Abstract

Dietary fiber incorporation into bread dough systems greatly interferes with protein association and behavior during heating and cooling. The objective of this study was to understand the individual and combined effects of dietary fibers on dough behavior during mixing, overmixing, pasting and gelling using the Mixolab® device. Impact of different commercial dietary fibers (inulin, sugar beet fiber, pea cell wall fiber and pea hull fiber) on wheat dough mixing, pasting and gelling profiles has been investigated. Mixolab® plots indicate that the incorporation of sugar beet fiber into the dough matrix induces the disruption of the viscoelastic system yielding weaker doughs, and it greatly competes for water with starch affecting pasting and gelling. Conversely, inulin in the range tested seems to integrate into the dough increasing its stability. Additionally, the responses acquired with this device were compared with those obtained with other available methodologies, such as the Brabender Farinograph and the Rapid Visco Analyser, to explore its use as a suitable technique for studying fiber-enriched bread dough physical properties. A broad range of correlation between Mixolab® and traditional devices were found.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The stated link between the intake of dietary fiber and several health benefits [1, 2] has prompted the interest in fiber-enriched foods and, moreover, in fiber-enriched baked goods. Nevertheless, the design of fiber-enriched baked goods is always encountered with the consumer resistance to accept breads with reduced loaf volume and hard crumb accompanied by particular flavors [3, 4].

Dietary fiber incorporation into wheat dough greatly interferes with protein association and its further aggregation during heating. Presumably, fibers occupy the space of the proteins in the gluten network [5]. In addition, fibers also affect pasting characteristics of starch such as peak viscosity, breakdown and final viscosity [6]. Moreover, the resultant fiber-rich doughs have high water absorption, become shorter and have reduced fermentation tolerance [5, 7, 8]. Physicochemical properties of fibers greatly vary depending on the source and the type and degree of processing [9]. Those characteristics have great impact on the functional quality of the intermediate manufacturing and end products when obtained by conventional bread-making processes [10, 11]. Therefore, it becomes necessary to assess the impact of fibers on bread dough rheology when potential use of fibers is considered for enriching baked goods.

It is widely accepted that rheological tests on dough can predict their behavior in a bakery, although only if the rates and the extent of the deformation in these tests are in the same range as those taking place during dough processing [12, 13]. During mixing, fermentation and baking, dough is subjected to different shear and extensional large deformations (including fracture), which are largely affected by temperature and water hydration. Bread dough behaves as a viscoelastic material. Dough shows an intermediate rheological conduct between viscous liquid and elastic solid, which is consequence of the main dough biopolymers, starch and gluten [14]. However, only large deformation measurements can provide suitable information about the extent of the contribution of long-range (protein–protein) and short-range (starch–starch, starch–protein) interactions to the viscoelastic behavior of wheat flour dough [15]. Traditionally, these changes have been studied with equipments controlling separately mixing step and baking process.

Devices for recording dough consistency during mixing, like Brabender Farinograph, Mixograph and Consistograph, have been extensively applied to study dough performance [10, 16]. Similarly, starch changes associated with thermal processes have been followed by recording paste viscosity during cooking–cooling cycles using Brabender Viscoamylograph or Newport Rapid Visco Analyser [17]. However, the temperature range, where both initial protein unfolding and hydration of starch granules takes place, can not be recorded with those devices.

The Mixolab® technique can be considered as an empirical method that record the dough changes when subjected to large deformations and to temperature sweeps. Dough rheological assessment by Mixolab® has been successfully applied to the evaluation of bread wheat genotypes [18], and the cake making quality of flours [19]. Bonet et al. [20] investigated the effectiveness of transglutaminase for the formation of heteropolymers of wheat and wheat-exogenous proteins by using Mixolab®. The effect of different molecular structure hydrocolloids on wheat dough [21], and even the rheological response of formulated bread doughs was effectively monitored during mixing and heating with this device [22].

The objective of this study was to understand the individual and combined effects of dietary fibers on dough behavior during mixing, overmixing, pasting and gelling in the Mixolab®. In addition, this study aimed at determining possible correlations between Mixolab® parameters and the ones obtained with traditional devices which characterize gluten and starch behavior, such a Brabender Farinograph and Newport Rapid Visco Analyser, respectively.

Materials and methods

Basic ingredients

Commercial blend of Spanish wheat bread-making flours of 14.1% moisture (ICC 110/1) [23], 0.33% ash content (ICC 104/1) [23], 14.22% protein (ICC 105/2) [23], 1.28% fat (ICC 136) [23], 95% gluten index (ICC 155) [23] and Chopin Alveograph parameters: energy of deformation 354 × 10−4 J (W) and curve configuration ratio (P/L) 0.64 (ICC 121) [23] were used.

Fibers included inulin (Fibruline [FN] from Trades SA, Spain), sugar beet fiber (Fibrex [FX] from Nutritec, Spain), pea cell wall fiber (Swelite [TX] from Trades SA, Spain) and pea hull fiber (Exafine [EX] from Trades SA, Spain).

Dietary fiber characterization

Fibers were analyzed for physicochemical characteristics (Table 1). Chemical composition—moisture, protein, ash and fat—was determined following the corresponding ICC methods [23]. Carbohydrates were calculated by difference. Water binding capacity was determined as previously described by Nelson [24].

Particle size distribution (PSD) was determined using a MasterSizer Laser Diffraction Particle Size Analyzer (Malvern Instrument Ltd., Malvern, England) equipped with PS 65 Sample Presentation Unit (Refractive Index 1.590). Distributions were made in triplicate for each sample, using 10–20 g sample weight for dry particle size distribution. Size distribution was quantified as relative volume of particles in size bands (Malvern MasterSizer Micro software v 5.40).

Dietary fiber-enriched dough preparation

For the assays, wheat flour was replaced by different combinations of dietary fibers according to a Draper–Lin small composite design for sampling. Design factors (quantitative-independent factors) were tested at three levels (−1, 0, 1), including Fibruline (from 1 to 5 g/100 g flour–fiber blend basis), Fibrex (from 3 to 13 g/100 g flour–fiber blend basis) and both pea fibers—Exafine and Swelite—(from 1 to 10 g/100 g flour–fiber blend basis). The model resulted in 18 different combinations of fiber-enriched doughs from 6 to 34% of flour replacement (Table 2).

The effect of the different fibers on dough rheology during mixing was determined by a Brabender Farinograph mixer (300-g flour capacity) (Brabender, Duisburg, Germany), following the ICC 115/1 [23]. The parameters determined were the following: water absorption or percentage of water required to yield a dough consistency of 500 BU (Brabender units), arrival time (time to reach 500 BU consistency), dough-development time (time to reach maximum consistency in minutes), stability (elapsed time at which dough consistency is kept at 500 BU), mixing tolerance index (consistency difference between height at peak and to that 5 min later, BU), departure time (time till dough consistency decrease below 500 BU) and dough degree of softening at 8 or 20 min (difference between maximum dough consistency and that after 8 or 20 min).

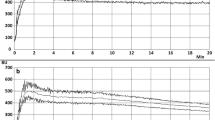

Dough torque measurement by Mixolab®

Fiber–flour blends (Table 2) were introduced in the Mixolab® bowl and mixed with the necessary amount of water. The amount of water added was the one obtained in the Brabender Farinograph for reaching optimum dough development (ICC 115/1) [23]. The resulting fiber-enriched dough weight was 75 g in all the samples. The Mixolab® profile carried out in order to characterize dough viscoelasticity due to dual mixing and temperature constraint starts at 30 °C and with constant mixing speed of 75 rpm. The fiber-enriched dough was held at 30 °C up to maximum dough development (previously assessed in Brabender Farinograph), and then heated to 90 °C over 15 min at the rate of 4 °C/min. Sample dough was held at 90 °C for 7 min, and finally cooled to 50 °C over 10 min at the rate of 4 °C/min and finally held at 50 °C for 5 min. The duration of each assay depended on the time to reach the maximum dough development. Figure 1 shows the different stages recorded in the Mixolab® plot. Detailed description of the physical changes that occurred along Mixolab® measurement was reported by Rosell et al. [21]. Briefly, the first part of the Mixolab® curve records the dough behavior during mixing and overmixing; during this stage, the torque increased until it reaches a maximum (C1). At that point, the dough is able to resist the deformation for certain time, which determines the dough stability. The simultaneous mechanical shear stress and temperature constraint (2nd stage) decrease the torque, until a minimum value (C2) that could be related to the beginning of the protein structure destabilization or protein weakening. As the temperature increases, starch gelatinization takes place (3rd stage) with a concomitant increase in the torque until a new maximum value (C3). A reduction in viscosity is observed in the 4th stage derived from the physical breakdown of the starch granules, leading to a minimum value of the torque (C4). The decrease in the temperature produces an enhancement in the dough consistency (stage 5th), resulting in a maximum torque (C5). Parameters obtained from the recorded curve are detailed in Table 3. In addition, the slopes and the angles between ascending and descending curves were calculated. For each Mixolab® measurement, three samples were used.

Description of a typical curve obtained in the Mixolab®. Numbers indicate the different zones detected in the curve according to physical bread dough changes. Detailed information is included in “Materials and methods” section

Viscometric properties

The pasting profiles (gelatinization, pasting and setback properties) were obtained with a Rapid Visco Analyser (RVA-4, Newport Scientific, Warriewood, Australia) using ICC 162 method [23]. Freeze-dried hydrated flour–fiber blends (3.5 g, 14% moisture basis) were transferred into canisters and ≈25 ± 0.1 mL of distilled water were added (corrected to compensate for 14% moisture basis). The slurry was heated to 50 °C and stirred at 160 rpm for 10 s for ensuring dispersion. The slurry was held at 50 °C for up to 1 min, and then heated to 95 °C over 3 min 42 s and held at 95 °C for 2 min 30 s, and finally cooled to 50 °C over 3 min 48 s, and held at 50 °C for 2 min. The pasting temperature ( °C) (when viscosity first increases by at least 25 cP over a 20-s period), peak viscosity (maximum hot paste viscosity), holding strength or trough viscosity (minimum hot paste viscosity), breakdown, peak time and temperature, viscosity at 95 and 50 °C, setback and total setback (final viscosity minus holding strength) were calculated from the pasting curve using Thermocline v. 2.2 software.

Statistical analysis

One-variable analysis of the main fiber-enriched dough viscoelastic parameters obtained using a Brabender Farinograph and RVA were performed by means of Statgraphics V.7.1 program (Bitstream, Cambridge, MN). Multivariate analysis—including stepwise regressions of the fiber-enriched dough viscoelastic parameters obtained using a Mixolab® and the correlation matrix obtained by Pearson correlation analysis—was performed by means of Statgraphics V.7.1 program (Bitstream, Cambridge, MN).

Results and discussion

Effect of flour replacement by dietary fibers on physical characteristics obtained with a Mixolab®

Plots of the fiber-enriched doughs recorded with the Mixolab® are shown in Fig. 2. The patterns obtained during mixing, pasting and gelling greatly varied with the fibers blend composition. Therefore, fiber blend incorporation modifies protein–protein interactions and also both starch gelatinization and gelling processes.

Mixolab® curves of 18 different fiber-enriched doughs resulting from a Draper–Lin small composite design for sampling according to Table 2. Design factors (quantitative-independent factors) were tested at three levels (−1, 0, 1), including Fibruline (from 1 to 5 g/100 g flour–fiber blend basis), Fibrex (from 3 to 13 g/100 g flour–fiber blend basis) and both pea fibers—Exafine and Swelite—(from 1 to 10 g/100 g flour–fiber blend basis)

Analytical data from Draper–Lin small composite design of fiber-enriched doughs along dual mixing and heating constraint (Fig. 2) were fitted to multiple regression equations using added fibers as independent variables to estimate response surfaces of dependent functional dough quality Mixolab® variables. Stepwise regression equations included only significant coefficients (p < 0.05), and only dependent Mixolab® parameters with adjusted square coefficient of the fitting model (R 2) greater than 0.70 are displayed (Table 4).

Flour replacement at different levels (from 6 up to 34%) by fibers from different sources and nature (Table 1, 2) significantly changed the qualitative and quantitative thermo-mechanical pattern of fiber-enriched doughs (Table 4; Fig. 2). Dependence of mixing, pasting and gelling parameters on flour–fiber blends was particularly significant for stability during heating (R 2 = 0.8429), protein weakening (R 2 = 0.8105), starch gelatinization (R 2 = 0.8255), amylase activity (R 2 = 0.8866) and starch gelling (R 2 = 0.7980) (Table 4). The cooling setback and the pasting temperature range did not show any dependence on the fiber blends giving constant values of 0.40 Nm and 12.29 °C, respectively (data not showed).

Dough stability during mixing was negatively affected by the pair FN–FX, whereas the opposite effect was observed when inulin (FN) was incorporated with TX. In the course of the mixing step, hydration of blend compounds take place, and dough consistency and stability are determined by the interactions between polymeric compounds resulting from disulfide-linked proteins, hydrogen-bonding aggregates and di-tyrosine bonds.

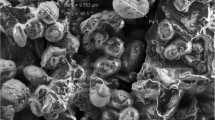

Simultaneous mechanical shear stress and temperature constraint significantly changed the stability during heating, the trend depending on the fiber composition. FX strongly decreased heating stability when added singly, even more in the presence of EX that has no single effect on this parameter. Conversely, single incorporation of FN into dough formulation increased heating stability when added at 5% of flour replacement. This fiber with no single effect on total dough stability, led to a sharp decrease (−60%) when FX was incorporated to the dough, and conversely, yielded great increase (+150%) in the presence of TX, when fibers were added at maximum dosage. It would be expected that fine particles would be easily integrated into the gluten structure, although there is no general agreement about the right particle size of fibers for bakery applications. The particle size distribution of the tested fibers was determined (Fig. 3). Inulin showed the lowest particle size (mean particle diameter 41 μm), in contrast, EX contained the highest particles (mean particle diameter 471 μm). Considering the particle size distribution of the tested fibers, it seems that inulin is solubilized and included into the bread dough yielding good stability, which is kept even when combined with fiber of bigger particle size like TX (mean particle diameter 273 μm). Presumably, the increasing number of hydrogen bonds formed with the hydroxyl groups presented in fiber molecules can contribute to the dough stability, likewise to the interaction already described with hydrocolloids [16, 25]. Similar results were obtained when 3% of inulin was added into dough [26]. Nevertheless, results obtained with FX indicate that fiber size is not the only decisive parameter when stable bread doughs are foreseen.

Positive quadratic effect was achieved when both pea fibers were added into dough formulation producing a significant increase in the torque value C2. In opposition, single presence of FX led to a decrease in the torque value C2. FX–EX blend also resulted in notable delay in the beginning of protein weakening (−15%). Simultaneous presence of both commercial pea fibers did not add any advantage, since additive effects were not observed, and the extent of the changes was comparable to the one provided by the single addition. When heating dough experienced a progressive loss of strength due to protein unfolding, which is maximum around 55–60 °C [27, 28]. Further increase of temperature results in the formation of a more elastic gluten network, derived from the protein crosslinking involving SH/SS interchange, oxidation and hydrophobic interactions, leading to protein association and in turn the formation of protein aggregates [29, 30]. Fiber-enriched dough also showed maximum protein weakening at around 55–60 °C (results not showed), but no significant effect could be ascribed to the individual or combined incorporation of the fibers.

The effect of fiber’s blend on C2 might be the result of the gluten dilution and the fibers interference with the protein unfolding. An increase in C2 will be the consequence of some impediments in the protein unfolding, as observed with EX and TX. Conversely, lower C2 values will be reached when weaker protein network hold dough structure.

When hydrated doughs are heated above a characteristic temperature, temperature-induced swelling and amylose leaching lead to the formation of viscous pastes. Viscosity enhancement continues until the physical breakdown of the starch granules. When temperature decreases, amylose chains are prompted to recrystalize producing the gelation of the starch. This process results in the formation of a gel structure [17] and in consequence a new increase in the torque. In fiber–flour blends, torque values related to temperature changes mainly depended on the presence of FX (Table 4). FX led to a decrease of 26% in the torque for starch gelatinization (C3) and a concurrent lower torque by 34% for both amylase activity (C4) and starch gelling (C5) due to the linear negative and quadratic positive effect obtained for these parameters. Addition of EX to FX-formulated doughs provided a small extra decline in C4 and C5 by 7 and 3%, respectively, while single addition of EX provided a significant decrease in both torque values by 20%. The reduction in starch gelatinization, in good accordance with reduced starch content, can also indicate a reduced degree of starch granule swelling as stated before [22, 31].

Related to the secondary parameters, the addition of FN provided a decrease in torque values for protein weakening range (−26%) and cooking stability range (−77%) (Table 4). However, simultaneous presence of FN–EX provided a slight decrease (−6%) when fibers are incorporated at the maximum level tested, in good accordance with the partial restoration of initial breakdown viscosity observed for the mix of fibers in RVA [31]. Cooking stability range also slightly decreased by simultaneous presence of FX–EX, while EX alone allowed increasing significantly the corresponding torque. Breakdown of viscosity is caused by rupture of the swollen granules upon heating. The observed decrease in cooking stability due to the presence of fibers can be attributed to a decreased rate of starch granule rupturing during heating caused by a decrease in the rate and in the extent of water absorption by starch granules, facilitated by the presence of the fibers. Added fibers compete for water with starch and showed preferential water binding, especially for FX [10] that account for major effects in the Mixolab® parameters. The interference with intermolecular associations among amylopectin molecules by added fibers has been proposed as an additional factor affecting the pasting and gelatinization characteristics. Lower torque values during heating are an indication of a reduction in available starch for gelatinization. This reduction is likely due to a general reduction in the starch content of the pastes because of replacement with dietary fibers that can additionally retain water from the starch granules. The reduction of available water in the system would reduce initial starch granule swelling and, hence, add to the explanation of lower peak torques of the pastes. Upon subsequent cooling, a gel is formed that consists of an amylose matrix in which amylopectin-enriched granules are embedded. Effects of fiber blends on the parameters characterizing the gelling process (Table 4) were not significant for total cooling setback.

Overall, in fiber-enriched wheat doughs, fiber replacement of flour implicates a gluten-diluting effect, a disruption of the starch–gluten matrix that forces gas cells to expand in a particular dimension and an increased concentration of cell wall material, leading to poorer mixing and overmixing parameters [10], a significant dough weakening as observed by compression and uni-axial extensional measurements [11], and lower viscosity and thermal profiles [5, 31]. The gel formed at the end of the cooling cycle is essentially a three-dimensional network of intertwined amylose molecules incorporating dispersed swollen and ruptured starch granules. The decreased final torque of samples with added fibers suggests that the three-dimensional network is weakened by the presence of fibers in the matrix particularly by those of larger particle size and water insolubility (EX, FX). The result is an increase in concentration of soluble and insoluble cell wall material that hinder the intermolecular association that takes place in the macromolecular network upon cooling by physical interference, disruption of secondary forces and sterical hindrance.

Relationships within parameters from Brabender Farinograh, Newport Rapid Visco Analyser and Mixolab® along mixing, overmixing, pasting and gelling

Fiber-enriched wheat flour doughs were used to find relationships between parameters characterizing the main dough biopolymers, proteins and starch. Relationships were established between Mixolab® parameters and the ones obtained with traditional devices used to characterize gluten and starch behavior, such a Brabender Farinograph and Newport Rapid Viscoanalyser (RVA), respectively. The range of values obtained for the main Farinograph and RVA parameters is shown in Table 5. The fiber-enriched doughs resulted from the experimental design generate a set of samples with very diverse physical responses during mixing–pasting–gelling, which vary substantially from one sample to the other.

Mixing and overmixing parameters obtained from Mixolab® and a traditional device such as Brabender Farinograph were significantly correlated (0.457–0.776) (Table 6). Dough stability positively correlated with stability obtained from Brabender Farinograph (r = 0.771), whereas it was negatively correlated with the parameters that characterize overmixing in the Brabender Farinograph (mixing tolerance index, and softening degree at 8 and 20 min). Relationships between mixing parameters recorded at the Mixolab® and the Farinograph were particularly significant (p < 0.05) for parameters characterizing dough along overmixing and heating, which were mainly associated to protein modifications [20]. Dough stability during heating recorded in the Mixolab® showed negative relationship with the water absorption (r = −0.7666), arrival time (r = 0.7475) and development time (r = 0.7618) determined in the Farinograph. It has been reported that dough consistency, and thus water absorption, significantly affected almost all the responses during mixing, heating and cooling of wheat dough [32]. Beginning of protein weakening, related to protein unfolding, showed negative correlation with water absorption, stability, mixing tolerance index and softening degree at 8 min. Protein weakening showed positive correlation with stability and departure time. Protein weakening range showed positive correlations with water absorption, development time and arrival time. All these correlations confirm the positive relationship between dough development determined in the Farinograph with the secondary parameters of the Mixolab® associated with overmixing and heating. Significant correlations already established between Mixolab® parameters, namely water absorption, development time and dough stability, and those parameters determined with the Brabender Farinograph [33, 34] must be emphasized due to their extended use in wheat dough characterization.

Pasting and gelling processes simulated in the Mixolab® and the RVA were significantly correlated (0.468–0.895) (Table 7). Starch gelatinization (C3), starch gelatinization range or pasting (C3–C2) and the amylase activity (C4) showed positive relationships with all the RVA parameters determined during the cooking stage, with the exception of pasting temperature. During cooling cycle, starch gelling (C5) was highly correlated with the entire cooking and cooling RVA parameters excepting peak temperature. Gelling range, which describes the zone between C4 and C5, positively correlated (r = 0.6958) with the total setback from RVA. Overall, despite the water limitation existing in wheat dough systems developed in the Mixolab® compared to suspensions for RVA, very high correlations were found between parameters characterizing dough pasting and gelling obtained from both devices.

It must be stressed that parameters derived from overmixed doughs revealed that the higher the stability during heating, the later the beginning of protein weakening, the bigger the protein breakdown and the narrower the protein weakening range. In general, most parameters derived from pasted and gelled states strongly correlated, particularly for starch gelatinisation, amylase activity and starch gelatinisation range versus starch gelling and gelling range.

Conclusions

Flour replacement at different levels (6–34%) by fibers from different sources significantly changes the qualitative and quantitative dough pattern of the resulting hydrated flour–fiber blends, as showed the Mixolab® plots. In general, a deleterious effect in mixing, overmixing, pasting and gelling torque profiles was provided by dietary fiber presence into wheat dough formulation. Added fibers were competing for water with the dough main polymers, gluten and starch. It could be stressed that during mixing, dough stability was negatively affected by the pair FN–FX, whereas an increase was induced when inulin (FN) was incorporated with TX. The same positive effect was observed on the dough thermal stability when the pair FN–TX was added. Concerning starch behavior, it seems that the presence of fibers limited water availability for starch pasting and that effect was especially intense for FX. Overall, results indicate that incorporation of FX into the dough matrix induces the disruption of the viscoelastic system leading to weaker doughs, and it greatly competes for water with starch affecting pasting and gelling. Conversely, inulin seems to integrate into the dough increasing its stability. The magnitude of the effect in dough viscoelastic characteristics during dual mixing and heating constraint depends on the extent of flour substitution in the first place and on the nature of the fibers in the blend in the second place.

References

Lairon D, Arnault N, Bertrais S, Planells R, Clero E, Hercberg S, Boutron-Ruault MC (2005) Dietary fiber intake and risk factors for cardiovascular disease in French adults. Am J Clin Nutr 82:1185–1194

Rodríguez R, Jiménez A, Fernández-Bolaños J, Guillén R, Heredia A (2006) Dietary fibre from vegetable products as source of functional ingredients. Trends Food Sci Technol 17:3–15

Knuckles BE, Hudson CA, Chiu MM, Sayre RN (1997) Effect of ß-glucan barley fractions in high-fiber bread and pasta. Cereal Foods World 42:94–100

Collar C (2008) Novel high-fiber and whole grain breads. In: Hamaker B (ed) Technology of functional cereal products. Woodhead Publishing Ltd, Cambridge, UK, pp 336–361

Gan Z, Galliard T, Ellis PR, Angold RE, Vaughan JG (1992) Effect of the outer bran layers on the loaf volume of wheat bread. J Cereal Sci 15:151–163

Santos E, Rosell CM, Collar C (2008) Gelatinization and retrogradation kinetics of high-fiber wheat flour blends: a calorimetric approach. Cereal Chem 85:455–463

Laurikainen T, Harkonen H, Autio K, Poutanen K (1998) Effects of enzymes in fibre-enriched baking. J Sci Food Agric 76:239–249

Park H, Seib PA, Chung OK (1997) Fortifying bread with a mixture of wheat fibre and Psyllium Husk fibre plus three antioxidants. Cereal Chem 74:207–211

Rosell CM, Santos E, Collar C (2009) Physico-chemical properties of commercial fibres from different sources: a comparative approach. Food Res Int 42:176–184

Rosell CM, Santos E, Collar C (2006) Mixing properties of fiber enriched wheat bread doughs: a response surface methodology study. Eur Food Res Technol 223:333–340

Collar C, Santos E, Rosell CM (2007) Assessment of the rheological profile of fiber-enriched bread doughs by response surface methodology. J Food Eng 78:820–826

Dobraszczyk BJ, Morgenstern MP (2003) Rheology and the breadmaking process. J Cereal Sci 38:229–245

Van Vliet T, Janssen AM, Bloksma AH, Walstra P (1992) Strain hardening of dough as a requirement for gas retention. J Texture Studies 23:439–460

Larsson H, Eliasson AC, Johansson E, Svensson G (2000) Influence of added starch on mixing on dough made with three wheat flours differing in high molecular weight subunit composition: rheological behavior. Cereal Chem 77:633–639

Amemiya JL, Menjivar JA (1992) Comparison of small and large deformation measurements to characterize the rheology of wheat-flour doughs. J Food Eng 16:91–108

Rosell CM, Rojas JA, Benedito C (2001) Influence of hydrocolloids on dough rheology and bread quality. Food Hydrocolloids 15:75–81

Collar C (2003) Significance of viscosity profile of pasted and gelled formulated wheat doughs on bread staling. Eur Food Res Technol 216:505–513

Koksel H, Kahraman K, Sanal T, Ozay DS, Dubat A (2009) Potential utilization of mixolab for quality evaluation of bread wheat genotypes. Cereal Chem 86:522–526

Ozturk S, Kahraman K, Tiftik B, Koksel H (2008) Predicting the cookie quality of flours by using Mixolab (R). Eur Food Res Technol 227:1549–1554

Bonet A, Blaszczak W, Rosell CM (2006) Formation of homopolymers and heteropolymers between wheat flour and several protein sources by transglutaminase-catalyzed cross-linking. Cereal Chem 83:655–662

Rosell CM, Collar C, Haros M (2007) Assessment of hydrocolloid effects on the thermo-mechanical properties of wheat using the Mixolab®. Food Hydrocolloids 21:452–462

Collar C, Bollaín C, Rosell CM (2007) Rheological behaviour of formulated bread doughs during mixing and heating. Food Sci Technol Int 13:99–108

ICC (1976–1996) Standard methods of the international association for cereal chemistry. 104/1, 105/2, 110/1, 115/1, 121, 136, 155, and 162. The Association: Vienna

Nelson AL (2001) Properties of high-fibre ingredients. Cereal Foods World 46:93–97

Collar C, Andreu P, Martinez JC, Armero E (1999) Optimization of hydrocolloid addition to improve wheat bread dough functionality: a response surface methodology study. Food Hydrocolloids 13:467–475

Wang J, Rosell CM, Benedito C (2002) Effect of the addition of different fibres on wheat dough performance and bread quality. Food Chem 79:231–236

Hayta M, Schofield J (2004) Heat and additive induced biochemical transitions in gluten from good and poor breadmaking quality wheats. J Cereal Sci 40:245–256

Rosell CM, Foegeding A (2007) Interaction of hydroxypropylmethylcellulose with gluten proteins: Small deformation properties during thermal treatment. Food Hydrocolloids 21:1092–1100

Kokini JL, Cocero AM, Madeka H, de Graaf E (1994) The development of state diagrams for cereal proteins. Trends Food Sci Technol 5:281–288

Li M, Lee TC (1998) Effect of cysteine on the molecular weight distribution and the disulfide crosslink of wheat flour proteins in extrudates. J Agric Food Chem 46:846–853

Collar C, Santos E, Rosell CM (2006) Significance of dietary fiber on the viscometric pattern of pasted and gelled flour-fiber blends. Cereal Chem 83:370–376

Rosell CM, Collar C (2009) Effect of temperature and consistency on wheat dough performance. Int J Food Sci Technol 44:493–502

Le Brun J, Geoffroy S, Dubat A, Sinnaeve G (2007) Niveau de performances de la mesure du taux d’adsorption d’eau des farines et des caracteristiques rhéologiques de la pate pendant le pétrissage avec le Mixolab® Chopin. Industries des Cereales, p 154

Le Brun J, Geoffroy S, Dubat A, Sinnaeve G (2008) Misurazione dell’assorbimento d’acqua delle farine e delle caratteristiche reologiche dell’impasto. Tecnica Molitoria, pp 1–11

Acknowledgments

Authors acknowledge the financial support of Spanish Scientific Research Council (CSIC) and the Spanish Ministerio de Ciencia e Innovación (Project AGL2008-00092/ALI).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rosell, C.M., Santos, E. & Collar, C. Physical characterization of fiber-enriched bread doughs by dual mixing and temperature constraint using the Mixolab® . Eur Food Res Technol 231, 535–544 (2010). https://doi.org/10.1007/s00217-010-1310-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-010-1310-y