Abstract

Liposomal encapsulation was used in this research to bring about sustainable release of the essential oil from the edible film. For this purpose, the Psyllium seed gum (PSG) film was enriched with various levels (1–3% w/w) of Oliveria decumbens essential oil nanoliposomes and the physicochemical, mechanical, structural (FTIR and SEM), thermal (DSC), antimicrobial and antioxidant properties of films as well as the release of essential oil from the films were evaluated. GC-MS analysis showed that Thymol is the main compound in O. decumbens essential oil. Based on the results, with increasing the concentration of nanoliposomes in the film structure from 1 to 3%, thickness and contact angle increased. Water vapor permeability decreased with increasing nanoliposomes concentration. The control film indicated lower tensile strength and higher elongation compared to the films incorporated with nanoliposomes. The nanoliposomes significantly improved the antioxidant and antibacterial properties and the melting point of the film. The results of Fourier transform infrared spectroscopy and scanning electron microscopy confirmed the loading of essential oil in the structure of nanoliposomes and the placement of nanoliposomes in the structure of PSG films. The increase of nanoliposome concentration significantly effects the release profile of the essential oil from PSG films. PSG films loading O. decumbens essential oil encapsulated in nanoliposomes can be applied to selected foods, partially replacing non-biodegradable/non-edible plastics.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Because of their remarkable aroma, oil and oxygen barrier characteristics, polysaccharide-based films are gaining popularity in the food packaging industry [1]. Psyllium (Plantago ovata Forsk) is an annual plant belongs to the Plantago family that it is the native of Iran [2]. PSG is an arabinoxylan polysaccharide containing 74.6% xylose and 22.6% arabinose [3]. PSG has many benefits in medicine, pharmaceutics, and food manufacture [4]. Recently, Psyllium seed gum (PSG) has been introduced and applied as a novel resource of sustainable films due to its low cost, biodegradable, abundance, and gel-forming properties [5]. However, some disadvantages such as poor mechanical properties of the films based on PSG have limited its practical applications [3]. Furthermore, previous studies have been shown that incorporation of bioactive compounds into PSG-based films influenced the physicochemical properties of films and controlled the release of bioactive compounds into the food during storage [2].

Insertion of natural bioactive components such as essential oils, phenolic compounds or alpha-tocopherol in the packaging systems for the development of active packaging and enhancing food shelf life is a recent trend in the food research centers [6]. These active compounds can be embedded into films to maximize supplementary properties of the films such as their antioxidant capacities and desirable sensory properties [7]. However, the direct addition of bioactive compounds in edible films faces with some limitations such as undesirable effects on the quality of the packages [8]. Furthermore, the phase separation and chemical and thermal degradation can be occur during production of the film after the addition of bioactive compounds into film forming polymer [9].

Oliveria decumbens is a valuable medicinal plant which can be used for the preparation of such active packaging with numerous phenolic compounds [10]. O. decumbens belongs to the umbelliferae family, is an endemic plant of Flora Iranian, and a couple of important phenolic compounds including β-pinene, β-myrcene, p-cymene, limonene, δ-terpinene, thymol, carvacrol and miristicin have been found in the compositional investigations of O. decumbens [10]. Sensitivity of O. decumbens active compounds to light and oxygen leads to lower stability of these compounds during processing and storage, limiting application and potential health benefits of O. decumbens bioactive components in food industry. In order to preserve O. decumbens nutraceuticals from degradation, entrapment techniques including nanoparticles [9], microcapsules [11] and emulsions [12] have been employed.

In recent years, nanoliposome is considered as an appropriate transfer system in food industry. These lipid careers are formed of phospholipid bilayer membranes surrounding an aqueous part [13]. Consequently, nanoliposomes can encapsulate both hydrophilic and hydrophobic bioactive compounds by maintaining them in the aqueous phase (hydrophilic compounds) or in their bilayer walls (hydrophobic compounds) [14]. Due to improve in vivo and in vitro stability along with bioavailability of bioactive compounds, nanoliposomes are valuable transfer systems. Nanoliposomes are enable to load a wide range of bioactive components into their structure such as curcumin, polyphenols, essential oils, antociyanins, plant extracts and bioactive peptides [9]. However, the present study is first report on the encapsulation of O. decumbens essential oil in nanoliposomes.

Although, application of liposomal-encapsulated essential oils in packaging films has been evaluated before but the present study is first report on the encapsulation of liposomal-encapsulated O. decumbens essential oil in edible films. As an example, Kamkar et al. [15] assessed the potential of active packaging films prepared by loading essential oil nanoliposomes in chitosan biopolymers for enhancing the shelf life of chicken breast fillet, and found out that the population of total viable count, psychrotrophic bacterial count, coliforms and S. aureus of fillets packaged with chitosan biopolymers having liposomes was roughly 1 Log CFU/g less than their population of fillets covered with chitosan alone after 7 days.

Therefore, our main objective of the present study was to facilitate “nanoliposomal” encapsulation of O. decumbens essential oil in an edible film to enhance physicochemical, mechanical, antioxidant and antimicrobial properties of PSG-based films. Physicochemical interactions between nanoliposomes and encapsulated O. decumbens essential oil were analyzed as well as release behavior of bioactive compounds from liposomes were assessed. The morphological properties and molecular interactions between PSG molecules and bioactive compounds of O. decumbens essential oil were also studied by SEM and FTIR analysis.

Material and methods

Materials

Phosphatidylcholine (purity > 99%) was purchased from Sigma (Germany). O. decumbens plant and Psyllium seed were bought from a local market (Shiraz, Iran). 2,2-Diphenyl-1-picrylhydrazyl (DPPH), acetic acid, sodium dodecylsulphate, n-hexane, 1,4-dioxane, methanol and other chemicals were purchased from Fisher Chemical Company (USA).

Preparation of Oliveria decumbens essential oil

Frist, the flowering aerial parts of O. decumbens were cleaned and washed. Then, the plant was powdered using a lab grinder. The powders were subjected to hydrodistillation with the Clevenger under optimal operational conditions with a temperature of 40 °C as described by Behbahani et al. [10]. One hundred grams (100 g) of the powdered plant was mixed with 800 mL of distilled water. The distillation process was performed for 3 h, and the obtained essential oil was collected and dehydrated using anhydrous sodium sulphate.

Identification and quantitation of the essential oil chemical composition

The chemical composition of O. decumbens essential oil was identified and quantized by a gas chromatography/mass spectrometry (GC/MS) (Agilent Technologies Inc., USA) with a flame ionization detector (FID). Helium gas in a 30 m DB-5 capillary column was used as carrier at a rate of 1.2 mL/min with an injection volume of 1.5 μL. The column temperature program was as follows: 5 min isothermal at 50 °C, increased to 280 °C at a rate of 3 °C/min and finally held at this temperature for 10 min. Injector and detector temperatures were 280 °C and 300 °C, respectively. Mass spectra were analyzed at 70 eV ionization energy. The obtained information of the device were calculated by EZChrom Compact Elite software (Agilent, USA).

Preparation of nanoliposome

Nanoliposome was prepared according to Molaveisi et al. [16, 17]. Briefly, 5 mg of O. decumbens essential oil and 400 mg of phosphatidylcholine were added to 20 mL of distilled water in a 50 mL flask. Then, the content of the flask was stirred for 5 h under nitrogen atmosphere. At this stage, micrometer multilayer liposomes will be formed. To obtain monolayer liposomes, first, the liposome solution was homogenized (IKA Company, Staufen, Germany) at 12,000 rpm for 5 min. Then, the resulting emulsion was sonicated (5 cycles, 1 min on, 3 min off, 40 kHz, 40% power) with a sonicator Vibra Cell 75,115 (Bioblock Scientific, Illkirch, France) inside the ice bath. The monolayer nanoliposome was kept in plastic tubes under nitrogen in the dark at refrigeration temperature.

Characterization of nanoliposome

Particle size

After dispersing 5 mg of the sample in 10 mL deionized water, a Zetasizer Nano ZS90 (Malvern Instruments Ltd., UK) was used for the determination of the mean diameter of nanoliposomes.

Ζ-Potential

The ζ-potential of nanoliposome was measured by a Zetasizer Nano ZS90 (Malvern Instruments Ltd., UK).

Extraction of Psyllium seed gum

The extraction and purification of PSG was carried out according to the method of Askari et al. [3]. In brief, 10 g of psyllium seeds were washed three times with ethanol (96% w/v) on a magnetic stirrer at 800 rpm for 15 min. The psyllium seeds were then dried in an oven at 70 °C for 45 min. After drying, to extract gum from psyllium seeds, the seeds were mixed with 200 mL of distilled water at 70 °C. The resulting solution was then placed on a heater (at 70 °C) and stirred at 1200 rpm for 90 min. The solution was then filtered through a suitable cloth and dried in an oven at 40 °C for 24 h. The dried gums were powdered by an electric grinder (Impact mill M 20, IKA, Germany). The powdered gum was kept at room temperature.

Film preparation

Frist, 1.2 g of the dried PSG powder was added to 100 mL of distilled water in a 200 mL flask and then stirred on a heater stirrer at 1200 rpm for 30 min and allowed to hydrate for 24 h at 70 °C. After reaching this temperature, glycerol was added as a plasticizer to 1.2% w/w and stirred for one hour at 70 °C. Then, after cooling the film solution, the prepared nanoliposomes with 3 different levels (1%, 2% and 3% w/w based on gum weight) were added to the film solution, and 30% v/v of Tween-20 was added to each sample. After complete homogenization of the film solutions, each of them was dried for 48 h at room temperature. All measurements were performed at 25 ◦C and 4 times. All the experiments were replicated three times [16, 17].

Film characterization

Scanning electron microscope (SEM)

A scanning electron microscope (S-360, Oxford) was used for observing the morphology of the developed films according to the method of Hajirostamloo et al. [18]. The films in both vertical and horizontal directions were coated with a thin layer of gold in a high vacuum coating system for 10 min. Then, the films were imaged at an operating voltage of 20 kV. The surface and cross-section of the films were observed at magnification of 500–1000×, respectively.

Fourier-transform infrared (FTIR)

A FTIR spectrophotometer was used to collect Fourier transform infrared (FTIR) spectra of the film samples, equipped with the ATR diamond module (Jasco® series 4200). Assessments were performed at room temperature with 18 scans per sample in the range of 500–4000 cm−1 while the resolution was monitored at 32 cm−1 [19].

Differential scanning calorimetry (DSC)

A differential scanning calorimetry instrument (Shimadzu Scientific Instruments, 154 Kyoto, Japan) was used for determination of the thermal properties of the films. The samples (5 ± 0.2 mg film) were sealed in aluminum tubes. The samples were put in device and heated under nitrogen flow (50 mL/min) from − 20 to 250 °C at a rate of 10 °C/min [20].

Thickness

The thickness of the films obtained from psyllium gum was measured by a digital micrometer. Thickness was determined from ten points of the film and the average of the numbers was considered as the film thickness [3].

Water vapor permeability

WVP was measured according to Kadam et al. [21]. For this purpose, anhydrous calcium chloride was poured into special glass containers. The surface of the dishes was then covered with film using parafilm. Thus, due to the moisture absorption of anhydrous calcium chloride, the relative humidity (RH) inside the cells became zero (0% RH). The cells were then transferred to a desiccator containing saturated brine (75% RH). Changes in cell weight over time were measured using a digital scale with an accuracy of 0.0001.

Mechanical properties of film

The mechanical properties of the films [tensile strength (TS) and elongation at break (E)] were investigated by a texture analyzer (TA-XT PlusTM, Stable Micro Systems, England) using Exponent software (ASTM, D882-10). The films were cut in 20 × 60 mm2. Then, the film samples were drawn between two grips at a speed of 1 mm/s [22].

Contact angle

The contact angle of the films was measured using a Canon digital camera (EOS 550). Briefly, a small drop of water was placed on the surface of the film using a microsyringe and then the contact angle of the drop with the surface of the film was immediately photographed. Image J software was used to calculate the contact angle of the drop with the surface of the films. The angle between the tangent line on the drop at the point of contact and the line drawn along the surface of the film represents the contact angle. Experiments were performed for each film in three replications with five drops on the surface [23].

Release of Oliveria decumbens essential oil from the films

Release of O. decumbens essential oil from the films was estimated according to Hajirostamloo and Molaveisi [19]. For this purpose, water was used as a food simulator to study the release of the essential oil from the coatings. Briefly, after cutting the samples in a dimension of 2 × 2 cm2 and immersing in vials containing 10 mL water, the vials were kept in the dark for 4 days and the volume of the released essential oil was read continuously by a UV–Vis spectrophotometer at 298 nm.

Antioxidant activity of films

This parameter was obtained on the basis of DPPH discoloration as described by Sani et al. [24], indeed, after sample preparation (which involves the mixture of film solution with DPPH methanolic solution), a spectrophotometer (UV Visible, Model Shimadzu, UV-160A, Japan) was used to monitor the absorbance reduction at specific wavelength (517 nm).

Antibacterial activity of films

The antibacterial activity of PSG-based films was studied against E. coli as Gram-negative and S. aureus as Gram-positive bacteria by disk diffusion. In short, the film samples were cut into 6 mm disks and putted on the plates inoculated with the bacterial cultures. Then, the plates were incubated at 37 °C for 24 h and the inoculum turbidity was adjusted to McFarland 0.5. Finally, the inhibition zones of disks towards the mentioned bacteria were determined [19].

Total phenolic content

Total phenolic content of PSG-based films was determined according to the method of Moghadam et al. [25] using the Folin-Ciocalteu. The film extract was obtained by plunging 40 mg of PSG films in 8 mL distilled water and stirred at 25 °C for 6 h. Then, 2 mL of Folin-Ciocalteu reagent was added to 0.5 mL of the film extract and allowed to stand in the dark for 20 min. After that, a UV–Vis spectrophotometer at the wavelength of 750 nm was used to record the absorbance of the film solutions. Then, different concentrations of Gallic acid (0–100 μg/mL) was prepared and used as the standard to obtain the calibration curve. Total phenolic content was expressed in mg Gallic acid per g of PSG film.

Statistical analysis

In this research, a complete randomized optimization design with three replications was used for the statistical analysis of the samples. SPSS version 16.0, one-way ANOVA test and Duncan’s multiple range test were applied for determination of statistical differences among the means (p < 0.05).

Results and discussion

Chemical composition of Oliveria decumbens essential oil

The chemical composition of O. decumbens essential oil was analyzed by GC-MS. Results indicated that the main constituents of essential oil are 8 different components. Based on GC-MSS analysis, it was found that the most important component of essential oil of O. decumbens is Thymol (41.24%). Furthermore, in the essential oil of O. decumbens other compounds such as carvacrol (11.76%), γ-terpinene (15.95%), ρ-cymene (5.49%), limonene (3.45%), myristicin (16.90%), β-pinene (2.84%) and β-myrcene (0.23%) were found. Other researchers have found similar compounds by analyzing O. decumbens essential oil. Behbahani et al. [10], found that the predominant compounds of O. decumbens essential oil include Thymol (28.45%), γ-terpinene (22.2%), ρ-cymene (17.90%), myristicin (13.55%), carvacrol (8.50%) and limonene (2.60%). The presence of Thymol, ρ-cymene, γ-terpinene, carvacrol, and myristicin in O. decumbens essential oil has also been reported by Nikravan et al. [26]. As it turned out, Thymol is the predominant compound in O. decumbens. Therefore, it can be said that the predominant compounds in Thymol essential oil are carnacrol and γ-terpinene. Therefore, many bioactive properties (antimicrobial, free radical scavenging, anti-cancer and anti-inflammatory) of this essential oil are related to the presence of these compounds. This essential oil has been loaded into films based on nanofibers [27, 28]. However, the use of this essential oil in the structure of nanoliposomes and its application in the structure of films and edible coatings has not been reported.

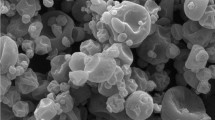

Characterization of nanoliposome

The physicochemical properties of nanoliposome were investigated. The average particle size and PDI values were 167.8 ± 0.65 nm and 0.174 ± 0.07 while zeta potential was as high as − 64.4 ± 0.42 mV. Small particle sizes obtained in this study is suitable for incorporation of more essential oil content [29]. Reduced PDI value of nanoliposome suggestions narrow and stable size distribution [30]. Moreover, as zeta potential is > − 30 mV, high repelling force among particles as well as elevated liposome stability are expected [31], especially that more effective protection of encapsulated cores happens at negative zeta potentials [15].

Film characterization

Thickness

The lowest thickness belonged to the control film (without liposome) as observed in Table 2. With the intensification of the nanoliposome in the film structure, the film thickness increased as well, which could be attributed to the amphipathic characteristics of nanoliposome and, indeed, its ability for incorporation with both glycerine and PSG solution [29] (Table 1).

Mechanical properties

Based on the results obtained in this study, it was found that the use of different levels of nanoliposomes loaded with O. decumbens essential oil in the structure of PSG films significantly (p < 0.05) affect their mechanical properties. Thus, the mechanical indices of TS and E of the films, as well as the comparison of the mean data based on Duncan's multi-range test are shown in Table 2. As nanoliposome concentration enhanced gradually, the TS parameter of the base film improved continuously from 20.42 ± 1.69 to 37.30 ± 2.87 MPa, which may be ascribed to the interaction between O. decumbens essential oil and PSG molecules. However, the E value of PSG film first descended and then ascended with the enhancement of O. decumbens essential oil concentration; the decrease could be attributed to the reduction of film fluidity caused by cross-linking formation between O. decumbens essential oil and PSG.

Mechanical indicators are used to evaluate the strength of food films and coatings used to hold food against physical and mechanical stress during transportation [20]. These characteristics are directly related to the microstructural and inhibitory properties of the films. The nanostructures used in the preparation of nanocomposites, due to their very small size, are well dispersed in the film matrix, which is accompanied by the strengthening of their mechanical properties and their inhibition. When nanoparticles are well dispersed in the film matrix, various interactions such as hydrogen bonds and electrostatic bonds between the film matrix and nanoliposomes may occur between these compounds [19]. By creating an interaction between the film matrix and nanoliposomes containing O. decumbens essential oil, cross-links are formed between the hydrocolloid chains of the PSG, which strengthens the film matrix. Therefore, these crosslinkings increase the tensile strength of the films and reduce the elongation at break. Reduction of the elongation at break index of films may be due to the placement of nanoliposomes instead of water molecules in the film matrix and filling their pores, resulting in reduced molecular mobility in biopolymer chains [18].

Eko Wahyuningtiyas and Suryanto [32] evaluated the effect of different levels of nanoclay (2.5, 5, 7.5 and 10%) on the matrix of cassava starch-based nanocomposite films. Their results showed that increasing nanoparticles up to 5% nanoparticles strengthens the structure of films, but the formation of nanoparticles at concentrations above 5% and the lack of effective bonds between the matrix of film components weakens the tensile strength. They also stated that the trend of changes in the elongation at break index of films is different from the other two indicators.

Water vapor permeability

The use of hydrocolloid compounds such as gums as a base matrix for the preparation of films and coatings has various aspects such as high WVP and poor mechanical properties with significant limitations. The high WVP of these films is due to the hydrophilic nature of their biopolymer chains, which challenges the durability of moisture-sensitive products [33]. Table 2 presents the results related to the application of different levels of nanoliposomes containing O. decumbens essential oil in the structure of PSG-based films based on WVP. Based on the results, it was found that the WVP index decreased significantly from 0.23 ± 0.11 to 0.12 ± 0.03 for the control film and the loaded film by 3% nanoliposomes (p < 0.05), respectively. Various factors affect the WVP index of the films. The hydrophobic/hydrophilic nature of the loaded compounds, the porosity, the complexity of the path, and the uniformity of the films are important factors that affect the WVP index. It is clear that by increasing the lipophilicity of the additives to the films and the uniformity of its matrix (reaction of nanoliposome components with biopolymer chains of PSG), the resistance to penetration of water vapor molecules will increase and the WVP index will decrease. On the one hand, O. decumbens essential oil is hydrophobic in nature, and on the other hand, nanoliposomes are placed in the voids and pores of the film matrix due to their very small size, and this is accompanied by a decrease in WVP. In addition, by using nanoliposomes loaded with O. decumbens essential oil, the tortuous path of infiltration of water vapor molecules will increase, which will also reduce the WVP index. These results were consistent with other researchers' findings on reducing WVP. Cui et al. [29], studying the effect of using liposomes in chitosan-based film matrices. They observed that liposomes increase the microstructure uniformity of films, which is associated with a decrease in WVP in chitosan films. Alinaqi et al. [34] also reported that the hydrophobic nature of clove-loaded zein nanoparticles would prevent an increase in the WVP index in starch-based bionanocomposite films.

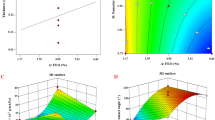

Contact angle (CA)

Contact angle of a water drop with the film surface is a common method for determining the hydrophilicity/surface hydrophobicity of films [35]. The effect of using the application surfaces of nanoliposomes loaded with O. decumbens essential oil (0, 1, 2 and 3%) on the changes in the CA of water droplets with the surface of active films based on PSG is shown in Fig. 1. The results showed that the lowest contact angle was observed in the control sample and with increasing the percentage of nanoliposomes loaded with essential oil, the contact angle of the droplets with the film surface increased from 35.08 to 63.40 (Table 2). The nature of the compounds used in the structure of the films directly affects their hydrophobicity/hydrophilicity. Therefore, it is obvious that the use and increase of nanoliposomes loaded with O. decumbens essential oil in the film structure due to their hydrophobic nature increase the contact angle of water droplets with the film surface [36]. Similar results have been reported for changes in the contact angle of water droplets with the surface of kefir-carboxymethylcellulose biocomposite films loaded with safflower essential oil. It was stated that the contact angle of the films with water droplets increased significantly (p < 0.05) as a result of using essential oil (hydrophobic nature) and reaction of essential oil with biopolymer chains (reduction of –OH groups) [37].

DSC analysis

DSC curves of the control film and the films incorporated with nanoliposomes containing O. decumbens essential oil are given in Fig. 2. The slight slip at around 0 °C was observed in the thermograms of all film samples, relating to the melting of free water in the films. The endothermic peaks were observed between 95 and 120 °C for all PSG films which can be due to evaporation of water because of the hydrophilic nature of PSG [9]. Tg was obtained in pure PSG films around 70 °C and Tg of the films loaded with nanoliposomes containing O. decumbens essential oil was around 80 ◦C. The incorporation of nanoliposomes caused an increase in Tg of PSG films, which can be due to the interaction between nanoliposomes and PSG molecules. This interaction could decrease movement of the polymer chains and leads to higher Tg values [38].

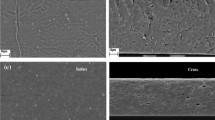

Scanning electron microscopy (SEM)

In order to investigate the morphological characteristics and also to confirm the placement of nanoliposomes in the structure of active films prepared on the basis of PSG, SEM images were used. Therefore, the effect of using nanoliposomes loaded with O. decumbens essential oil at levels of 1, 2 and 3% on the surface and cross-section of the films compared to the control film is shown in Fig. 3. Using nanoliposomes loaded with O. decumbens essential oil in the structure of films up to 3% had significant effects on their morphological properties. The uniform and smooth surface of the control film made of pure PSG has no protrusions and surface roughness (Fig. 3a). The use of nanoliposomes loaded with O. decumbens essential oil in the structure of the films at levels 1% (Fig. 3b), 2% (Fig. 3c) and 3% (Fig. 3d) led to surface roughness in the structure of the films, which indicates nanoliposomes are in the film matrix. As the pictures show, the use of nanoliposomes up to 2% maintained the uniform structure of the films, which is a good dispersion with significant advantages for the mechanical properties of the films. With uniform distribution of nanoparticles, the probability of reaction between nanoliposomes loaded with O. decumbens essential oil and hydrocolloid matrix of active films based on PSG increases through hydrogen bonding (see “Fourier-transform infrared (FTIR)” section). Numerous aggregations were observed in the film matrix as a result of the application of amounts higher than 2% (3%) of nanoliposomes loaded with O. decumbens essential oil, which disturbed their surface uniformity (Fig. 3d). These aggregations may be due to the adhesion of nanoliposomes in the film matrix, which weaken the mechanical properties of the films by creating lumps in the film matrix. By weakening the mechanical properties as a result of these aggregations, indicators such as the Young’s modulus and the tensile strength of the films are reduced (see “Mechanical properties” section). Similar results have been reported by Farajpour et al. [39] for morphological and mechanical properties for nanocomposite films based on potato starch. They applied zein nanoparticles at different levels (1, 3, 5 and 9 w / w) in the film structure. The results showed that the use of 3% of zein nanoparticles in the structure of the films led to a regular, uniform and uniform microstructure that these results could be seen with the proper distribution of zein nanoparticles in the structure of the films. In addition, the proper distribution of nanoparticles at the 3% level was accompanied by improved mechanical properties, including increased tensile strength of nanocomposite films.

FTIR measurements

The possibility of interaction between nanoliposomes containing O. decumbens essential oil with the active film matrix based on PSG is investigated using FTIR analysis. The FTIR spectra of the control film and PSG films loaded with nanoliposomes containing O. decumbens essential oil are shown in Fig. 4. The FTIR spectra of pure PSG films (control film) showed peaks in the regions of 3384, 2934, 1633, 1415, 1043, 927 and 857 cm−1, which correspond to the hydroxyl groups, C–H (CH, CH2, and CH3 respectively), asymmetric stretching C–O–O, asymmetric stretching C–O–O, C–O, C–O–C glycosidic, and C–O–H (Fig. 4). By loading nanoliposomes loaded with O. decumbens essential oil at levels of 1 to 3%, changes in the position and intensity of the peaks related to the pure film of PSG were made, which are shown in Fig. 4. Therefore, as shown in Fig. 4, by adding 1, 2 and 3% nanoliposomes containing O. decumbens essential oil in the film structure, the peaks of the hydroxyl groups were shifted to lower wave numbers of 3380, 3372 and 3367 cm−1, respectively. Also, the formation of new peaks in the wave number regions of 1008 to 1744 for active film samples containing nanoliposomes loaded with O. decumbens essential oil at levels of 1 to 3% is related to carbonyl groups and aromatic groups, which indicates the presence of essential oil in these structures. Studies have shown that changes in the position of peaks is related to the hydroxyl group (moving to lower wave numbers) and changes in their intensity indicate the strengthening of hydrogen bonds between the free hydroxyl groups of the film matrix with the components of nanoliposomes loaded with O. decumbens essential oil [40]. Also, the appearance of aromatic bonds in the FTIR spectrum of films loaded with nanoliposomes indicates the successful placement of nanoliposomes containing essential oil in the matrix of films based on PSG. All these results indicate good biocompatibility between the film matrix and the nanoliposomes loaded with O. decumbens essential oil. Alinaqi et al. [34] achieved similar results by designing a starch-based bio-nanocomposite film containing electrosprayed zein nanoparticles. They loaded the electrospray nanoparticles at levels of 5, 10, and 15% in the structure of the nanocomposite films, which altered the FTIR spectrum of the films. Based on the results obtained by these researchers, it was found that with increasing the application of nanoparticles in the film matrix, the position of hydroxyl groups of starch films was transferred to lower wave numbers and also peaks related to aromatic groups of clove essential oil in FTIR spectrum of nanocomposite films compared to control film sample were appeared. They stated that proper biocompatibility between nanoparticles and film matrices leads to acceptable dispersion of nanoparticles in film matrices, which is accompanied by improved mechanical properties and film inhibition.

Total phenolic content and antioxidant potential

Table 2 shows that the addition of nanoliposomes increased the total phenolic content of PSG films because O. decumbens essential oil is a rich source of phenolic compounds such as Thymol, carvacrol, terpinene, and ρ-cymene [41]. The results show that total phenolic content of the control film has been successfully increased twenty-five times by the insertion of 3% nanoliposomes containing O. decumbens essential oil. Samadi et al. [42] and Jamali et al. [41] reported that different phenolic compounds present in O. decumbens essential oil display antioxidant characteristics; consequently, total phenolic content is a very substantial criterion since its higher value is indicator of a film with elevated antioxidant activity.

As shown in Table 2, the control film and PSG films incorporated with 1% of nanoliposomes containing O. decumbens essential oil presented a lower antioxidant activity compared to those enriched with 2% and 3% of nanoliposomes; in this regard, the films containing 3% of nanoliposomes indicated the highest antioxidant activity. Therefore, this can be realized that the high antioxidant activity obtained for the films is related to essential oil as O. decumbens essential oil is a phenolic monoterpene with the capability to decelerate or postpone the oxidation of an oxidizable material [42]. The antioxidant activity of O. decumbens essential oil is relevant to its phenolic compounds such as Thymol, carvacrol, terpinene, and ρ-cymene [41]. In the similar way, Samadi et al. [42] stated that O. decumbens essential oil has the high percentage of inhibition potential towards DPPH free radical attributed to the available phenolic compounds in it [42].

Antibacterial properties

The inhibition zones were studied to investigate the antibacterial effects of PSG films against the bacteria strains including E. coli (Gram-negative) and S. aureus (Gram-positive). The presented results in Table 2 showed that the control film did not show any antimicrobial effect on the bacteria strains. However, the addition of nanoliposomes containing O. decumbens essential oil at the levels of 1%, 2% and 3% resulted in bigger inhibition zones against E. coli and S. aureus as the most significant inhibition was obtained for PSG film enriched with 3% of the nanoliposome. Similarly, Mushtaq et al. [43] expressed that the control film didn’t result in any significant inhibitory effect on bacteria population while the antibacterial effect of the zein film against different pathogenic strains was enhanced by the enrichment of pomegranate peel extract. The antimicrobial effect of O. decumbens essential oil was related to the existence of polyphenols, which act as antimicrobial compounds through various phenomena such as membrane perforation, the decrease of membrane fluidity, protein/cell wall binding, as well as microbial enzyme inhibition [19].

Release of Oliveria decumbens essential oil

Figure 5 shows that the release profiles of O. decumbens essential oil from the films containing different concentrations of nanoliposomes follow a typical exponential pattern. In agreement with our results, Hajirostamloo and Molaveisi [19], stated that the release profiles of Echinacea purpurea (L.) extract from Alyssum homolocarpum seed gum films followed an exponential pattern. As observed in Fig. 5, the increase of O. decumbens essential oil concentration significantly effects the release profile of the essential oil from PSG films. It can be concluded that the film containing 3% nanoliposomes owns more non-uniform structure than other films, due to the formation of the stronger intermolecular interactions, verified by FTIR and DSC analysis before. PSG films form networks that can be dissolved and eroded by means of hydrolysable cross-links, which generally involve hydrophilic groups and are permeable by release media [23]. This mass transfer behavior is possibly because of the hydrophobic nature of PSG, resulting in penetration of water into the intensely porous composition of PSG-based films containing nanoliposomes loaded with O. decumbens essential oil [44].

Conclusion

In this study, an active film based on PSG enriched with different concentrations of nanoliposomes loaded with O. decumbens essential oil were prepared to obtain edible films with satisfactory physical, mechanical, and chemical properties as this enrichment decreased WVP while enhancing mechanical, antioxidant and antibacterial properties. Our study provided valuable information on the interactions between PSG and nanoliposomes loaded with O. decumbens essential oil according to FTIR results. Finally, we can conclude that PSG-based films have a good potential for application as functional edible film for packaging due to very good WVP and probable antioxidative properties of nanoliposomes loaded PSG films. Moreover, they can provide benefiting from health promoting properties of O. decumbens essential oil bio-components through their encapsulation in nanoliposomes and protection of them from degradation during release in the target medium.

References

P. Cazón, G. Velazquez, J.A. Ramírez, M. Vázquez, Polysaccharide-based films and coatings for food packaging: a review. Food Hydrocoll. 68, 136–148 (2017)

X. Zhang, Y. Zhao, Y. Li, L. Zhu, Z. Fang, Q. Shi, Physicochemical, mechanical and structural properties of composite edible films based on whey protein isolate/psyllium seed gum. Int. J. Biol. Macromol. 153, 892–901 (2020)

F. Askari, E. Sadeghi, R. Mohammadi, M. Rouhi, M. Taghizadeh, M. Hosein Shirgardoun, M. Kariminejad, The physicochemical and structural properties of psyllium gum/modified starch composite edible film. J. Food Process. Preserv. 42(10), e13715 (2018)

M.R. Rao, D.U. Warrier, S.R. Gaikwad, P.M. Shevate, Phosphorylation of psyllium seed polysaccharide and its characterization. Int. J. Biol. Macromol. 85, 317–326 (2016)

X. Zhang, Y. Zhao, Q. Shi, Y. Zhang, J. Liu, X. Wu, Z. Fang, Development and characterization of active and pH-sensitive films based on psyllium seed gum incorporated with free and microencapsulated mulberry pomace extracts. Food Chem. 352, 129333 (2021)

M.J. Fabra, A. López-Rubio, J.M. Lagaron, Use of the electrohydrodynamic process to develop active/bioactive bilayer films for food packaging applications. Food Hydrocoll. 55, 11–18 (2016)

S. Jafarzadeh, A. Salehabadi, A.M. Nafchi, N. Oladzadabbasabadi, S.M. Jafari, Cheese packaging by edible coatings and biodegradable nanocomposites; improvement in shelf life, physicochemical and sensory properties. Trends Food Sci. Technol. 116, 218–231 (2021)

O.L. Pop, C.R. Pop, M. Dufrechou, D.C. Vodnar, S.A. Socaci, F.V. Dulf, F. Minervini, R. Suharoschi, Edible films and coatings functionalization by probiotic incorporation: a review. Polymers 12(1), 12 (2019)

Z. Najafi, C.J. Kahn, F. Bildik, E. Arab-Tehrany, N. Şahin-Yeşilçubuk, Pullulan films loading saffron extract encapsulated in nanoliposomes; preparation and characterization. Int. J. Biol. Macromol. 188, 62–71 (2021)

B.A. Behbahani, F.T. Yazdi, A. Vasiee, S.A. Mortazavi, Oliveria decumbens essential oil: chemical compositions and antimicrobial activity against the growth of some clinical and standard strains causing infection. Microb. Pathog. 114, 449–452 (2018)

M. Shahidi Noghabi, M. Molaveisi, Microencapsulation optimization of cinnamon essential oil in the matrices of gum Arabic, maltodextrin, and inulin by spray-drying using mixture design. J. Food Process Eng 43(2), e13341 (2020)

A.F. Esfanjani, S.M. Jafari, E. Assadpour, Preparation of a multiple emulsion based on pectin-whey protein complex for encapsulation of saffron extract nanodroplets. Food Chem. 221, 1962–1969 (2017)

I. Katouzian, A.F. Esfanjani, S.M. Jafari, S. Akhavan, Formulation and application of a new generation of lipid nano-carriers for the food bioactive ingredients. Trends Food Sci. Technol. 68, 14–25 (2017)

N. Khatib, M.J. Varidi, M. Mohebbi, M. Varidi, S.M.H. Hosseini, Co-encapsulation of lupulon and xanthohumol in lecithin-based nanoliposomes developed by sonication method. J. Food Process. Preserv. 43(9), e14075 (2019)

A. Kamkar, E. Molaee-Aghaee, A. Khanjari, A. Akhondzadeh-Basti, B. Noudoost, N. Shariatifar, M. Alizadeh Sani, M. Soleimani, Nanocomposite active packaging based on chitosan biopolymer loaded with nano-liposomal essential oil: its characterizations and effects on microbial, and chemical properties of refrigerated chicken breast fillet. Int. J. Food Microbiol. 342, 109071 (2021)

M. Molaveisi, M.S. Noghabi, K. Parastouei, R.A. Taheri, Fate of nano-phytosomes containing bioactive compounds of Echinacea extract in an acidic food beverage. Food Struct. 27, 100177 (2021)

M. Molaveisi, M. Shahidi-Noghabi, S. Naji-Tabasi, Controlled release and improved stability of vitamin D3 within nanoliposomes stabilized by palmitic acid. J. Food Saf. 41(5), e12924 (2021)

B. Hajirostamloo, M. Molaveisi, D. Dehnad, Structural, nutritional and antimicrobial properties of soy protein isolate and Alyssum homolocarpum seed gum films containing carrot seed and pomegranate peel extracts. J. Food Meas. Charact. (2022). https://doi.org/10.1007/s11694-022-01471-6

B. Hajirostamloo, M. Molaveisi, Active Alyssum homolocarpum seed gum films containing microencapsulated Echinacea purpurea (L.) extract; study of physicochemical properties and its application in quail meat packaging. J. Food Meas. Charact. 16, 1997–2010 (2022)

B. Hajirostamloo, S.A. Mortazavi, M. Molaveisi, D. Dehnad, Improvement of soy protein isolate-Alyssum homolocarpum seed gum blend film through intermolecular bonds induced by the mixture of plant extracts. J. Food Meas. Charact. (2022). https://doi.org/10.1007/s11694-022-01359-5

D. Kadam, B. Momin, S. Palamthodi, S.S. Lele, Physicochemical and functional properties of chitosan-based nano-composite films incorporated with biogenic silver nanoparticles. Carbohydr. Polym. 211, 124–132 (2019)

R.Q. Assis, S.M. Lopes, T.M.H. Costa, S.H. Flôres, A. de Oliveira Rios, Active biodegradable cassava starch films incorporated lycopene nanocapsules. Ind. Crops Prod. 109, 818–827 (2017)

L.M. Marvdashti, A. Koocheki, M. Yavarmanesh, Alyssum homolocarpum seed gum-polyvinyl alcohol biodegradable composite film: physicochemical, mechanical, thermal and barrier properties. Carbohydr. Polym. 155, 280–293 (2017)

I.K. Sani, S.P. Geshlaghi, S. Pirsa, A. Asdagh, Composite film based on potato starch/apple peel pectin/ZrO2 nanoparticles/microencapsulated Zataria multiflora essential oil; investigation of physicochemical properties and use in quail meat packaging. Food Hydrocoll. 117, 106719 (2021)

M. Moghadam, M. Salami, M. Mohammadian, M. Khodadadi, Z. Emam-Djomeh, Development of antioxidant edible films based on mung bean protein enriched with pomegranate peel. Food Hydrocoll. 104, 105735 (2020)

L. Nikravan, S. Maktabi, M. Ghaderi Ghahfarrokhi, M. Mahmoodi Sourestani, The comparison of antimicrobial and antioxidant activity of essential oil of Oliveria decumbens and its nanoemulsion preparation to apply in food industry. Iran. Vet. J. 17(72), 78–87 (2020)

N. Zahabi, M.T. Golmakani, M.Fazaeli, F. Ghiasi, M. Khalesi, Electrospinning of glutelin-hordein incorporated with Oliveria decumbens essential oil: Characterization of nanofibers. Colloids Surf. B: Biointerfaces 208, 112058 (2021)

S. Barzegar, M.R. Zare, F. Shojaei, Z. Zareshahrabadi, O. Koohi-Hosseinabadi, M.J. Saharkhiz, A. Iraji, K. Zomorodian, M. Khorram, Core-shell chitosan/PVA-based nanofibrous scaffolds loaded with Satureja mutica or Oliveria decumbens essential oils as enhanced antimicrobial wound dressing. Int. J. Pharm. 597, 120288 (2021)

H. Cui, L. Yuan, L. Lin, Novel chitosan film embedded with liposome-encapsulated phage for biocontrol of Escherichia coli O157: H7 in beef. Carbohydr. Polym. 177, 156–164 (2017)

M. Molaveisi, M. Shahidi-Noghabi, S. Naji-Tabasi, Vitamin D3-loaded nanophytosomes for enrichment purposes: formulation, structure optimization, and controlled release. J. Food Process Eng. 43(12), e13560 (2020)

D.R. Telange, A.T. Patil, A.M. Pethe, H. Fegade, S. Anand, V.S. Dave, Formulation and characterization of an apigenin-phospholipid phytosome (APLC) for improved solubility, in vivo bioavailability, and antioxidant potential. Eur. J. Pharm. Sci. 108, 36–49 (2017)

N. Eko Wahyuningtiyas, H. Suryanto, Effect of ultrasonic treatment on morphology and mechanical properties of bioplastic from cassava starch with nanoclay reinforcement. J. Metastable Nanocryst. Mater. 29, 35–41 (2017)

F. Ge, Y. Chen, A. Liu, S. Guang, Z. Cai, Flexible and recyclable SERS substrate fabricated by decorated TiO2 film with Ag NPs on the cotton fabric. Cellulose, 26(4), 2689–2697 (2019)

Z. Alinaqi, A. Khezri, H. Rezaeinia, Sustained release modeling of clove essential oil from the structure of starch-based bio-nanocomposite film reinforced by electrosprayed zein nanoparticles. Int. J. Biol. Macromol. 173, 193–202 (2021)

J.A. Scramin, D. de Britto, L.A. Forato, R. Bernardes-Filho, L.A. Colnago, O.B. Assis, Characterisation of zein–oleic acid films and applications in fruit coating. Int. J. Food Sci. Technol. 46(10), 2145–2152 (2011)

Y. Lei, H. Wu, C. Jiao, Y. Jiang, R. Liu, D. Xiao, J. Lu, Z. Zhang, G. Shen, S. Li, Investigation of the structural and physical properties, antioxidant and antimicrobial activity of pectin-konjac glucomannan composite edible films incorporated with tea polyphenol. Food Hydrocoll. 94, 128–135 (2019)

S.M. Hasheminya, R.R. Mokarram, B. Ghanbarzadeh, H. Hamishekar, H.S. Kafil, J. Dehghannya, Development and characterization of biocomposite films made from kefiran, carboxymethyl cellulose and Satureja khuzestanica essential oil. Food Chem. 289, 443–452 (2019)

D. Kowalczyk, T. Skrzypek, M. Basiura-Cembala, K. Łupina, M. Mężyńska, The effect of potassium sorbate on the physicochemical properties of edible films based on pullulan, gelatin and their blends. Food Hydrocoll. 105, 105837 (2020)

R. Farajpour, Z.E. Djomeh, S. Moeini, H. Tavakolipour, S. Safayan, Structural and physico-mechanical properties of potato starch-olive oil edible films reinforced with zein nanoparticles. Int. J. Biol. Macromol. 149, 941–950 (2020)

A.I. Bourbon, M.A. Cerqueira, A.A. Vicente, Encapsulation and controlled release of bioactive compounds in lactoferrin-glycomacropeptide nanohydrogels: curcumin and caffeine as model compounds. J. Food Eng. 180, 110–119 (2016)

T. Jamali, G. Kavoosi, Y. Jamali, S. Mortezazadeh, S.K. Ardestani, In-vitro, in-vivo, and in-silico assessment of radical scavenging and cytotoxic activities of Oliveria decumbens essential oil and its main components. Sci. Rep. 11(1), 1–19 (2021)

N. Samadi, S. Masoum, B. Mehrara, H. Hosseini, Application of linear multivariate calibration techniques to identify the peaks responsible for the antioxidant activity of Satureja hortensis L. and Oliveria decumbens Vent. essential oils by gas chromatography–mass spectrometry. J. Chromatogr. B 1001, 75–81 (2015)

M. Mushtaq, A. Gani, A. Gani, H.A. Punoo, F.A. Masoodi, Use of pomegranate peel extract incorporated zein film with improved properties for prolonged shelf life of fresh Himalayan cheese (Kalari/kradi). Innov. Food Sci. Emerg. Technol. 48, 25–32 (2018)

L.M. Marvdashti, A. Koocheki, M. Yavarmanesh, Characterization, release profile and antimicrobial properties of bioactive polyvinyl alcohol—Alyssum homolocarpum seed gum-nisin composite film. Food Biophys. 14(2), 120–131 (2019)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chavoshi, F., Didar, Z., Vazifedoost, M. et al. Psyllium seed gum films loading Oliveria decumbens essential oil encapsulated in nanoliposomes: preparation and characterization. Food Measure 16, 4318–4330 (2022). https://doi.org/10.1007/s11694-022-01533-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01533-9