1

M. Jouki, M.J. Shakouri, N. Khazaei, J. Food Meas. Charact. 15, 5485 (2021). https://doi.org/10.1007/s11694-021-01116-0

R. Ghadermazi, J. Keramat, S.A.H. Goli, J. Food Nutr. Res. 55, 22 (2016)

R. Suhag, N. Kumar, A.T. Petkoska, A. Upadhyay, Food Res. Int. 136, 109582 (2020). https://doi.org/10.1016/j.foodres.2020.109582

J.A. Jennings, Controlling chitosan degradation properties in vitro and in vivo, in Controlling chitosan degradation properties in vitro and in vivo. ed. by J.A. Jennings, J.D. Bumgardner (Woodhead Publishing, 2017), p.159

M. Bajić, T. Ročnika, A. Oberlintnera, F. Scognamigliob, U. Novaka, B. Likozar, Food Packag Shelf Life. 21, 100365 (2019). https://doi.org/10.1016/j.fpsl.2019.100365

J.R. Rodríguez-Núñez, T.J. Madera-Santana, D.I. Sánchez-Machado, J. López-Cervantes, H. Soto-Valdez, J. Polym. Environ. 22, 41 (2014). https://doi.org/10.1007/s10924-013-0621-z

D.I. Chan-Matú, V.M. Toledo-López, M.L. de Vargas y Vargas, S. Rincón-Arriaga, A. Rodríguez-Félix, T.J. Madera-Santana, J. Food Meas. Charact. 15, 4813 (2021). https://doi.org/10.1007/s11694-021-01055-w

S. Kalkan, M.R. Otag, M.S. Engin, Food Chem. 307, 125524 (2019). https://doi.org/10.1016/j.foodchem.2019.125524

A.M. Ribeiro, B.N. Estevinho, F. Rocha, Food Bioproc. Tech. 14, 209 (2020). https://doi.org/10.1007/s11947-020-02528-4

C.U. López-Palestina, C.L. Aguirre-Mancilla, J.C. Raya-Pérez, J.G. Ramirez-Pimentel, A. Vargas-Torres, A.D. Hernández-Fuentes, CYTA—J. Food. 17, 1 (2019). https://doi.org/10.1080/19476337.2018.1564793

N. Jodaini-Jafari, M. Kargozari, R. Ranjbar, H. Rostami, H. Hamedi, J. Food Process. Preserv. 42, e13336 (2018). https://doi.org/10.1111/jfpp.13336

J. Bonilla, P.J. Sobral, Food Biosci. 16, 17 (2016). https://doi.org/10.1016/j.fbio.2016.07.003

C. Tanase, S. Coșarcă, D.L. Muntean, Molecules 24, 6 (2019). https://doi.org/10.3390/molecules24061182

R. Perveen, H.A.R. Suleria, F.M. Anjum, M.S. Butt, I. Pasha, S. Ahmad, Crit. Rev. Food Sci. Nutr. 55, 7 (2015). https://doi.org/10.1080/10408398.2012.657809

S. Azabou, H. Sebii, F.B. Taheur, Y. Abid, M. Jridi, M. Nasri, Food Biosci. 36, 100664 (2020). https://doi.org/10.1016/j.fbio.2020.100664

A. Zanfini, G. Corbini, C. La Rosa, E. Dreassi, LWT—Food Sci. Technol. 43, 67 (2010). https://doi.org/10.1016/j.lwt.2009.06.011

N.M. Mgbemena, G.A. Obodo, J. Mol. Stud. Med. Res. 1, 2 (2016). https://doi.org/10.18801/jmsmr.010216.07

A. Bukar, A. Uba, T. Oyeyi, Bayern J. Pure Appl. Sci. 3, 1 (2010). https://doi.org/10.4314/bajopas.v3i1.58706

M. Nouraddini, M. Esmaiili, F. Mohtarami, Int. J. Biol. Macromol. 120, 1639 (2018). https://doi.org/10.1016/j.ijbiomac.2018.09.126

E. Genskowsky, L.A. Puente, J.A. Pérez-Álvarez, J. Fernandez-Lopez, L.A. Muñoz, M. Viuda-Martos, LWT—Food Sci. Technol. 64, 2 (2015). https://doi.org/10.1016/j.lwt.2015.07.026

W. Brand-Williams, M.E. Cuvelier, C. Berset, LWT—Food Sci. Technol. 28, 25 (1995). https://doi.org/10.1016/S0023-6438(95)80008-5

L. Müller, K. Fröhlich, V. Böhm, Food Chem. 129, 139 (2011). https://doi.org/10.1016/j.foodchem.2011.04.045

S.M.B. Hashemi, D. Jafarpour, J. Food Process. Pres. 44, e14651 (2020). https://doi.org/10.1111/jfpp.14651

H. Zhang, P. He, H. Kang, X. Li, LWT—Food Sci. Technol. 93, 470 (2018). https://doi.org/10.1016/j.lwt.2018.04.005

J. Bonilla, L. Atarés, M. Vargas, A. Chiralt, Food Hydrocoll. 26, 9 (2012). https://doi.org/10.1016/j.foodhyd.2011.03.015

R.Q. Assis, S.M. Lopes, T.M. Costa, S.H. Flores, A. Oliveira-Rios, Ind. Crops Prod. 109, 818 (2017). https://doi.org/10.1016/j.indcrop.2017.09.043

R.A. de Carvalho, C.S. Fávaro-Trindade, P.J. Sobral, In Novel technologies in food science: their impact on products, consumer trends and the environment, ed. by A. McElhatton, P.J.A. Sobral (Integrating Food Science and Engineering Knowledge Into the Food, 2012), pp. 361–380. https://doi.org/10.1007/978-1-4419-7880-6.

J.H. Li, J. Miao, J.L. Wu, S.F. Chen, Q.Q. Zhang, Food Hydrocoll. 37, 166 (2014). https://doi.org/10.1016/j.foodhyd.2013.10.015

M.G.A. Vieira, M.A. da Silva, L.O. dos Santos, M.M. Beppu, Eur. Polym. J. 47, 3 (2011). https://doi.org/10.1016/j.eurpolymj.2010.12.011

J.T. Martins, M.A. Cerqueira, A.A. Vicente, Food Hydrocoll. 27, 220 (2012). https://doi.org/10.1016/j.foodhyd.2011.06.011

Z. Shen, D.P. Kamdem, Int. J. Biol. Macromol. 74, 289 (2015). https://doi.org/10.1016/j.ijbiomac.2014.11.046

C. Anderson, S. Simsek, Food Hydrocoll. 86, 78 (2019). https://doi.org/10.1016/j.foodhyd.2018.02.016

N. Hari, S. Francis, A.G. Rajendran Nair, A.J. Nair, Foof Packag Shelf Life 16, 69 (2018). https://doi.org/10.1016/j.fpsl.2018.02.003

L. Pollini, C. Tringaniello, F. Ianni, F. Blasi, J. Manes, L. Cossignani, Antioxidants. 9, 277 (2020). https://doi.org/10.3390/antiox9040277

Y. Ali, A.A.I. Sina, S.S. Khandker, L. Neesa, E.M. Tanvir, A. Kabir, I. Khalil, S.H. Gan, Foods. 10, 1 (2020). https://doi.org/10.3390/foods10010045

Y.H.B. Kim, R.D. Warner, K. Rosenvold, Anim. Prod. Sci. 54, 4 (2014). https://doi.org/10.1071/AN13329

M. Hunt, A. King, In Meat color measurement guidelines, 1st edn. (American Meat Science Association, Champaign, 2012), pp.3–10

M. Noshad, B. Alizadeh Behbahani, H. Jooyandeh, M. Rahmati-Joneidabad, M.E. Hemmati Kaykha, M. Ghodsi Sheikhjan, Food Sci. Nutr. 9, 3 (2021). https://doi.org/10.1002/fsn3.2137

A.C.P. Vital, A. Guerrero, J.D.O. Monteschio, M.V. Valero, C.B. Carvalho, B.A. de Abreu Filho, G. Scaramal Madrona, I.N. Do Prado, PLoS ONE 11, 8 (2016). https://doi.org/10.1371/journal.pone.0160535

G.P. Cardoso, M.P. Dutra, P.R. Fontes, A.L.S. de Ramos, L.A.M. de Gomide, E.M. Ramos, Meat Sci. 114, 85 (2016). https://doi.org/10.1016/j.meatsci.2015.12.012

S. Heydari, H. Jooyandeh, B. Alizadeh Behbahani, M. Noshad, Food Sci. Nutr. 8, 12 (2020). https://doi.org/10.1002/fsn3.1940

Y. Xiong, M. Chen, R.D. Warner, Z. Fang, Food Control 110, 107018 (2020). https://doi.org/10.1016/j.foodcont.2019.107018

F. Anwar, S.L. Muhammad Ashraf, A.H. Gilani, Phytother. Res. 21, 17 (2007). https://doi.org/10.1002/ptr.2023

L. Liu, S. Chen, X. Zhang, Z. Xue, S. Cui, X. Hua, L. Cong, J. Wang. Sci. Adv. 6, 27 (2020). https://doi.org/10.1126/sciadv.abb9593

S. Chaparro-Hernández, S. Ruiz-Cruz, E. Márquez-Ríos, J.D.J. Ornelas-Paz, C.L. Del Toro-Sánchez, L.E. Gassos-Ortega, G.E. Devora-Isiordia, Coatings 9, 12 (2019). https://doi.org/10.3390/coatings9120827

Acknowledgements

MSc. Canché-López received a scholarship from The Consejo Nacional de Ciencia y Tecnología (CONACYT). The authors would like to thank MSc. Judith Fortiz-Hernandez at CIAD, A.C. for her technical assistance.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known conflict of interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Canché-López, K.C., Toledo-López, V.M., Vargas y Vargas, M. et al. Characterization of chitosan edible coatings made with natural extracts of Solanum lycopersicum and Moringa oleifera for preserving fresh pork tenderloin. Food Measure 17, 2233–2246 (2023). https://doi.org/10.1007/s11694-022-01784-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01784-6