Abstract

Potato pulp is a poorly utilized, high-volume co-processing product resulting from industrial potato starch manufacturing. Potato pulp mainly consists of the tuber plant cell wall material and is particularly rich in pectin, notably galactan branched rhamnogalacturonan I type pectin which has previously been shown to exhibit promising properties as dietary fiber. The objective of this study was to solubilize dietary fibers from potato pulp by a one-step minimal treatment procedure and evaluate the prebiotic potential of the fibers. Statistically designed experiments were conducted to investigate the influence of enzyme type, dosage, substrate level, incubation time, and temperature on the enzyme catalyzed solubilization to define the optimal minimal enzyme treatment for maximal fiber solubilization. The result was a method that within 1 min released 75% [weight/weight (w/w)] dry matter from 1% (w/w) potato pulp treated with 1.0% (w/w) [enzyme/substrate (E/S)] pectin lyase from Aspergillus nidulans and 1.0% (w/w) E/S polygalacturonase from Aspergillus aculeatus at pH 6.0 and 60 °C. Molecular size fractionation of the solubilized fibers revealed two major fractions: one fraction rich in galacturonic acid of 10–100 kDa indicating mainly homogalacturonan, and a fraction >100 kDa rich in galactose, presumably mainly made up of β-1,4-galactan chains of rhamnogalacturonan I. When fermented in vitro by microbial communities derived from fecal samples from three healthy human volunteers, both of the solubilized fiber fractions were more bifidogenic than fructo-oligosaccharides (FOS). Notably the fibers having molecular masses of >100 kDa selectively increased the densities of Bifidobacterium spp. and Lactobacillus spp. 2–3 times more than FOS.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Potato pulp resulting as a co-processing product from industrial potato starch production is made up of the cell walls of the potato tuber and is mainly composed of pectin, cellulose, hemicelluloses, in addition to containing residual starch (Meyer et al. 2009). The monomeric composition of destarched potato pulp indicates that the potato pulp cell wall polysaccharides are mainly composed of galactose, galacturonic acid, arabinose, and rhamnose indicating most of the cell wall material is made up of homogalacturonan and rhamnogalacturonan I with long galactan side chains (Thomassen and Meyer 2010). The fermentability of enzymatically solubilized fibers from potato pulp was studied already in 1998 in a small intervention trial in which seven healthy human volunteers consumed the potato fiber in different ways (raw, baked, etc.; Olesen et al. 1998). Consumption of the enzymatically solubilized potato fibers increased the end-expiratory H2 and delayed the oro-cecal transit time and the study therefore concluded that the soluble potato fibers were fermentable dietary fibers (Olesen et al. 1998). When rats consumed similar enzymatically solubilized fibers from potato pulp, they exhibited a significantly lower weight gain than control groups fed with cellulose fibers or insoluble potato pulp fibers (Lærke et al. 2007). In these studies, the solubilized potato fibers were mixtures of different molecular structures having different molecular masses. A first step in obtaining at least a provisional understanding, and a direction for designing the enzymatic solubilization to produce fibers exerting maximal biological benefits, would be to map the possible relationship between the solubilized polysaccharide structures and their putative biological effects by assessing the influence of the molecular size and composition on the growth of human intestinal bacteria.

Pectin can be solubilized from plant material by different enzymes which has been shown by, e.g., Ishii (1981; 1982). Previously in our lab, multicomponent plant cell wall degrading enzyme preparations were used to solubilize pectinaceous fibers from potato pulp (Meyer et al. 2009). However, the use of monocomponent enzymes for solubilization entails the possibility of targeting the enzymatic attack of the substrate, avoiding undesirable enzyme catalyzed degradation of the released fibers, and may furthermore provide knowledge about the accessibility of the pectin in the plant cell wall material. Based on the available compositional data, the soluble potato fibers may be hypothesized to be mainly made up of rhamnogalacturonan I fragments having extensive galactan side chains (Meyer et al. 2009). Pectin lyase, polygalacturonase, and presumably pectin methyl esterase would therefore be relevant enzyme candidates for solubilization of such dietary fibers from potato pulp. Hence, the hypothesis behind this study was that it should be possible to solubilize the potential galactan-rhamnogalacturonan I dietary fiber fraction from potato pulp by use of a few selected enzyme activities attacking the pectin homogalacturonan backbone, and the objective of the work was to test this hypothesis. The action of selected pectinolytic enzymes on potato pulp was examined in statistically designed experiments in which the separate and interactive effects of different reaction factors were also evaluated in order to design a minimal procedure by which the maximal amount of fiber could be released. The solubilized fibers were subsequently fractionated into two large fractions according to molecular mass and the effect of the potential dietary fibers on the composition of human intestinal bacterial ecosystems was evaluated by small scale in vitro fermentation.

Materials and methods

Chemicals

Pectin from citrus fruits, isopropanol, pullulan, polygalacturonic acid, d-galactose, l-arabinose, l-rhamnose monohydrate, d-fucose, d-mannose, d-galacturonic acid monohydrate, and vitamin K1 were purchased from Sigma-Aldrich (Steinhein, Germany). Dextran was from Pharmacia (Uppsala, Sweden) and d-xylose and d-glucose from Merck (Darmstadt, Germany). Trifluoroacetic acid was from Riedel-deHaën (Seelze, Germany), anoxic phosphate buffered saline (PBS) was from Oxoid (Greve, Denmark), FOS (DP 2–8; Orafti®P95) were obtained from Beneo-Orafti (Tienen, Belgium), and Tween80 from VWR (Darmstadt, Germany). All chemicals used were analytical grade.

Pulp and enzymes

Fresh potato pulp was supplied by Lyckeby Stärkelsen (Kristianstad, Sweden). The potato pulp was stored at −21 °C until use. The enzymes used are listed in Table 1. The pectin lyase (PL1), the polygalacturonase (PG1), and the pectin methyl esterase (PME), all from Aspergillus nidulans, were produced in fermentations essentially as described by Stratton et al. (1998). The Pichia pastoris clones transformed with the pectin lyase gene AN2569.2, the polygalacturonase gene AN4372.2, and the pectin methyl esterase gene AN3390.2 were obtained from the Fungal Genetic Stock Center as described by Bauer et al. (2005). The pectin lyase (PL2) from Aspergillus niger was supplied by Danisco (Brabrand, Denmark), and the polygalacturonase (PG2) from A. aculeatus and the Viscozyme® L preparation were from Novozymes (Bagsværd, Denmark).

Protein concentration in enzyme solutions

Protein was determined by bicinchoninic acid protein assay with bovine serum albumin as standard (Thermo Fisher Scientific, Rockford, IL).

Reducing ends

The amount of reducing ends was determined by a modified down-scaled method described by Lever (1972, 1977). In brief, 1 M bismuth, 1 M potassium sodium tartrate, and 3 M sodium hydroxide were mixed with 0.5 M sodium hydroxide and 5% [weight/volume (w/v)] 4-hydroxybenzoic acid hydrazide in 0.5 M hydrochloric acid in the ratio 1:899:100. The reagent was mixed with a sample and incubated at 70 °C for 10 min, cooled to room temperature, and the absorbance was measured at 410 nm in an Infinite200 microplate reader (Tecan, Salzburg, Austria). Data collection was controlled by the program Tecan i-control version 1.5.14.0 (Tecan). Galacturonic acid was applied as standard.

Acid hydrolysis and high-performance anion-exchange chromatography

Hydrolysis of polysaccharides and separation and quantification of the monosaccharides by high-performance anion-exchange chromatography were done as described by Thomassen and Meyer (2010).

Protein determination in fiber

The protein content was determined as total amino acid assessment after 6 M hydrochloric acid hydrolysis followed by separation by ion exchange chromatography (Barkholt and Jensen 1989).

High-performance size-exclusion chromatography

High-performance size-exclusion chromatography was performed as described by Rasmussen and Meyer (2010) with the following modifications: The mobile phase and the sample solution matrix were 0.1 M acetate buffer pH 6.0. The injected volume was 25 μl and the analysis was carried out at 30 °C. Molecular markers were pullulan standards with a mass of 1.3, 10, and 400 kDa, respectively, and dextran with a mass of 110 kDa.

Enzyme activities

Pectin lyase activity was measured on 1 g/l pectin from citrus fruits by incubating 1% (w/w) E/S in Mcilvaine buffer (mixture of 0.1 M citric acid and 0.2 M disodium hydrogen phosphate) at pH 6.0 and 60 °C. The increase in absorbance was determined at 235 nm during 4 min in an Infinite200 microplate reader (Tecan, Salzburg, Austria); the data collection was controlled by the program Tecan i-control version 1.5.14.0 (Tecan). The extinction coefficient used was 5.5 mM−1·1 -1 (Van den Broek et al. 1997). The polygalacturonase activity was measured on 2 g/l polygalacturonic acid by incubating 0.01–0.5% (w/w) E/S in Mcilvaine buffer at pH 6.0 and 60 °C. Samples were collected every minute for 5 min. The enzyme was inactivated by adding 50 mM NaOH and the amount of reducing ends was measured as described above.

Removal of starch from potato pulp

The starch was removed from the potato pulp using the rationalized one-step method described by Thomassen and Meyer (2010).

Release of fiber from potato pulp

Definition of the required enzyme activities

The statistically designed experiments were randomized, quadratic modified simplex centroid designs. The tree factors were: PL1 dose, PG1 dose, PME dose [each 0–5% (w/w) E/S] in all runs. 1% (w/w) destarched potato pulp in 0.1 M phosphate buffer pH 6.0 was preheated to 40 °C for 5 min and the enzymes added. The samples were incubated in a heating shaker (Eppendorf, Hauppauge, NY) at 750 rpm for 15 min at 40 °C followed by incubation at 100 °C for 10 min before centrifugation (15,000 × g for 10 min). The supernatant was filtered using a 0.2 μm syringe tip filter (Phenomenex, Torrance, CA) and precipitated with 70% isopropanol for 30 min at room temperature. After centrifugation (5,000 × g for 5 min) remaining liquid was removed by incubation over night at 105 °C and the dry matter determined.

Definition of the optimal experimental conditions

The experiments were randomized, quadratic central composite designs. Each design contained 26 different combinations of the five factors: dry matter [1–6% (w/w)], temperature (40–60 °C), time (1–15 min), PL1 dose [0.2–2.5% (w/w) E/S], and PG1 dose [0.2–2.5% (w/w) E/S] with three center points. Destarched potato pulp [1% (w/w)] in 0.1 M phosphate buffer pH 6.0 was preheated to 40–60 °C for 5 min, and the enzymes were added. The samples were incubated in a heating shaker at 750 rpm for 1–15 min at 40–60 °C then at 100 °C for 10 min before centrifugation (15,000 × g for 10 min). The supernatant was then filtered and the solubilized polysaccharides precipitated in isopropanol as described above.

Definition of the right enzyme combination and dose

Destarched potato pulp [1% (w/w)] was preheated at 60 °C in 0.1 M phosphate buffer pH 6.0 for 5 min. PL1, PL2, PG1, and PG2 [0–2.5% (w/w)] were added in different combinations, and the samples were incubated in a heating shaker at 750 rpm at 60 °C for 0–1 min and at 100 °C for 10 min followed by centrifugation, filtration, and precipitation as described above.

Minimal procedure on destarched or crude potato pulp

Destarched potato pulp [1% (w/w)] or crude potato pulp corresponding to 1% (w/w) destarched potato pulp was preheated at 60 °C in 0.1 M phosphate buffer pH 6.0 for 5 min. PL1 [1.0% (w/w) E/S] and PG2 [1.0% (w/w) E/S] were added and the samples were incubated at 750 rpm at 60 °C for 1, 15, 30, or 60 min and 100 °C for 10 min followed by centrifugation, filtration, and precipitation as described above. Samples where no enzyme was added were treated by incubating the samples at 60 °C for 1 min.

Solubilization of dry matter by Viscozyme® L

Destarched potato pulp [1% (w/w)] or crude potato pulp corresponding to 1% (w/w) destarched potato pulp was treated by the optimized procedure described by Meyer et al. (2009).

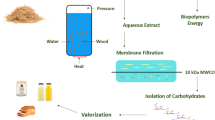

Fiber production and fractionation: 3 L process

Crude potato pulp was preheated at 60 °C in 0.1 M phosphate buffer pH 6.0 for 5 min. PL1 [1% (w/w) E/S] and PG2 [1% (w/w) E/S] was added and incubated at 60 °C for 1 min followed by heat treatment at 100 °C for 10 min. The supernatant was filtered through Celite® 545 followed by ultrafiltration. First, the supernatant was filtered using a 100 kDa polyethersulfone spiral wound ultrafiltration module (Millipore, Ballerica, MA). Then the permeate was filtered through a 10 kDa polyethersulfone spiral wound ultrafiltration module (Millipore). The ultrafiltration lead to three fractions: <10, 10–100, and <100 kDa. The fractions were concentrated and precipitated by isopropanol. The precipitated material was collected after centrifugation (2,000 × g, 15 min) and dried over night at 40 °C. The fractions were ground to <2 mm in an Ultra Centrifugal Mill ZM 200 (Retsch, Haan, Germany). The protein content, monosaccharide composition, and size distribution were analyzed as described above.

Analysis of biological activity

Subjects and fecal sampling

Fecal samples were obtained from three healthy volunteers (mean age 42.7 ± 10.0 years). None of the participants had been treated with antibiotics for at least 3 months before attendance and had no history of gastrointestinal disorder. Whole stools were collected in airtight containers, immediately stored at 4 °C, and processed within 12 h. The fresh feces samples were homogenized in 50% glycerol (1:1 dilution) in an anerobic cabinet (containing 10% H2, 10% CO2, and 80% N2) and stored at −80 °C until further analysis as described below.

In vitro fermentation

Fibers or FOS were added to an autoclaved minimal basal medium to a final concentration of 5 g (dry matter)/l in a reaction volume of 2 ml. FOS was applied as a standard with known bifidogenic effect. The minimal basal medium contained 2 g/l peptone water, 1 g/l yeast extract, 0.1 g/l NaCl (1.71 mM), 0.04 g/l (0.23 mM) K2HPO4, 0.04 g/l (0.29 mM) KH2PO4, 0.01 g/l (0.04 mM)MgSO4∙7H2O, 0.01 g/l (0.07 mM) CaCl2∙2H2O, 2 g/l (23.81 mM) NaHCO3, 0.5 g/l bile salts, 0.5 g/l l-cysteine hydrochloride, 0.005 g/l hemin, 10 μl/l vitamin K1 (0.02 mM), 2 ml/l Tween 80, and 0.05‰ (w/v) resazurin solution. A 10% (w/v) fecal slurry was prepared by mixing the feces stored in 50% glycerol with anoxic PBS. The fiber samples were sterilized by ultraviolet light for 3 min and reduced for 24 h in an anerobic cabinet. After the reduction, the samples were checked to ensure that no contamination was present. The reduced minimal medium with added fibers was inoculated to a final concentration of 1% (w/v) feces. Fermentations of each fecal sample of each healthy volunteer was done in triplicate to give 3 × 3 fermentations that were incubated at 37 °C for 24 h in an anerobic cabinet.

Extraction of bacterial DNA from fermentation samples

Deoxyribonucleic acid (DNA) was extracted from fermentation samples using the QIAamp DNA Stool mini kit (Qiagen, Hilden, Germany) with a bead beater step in advance, as previously described (Leser et al. 2000). The purified DNA was stored at −20 °C until use.

Real-time PCR assay conditions

Amplification and detection of purified bacterial DNA by real-time polymerase chain reaction (PCR) was performed with the ABI-Prism 7900 HT (Applied Biosystems, Carlsbad, CA) using optical grade 384-well plates. Each amplification reaction was done in duplicate in a final volume of 20 μl containing; 10 μl EXPRESS SYBR® GreenER™ qPCR SuperMix (Invitrogen, Taastrup, Denmark), 10 pmol of each of the primers (Eurofins MWG Synthesis, Ebersberg, Germany), 2 μl template DNA, and nuclease-free water purified for PCR. The amplification program consisted of 1 cycle at 50 °C for 2 min; 1 cycle at 95 °C for 10 min; 40 cycles at 95 °C for 15 s, 60 °C for 1 min; and finally 1 cycle of melting curve analysis for amplicon specificity at 95 °C for 15 s, 60 °C for 20 s, increasing ramp rate by 2% until 95 °C for 15 s. The 16 S rRNA primers used are listed in Table 2. Standard curves were created for each primer set using serial tenfold dilutions of bacterial DNA extracted from one of the fermentation samples with the threshold cycle (Ct) values calculated by the ABI software (SDS 2.2). The analysis of the standard curves allowed verification of PCR efficiency for the chosen PCR conditions (Table 2). The DNA level of the bacterial target groups for each reaction was calculated from the standard curves. All results were calculated relatively as ratios of species DNA levels to total bacteria expression levels in order to correct data for differences in total DNA concentration between individual samples.

Statistics

Calculation of means and standard deviations were done in Excel (Microsoft). The program used for design of the experimental templates and the evaluation of the effects and the interactions by multiple linear regression was MODDE version 7.0.0.1 (Umetrics, Umeå, Sweden). Statistical analysis of the bioactivity data was performed using GraphPad PRISM v5.03 for Windows. One-way analysis of variance (ANOVA) and Dunnett’s posthoc test were used to determine significant differences among bacteria populations using the different applied fibers compared to FOS. Differences were considered to be significant when P < 0.05. All reported data are given as average values determined after minimum duplicate determination.

Results

Enzyme concentration and activity

The activities of the pectin lyases ranged from 0.2 to 0.8 U/mg, and the activity of the two polygalacturonases were 11 and 107 U/mg, respectively, lowest for PG2, the enzyme from A. aculeatus (Table 1).

Release of fibers from potato pulp

Enzyme activities needed

The response contour plot prepared from the data indicated that it was possible to release at least 70% of the dry matter by employing only PL1 and PG1 (Fig. 1). Furthermore, the data indicated that some dry matter was released from the pulp even without addition of PL1, PG1 or PME (Fig. 1).

A response contour plot showing the amount of released dry matter from potato pulp using PL1, PG1, and PME at pH 6, 40 °C. PL1 = 1.00 means that PL1 was present in the highest dose [5% (w/w) E/S] and no other enzymes were added, and PL1 = 0.00 means that PL1 was not present and that the full dose of enzyme was split equally between PME [2.5% (w/w) E/S] and PG1 [2.5% (w/w) E/S], etc

Optimal experimental conditions

Since PME was not needed to release >70% of the dry matter from destarched potato pulp, only the temperature, dry matter, incubation time, and enzyme dose of PL1 and PG1 were varied. It was possible to release 74–75% of the dry matter using 1% (w/w) potato pulp, and 2.5% (w/w) E/S of both enzymes at 40 °C for 15 min or at 60 °C for 1 min (data not shown). The response surface plot also indicated that 70% (w/w) of the dry matter could be released from destarched potato pulp by enzymatic treatment for 1 min at 60 °C, 1% (w/w) dry matter using either of three different treatments: 2.5% (w/w) E/S PL1 and 0.2% (w/w) E/S PG1, or 0.7% (w/w) E/S PL1 and 2.5% (w/w) E/S PG1, or 1.5% (w/w) E/S of both enzymes (Fig. 2). The initial dry matter level had a significant effect on the amount of released dry matter (Fig. 3). The response surface plots indicated that to have a yield of at least 70%, the amount of dry matter should be maximum 1.3% (w/w). Multiple linear regression analysis of the data showed that an increase in PL1 and PG1 dose would significantly increase the amount of released dry matter whereas a decrease in dry matter also increased the release of dry matter (Table 3). In addition, pectin lyase and dry matter interaction had a significant effect on the amount of released dry matter.

Enzyme combination and dose

To assess the optimal procedure for release of minimum 70% (w/w) dry matter from destarched potato pulp, experiments were made using PL1, PL2, PG1, and PG2 in different doses and combinations under the conditions found above. Of the dry matter, 15% (w/w) was released during the 5 min of preheating with no enzyme present and around 41% (w/w) after additional 1 min of heating (Fig. 4a). Incubation with 0.8 and/or 1.6% (w/w) E/S PL1, PL2, PG1, or PG2 released 41–68% (w/w) dry matter (Fig. 4a).

The yield increased in response to PL1 and PG1 dosage; dry matter yield started from 59%, when 0.2% (w/w) E/S PL1 and PG1 was added and seemed to reach a maximum at 74–75% (w/w) dry matter, when 1.0% or 2.5% (w/w) of each enzyme were added (Fig. 4a).

Treatments with a combination of 0.2–0.8% (w/w) E/S PL1 and PG2 released 60–70% (w/w) of the dry matter, whereas 1.0–2.5% (w/w) E/S of PL1 and PG2 released 73–76% of the dry matter (Fig. 4b).

Similar experiments were made with PL2 + PG1 and PL2 + PG2, but the general yields obtained were lower than those obtained with PL1 + PG1 and PL1 + PG2 (data not shown).

Based on the results presented above, the best minimal procedure for releasing 75% of the dry matter was: 1.0% (w/w) E/S PL1 and 1.0% (w/w) E/S PG2 incubated with 1% (w/w) destarched potato pulp for 1 min at pH 6, 60 °C. If the objective was to use only one enzyme, it was possible to release 68% dry matter by applying 0.8% (w/w) E/S PG2 (Fig. 4a). The minimal enzyme dose for releasing 70% by weight of dry matter was 0.8% (w/w) E/S PL1 and 0.8% (w/w) E/S PG2 (Fig. 4b). It may be possible to use lower enzyme dosage, but most likely, it requires the incubation time to be extended.

Fractionation of released fibers

The minimal procedure using PL1 + PG2 was scaled up and the released fibers were fractionated into three fractions: >10, 10–100, and >100 kDa. The distribution of the dry matter in fraction 10–100 and >100 kDa was 17% and 71%, respectively. The fraction containing molecules with a mass < 10 kDa was not possible to precipitate with isopropanol and was therefore considered to be the mass not present in the two other fractions (11%).

Fiber from destarched versus from crude potato pulp

Extended treatment of crude and destarched potato pulp for up to 1 h under minimal conditions neither increase nor decrease the yield of released fibers; neither did the yield of dry matter released during extended treatment without addition of enzyme change (data not shown). Incubation of crude and destarched potato pulp with Viscozyme® L (as described by Meyer et al. 2009) released significantly less dry matter than incubation with the optimal procedure (data not shown).

Characterization of the released fibers

Monosaccharide composition of released fibers

The monosaccharide composition in the samples DNE, CNE, DPP, CPP, and CPP > 100 (Table 4) were generally similar, containing approximately 55–66% galactose, 9–10% arabinose, and 1.3–1.7% rhamnose, but with some variation in the glucose levels (Table 5). In contrast, the main component in CPP10–100 was galacturonic acid (47.7 ± 5.6%), but the rhamnose level was approximately the same as in the other fibers (1.4 ± 0.1%; Table 5). No fucose or xylose was detected in any of the fiber samples.

Molecular size of released fibers

Size exclusion chromatograms of the DNE showed that the majority of the released dry matter had a molecular mass of approximately 0.4 and 1.0 kDa (Fig. 5). A limited part of the sample was made up of molecules having a higher molecular mass. A similar chromatogram was obtained for CNE (data not shown). The chromatogram for CPP contained four main peaks: 0.4, 1.0, 4.8, and >400 kDa. A similar chromatogram was obtained for DPP (data not shown). The molecular mass of CPP10–100 was 5.4 kDa at the highest point of molecular mass distributed almost equally on each side of the chromatogram top point. Furthermore, there was a minor peak at molecular mass of around 0.4 kDa (Fig. 5). In CPP > 100, the majority of the dry matter had molecular mass > 110 kDa with maximum >400 kDa (Fig. 5).

Biological activity

After fermentation in fecal slurries obtained from three different subjects, quantitative real-time PCR was applied to measure the density of gene targets encoding 16 S rRNA of selected bacterial taxonomic units (Fig. 6). The ability of the released fibers (Table 4) to selectively stimulate the growth of the given bacterial taxa was compared to that of FOS. The fecal communities fermented on CPP > 100 had a significantly higher content of Bifidobacterium than the same fecal communities fermented on FOS (P < 0.05; Fig. 6a). A similar trend was found for the samples fermented on CPP10–100, but the difference to FOS did not reach statistical significance (P < 0.10). The Bacteroidetes 16 S rRNA gene content was significantly higher in the fecal communities fermented on CNE than those fermented on FOS (P < 0.05; Fig. 6c). There were no differences in the Lactobacillus and Firmicutes content between the fermentation samples containing the applied fibers and FOS (Fig. 6b, d, respectively).

The biological activity of the fibers on a Bifidobacterium, b Lactobacillus, c Bacteroidetes, and d Firmicutes. The bars represent the average ± SEM of triplicate fermentations. DNA amount in the fermentation samples of FOS was set to 100%. Asterisks indicate a significant difference from the fermentation samples containing FOS; *P < 0.05

Discussion

When evaluated in a tertiary mixture design using PME, PL1 and PG1, it was possible to release >70% of the dry matter from destarched potato pulp by a combination of PL1 and PG1; the combination released more dry matter than either enzyme separately (Fig. 1). This confirmed that homogalacturonan contained galacturonic acid units both with and without methyl group substitutions and that bonds between both substituted and unsubstituted galacturonic acid moieties should be hydrolyzed in order to release the fibers. PME was expected to catalyze the removal of the methyl groups, reducing the need for the pectin lyase. However, the direct effect of PL treatment was higher in this experimental setup.

Optimization of fiber release

The incubation time and temperature did not significantly change the amount of dry matter released and therefore 1 min and 60 °C was chosen as optimal (Table 3). The higher temperature was chosen to minimize the risk of microbial growth. Approximately 21–22% by weight of the crude (dry) potato pulp is starch (Thomassen and Meyer 2010). The optimization experiments were carried out on destarched potato pulp to avoid interference from starch on the enzymatic release and the in vitro fermentation. The same amount of dry matter was released from destarched and crude potato pulp by applying the minimal procedure, indicating that the remaining starch polymers in crude potato pulp were insoluble.

Release of fiber from potato pulp by Viscozyme® L

It has been shown that it is possible to release 28% by weight of dry matter from destarched potato pulp by and optimized Viscozyme® L treatment (Meyer et al. 2009). The experiment was repeated during this study, but the amount of released dry matter was insignificant as compared to the amount released by the minimal procedure. The difference might be due to the Viscozyme® preparation comprising a number of pectinolytic activities vatalyzing the degradation of the fibers to a low molecular size, not able to be precipitated by isopropanol and thereby determined by the present method.

Release of fibers from potato pulp without addition of enzyme

When destarched potato pulp was incubated at pH 6 and 60 °C for 1 min 41% by weight of the dry matter was released (Fig. 4b). A similar amount of dry matter was released from crude potato pulp (data not shown) eliminating the possibility that the enzyme used for starch removal caused the increased amount of released dry matter. The possible influence of divalent cations viz. chelation might play a role, but this hypothesis requires further experimental substantiation.

Characterization of the released fibers

The monosaccharide compositions indicated that CPP10–100 and CPP > 100 were mainly made up of homogalacturonan and rhamnogalacturonan I polysaccharides, respectively. The monosaccharide composition and size-exclusion chromatogram indicated that CPP > 100 mainly consisted of polysaccharides of homogalacturonan and rhamnogalacturonan I with large galactan side chains. This is in complete accordance with the data obtained with Viscozyme® L treatment on destarched potato pulp (Meyer et al. 2009) and the tentative conclusion that the enzymatically released high molecular weight fraction contained relatively large galactan side chains (Meyer et al. 2009).

Biological activity

The bioactivity of the released fibers (Table 5) was tested by fermentation in fecal bacterial communities obtained from three healthy human subjects. The effect of the fibers on the content of Bifidobacterium and Lactobacillus was compared to the effect of FOS. FOS was used as a standard based on its known selective effect on the content of Bifidobacterium and Lactobacillus (Palframan et al. 2002; Rycroft et al. 2001; Sanz et al. 2005). Bifidobacterium and Lactobacillus (in adults consisting of about 4% and less than 2% of the total microbiota, respectively) were included in the analysis, since they are associated with various health benefits in the colon and hence target for prebiotic treatment (Kleerebezem and Vaughan 2009). The Bacteroidetes and Firmicutes phyla were included in the qPCR analysis to study changes in the overall composition of the intestinal microbiota, which in humans is dominated by these two phyla. The balance between them is believed to play a role, e.g., in development of obesity and intestinal inflammation (Guo et al. 2008; Sokol et al. 2009; Turnbaugh et al. 2006).

The density of Bifidobacterium was higher after fermentation on four out of six applied fibers compared to FOS (Fig. 6a). The stimulation of Bifidobacterial growth by CPP > 100 was significantly higher than FOS (P < 0.05), and a similar trend was observed for CPP10–100. Additionally, CPP10–100 and CPP > 100 also stimulated the growth of Lactobacillus equally well as FOS. These results indicate that CPP10–100 and CPP > 100 have beneficial effects on the fecal microbiota composition. When considering the differences in the monosaccharide compositions of the CPP10–100 and CPP > 100 fibers, described above, the data also indicate that especially long galactan side chains and presumably also homogalacturonan could be the reason for the selective stimulation of the growth of Bifidobacterium and Lactobacillus. Van Laere et al. (2000) tested the fermentability of arabinogalactan-enriched polysaccharides from soy on pure cultures of Bifidobacterium and Lactobacillus and showed that both Bifidobacterium and Lactobacillus species were able to partly degrade these fibers. The level of Bacteroidetes was significantly higher in the microbial communities fermented on CNE than on FOS. DNE and CNE have similar monosaccharide composition as some of the other fibers but lower average molecular mass (mainly <1 kDa). Van Laere et al. (2000) showed that Bacteroides strains (belonging to the Bacteroidetes phylum) were able to degrade arabinogalactooligosaccharides which could cause the effect shown in Fig. 6c, where CNE containing mainly oligosaccharides have predominant ability to selectively increase the abundancy of the Bacteroidetes. It should be noted that the amount of dry matter added in the in vitro fermentation was the same for all fibers and since the amount of dry matter released without addition of enzymes was less than when enzymes were added, the relative amount of added starch/glucose in fermentation with CNE and DNE was higher. Pure culture experiments have been conducted in previews studies to reveal differences in the growth and degradation kinetics of specific bacteria (Olano-Martin et al. 2002; Rossi et al. 2005). However, the use of human feces as inocula, as done in this study, gives the ability to examine simultaneous effects on growth of more bacterial groups at the same time and to address selective stimulation of given bacterial taxa in the complex ecosystem constituted by the fecal population. However, one cannot draw conclusions from in vitro fermentation on the efficiency of the prebiotic capacity of the fiber fractions but the prebiotic (bifidogenic) effect must be considered as promising with regard to enzymatic released potato fiber as a prebiotic candidate.

In potato pulp galactan, the galactose units are expected to be mainly β-1,4-linked. By use of the CAZY database (Cantarel et al. 2009) different species within Bifidobacterium, Bacteroidetes, and Firmicutes were all found to contain both β-galactosidase (EC 3.2.1.23), endo-β-1,6-galactanase (EC 3.2.1.-), β-1,3-galactosidase (EC 3.2.1.145), and endo-β-1,4-galactanase (EC 3.2.1.89). Lactobacillus species contain the same enzyme activities except endo-β-1,6-galactanase (EC 3.2.1.-). The response in Fig. 6a for CPP > 100 might indicate that bifidobacteria express particularly high levels of β-galactanase activity that catalyze the degradation of β-1,4-galactan allowing the bacteria to utilize the β-1,4-galactan as a carbon source. Further research is, however, required to confirm this. In any case, the results obtained in this study indicate that the enzymatically produced β-1,4-galactan rich potato fibers, especially those with high molecular weights, may have potential as functional food ingredients with bifidogenic properties.

References

Barkholt V, Jensen AL (1989) Amino-acid analysis—determination of cysteine plus half-cystine in proteins after hydrochloric-acid hydrolysis with a disulfide compound as additive. Anal Biochem 177:318–322

Bauer S, Vasu P, Mort AJ, Somerville CR (2005) Cloning, expression, and characterization of an oligo-xyloglucan reducing end-specific xyloglucanobiohydrolase from Aspergillus nidulans. Carbohydr Res 340:2590–2597

Bauer S, Vasu P, Persson S, Mort AJ, Somerville CR (2006) Development and application of a suite of polysaccharide-degrading enzymes for analyzing plant cell walls. Proc Natl Acad Sci USA 103:11417–11422

Cantarel BL, Coutinho PM, Rancurel C, Bernard T, Lombard V, Henrissat B (2009) The carbohydrate-active enzymes database (CAZy): an expert resource for glycogenomics. Nucleic Acids Res 37:D233–D238. http://www.cazy.org/b.html. Accessed 27 September 2010

Delroisse JM, Boulvin AL, Parmentier I, Dauphin RD, Vandenbol M, Portetelle D (2008) Quantification of Bifidobacterium spp. and Lactobacillus spp. in rat fecal samples by real-time PCR. Microbiol Res 163:663–670

Denman SE, McSweeney CS (2006) Development of a real-time PCR assay for monitoring anaerobic fungal and cellulolytic bacterial populations within the rumen. FEMS Microbiol Ecol 58:572–582

Guo X, Xia X, Tang R, Zhou J, Zhao H, Wang K (2008) Development of a real-time PCR method for Firmicutes and Bacteroidetes in faeces and its application to quantify intestinal population of obese and lean pigs. Lett Appl Microbiol 47:367–373

Heilig HGHJ, Zoetendal EG, Vaughan EE, Marteau P, Akkermans ADL, de Vos WM (2002) Molecular diversity of Lactobacillus spp. and other lactic acid bacteria in the human intestine as determined by specific amplification of 16 S ribosomal DNA. Appl Environ Microbiol 68:114–123

Ishii S (1981) Isolation and characterization of cell-wall pectic substances from potato-tuber. Phytochemistry 20:2329–2333

Ishii S (1982) Enzymatic extraction and linkage analysis of pectic polysaccharides from onion. Phytochemistry 21:778–780

Kleerebezem M, Vaughan EE (2009) Probiotic and gut Lactobacilli and Bifidobacteria: molecular approaches to study diversity and activity. Annu Rev Microbiol 63:269–290

Lærke HN, Meyer AS, Kaack KV, Larsen T (2007) Soluble fiber extracted from potato pulp is highly fermentable but has no effect on risk markers of diabetes and cardiovascular disease in Goto-Kakizaki rats. Nutr Res 27:152–160

Leser TD, Lindecrona RH, Jensen TK, Jensen BB, Moller K (2000) Changes in bacterial community structure in the colon of pigs fed different experimental diets and after infection with Brachyspira hyodysenteriae. Appl Environ Microbiol 66:3290–3296

Lever M (1972) New reaction for colorimetric determination of carbohydrates. Anal Biochem 47:273–279

Lever M (1977) Carbohydrate determination with 4-hydroxybenzoic acid hydrazide (Pahbah)—effect of bismuth on reaction. Anal Biochem 81:21–27

Limberg G, Korner R, Buchholt HC, Christensen TMIE, Roepstorff P, Mikkelsen JD (2000) Analysis of pectin structure part 1—analysis of different de-esterification mechanisms for pectin by enzymatic fingerprinting using endopectin lyase and endopolygalacturonase II from A. niger. Carbohydr Res 327:293–307

Meyer AS, Dam BR, Laerke HN (2009) Enzymatic solubilization of a pectinaceous dietary fiber fraction from potato pulp: optimization of the fiber extraction process. Biochem Eng J 43:106–112

Olano-Martin E, Gibson GR, Rastall RA (2002) Comparison of the in vitro bifidogenic properties of pectins and pectic-oligosaccharides. J Appl Microbiol 93:505–511

Olesen M, Gudmand-Hoyer E, Norsker M, Kofod L, Adler-Nissen J (1998) Fermentability of an enzymatically modified solubilised potato polysaccharide (SPP). Eur J Clin Nutr 52:110–114

Palframan RJ, Gibson GR, Rastall RA (2002) Effect of pH and dose on the growth of gut bacteria on prebiotic carbohydrates in vitro. Anaerobe 8:287–292

Rasmussen LE, Meyer AS (2010) Size exclusion chromatography for the quantitative profiling of the enzyme-catalyzed hydrolysis of xylo-oligosaccharides. J Agric Food Chem 58:762–769

Rossi M, Corradini C, Amaretti A, Nicolini M, Pompei A, Zanoni S, Matteuzzi D (2005) Fermentation of fructooligosaccharides and inulin by bifidobacteria: a comparative study of pure and fecal cultures. Appl Environ Microbiol 71:6150–6158

Rycroft CE, Jones MR, Gibson GR, Rastall RA (2001) A comparative in vitro evaluation of the fermentation properties of prebiotic oligosaccharides. J Appl Microbiol 91:878–887

Sanz ML, Gibson GR, Rastall RA (2005) Influence of disaccharide structure on prebiotic selectivity in vitro. J Agric Food Chem 53:5192–5199

Sokol H, Seksik P, Furet JP, Firmesse O, Nion-Larmurier L, Beaugerie L, Cosnes J, Corthier G, Marteau P, Dore J (2009) Low counts of Faecalibacterium prausnitzii in colitis microbiota. Inflamm Bowel Dis 15:1183–1189

Stratton J, Chiruvolu V, Meagher M (1998) High cell-density fermentation. In: Pichia protocols, 103rd edn. Humana Press, Totowa, NJ, pp 107–120

Thomassen LV, Meyer AS (2010) Statistically designed optimisation of enzyme catalysed starch removal from potato pulp. Enzyme Microb Technol 46:297–303

Turnbaugh PJ, Ley RE, Mahowald MA, Magrini V, Mardis ER, Gordon JI (2006) An obesity-associated gut microbiome with increased capacity for energy harvest. Nature 444:1027–1031

Van den Broek LAM, denAantrekker ED, Voragen AGJ, Beldman G, Vincken JP (1997) Pectin lyase is a key enzyme in the maceration of potato tuber. J Sci Food Agric 75:167–172

Van Laere KMJ, Hartemink R, Bosveld M, Schols HA, Voragen AGJ (2000) Fermentation of plant cell wall derived polysaccharides and their corresponding oligosaccharides by intestinal bacteria. J Agric Food Chem 48:1644–1652

Walter J, Tannock GW, Tilsala-Timisjarvi A, Rodtong S, Loach DM, Munro K, Alatossava T (2000) Detection and identification of gastrointestinal Lactobacillus species by using denaturing gradient gel electrophoresis and species-specific PCR primers. Appl Environ Microbiol 66:297–303

Acknowledgments

We thank the employees at Gums and Systems Development, Danisco (Brabrand, Denmark) for the help and supervision during upscaling the dietary fiber release procedure. The authors would like to acknowledge Fungal Genetic Stock Center for the Pichia pastoris clone expressing the pectin lyase gene AN2569.2, the polygalacturonase gene AN4372.2, and the pectin methyl esterase gene AN3390.2 and Lyckeby Stärkelsen (Kristianstad, Sweden) for supplying the potato pulp. This study was supported by the Danish Strategic Research Council’s Committee on Food and Health (FøSu, Center for Biological Production of Dietary Fibres and Prebiotics, no. 2101-06-0067). Financial support from the FOOD Denmark Graduate School, Center for Advanced Food Studies, Denmark, is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thomassen, L.V., Vigsnæs, L.K., Licht, T.R. et al. Maximal release of highly bifidogenic soluble dietary fibers from industrial potato pulp by minimal enzymatic treatment. Appl Microbiol Biotechnol 90, 873–884 (2011). https://doi.org/10.1007/s00253-011-3092-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-011-3092-y