Abstract

To produce cooked rice that can be stored under a chilled condition, the effect of maltotriose syrup on the retrogradation of gelatinized rice starch and cooked rice was investigated using dynamic mechanical thermal analysis, rheometer, differential scanning calorimetry, and sensory analysis. The storage modulus (G’) of gelatinized rice starch increased considerably after chilled storage at 5 °C for up to 72 h. The time course of the G’ corresponded to that of the re-gelatinization enthalpy of retrograded starch. The G’ decreased with increasing maltotriose syrup content, but there was no significant difference in the G’ between samples with 20% and 30% maltotriose syrup. According to the results, cooked rice samples with (additive samples) and without (non-additive samples) 20% maltotriose syrup were prepared with preset water contents of 60% and 65%. After chilled storage at 5 °C for 24 h, the G’ and hardness (force generated by 50% compressive strain) of the additive samples were much lower than those of the non-additive samples. In addition, the G’ and hardness decreased with increasing water content. The G’ of the additive sample with a preset water content of 65% was lower than that (G’ = 26.9 kPa) of the tolerance limit determined by the sensory analysis. However, the additive samples showed substantial browning. The pH of the samples was adjusted to diminish the browning. The color parameter (b *) did not differ significantly between the additive sample at pH 5.5 and the non-additive sample at pH 7.0.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Rice is a popular staple food in many countries, especially in Asia. Rice is commonly cooked by heating with an optimum amount of water, and rice starch gelatinizes during the thermal process, which gives the cooked rice a desirable texture. Rice is sometimes modified to rice flour and employed as food stuff for various food products. In fact, there has recently been considerable interest in rice flour for the production of gluten-free foods [1].

When starchy foods (except for low-moisture foods) are stored at a low temperature, the texture becomes harder in a storage temperature- and time-dependent manner. This physical deterioration is explained by starch retrogradation, i.e., the re-crystallization of gelatinized starch that occurs when amorphous starch (mainly amylopectin and amylose) partially reforms double-helices [2]. Since starch retrogradation is promoted at low temperatures above the freezing point [3], the texture of starchy foods becomes much harder during chilled storage. Retrograded starch can be re-gelatinized by heating, and thus, chilled starchy foods have to be reheated (commonly using a microwave oven) before eating. This is an obstacle for the further growth of the starchy foods industry.

There have been many studies on the prevention of starch retrogradation. From fundamental studies, it is known that starch retrogradation depends mainly on the amylose content, chain length of amylopectin, water content, and additives. There are two processes in starch retrogradation. Amylose, which is a linear chain linked by α(1,4)-glycosidic bonds of glucose, contributes to short-term retrogradation [4]. Amylopectin, on the other hand, has many branches linked by both α(1,4) and α(1,6)-glycosidic bonds of glucose, and it contributes to long-term retrogradation [5]. Starch retrogradation is mainly observed in foods with 30–80% water content. The maximum retrogradation depends on the botanical source of the starch and the storage conditions [4].

To diminish starch retrogradation, various types of additives, including lipids [6], proteins [7], salts [8], emulsifiers [9], and saccharides [10] have been employed. Many previous studies have shown the effectiveness of saccharides for diminishing starch retrogradation. The saccharides inhibit the double-helix formation of amorphous starch, because of the hydrogen bonding that occurs between the saccharides and starch [11]. For example, Lii et al. investigated the effects of saccharides (5–20% ribose, xylose, glucose, fructose, sucrose, and maltose) on the retrogradation of gelatinized starch [12]. They demonstrated that the progression of starch retrogradation decreased with increasing saccharide content depending on the type of saccharide used.

When aiming to produce cooked rice that can be stored under a chilled condition, the most effective approach is to optimize the addition of saccharides. Taking the results mentioned above into account, there is a possibility that starch retrogradation during chilled storage can be prevented completely by the addition of a large amount of saccharides. Previous studies, however, did not focus on how much saccharide should be added to produce cooked rice that can be stored under a chilled condition. A possible problem that may be caused by the addition of a large amount of saccharides is the loss of quality in other areas. For example, trehalose is an effective saccharide for the suppression of starch retrogradation [13]. However, a large amount of added trehalose results in an unnatural sweetness that alters the taste of cooked plain rice. Since cooked plain rice is a simple food consisting only of rice and water, alterations of its taste due to additives are easily perceptible. Saccharides originating from starch (e.g., glucose, maltose, maltotriose, and dextrin) provide a more natural sweetness to cooked rice.

Among the saccharides originating from starch, maltotriose is a potentially attractive material. In fact, it was reported that maltotriose prevented starch retrogradation more than glucose, maltose, and dextrin [14]. In addition, maltotriose has a mild sweetness; it has approximately 17% of the sweetness of sucrose [15]. A large amount of added maltotriose, however, causes the browning of rice since a non-enzymatic browning reaction occurs between the reducing sugars and proteins in rice. There is a possibility that a reduction in the pH may prevent browning [16].

To produce cooked rice that can be stored under a chilled condition, the effect of maltotriose syrup on the retrogradation of gelatinized rice starch and cooked rice was investigated. Since it was practically and experimentally difficult to use purified maltotriose due to its high cost, maltotriose syrup (hydrolyzed starch containing a large amount of maltotriose) was used in this study. In the first part of this study, a gelatinized rice starch sample was prepared as a model of rice, and the time course of starch retrogradation was evaluated using rheological and calorimetric approaches. In addition, the effect of the maltotriose syrup content on the retrogradation of gelatinized rice starch was investigated, and the optimal additive content required for the suppression of starch retrogradation was determined. In the second part of the study, a cooked rice sample was prepared, and rheological approaches that corresponded to the sensory analysis were applied. In addition, the effects of maltotriose syrup and water content on the starch retrogradation and browning of cooked rice were investigated. Furthermore, to diminish the browning, the effect of pH on the browning of cooked rice with maltotriose syrup was investigated. Based on the results, the possibility and practicality of producing cooked rice that can be stored under a chilled condition are discussed.

Materials and methods

Materials

Rice starch and citric acid were obtained from Sigma-Aldrich Japan (Tokyo, Japan) and Nacalai Tesque, Inc. (Kyoto, Japan), respectively. Maltotriose syrup was provided by San-ei Sucrochemical Co., Ltd. (Aichi, Japan). The maltotriose syrup was a hydrolyzed starch containing more than 55% maltotriose. According to the supplier’s information, the maltotriose syrup contained 56% (w/w, dry basis) maltotriose, 20% maltose, 4% glucose, and 20% other oligosaccharides. A commercially available japonica white rice (Hitomebore from Hiroshima, Japan) was purchased at a local market.

Preparation of gelatinized rice starch samples

Rice starch (2 g, dry basis) was placed in a vial, and distilled water was added and adjusted to 65% (w/w) water content. For the additive samples, rice starch was replaced by 5–30% (w/w, dry basis) maltotriose syrup. A magnetic stir bar was placed into each vial, and the vials were screw-capped. The vials were placed in a boiling water bath (approximately 98 °C) and heated for 15 min with magnetic stirring. The samples were then cooled down to room temperature and used for the following experiments.

Preparation of cooked rice samples

White rice (155.6 g, dry basis) was placed in a vessel, and tap water was added and adjusted to 60% or 65% (w/w) water content. Since the water content of cooked rice decreases as a result of water evaporation during cooking, in this paper, we refer to the water content in terms of the content prior to heating (the preset water content) unless otherwise indicated. For the additive samples, white rice was replaced by 20% (w/w, dry basis) maltotriose syrup according to the results of the experiment on the effects of maltotriose syrup on the storage modulus (G’) value (described below). The samples were confirmed to be at pH 7.0. For pH adjustment of the samples, citric acid was added until the pH reached 4.0 and 5.5. Citric acid is an effective pH modifier, because it is much less acidic than other acids, such as acetic acid. The samples were cooked in a commercially available rice cooker (NP-GF05E9, Zojirushi Co., Ltd., Osaka, Japan). After cooking, the rice was cooled down to room temperature, and used for the following experiments.

Dynamic mechanical thermal analysis

The G’ of the gelatinized rice starch and cooked rice samples was evaluated by dynamic mechanical thermal analysis (Haake Mars III System; Thermo Fisher Scientific K. K., Tokyo, Japan). The gelatinized rice starch sample was directly set on the sample stage. Cooked rice was modified to a paste form by mushing manually with a pestle and mortar before measurement, and then immediately set on the sample stage. A flat plate (diameter, 20 mm) was employed, and G’ was evaluated in the frequency range between 0.1 and 10 Hz at 25 °C. The shear stress for the measurement was 10 Pa; the stress condition was preliminarily determined as a linear stress value in the G’-stress curve at 1 Hz. The measurements were repeated three times for the gelatinized rice starch samples and ten times for the cooked rice samples, and the results were averaged.

Differential scanning calorimetry (DSC)

The re-gelatinization enthalpy (ΔH retro) of the retrograded rice starch samples was evaluated by DSC (DSC120; Seiko Instruments Inc., Tokyo, Japan). Alumina powder was used as a reference. The temperature was calibrated using indium and distilled water. The heat flow was calibrated using indium. Each sample (20 to 35 mg) was placed in an aluminum pan and hermetically sealed. DSC measurements were conducted at 5 °C/min between 20 and 80 °C. The ΔH retro value was determined from the endothermic peak area observed at approximately 40 °C [17]. The measurements were performed in triplicate, and the results were averaged.

Hardness of the cooked rice grains

The hardness of the cooked rice grain samples was evaluated using a rheometer (Nissin Seiki Co., Ltd., Hiroshima, Japan) according to a previous study [18] with minor modifications. Three grains of cooked rice were randomly selected and placed on the sample stage at a regular interval. The samples were compressed at 1.0 mm/s using a plate plunger. The force generated by 50% compressive strain was evaluated as the hardness [19]. The measurements were repeated ten times, and the results were averaged.

Sensory analysis

A rice sample without maltotriose syrup was prepared with a preset water content of 65%, and the rice was stored at 5 °C for 0, 3, 6, 12, 18, and 24 h. Sensory analysis of the cooked rice was carried out by ten panelists, including 3 males and 7 females between the ages of 21 and 27 years. Each rice sample (approximately 20 g) was served in random order to the panelists, and the hardness of the samples was evaluated using a scale from 1 (soft) to 6 (hard). Before the analysis, samples stored at 5 °C for 0 h and 24 h were preliminarily served as references for the softest value (score = 1) and hardest value (score = 6), respectively.

Water content of cooked rice samples

The water content of cooked rice samples was determined gravimetrically by oven-drying at 105 °C for 16 h. The measurements were performed in triplicate, and the results were averaged.

Browning of cooked rice samples

The browning of cooked rice samples was measured using a handheld colorimeter (NR-3000; Nippon Denshoku Ind. Co., Ltd., Tokyo, Japan). A cooked rice sample was placed in a vessel (44 mm in diameter and 12 mm in height), then the photometer was positioned to the center of the cooked rice sample, and the brightness value (L *), red-to-green value (a *), and yellow-to-blue value (b *) were determined. The measurements were performed in quintuplicate, and the results were averaged.

Statistical analysis

Analysis of variance was carried out using the t-test (p < 0.05) or Tukey’s honestly significant difference test (p < 0.05) with Kaleida Graph software (Version 3.6; Hulinks Inc., Tokyo, Japan).

Results and discussion

Effect of maltotriose syrup on the storage modulus of rice starch

Retrogradation of gelatinized starch occurs through the re-crystallization of amorphous starch, and the re-crystallized part has a harder texture than the amorphous part. Thus, the G’ of gelatinized starch increases with the progression of retrogradation [4]. The effect of storage time on the G’-frequency behavior of the gelatinized rice starch samples stored at 5 °C is shown in Fig. 1-a. As expected, the G’ increased with increasing storage time under the chilled condition due to the progression of retrogradation. The G’ was independent of the frequency. This indicated that the rice starch samples have a solid-like rheology. The G’ at 1 Hz was evaluated [20] and plotted against the storage time (Fig. 1-b). The G’ increased significantly with increasing storage time, and reached equilibrium within 24 h; there was no significant difference in G’ at 24 and 72 h. Similar results were reported by Prokopowich and Biliaderis [10], who investigated the effect of sugars on the G’ of gelatinized waxy maize, wheat, potato, and pea starch gels stored at 8 °C for up to 36 h. The G’ of the samples (except for wheat starch) increased with increasing storage time, and reached equilibrium within 24 h. From these results, the storage time was set to 24 h for the following experiments.

To confirm that the G’ increased due to the progression of retrogradation, DSC measurements were performed. Typical DSC curves are shown in Fig. 2-a. There was no thermal response in the sample before chilled storage (0 h), because the sample was gelatinized completely. After chilled storage at 5 °C for 3, 6, and 24 h, the samples showed a broad endothermic peak at approximately 40 °C. This melting peak indicates the re-gelatinization of retrograded starch [17]. Similar to the G’ value, the ΔH retro value (peak area) increased with increasing storage time due to the progression of retrogradation. The relationship between ΔH retro and G’ at each storage time is shown in Fig. 2-b; a relationship was seen between ΔH retro and G’ (ΔH retro = 4.433ln(G’) − 11.06, R2 = 0.9944). These results confirmed that retrogradation was reflected in the G’, and the G’ value was thus employed as an indicator of retrogradation in the following experiments.

The effect of maltotriose syrup on the G’ of gelatinized rice starch before and after chilled storage at 5 °C for 24 h is shown in Fig. 3. There was no significant difference in G’ among the samples before storage. The stored samples had a significantly higher G’ than those before storage due to the progression of starch retrogradation. The G’ decreased with increasing maltotriose syrup content, but there was no significant difference in the G’ between samples with 20% and 30% maltotriose syrup. This suggests that the effect of maltotriose syrup on the suppression of starch retrogradation reached a plateau. From these results, 20% (w/w) maltotriose syrup was taken to be the optimum content for cooked rice in chilled storage.

Appearance of the cooked rice with maltotriose syrup

Rice samples with and without 20% (w/w, dry basis) maltotriose syrup were prepared with a preset water content of 60% and 65% (w/w, wet basis); as a result of water evaporation during cooking, the water content decreased to 56% and 62% (w/w) for the non-additive samples, and 54% and 61% (w/w) for the additive samples, respectively, after cooking. In our preliminary research, the water content of three kinds of commercial cooked rice was confirmed to be 58–63%. Similarly, Yu et al. employed cooked rice adjusted to approximately 62% water content for their study on retrogradation [21]. The water content of the cooked rice employed in this study was almost the same.

There were two issues with the rice cooked with maltotriose syrup. One issue was the partial collapse of the rice granules. When the rice was cooked with 20% maltotriose syrup and a preset water content of 65%, the rice granules located at the bottom of the rice cooker collapsed. To prevent the collapse of rice granules, the cooking conditions (e.g., cooking at a lower temperature and spreading the rice to avoid stacking) should be adjusted. This issue should be examined in more detail in the future. In this experiment, only the rice granules located in the upper half of the rice cooker were used.

The other issue was browning. Unlike isolated rice starch, rice contains proteins, and a non-enzymatic browning reaction occurs when reducing sugars are present [22]. The effect of maltotriose syrup on the color (L *, a *, and b *) of cooked rice samples is shown in Fig. 4. The L * (brightness) of the additive samples was significantly lower than that of the controls (non-additive samples) at each preset water content. For each sample, the L * decreased with decreasing water content. There was a minor difference in a * (red-to-green value) between the controls and additive samples at each preset water content. The b * (yellow-to-blue value) of additive samples, on the other hand, was much higher than that of the controls at each preset water content. There was no significant contribution of the water content to changes in b *. From these results, it was noted that the browning of cooked rice was reflected mainly as an increase in b *. These results differed from the browning process of bakery starchy foods, in which it is known that L * and b * commonly decrease with increasing browning [23, 24]. In addition, a * initially increases, but then decreases. This occurs because not only non-enzymatic browning, but also caramelization contributes to browning in bakery products [25]. The suppression of the browning of rice samples will be discussed below.

Effect of maltotriose syrup on the sensory texture, storage modulus, and hardness of cooked rice

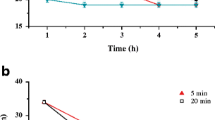

To characterize the texture of the cooked rice samples, G’ was evaluated by modifying the rice grains to a paste. To understand the relationship between G’ and the sensory texture, the non-additive sample with a preset water content of 65% was stored at 5 °C, and rheological and sensory analyses were carried out. The time course of the G’ of the rice samples is shown in Fig. 5-a. Similar to the gelatinized rice starch, G’ increased with increasing storage time. The time course of the sensory score (hardness) of the rice samples is shown in Fig. 5-b. The score increased with increasing storage time with a large deviation. It should be noted that the hardness of rice increased discontinuously between 6 and 12 h. The sensory texture was generally judged to have become harder after chilled storage for more than 6 h. From these results, the G’ value (26.9 kPa) of the rice sample stored for 6 h was taken to be the tolerance limit for the rice samples stored at 5 °C.

The effects of maltotriose syrup and water content on the G’ of cooked rice are shown in Fig. 6. Among the samples before storage (0 h), the G’ of the additive sample with a preset water content of 65% was significantly lower than that of the control. Since the rice was replaced by 20% (w/w) maltotriose syrup, the sample became softer in the high-water condition. After chilled storage (24 h), the G’ significantly increased due to starch retrogradation. At each water content, the G’ of the additive samples was significantly lower than that of the controls. As expected from the results mentioned above (Fig. 3), maltotriose syrup greatly suppressed starch retrogradation. For both of the control and additive samples, the ratio of the change in G’ induced by starch retrogradation was diminished by an increased water content. This indicated that water molecules also play a role in preventing starch retrogradation. In fact, starch retrogradation is known to be sensitive to the water content. For example, starch retrogradation readily occurs when the water content is between 40% and 70% [5, 26]. Within this water content range, the lower the water content, the greater the observed starch retrogradation [4, 27]. Regarding the combined effects of both the maltotriose syrup and water, the additive sample with a preset water content of 65% had a lower G’ than the tolerance limit (G’ = 26.9 kPa) determined above.

The G’ of cooked rice samples was measured by modifying the rice grains to a paste. To examine the effect of maltotriose syrup on the texture of cooked rice grains, the hardness (force at 50% compressive strain) was evaluated. The effects of maltotriose syrup and the water content on the hardness of the cooked rice grain samples are shown in Fig. 7. There was no significant difference in hardness among the samples before storage (0 h). After chilled storage (24 h), the hardness significantly increased due to starch retrogradation. At all of the tested water contents, the hardness was significantly lower in the additive samples than in the controls. These results confirmed that the hardness changed in a similar manner as the G’ value in the rice paste samples.

Effect of pH on the browning of cooked rice with maltotriose syrup

Non-enzymatic browning is promoted under conditions of high temperature and low moisture content [28]. It is possible that browning may be prevented in rice samples with a higher preset water content than those employed in the present study. In fact, when cooked rice samples with maltotriose syrup were prepared with a preset water content of 70%, the browning diminished (L * = 53.4 ± 0.8, a * = -5.8 ± 0.3, and b * = 3.6 ± 0.8). At the same time, the rice granules largely collapsed due to the softening induced by the excessive water content. As another approach, the adjustment of pH was examined as it has been shown that non-enzymatic browning is greatly accelerated under alkaline conditions [29].

To diminish non-enzymatic browning, the effect of pH on browning was investigated (Fig. 8). The results at pH 7.0 were taken from Fig. 4. There was no significant difference in a * among the samples. The L * of the additive samples was significantly lower than that of the controls in a pH-independent manner. As mentioned above, b * was a major indicator of browning in cooked rice; the additive samples had a much higher b * than the controls at pH 7.0. The b * of the additive samples, however, was reduced significantly by the reduction of the pH to 5.5. It is noted that there was no significant difference in b * between the controls at pH 7.0 and the additive samples at pH 5.5. From these results, it was found that the reduction of pH was an effective approach for suppressing the browning of cooked rice with maltotriose syrup.

Conclusions

The effect of maltotriose syrup on the retrogradation of gelatinized rice starch and cooked rice was investigated to prevent starch retrogradation during chilled storage. When cooked rice with 20% maltotriose syrup was prepared with a preset water content of 65% and a pH of 5.5, the physical quality of the cooked rice could be maintained even after storage at 5 °C for 24 h. These conditions may enable the production of cooked rice that can be kept under a chilled condition and does not require reheating prior to consumption. Although maltotriose syrup caused browning of the cooked rice, browning is a minor factor for food quality in some seasoned rice products that are intrinsically colored (e.g., pilaf and paella), and in wrapped rice products (e.g., rice croquettes that are covered in a deep-fried layer of breadcrumbs, and rice balls that are covered in seaweed) in which the color of the rice cannot be seen. In contrast, the partial collapse of rice granules remains an issue at this stage. Since the collapse is caused by the weight of the rice itself, this issue may be solved by spreading the rice granules into a thinner layer before the cooking process, and by cooking at a lower temperature. This will be the subject of a future study.

References

L. Roman, M. Belorio, M. Gomez, Compr. Rev. Food Sci. Food Saf. (2019) https://doi.org/10.1111/1541-4337.12437

F. Zhu, Trends Food Sci Technol. (2018) https://doi.org/10.1016/j.tifs.2018.05.024

K.H. Colwell, D.W.E. Axford, N. Chamberlain, G.A.H. Elton, J. Sci. Food Agric. (1969) https://doi.org/10.1002/jsfa.2740200909

M.J. Miles, V.J. Morris, P.D. Orford, S.G. Ring, Carbohydr. Res. (1985) https://doi.org/10.1016/S0008-6215(00)90778-X

R. Hoover, Food Rev. Int. (1995) https://doi.org/10.1080/87559129509541044

E.A. Arik Kibar, I. Gönenç, F. Us, Int. J. Food Prop. (2014) https://doi.org/10.1080/10942912.2011.619289

Y. Zhang, C. Chen, Y. Chen, Y. Chen, Food Hydrocoll. (2019) https://doi.org/10.1016/j.foodhyd.2019.01.015

W. Wang, H. Zhou, H. Yang, S. Zhao, Y. Liu, R. Liu, Food Chem. (2017) https://doi.org/10.1016/j.foodchem.2016.07.040

Z. Din, H. Xiong, Z. Wang, L. Chen, I. Ullah, P. Fei, N. Ahemad, Colloids Surf. A Physicochem Eng. Asp. (2018) https://doi.org/10.1016/j.colsurfa.2017.11.002

D.J. Prokopowich, C.G. Biliaderis, Food Chem. (1995) https://doi.org/10.1016/0308-8146(95)92820-A

K. Kohyama, K. Nishinari, J. Agric. Food Chem. (1991) https://doi.org/10.1021/jf00008a010

C. Lii, M.-F. Lai, K.-F. Liu, J. Cereal Sci. (1998) https://doi.org/10.1006/jcrs.1998.0198

J. Babić, D. Šubarić, B. Milicevic, D. Ačkar, M. Kopjar, N. Nedic Tiban. Czech J. Food Sci. (2009). https://doi.org/10.17221/31/2009-CJFS

K. Katsuta, A. Nishimura, M. Miura, Food Hydrocoll. (1992) https://doi.org/10.1016/S0268-005X(09)80007-6

Y. Takasaki, M. Kitajima, T. Tsuruta, M. Nonoguchi, S. Hayashi, K. Imada, Agric. Biol. Chem. (1991) https://doi.org/10.1080/00021369.1991.10870677

Y. Mikami, M. Murata, Food Sci. Technol. Res. (2015) https://doi.org/10.3136/fstr.21.813

K. Kawai, K. Fukami, K. Yamamoto, Carbohydr. Polym. (2007) https://doi.org/10.1016/j.carbpol.2006.06.026

M. Otahara, Y. Sato, M. Kasai. Food Sci. Technol. Res. (2018) https://doi.org/10.3136/fstr.24.427

S. Qiu, M.E. Punzalan, A. Abbaspourrad, O.I. Padilla-Zakour, Food Hydrocoll. (2020) https://doi.org/10.1016/j.foodhyd.2019.105247

Y. Wu, H. Xu, Q. Lin, W. Wu, Y. Liu, J. Food Process. Preserv. (2015) https://doi.org/10.1111/jfpp.12450

S. Yu, Y. Ma, T. Liu, L. Menager, D.-W. Sun, J. Food Eng. (2010) https://doi.org/10.1016/j.jfoodeng.2009.08.019

M.N. Lund, C.A. Ray, J. Agric. Food Chem. (2017) https://doi.org/10.1021/acs.jafc.7b00882

E. Purlis, V.O. Salvadori, Food Res. Int. (2009) https://doi.org/10.1016/j.foodres.2009.03.007

E. Lara, P. Cortés, V. Briones, M. Perez, LWT. (2011) https://doi.org/10.1016/j.lwt.2010.10.007

A. Hadiyanto, G. Asselman, R.M. van Straten, D.C. Boom, A.J.B. Esveld, van Boxtel, Innov. Food Sci. Emerg. Technol. (2007) https://doi.org/10.1016/j.ifset.2007.01.006

K. Kawai, K. Fukami, K. Yamamoto, Carbohydr Polym. (2012) https://doi.org/10.1016/j.carbpol.2011.07.046

P. Orford, S.G. Ring, V. Carroll, M.J. Miles, V.J. Morris, J. Sci. Food Agric. (1987) https://doi.org/10.1002/jsfa.2740390210

L. Laguna, A. Salvador, T. Sanz, M. Fiszman, LWT. (2011) https://doi.org/10.1016/j.lwt.2010.05.034

E.H. Ajandouz, A. Puigeserver, J. Agric. Food Chem. (1999) https://doi.org/10.1021/jf980928z

Acknowledgements

This study (excluding the sensory analysis) was financially supported by a Toyo Institute of Food Technology Research Grant (2014). The sensory analysis was financially supported by a Satake Foundation Research Grant (2019). We thank San-ei Sucrochemical Co., Ltd. (Aichi, Japan) for providing maltotriose syrup.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Kiyoshi Kawai (the corresponding author) has carried out collaborative research with San-ei Sucrochemical Co., Ltd. (Aichi, Japan). The collaborative research was on a subject completely different from that of the present study. San-ei Sucrochemical Co., Ltd. had no part in the interpretation of data, writing, and publication of this study.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sumida, R., Inaguma, C. & Kawai, K. Effects of maltotriose syrup, water content, and pH on the retrogradation of cooked rice in chilled storage. Food Measure 16, 2510–2517 (2022). https://doi.org/10.1007/s11694-022-01348-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01348-8