Abstract

This study aimed to assess whether an enzyme-treated pumpkin (Cucurbita moschata Duch.) pulp (EPP) could be applied as an ingredient in bread making. The results showed that EPP treated by pectinase, cellulase, and α-amylase had increased content in reducing sugar but decreased contents in pectin, cellulose, and starch. When EPP was added into wheat flour to replace the added water by 25% or 50% (on fresh basis), the generated dough samples after yeast fermentation showed reduced dough volume but enhanced textural indices including hardness, springiness, and adhesiveness than the control dough. The EPP-supplemented bread samples showed close weight and similar composition in moisture, lipid, protein, and reducing sugar to the control bread, but had higher ash and crude fiber contents. Compared with the control bread, the EPP-supplemented bread samples also showed less baking loss, higher values in four textural indices including hardness, chewiness, springiness, and adhesiveness, lower bread volume and specific volume, and were more red and yellow. Image analysis results confirmed that EPP caused higher cell density but lower cell area and porosity in the bread samples. Interestingly, the untreated pumpkin pulp (PP) was more potent than EPP to affect these assessed indices in both dough and bread samples, while a higher PP/EPP level caused more index changes. Although EPP induced several adverse impacts on both dough and bread quality, it could be regarded a potential ingredient in bread making, because its application at lower level could enhance dietary fiber content and only had less influence on bread quality.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Pumpkin is a cultivar of the genus Cucurbita and the family Cucurbitaceae, while pumpkin varieties can be classified as Cucurbita pepo, Cucurbita moschata, Cucurbita maxima and Cucurbita mixta [1]. According to FAO statistics, more than 2796 million tons of pumpkin were produced worldwide in 2020 [2]. Generally, pumpkin contains various components like polysaccharides, proteins, vitamins, minerals, and natural pigments. The analysis results showed that these components might vary greatly in their contents. For example, pumpkin of 1 kg was reported to contain water about 790−930 g; meanwhile, pumpkin on dry basis also was measured with carbohydrate, protein, lipid, and ash contents of 43.8−533.3, 7.6−196.1, 0.4−48.1, and 5.7−13.4 g/kg, respectively [3,4,5]. The textural properties of pumpkin are revealed to be controlled by its starch content and starch property. However, pumpkin also has non-starch polysaccharides ranging from 140.0 to 312.7 g/kg on dry basis [6]. Interestingly, these non-starch pumpkin polysaccharides are regarded to have hypoglycemic, hypolipidemic, and anti-tumor effects in the body [7]. Pectin as one of the well-known non-starch polysaccharides in plant foods is mainly found in pumpkin peels [5], and was reported able to reduce blood cholesterol and plaque-forming low-density lipoprotein levels, protect the mucosal membrane of the gastrointestinal tract, and eliminate bacterial toxins and heavy metals from the body [8, 9]. Moreover, the hydrolyzed products of pectin like galacto-oligosaccharides and monosaccharide are regarded to have better healthcare function in the body; for example, they could promote the absorption and utilization of minerals, activate and promote the growth of bifidobacteria, and reduce the attachment ability of toxic substances to the advocacy [10, 11]. Pumpkin also includes cellulose as one of the non-starch polysaccharides [12]. Past results had shown that the hydrolyzed products of cellulose (e.g. soluble cello-oligosaccharide and monosaccharide) had higher anti-bacterial activity than the insoluble cellulose [13]. It thus could be expected that if an enzymatic treatment of pumpkin pulp (PP) is used purposely to degrade these polysaccharide components like starch, pectin, and cellulose, the treated PP thus might obtain property alteration and especially bioactivity change, which might enlarge its application in the processed foods. Such an investigation thus deserves attention.

In general, polysaccharide degradation can be carried out by using both acid and enzyme hydrolysis. For example, 2 mol/L HCl could hydrolyze pumpkin to enhance its anti-oxidant effect [14], while the alkaline and neutral polysaccharides could be degraded by 3 mol/L HCl at 100 °C with the aid of 100 W microwave [15]. However, acid hydrolysis is a non-specific action and more importantly may cause increased ash content due to necessary neutralization. Unlike the acid hydrolysis of polysaccharides, the enzymatic hydrolysis of polysaccharides is a specific action and thus usually used to cleave polysaccharide molecules. For example, both malto-oligosaccharides and isomalto-oligosaccharides could be prepared via the action of α-amylase on starches [16], while the pectic oligosaccharides might be obtained via applying two enzymes ViscozymeL and Glucanex200G on citrus and apple [17]. Cellobiose and other oligosaccharides could also be generated from the cellulose-rich white asparagus wastes by a cellulase preparation [18]. Thus, a treatment of plant foods with cellulase, pectinase, and α-amylase is an effective way to convert these polysaccharides into more active counterparts.

A growing body of evidence indicates that the addition of the non-grain ingredients from fruits, vegetables, and legumes into baked goods can enhance nutritional composition and more importantly alter physical properties of the fortified goods. For example, an incorporation of grape pomace significantly enhanced the anti-oxidation and total phenolic contents of the bread samples, together with changed color and texture [19]. Cao and co-authors reported that the steamed bread, in which wheat flour was substituted with potato pulp by 30−50%, had decreases in the specific volume, springiness and cohesiveness but increases in the hardness and chewiness [20]. Meanwhile, the incorporation of ginger powder into bread samples could increase total phenolic/flavonoid contents, anti-oxidant activity, and mineral contents, but did not affect sensory acceptability clearly [21]. Pumpkin also had been used as a supplement and quality improver in bread making [1, 22]. Generally, pumpkin can be rotted easily due to its higher water content, which inhibits its application in the food industry. Thus, PP with sterilization treatment is a value-added product of pumpkin, and is more applicable to the food processing because of its low cost of production and longer storage time. However, there is still a lack of relevant research about whether the enzyme-treated PP is a potential ingredient in bread making. Such potential deserves an investigation.

The aim of this study was to investigate the potential use of an enzyme-treated PP (i.e. EPP) in bread making, and to clarify whether the EPP addition had positive or negative influence on both dough and bread quality. In brief, PP was hydrolyzed with three enzyme preparations (cellulase, pectinase, and α-amylase), and then added to dough at two levels. Afterwards, the dough samples with or without PP/EPP supplementation were assessed for their fermentation and texture, while the bread samples prepared were evaluated for their physicochemical and textural characteristics.

Materials and methods

Materials and reagents

Fresh pumpkin used in this study was purchased from a local market (Harbin, China) during Mar to Jun, 2021. The wheat flour, containing respective protein, fat and carbohydrate contents of 140, 12, and 765 g/kg on dry basis (as shown in its compositional list), was provided by Xinxiang Liang Run Whole Grain Foods Co. Ltd. (Xinxiang City, Henan Province, China). The commercial yeast used in bread making was purchased from Angel Yeast Co., Ltd. (Yichang City, Hubei Province, China), while other additives or ingredients used in bread were brought from the local market (Harbin, China). The thermostable α-amylase, cellulase, and pectinase were all provided by Aladdin Biochemical Technology Co., Ltd. (Shanghai, China). All chemicals used in this study were of analytical grade.

Preparation and enzymatic treatments of PP

In this study, the preparation of PP was performed as previously described [23]. Prior to PP preparation, the inedible portion of pumpkin was removed. The left edible portion of pumpkin was thus cut into small cubes, steam-cooked with water at 100 °C for 20 min, mixed with water at a ratio of 2:1 (w/w), and then mashed into a pulp statue by a portable homogenizer (Type T25, IKA, Staufen, Germany) to generate PP, which was placed in the sealed plastic bags and stored at−20 °C before its use.

The frozen PP after thawing was treated with thermostable α-amylase at 2.5 U/g for 1 h as previously described [24], or treated with cellulase 3000 U/g for 2 h using the reference conditions [25], or treated with pectinase 20 U/g for 2 h using the reported conditions [26]. After the mentioned cellulose/pectinase treatments, PP was heated at 100 °C for 30 min to inactivate cellulase or pectinase. After the treatment of thermostable α-amylase, PP was treated with alcalase of 300 U/g at 55 °C for 30 min to destroy α-amylase and then heated at 100 °C for 30 min to inactivate alcalase. The treated PP samples were then measured for their contents in starch, cellulose, pectin, and reducing sugar after cooling. The untreated PP was used as a control in this study.

The frozen PP after thawing was treated simultaneously with both pectinase (20 U/kg) and cellulase (3000 U/g) using a temperature of 50 °C and hydrolysis time of 2 h, and then treated with thermostable α-amylase of 2.5 U/g at 95 °C for 1 h. After these treatments, the enzymes were inactivated by the alcalase addition at 55 °C for 30 min and a heat treatment at 100 °C for 30 min. After cooling, the resultant PP sample (i.e. EPP) was also measured for its contents in starch, cellulose, pectin, and reducing sugar.

Chemical measurements

The contents of moisture, ash, protein, and lipid were assayed using the respective methods of AOAC 934.01, AOAC 937.09, AOAC 984.13, and AOAC 2003.05 [27]. Pectin content was determined as previously described [28], using the carbazole spectrophotometric method and galacturonic acid as a standard. The content of crude cellulose was measured with the acidic detergent as previously described [29]. In addition, the content of reducing sugar was measured using the dinitrosalicylic acid spectrophotometric method and d-glucose as a standard [30].

Dough preparation and quality analysis

Overall, the used dough formulation consisted of 250 g wheat flour, 12 g skim milk powder, 5 g commercial yeast, 25 g hen egg, 55 g butter, 2.5 g table salt, and 100 water or water plus PP/EPP (using mass ratios of 75:25 or 50:50) (Table 1). Dough samples were generated by part of the wheat flour, water, hen egg and yeast with a flour-mixing machine for 5 min, and then fermented at 25 °C for 2 h in an electric incubator (DHP-9082, Shanghai, China) with 75% relative humidity. The rest of the ingredients were all added into the dough samples. After mixing and kneading for 10 min, the dough samples were cut into dough pieces and put into bread moulds, while some dough samples were placed in the volumetric apparatus and fermented at 25 °C for 3 h to evaluate their fermentation characteristics. The change in the dough volume was measured to reflect the change of CO2 generation briefly, which was expressed as the percentage value relative to the initial dough volume.

The prepared dough samples (10 g) were subjected to the Texture profile analysis (TPA) by a Stable Micro Systems Texturometer (Type TA.XT2i, Plus Stable Micro Systems Ltd., Surry, UK), using a 5 kg load cell, a cylindrical probe of 36 R, a double compression cycle up to 60% deformation of its original height, and a test speed of 1 mm/s. Based on the generated force–time curves, three textural indices namely hardness, springiness, and adhesiveness were calculated by using the XT.RA Dimension version 3.7 software (Stable Micro Systems Ltd., Surry, UK).

Bread making and quality analysis

As mentioned above, the rest of the dough samples were used to prepare bread samples. After a yeast fermentation of 1 h, the dough samples were placed in stainless steel containers (size 19.6 × 10.6 × 10 cm) and baked by an electric oven (Type DSL-4B, Guangzhou, China) for 40 min at 150 °C. At the end of the baking process, the bread samples were taken out of the containers and stood at 25 °C for 1 h. The bread samples were wrapped in polyethylene bags. The contents of moisture, ash, protein, and lipid were determined using the AOAC methods as mentioned before, while those of crude fiber and reducing sugar were measured using the respective acidic detergent and dinitrosalicylic acid spectrophotometric methods.

The bread samples were weighed with an AL-204 electronic balance [Mettler-Toledo (China), Shanghai, China], while their volumes were measured by the method of AACC 10-05 [31]. Specific volume and baking loss were thus calculated using the respective equations below.

The bread samples stored at 20 °C were subjected to TPA at the Texturometer to detect their textural features, using a 5 kg load cell and a cylindrical probe of 36 R. In brief, the bread samples were compressed twice until 50% deformation at a set test speed of 1 mm/s, together with a set surface trigger of 5 g and resting period of 2 s between the two cycles. Based on the generated force–time curves, four textural indices namely hardness, springiness, adhesiveness, and chewiness were estimated by the XT.RA Dimension version 3.7 software.

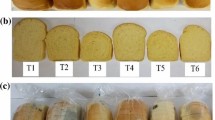

Color and microscopic assays

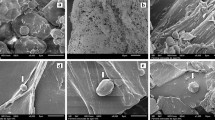

The cut bread slices (1 × 2 × 2 cm) were detected for color features using a colorimeter (Type ZE-6000, Nippon Denshoku, Osaka, Japan), to obtain the values of three parameters namely L (lightness), a (redness/greenness), and b (yellowness/blueness). Meanwhile, the microscopic features of the bread samples were characterized by assaying a bread section of 10 cm2, which was taken from the center of the slice as previously described [32]. The images were converted into 8 bits and threshold using the Ostu algorithm of the Image J software (Wayne Rasband National Institutes of Health, Bethesda, MD, USA) automatically to divide into different parts. Three indices namely cell area (S), cell number (N), and porosity were thus obtained, while cell density was calculated using the equation below.

Statistical analysis

All sample preparations or assays were conducted in triplicate, while the results were expressed as means or means ± standard deviations. The statistical analysis was performed using the One-way ANOVA followed by the Duncan’s multiple range tests with the SPSS software (version 26.0, IBM, Chicago, IL, USA), while p < 0.05 indicated significant differences among the means.

Results and discussion

Chemical changes of PP in response to the performed enzymatic treatments

The original PP and all enzyme-treated PP were detected for the resultant chemical changes. In response to these performed enzymatic treatments, the treated PP showed content alteration in pectin, cellulose, starch, and reducing sugar (Table 2). When cellulase alone was used to degrade cellulose, the treated PP showed a reduction in cellulose content (from 17.9 to 11.9 g/kg) but an increase in reducing sugar content (from 11.4 to 20.9 g/kg). When PP was treated with pectinase alone, the occurred pectin degradation resulted in decreased pectin content (from 11.8 to 10.1 g/kg) but increased reducing sugar content (from 13.7 to 16.3 g/kg) in the treated PP. If PP was hydrolyzed by the thermostable α-amylase only, the treated PP also showed reduced starch content (from 96.0 to 54.6 g/kg) with enhanced reducing sugar content (from 13.7 to 46.0 g/kg). When PP was hydrolyzed by pectinase and cellulase first and then hydrolyzed with thermostable α-amylase, the resultant EPP received a clear degradation in cellulose, pectin, and starch, causing reduced cellulose, pectin, and starch contents of 10.1, 11.9, and 71.1 g/kg, respectively, and increased reducing sugar content to 49.9 g/kg. These data demonstrated that the three enzymes converted part of the three components namely cellulose, pectin, and starch into reducing sugars. Thus, the obtained EPP had lower contents in cellulose, pectin, and starch but higher level in reducing sugars than the original PP, and then might had an impact on dough and bread samples once used as bread ingredients to substitute some water.

Cheng and co-authors had reported that when potato pulp was treated with cellulase, the content of soluble fibers increased to 31.9% as a result of the degradation of insoluble cellulose [24]. If pectinase was used to treat guava puree, the content of galacturonic acid in the juice was enhanced, especially when a longer treatment time was used [33]. It was also reported that if chestnut puree was treated with an amylase mixture, glucose was the main product generated throughout the process [34]. Moreover, when a mixture of cellulase and pectinase was applied to extract date syrup, a higher reducing sugar content was detected in the final date syrup, compared with the date syrup treated with one enzyme only [35]. The carrot matrix treated by cellulase and pectinase also had a large amount of galacturonic acid and the sugars of lower molecular weights [36]. Sharing result consistence with these mentioned studies, each of the three enzymes used in the present study could ensure the degradation of the targeted substrate and formation of reducing sugar. Furthermore, PP treatment with the three enzymes thus caused an enhanced degradation of the three substrates simultaneously in EPP. It was reasonably that EPP was higher in reducing sugar than PP. Thus, it was necessary to evaluate whether EPP possessed a poor or superior ability than PP to affect dough and bread quality, when being applied in bread making.

Effect of PP/EPP supplementation on dough properties

The dough samples with or without PP/EPP supplementation were measured for their volume increases during a fermentation period of 3 h, to reveal the fermentation characteristics of the dough samples. The results indicated that all dough samples had volume increases, and they showed 0.9- to 1.2-fold increases in dough volumes at the fermentation end (Fig. 1). In brief, the control dough showed the highest volume increase at each time point, while PP or EPP supplementation consistently caused less volume increases in the dough samples. That is, both PP and EPP caused volume decreases in the dough samples. Mostly, a higher PP/EPP supplementation (i.e. PP-50/EPP-50) resulted in more volume decreases, while EPP was weaker than PP to reduce dough volume. Why PP/EPP showed an ability to reduce dough volume was probably because they could inhibit the elongation of the dough samples. It had been observed that the addition of potato pulp to the steam bread could reduce the height of the fermented dough [20], while a substitution of wheat flour with coffee cherry pulp flour also resulted in less expanded dough volume [37]. Clearly, a diluted gluten structure, which was arisen from the supplemented potato pulp or coffee cherry pulp flour, might induce limited dough expansion [20, 37]. Thus, PP/EPP supplementation also led to reduced dough volume, especially when the unhydrolyzed PP was added into the dough samples.

Volume increase proportions of the dough samples with or without pumpkin pulp (PP) and the enzyme-treated PP (EPP) supplementation during a fermentation period of 3 h. The numbers after the symbols PP and EPP represent the replacing levels of water by PP and EPP during dough making, while different lowercase letters above the columns of the same fermentation time indicate that the one-way ANOVA of the mean values differs significantly (p < 0.05)

The TPA results (Table 3) also demonstrated that both PP and EPP had a clear effect on the three textural indices of the dough samples (p < 0.05). Regarding the control dough, 25% PP supplementation led to increased values for the three indices namely hardness, springiness and adhesiveness by about 40%, 25%, and 230%, while 50% PP usage enhanced the three indices by 80%, 110%, and 410%, respectively. Meanwhile, 25% (or 50%) EPP addition increased the values of the three indices by 17% (or 45%), 20% (or 80%), and 180% (or 290%), respectively. These data pointed out that PP/EPP supplementation led to increased values for the three textural indices; moreover, this increasing effect of PP/EPP on dough samples became more pronounced when PP/EPP was used at a higher level (i.e. 50% PP/EPP). Consistently, PP was more potent than EPP to increase the values of the indices, suggesting that the performed enzymatic hydrolysis alleviated the ability of PP to enhance the textural values for the dough samples. It was found that the hardness and adhesiveness of wheat dough would be increased accompanying the addition of carob flour [38]. A higher addition level of flaxseed meal in the wheat dough was observed to cause an increase in dough adhesiveness [39]. In another study, moreover, the wheat dough made from the blends of chayotextle flour and wheat semolina was also measured with higher values in hardness, springiness, and adhesiveness than the control ones [40]. Thus, hardness, springiness and adhesiveness of bread may be increased by adding various plant products to the dough as raw materials, as demonstrated by the results of the present study and these reported ones. Why the dough samples with PP/EPP supplementation had a firmer texture than the control one might be attributed by the interactions between the PP components and wheat flours as well as the greater water absorption in the pumpkin-wheat system. Pumpkin has insoluble dietary fibers like cellulose, hemicellulose, and lignin. When PP or EPP was incorporated into the dough samples, there was a competition for water absorption between these fibers and wheat flour components. This competition could interfere with the formation of the gluten network and thereby lead to an increase in hardness. Clearly, a higher PP/EPP supplementation meant a much incorporation of these fibers into the dough samples, therefore much increases in these textural indices were detected. In addition, compared with PP addition, EPP addition endowed the dough samples with lower hardness, springiness, and adhesiveness. This fact reflected that the performed enzymatic hydrolysis reduced both cellulose and pectin levels in EPP, and thus endowed the dough samples with less value increases in hardness, springiness and adhesiveness. Considering that PP/EPP addition led to altered textural features in the dough samples, PP/EPP addition should have a potential to affect bread quality.

Effect of PP/EPP supplementation on main compositions and textural characters of the bread samples

The main compositions of the prepared bread samples with or without PP/EPP supplementation were thus evaluated. The results (Table 4) indicated that PP/EPP at the two used levels generally had none or only a slight impact on the three indicators like moisture (383.5−391.6 g/kg), lipid (54.6−55.8 g/kg), and protein (70.7−78.7 g/kg), but enhanced the contents of ash and crude fibers (from 22.0 and 13.8 to 32.2 and 17.2 g/kg, respectively). Meanwhile, PP/EPP supplementation totally showed a trend in the bread samples to enhance reducing sugar content, because PP and EPP themselves also contained reducing sugar. Overall, PP/EPP supplementation of the wheat flour did not cause a significantly alteration on contents of these components in the bread samples. Additionally, the results listed in Table 5 also demonstrated that PP/EPP usage totally could increase the values of three textural indices of bread samples, namely hardness, chewiness, and adhesiveness. Regarding the control dough, 25% PP supplementation led to increased values for the three indices about 20%, 5%, and 30%, while 50% PP supplementation enhanced the three indices near 44%, 25%, and 180%, respectively. Meanwhile, 25−50% EPP supplementation increased the values of the three indices to about 20−35%, 3−15%, and 25−130%, respectively. When PP and EPP were used at a higher level (i.e. 50% PP/EPP), the bread samples consistently showed much enhanced values for the three indices; more importantly, PP was more potent than EPP to enhance these index values. For the fourth textural index (i.e. springiness) of the bread samples, however, PP/EPP supplementation was found without a clear impact on the value of springiness.

In the two past studies, increased pumpkin content in wheat dough was detected to cause a linear value increase for hardness and chewiness of bread samples [23], while a higher addition of pumpkin powder yielded a hardness increase in bread crumb [41]. Moreover, it was observed that the firmness, chewiness, and adhesiveness values of bread samples increased when the sunn pest-damaged wheat was added to wheat flour [42]. Usually, the factors that affect bread hardness include moisture content, degree of stomatal development, volume, and others. Pumpkin contains both soluble and insoluble fibers, which are able to absorb a lot of water [42, 43]. After replacing water with the same amount of PP/EPP, the presence of relatively high amount of carbohydrates in the form of soluble or insoluble fibers might increase water holding capacity of the dough samples and promote the formation of a stable and continuous gluten network; the bread samples thus possessed higher hardness. Generally, chewiness value depends on hardness value, thus the measured behavior of chewiness also follows a similar trend as that of hardness. Adhesiveness is the work required to overcome the attractive forces between the surface of the food and the surface of other materials that the food comes into contact with (e.g. tongue, teeth, palate, and others) [44]. When PP/EPP were added into the wheat flour at a higher level, the bonds between wheat gluten were destroyed; the bread samples thus trended to stick to the probe during the textural analysis, which led to increased adhesiveness value. It was thus observed that adhesiveness value of the assessed bread sample was enhanced when sweet pumpkin powder was added [45]. Furthermore, the two indicators namely hardness and crumbling increase can be used to evaluate bread staling [46]. In this study, PP/EPP addition induced value increases in hardness, chewiness, and adhesiveness for the bread samples, indicating that the bread samples might have a harder nature and a slower staling trend.

Effect of PP/EPP supplementation on other quality indicators of bread samples

Other quality indices of the bread samples with or without PP/EPP supplementation, including bread mass, volume, specific volume, baking loss, and color values, are listed in Table 6. All bread samples had the same weight value but different values in both bread volume and specific volume. Compared with the control bread, PP/EPP supplementation led to decreased bread volume and specific volume. In detail, 25% PP/EPP addition resulted in 5−9% and 7−8% decreases in bread volume and specific volume, while 50% PP/EPP usage caused 15−18% and 18−20% decreases in the two indices, respectively. Meanwhile, PP/EPP addition reduced baking loss by 2−3%. However, PP/EPP addition endowed the bread samples with more red and yellow color (reflected by enlarged values in the two parameters a and b) and less brightness (reflected by reduced values in the parameter L). Overall, it could be concluded that a higher addition level of PP/EPP would bring about more decreases in bread volume, specific volume, baking loss, and L value, accompanying by increased a/b values, whilst PP was more potent than EPP to impact these indices. Sharing result consistence with the present study, it was found that a substitution of wheat flour with yellow pumpkin powder or pumpkin byproducts resulted in a reduction in both bread volume and specific volume [42], or the flatbread added with quinoa flour also had significant decreases in bread volume and specific volume [47]. In usual, bread volume depends on dough expansion during the process of fermentation and baking as well as the ability of the matrix to stabilize the retained gas. The gluten network can retain the gas during final baking, whereas starches are served as filler [42]. Thus, both PP and EPP were regarded able to hamper the stretching of the thin-walled gluten cells after baking, which then resulted in volume reduction. Pumpkin is rich in β-carotene and lutein. The color of the crumb sample had a significant increase in both redness and yellowness, when a higher level of pumpkin flour was added into wheat flour [1]. Moreover, it was also reported that pumpkin flour could increase the redness and yellowness but did not affect the lightness of the crumb sample significantly [48]. The two studies thus provided partly support for the present results.

The cross-sectional views of these bread samples are presented in Fig. 2, while the image analysis results of the crumbs are listed in Table 7. Compared with the control bread, 25% PP/EPP addition caused higher cell density about 17−20% but led to respective decreases in cell area and porosity by 17−22% and 2−7%; meanwhile, 50% PP/EPP addition led to decreased cell area and porosity near 30% and 10%, and increased cell density near 27−29%. Therefore, PP/EPP supplementation was regarded to increase cell density, reduce cell area, and weaken internal grain structure; furthermore, EPP and a higher addition level totally led to more value changes for these indices. Two previous studies had shown that an incorporation of lupinus and Jatropha protein concentrates caused more compact bread structure and a decreased cell area about 3−57% [49], while the replacement of wheat flour by barley flour led to reduced cell area by 14−30% but increased cell density near 92−117% in the bread samples [50]. It was also proven that the porosity of the bread samples was decreased when a higher level of pear pomace powder or rice bran sourdough was applied [51, 52]. Thus, PP/EPP addition would decrease cell expansion during the process of fermentation and baking, and create a more compact crumb structure to yield a smaller bread volume (as the data demonstrated in Table 6). A larger cell volume of wheat bread is contributed by gluten viscoelasticity that allows cell expansion during and after fermentation and baking [50]. PP/EPP addition caused a harder dough texture, suppressed gas expansion during baking, and thus resulted in a larger number of gas cells, which might be the reason why the crumb from the PP/EPP supplemented bread samples had higher cell density than that from the control bread [53]. Collectively, it was considered that EPP used at 25% level to replace water might have less impact on these assessed quality indices. In other words, although EPP supplementation might cause some adverse impacts on both dough and bread quality, EPP also could be regarded a potential ingredient for bread making, considering it application at a lower level could bring about higher dietary fiber content.

Conclusion

The performed enzymatic hydrolysis of PP by pectinase, cellulase, and thermostable α-amylase caused partly decomposition for the targeted substrates in PP, yielding an increased content of reducing sugar. Consequently, EPP thus obtained could be used in bread making to replace water amount by 25% or 50%. In response to EPP supplementation, the dough samples showed an inhibited fermentation but enhanced textural indices, while the prepared bread samples also had enhanced textural indices, decreased bread volume and specific volume, higher cell density, and lower cell area and porosity. Moreover, EPP supplementation did not change main compositions of the bread samples significantly, but resulted in reduced baking loss, higher dietary fiber content, and deeper red/yellow color. In total, EPP was less potent than PP to impact these quality indices of the dough and bread samples. It was concluded that EPP at a lower level (i.e. 25%) could be applied as a potential ingredient in bread making to enhance the content of dietary fibers, although it also could bring about some negative impacts on bread quality.

References

T. Rakcejeva, R. Galoburda, L. Cude, E. Strautinece, Use of dried pumpkins in wheat bread production. Procedia Food Sci. 1, 441–447 (2011). https://doi.org/10.1016/j.profoo.2011.09.068

FAOSTAT. (2020), https://www.fao.org/faostat/en/#search/pumpkin

X. Men, S.I. Choi, X. Han, H.Y. Kwon, G.W. Jang, Y.E. Choi, S.M. Park, O.H. Lee, Physicochemical, nutritional and functional properties of Cucurbita moschata. Food Sci. Biotechnol. 30, 171–183 (2021). https://doi.org/10.1007/s10068-020-00835-2

J. Armesto, G. Rocchetti, B. Senzizza, M. Pateiro, F.J. Barba, R. Dominguez, L. Lucini, J.M. Lorenzo, Nutritional characterization of butternut squash (Cucurbita moschata D): Effect of variety (Ariel vs Pluto) and farming type (conventional vs organic). Food Res. Int. 132, e109052 (2020). https://doi.org/10.1016/j.foodres.2020.109052

S. El Khatib, M. Muhieddine, The Health Benefits of Foods – Current Knowledge and Further Development, 1st ed. (Rijeka, Croatia, 2020), pp.76–95.

Y.M. Bai, M.S. Zhang, S.C. Atluri, J.L. Chen, R.G. Gilbert, Relations between digestibility and structures of pumpkin starches and pectins. Food Hydrocoll. 106, e105894 (2020). https://doi.org/10.1016/j.foodhyd.2020.105894

V.K. Corrigan, P.L. Hurst, J.F. Potter, Winter squash (Cucurbita maxima) texture: sensory, chemical, and physical measures. New Zealand J. Crop Sci. 29, 111–124 (2001). https://doi.org/10.1080/01140671.2001.9514169

E.A. Guz, E.G. Novitskaya, T.K. Kalenik, L.V. Levochkina, W. Piekoszewski, The influence of vegetable puree containing carotenoids on the nutrient composition and structure of milk yogurt. Int. J. Dairy Technol. 71, 89–95 (2018). https://doi.org/10.1111/1471-0307.12392

S. Eswaran, J. Muir, W.D. Chey, Fiber and functional gastrointestinal disorders. Am. J. Gastroenterol. 108, 718–727 (2013). https://doi.org/10.1038/ajg.2013.63

L.V. Thomassen, L.K. Vigsnæs, T.R. Licht, J.D. Mikkelsen, A.S. Meyer, Maximal release of highly bifidogenic soluble dietary fibers from industrial potato pulp by minimal enzymatic treatment. Appl. Microbiol. Biotechnol. 90, 873–884 (2011). https://doi.org/10.1007/s00253-011-3092-y

J. Rhoades, K. Manderson, A. Wells, A.T. Hotchkiss, G.R. Gibson, K. Formentin, M. Beer, R.A. Rastall, Oligosaccharide-mediated inhibition of the adhesion of pathogenic Escherichia coli strains to human gut epithelial cells in vitro. J. Food Prot. 71, 2272–2277 (2008). https://doi.org/10.4315/0362-028x-71.11.2272

M. Yadav, S. Jain, R. Tomar, G.B.K.S. Prasad, H. Yadav, Medicinal and biological potential of pumpkin: an updated review. Nutr. Res. Rev. 23, 184–190 (2010). https://doi.org/10.1017/s0954422410000107

Z.G. Qian, Cellulase-assisted extraction of polysaccharides from Cucurbita moschata and their antibacterial activity. Carbohyd. Polym. 101, 432–434 (2014). https://doi.org/10.1016/j.carbpol.2013.09.071

A.X. Lu, M.G. Yu, Z.Y. Fang, B. Xiao, L. Guo, W.M. Wang, J. Li, S. Wang, Y.J. Zhang, Preparation of the controlled acid hydrolysates from pumpkin polysaccharides and their antioxidant and antidiabetic evaluation. Int. J. Bio. Macromol. 121, 261–269 (2019). https://doi.org/10.1016/j.ijbiomac.2018.09.158

H. Gao, W.C. Zhang, Z.Y. Wu, H.Y. Wang, A.L. Hui, L. Meng, P.P. Chen, Z.J. Xian, Y.W. He, H.H. Li, B. Du, H.W. Zhang, Preparation, characterization and improvement in intestinal function of polysaccharide fractions from okra. J. Funct. Foods 50, 147–157 (2018). https://doi.org/10.1016/j.jff.2018.09.035

S.I. Mussatto, I.M. Mancilha, Non-digestible oligosacharides: a review. Carbohyd. Polym. 68, 587–597 (2007). https://doi.org/10.1016/j.carbpol.2006.12.011

C. Sabater, A. Ferreira-Lazarte, A. Montilla, N. Corzo, Enzymatic production and characterization of pectic oligosaccharides derived from citrus and apple pectins: a GC-MS study using random forests and association rule learning. J. Agric. Food Chem. 67, 7435–7477 (2019). https://doi.org/10.1021/acs.jafc.9b00930

J.W. Siccama, R. Oudejans, L. Zhang, M.A. Kabel, M.A.I. Schutyser, Steering the formation of cellobiose and oligosaccharides during enzymatic hydrolysis of asparagus fibre. LWT-Food Sci. Technol. 160, e113273 (2022). https://doi.org/10.1016/j.lwt.2022.113273

R. Walker, A. Tseng, G. Cavender, A. Ross, Y.Y. Zhao, Physicochemical, nutritional, and sensory qualities of wine grape pomace fortified baked goods. J. Food Sci. 79, 1811–1822 (2015). https://doi.org/10.1111/1750-3841.12554

Y.F. Cao, F.J. Zhang, P. Guo, S. Dong, H.J. Li, Effect of wheat flour substitution with potato pulp on dough rheology, the quality of steamed bread and in starch digestibility. LWT-Food Sci. Technol. 111, 527–533 (2019). https://doi.org/10.1016/j.lwt.2019.01.034

M.M. Özcan, The effect of ginger (Zingiber officinale) powders at different concentrations on bioactive compounds, antioxidant activity, phenolic constituents, nutrients and sensory characteristics of wheat bread. Int. J. Gastrono. Food Sci. 28, e100532 (2022). https://doi.org/10.1016/j.ijgfs.2022.100532

N.M. Ptitchkina, L.V. Novokreschonova, G.V. Piskunova, E.R. Morris, Large enhancements in loaf volume and organoleptic acceptability of wheat bread by small additions of pumpkin powder: possible role of acetylated pectin in stabilising gas-cell structure. Food Hydrocoll. 12, 333–337 (1998). https://doi.org/10.1016/S0268-005X(98)00024-1

R. Różyło, U. Gawlik-Dziki, D. Dziki, A. Jakubczyk, M. Karaś, K. Różyło, Wheat bread with pumpkin (Cucurbita maxima L.) pulp as a functional food product. Food Technol. Biotechnol. 52, 430–438 (2014). https://doi.org/10.17113/ftb.52.04.14.3587

L. Cheng, X.M. Zhang, Y. Hong, Z.F. Li, C.M. Li, Z.B. Gu, Characterisation of physicochemical and functional properties of soluble dietary fibre from potato pulp obtained by enzyme-assisted extraction. Int. J. Biol. Macromol. 101, 1004–1011 (2017). https://doi.org/10.1016/j.ijbiomac.2017.03.156

S.W. Cui, Y.H. Chang, Emulsifying and structural properties of pectin enzymatically extracted from pumpkin. LWT-Food Sci. Technol. 58, 396–403 (2014). https://doi.org/10.1016/j.lwt.2014.04.012

F. Shavakhi, H.C. Boo, A. Osman, H.M. Ghazali, Effects of enzymatic liquefaction, maltodextrin concentration, and spray-dryer air inlet temperature on pumpkin powder characteristics. Food Bioprocess Technol. 5, 2837–2847 (2012). https://doi.org/10.1007/s11947-011-0686-4

AOAC, Official Methods of Analysis, 15th edn. (Arlington, Virginia 2000).

T. Bitter, H.M. Muir, A modified uronic acid carbazole reaction. Anal. Biochem. 4, 330–334 (1962). https://doi.org/10.1016/0003-2697(62)90095-7

P.J.V. Soest, Use of detergents in the analysis of fibrous feeds II: A rapid method for the determination of fiber and lignin. J. AOAC Int. 46, 829–835 (1963). https://doi.org/10.1093/jaoac/46.5.829

G.L. Miller, Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31, 426–428 (1959). https://doi.org/10.1021/ac60147a030

AACC, Approved methods of American Association of Cereal Chemists, 10th edn. (American Association of Cereal Chemists, Inc, Minnesota, 2000).

R.R. Farrera-Rebollo, M. Salgado-Cruz, J. Chanona-Pérez, G.F. Gutiérrez-López, L. Alamilla-Beltrán, L. Alamilla-Beltrán, G. Calderón-Domínguez, Evaluation of image analysis tools for characterization of sweet bread crumb structure. Food Bioprocess Tech. 5, 474–484 (2012). https://doi.org/10.1007/s11947-011-0513-y

K.A. Ninga, Z.S.C. Desobgo, S. De, E.J. Nso, Pectinase hydrolysis of guava pulp: effect on the physicochemical characteristics of its juice. Heliyon. 7, e08141 (2021). https://doi.org/10.1016/j.heliyon.2021.e08141

C. López, A. Torrado, P. Fuciños, N.P. Guerra, L. Pastrana, Enzymatic inhibition and termal inactivation in the hydrolysis of chestnut puree with an amylases mixture. Enzyme Microb. Technol. 39, 252–258 (2005). https://doi.org/10.1016/j.enzmictec.2005.10.012

F. Abbès, M.A. Bouaziz, C. Blecker, M. Masmoudi, H. Attia, S. Besbes, Date syrup: Effect of hydrolytic enzymes (pectinase/cellulase) on physico-chemical characteristics, sensory and functional properties. LWT-Food Sci. Technol. 44, 1827–1834 (2011). https://doi.org/10.1016/j.lwt.2011.03.020

H.K. Sreenath, M.D. Frey, B.J. Radola, H. Scherz, Degradation of a washed carrot preparation by cellulases and pectinases. Biotechnol. Bioeng. 26, 788–796 (1984). https://doi.org/10.1002/bit.260260725

G.A. Rosas-Sánchez, Z.J. Hernández-Estrada, M.L. Suárez-Quiroz, O. González-Ríos, P. Rayas-Duarte, Coffee cherry pulp by-product as a potential fiber source for bread production: A fundamental and empirical rheological approach. Foods 10, e742 (2021). https://doi.org/10.3390/foods10040742

M.V. Salinas, B. Carbas, C. Brites, M.C. Puppo, Influence of different carob fruit flours (Ceratonia siliqua L.) on wheat dough performance and bread quality. Food Bioprocess Technol. 8, 1561–1570 (2015). https://doi.org/10.1007/s11947-015-1527-7

P. Marpalle, S.K. Sonawane, S.S. Arya, Effect of flaxseed flour addition on physicochemical and sensory properties of functional bread. LWT-Food Sci. Technol. 58, 614–619 (2014). https://doi.org/10.1016/j.lwt.2014.04.003

L.G. Victoriano, N.G. Vera, S.S. Simental, J.P. Hernandez, A.Q. Lira, J.P. Martini, Quality properties of doughs and noodles using chayotextle (Sechiem edule) flours. Food Sci. Technol. 41, 158–166 (2021). https://doi.org/10.1590/fst.30219

A. Sadeghi, M. Ebrahimi, M. Raeisi, S. Mofidi, Improving the antioxidant capacity of bread rolls by controlled fermentation of rice bran and addition of pumpkin (Cucurbita pepo) puree. J. Food Meas. Charact. 13, 2837–2845 (2019). https://doi.org/10.1007/s11694-019-00204-6

A.H. Aljahani, Wheat-yellow pumpkin composite flour: Physico-functional, rheological, antioxidant potential and quality properties of pan and flat bread. Saudi J. Biol. Sci. 29, 3432–3439 (2022). https://doi.org/10.1016/j.sjbs.2022.02.040

E. Curti, E. Carini, A. Diantom, E. Vittadini, The use of potato fiber to improve bread physico-chemical properties during storage. Food Chem. 195, 64–70 (2015). https://doi.org/10.1016/j.foodchem.2015.03.092

R.C. Hoseney, J.O. Smewing, Instrumental measurement of stickiness of doughs and other foods. J. Texture Stud. 30, 123–136 (2007). https://doi.org/10.1111/j.1745-4603.1999.tb00206.x

J. Yoo, E. Seog, J. Lee, Quality bread as influenced by sweet pumpkin powder. J. Food Sci. Nutr. 11, 339–343 (2006). https://doi.org/10.3746/jfn.2006.11.4.339

G.J. Ahlborn, O.A. Pike, S.B. Hendrix, H.W. Hess, C.S. Huber, Sensory, mechanical, and microscopic evaluation of staling in low-protein and gluten-free bread. Cereal Chem. 82, 328–335 (2005). https://doi.org/10.1094/CC-82-0328

S.A. EI-Sohaimy, M.G. Shehata, T. Mehany, M.A. Zeitoun, Nutritional, physicochemical, and sensorial evaluation of flat bread supplemented with quinoa flour. Int. J. Food Sci. 19, e4686727 (2019). https://doi.org/10.1155/2019/4686727

A. Wahyono, A.Z. Tifania, E. Kurniawati, W.W. Kang, S.K. Chung, Physical properties and cellular structure of bread enriched with pumpkin flour. IOP Conf. Ser. 207, 1012054 (2018). https://doi.org/10.1088/1755-1315/207/1/012054

A. Totosaus, H. López, N. Güemes-Vera, Effect of lupinus (Lupinus albus) and jatropha (Jatropha curcas) protein concentrates on wheat dough texture and bread quality: optimization by D-optimal mixture design. J. Texture Stud. (2013). https://doi.org/10.1111/jtxs.12031

M.C. Robles-Ramírez, E. Ortega-Robles, R. Monterrubio-López, R. Mora-Escobedo, M.C. Beltrán-Orozco, Barley bread with improved sensory and antioxidant properties. Int. J. Gastron. Food Sci. 22, e100279 (2020). https://doi.org/10.1016/j.ijgfs.2020.100279

N. Bozdogan, E. Ormanli, S. Kumcuoglu, S. Tavman, Pear pomace powder added quinoa- based gluten-free cake formulations: effect on pasting properties, rheology, and product quality. Food Sci. Technol. 42, e39121 (2022). https://doi.org/10.1590/fst.39121

M. Ebrahimi, S.M.A. Noori, A. Sadeghi, O. Coban, J. Zanganch, S.M. Ghodsmofidi, Z. Malvandi, M. Raeisi, Application of cereal-bran sourdoughs to enhance technological functionality of white wheat bread supplemented with pumpkin (Cucurbita pepo) puree. LWT-Food Sci. Technol. 158, e113079 (2022). https://doi.org/10.1016/j.lwt.2022.113079

I. Mohammed, A.R. Ahmed, B. Senge, Dough rheology and bread quality of wheatchickpea flour blends. Ind. Crop Prod. 36, 196–202 (2012). https://doi.org/10.1016/j.indcrop.2011.09.006

Acknowledgements

This study was funded by the Scientific Research Foundation of Guangdong University of Petrochemical Technology (Project No. 2020rc026) and Start-up Research Project of Maoming Laboratory (2021TDQD002). The authors thank the anonymous reviewers for their valuable advice.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, XH., Shi, J., Zhao, JR. et al. The effect of enzyme-hydrolyzed pumpkin (Cucurbita moschata Duch.) pulp supplementation on dough and bread quality. Food Measure 17, 1783–1793 (2023). https://doi.org/10.1007/s11694-022-01757-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01757-9