Abstract

Pineapple juice clarification was performed by a continuous dead-end microfiltration process with low-cost ceramic membranes (M1-M3). Membranes were characterized using thermogravimetric analysis (TGA), X-ray diffraction (XRD), particle size distribution (PSD), and scanning electron microscopy (SEM). Membranes were observed to have contact angle (34-42o), membranes porosity (56 − 48%), average pore size (0.87 − 0.56 μm), water permeability (3.00 × 10− 6 − 1.07 × 10− 6 m3/m2skPa), and corrosion resistance (1-1.2% weight loss) that are significant to be employed for juice clarification. Based on the comparative evaluations, membrane M3 was determined to be the best solution for juice clarification. The juice pH and total dissolved solids (TDS) remained unchanged during clarification, indicating that the membrane produced was promising. However, acidity density, total soluble solids (TSS), and vitamin C levels were reduced from 0.3072 ± 0.06–0.3063 ± 0.05%, 1.04 ± 0.08 to 0.94 ± 0.07 g/mL, 7.9 ± 0.08 to 6 ± 0.05oBrix, and 38.4 ± 0.02 to 36.6 ± 0.9 mg/100 mL, respectively. Also, minor changes in colour, and non–enzymatic browning index (NEBI) were observed. Total phenolic content, total flavonoid content, and antioxidant activity were dropped from 27.9 ± 0.83–76.92 ± 1.30 mg GAE/g, 79.23 ± 1.37– 24 ± 0.62 mg RE/g, and 85.52 ± 1.56–75.34 ± 1.26%, respectively. At a pressure of 345 kPa, the membrane provided a maximum permeate flux of 1.82 × 10− 4 m3/m2s. The cake filtration model depicts the relevant fouling mechanism, which is reversible and the membrane may be readily cleaned. As a result, a membrane made from low-cost raw materials is recommended for the microfiltration of pineapple juice without enzymatic treatment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The membranes have received massive attention in juice clarification applications for the past few decades [1]. Employing membranes, the organoleptic quality of the juice can be completely retained because membrane separation is a non-thermal process. Furthermore, membranes save energy, improve aroma retention, reduce thermal damage, and use less equipment [2]. Moreover, membrane microfiltration (MF) of fruit juice removes microbial content from the juice (hence disinfection), which is the primary aim of the preservation process [3, 4]. From the materials perspective, the polymeric membranes were mainly deployed for juice clarification applications [5]. Clay-based membranes are gaining significant interest for juice clarification because of their excellent corrosion resistance, wider pH range applicability, high thermal stability, and ease of cleaning [6–9].

Clarification is performed in traditional procedures by hydrolysis of the molecular components present. With the addition of fining agents and enzymes, plant residues such as fibre, cellulose, starch, fat, pectin, and protein colloid together, reducing turbidity and forming a clear juice [10]. Acids like as galacturonic acid are formed during the hydrolysis of pectin, altering the sensory properties of the juice as well as the quantity of sedimentation. In most cases, this form of clarification takes 1 to 2 h at 50 oC [11]. Evaporation is the most frequently used method for concentrating juice; however it causes nutritional properties to be lost. Anthocyanin, chlorophyll, and carotenoids can be destroyed by the oxidation of ascorbic acid, which may also result in browning events [12]. In microfiltration, the membrane process is more energy efficient because the heat-generating equipment is excluded [13, 14].

There are few reports for the clarification of pineapple juices using clay-based ceramic membranes. Jiraratananon et al. [15] used the multichannel monolith alumina tubes with pore sizes of 100 and 10 nm for the microfiltration of diluted pineapple juice having 12o Brix. At a pressure of 300 kPa and 2 m/s, the membrane showed macromolecular and sugar rejection of 84–87% and 6%, respectively. Using an alumina-titania tubular membrane with a pore size of 10 nm, the clarification of pineapple juice was conducted. In this study, about 93% of soluble solids were recovered in permeate at a pressure and temperature of 4 bar and 50 oC, respectively [16]. Carvalho et al. [17] demonstrated the microfiltration of diluted pineapple (12oBrix) juice using an alumina membrane whose average pore size was 220 nm. The membrane showed excellent recovery of Brix (94.16%), acidity (91.6%), glucose (90.13%), sucrose (91.48%), and total sugars (92.42%). Even though, the ceramic membranes provide good performance for pineapple juice clarification, the ceramic membranes utilized so far are expensive. In this context, the design and development of low-priced ceramic membranes will be encouraging further commercialization of membrane technology.

In comparison to previous procedures, the membrane process has little or no influence on their physicochemical properties. Nandi et al. [18] developed ceramic membranes for dead-end microfiltration of orange juice, using kaolin, quartz, boric acid, feldspar, sodium metasilicate, and sodium carbonate. The physicochemical parameters were also examined before and after the microfiltration testing. Due to enzymatic treatment, microfiltration resulted in a significant decrease in colour, viscosity, AIS, and rise in clarity. Qin et al. [19] made a fly ash membrane for kiwi juice microfiltration, the density, TSS, and pH of the original juice and permeate were quite similar. The colour of kiwifruit juice, filtered via membranes, dropped from 3 to 0.24. The percentage of suspended solids reduced from 12.1 to 6.5%. Brasil et al. [20] performed the extraction and clarification of guava juice with pectic enzymes and finning agents. The clarified juice was tested for its physicochemical characteristics and found that the ascorbic acid level was reduced by 26.7% from the natural pulp. Processing techniques like extraction, fining, and heat treatment may be responsible for this decline. Fukumoto et al. [21] performed clarification of apple juice with a ceramic membrane (0.2 μm). The micro filtrated apple juice was found to have some loss in colour, turbidity, TSS, and flavanol content as 0.42 − 0.40, 0.40–0.39 NTU, 12.4–12.2oBrix, and 78–61 g/mL, respectively, and found no changes in titratable acidity.

Chakraborty et al. [22] employed a low-cost kaolin-based membrane for clearing gourd juice, and the membrane functioned satisfactorily at 137.9 kPa. Both the pH and salt levels of the feed and permeate samples remained consistent at the above pressure. Fresh juice and the permeate sample both showed improvements in juice clarity as 92.46 ± 0.59% and 85.31 ± 1.81%, respectively. Additionally, for the fresh juice and permeate sample, a considerable colour reduction was observed as 0.15 ± 0.09 and 0.45 ± 0.18 respectively. Similarly, Emani et al. [23] deployed a low-cost kaolin membrane to clarify mosambi juice, and the membrane performance was good. It was discovered that critical characteristics like density, AIS, TSS, and acidity did not differ much. At the same time, unique properties for colour index (0.02 to 0.03), density (1.17 g/cm3), and AIS were detected (negligible). Changmai et al. [24] used a kaolin-based membrane for pineapple juice clarification, and the membrane performance was satisfactory. There is a difference in vitamin C levels between the control juice and the enzyme-treated juice, ranging from 25.39 to 25.62 to 23.44–23.65 mg/100 mL, respectively. Carneiro et al. [25] have reported that Brix, pH, acidity, total sugar, colour, and haze were not affected by the transmembrane pressure used in the microfiltration or ultrafiltration employing the tubular polyethersulfone 0.3 μm pore size membrane. In terms of both cost and quality, membrane-based operations are a better solution for traditional fruit juice clarification and concentration techniques. The microfiltration procedures primarily show a significant improvement in the reduction of waste products and enzymes, the decrease of thermal degradation, the costs and energy requirements being extremely low, and the ease of cleaning and maintaining the equipment [26].

Only a few research had documented the use of a low-cost ceramic membrane, especially a kaolin-based membrane, in pineapple juice clarification. With this gap, the present work investigates pineapple juice clarification without enzymatic treatment using a low-priced kaolin membrane. Disc ceramic membranes, synthesized using different compositions of precursors like kaolin clay, calcium carbonate, quartz, and titanium dioxide, were subjected to various tests to evaluate their porosity, water permeability, pore size, chemical stability, and hydrophilicity. The change in the physicochemical properties of the pineapple juice was analyzed before and after the microfiltration process at various pressures. Additionally, the fouling models are studied for each pressure with the help of pore-blocking models. Cost valuation of clay membranes comparisons with commercial membranes was also presented.

Materials and methods

Materials

Table 1 shows the basic formulation of the precursor utilised to create three distinct membranes. Royalty minerals located in Mumbai, India have supplied kaolin and quartz. Calcium carbonate, titanium dioxide, and polyvinyl alcohol were supplied by Loba Chemie, Ltd. India. The precursors used in this work, have their specific roles to play, for instance, kaolin was used as a base material that offers refractory properties to the membranes; quartz and titanium dioxide improve the membrane’s thermal stability and calcium carbonate offers a porous structure to the membrane. The chemicals used in the physicochemical analysis are aluminium chloride, soluble starch, potassium iodide, potassium iodate, sulphuric acid, gallic acid, Rutin, and hydrochloric acid which are procured from Loba Chemie Pvt. Ltd. Folin–Ciocalteu’s phenol reagent and 1- diphenyl-2-picrylhydrazine(DPPH) are obtained from Hi-Media Laboratories Pvt. Ltd. Sodium carbonate and L - ascorbic acid are obtained from Molychem Pvt Ltd. Ethanol, methanol, and sodium hydroxide of analytical grade are purchased from Rankem Pvt. Ltd. Phenolphthalein was procured from Thermo Fisher Scientific India Pvt Ltd.

Membrane preparation

The membranes were fabricated by the uniaxial compaction method as described elsewhere [27]. For this, the precursors were vigorously mixed with a binder using a pestle and mortar, until it is distributed uniformly. About 4 mL of 2wt% polyvinyl alcohol was used as a binder for each 100 g of the raw mixture. The mixture obtained was moulded in a circular shape (51 mm diameter and 5 mm thickness) by pressing at a compaction load of 50 MPa in a hydraulic press through a stainless-steel mould. After that, the drying process was carried out at 100 oC for 24 h and sintered at 1000 oC in a box furnace (Nanotec lab, Chennai, India). The heating rate was maintained at 2 oC per min. to achieve uniform sintering and reduce the bending of the membrane due to the thermal stress. The flat and smooth surface of membranes was made by rubbing them using abrasive sheets (No.C-220, India). Subsequently, ultrasonic cleaning was performed to remove any slack particles sticking to the membrane using an ultrasonicator (PCI Analytics, India) at 20 watts for 15 min for both sides of the membrane. The wet membranes were dried completely to remove the moisture, with the help of an oven at 110 oC for 24 h.

Characterization

The membranes were characterized using scanning electron microscopy (SEM), x-ray diffraction (XRD), thermogravimetric analysis (TGA), particle size distribution (PSD), porosity, water permeability, pore size, and chemical tolerance, which were also measured. XRD (Bruker AXS instrument, Karlsruhe, Germany) was conducted using CuKα (1.5406 Å) radiation for a 2θ angle between 10o and 80o. The scanning speed was 0.05o/s. TGA (Mettler Toledo, TGA1 SF/ 1100, Switzerland) was carried out from 25 oC to 1000 oC. The experiment was done under a nitrogen atmosphere and the heating rate was 10 oC/min. SEM (ZEISS, EVO18, Germany) was performed to investigate the microstructure of the membrane surface. The samples were gold coated for 2 min and images at different magnifications were taken to investigate the surface morphology. PSD (Anton-Paar, Litesizer 500, Austria) of the raw material mixture was done in wet dispersion mode to determine the particle size range and average particle size. Using water as a solvent, the membrane’s porosity was measured by Archimede’s principle. Porosity can be defined as the ratio of the volume of total pores to the volume of the membrane. The volume of pores was measured by the water absorption method. For this, the membrane’s dry weight (W1) was first taken after removing moisture from the membranes. The drying was done at 100 oC for 6 h which ensures complete removal of moisture. Then, the water absorption was performed by soaking the membranes in pure water for 24 h. Eventually, the wet weight (W2) was taken after gently wiping of membranes. The porosity (ε) was determined using Eq. (1) and expressed in percentage

Here, W2,W1,ρwater,and νmem indicate the wet and dry weight of membranes, the density of water, and the volume of the membranes, respectively.

The pure water permeation was obtained by measuring water flux (J) using a continuous dead-end membrane filtration setup. Figure 1 shows the primary parts of the filtration system were a cylinder-shaped upper unit and a support plate that holds the facility to fit the membrane and it was mounted in a perforated membrane casing using M-seal and seated in the base plate of the setup. The water was fed to the filtration unit by a diaphragm pump and the pressure was regulated using the valves given in the feed and circumvent pipe. After fixing the membrane, the membrane was cleaned by circulating the water at a higher pressure, and subsequently, the water flux was evaluated at various pressures ranging from 69 to 345 kPa. The permeate volume was quantified as a function of time using a measuring cylinder and noted as volume (Q). At every individual pressure, the volume of permeate was noted at 10 min time interval fora total time of 1 h. The flux is the ratio of the volume of permeate to the product of the area of the membrane with sampling time and expressed as m3/m2s.

Water permeability is the ratio of water flux to applied pressure and it is usually expressed in m3/m2skPa. The water flux assessed at 69, 138, 207, 276, and 345 kPa pressures were plotted against each other. The pressure and flux relation were linear and the slope value expresses the membrane’s permeability. The pore size was calculated by assuming the membranes contain cylinder-shaped pores as per the following Eq. 2 [27].

Where, Lh is the permeability of water (m3/m2skPa), µ is the viscosity of water (Pa. s), l is the membrane thickness (m) and ε is the porosity of the membrane (%).

Chemical stability was studied based on the acid, alkali, and chlorine stability of the membranes. This experiment was carried out by soaking the membranes in acid and alkali solutions (pH 1 to 14).The samples were completely dried in a hot air oven and the initial weight of the membrane was taken. Next, the samples were immersed in acid and alkali solutions individually for a week. Hydrochloric acid and sodium hydroxide were used to prepare the acid and alkaline solutions, respectively. After one week of immersion, the membranes were dried to remove the complete moisture and dry weight was taken. The stability was determined based on the membrane’s weight loss in chemical solutions. Similarly, the chlorine resistance of the membranes was studied by immersing the membranes in the chlorine solution for seven days. The concentration of the liquid chlorine solutions was 5000 mg/L which was prepared using sodium hypochlorite (4–6% active chlorine) solutions. The weight loss of the membrane in chlorine solution characterizes chlorine stability.

The hydrophilicity of the membrane was quantified in terms of its water contact angle measured by the sessile drop method, and the tangent angle formed after dropping the liquid gives the contact angle, by a contact angle analyzer (Surface Electro-Optics, Korea). Water droplet on the membrane surface was captured with appropriate magnification using a digital camera. Windows-based software namely contact angle measurement system, version 8 was applied to quantify the contact angle.

Microfiltration of pineapple juice

Pineapple juice preparation

Fully ripened pineapple fruits were purchased from the local market in Raipur, India. The fruits were washed thoroughly using tap water to remove dust followed by the removal of the outer skin, and the crown. The pulp obtained was cut into small pieces followed by crushing using a 500 W Philips juicer, India. The extracted juice was then filtered using a muslin cloth, as a pre-treatment, before the microfiltration process.

Microfiltration of juice

The microfiltration of pineapple juice was conducted using a continuous dead-end filtration setup. At each applied pressure (69–345 kPa), the variation in permeate flux with time was measured. The flux was determined at every 10 min time interval for 1 h. The membrane was regenerated between each pressure as follows; (1) the clean water was circulated through the membrane at high pressure (345 kPa) for 30 min to remove the solids from the membrane surface, and (2) the membrane surface was washed thoroughly using surfactant solution for 5 min. (3) washing the membrane with deionized water to eliminate residual surfactant solution from the membrane and (4) the membrane was sonicated for 20 min with Millipore water to remove solids from membrane pores. To ensure efficient cleaning and regeneration, the membrane clean water flux was evaluated after cleaning.

Analytical techniques

Acidity and pH

The acidity of the feed and permeate juice was estimated by the titration method [28]. The juice was diluted by mixing 10 g of juice with 250 mL of deionized water and transferred to 500 mL of Erlenmeyer flask. Phenolphthalein indicator (1 mL) was added to the juice and titrated against NaOH (0.1 N) solution. The faint pink colour was noted as the endpoint. The titration was performed at least in triplicates. The pH of the pineapple juice was measured using a pH meter (EUTECH instruments, pH tutor, Singapore) with 100 mL of juice in a beaker. The standard procedure was followed for the measurement of pH.

Total soluble solids

Total soluble solids (TSS) of the pineapple juice were measured using a refractometer (Contech Abbe Refractometer, CAR – 02, India). Brix (o) is the indicator for soluble solid content of the samples [29].

Total dissolved solids

The total dissolved solids (TDS) were evaluated using a conductivity meter (Hanna Instruments, U.S.A.). The measurement was carried out in triplicates for feed and permeates obtained at each pressure.

Density

The density of the feed and permeate pineapple juice was measured using a pycnometer of 25 mL capacity. Firstly, the pycnometer was calibrated with distilled water and the empty weight of the bottle was also taken. The pineapple juice (25mL) was filled in the pycnometer and weighed using an analytical weighing balance (Sartorius lab instruments, QUINTIX 224-10IN, Germany). The density was calculated as the ratio of the weight of the juice to the volume of the juice (g/mL).

Determination of colour

The variation in colour of the microfiltered juice sample was analyzed using (Konica Minolta, CR-10 plus, Japan) colour reader based on the CIE L*, a*, and b* colour system. The colour was measured as a* (+, redness/-, greenness), b* (+, yellowness/ -, blueness), and L* (+, whiteness or brightness/-, darkness). The colour differences were observed by the colour reader [30].

Vitamin C

The vitamin C of the feed and permeate juice was estimated by the iodometric method as reported elsewhere [31]. Firstly, 5 g of potassium iodide along with 0.268 g of potassium iodate was dissolved in 200 mL of distilled water. After that, 30 mL of sulphuric acid (3 M) was added to the solution and made up to 500 mL. On the other hand, a standard solution of vitamin C was made by mixing 0.250 g of ascorbic acid in 100 mL of distilled water. The final volume of vitamin C standard solution was 250 mL. The iodine solution was standardized with vitamin C standard solution by titrating 25 mL of vitamin C solution against the iodine solution. About 10 drops of starch solution (1%) were used as an indicator. The titration was performed until the solution turns blue-black colour as the endpoint. Similarly, 25 mL of sample was titrated with iodine solution until the blue-black colour appeared. Using standard, the concentration of vitamin C was calculated as mg/100 mL.

Total phenolic content

The total phenolic content (TPC) of the feed and permeate juice was measured as per the protocol reported in the literature [30] with slight modifications. In this, the diluted pineapple juice was mixed with 200 µL of Folin–Ciocalteu reagent and incubated for 5 min. Then, 0.2 µL of Na2CO3 was added and incubated for 2 h at room temperature. The absorbance was recorded at the wavelength of 765 nm using a UV-vis spectrophotometer (SHIMADZU, UV-1800, Japan). A calibration curve was prepared by measuring the absorbance of a standard gallic acid solution prepared at different concentrations without the addition of a test sample. Total phenolic content is calculated using the calibration curve of the gallic acid.

Total flavonoid content

The aluminium chloride colorimetric method with slight modification was adopted to determine the total flavonoid content (TFC) as reported by Sharma et al. [30]. Briefly, 2 mL of diluted juice sample was added to 2 mL of 2% of AlCl3 (1:1) prepared in ethanol and incubated for 1 h in the darkroom, and absorbance was recorded at 420 nm. The standard curve of Rutin was constructed using different concentrations of Rutin solution and the absorbance value. With the help of a calibration curve, total flavonoid content was determined.

Radical scavenging activity

The antioxidant was quantified based on free-radical scavenging activity as reported by Sharma et al. [30] with slight modification. A 25 µL of diluted juice was mixed with 975 µL of 0.1mM 2,2-diphenyl-1-picrylhydrazyl in methanol and incubated in a dark room for 1 h. Subsequently, the absorbance was taken at 517 nm. Radical scavenging activity was measured as the percentage of inhibition.

Non-enzymatic browning index

The non-enzymatic browning index (NEBI) was evaluated according to the method reported elsewhere [32]. In this, 10 mL of pineapple juice was centrifuged at 3000 rpm to remove the coarse particle from the juice using a benchtop centrifuge (REMI, NEYA 8, India). After that, 5 mL of the supernatant obtained was mixed with 5 mL of ethanol (95%) and centrifuged at 3000 rpm for 10 min. The optical density of the supernatant juice was measured at 420 nm. The absorbance of the control and centrifuged fresh juice was measured to compare the browning index result. All the experimental work was performed in triplicates and the average values were reported. To statistically analyse the experimental data, one-way ANOVA was employed.

Investigation of fouling models

Various fouling models applicable for constant pressure filtration namely complete, standard, and intermediate pore blocking models as well as cake filtration models were investigated to identify pertinent fouling models for microfiltration of pineapple juice [33]. Complete pore blocking has an effect when the molecule/solutes completely chunk the pores of the membranes. This happens when the particles bigger than the membrane’s pore size arrive at the membrane surface. In such conditions, the active membrane area available for fluid transport decreases equally to the volume of permeates. During standard pore blocking, when the solute size is lesser than the membrane pore size, deposition of solutes occurs in the internal pore wall resulting in a proportional reduction in pore volume leading to a decrease in permeate volume. In the case of intermediate blocking, the solutes either settle on the membrane surface or chock the membrane pores which happened as solute size is comparable with the membrane pore size. The last fouling model, namely cake filtration takes place due to the formation of gel layers over the membrane’s surface as a result of the layer formation of solutes/colloids/macromolecules on the membrane. The gel layer offers resistance to the permeate flow. All these models can be expressed as follows.

-

a.

Complete pore blocking :

$$\ln ({J^{ - 1}}) = \ln ({J_0}^{ - 1}) + {k_b}t$$(3) -

b.

Standard pore blocking :

$${J^{ - 0.5}} = {J_0}^{ - 0.5} + {k_s}t$$(4) -

c.

Intermediate pore blocking :

$${J^{ - 1}} = {J_0}^{ - 1} + {k_i}t$$(5) -

d.

Cake filtration :

$${J^{ - 2}} = {J_0}^{ - 2} + {k_c}t$$(6)

the coefficient (R2), initial permeate flux (J0), and slope (k) can be obtained by fitting the obtained flux data as function time with the above four models as expressed in Eqs. (3–6). For example, ln(J− 1) and t, J− 0.5 and t, J− 1 and t, and J− 2 and t for complete, standard, intermediate pore blocking models and cake filtration, respectively. Eventually, the coefficient (R2) value close to 1 indicates the relevant fouling mechanism during pineapple juice filtration.

Result and discussion

Characterizations of the prepared membranes

The TGA patterns of membranes M1, M2, and M3 are shown in Fig. 2. The weight loss of membranes M1, M2, and M3 was about 11, 14, and 6%, respectively. Generally, the weight loss below 150 oC temperature was due to drying of moisture content from the samples and the weight loss between 150 and 400 oC, was attributed to loss of structural hydroxyl group which results in conversion of kaolinite to meta-kaolinite [34]. For membranes M1and M2, the major weight loss occurred due to the decomposition of calcium carbonate (CaCO3) at the temperature range of 550–750 oC, and this results in the conversion of CaCO3 into CaO and CO2. The morphology and porous texture of the membrane depend on the generated CO2. For M2 and M3 membranes, a small amount of weight loss was also observed between 250 and 500 oC, attributed to the loss of organic matter of titanium dioxide [35]. Moreover, the membrane M1 showed less weight loss as compared to M2 which is due to the presence of quartz. It is well-known fact that quartz is a thermally stable material as compared to TiO2. Overall, membrane M3 showed less weight loss as compared to the other membranes (M1 and M2). This is because the membrane M3 does not have calcium carbonate which is directly related to the loss in weight of the membranes. Figure 3 presents the DTA curve of the membranes prepared using different compositions of precursors. The DTA curve of membranes M1, M2, and M3 shows endothermic peaks at 715, 740, and 700 oC, respectively. The presence of an endothermic peak in M1 and M2 membranes was due to the degradation of calcium carbonate, whereas, the endothermic peak of the M3 membrane was due to the loss of organic matter of TiO2. The sample mixture doesn’t show any weight loss after 800 oC which can be considered the lowest sintering temperature essential for the fabrication of membranes. In this study, the sintering temperature of 1000 oC was chosen considering the mechanical strength of the membrane.

Figure 4 depicts XRD patterns of the membranes synthesized using different precursor compositions before and after sintering. The main peak that appeared in all the unsintered membranes was kaolinite. The peak corresponding to kaolinite was observed to be diminished in the sintered membranes. This is because of the conversion of kaolinite to mullite through meta-kaolinite [34]. On the other hand, the characteristics peak of quartz has not changed in the sintered membrane which shows its thermal stability. Moreover, the anorthite phase was observed in the sintered membrane from M2 and M3 this is because of the reaction between calcium oxide and amorphous silica present in the raw material [35]. The characteristics peak of calcite was observed to be diminished in the sintered membranes of M1 and M2 which is due to the degradation of CaCO3. The rutile and anatase phases were observed in the M2 and M3 membranes which confirms the presence of TiO2 [36, 37]. Moreover, the addition of TiO2 did not enable significant phase transformations in both M2 and M3 membranes. The results obtained in this work have a correlation with the work described in the literature [38].

Particle size distribution (PSD) was performed to quantify the average particle size of the starting materials used to fabricate the membranes. The distribution of particle size and mean particle size of the precursors greatly affect the porosity and average pore size. The finer particles yield a membrane with smaller pore size and narrow pore size distributions, whereas, coarser particles increase their average pore size [23]. PSD of the powder mixture for the corresponding composition of membranes M1, M2, and M3 are presented in Fig. 5. All the membranes showed unimodal PSD, and particle size varies between 3.3 and 16.8 μm, 0.58–4.09 μm, and 0.11–4.09 μm for M1, M2, and M3 membranes, respectively. The average particle size of the raw material mixture was found to be 0.95 μm, 1.96 μm, and 0.36 μm for M1, M2, and M3 membranes, respectively.

Figure 6 depicts the morphology of membranes produced using various precursor compositions. The composition of starting materials greatly affects the morphology of the membranes [38]. The membranes showed crack-free surfaces with distinct morphological textures. Also, the membranes are having a good porous texture. It is therefore concluded that the membrane’s surface morphology primarily depends on the composition of the precursors.

The average porosity was quantified using Archimedes’ principle. The average porosity was found to be 56, 53 and 48% for M1, M2, and M3, respectively. The porosity of the membranes is influenced by the varying composition of the precursors. Usually, calcium carbonate is used as one of the raw materials to produce porosity in the membrane. But in this work, it is evident that a membrane prepared without calcium carbonate also produces a good porous membrane suitable for microfiltration. A similar kind of result of porosity is reported by Dong et al. [39]. The water flux was quantified for all the membranes. Figure 7 presents water flux measured at different pressure (69–345 kPa). The figure conveys that there is no change in water flux with time showing that there is no resistance to water transport. The water flux increases with increasing pressure because the pressure is the driving force for permeate flow. Moreover, the flux increases linearly with applied pressure. The water permeability was measured to be 3.00 × 10− 6m3/m2skPa, 2.00 × 10− 6m3/m2skPa, and 1.07 × 10− 6 m3/m2skPa for M1, M2, and M3, respectively. The pore size was estimated according to Eq. (2) and that was 0.87 μm, 0.73 μm, and 0.56 μm, for M1, M2, and M3, respectively.

Chemical stability was conducted in terms of acid, alkali and chlorine tolerance. It was observed that the membranes M1 and M2 showed insignificant weight loss of about 1 and 1.2%, respectively at the pH of 1. However, no weight loss was observed in other acid and alkaline conditions (pH 2–14). On the other hand, membrane M3 shows no weight loss in both acid and alkaline solutions. For all membranes, the weight loss in chlorine solutions was found to be negligible. These results indicate that the membranes do have better chemical stability in chemical solutions.

Contact angle analysis was performed by the sessile drop method as shown in Fig. 8. The average contact angle was evaluated to 34o, 36o, and 42o for M1, M2, and M3, respectively. Generally, the angle formed above 90o is said to be hydrophobic and below 90o is hydrophilic. Hence, it is proved that the membranes prepared in this work are found to be hydrophilic and thus suitable for the microfiltration of fruit juice applications. Table 2 presents literature data [40,41,42,43] on various low-cost ceramic membranes. The prepared membranes in this study are compared well with literature data. Based on the results obtained, the membrane M3 is selected as the suitable membrane for pineapple juice clarification, and further studies were conducted with the M3 membrane.

Microfiltration of pineapple juice

Trend of permeate flux

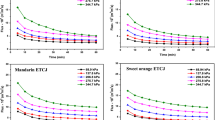

Figure 9 shows the membrane flux of pineapple juice with respect to time at various applied pressures in the range of 69–345 kPa. The flux was increased with applied pressures (69–345 kPa) which are due to an increase in driving force with an increase in pressure. However, flux variation with pressure was not found to be linear and this may be due to the incident of additional resistance during juice transport namely adsorption of suspended particles and concentration polarization [44]. During the initial period, the flux decreases sharply, and the flux decreases gradually as time proceeds and eventually attains a steady state. The rapid flux reduction at the early stage can be explained by pore blocking of membranes because of the deposition of suspended matters from the juice which significantly reduces the flux. In the later stage, the concentration polarization takes place which contributes to the flux decline. The flux decline rate is decreased at a later stage as concentration polarization is a slow process. The average permeate flux was found to be 2.26 × 10− 5 m3/m2s, 5.65 × 10− 5 m3/m2s, 7.54 × 10− 5 m3/m2s, 1.31 × 10− 4 m3/m2s, and 1.82 × 10− 4 m3/m2s for 69, 138, 207, 276 and 345 kPa, respectively.

Analysis of physicochemical properties

The physicochemical properties (such as acidity, pH, TSS, TDS, density, colour, vitamin C, browning index TPC, TFC, and antioxidant activity) of feed and permeate samples are presented in Table 3. It can be observed that the pH of the permeate remains constant at all applied pressure, whereas slight changes in acidity were observed with varying pressure. The acidity of pineapple juice feed was 0.3072 ± 0.06%. The acidity of pineapple juice was reduced by 0.3071 ± 0.01–0.3063 ± 0.05% at 69–345 kPa.

Effect of TSS and TDS in pineapple juice during microfiltration

Generally, pineapple juice contains a number of polysaccharides, protein, fibre, and some colloidal particles that can be removed through the microfiltration process. From Table 3, and Fig. 10, it was observed that the TSS (oBrix) of the permeate pineapple juice is slightly reduced as compared to feed juice. The Brix reduced from 7.6 ± 0.3 to 6 ± 0.05 as pressure increased from 69 kPa to 345 kPa. The reduction in Brix was about 21% of the total TSS level. The decrease in TSS level with increasing pressure is concurrence with the result presented by Pagliero et al. [45]. The total dissolved solids (TDS) were found to remain the same at all applied pressure and this is because the membrane’s pore size is higher than the dissolved solids present in the juice.

Effect of density of pineapple juice during microfiltration

Figure 11 shows the density reduction with pressure, from 1.04 ± 0.08 g/mL at the feed to 0.94 ± 0.07 g/mL at the last applied pressure of 345 kPa. The density of the permeate juice was measured using a pycnometer at all the applied pressure. As seen, the density of the permeate sample slightly decreases with increasing pressure which may be due to the elimination of suspended matters from the juice. Therefore, it can be concluded that microfiltration enabled the removal of particulate material from the juice. A similar trend of decrease in density with increasing pressure was reported in the literature [46].

Effect of colour in pineapple juice feed and permeates

The quality of food primarily depends on its flavour, colour, and aroma. The colour of the food plays an important role during the quality evaluation of the food. From Table 3, it can be observed that the value of total colour (∆E) increases from 7.5 ± 0.07 to 7.8 ± 0.09 from feed to permeate. ∆L is the indication of the lightness of the juice and that was found to be increased from 7.0 ± 0.01 to 7.6 ± 0.02, ∆a* denoting the greenness of the pineapple juice which varies from − 2.4 ± 0.2 to -2.1 ± 0.02, ∆b* denoting the yellowness of the juice and decreases from 0.6 ± 0.05 to 0.1 ± 0.05. The obtained results indicate that the permeate juice was of good quality with a greenish-yellow colour.

Effect of vitamin C in pineapple juice during microfiltration

Figure 12 depicts the variations in vitamin C during the microfiltration process using a ceramic membrane. The vitamin C content of the permeate was evaluated after conducting microfiltration at various pressures (69–345 kPa). The vitamin C content of fresh pineapple juice was 38.4 ± 0.02 mg/100 mL. The vitamin C slightly decreases (37.9 ± 0.07– 36.6 ± 0.9 mg/100 mL) with increasing pressure (69–345 kPa). Minimal loss is expected during microfiltration at higher pressures [47]. In the literature, a similar pattern of decreasing vitamin C with increasing pressure was found [14].

Effect of non- enzymatic browning in pineapple juice

Figure 13 shows the absorbance at 420 nm from feed to permeate at various pressures. The non-enzymatic browning index (NEBI) is to determine the brown pigmentation that occurred in the pineapple juice without the activity of an enzyme. When combined with ethanol, the evaluation of the brown compounds found in the juice sample reveals the development of browning. The NEBI was measured at an absorbance of 420 nm with ethanol as a blank. There is no significant improvement in brown pigments of the permeates obtained at different pressure. The browning index of the feed pineapple juice was 0.097 ± 0.01 and increased in permeate juice. The NEBI varies from 0.098 ± 0.05 – 0.103 ± 0.01 as the pressure varies from 69 to 345 kPa. The above value obtained is a negligible value in NEBI. There is no big variance from the visual colour observations [48].

Effect of phytochemicals in microfiltration

Phytochemicals are the compounds generally present in fruits and vegetables which are responsible for the flavour, colour, and aroma of the product. Some of them stimulate the immune system, helping in slowing down the growth of cancer cells, building up immunity, etc., Pineapple juice is rich in polyphenols that are responsible for the yellow colour. Hence, the permeates obtained after microfiltration was subjected to polyphenolic analysis. Figure 14; Table 3 illustrates the total phenolic compounds present in the pineapple juice before and after the microfiltration process at different pressures. The feed pineapple juice contains phenolic content of about 27.9 ± 0.83 mg/GAE g. The phenolic content in the permeate was found to be slightly decreased. The total phenolic content (TPC) decreases (27 ± 0.81–24 ± 0.62 mg/GAEg) with pressure (69–345 kPa). This is because some of the polyphenols attached to the other components are retained at the membrane surface. Hence, the total soluble solids (TSS) reduction made significant changes in the TPC loss. A similar pattern of results for total phenolic content was demonstrated by Owolade et al. [29], and Laorko et al. [49, 50]. The total flavonoid content (TFC) was found to have a minor loss during microfiltration, decreasing from 79.23 ± 1.37 to 76.92 ± 1.30 mg/RE g as the pressure increased from 69 to 345 kPa. Hossain et al. [51] demonstrated the loss of total flavonoid content with increasing pressure is similar to that of this study. Similarly, the antioxidant activity of the feed was 85.52 ± 1.56%, as the pressure increases, the antioxidant activity drops to 75.34 ± 1.26% at a higher pressure of 345 kPa. On the whole, it was observed that there was some minimal loss in antioxidant activity (12%), TFC (3%), and TPC (14%) in the permeate juice during microfiltration. Table 4 presents the literature data [52,53,54,55] for pineapple juice clarification by membrane filtration using both polymeric and ceramic membranes. From the table, it can be observed that the membrane prepared in this study perform well for pineapple juice clarification.

Analysis of fouling

The flux decline as a function of time was studied using different pore blocking models during the microfiltration of pineapple juice. Figure 15 displays the fitness of four pore blocking models with flux measured at 69, 138, 207, 276, and 345 kPa pressures. The cake filtration model was the best model as compared to the other models as it showed the best fit with experimental data. The coefficient of correlation (R2), slope (k), and initial permeate flux (J0 at t = 0) obtained using pore blocking models are presented in Table 5. For all the pressure, the cake filtration offers the highest R2 value (Table 5). Thus, it is concluded that cake filtration signifies the most pertinent flux decline mechanism during the filtration of pineapple juice. The obtained results agree with the observations reported by Nandi et al. [56], Kumar et al. [27], and Emani et al. [23] during filtration of oil-water emulsions, bacterial solutions, and mosambi juice, respectively. Table 5 also presents the model parameters (k values) obtained from different pore blocking models and k values indicating the fouling severity of the membrane. Overall, the cake filtration displays good to comply with experimental values and anticipated that cake filtration only contributes to external fouling.

Cost estimation

The cost of the prepared membranes was evaluated based on the precursors, moulding, and sintering costs. Table 6 presents the detailed cost estimation for the membranes M1, M2, and M3 prepared with different compositions of raw materials. The production cost was evaluated as Rs.1.17, Rs.10.61, and Rs.12.01 for M1, M2, and M3, respectively. The most widely used polymeric membrane for juice clarification was mixed cellulose ester (0.45 μm pore size, hydrophilic, 47 mm diameter), and its costs about Rs. 150 per piece (HAWP04700, MF-Millipore™ Membrane Filter). Similarly, the cost required for the microfiltration process was estimated. The pineapples were procured to make 6 L of juice for microfiltration and its cost was about Rs.600. The total cost for the microfiltration process cost was evaluated to be Rs. 612. Thus, the membrane produced is cost-effective for the microfiltration of pineapple juice.

Conclusion

The inexpensive ceramic membranes were successfully applied for pineapple juice clarification. Along with good chemical stability, the membranes (M1-M3) possessed good porosity (56–48%), and less average pore size (0.87 to 0.56 μm). The water permeability was in the range of 3.00 × 10− 6 − 1.07 × 10− 6 m3/m2skPa for the membranes M1-M3 which showed that the membranes were suitable for microfiltration applications. The microfiltration of pineapple juice was carried out to clarify the juice using the M3 membrane. The pH and acidity of the permeate juice remained constant after clarification. A slight loss of TSS, vitamin C, TPC, and TFC in permeate was observed indicating that the membranes retained all the essential components. The colour of the permeate juice had insignificant changes, which helps in the quality of the juice to be maintained. Henceforth, the membranes prepared with inexpensive raw materials are suggested for the microfiltration application of fruit juice without any changes in the natural compounds.

References

R.C. de Oliveira, R.C. Docê, S.T. de Barros, J. Food Eng. 111, 432 (2012)

C. Bhattacharjee, V.K. Saxena, S. Dutta, Innov. Food Sci. Emerg. Technol. 43, 136 (2017)

F. Vaillant, M. Cisse, M. Chaverri, A. Perez, M. Dornier, F. Viquez, C. Dhuique-Mayer, Innov. Food Sci. Emerg. Technol. 6, 213 (2005)

B. Van der Bruggen, C. Vandecasteele, T. Van Gestel, W. Doyen, R. Leysen, Environ. Prog 22, 46 (2003)

I. L.Carneiro, F. dos Santos Sa, V.M. dos Santos Gomes, L.M. Matta, Cabral, Desalination. 148, 93 (2002)

Y.S. Lin, A.J. Burggraaf, J. Am. Ceram. Soc. 74, 219 (1991)

G. Pugazhenthi, S. Sachan, N. Kishore, A. Kumar, J. Membr. Sci. 254, 229 (2005)

Y. Yoshino, T. Suzuki, B.N. Nair, H. Taguchi, N. Itoh, J. Membr. Sci. 267, 8 (2005)

J.M. Benito, A. Conesa, F. Rubio, M.A. Rodriguez, J. Eur. Ceram. Soc. 25, 1895 (2005)

L. Vasilišin, M. Grubačić, J. Yugosl. Pomol. 163 (2003)

Z.H.A.O. Hui, J. Jiangsu Inst Edu (Natural Sciences). (2006)

M. Maskan, J. Food Eng. 72, 218 (2006)

B. Girard, L.R. Fukumoto, Crit. Rev. Food Sci. Nutr. 40, 91 (2000)

T. Urošević, D. Povrenović, P. Vukosavljević, I. Urošević, S. Stevanović, Food Bioprod. Process. 106, 147 (2017)

R. Jiraratananon, D. Uttapap, C. Tangamornsuksun, J. Membr. Sci. 129, 135 (1997)

S.T. De Barros, C.M. Andrade, E.S. Mendes, L. Peres, J. Membr. Sci. 215, 213 (2003)

L.M. Jaeger de Carvalho, C.A. Bento da Silva, A.P. Pierucci, J. Agric. Food Chem. 46, 2185 (1998)

B.K. Nandi, B. Das, R. Uppaluri, J. Food Process. Eng. 35, 403 (2012)

G. Qin, X. Lü, W. Wei, J. Li, R. Cui, S. Hu, Food Bioprod. Process. 96, 278 (2015)

I.M. Brasil, G.A. Maia, R.W. de Figueiredo, Food Chem. 54, 383 (1995)

L.R. Fukumoto, P. Delaquis, B. Girard, J. Food Sci. 63, 845 (1998)

S. Chakraborty, C. Das, R. Uppaluri, Food. Bioproc. Tech. 6, 1009 (2020)

S. Emani, R. Uppaluri, M.K. Purkait, Desalination. 317, 32 (2013)

M. Changmai, S. Emani, R. Uppaluri, M.K. Purkait, Advances in Sustainable Polymers (Springer, Singapore, 2019), pp. 459–483

I. L.Carneiro, F. Santos Sa, V.M. Santos Gomes, L.M.C. Matta, Cabral, Desalination. 148, 93 (2002)

C. Conidi, E. Drioli, A. Cassano, Foods. 9, 889 (2020)

C.M. Kumar, M. Roshni, D. Vasanth, J. Water Process. Eng. 29, 100797 (2019)

M. Sairi, J.Y. Law, M.R. Sarmidi, Universiti Teknologi Malaysia. (2004)

S.O. Owolade, A.O. Akinrinola, F.O. Popoola, O.R. Aderibigbe, O.T. Ademoyegun, I.A. Olabode, Int. Food Res J. 24, (2017)

A. Sharma, B. Mazumdar, A. Keshav, J. Food Meas. Charact. 15, 466 (2021)

C.C. Nweze, M.G. Abdulganiyu, O.G. Erhabor, Int. J. Sci. Environ. Technol. 4, 17 (2015)

B.K. Tiwari, K. Muthukumarappan, C.P. O’donnell, P.J. Cullen, LWT-Food Sci. Technol. 41, 1876 (2008)

J. Hermia, Inst. Chem. Eng. 60, 183 (1982)

N. Saffaj, M. Persin, S.A. Younsi, A. Albizane, M. Cretin, A. Larbot, Appl. Clay Sci. 31, 110 (2006)

S. Kurama, E. Ozel, Ceram. Int. 35, 827 (2009)

K. Thamaphat, P. Limsuwan, B. Ngotawornchai, Agric. Nat. Resour. 42, 357 (2008)

S. Nur’Aini, J Phys Conf Ser. 1282 012049 (IOP Publishing 2019)

B.K. Nandi, R. Uppaluri, M.K. Purkait, Appl. Clay Sci. 42, 102 (2008)

Y. Dong, X. Feng, D. Dong, S. Wang, J. Yang, J. Gao, X. Liu, G. Meng, J. Membr. Sci. 304, 65 (2007)

D. Vasanth, G. Pugazhenthi, R. Uppaluri, J. Membr. Sci. 379, 154 (2011)

S.B. Rekik, S. Gassara, J. Bouaziz, A. Deratani, S. Baklouti, Appl. Clay Sci. 143, 1 (2017)

F. Bouzerara, A. Harabi, S. Achour, A. Larbot, J. Eur. Ceram. Soc. 26, 1663 (2006)

E. Garmsiri, Y. Rasouli, M. Abbasi, A.A. Izadpanah, J. Water Process. Eng. 19, 81 (2017)

B. Chakrabarty, A.K. Ghoshal, M.K. Purkait, J. Membr. Sci. 325, 427 (2008)

C. Pagliero, N.A. Ochoa, J. Marchese, Lat Am. Appl. Res. 41, 279 (2011)

A. Leahu, C. Damian, M. Oroian, S. Ropciuc, LucrariStiintifice-SeriaZootehnie. 59, 213 (2013)

M.H. Hounhouigan, A.R. Linnemann, M.M. Soumanou, M.A. Van Boekel, Food Res. Int. 30, 112 (2014)

D. Zhu, B. Ji, H.L. Eum, M. Zude, Food Chem. 113, 272 (2009)

A. Laorko, Z. Li, S. Tongchitpakdee, S. Chantachum, W. Youravong, J. Food Eng. 100, 514 (2010)

A. Laorko, Z. Li, S. Tongchitpakdee, W. Youravong, Sep. Purif. Technol. 80, 445 (2011)

M.A. Hossain, S.M. Rahman, Food Res. Int. 44, 672 (2011)

L.M.J. De Carvalho, I.M. De Castro, C.A.B. Da Silva, J. Food Eng. 87, 447 (2008)

A. Laorko, S. Tongchitpakdee, W. Youravong, J. Food Eng. 116, 554 (2013)

L.M.J.D. Carvalho, C.A.B.D. Silva, Food Sci. Technol. 30, 828 (2010)

A. Laorko, Z. Li, S. Tongchitpakdee, S. Chantachum, W. Youravong, J. Food Eng. 100, 514 (2010)

B.K. Nandi, A. Moparthi, R. Uppaluri, M.K. Purkait, Chem. Eng. Res. Des. 88, 881 (2010)

Acknowledgements

Mrs Dhivya acknowledges the TEQIP III for financial support in the form of a stipend and Mrs Roshni Meghnani for her support throughout the work. The authors express their sincere thanks to the Department of Biotechnology, Physics, Mining, and Metallurgical for providing instrumental facilities such as Hydraulic Press, membrane filtration set-up, muffle furnace, SEM, and XRD Analysis.

Author information

Authors and Affiliations

Contributions

Dhivya Arikrishnan: Conceptualization; Formal analysis; Methodology; Writing-original draft.Amit Keshav: Data curation; Investigation; Project administration; Supervision; Writing-review & editing.

Corresponding author

Ethics declarations

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Arikrishnan, D., Keshav, A. Pineapple juice clarification by continuous dead-end microfiltration using a low-cost ceramic membrane. Food Measure 17, 863–881 (2023). https://doi.org/10.1007/s11694-022-01634-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01634-5