Abstract

The antioxidant activities of natural phenolic compounds (thymol, carvacrol, and thymoquinone) were compared with commercial antioxidants (α-tocopherol, BHT, and BHA) using DPPH·, conjugated diene (CD) in the linoleic acid emulsion, and ferric reducing power methods. Commercial antioxidants had higher DPPH· antiradical activity than natural phenolics. Thymoquinone (TQ) at 1000 ppm showed higher inhibition (65.7%) on DPPH· radicals than other natural phenolics at 1000 ppm (25.0% for thymol, and 18.3% for carvacrol). Carvacrol and thymol showed similar antioxidant activities compared with BHT and BHA in linoleic acid emulsion test at different concentrations, while TQ and α-tocopherol exhibited lower activity among analyzed samples. The results from reducing power test showed that natural phenolics were less effective than commercial antioxidants. The impacts of natural phenolics and BHT on the oxidative stabilities of refined and stripped corn oils were investigated using the Rancimat, Schaal oven, peroxide value (PV), CD (K232) and p-anisidine value (p-AV) methods. The loss in total tocopherols in refined corn oils was recorded during storage under Schaal oven conditions (60 °C). BHT showed a higher induction period (15.01 h) than phenolic compounds added to corn oils (3.88–5.69 h) and a control sample (2.82 h). According to the results of the Schaal oven test, BHT much better protected the refined and stripped corn oils from oxidation than natural phenolic compounds. Among phenolic compounds, TQ at 250 and 500 ppm exhibited high antioxidant potential in refined and stripped corn oils.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lipid oxidation is the major deterioration problem in foodstuffs rich in lipids. During the lipid oxidation process, a variety of compounds formed and most of them influence the food quality parameters including aroma, texture, nutritional value and color. Besides, some of these oxides have toxic impacts on human health [1,2,3,4,5,6].

Antioxidants are used to retard the lipid oxidation process, thus preserve the aroma, color, and nutrition values of foods [7,8,9,10,11]. Synthetic and natural antioxidants are utilized to preserve lipid oxidation. Synthetic antioxidants are effective and less expensive than natural ones. Butylated hydroxyanisole (BHA) and butylated hydroxytoluene (BHT) are commonly synthetic antioxidants used in the vegetable oil industry [12,13,14]. Natural antioxidants are present in fruits, vegetables, herbs and medicinal plants. Phytochemicals can be used for food preservation and have been applied in food chemistry and pharmacy, demonstrating that these bioactive constituents are innovation hotspot in several technological domains [15]. Natural antioxidants are preferred for consumers than synthetic ones due to safety concerns. Besides, natural antioxidants ensure some health implications [8, 16,17,18].

Phenolics are a potential source for natural antioxidants to protect some diseases induced by free radicals [3]. The most effective natural antioxidants contain phenolic compounds that have strong H-donating activity [14, 19]. Natural compounds such as coumarins, curcumanoids, flavonoids, lignans, tannins, phenolics are found in fruits, vegetables, leaves, and seeds and they are known to protect food ingredents from oxidation [14, 20]. Herbs and spices have been used in food industry as antioxidants and flavoring agents. Phenolics such as thymol, carvacrol, and thymoquinone (TQ) exhibited high antioxidant and health-promoting activities. Thymol and carvacrol are the main bioactive components in the essential oils of the Lamiaceae family [21, 22]. TQ, a biologically active compound in black cumin (Nigella sativa) seeds, is responsible for its health beneficial effects [23,24,25,26,27,28].

Different vegetable oils (palm, corn, canola, soybean, sunflower, etc.) are commonly utilized for frying, each with its specific fatty acids profile, taste, and stability [29]. Some phenolic substances were used to delay the deterioration and oxidation of oils. Studies demonstrated that some phenolic substances could be considered as proper alternatives to synthetic antioxidants. Horuz and Maskan [30] evaluated the effects of thymol and carvacrol on the thermal stability of corn oil during frying. At frying temperature, carvacrol was an effective alternative to BHT for the preservation of corn oil. A study by Karoui et al. [31] showed that refined corn oil mixed with Thymus capitatus improved the oxidative stability of the oil under heating and deep-frying temperatures. Black cumin (Nigella sativa) oil is rich in bioactive compounds such as TQ. The addition of black cumin (Nigella sativa) oil increased the stability of corn oil when heated at 60 °C [24]. Mariod et al. [32] evaluated the effect of Nigella sativa cake methanol extract and its fractions (n-hexane, ethyl acetate, and water) on the oxidation of corn oil at 70 °C. Nigella sativa cake methanol extract and/or fractions improved the oxidative stability of corn oil.

The present study aims to investigate the antioxidant activity of natural antioxidants (thymol, carvacrol, and TQ) compared with commerical ones (α-tocopherol, BHT, and BHA). Morover, the effects of natural phenolics (thymol, carvacrol, and TQ) on the oxidative stability of refined and stripped corn oils using antioxidant tests and tests under thermal storage conditions were invesigated.

Materials and methods

Materials

Commercial refined corn oil (RCO) was obtained from the market (Bolu, Turkey) and stored at − 18 °C until use. BHA, BHT, 1,1-diphenyl-2-picrylhydrazyl (DPPH·), and p-anisidine were purchased from Sigma (St. Louis, MO, USA). All chemicals and solvents used in the study were of analytical reagent grade and purchased from Sigma-Aldrich (St. Louis, MO, USA).

Methods

Analytical analyses of refined corn oil

Free fatty acid content (FFA) (Ca 5a-40), p-anisidine value (p-AV) (AOCS Cd 18-90), peroxide value (PV) (Cd 8-53), and specific absorbance values (K232, and K268) (Ch 5-91) were analyzed in the corn oil using AOCS [33] official methods.

Total tocopherols content was determined according to Wong et al. [34]. Oil sample (200 mg) was weighed in a 10-mL flask. Toluene (5 mL) were added then 3.5 mL 2,2′-bipyridine (0.07% w/v in ethanol 95%) and 0.5 mL of FeC13·6H2O (0.2% w/v in ethanol 95%) were added and the solution was made up to 10 mL using ethanol 95%. After 1 min the absorption at 520 nm was determined using as a reference blank solution (without oil). The test was calibrated using standards containing 0–250 µg α-tocopherol in toluene. Total tocopherols in the oil was calculated as follow:

where A = sample absorption in 10 mm-cell, B = blank absorption in 10 mm-cell, M = gradient of absorbance vs. weight graph for α-tocopherol calibration, and W = weight of sample (g).

The thermal oxidative stability was tested with the Rancimat apparatus (Metrohm, Herisau, Switzerland). The airflow rate was kept at 10 L/h and the heating block temperature was maintained at 90 °C.

The fatty acid profile was determined by GLC after methylation (Ce 2-66, AOCS method), using an Agilent 7890A fused silica capillary column (J & W Scientific, USA). The column is 100 m long, 0.2 µm film thickness and 0.25 mm inner diameter. The injector temperature was maintained at 250 °C and the detector temperature at 260 °C. Helium was the carrier gas at 1 mL/min flow rate. One µL sample was injected into the column and the split ratio was 1:30. The column temperature was set at 140 °C for 5 min, then programmed to 240 °C at 4 °C/min and held at 240 °C for 10 min. Fatty acid methyl ester (FAME) standard solution (37 FAME mix, Sigma, St. Louis, USA) was used to identify the peaks. Fatty acid composition of oils was given in percentage proportions of FAME using the peak areas.

Evaluation of the antioxidant properties of phenolics and commercial antioxidants

DPPH· radical scavenging test

The solution of phenolic standards was prepared at 25, 50, 100, 250, 500 and 1000 ppm concentrations in methanol and/or acetone. The antiradical potential of the solutions was tested according to Brand-Williams et al. [35]. 3.9 mL of a 0.039 g/L DPPH· methanolic solution was added to 0.1 mL of different concentrations of phenolic standard solutions as well as α-tocopherol, BHA and BHT. The mixture was shaken and left to stand at room temperature for 30 min. The absorbance was measured at 515 nm and the scavenging activity was calculated according to following equation:

where Acontrol and Asample were the absorbance values of control and sample solutions, respectively. Phenolic concentration providing 50% inhibition (IC50) was calculated from the plot of inhibition % against the certain phenolic concentration. All assays were conducted in triplicate.

Linoleic acid test

The antioxidant activities of phenolics in the linoleic acid emulsion were measured according to Mau et al. [36] and Iqbal et al. [37]. To prepare the 0.02 M linoleic acid emulsion, linoleic acid (1.402 g) and Tween 20 (1.402 g) were dissolved in potassium phosphate buffer (50 mL, pH 7.4, 0.05 M). The mixture was homogenized for 5 min to stabilize the emulsion. Linoleic acid 0.02 M emulsion (2.5 mL), phenolic solution (0.2 mL, at different concentrations) and potassium phosphate buffer (2.3 mL, pH 7, 0.2 M) were mixed in flasks. Methanol and/or acetone were used for the control sample instead of a sample solution. Flasks were incubated for 22 h without a cap at 37 °C in the dark. Before and after incubation, 0.1 mL of samples from every bottle were mixed with 6 mL of methanol solution (60%, v/v). Absorbance differences of each sample before and after incubation were calculated as the absorbance of each sample. These values were compared with those of BHA, BHT, and α-tocopherol at 0.2 mg/mL.

ΔAcontrol: absorbance difference of control before and after incubation, ΔAsample: absorbance difference of sample before and after incubation.

Reducing power test

Reducing power assay of phenolic compounds was performed according to Mau et al. [36] with slight modifications. Briefly, 1.5 mL phenolic solutions with different concentrations added to 1 mL of 2.4 mM sodium phosphate (pH 6.6) and 2.5 mL potassium ferricyanide solution (1%). The mixture was incubated for 20 min at 50 °C, then 2.5 mL of 10% (w/v) trichloroacetic acid were added, and the mixture was centrifuged for 10 min at 4000 rpm. The upper layer (5 mL) was mixed with 5 mL of deionized water and 0.1% ferric chloride (1 mL). The absorbance, against a blank, was recorded at 700 nm using a Shimadzu spectrophotometer.

Stripping of refined corn oil (RCO)

RCO was purified to obtain stripped corn oil (SCO) using the method described by Karabulut et al. [38] using activated carbon and alumina column chromatography.

Enrichment of RCO and SCO with phenolics and commercial antioxidants

Eight RCO and eight SCO (triglycerides) experimental designs were prepared.

-

Refined corn oil (RCO)

-

RCO supplemented with 100 ppm of BHT.

-

RCO supplemented with 250 ppm of thymol.

-

RCO supplemented with 500 ppm of thymol.

-

RCO supplemented with 250 ppm of carvacrol.

-

RCO supplemented with 500 ppm of carvacrol.

-

RCO supplemented with 250 ppm of TQ.

-

RCO supplemented with 500 ppm of TQ.

-

Stripped corn oil (SCO)

-

SCO supplemented with 100 ppm of BHT.

-

SCO supplemented with 250 ppm of thymol.

-

SCO supplemented with 500 ppm of thymol.

-

SCO supplemented with 250 ppm of carvacrol.

-

SCO supplemented with 500 ppm of carvacrol.

-

SCO supplemented with 250 ppm of TQ.

-

SCO supplemented with 500 ppm of TQ.

.

Accelerated thermal oxidation tests

Rancimat test for RCO

The induction periods of purified corn oils enriched with TQ, thymol or carvacrol were carried out using Rancimat apparatus (Metrohm, Herisau, Switzerland). The oil sample (3 g) was placed in the Rancimat apparatus at 90 °C under 10 L h−1 airflow rate.

Schaal oven test for RCO and SCO

Fifty grams of RCO were weighted in 50-mL open glass bottles and kept 21 days at 60 °C in an oven. Samples were examined at 3-days intervals by collecting sample from the same bottles at a particular period. Besides, 10 g of SCO were used under the same storage conditions for 7 days and examined at everyday intervals. The thermal oxidative stability of the samples was evaluated using PV, p-AV, and CD (K232) tests. All experiments were carried out in two repetitions for each sample.

Statistical analysis

Oxidation experiments were carried out in two replicates. Results were given as mean ± standard deviation. Results were statistically evaluated using the Minitab 17 Statistical Software (v17.3.1) package program. The difference between the group means was determined according to variance analysis technique (ANOVA) (p < 0.05).

Results and discussion

Composition and chemcial characteristics of RCO and SCO

FFA, PV, K232, K268, p-AV, total tocopherol content, induction period and fatty acid compositions of the refined and purified corn oils under study are given in Table 1. FFA, PV, K232, K268, p-AV, and total tocopherols in RCO were 0.10%, 3.90 meq O2/kg, 2.68, 1.84, 8.45 and 842.6 mg/kg, respectively. The initial values of PV, CD, CT, p-AV, and total tocopherols agree with those in the literature [39,40,41]. The PV, K232, K268, and p-AV of the SCO decreased to 1.90 meq O2/kg, 1.84, 1.12 and 0.17, respectively. Besides, tocopherols were absent in the SCO. Tocols are the most active natural antioxidants present in vegetable oils that retard oxidation and the formation of polar compounds [29]. Data in Table 1 demonstrate that RCO have better oxidative stability (39.48 h) than SCO (2.82 h). Linoleic acid was the predominant fatty acid in corn oil (55.1% of total fatty acids), followed by oleic acid (30.72% of total fatty acids), while palmitic acid was the main saturated fatty acid. The fatty acid profile reported in the current study agrees with those reported in the literature [42].

Antioxidant activities of thymol, carvacrol, TQ and commercial antioxidants

Several natural antioxidants were applied to enhance the stability of vegetable oils during the thermal treatments [43]. No single test is enough to screen the antioxidant potential of phytochemicals or plant extracts, since different methods could yield different results [1, 44]. Thus, different methods based on different mechanisms should be tested [45, 46].

DPPH· assay

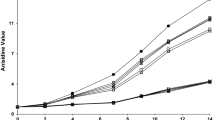

Using DPPH· free radicals, the antiradical potential of phenolics and commercial antioxidants was tested in vitro considering that DPPH· radicals are widely used for testing the antioxidant effects. DPPH· are stable free radicals with violet color that gives absorption maxima at 515–528 nm [1, 45,46,47]. DPPH· antiradical activities of thymol, carvacrol, TQ, α-tocopherol, BHA and BHT are presented in Fig. 1. For all tested samples, DPPH· antiradical activities increased with the increase of antioxidant concentration. At 1000 ppm concentration, α-tocopherol had the highest DPPH· antiradical activity (94.9%) among all tested samples, followed by BHA (93.6%). Among the phenolic compounds, TQ had higher DPPH· antiradical activity (65.8%) than thymol (25.0%) and carvacrol (18.3%) at 1000 ppm concentration, which was closed that of BHT (75.0%). Gavaric et al. [48] observed that the antiradical activity of BHT was higher than thymol and carvacrol, as well as the antiradical activity of thymol was higher than carvacrol. In contrast, Milos and Makota [49] demonstrated that thymol had higher antiradical activity than carvacrol and TQ. IC50 values of phenolics and commercial antioxidants are presented in Fig. 2. Antioxidant activities of the samples according to the IC50 values increased in the following order: BHA > α-tocopherol > BHT > TQ > thymol > carvacrol.

The results of the DPPH· radical scavenging test suggest that phenolics under study (thymol, carvacrol, and TQ) are able to scaveng DPPH· radicals through hydrogen-donating mechanism. The antiradical effect of phenolics is due to their redox characteristics, which play a role in quenching singlet and triplet oxygen, neutralizing radicals, and decomposing peroxides [46, 50].

Linoleic acid test

Antioxidant activities of phenolic compounds were tested in linoleic acid emulsion and compared with BHA, BHT, and α-tocopherol as shown in Table 2. BHT and BHA showed strong antioxidant activities (95% and above) at all concentrations. Antioxidant activities of thymol, carvacrol, TQ and BHT increased with the increase of concentration, while there was no increase for BHA and α-tocopherol with the increase of concentration. Among phenolic compounds, thymol and carvacrol showed stronger antioxidant activity than TQ. Besides, α-tocopherol recorded the lowest activity among tested samples. The results presented here agree with previous literature wherein α-tocopherol was reported to be less active than BHA, and BHT [51].

Ferric reducing power test

Ferric reducing power of phenolic compounds, BHA, BHT, and α-tocopherol are presented in Table 3. In this assay, commercial antioxidants exhibited stronger reducing power compared to natural phenolic compounds. At 1000 ppm concentration, BHT and α-tocopherol showed similar values and slightly higher values than BHA. Similar results for BHA, BHT, and α-tocopherol reported previously by Elmastas et al. [52]. Regarding phenolic compounds, TQ and thymol exhibited stronger antioxidant activities compared to carvacrol.

Efficiency of phenolics and commercial antioxidants on the stability of RCO and SCO

Oil oxidative stability is commonly tested under thermal conditions (60 °C). To test the antioxidant effects of phenolics and commercial antioxidants in RCO and SCO, PV, p-AV and CD were determined as indices of oxidation [1, 46, 47].

Induction periods of stripped corn oil (SCO)

Induction periods and the protection factor of SCO enriched with phenolics and commercial antioxidants are given in Table 4. A high induction period (15.01 h) at 90 ̊C was reported for SCO with 100 ppm BHT. The addition of phenolic compounds to SCO improved the oxidative stability of the oil (p < 0.05). At 500 ppm concentration, the induction period of thymol, TQ and carvacrol was 5.69, 4.04 and 5.44 h, respectively, while the induction period of SCO was 2.82 h.

Effect of phenolics and commercial antioxidants on the stability of RCO (Schaal oven test)

PV is a measure of the peroxides and hydroperoxides induced in the initial stages of oxidation. PV is a widely used test for the measurement of oils and fats rancidity. The changes of PV of RCO during storage at 60 °C are presented in Fig. 3. At the end of 21 days of storage, PV values of samples enriched with phenolic compounds (except thymol) were lower compared with the control sample. Phenolic compounds improved the oxidative stability of RCO. Among phenolics, TQ showed higher antioxidant effects than thymol and carvacrol. Besides, PV values of samples containing 250 and 500 ppm of TQ (103.7 and 108.0 meq O2/kg, respectively) showed lower PV than that of BHT (128.7 meq O2/kg). Black cumin oil rich in TQ improved the stability of RCO stored under thermal oxidative conditions (60 °C) [53]. The results also showed that thymol does not affect the oxidative stability of RCO. As compared with thymol, carvacrol was an effective phenolic compound in the inhibition of PV during the oxidation process. Horuz and Maskan [30] found that thymol had a slight effect on the induction period of corn oil under frying temperatures, while carvacrol showed strong antioxidant potential on corn oil under the same conditions. These findings are in agreement with the present study.

CD is a good indicator to measure oils and fats stability. During oxidation, methylene-intrupted dienes in lipids show a shift in their double bond position. The induced CD exhibit absorption maxima at 232 nm [1, 46, 47, 54]. Figure 4 shows the CD (K232) values of RCO samples during 21 days of storage. After 21 days, the CD value of the control oil reached to 28.23 from an initial value of 2.95. Except for thymol, the other two phenolic compounds, TQ and carvacrol showed lower CD values than the control, thus showing enhancement of the oxidative stability of RCO. Especially, TQ-enriched samples had a significant (p < 0.05) effect on lowering CD formation among phenolic compounds and also showed a stronger effect on lowering CD compared to BHT.

p-AV is an old method to measure secondary lipid oxidation. The test based on the reactiveness of aldehyde carbonyl bond on p-anisidine amine group, that leads to Schiff base formation which absorbs at 350 nm [46, 55]. At 60 °C and after 21 days of storage, changes in the p-AV value of samples are presented in Table 5. The p-AV of the control sample reached 11.1, while p-AV in BHT-enriched RCO was 8.3. Like BHT, TQ showed an effect on the formation of secondary oxidation products and had lower values (7.6 at 250 ppm, and 8.3 at 500 ppm) as compared with those of the phenolics-enriched RCO. However, thymol-enriched oil had a slightly lower p-AV during the later stages of storage.

Changes in total tocopherol content of RCO samples during storage are given in Table 6. During storage, the total tocopherol content of all RCO samples with or without added antioxidants decreased with increasing the storage time. During the 21-days storage, the total tocopherol content of the control sample decreased sharply (76.7 mg/kg). The addition of phenolic compounds and also BHT to RCO inhibited the reduction in total tocopherols at 60 °C. At the end of storage, the remained tocopherols in oil treated with BHT were 131 mg/kg. Thymoquinone addition was more effective than BHT on RCO. For 250 and 500 ppm TQ concentrations, the total tocopherol content decreased to 176.2 and 189.6 mg/kg, respectively. Besides, the effect of the addition of carvacrol (500 ppm) to RCO was better than that of BHT. Thymol in RCO was more effective than the control sample, while lower than that of oil enriched with BHT.

Effect of phenolics and commercial antioxidants on the stability of SCO (Schaal oven test)

Figure 5 shows the PV development in SCO during the storage at 60 °C for 7 days with various concentrations of phenolic compounds and BHT. The control sample reached the maximum PV (452 meq O2/kg) after 7 days of storage. A significant (p < 0.05) difference in PV was recorded between the control and SCO containing BHT that slowed the rate of peroxide induction. The effect of phenolic compounds was lower on peroxide formation after 7 days of storage compared with BHT-enriched oil. However, PV of all oils enriched with phenolic compounds was lower than that of the control. Among phenolics, TQ was more effective in lowering the PV of SCO during storage. The effect of thymol and carvacrol showed similar effects on peroxide formation in SCO during the storage experiment.

CD values of SCO samples were given in Fig. 6. The CD of the control sample increased from 2.05 to 84.5, whereas 100 ppm of BHT could considerably inhibit SCO oxidation and showed an increase from 2.01 to 3.21. However, SCO enriched with phenolic compounds was oxidized fastly compared with BHT-enriched oil. Moreover, the increase in CD of oils including phenolic compounds was lower than the control sample. Thymoquinone exhibited a strong effect on the formation of CD from oil samples among phenolic compounds.

Table 7 shows the changes in p-AV of SCO oils during storage experiment. There was an increase in p-AV in all oil samples with increasing the storage time. The p-AV in the control sample increased up to 58.8 at the end of storage. SCO enriched with BHT exhibited lower p-AV (0.3) at the end of storage as compared with the control sample. The phenolic compounds seem to be less effective in inhibition of p-AV than BHT. On the other hand, samples treated with phenolic compounds showed lower p-AV compared with the control sample. Among phenolic compounds, TQ at 250 and 500 ppm inhibited the induction of the secondary oxidation products in comparison with control, while p-AV values seem to be less than that formed in thymol and carvacrol enriched SCO samples.

Conclusions

Clean label foodstuffes enriched with phytochemicals have attracted more and more attention due to health-promoting effects. Phenolic compounds are known as strong antioxidant compounds. Thymol, carvacrol, and TQ were selected to study its antioxidant potential on the stabilization of refined and stripped corn oils compared with commercial antioxidants. Different tests showed that the free radical scavenging activity of phenolic compounds under study was comparable with that of commercial antioxidants. Phenolic compounds improve the oxidative stability of refined and stripped corn oils stored at 60 ̊C, while its efficacy was less than that of BHT. It could be concluded that phenolics under study (thymol, carvacrol, and TQ) can stabilize RCO and SCO effectively. Thymol, carvacrol, and TQ showed different antioxidant characteristics in different tests in a dose-dependent manner. Thymol, carvacrol, and TQ could inhibit thermal oxidation of corn oil by inhibiting double bond conjugation and enhancing its hydrolytic stability. TQ could be recommended as a potent natural antioxidant for the stabilization of vegetable oils. Further studies are needed to investigate the mechanism by which thymol, carvacrol, and TQ retard the oxidation during thermal treatment of corn oil.

Data availability

Data and material are available on request.

References

M.F. Ramadan, J.-T. Moersel, Oxidative stability of black cumin (Nigella sativa L.), coriander (Coriandrum sativum L.) and niger (Guizotia abyssinica Cass.) upon stripping. Eur. J. Lipid Sci. Technol. 106(1), 35–43 (2004)

D.R. Johnson, E.A. Decker, The role of oxygen in lipid oxidation reactions: a review. Ann. Rev. Food Sci. Technol. 6, 171–190 (2015)

F. Shahidi, P. Ambigaipalan, Phenolics and polyphenolics in foods, beverages, and spices: antioxidant activity and health effects—a review. J. Funct. Foods 18, 820–897 (2015)

M.F. Ramadan, Oxidation of β-sitosterol and campesterol in sunflower oil upon deep- and pan-frying of French fries. J. Food Sci. Technol. 52, 6301–6311 (2015)

C. Jacobsen, F. Paiva-Martins, K. Schwarz, V. Bochkov, Lipid oxidation and antioxidants in food and nutrition. Eur. J. Lipid Sci. Technol. 121(9), 1900298 (2019)

H. Karami, M. Rasekh, E. Mirzaee-Ghaleh, Qualitative analysis of edible oil oxidation using an olfactory machine. J. Food Meas. Charact. 14(5), 2600–2610 (2020)

M.F. Ramadan, Quercetin increases antioxidant activity of soy lecithin in a triolein model system. LWT-Food Sci. Technol. 41, 581–587 (2008)

M.F. Ramadan, M.M.A. Amer, A.E. Awad, Coriander (Coriandrum sativum L.) seed oil improves plasma lipid profile in rats fed a diet containing cholesterol. Eur. Food Res. Technol. 227, 1173–1182 (2008)

A.A. Mohdaly, A.A. Mahmoud, M.H. Roby, I. Smetanska, M.F. Ramadan, Phenolic extract from propolis and bee pollen. J. Food Biochem. 39, 538–547 (2015)

M. Carocho, P. Morales, I.C. Ferreira, Antioxidants: reviewing the chemistry, food applications, legislation, and role as preservatives. Trends Food Sci. Technol. 71, 107–120 (2018)

M. Olszowy, A.L. Dawidowicz, M. Jóźwik-Dolęba, Are mutual interactions between antioxidants the only factors responsible for antagonistic antioxidant effect of their mixtures? Additive and antagonistic antioxidant effects in mixtures of gallic, ferulic and caffeic acids. Eur. Food Res. Technol. 245(7), 1473–1485 (2019)

M. Wojcik, I. Burzynska-Pedziwiatr, L.A. Wozniak, A review of natural and synthetic antioxidants important for health and longevity. Curr. Med. Chem. 17(28), 3262–3288 (2010)

M. Carocho, I.C. Ferreira, A review on antioxidants, prooxidants and related controversy: natural and synthetic compounds, screening and analysis methodologies and future perspectives. Food Chem. Toxicol. 51, 15–25 (2013)

D. Günal-Köroğlu, S. Turan, M. Kiralan, M.F. Ramadan, Enhancement of sunflower oil stability during deep-frying using extracts from olive oil by-products and soy lecithin. Inter. Food Res. J. 26(4), 1269–1277 (2019)

F.F. de Araújo, D. de Paulo Farias, I.A. Neri-Numa, G.M. Pastore, Polyphenols and their applications: an approach in food chemistry and innovation potential. Food Chem. 338, 127535 (2021)

A. Moure, J.M. Cruz, D. Franco, J.M. Domínguez, J. Sineiro, H. Domínguez, J.C. Parajó, Natural antioxidants from residual sources. Food Chem. 72(2), 145–171 (2001)

B. Dimitrios, Sources of natural phenolic antioxidants. Trends Food Sci. Technol. 17(9), 505–512 (2006)

F.M. Roleira, E.J. Tavares-da-Silva, C.L. Varela, S.C. Costa, T. Silva, J. Garrido, F. Borges, Plant derived and dietary phenolic antioxidants: anticancer properties. Food Chem. 183, 235–258 (2015)

M.S. Brewer, Natural antioxidants: sources, compounds, mechanisms of action, and potential applications. Compr. Rev. Food Sci. Food Saf. 10(4), 221–247 (2011)

S.M. Jeong, S.Y. Kim, D.R. Kim, K.C. Nam, D.U. Ahn, S.C. Lee, Effect of seed roasting conditions on the antioxidant activity of defatted sesame meal extracts. Food Chem. Toxicol. 69, 377–381 (2004)

B. Tohidi, M. Rahimmalek, A. Arzani, Essential oil composition, total phenolic, flavonoid contents, and antioxidant activity of Thymus species collected from different regions of Iran. Food Chem. 220, 153–161 (2017)

J. Rúa, P. del Valle, D. de Arriaga, L. Fernández-Álvarez, M.R. García-Armesto, Combination of carvacrol and thymol: qntimicrobial activity against Staphylococcus aureus and antioxidant activity. Foodborne Pathog. Dis. 16(9), 622–629 (2019)

B.H. Ali, G. Blunden, Pharmacological and toxicological properties of Nigella sativa. Phytother. Res. 17(4), 299–305 (2003)

M.F. Ramadan, K.M.M. Wahdan, Blending of corn oil with black cumin (Nigella sativa) and coriander (Coriandrum sativum) seed oils: impact on functionality, stability and radical scavenging activity. Food Chem. 132(2), 873–879 (2012)

H. Lutterodt, M. Luther, M. Slavin, J.J. Yin, J. Parry, J.M. Gao, L.L. Yu, Fatty acid profile, thymoquinone content, oxidative stability, and antioxidant properties of cold-pressed black cumin seed oils. LWT-Food Sci. Technol. 43(9), 1409–1413 (2010)

M.F.R. Hassanien, A.M.A. Assiri, A.M. Alzohairy, H.F. Oraby, Health-promoting value and food applications of black cumin essential oil: an overview. J. Food Sci. Technol. 52, 6136–6142 (2015)

M.F.R. Hassanien, S.A. Mahgoub, K.M. El-Zahar, Soft cheese supplemented with black cumin oil: Impact on food borne pathogens and quality during storage. Saudi J. Biol. Sci. 21(3), 280–288 (2014)

M. Soleimanifar, R. Niazmand, S.M. Jafari, Evaluation of oxidative stability, fatty acid profile, and antioxidant properties of black cumin seed oil and extract. J. Food Meas. Charact. 13(1), 383–389 (2019)

G. Rodríguez, G. Squeo, L. Estivi, S. Quezada Berru, D. Buleje, F. Caponio, A. Brandolini, A. Hidalgo, Changes in stability, tocopherols, fatty acids and antioxidant capacity of sacha inchi (Plukenetia volubilis) oil during French fries deep-frying. Food Chem. 340, 127942 (2021)

T. Horuz, M. Maskan, Effect of the phytochemicals curcumin, cinnamaldehyde, thymol and carvacrol on the oxidative stability of corn and palm oils at frying temperatures. J. Food Sci. Technol. 52(12), 8041–8049 (2015)

I.J. Karoui, W. Dhifi, M. Ben Jemia, B. Marzouk, Thermal stability of corn oil flavoured with Thymus capitatus under heating and deep-frying conditions. J. Sci. Food Agric. 91(5), 927–933 (2011)

A.A. Mariod, R.M. Ibrahim, M. Ismail, N. Ismail, Antioxidant activity and phenolic content of phenolic rich fractions obtained from black cumin (Nigella sativa) seedcake. Food Chem. 116(1), 306–312 (2009)

AOCS, Official and Recommended Methods of the American Oil Chemist’s Society (American Oil Chemist’s Society Press, Champaign, 2000)

M.L. Wong, R.E. Timms, E.M. Goh, Colorimetric determination of total tocopherols in palm oil, olein, and stearin. J. Am. Oil Chem. Soc. 65(2), 258 (1988)

W. Brand-Williams, M.E. Cuvelier, C.L. Berset, Use of a free radical method to evaluate antioxidant activity. LWT-Food Sci. Technol. 28(1), 25–30 (1995)

J.L. Mau, C.N. Chang, S.J. Huang, C.C. Chen, Antioxidant properties of methanolic extracts from Grifola frondosa, Morchella esculenta, and Termitomyces albuminous mycelia. Food Chem. 87(1), 111–118 (2004)

S. Iqbal, S. Haleem, M. Akhtar, M. Zia-ul-Haq, J. Akbar, Efficiency of pomegranate peel extracts in stabilization of sunflower oil under accelerated conditions. Food Res. Int. 41(2), 194–200 (2008)

I. Karabulut, A. Topcu, C. Akmil-Basar, Y. Onal, A.M. Lampi, Obtaining butter oil triacylglycerols free from β-carotene and α-tocopherol via activated carbon adsorption and alumina-column chromatography treatments. J. Am. Oil Chem. Soc. 85(3), 213–219 (2008)

C.P. Tan, Y.C. Man, J. Selamat, M.S.A. Yusoff, Comparative studies of oxidative stability of edible oils by differential scanning calorimetry and oxidative stability index methods. Food Chem. 76(3), 385–389 (2002)

A. Gliszczyńska-Świgło, E. Sikorska, Simple reversed-phase liquid chromatography method for determination of tocopherols in edible plant oils. J. Chromatogr. A 1048(2), 195–198 (2004)

I.A. Nehdi, H. Sbihi, C.P. Tan, H. Zarrouk, M.I. Khalil, S.I. Al-Resayes, Characteristics, composition and thermal stability of Acacia senegal (L.) Willd. seed oil. Ind. Crops Prod. 36(1), 54–58 (2012)

M. Topkafa, H.F. Ayyildiz, An implementation of central composite design: effect of microwave and conventional heating techniques on the triglyceride composition and trans isomer formation in corn oil. Int. J. Food Prop. 20(1), 198–212 (2017)

J.H. Yang, T.T.T. Tran, V.V.M. Le, Effects of natural antioxidants on the palm olein quality during the heating and frying. J. Food Meas. Charact. 14(5), 2713–2720 (2020)

D. Huang, O. Band, R.L. Prior, The chemistry behind antioxidant capacity assays. J. Agric. Food Chem. 53, 1841–1856 (2005)

A.A.A. Mohdaly, I. Smetanska, M.F. Ramadan, M.A. Sarhan, A. Mahmoud, Antioxidant potential of sesame (Sesamum indicum) cake extract in stabilization of sunflower and soybean oils. Ind. Crops Prod. 34(1), 952–959 (2011)

A.A. Mohdaly, M.A. Sarhan, I. Smetanska, A. Mahmoud, Antioxidant properties of various solvent extracts of potato peels, sugar beet pulp, and sesame cake. J. Sci. Food Agric. 90, 218–226 (2010)

K. Zhou, L. Yu, Effects of extraction solvent on the wheat bran antioxidant activity estimation. LWT-Food Sci. Technol. 37, 717–721 (2004)

N. Gavaric, S.S. Mozina, N. Kladar, B. Bozin, Chemical profile, antioxidant and antibacterial activity of thyme and oregano essential oils, thymol and carvacrol and their possible synergism. J. Ess. Oil Bear. Plants 18(4), 1013–1021 (2015)

M. Milos, D. Makota, Investigation of antioxidant synergisms and antagonisms among thymol, carvacrol, thymoquinone, and p-cymene in a model system using the Briggs-Rauscher oscillating reaction. Food Chem. 131(1), 296–299 (2012)

T. Osawa, Novel natural antioxidants for utilization in food and biological systems, in Postharvest biochemistry of plant food materials in the tropics. ed. by I. Uritani, V.V. Garcia, E.M. Mendoza (Japan Scientific Societies Press, Tokyo, 1994), pp. 241–251

İ Gülçin, Antioxidant activity of caffeic acid (3,4-dihydroxycinnamic acid). Toxicology 217(2–3), 213–220 (2006)

M. Elmastas, O. Isildak, I. Turkekul, N. Temur, Determination of antioxidant activity and antioxidant compounds in wild edible mushrooms. J. Food Comp. Anal. 20(3–4), 337–345 (2007)

K.M. Mohamed, R.M. Elsanhoty, M.F. Hassanien, Improving thermal stability of high linoleic corn oil by blending with black cumin and coriander oils. Inter. J. Food Prop. 17(3), 500–510 (2014)

S. Bushra, A. Farooq, P. Roman, Antioxidant potential of corncob extracts for stabilization of corn oil subjected to microwave heating. Food Chem. 104, 997–1005 (2007)

Z. Ying, Y. Lei, Z. Yuangang, C. Xiaoqiang, W. Fuji, L.Fang, Oxidative stability of sunflower oil supplemented with carnosic acid compared with synthetic antioxidants during accelerated storage. Food Chem. 118, 656–662 (2010)

Acknowledgements

This study was supported by Bolu Abant Izzet Baysal University Scientific Research Center with the Project Number 2018.09.04.1288. Some of the results were from the M.Sc. Thesis of Şeyma Yıldız. The authors thank Professor Dr. Ihsan Karabulut for the usage of the Rancimat apparatus and GC-FID.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Yildiz, S., Turan, S., Kiralan, M. et al. Antioxidant properties of thymol, carvacrol, and thymoquinone and its efficiencies on the stabilization of refined and stripped corn oils. Food Measure 15, 621–632 (2021). https://doi.org/10.1007/s11694-020-00665-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-020-00665-0