Abstract

Optimization of proteins extraction from muskmelon (Cucumis melo) seeds was investigated using a central composite rotatble design involving four factors at five levels: temperature (X1) (40, 45, 50, 55 and 60 °C); pH (X2) (8.5, 9, 9.5, 10, 10.5); extraction time (X3) (30, 40, 50, 60 and 70 min); and solvent/meal (S/M) ratio (X4) (5, 10, 15, 20 and 25 v/w). Protein yield varied from 17.46 to 78.77% for the different combination of four independent factors. Non-significant lack of fit validated the adequacy of the model. The linear factors X1, X2, X3 and X4 along with X13 (temperature and time), X23 (pH and time), X34 (time and S/M) and quadratic coefficient X42 (S/M) showed the significant effect on the response variable. Optimized conditions for protein extraction were 55 °C, pH 10, extraction time 62 min and S/M ratio (v/w) 23. Confirmation study gave the extracted yield of 84.11% which was slightly lower than the predicted value (85.07%) under optimized conditions. Lightness of MPC was lower than the MDSM. Protein content of MDSM was 84.12%. A significant effect of pH was observed on protein solubility, EAI and ESI, foaming capacity and stability. Secondary structure or proteins had more number of β-sheets than random coil and α-helix structures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Plant proteins contribute nearly 65% of human requirement worldwide due to easy access, abundant supply and being economical [1]. Increasing trend and obsession towards the vegan protein has encouraged us to look for the novel and cheap sources of proteins to bridge the gap between demand and supply. A huge amount of waste is generated from either direct consumption or processing of fruits in the form of peel and seeds. Fruit processing waste possesses potential nutrients and biomass which can be further utilized as both raw material and value addition sources. Many unconventional protein sources are being exploited including rice bran, watermelon seeds, pumpkin seeds and bitter melon seeds. Utilization of oil seeds as an alternative protein source facilitates to supplement the protein deficient staple products.

Muskmelon (Cucumis melo) is an important member of Cucurbitaceae family and commonly grown in tropical areas of Asia and Africa. Approximately ten commercial varieties of muskmelon are grown in Indian states which include Punjab, Tamil Nadu, Uttar Pradesh, Maharashtra, and Andhra Pradesh [2]. The fruit is consumed as fresh or processed into juices and nectars [3]. It ranked fourth in U.S. annual per capita consumption of fresh fruits preceded by bananas, watermelons and apples [4]. Global melon production was about 27.5 million tons in 2019 and India produced about 1.26 million tons (FAOSTAT, 2019). Kernels from seeds are mainly used as decorating, stuffing, topping and thickening agents in desserts. Seeds of melon are rich in protein and oil with many medicinal properties [5, 6]. Freshly dehulled melon seeds contain 34.24% protein, 45.95% fat, 7.18% crude fibre, 4.05% ash, 8.03% moisture and 0.56% carbohydrate. Muskmelon seeds contain various essential and non-essential amino acids comparable to soy bean, thus can be considered as an unconventional source of protein [7].

The demand of the protein is increasing mainly due to population growth, food processing and dietary supplements. The irony is that a large section of population is consuming protein deficient diet, especially in developing countries. Efforts are being made to find the new sources of protein to bridge the gap between demand and supply. Food processing waste is a non-conventional source of protein and oil especially from seeds. Protein isolate and concentrate are required to improve the supply of protein. Many factors including pH, temperature, ionic strength, solvent type, extraction time, solid–liquid ratio affect the extraction of protein [8]. However, depending on the product, the extraction procedures differ and thus affect of control parameters. The response surface methodology (RSM) is a statistical tool most frequently used to carry out series of experiments. The main objective of RSM is to determine the combined effect of process parameters on the response variable as well as to get the optimized operating conditions. Selected number of experiments helps in saving time and cost. Functional properties are the function of hydration properties, molecular size, net protein charge and surface properties. These properties vary for seed flours and protein extracted from them. The objective of present study is to optimize the temperature, pH, time and solvent to meal ratio for the protein extraction from muskmelon seeds and determine the difference between the functional properties of MDSM and MPC for food applications.

Materials and methods

Raw material

Fresh muskmelon fruits of variety Muskaan matured for 65–70 days were collected in the month of May and June from the local vegetable market located in Valla, Amritsar, Punjab, India.

Seed meal preparation

Fruits were cut with stainless steel knife and seeds were separated. Further seeds were washed with hands under tap water and air dried. Dried seeds were triturated in a mill and defatted by triple extractions with n-hexane (solvent: meal ratio—10:1 v/w). The solvent was further removed by oven drying at 40 °C for 6 h. The muskmelon defatted seed meal (MDSM) were ground again and screened through a mesh of 0.5 mm diameter and packed in polyethylene bags and stored at – 20 °C till further use.

Proximate composition

Ground whole seeds were analyzed for moisture, ash, fat and crude protein contents following the AOAC 950.46, 938.08, 948.22 and 981.10 methods [9], respectively. Crude protein content was determined by the Kjeldahl method, with a conversion factor of 6.25 to convert total nitrogen to crude protein. Carbohydrates were calculated by difference [10].

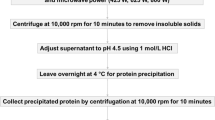

Protein extraction

Protein was extracted from defatted muskmelon seed meal following the alkaline extraction method. Conditions were sustained according to 30 different selected trials by varying the independent variables at five levels. Extraction of protein was carried out in incubator shaker (Lab-Tech, Italy) for maintaining the required temperature and the shaking required. Further, the solution was centrifuged (Eppendorf, Hamburg, Germany) at 12857×g, 4 °C for 15 min to collect the supernatant. The supernatant was further filtered through Whatman filter paper no. 1 and was further analysed for soluble protein content according to the method of Lowry et al. [11]. All the trials were conducted in triplicates. Defatted muskmelon seed flour contains 48.12% of protein.

Experimental design

The effect of four independent variables; temperature (X1), pH (X2), time (X3) and solvent to meal ratio (S/M) (X4) at five different levels was studied on the dependent variable (Y), protein yield by designing a 30 trial central composite design using design expert (Ver. 7, Stat-Ease Inc, Minneapolis, USA) (Table 1). Thirty experimental trials including 16 factorial, 8 axial and 6 repetitive central points are as shown in Table 1.

Confirmative test

Protein was extracted from defatted muskmelon seed meal using the optimized values of independent variables including temperature, pH, time and S/M as derived. Experimental and predicted values of response were further compared for the adequacy and validation of the model.

Statistical analysis

The data of independent and response variables were used to obtain a second order polynomial model which was further employed to calculate the predicted value of response variables:

where Y: Response variable- protein yield (g/100 g); X: Independent variable-temperature, pH, time and S/M ratio. b0, bn, bm and bmn: coefficients of intercept, linear, quadratic and interaction parameters respectively.

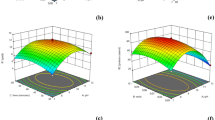

Regression coefficient (R2), adjusted R2, lack of fit, coefficient of variance and significance of individual factor and their interaction from the analysis of variance (ANOVA) table were analysed for the predicted response values. 3D surface graphs were plotted by varying two variables at a time and keeping the remaining two at coded zero level. The data was analyzed by design expert (Stat Ease Inc., Minneapolis, USA) to obtain the optimum levels for protein extraction and thus further validated for maximum and economic response. The response was evaluated using numerical optimization to get most acceptable response by design expert. The best solution was selected on the basis of convenience and cost for further validation and optimized.

Muskmelon seeds protein concentrate (MPC)

MPC was prepared on the optimized conditions obtained from defatted muskmelon seed flour after RSM analysis. Further MDSM and MPC were characterized by their color, functional properties and SDS-PAGE analysis.

Color

Hunter color Lab (Ultra Scan VIS, Hunter Associates Laboratory Inc., Reston, USA) was used to determine the colors of MDSM and MPC. Calibration of the apparatus was done by using black white tile. Color analysis were documented in terms of CIE units where L* implies the lightness, a* implies red-green color and b* implies yellow-blue color. Chroma, Hue value and whiteness index were calculated by as follows [12]:

Functional properties

Water and oil absorption capacity

MDSM (2 g) and MPC (50 mg) were suspended in distilled water or soybean oil and vortexed thoroughly. Samples were hold at room temperature for 30 min with shaking at regular interval. The samples were centrifuged further at 5000 rpm for 10 min and supernatant were discarded. Increase in the weight by samples was reported as water and oil absorption capacity. Water dispersibility was calculated by the method described by Kulkarni et al. [13].

Protein solubility

Protein solubility of MDSM and MPC was investigated by varying the pH from 2 to 10. Samples (MDSM (1%) and MPC (0.1%)) were mixed with phosphate buffer (pH 2, 6, 8), acetate buffer (pH 4) and borate buffer (pH 10). Suspensions were allowed to incubate along with continuous shaking for hour at 30 °C. Samples were centrifuged at 10,000 rpm for 15 min and supernatant were analysed for protein content by Lowry analysis [11].

Emulsion activity and stability index

Emulsion activity and stability of samples were investigated at different pH by method described by Pearce and Kinsella [14] with slight modification. 6 ml of MDSM (1%) and MPC (0.1%) solutions of pH 2, 4, 6, 8, 10 was dispersed with 2 ml of soybean oil and homogenized for 1 min at 10,000 rpm. 50 µl of samples were pipette out from the bottom and added to 0.1% SDS solution. Absorbance of the samples was determined at 500 nm at 0 min and after 10 min and emulsion activity and stability index was calculated by:

Where, T = 2.303, A0 = Absorbance at 0 min, C = initial concentration of sample (g), ΔA = difference in absorbance between 0 and 10 min, Δt = time interval.

Foaming capacity and stability

MDSM (1%) and MPC (0.1%) were dispersed in different buffers from pH 2 to 10 as mentioned earlier. Samples were homogenized for 1 min at 10,000 rpm. Increase in foam volume was immediately recorded and expressed as foam capacity by following equation as referred by Cruz-Solorio [15]:

where A and B are total volume after and before homogenization.

Decrease in foam volume at regular intervals was recorded and expressed as foam stability by following equation:

where Vt is foam volume at t time and V0 is initial foam volume.

FTIR—secondary structure

Secondary structure of MDSM and MPC was determined through fourier transform infrared spectrometer (Perkin Elmer Inc, Waltham USA) within the range of 4000–400 cm−1. Dried powder of MDSM and MPC were mixed with potassium bromide to form the transparent pellet using the hydraulic press. Peak Fit Software (Systat Software, Inc., Richmond, USA) was used for the deconvolution of the peaks and for curve fitting. To confirm the number and position of peaks deconvoluted peak fit spectrum was compared against secondary derivative plot. Band positioning of flour was confirmed as reported by Amir et al. [16].

SDS–PAGE

10 mg of MDSM and MPC from muskmelon seeds were mixed with 10 ml of unreduced (62.5 mM Tris–HCl pH 6.8, 2% SDS, 0.01% bromophenol blue and 25% glycerol) and reduced (along with 5% mercaptoethanol) buffer as illustrated by Laemmli [17]. The samples were completely suspended in the buffer by vortex and incubated for 1 h at 50 °C at 150 rpm. Further, the tubes were heated in boiling water bath for 10 min and centrifuged at 10,000 rpm for 10 min. 5 µl of the supernatant were loaded in the gel containing 4% stacking gel and 12% resolving gel. Protein bands were resolved by applying 30 mA of constant current to the gel. Staining of the gel was done overnight in Coomassaie Brilliant Blue R250 (0.1%) and further destained with the solution containing 40% methanol and 10% acetic acid. Bio-Rad GelDoc system (EZ imager, Hercules, USA) was used to quantify the bands from destained gels.

Statistical analysis

All the values were expressed as mean ± SD One-way analysis of variance (ANOVA) was applied using Minitab version 17, Minitab Inc., State College, PA, USA. Comparisons of mean values were done by Tukey’s post-hoc test.

Results and discussion

Proximate composition

Whole seed meal of muskmelon seeds cv Muskaan contained 23.75% fat, 15.16% protein, 46.82% fibre, 3.19% ash, 6.48% carbohydrate and 4.62% moisture. The removal of husk and fat altered the composition of seed meal. Dehusked muskmelon kernel meal contained 38.77% fat, 35.17% protein, 11.86% fibre, 4.85% ash, 2.26% carbohydrate and 7.09% moisture. Furthermore, protein content of defatted kernel meal increased to 48.12%. Mello et al. [18] reported 19.3% protein in whole seed meal. Hu and Ao [19] reported 35.36% fat, 29.90% protein, 19.52% fibre, 4.05% ash, 5.85% carbohydrate and 5.32% moisture in whole muskmelon seed meal. Previous results showed that the composition of muskmelon was comparable with the reported values.

Protein extraction

Four independent variables including temperature (X1), pH (X2), time (X3) and solvent to meal ratio (S/M) (X4) were optimized to get maximum protein yield. Combination of these independent variables as per CCRD design resulted in experimental protein yield of 17.46–78.77% (Table 1).

A similar study has been conducted by Devi & Badwaik [20], on muskmelon seed meal with different factors and got the protein yield in the range of 70.31–77.31%. On contrary, authors did not find any significant effect of temperature on response; however, they further reported an increase in protein yield with increase in extraction time. Wani et al, [3] reported the extraction of protein yield from watermelon seeds from 75.49 to 86.08%.

The results of present study are in agreement with aforesaid study. The slight variation in results may be due to the different variety, operating conditions, different independent variables chosen and their combinations at different levels. Furthermore, use of Box–Behnken design may also contributed to the variations.

Analysis of data

Data of independent and response variables in 30 runs as per CCRD design were analyzed using Design Expert software-7 (Stat Ease Inc., Minneapolis, USA) to get a model that could explain the relationship between the variables. A polynomial model was obtained with linear, constant and interaction relationship between the aforesaid factors.

Where Y—Protein Yield (%). X1, X2, X3, and X4—Coded values of temperature, pH, time and S/M respectively.

The regression equation was used to calculate the predicted values of response variable. Table 2 showed the results of quadratic response surface model fitting in the form of ANOVA. The p value of quadratic model was highly significant. It has been suggested to choose the model with highest significant additional terms and it should not be aliased. Further, cubic model was found to be aliased and thus not used for the prediction of a response. Table 3 represents lack of fit test of various models. Fitness and adequacy of the model requires insignificant lack of fit. Quadratic model was opted as its F-value and p-value were 3.29 and 0.1002 respectively that shows the lack of fit for model was non-significant.

Analysis of variance

In present study, a two-way ANOVA has been implanted to illustrate the significance of different independent variables on protein extraction. Data was evaluated to get a second order model for response variable (Y) consisting of a constant, linear and interaction terms (Table 4). Results showed that the model was highly significant (p ≤ 0.0001).

The significance of model can be confirmed since F-value is 16.70 (p < 0.0001) and lack of fit was non-significant (p > 0.05). All the linear terms including temperature (X1), pH (X2), time (X3) and S/M (X4) showed significant effect (p < 0.05) on protein extraction. Furthermore, the interaction between temperature & time (X1 X3), pH & time (X2 X3), and time & S/M (X3 X4) showed significant effect on protein extraction (p < 0.05). However, quadratic coefficients X12, X22, X32 and X42 did not show any significant effect on the response. Negative quadratic coefficients further imply the parabolic effect of response. It concluded the increase of response to limited extent, afterwards inverse behaviour is followed. Similar results were concluded by Baca-Bocanegra et al. [21]. Coefficient of determination (R2) was 0.9397. The Predicted R2 of 0.6871 is in reasonable agreement with the Adjusted R2 of 0.8835; i.e. the difference is less than 0.2. The coefficient of variation (CV) implies the ratio of the standard error of estimate to the mean value of the response observed expressed as a percentage. It is considered that a model can be reasonably reproducible if its CV is not greater than 10% [22]. Coefficient of variance in present study was 9.78% which further validates the model. All the aforesaid results are in agreement and can be further used to describe the effect of variables on response. The experimental values of response variable were plotted against the predicted values obtained by the regression model which further authenticated the model since the experimental values were evenly distributed along the graph (Fig. 1a). The residual plot showing the difference between the experimental and predicted values of response is shown in Fig. 1b.

Diagnostic plots for model adequacy: a Relationship between the observed and predicted values of the extraction of protein, b Normal probability plots of studentized residuals for protein yield, c Plot of residual fit of regression model for protein extraction from muskmelon defatted seed meal. Response surface plots showing the effect of two independent variables on the protein yield (g/100 g) from muskmelon defatted seed meal while remaining two kept at zero level: d temperature and pH, e temperature and time, f temperature and S/M, g pH and time, h pH and S/M, i time and S/M

Response graphs

In order to find the optimum values of independent variables, two independent variables were varied while keeping the remaining two constant to get three dimensional graphs (Fig. 1).

Temperature

Protein yield increased with increase in temperature as shown in Fig. 1d and f. However, protein content also increased with increase in temperature and time simultaneously and keeping pH and S/M ratio constant (Fig. 1e). Similar results were concluded by Wani et al. [3] for protein extraction from watermelon seeds. Optimum temperature obtained for protein extraction was 55 °C. Effect of temperature on protein extraction has been reported in numerous studies. A significant direct effect of temperature has been observed on the protein content from cassava leaves [23] and brown rice [24]. Above 20 °C the protein content increases with increase in the protein solubility, since, breakage of hydrogen and disulfide bonds may occur with heat treatments and results in high solubility of protein. Protein content increases till 60 °C. Further increase in temperature may degrade the protein as high temperature promotes aggregation and cross-linking of partially hydrolyzed proteins, thus decreasing their solubility and is not recommended [25,26,27].

pH

A linear and interactive significant effect of pH was seen on the protein extraction. An increase in protein yield was observed with the interaction of pH with time and S/M. Maximum response was observed when pH was 10.5 and time was 70 min (Fig. 1g) and S/M was 25 (Fig. 1h). Protein content increased till pH 10.5, however, with interaction among different variables protein content maximized at pH 10. The pH plays an important role in protein extraction as the solubility of protein depends on pH. Protein yield increased with increase in pH or alkaline conditions. Similar results on protein extraction were obtained by Wani et al. [3] for watermelon seeds while Baca-Bocanegra et al. [21] for grape seed meal. At high pH more number of amino group from amino acids dissociate into − NH2 and H+ and with the presence of − COO− the solubility of protein increases [28]. High solubility of proteins enables them to use for further food applications, since dispersed protein particles are non-desirable.

Time

A significant linear effect of time has been seen on the response. Further, protein yield rose with increase in time along with other factors including temperature, pH and S/M. Protein yield was highest when temperature was 60 °C for 70 min (Fig. 1e). Maximum protein yield was obtained at pH 10.5 with 70 min of extraction time (Fig. 1g). Similar trend for protein content was observed with varying S/M and protein yield was maximized at 25 S/M for 70 min of time (Fig. 1i). Kain et al. [28] concluded that proteins are mostly stable between the extraction time of 30–60 min. Authors extracted maximum protein till 60 min from peanut meal. Optimum time obtained for protein extraction from present study is for 60 min. Authors also reported decrease in protein yield with further increase in extraction time beyond 60 min. On contrary, Cao et al. [24] reported the increase of soluble protein from brown rice till 2 h of extraction time. Further, Wani et al. [6] and Deng et al. [29] did not report any significant effect of time on the extraction of protein.

S/M ratio

Solvent to meal ratio did show a significant linear and interactive effect on the response generated. Similar results were reported by Rustom et al. [27] and Rhee et al. [30] for peanut proteins and concluded that protein extraction could be increased if solids-to-water ratio was increased to 1:20. Effect of S/M can be seen in Fig. 1f, h, i. Increase in protein content can be seen when S/M was increased along with pH and time, however, negative coefficient of interaction among temperature revealed no impact of S/M on protein yield along with increase in temperature. Furthermore, highest coefficient of interaction of time and S/M implies their maximum effect on the response. The results were supported by Deng et al. [29] for the protein extraction from Kiwi seeds. Maximum protein content was obtained when S/M was 25 for 70 min keeping temperature and pH constant at 9.5. However, 20 level of S/M was concluded as optimum in agreement with Rustom et al. [27]. Protein content was maximized at 55 °C at pH 10 with 60 min of extraction time and 20 S/M.

Desirability function

In this technique, the optimal conditions were attained in order to get maximum protein yield from the muskmelon defatted seed meal and this was determined by Derringer’s desired function methodology. Desirability varied from 0.0 as lowest level to 1.0 to highest level, where 0 value of desirability represent completely undesirable response and 1.0 value represents fully desirable response. Approximately, 85.07% of protein yield was desired at level 1.0. According to desirability function methodology, the predicted optimal conditions were temperature 55 °C, pH 10, time 62 min and S/M 23 which was further analyzed to validate the model. Figure 2 showed the ramp graphs with desirability 1.0.

Confirmative test

Optimum response was predicted using polynomial equation at recommended levels to attain 1.0 level of desirability. The results were confirmed by analyzing the protein yield at the optimum conditions of temperature 55 °C, pH 10, time 62 min and S/M 23 v/w. Experimental protein yield was 84.11% whereas the predicted protein yield was 85.07%. The experimental value was slightly lower than the predicted response which was also supported by Wani et al. [3]. The comparable predicted and experimental response depict adequacy of the model.

Color

L* signifies the lightness of the sample, ΔE stands for the total color difference, Hue value represents the intensity of the lightness of the sample however, chroma defines the saturation of the color. MDSM exhibited higher (Table 5) value for L*, ΔE, Hue value and Chroma (90.44, 90.89, 87.05 and 86.81) than MPC (65.49, 67.37, 83.57 and 61.96). Lower L*, ΔE, Hue value and Chroma values for MDSM implies the comparative darkness than the MDSM which may be due to the alkaline extraction followed by the acid precipitation [31]. Higher a* and b* values of MPC (1.77 and 15.66) than MDSM (0.46 an 8.99) signifies the higher extent of yellowness and redness in the MPCs. CIE values of muskmelon seeds MPC are in agreement with Singh and Sogi [31].

Functional properties

Water and oil absorption capacity

Water absorption capacity (WAC), Oil absorption capacity (OAC), and water dispersibility of muskmelon seeds MDSM and MPC is reported in Table 5. WAC, water dispersibility and OAC of MDSM were 1.799, 11.41 and 2.105 respectively. MPC exhibited 1.95, 2.46 and 2.55 values for WAC, water dispersibility and OAC respectively. Ogundele et al. [32] studied the functional properties of gourd melon protein isolates and supports the present outcome. WAC and OAC of flour and protein are influenced by the hydration sites present, pH, temperature, method of treatment and protein conformation. Higher OAC of MDSM and MPC may be attributed to the presence of more number of non-polar side chains [33,34,35]

Protein solubility

Protein solubility contour depending on the pH of MDSM and MPC has been depicted in Fig. 3. Protein solubility mainly depends on the presence of net charge on protein molecules and protein inter and intra molecular interactions. As shown in Fig. 3 protein solubility was lowest at pH 4 near to its isoelectric point, where there is no net charge on protein molecules which further strengthens the protein–protein interaction. Protein solubility increases on the either side of isoelctric point due to gain in net positive charge at acidic pH and negative charge at alkaline pH [31, 36]. Protein solubility of seed flour was lower than that of MPC and found to be highest at pH 10. Study conducted by Ogundele et al. [32] supports the present study.

Foaming capacity and stability

Foam capacity is expressed as the function of protein solubility and its suppleness to get unfold. Foam capacity of MDSM and MPC is depicted in figure and followed the same trend as protein solubility at different pH. Foam capacity was minimal at pH 4 and followed the same trend as pH solubility (Fig. 4a). As protein intra molecular interaction is reported to be maximal at pH near isolectric point, proteins are less flexible to unfold which decrease their absorption at water air interface resulting low foaming capacity at pH 4 [31]

Foam stability of MDSM and MPC at different pH for up to 180 min has been depicted in Fig. 4b. Maximum foam stability was observed at pH 4 near isoelectric point due to higher protein–protein interaction and firm protein molecular structures [31].

Emulsion activity and stability

Emulsion activity index (EAI) and stability (ESI) of muskmelon MDSM and MCP is shown in Table 6. EAI and ESI were observed to be minimal at or near isoelectric point (pI) of protein (pH 4, 6), as less soluble protein availability. However, EAI and ESI rise on either side of pI. Similar trends have been reported in literature by Ahmed et al. [37] for legume flours and MPCs Jamdar et al. [38] for peanut protein hydolysates. EAI of proteins depends on the concentration, solubility and hydrophobicity of proteins. It has been reported that EAI decreased with increasing concentration of protein [39], which proves to be consistent with the present study as seed flour emulsions with higher concentrations exhibited lower EAI than of MPC.

Secondary structure

FTIR is a very sensitive technique to analyse the structures of protein based on the hydrogen bonding. It detects the different functional groups in protein by change in vibrations. 1500–500 cm−1 is known as fingerprint region of the sample [39]. Proteins can be identified within the range of 1600–1700 cm−1 for Amide I and 1,550–1,570 cm−1 for Amide II bands. Amide I bands consists of β-sheets & β-turns along with α-helix and random coils. FTIR spectrum of MDSM and MPC is depicted in Fig. 5a and deconvoluted peak fit for Amide I region is shown in Fig. 5b. β-sheets and β-turns were spotted in the region 1610–1640 cm−1 and 1660–1700 cm−1. Further α-helix and random coils are positioned at 1650–1658 cm−1 and 1640–1650 cm−1. Figure 5c shows the average proportion of different structures in Amide I region which conclude that β-sheets and β-turns are the major component of MPC. Fassai et al. [40] also shown β-sheets as the major component of secondary structure of Amide I region for egusi melon seed proteins. Second derivative plot Fig. 5d confirmed the peaks placement in accordance with deconvoluted peak fit graph for MDSM and MPC. Higher intensity or area of peaks in MPC in comparison to MDSM may be attributed to higher protein concentration.

SDS-PAGE

SDS-PAGE of MDSM and MPC performed in unreduced and reduced conditions are depicted in Fig. 6a, b. SDS gels resolved the polypeptides from 32.7–113.1 kDa to 22–49.5 kDa for unreduced and reduced bands of MDSM respectively. Further MPC SDS gels were having polypeptides ranging from 33.8–109 kDa to 22.2–52 kDa for unreduced and reduced conditions. Major bands of MDSM changed from 29.8–49.9 kda to 22–49.5 kDa from unreduced to reduced conditions. Similarly, major fractions of bands in unreduced condition transformed from 33.8–51.6 kDa to 22.2–52.0 kDa. Pumpkin seed flour total protein showed the major fractions of protein at 35 and 20 kDa [16]. A polypeptide range of 95–10 kDa was observed for total protein extracts from Citrullus lanatus under reduced and non reduced conditions by Singh and Matta [41].

Conclusion

The waste musk melon seeds were processed to obtain defatted seed meal containing 48.12% protein content. Response surface methodology was employed to optimize the maximum protein extraction from defatted muskmelon seed meal. Derringer’s desired function methodology revealed the optimal conditions for protein extraction from defatted seed meal were temperature 55 °C, pH 10, time 62 min and S/M 23:1 v/w. Under optimum condition, the experimental protein yield of 84.11% was quite close to the predicted protein yield of 85.07%. MPC exhibited enhanced values for functional properties along with the pH than MDSM. This can be due to the presence of more protein in pure form in MPC than the bounded form in MDSM. However; values for functional properties were minimal at pI, due to the absence of any net charge. Higher solubility of proteins at pH > 7 help in segregating their food applications. Higher foaming capacity of proteins depends on their solubility may find its application in whipping and cake formulations. Secondary structure of proteins in MDSM and MPC possessed higher proportion for β-sheets helps in their thermal stability. The results can be of substantial utility for further food application of muskmelon seed flour and MPC.

Data availability

The data used to support the findings of present study are attached here with the article.

References

M.C. Garcia, P. Puchalska, C. Esteve, M.L. Marina, Vegetable foods: a cheap source of proteins and peptides with antihypertensive, antioxidant, and other less occurrence bioactivities. Talanta 105, 328–349 (2013)

S. Parveen, M.A. Ali, M. Asghar, A.R. Khan, A. Salam, Physic-chemical changes in muskmelon as affected by maturity stage. J. Agric. Res. 50(2), 1 (2012)

A.A. Wani, D.S. Sogi, L. Grover, D.C. Saxena, Effect of temperature, alkali concentration, mixing time and meal/solvent ratio on the extraction of watermelon seed proteins—a response surface approach. Biosyst. Eng. 94(1), 67–73 (2006). https://doi.org/10.1016/j.biosystemseng.2006.02.004

S. Vallone, H. Sivertsen, G.E. Anthon, D.M. Barrett, E.J. Mitcham, S.E. Ebeler, F. Zakharov, An integrated approach for flavor quality evaluation in muskmelon (Cucumis melo reticulatus L. group) during ripening. Food Chem. 139, 171–183 (2013)

M.L.S. Mello, N. Narain, P.S. Bora, Characterisation of some nutritional constituents of melon (Cucumis melo hybrid AF-522) seeds. Food Chem. 68, 411–414 (2000)

T.A. El-Adawy, K.M. Taha, Characteristics and composition of different seed oils and flours. Food Chem. 74(1), 47–54 (2001)

M.B. Achu, E. Fokou, G. Kansci, M. Fotso, Chemical evaluation of protein quality and phenolic compound levels of some Cucurbitaceae oilseeds from Cameroon. Afr. J. Biotechnol. 12(7), 735–743 (2013). https://doi.org/10.5897/AJB10.1728

K. Liu, Soybeans: chemistry, technology and utilisation (Springer, New York, 1997)

AOAC. 2005. Official methods of analysis of AOAC International. 17th ed. Gaithersburg (MD): The Association of Official Analytical Chemists. Methods 950.46, 938.08, 948.22, 981.10.

H. Greenfield, D. Southgate, Food composition data: production, management and use (Elsevier Applied Science, New York, 1992), p. 243

O.H. Lowry, N.J. Rosebrough, A.L. Farr, R.J. Randal, Protein analysis with Folin–phenol reagent. J. Biol. Chem. 193, 265–275 (1951)

J. Rhim, Y. Wu, C. Weller, M. Schnepf, Physical characteristics of a composite film of soy protein isolate and propyleneglycol alginate. J. Food Sci. 64(1), 149–152 (1999)

K.D. Kulkarni, D.N. Kulkarni, U.M. Ingle, Sorghum malt-based weaning formulations: preparation, functional properties and nutritive value. Food Nutr. Bull. 13(4), 322–327 (1991)

K.N. Pearce, J.E. Kinsella, Emulsifying properties of proteins: evaluation of a turbidimetric technique. J. Agric. Food Chem. 26, 716–723 (1978)

A. Cruz-Solorio, R. Villanueva-Arce, M.E. Garın-Aguilar, H. Leal-Lara, G. Valencia-del Toro, Functional properties of flours and protein concentrates of 3 strains of the edible mushroom Pleurotus ostreatus. J. Food Sci. Technol. 55(10), 3892–3901 (2018). https://doi.org/10.1007/s13197-018-3312-x

R.M. Amir, F.M. Anjum, M.I. Khan, M.R. Khan, I. Pasha, M. Nadeem, Application of Fourier transform infrared (FTIR) spectroscopy for the identification of wheat varieties. J. Food Sci. Technol. 50(5), 1018–1023 (2011). https://doi.org/10.1007/s13197-011-0424-y

U.K. Laemmli, Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227, 680–685 (1970)

M.L.S. de Mello, P.S. Bora, N. Narain, Fatty and amino acids composition of melon (Cucumis melo Var. saccharinus) seeds. J. Food Compos. Anal. 14, 69–74 (2001)

M.H. Hu, Y. Ao, Characteristics of some nutritional composition of melon (Cucumis melo hybrid ‘Chun Li’) seeds. Int. J. Food Sci. Technol. 42, 1397–1401 (2007)

L.M. Devi, L.S. Badwaik, Influence of temperature, time and alkali concentration on protein extraction from muskmelon seed meal. Indian Chem. Eng. (2021). https://doi.org/10.1080/00194506.2021.1915887

B. Baca-Bocanegra, J. Nogales-Bueno, J.M. Hernández-Hierro, F.J. Heredia, Optimization of protein extraction of oenological interest from grape seed meal using design of experiments and response surface methodology. Foods 10, 79 (2021). https://doi.org/10.3390/foods10010079

A.M. Joglekar, A.T. Ma, Product excellence through design of experiments. Cereal Foods World 32(12), 857 (1987)

L. Urribarrí, D. Chacón, O. González, A. Ferrer, Protein extraction and enzymatic hydrolysis of ammonia-treated cassava leaves (Manihot esculenta Crantz). Appl. Biochem. Biotechnol. 153, 94–102 (2009). https://doi.org/10.1007/s12010-008-8422-x

X. Cao, C. Li, H. Wen, Z. Gu, Extraction technique and characteristics of soluble protein in germinated brown rice. Int. J. Food Prop. 13, 810–820 (2010). https://doi.org/10.1080/10942910902895200

Y. Sano, Differential regulation of waxy gene expression in rice endosperm. Theor. Appl. Genet. 68(5), 467–473 (1984)

P. Ilankovan, N.S. Hettiarachchy, S. Christian, I.B. Markus, Hydrophobicity, solubility and emulsifying properties of enzyme-modified rice endosperm protein. Cereal Chem. 84(4), 343–349 (2007)

I.Y.S. Rustom, M.H. Lopez-Leiva, B.M. Nair, Optimization of extraction of peanut proteins with water by response surface methodology. J. Food Sci. 56, 6 (1991)

R.J. Kain, Z. Chen, T.S. Sonda, J.C. Abu-Kpawoh, Study on the effect of control variables on the extraction of peanut protein isolates from peanut meal (Arachis hypogaea L.). Am. J. Food Technol. 4(1), 47–55 (2009)

J. Deng, T. Sun, W. Cao, D. Fan, N. Cheng, B. Wang, H. Gao, H. Yang, Extraction optimization and functional properties of proteins from kiwi fruit (Actinidia chinensis Planch.) seeds. Int. J. Food Prop. 17, 1612–1625 (2014). https://doi.org/10.1080/10942912.2013.772197

K.C. Rhee, C.M. Cater, K.F. Mattil, Simultaneous recovery of protein and oil from raw peanuts in an aqueous system. J. Food Sci. 37, 90 (1972)

T.P. Singh, S.S. Dalbir, Comparative study of structural and functional characterization of bran MPCs from superfine, fine and coarse rice cultivars. Biomac (2017). https://doi.org/10.1016/j.ijbiomac.2017.12.161

J.O. Ogundele, A.A. Oshodi, T.A. Sanni, I.A. Amoo, Protein isolates of gourd melon seeds and their functional properties. Am. J. Food Nutr. 3(4), 176–181 (2013)

D.H. Chou, C.V. Morr, Protein water interactions and functional properties. J. Appl. Organomet. Chem. 56, 53A-62A (1979)

J.E. Kinsella, Relationships between structure and functional properties of food proteins, in Food proteins. ed. by P.F. Fox, J.J. Condon (Applied Science Publishers, Basel, 1982), pp. 51–103

E.S. Lazos, Certain functional properties of defatted pumpkin seed flour. Plant Foods Hum. Nutr. 42, 257–273 (1992)

O.S. Lawal, K.O. Adebowale, Effect of acetylation and succinylation on soluble profile, water absorption capacity, oil absorption capacity, and emulsifying properties of Mucuna beans (Mucuna pruriens) MPC. Nahrung 48, 129–136 (2004)

S.H. Ahmed, A. Isam, M. Ahmed, M.M. Eltayeb, S.O. Ahmed, E.E. Babiker, Functional properties of selected legumes flour as influenced by pH. J. Agric. Technol. 7(5), 2091–2102 (2011)

S.N. Jamdar, V. Rajalakshmi, M.D. Pednekar, F. Juan, V. Yardi, A. Sharma, Influence of degree of hydrolysis on functional properties, antioxidant activity and ACE inhibitory activity of peanut protein hydrolysate. Food Chem. 121, 178–184 (2010). https://doi.org/10.1016/j.foodchem.2009.12.027

Y.A. Fassai, N. Mirjankar, A. Fasasi, Fourier transform infrared spectroscopic analysis of protein secondary structures found in egusi. Am. J. Appl. Ind. Chem. 1(1), 1–4 (2015). https://doi.org/10.11648/j.ajaic.20150101.11

M. Peng, D. Lu, J. Liu, B. Jiang, J. Chen, Effect of roasting on the antioxidant activity, phenolic composition, and nutritional quality of pumpkin (Cucurbita pepo L.) seeds. Front. Nutr. 8, 647354 (2021). https://doi.org/10.3389/fnut.2021.647354

N.P. Singh, N.K. Matta, Levels of seed proteins in Citrullus and Praecitrullus accessions. Plant Syst. Evol. 290, 47–56 (2010). https://doi.org/10.1007/s00606-010-0347-5

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared no conflicts of interest for this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pasrija, D., Sogi, D.S. Extraction optimization and functional properties of muskmelon seed protein concentrate. Food Measure 16, 4137–4150 (2022). https://doi.org/10.1007/s11694-022-01523-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01523-x