Abstract

The present study evaluated Amaranthus caudatus (AC) and A. hypochondriacus (AH) starches obtained as coproduct during protein extraction for composition, granule size, amylopectin fine structure, thermal, retrogradation, pasting and dynamic rheological-properties to elucidate structure-function relationships. The starches exhibited unimodal particle size distribution with mean granule size of 1.26–3.12 μm. AC starch with larger granules (mean granule size 3.12 μm) than AH starches (1.26–1.59 μm) gelatinized at lower temperatures (lower DSC transition and pasting temperatures), showed higher paste viscosities and produced more elastic gels (lower tan δ and higher Gʹ). Starch granule size related positively with the proportion of amylopectin chains with DP < 12, paste viscosities and dynamic rheological moduli while negatively with non-starch components, gel tan δ and the proportion of amylopectin chains with DP > 12. Starches with greater proportion of amylopectin chains with DP > 12 showed higher gelatinization temperatures, while shorter chains (DP < 12), lipids and proteins contributed to reduced retrogradation tendencies (lower percent retrogradation).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Amaranth, collectively known as Amaranthus, belongs to family Amaranthaceae. There are about 75 species of amaranth, of which six produce starchy seeds [1]. Amaranthus hypochondriacus (AH) and A. caudatus (AC) are two most commonly cultivated seedy species [1, 2]. AH produces pale to dark-yellow coloured grains while the grains of AC are characterized by pinkish-red colour. Starch is the most abundant constituent of amaranth grains. Amaranth starch is mainly amylopectin in nature (many varieties being waxy), exists in the form of very small granules (around 1-µm) and exhibits unique functional properties like low-gelling and retrogradation, high freeze-thaw stability, resistance to shear and high digestibility [1, 2]. Therefore, it can have numerous food and non-food applications, e.g. as fat-replacers, thickeners, encapsulation materials, stabilizers, paper coatings, dusting powders, laundry starch and biodegradable films. However, their ultimate application is determined by thermal, rheological and retrogradation properties which depend in turn on purity (content of non-starch constituents) as well as on physicochemical, morphological and structural features of starches that vary widely amongst different species/cultivars [1, 3,4,5].

Amaranth starch is mostly produced employing an alkali wet-milling process that involves steeping of grains or immersing/mixing of flour in dilute NaOH solution (0.05–0.1 %) for few hours, followed by grinding, washing, blending, centrifuging and drying to get starch [1]. The process produces starch of satisfactory purity with high recovery. However, in recent years, amaranth grains have been of great interest primarily because of high quality proteins that are characterized by balanced essential amino acids composition, high digestibility, health beneficial activities and functional properties [2]. Amaranth proteins products (e.g. isolates and concentrates) have been evaluated for nutritional and functional improvement of traditional and novel foods. They are usually prepared by alkaline extraction method involving protein solubilisation at pH 8.0–11.0, followed by recovery (separation of proteins from solution) at isoelectric pH or using membranes, neutralization and drying. In this process, an appreciable amount of sediment/residue is left behind, which should be utilized for extracting starch in order to ensure optimum utilization of grains and benefits of processor. Therefore, the present work was carried out to (1) compare composition, granule size, amylopectin chain length, thermal, retrogradation, pasting and dynamic rheological properties of AC and AH starches from residues obtained during protein extraction and (2) to evaluate relationships between the measured properties.

Materials and methods

Materials

Grains of four cultivars/lines of AH (IC 35407, PRA 1, PRA 3 and Annpurna) and one of AC (NIC 22549) were obtained from National Bureau of Plant Genetic Resource, Shimla, India. Grains were cleaned and ground to pass through a sieve with 250-µm apertures. Flours, thus obtained, were defatted three times using hexane at a flour-hexane ratio of 1:4 for 8 h. Finally, solvent was separated and residue was dried at 35 °C for 24 h [6].

Starch extraction and purification

The defatted flours were dispersed in deionized water (flour-water ratio of 1:10) and pH of dispersions was raised to 9.0 with 1 N NaOH solution. The dispersions were stirred on a magnetic stirrer at room temperature for 1 h and then centrifuged at 8000×g for 20 min. Sediments were re-dispersed with deionised water (1:5), stirred magnetically for another 1 h (pH 9.0) and centrifuged (8000×g for 20 min). Supernatants were used for protein isolation [7], while sediments for starch extraction. Sediments were dispersed in deionized water (1:5) and then washed with fresh deionized water on a sieve with 105-µm apertures to collect starch milk relatively free of fibres. Washings were continued until white starch milk washed out. The starch milks were centrifuged at 3000×g for 20 min. The upper yellow layer (tailings) in the sediments/pellets were carefully removed using a spatula. Starches were further purified by re-suspending in deionized water and centrifuging at 3000×g for 20 min. Four such purification cycles were carried out to wash out alkali and to obtain starch with high purity. Starches were finally dried at 40 °C in a laboratory oven, ground using a mortar-pastel, sealed in plastic pouches and stored at room temperature till evaluation.

Composition and blue value

Protein (N×5.85), ash and fat content of extracted starches were determined following standard methods [8]. Total carbohydrate content was calculated as difference. Blue value (BV) was recorded at 635-nm using a UV/Vis spectrophotometer (Lambda Bio 35, Perkin Elmer, Norwalk, CT, U.S.A.) following the method elaborated by Chandla et al. [9].

Laser diffraction particle size analysis

Granule size was determined using a laser diffraction particle size analyser (S3550, Microtrac Inc., USA) equipped with a delivery system for wet samples (SDC, Microtrac Inc., USA). For, the determination, starches were added to the sample port of the wet sample delivery system containing deionized water until the analyser read ≈ 40 % loading factor and ultrasonication was done for 60 s to achieve complete separation of granules. The particle size distribution of granules was expressed as volume percent of equivalent spheres.

Amylopectin chain length distribution

Unit chains of amylopectin between degree of polymerization (DP) 6 and 30 were analyzed by fluorophore-assisted capillary electrophoresis as described previously [10]. Starch was debranched with isoamylase and labeled with 8-amino-1,3,6-pyrenetrisulfonic acid (APTS) according to Edwards et al. [11]. The amylopection chains were grouped as short, medium and long chains based on their DP (short = DP6–12; medium = DP13–24; long = DP > 24) to elucidate the relationship of amylopectin chain length with other properties of starches.

Thermal and retrogradation properties

Thermal properties of starches were measured using a differential scanning calorimeter (DSC-822e, Mettler Toledo, Greifense, Switzerland) equipped with a thermal analysis data station as reported earlier [12]. To study the retrogradation, starch gels were again scanned between 40 and 100 °C after storage of 14 days at 4 °C.

Pasting properties

Pasting properties of starches (10 % suspensions) were determined using a dynamic rheometer (MCR301, AntonPaar, Austria) equipped with starch cell and stirrer probe as reported earlier [6]. The temperature-time conditions included a heating phase from 50 to 95 °C at the rate of 6 °C/min and a holding phase at 95 °C for 5 min, a cooling phase from 95 to 50 °C at a rate of 6 °C/min and a holding phase at 50 °C for 2 min. Pasting temperature (PT), peak viscosity (PV), hot paste viscosity (HPV), breakdown viscosity (BDV), cold paste viscosity (CPV) and setback viscosity (SBV) were noted.

Dynamic oscillatory measurements

Dynamic oscillatory measurements were performed using dynamic rheometer (Haake RS6000, Thermo Electron, Germany) equipped with parallel plate geometry (35-mm). The suspensions (20 %) were mixed on a magnetic stirrer at room temperature for 60 min before being loaded on the bottom plate of the rheometer. A thin layer of low-density silicon oil was applied to minimize evaporation. Gap between plates, strain and frequency were set at 1.0-mm, 1 % and 1-rad/s, respectively. A preliminary strain sweep test was performed to determine linear viscoelastic region. The suspensions were heated from 50 to 95 °C at a rate of 2 °C/min and then held at 95 °C for 10 min followed by cooling from 95 to 30 °C at same scan rate. Storage modulus (Gʹ, solid component), loss modulus (G″, liquid component) and their ratio i.e. loss tangent (tan δ = G″/Gʹ) were recorded. Following thermal sweeps, frequency sweeps of gels were also recorded over an angular frequency range of 1 to 100 rad/s.

Statistical analysis

The data reported is mean of triplicate values. The data was subjected to analysis of variance (ANOVA) employing Duncan’s test (P < 0.05) and Principal component analysis using Minitab Statistical Software (Minitab Inc., State College, PA, USA).

Results and discussion

Proximate composition and blue value

Non-starch constituents (protein, ash and lipids) were present in starches as minor components. Protein, ash and lipids content ranged from 0.24 to 0.62 %, 0.48 to 1.10 % and 0.34 to 0.98 %, respectively (Table 1). AC starch showed lower ash content (0.48 %) and higher carbohydrates content (98.90 %) than AH starches (0.56–1.10 % and 97.92–98.34 %, respectively). Starch purity has been reported to depend on extraction method [1]. However, the amaranth starches obtained from residues compared well with commercial (0.06–0.4 % proteins, 0.05–0.8 % lipids and 0.1–0.4 % ash on dry basis) and amaranth starches (0.02–0.98 % proteins, 0–1.8 % lipids and ash content up to 1.2 %) for protein, ash and lipids contents [1, 3, 13].

Starches from different amaranth lines/cultivars showed low BV (0.020–0.054). BV/iodine binding capacity of 0.031 and 0.085 have been reported for Rajgeera Amaranthus [14] and A. cruentus starches [15], respectively. Low BV suggested that starches were mainly amylopectin in nature; however, higher BV for AC starch (0.54) than AH starches (0.020–0.032) indicated relatively higher amylose content. BV measures the capacity of starch chains to bind iodine, which depends in turn on structural features of starch molecules. Amylose with essentially linear and long chain structure exhibits stronger affinity to iodine than highly branched amylopectin, hence starches with higher amylose content give deep blue complex with iodine (higher BV), while amylopectin gives reddish-yellow colouration [14]. PCA also corroborated the relationship as BV related positively with total carbohydrate content (as their curves laid close to each other on PCA loading plot and negatively with non-starch constituents (protein, lipids and ash-content) as their curves ran in opposite directions on the PCA loading plot (Fig. 1).

Principal Component Analysis loading plot illustrating relationship amongst various properties of amaranth starches from residues of protein extraction. BV blue value, Carb total carbohydrates, AC ash content, PC protein content, LC lipids content, PT pasting temperature, PV peak viscosity, HPV hot paste viscosity, CPV cold paste viscosity, BDV breakdown viscosity, GS mean granule size, To, TP, Tc onset, peak and endset transition temperatures of native starch granules, respectively; dH gel, enthalpy of gelatinization, Tor, Tpr, Tcr, onset, peak and endset transition temperatures of retrograded starches, respectively; dHr enthalpy of retrograded starches, PR percent retrogrdation, tand Tan δ of starch gel; Gʹp, Gʹʹp peak Gʹ and Gʹʹ, respectively; Gʹ95, Gʹʹ95 Gʹ and Gʹʹ of starch gels at 95°C, respectively; Gʹb, Gʹʹb Gʹbreakdown and Gʹʹbreakdown, respectively

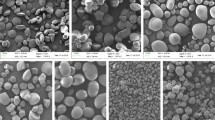

Granule size

Starches from different amaranth lines/cultivars showed unimodal particle size distribution with granule size ranging between 0.4 and 7.5 μm (Fig. 2). AH starches differed significantly from AC starch for their granule size (Table 2). AH starches consisted mainly of smaller granules of 0.47 to 3.31 μm (mean granule size = 1.26–1.59 μm) in size, while AC granules were larger in size (mean granule size = 3.12 μm). Smaller granule size of AH starches suggested that they would be suitable in applications where dispersion and coating are required [16]. Mean granule sizes of starches were in agreement of reports of Chandla et al. [9] for starches from Chaulai amaranth, AH and A. paniculates (1.182–1.431 μm) and Kong et al. [17] for AH (1.05–1.09 μm), A. hybridus (1.21 μm) and A. cruentus starches (1.12–1.32 μm). The genetic basis of starch morphology is not fully understood [1]; however, variations in starch granule size amongst different cultivars/species have been attributed to differences in amylopectin fine structure and packing within granule [18]. PCA revealed a negative relationship between granule size and non-starch constituents (Fig. 1), suggesting that smaller granules might contained higher amounts of proteins and lipids (possibly residual) on surface likely due to greater surface area per unit mass. Proteins and lipids locate both at surface and within interiors of starch granules from different botanical sources, though they tend to enrich at granule surface [19].

Amylopectin chain length distribution

The amylopectin chain length distribution for AC and AH starches from residues obtained during protein extraction is shown in Fig. 3. The starches exhibited a smooth polymodal distribution with the peak maxima at DP = 11, which was consistent with the findings of Singh et al. [10] for wheat starches. The proportion of short, medium and long-chains was 49.0 %, 46.6 and 4.5 %, respectively for AC starch, while it varied from 44.9 to 48.8 %, 47.0 to 49.8 % and 4.2 to 5.2 %, respectively for AH starches. PRA 1 starch showed the lowest proportion of short (44.9 %) and the highest proportion of medium and long amylopectin chains (49.8 and 5.2 %, respectively). In general, starches with higher proportion of long and medium-amylopectin chains contained lower proportion of short chains (Fig. 1). The amylopectin fine structure of starches from residues obtained during protein extraction compared well with AH and AC starches extracted using alkaline wet-milling procedure as reported in a previous study [5], in which proportions of amylopectin chains with DP6–12, 13–18, 19–24 and 25–30 were reported to be 43.60-55.72 %, 31.59–34.49 %, 10.14–16.37 % and 2.56–5.53 %, respectively, for AH and 50.67–57.53 %, 29.30-32.02 %, 10.04–13.09 % and 2.75–4.2 %, respectively for AC. PCA revealed a negative relationship of medium and long-amylopectin chains while positive of short chains with starch granule size (Fig. 1), which suggested that amylopectin molecules in larger granules had greater proportion of short amylopectin chains with DP6–12 than in smaller granules and vice-versa. Inconsistent results for relationships between amylopectin chain length and granule size have been reported in literature for starches from different sources. While Dhital et al. [20] reported no relationship of amylose and amylopectin branch chain lengths with granule size for maize and potato starches, Singh et al. [5] reported a positive correlation of amylopectin chains of DP6–12 with the proportion of 1–10 μm granules and negative with 11–30 μm granules of amaranth starches.

Thermal and retrogradation properties

Thermal/gelatinization properties of waxy starch granules depend primarily on quality and quantity of crystalline structures which depend in turn on double-helical structure and arrangement of amylopectin molecules within granules. DSC transition temperatures reflect the degree of crystalline perfection, while enthalpy measures energy required for dissociation of molecular order/double helices.

Thermal properties of native and retrograded starches from different AC and AH lines/cultivars extracted from residues of protein extraction are shown in Table 2. AC starch showed lower onset, peak and endset transition temperatures (To, Tp and Tc, respectively) than AH starches. Enthalpy (ΔHgel) was 11.47 J/g for AC starch, while it varied between 10.99 J/g and 11.94 J/g for AH starches. The observed values were comparative to that reported by Marcone [21] for AH starch (To, Tp, Tc and ΔHgel = 62.0 °C, 70.6 °C, 78.9 °C and 13.0 J/g, respectively) and Singh et al. [5] for different AH (63.20–70.01 °C, 68.88–72.88 °C, 74.47–76.95 °C and 7.78–13.94 J/g, respectively) and AC starches (60.46–63.28 °C, 65.05–67.05 °C, 70.93–74.40 °C and 11.55–14.38 J/g, respectively). PCA loading plot showed a negative relation of transition temperatures with short amylopectin chains and granule size (Fig. 1) suggesting that crystalline structure of larger granules might have disrupted at relatively lower temperature, possibly, due to the presence of higher proportion of amylopectin chains with DP6–12 that were unable to form stable double-helical structures, while the smaller granules of AH starches with greater proportion of amylopectin chains of DP > 12 gelatinized at relatively higher temperature by forming a stronger crystalline network [22]. Negative correlation of starch gelatinization temperatures with short amylopectin chains while positive with medium and long-chains have been reported earlier for wheat [10] and kidney bean starches [23]. PCA also revealed a positive relation of non-starch constituents (proteins, lipids and ash) with transition temperatures while negative with ΔHgel (Fig. 1), which is consistent with an earlier report [24], in which successive purification of maize starch during wet milling decreased transition temperatures and increased enthalpy. Increase in ΔHgel from 14.1 to 14.9 J/g to 15.6–16.5 J/g after removal of proteins using protease in different mediums has also been reported for commercial waxy maize starch [25]. Rosicka-Kaczmarek et al. [26] also reported that fatty acids (particularly linoleic, palmitic, erucic and tricosanoic acids) in wheat starches contribute to lesser susceptibility towards gelatinization.

Retrograded AC starch showed transition temperatures (Tor, Tpr and Tcr) of 47.5 °C, 53.3 and 56.6 °C, respectively against 46.4–47.8 °C, 53.8–54.1 °C and 58.3–59.6 °C, respectively for AH gels (Table 2). Enthalpy of retrogradation (ΔHret), a measure of energy required for dissociation of reassociated starch chains, was 2.70 J/g for AC and varied between 1.54 and 2.88 J/g for AH starches. Percent retrogradation (PR) was calculated as the percentage of ΔHret compared to ΔHgel [27], which varied significantly between 13.1 and 26.2 %. IC 35407 starch showed the least retrogradation tendencies (lowest ΔHret and PR), hence may be considered suitable in products (e.g. sauces/ketchups, puddings, dessert-like products, etc.) where soft texture and slow rate of syneresis is desired for getting extended shelf life. PRA 1 and Annapurna starches with higher proportion of medium and long-amylopectin chains than other cultivars showed higher values of ΔHret and PR. PCA analysis also confirmed this relationship as long and medium-amylopectin chains related positively while short chains negatively with ΔHret and PR (Fig. 1). Liu and Ng [28] also reported lesser retrogradation tendencies for bran starch with greater proportion of amylopectin chains with DP6–12. As retrogradation in waxy and low-amylose starches occurs primarily as a result of hydrogen bonding between dissociated/unravelled amylopectin molecules [22], it can be inferred that amylopectin chains in amaranth starches should have a DP > 12 for promoting the formation of double helices during storage. Moreover, negative relationships of proteins and lipids with PR and ΔHret while positive with short amylopectin chains (Fig. 1) further suggested that short amylopectin chains (present as external branches on amylopectin molecules) may have also contributed to lower retrogradation tendency, possibly by complexing with proteins and lipids during gelatinization which inhibited amylopectin reassociation during storage of gels [29]. Shorts amylopectin chains were reported to be located as external branches in amylopectin molecule [30]. Li et al. [31] reported increased retrogradation for normal and waxy wheat starches after removal of lipids and proteins.

Pasting properties

Pasting curves exhibited viscosity behaviour of starch suspension as a function of temperature at high shear rate. During heating, the viscosity of starch suspensions started to increase at temperatures between 67.5 and 69.8 °C (Fig. 4). This temperature was represented as PT which indicated the minimum temperature required for paste formation. AH starches showed higher PT (68.9–69.8 °C) than AC starch (67.5 °C). PCA revealed that PT of starches depended on their gelatinization temperature as PT related positively with To, Tp and Tc (Fig. 1). In addition, PCA also revealed a positive relation of PT and transition temperatures with non-starch constituents while negative with granule size, suggesting that smaller granules in amaranth starches were more resistant to swell and gelatinize likely due to greater amounts of residual non-starch constituents, e.g. proteins and lipids, which may have contributed to increased resistance towards gelatinization by competing for available water, delaying water absorption and forming starch-lipids complexes. Decrease in gelatinization and pasting temperature after removal of proteins and lipids has been reported for starches from normal and waxy maize [32] and wheat [31]. PV (the capacity of starch granules to swell), HPV (the minimum viscosity of paste during heating), BDV (susceptibility of swollen granules to disintegrate), CPV (viscosity of paste after cooling) and SBV (increase in viscosity during cooling) ranged from 2845 cP to 4563 cP, 1408 cP to 1757 cP, 1430 cP to 2806 cP, 1820 to 2841 cP, and 405 cP to 1084 cP, respectively. AC starch showed higher PV, HVP, BDV, CPV and SBV (4563 cP, 1757 cP, 2806 cP, 2841 cP and 1084 cP, respectively) than AH starches (2845–3088 cP, 1408–1469 cP, 1430–1680 cP, 1820–2055 cP and 405–621 cP, respectively). It seems that granules of AC starch swelled to a greater extent and occupied greater volume in the paste than AH granules because of higher proportion of short amylopectin chains and presence of bigger granules [10], hence contributed to higher paste viscosities. Also, the swollen AC granules might have undergone disintegration to a greater extent than AH granules, hence showed higher BDV. Positive relationship amongst granule size, swelling power, PV and BDV has been reported previously for starches from different cultivars of common wheat [12], durum wheat [33] and potato [34, 35]. PCA also supported this relationship as PV, HPV, BDV, CPV and BDV related positively with starch granule size (Fig. 1). However, the effect of non-starch constituents, such as residual proteins, lipids and minerals, cannot be denied as negative relationships between paste viscosities and non-starch constituents were also observed. Han et al. [36] also highlighted increased paste viscosities and shear-induced breakdown of maize starch pastes in the absence of proteins, while Du et al. [37] showed that presence of higher levels of lipids in flours may affect paste viscosities by retarding molecular reassociation through inhibiting directional arrangement of dispersed starch chains in paste.

Dynamic rheology

The changes in Gʹ and Gʹʹ of starch suspensions during heating, holding and cooling are illustrated in Fig. 5. During heating, Gʹ and Gʹʹ increased and started to decrease after reaching a peak. The increase in moduli was possibly due to the ability of granules to swell freely and fill available space in gels. Peak moduli values during heating (Gʹpeak and Gʹʹpeak) ranged from 20 to 198 Pa and 14 to 297 Pa, respectively. AC starch showed higher values of peak moduli (198 and 297 Pa, respectively) than AH starches (20–35 Pa and 14–24 Pa, respectively). This further supported that AC starch granules swelled to a greater extent during heating and occupied relatively greater available volume of the system than smaller AH granules. The differences in dynamic rheological moduli amongst starches from different rice cultivars were attributed to the difference in degree of granular swelling to fill the entire available volume of the system [38]. During extended heating, moduli decreased owing to rupturing and disintegration of swollen starch granules, melting of crystallites and weakening of inter-chain interactions as a result of increased molecular mobility [39]. The minimum Gʹ and Gʹʹ during heating (Gʹ95 and Gʹʹ95, respectively) ranged from 15 to 87 Pa and 9 to 55 Pa, respectively. The difference between Gʹpeak and Gʹ95 (Gʹbreakdown) varied between 3 and 111 Pa. During cooling, Gʹ increased due to the reassociation of starch leached from granules and interaction between molecules remaining inside granules those reinforced gel structure [12, 40]. Similar as pasting properties, AC starch showed higher values of moduli than AH starches. AC starch, therefore, may be considered superior thickening agent, while AH starches would be useful in applications requiring high starch concentrations at low viscosity e.g. weaning foods and soft candies [41,42,43]. PCA analysis revealed strong positive relationships amongst dynamic rheological moduli and paste viscosities (Fig. 1); therefore, the differences in dynamic moduli during heating, holding and cooling of starches may be attributed to the same factors discussed for pasting properties.

Starch gels were also evaluated for frequency sweep over a range from 1 to 100 rad/s to get further insights about their structure [44]. Amaranth starch gels exhibited frequency dependant behaviour as both Gʹ and Gʹʹ increased with increasing frequency (Fig. 5). AC starch gel showed the highest moduli at all frequencies measured, indicating greater viscoelasticity than AH gels. In addition, tan δ of cooked starch gels were also measured. The value of tan δ is infinity for an ideal liquid and approaches to zero for a solid. The starch gels showed a typical semi-solid (weak-gel) like behaviour as tan δ values ranged between 0.24 and 0.53. AC starch gel showed a lower value of tan δ (0.24) than AH starches (0.39–0.53). The results showed that more elastic gels could be obtained from AC starch as compared to AH starches, which might be due to greater granular swelling that contributed elasticity to starch gels by filling the entire available volume of the system. Tan δ related positively to the transition temperatures, PT and the proportion of medium and long amylopectin chains, but negatively to short amylopectin chains and starch granule size (Fig. 1) suggesting that amylopectin chains with DP > 12 might have made the starches resistant to gelatinization, hence, gel formation occurred to a lesser extent. Short chains, contrarily, promoted structure formation by unravelling completely, while large AC granules may have swollen to a greater extent than smaller ones possibly because of higher proportion of short amylopectin chains and thus contributed to elastic and stronger gel (lower tan δ) formation.

Conclusions

Amaranth starches extracted from residues of protein extraction contained non-starch constituents as minor components. AH starches differed significantly from AC starch for granule size, thermal, pasting and dynamic rheological properties. AC starch can be considered superior thickening agent because of lower gelatinization temperature, high paste viscosities and ability to produce strong (elastic) gels. Rheological properties of starches depended on granule size and amylopectin chains with DP 6–12, while retrogradation tendencies on amylopectin chains with DP > 12. Non-starch constituents, particularly, residual proteins and lipids, reduced retrogradation tendencies and susceptibility of granules to gelatinize.

References

F. Zhu, Structures, physicochemical properties, and applications of amaranth starch. Crit. Rev. Food Sci. Nutr. 57, 313–325 (2017)

N. Singh, P. Singh, K. Shevkani, A.S. Virdi, Amaranth: Potential source for flour enrichment, in Flour and Breads and their Fortification in Health and Disease Prevention (Ch. 10), Second Edition. ed. by V.R. Preedy, R.R. Watson (Academic Press Elsevier, London, 2019)

H. Choi, W. Kim, M. Shin, Properties of Korean amaranth starch compared to waxy millet and waxy sorghum starches. Starch-Staerke 56, 469–477 (2014)

R. González, C. Carrara, E. Tosi, M.C. Añón, A. Pilosof, Amaranth starch-rich fraction properties modified by extrusion and fluidized bed heating. LWT-Food Sci. Technol. 40, 136–143 (2007)

N. Singh, S. Kaur, A. Kaur, N. Isono, Y. Ichihashi, T. Noda, J.C. Rana, Structural, thermal, and rheological properties of Amaranthus hypochondriacus and Amaranthus caudatus starches. Starch-Staerke 66, 457–467 (2014)

K. Shevkani, N. Singh, A. Kaur, J.C. Rana, Physicochemical, pasting, and functional properties of amaranth seed flours: effects of lipids removal. J. Food Sci. 79, C1271–C1277 (2014)

K. Shevkani, N. Singh, J.C. Rana, A. Kaur, Relationship between physicochemical and functional properties of amaranth (Amaranthus hypochondriacus) protein isolates. Int. J. Food Sci. Technol. 49, 541–550 (2014)

Association of Official Analytical Chemists, Official Methods of Analysis, 15th edn. (AOAC, Washington, 1990)

N.K. Chandla, D.C. Saxena, C.S. Singh, Amaranth (Amaranthus spp.) starch isolation, characterization, and utilization in development of clear edible films. J. Food Process. Preserv. 41, e13217 (2017)

S. Singh, N. Singh, N. Isono, T. Noda, Relationship of granule size distribution and amylopectin structure with pasting, thermal, and retrogradation properties in wheat starch. J. Agric. Food Chem. 58, 1180–1188 (2010)

A. Edwards, D.C. Fulton, C.M. Hylton, S.A. Jobling, M. Gidley, U. Rössner, C. Martin, A.M. Smith, A combined reduction in activity of starch synthases II and III of potato has novel effects on the starch of tubers. Plant J. 17, 251–261 (1999)

K. Shevkani, N. Singh, S. Singh, A.K. Ahlawat, A.M. Singh, Relationship between physicochemical and rheological properties of starches from Indian wheat lines. Int. J. Food Sci. Technol. 46, 2584–2590 (2011)

J.J.M. Swinkels, Composition and properties of commercial native starches. Starch-Staerke 37, 1–5 (1985)

M.D. Teli, P. Rohera, J. Sheikh, R. Singhal, Use of Amaranthus (Rajgeera) starch vis-à-vis wheat starch in printing of vat dyes. Carbohydr. Polym. 76, 460–463 (2009)

X. Xia, G. Li, F. Liao, F. Zhang, J. Zheng, J. Kan, Granular structure and physicochemical properties of starches from amaranth grain. Int. J. Food Prop. 18, 1029–1037 (2015)

K.A. Schnetzler, W.M. Breene, in Amaranth: Biology, Chemistry and Technology (O. Parades-Lopez (ed.)). CRC Press, Boca Raton, FL, Ch. 9 (1994)

X. Kong, J. Bao, H. Corke, Physical properties of Amaranthus starch. Food Chem. 113, 371–376 (2009)

J.L. Jane, Structure of starch granules. J. Appl. Glycosci. 54, 31–36 (2007)

P.M. Baldwin, Starch granule-associated proteins and polypeptides: a review. Starch‐Staerke 53, 475–503 (2001)

S. Dhital, A.K. Shrestha, J. Hasjim, M.J. Gidley, Physicochemical and structural properties of maize and potato starches as a function of granule size. J. Agric. Food Chem. 59, 10151–10161 (2011)

M.F. Marcone, Starch properties of Amaranthus pumilus (seabeach amaranth): a threatened plant species with potential benefits for the breeding/amelioration of present Amaranthus cultivars. Food Chem. 73, 61–66 (2001)

K. Shevkani, N. Singh, R. Bajaj, A. Kaur, Wheat starch production, structure, functionality and applications-a review. Int. J. Food Sci. Technol. 52, 38–58 (2017)

N. Singh, S. Kaur, J.C. Rana, Y. Nakaura, N. Inouchi, Isoamylase debranched fractions and granule size in starches from kidney bean germplasm: distribution and relationship with functional properties. Food Res. Int. 47, 174–181 (2012)

N. Singh, K. Shevkani, A. Kaur, S. Thakur, N. Parmar, A.S. Virdi, Characteristics of starch obtained at different stages of purification during commercial wet milling of maize. Starch-Staerke 66, 668–677 (2014)

R.F. Tester, R. Yousuf, J. Karkalas, B. Kettlitz, H. Röper, Properties of protease-treated maize starches. Food Chem. 109, 257–263 (2008)

J. Rosicka-Kaczmarek, B. Makowski, E. Nebesny, M. Tkaczyk, A. Komisarczyk, Z. Nita, Composition and thermodynamic properties of starches from facultative wheat varieties. Food Hydrocoll. 54, 66–76 (2016)

L.A. Baker, P. Rayas-Duarte, Retrogradation of amaranth starch at different storage temperatures and the effects of salt and sugars. Cereal Chem. 75, 308–314 (1998)

Y. Liu, P.K. Ng, Isolation and characterization of wheat bran starch and endosperm starch of selected soft wheats grown in Michigan and comparison of their physicochemical properties. Food Chem. 176, 137–144 (2015)

M. Gudmundsson, A.C. Eliasson, Retrogradation of amylopectin and the effects of amylose and added surfactants/emulsifiers. Carbohydr. Polym. 13, 295–315 (1990)

S. Hizukuri, Polymodal distribution of the chain lengths of amylopectins, and its significance. Carbohydr. Res. 147, 342–347 (1986)

W. Li, J. Gao, G. Wu, J. Zheng, S. Ouyang, Q. Luo, G. Zhang, Physicochemical and structural properties of A-and B-starch isolated from normal and waxy wheat: effects of lipids removal. Food Hydrocoll. 60, 364–373 (2016)

M.R. Debet, M.J. Gidley, Three classes of starch granule swelling: Influence of surface proteins and lipids. Carbohydr. Polym. 64, 452–465 (2006)

A. Kaur, K. Shevkani, M. Katyal, N. Singh, A.K. Ahlawat, A.K. Singh, Physicochemical and rheological properties of starch and flour from different durum wheat varieties and their relationships with noodle quality. J. Food Sci. Technol. 53, 2127–2138 (2016)

I.S.M. Zaidul, H. Yamauchi, S. Takigawa, C. Matsuura-Endo, T. Suzuki, T. Noda, Correlation between the compositional and pasting properties of various potato starches. Food Chem. 105, 164–172 (2007)

N. Singh, A. Kaur, K. Shevkani, R. Ezekiel, P. Kaur, N. Isono, T. Noda, Structural, morphological, thermal, and pasting properties of starches from diverse Indian potato cultivars. Starch-Staerke 70, 1700130 (2018)

X.Z. Han, O.H. Campanella, H. Guan, P.L. Keeling, B.R. Hamaker, Influence of maize starch granule-associated protein on the rheological properties of starch pastes. Part II. Dynamic measurements of viscoelastic properties of starch pastes. Carbohydr. Polym. 49, 323–330 (2002)

S.K. Du, H. Jiang, X. Yu, J.L. Jane, Physicochemical and functional properties of whole legume flour. LWT-Food Sci. Technol. 55, 308–313 (2014)

N. Singh, N. Pal, G. Mahajan, S. Singh, K. Shevkani, Rice grain and starch properties: effects of nitrogen fertilizer application. Carbohydr. Polym. 86, 219–225 (2011)

G. Méndez-Montealvo, F.J. García-Suárez, O. Paredes-López, L.A. Bello-Pérez, Effect of nixtamalization on morphological and rheological characteristics of maize starch. J. Cereal Sci. 48, 420–425 (2008)

S. Hsu, S. Lu, C. Huang, Viscoelastic changes of rice starch suspension during gelatinization. J. Food Sci. 65, 215–220 (2000)

S.H. Yoo, C. Perera, J. Shen, L. Ye, D.S. Suh, J.L. Jane, Molecular structure of selected tuber and root starches and effect of amylopectin structure on their physical properties. J. Agric. Food Chem. 57, 1556–1564 (2009)

K.N. Jan, P.S. Panesar, S. Singh, Process standardization for isolation of quinoa starch and its characterization in comparison with other starches. J. Food Meas. Charact. 11, 1919–1927 (2017)

M. Shrivastava, R.B. Yadav, B.S. Yadav, N. Dangi, Effect of incorporation of hydrocolloids on the physicochemical, pasting and rheological properties of colocasia starch. J. Food Meas. Charact. 12, 1177–1185 (2018)

M.A. Rao, Rheology of Fluid and Semisolid Foods: Principles and Applications (Springer, New York, 2014)

Acknowledgements

Authors acknowledge Dr. J.C. Rana (NBPGR, India) for providing amaranth lines/cultivars for this research. KS acknowledge CUP, Bathinda for providing RSM grant and laboratory facilities. NS acknowledge DST, New Delhi for the grant of J.C. Bose Fellowship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shevkani, K., Singh, N., Isono, N. et al. Structural and functional properties of amaranth starches from residue obtained during protein extraction. Food Measure 15, 5087–5096 (2021). https://doi.org/10.1007/s11694-021-01070-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-021-01070-x