Abstract

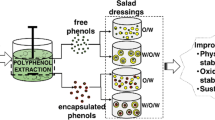

Flaxseed oil is one of the richest sources of Omega-3. This work was aimed at evaluating the physical qualities, sensory properties and the stability of a formulation for salad dressing characterized by a partial enrichment with flaxseed oil upon refrigerated storage. Samples were stabilized by n-OSA starch and sodium caseinate, and they were comparable with samples which had egg yolk only. All formulated dressings appeared as a weak gel-like structure with strong shear thinning behavior. The experimental data was fitted with the power-law model for all samples. The samples showed various degrees of oxidative stability after 90 days of storage. Salad dressings containing n-OSA starch and sodium caseinate (samples 1–4) exhibited a small phase separation at the bottom of the tubes in the third month of storage, while no oiling-off was observed. In the presence of egg yolk (sample 5), a higher stability was observed with no phase separation or oiling-off. When there was 5% (w/w) flaxseed oil, a higher sensory quality was obtained in general. Increasing the percentage of flaxseed oil replacement in salad dressings and prolonging the storage time led to a decrease in the L factor. Salad dressings could be enriched aptly with flaxseed oil emulsions (while being stabilized by n-OSA starch and caseinate).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Flaxseed oil is rich in essential polyunsaturated fatty acids (PUFAs), and it contains mainly omega-3 fatty acids which are known to possess a variety of health benefits [1]. Nowadays, the beneficial effect of consuming omega-3 fatty acids is common knowledge. A diet enriched with omega-3 PUFAs can effectively contribute to the prevention of coronary artery diseases (arteriosclerosis), arthritis, hypertension, cardiovascular and immune response disorders, besides reducing the risks of stroke and cancer [2, 3]. Therefore, the high content of PUFAs in flaxseed oil can make it useful for dietary supplementation in foods. Nevertheless, oils that are rich in PUFAs are susceptible to oxidation during processing and storage, and this can lead to a reduction in shelf life and nutritional quality, along with the occurrence of undesirable changes in the flavor and appearance [4, 5].

In recent years, salad dressings have received growing attention in the food industry due to the increase in consumer demand for salads [6]. Salad dressings have a unique taste and a creaminess which, when added to salads, can improve marketability among consumers [6]. The salad dressing is a low-pH oil in a water emulsion. It consists of three different components: oil (the dispersed phase), vinegar (the continuous phase) and egg yolk as an emulsifier at the interface [7].

As in the case of all foods which contain high amounts of oil, salad dressing is susceptible to deterioration due to auto-oxidation of the unsaturated fatty acids in the oil. Thus, previous studies have used n-octenylsuccinate-derivatized (n-OSA) starch and caseinate as good emulsifiers and stabilizer agents in the formulation of salad dressing. Proteins and polysaccharides are used safely for reducing the oxidative stability of oil-in-water emulsions, while changing the interface properties of the emulsion droplet, [8,9,10]. Previous cases of research have shown that oil droplets, coated with protein-polysaccharide complexes, have better physical and oxidative stability [11]. Protein-coated droplets can be enriched by adding a polysaccharide that adsorbs onto the droplet surface and creates a protective layer, thereby preventing the droplets from approaching each other and forming aggregates [12, 13]. The n-OSA starch is an octenylsuccinate-derived starch which has also been widely used for increasing the physicochemical stability of emulsions when compared to other polysaccharides. It is a modified starch with some side chains of lipophilic succinic acid with good emulsifying properties, which promotes good oil retention [14, 15]. On the other hand, sodium caseinate is able to prevent lipid oxidation in emulsions when it is either at the surface of the emulsion droplet or in the aqueous phase [16]. The droplet stability against aggregation is known to increase by increasing the repulsive colloidal interactions between the droplets, thereby lowering interfacial tensions and forming protective membranes around the oil [17]. These materials are considered to be ideal for the protection of lipid droplets, as they fulfill the roles of both surface and active agents [18].

Considering these aspects, the objective of this study is to evaluate the effect of refrigerated storage on the stability, rheological properties, color and sensory characteristics of a salad dressing supplemented with flaxseed oil. Furthermore, we prepared and applied formulations using n-OSA starch and sodium caseinate as emulsifying/stabilizing agents to replace the lecithin in egg yolk.

Materials and methods

Materials

The oil of flaxseed (Linum usitatissimum L.) was extracted by the cold press method and the fatty acids were identified by Gas chromatography-flame ionization detector (GC-FID) (B420A, BEIFEN, China). According to previous experiments, the cold press method can yield oil with a high percentage of ω-3 and ω-6 fatty acids and, in terms of peroxide and acid values, it yields the highest oil quality compared to the methods of solvent extraction and ultrasonic assisted-extraction. All chemicals and external standards for the identification of volatile oxidation products were purchased from either Sigma-Aldrich, Steinheim, Germany, or Merck, Darmstadt, Germany.

Preparation of flaxseed oil enriched salad dressings

Salad dressing formulations for each sample were firstly optimized with trial and error, then the best formulation for each sample was used (Table 1) and salad dressing was produced for next experiments. Starch can be modified to improve its properties and tolerance to processing conditions. The physical modification of starch can include procedures such as pregelatinization which can be used safely since chemicals are not involved therein [19]. Already, the application of pregelatinized corn starch has enabled enhancements in cold-prepared food emulsions with a wide range of textural and rheological properties [20]. In this study, the corn starch was pregelatinized by heating. The n-octenyl succinate starch (n-OSA starch) and sodium caseinate were dissolved in water with a slow stirring of a propeller-type mechanical stirrer for at least 4 h. This was to ensure a complete dissolution of the water phase in the emulsion. The oil was mixed into the water phase using a high speed mixer (National, Japan), and then the vinegar and pregelatinized corn starch were added during the mixing. The full-sunflower oil (sample 1) and full-flaxseed oil (samples 2) salad dressing formulations were prepared. The other samples were prepared by replacing the sunflower oil with the flaxseed oil at 14.28% w/w (sample 3) and 28.57% w/w (sample 4) of total oil (35%). These amounts are equivalent to 5% and 10% (w/w) flaxseed oil weight in the formulations. We added egg yolk (8.7%) to sample 5 to study its effect on the textural properties of salad dressings, compared to those formulations enriched with n-OSA starch and sodium caseinate. Dressings were stored in closed glass jars in a dark place at 5 °C for a maximum period of 90 days. The samples were analyzed after intervals of 1, 30, 60 and 90 days. All experiments on salad dressing were done in two replications.

Sensory evaluation

Five salad dressing formulations were prepared according to Table 1. The sensory evaluation was performed using a Quantitative Descriptive Analysis (QDA) test [21] by at least ten trained panelists on refrigerated samples on days 1, 30, 60 and 90. Samples were served in a randomized order with lettuce and water. Several sensory attributes were assessed by panelists, including the taste, viscosity, color, texture and overall quality, using the hedonic scales. A descriptive scale from 1 to 5 for each attribute was used in the QDA test (Table 2). Before sensory evaluation, the meaning of attributes was explained to the panelists to avoid any misinterpretation. Panelists were also asked to read the instructions and answer the questionnaire. Sample 1, among the samples of salad dressing (SD), served as the reference sample. For each attribute, the scores given by the panelists were averaged, and the total of each four attribute was calculated on each sampling day.

Peroxide test

An amount of 0.3 ml salad dressing was mixed with 1.5 ml of isooctane/2-propanol solvent (3:1, v/v), vortexed (high speed) three times, each time for 10 s, followed by 2 min centrifugation at 3600×g (SW14R, Froilabo, Meyzieu, France). The nitrogen stream was used for evaporating the solvent and purified the lower layer of the extracted oil. The PV of oil samples was measured by means of a spectrophotometric device at 500 nm by an UV–VIS instrument (VIS-7220G/UV-9200, Rayleigh, China) after 5 min of incubation at room temperature. To prepare the iron(II) chloride solution, 0.4 g barium chloride was dissolved in 50 ml water inside an Erlenmeyer flask. This solution was added slowly to an iron(II) sulfate solution (0.5 g FeSO4·7H2O dissolved in 50 ml water), and the mixture was stirred constantly. An amount of 2 ml of 10 M HCl was added to the resulting solution. The barium sulfate precipitate was filtered off to give a clear iron(II) solution, which was stored in a brown bottle and kept in the dark. To prepare the ammonium thiocyanate solution, 30 g ammonium thiocyanate was dissolved in water until the volume reached 100 ml. To determine the peroxide value, the organic solvent phase (0.2 ml) was mixed with 2.8 ml methanol/1-butanol (2:1, v/v) on a vortex mixer for 2–4 s. The ammonium thiocyanate solution (50 µl) was added, and the sample was mixed on a vortex mixer for 2–4 s. Then, 50 µl iron(II) solution was added, and the sample was mixed on a mixer for 2–4 s. Hydroperoxide concentrations were evaluated using the Fe3 standard curve with the iron concentration varying from 1 to 25 µg [22].

The physical stability of the salad dressing

Salad dressing samples (10 ml) were placed in sealed plastic tubes, which were stored at 5 °C for 90 days. Samples were visually evaluated in terms of phase separation and oiling-off or creaming [23].

Rheological measurements

Rheological tests were performed using a rotary viscometer (Brookfield, DV-II + Pro model). The instrument was equipped with a cone and plate geometry with a gap of 1 mm. The viscosities were subjected to duplicate measurements and were determined at a probe speed of 1–50 rpm at 20 °C. The rheological properties of food materials can be described by a number rheological models, and the Power-Law model is one which is used in many non-Newtonian liquid foods. The Power-Law equation is as follows:

where τ is the shear stress (Pa), γ is the shear rate (1/s), K is the consistency coefficient (Pas) and n is the flow behavior index. In this work, this model was used so as to fit the results obtained from the steady shear experiments.

Color measurements

Samples of salad dressing were stored at room temperature (20 °C) and their color was measured after 1, 30, 60 and 90 days following the beginning of storage. Color was measured in three parameters L*, a*, b* system, based on computed image analysis. The salad dressing pictures were taken using a digital camera with 5.0 megapixel resolution and were transferred to a computer. Color parameters were determined using Photoshop CS5 version 12.0 [24].

The color changes during storage are expressed as ΔE with the color of the fresh salad dressing measured on the same day as a reference sample [25]. ΔE is the total color change calculated according to the following equation:

where \({L}_{2}^{*}\), \({a}_{2}^{*}\), and \({b}_{2}^{*}\) are the color parameters of the control samples, the \({L}_{1}^{*}\), \({a}_{1}^{*}\) and \({b}_{1}^{*}\) are the color parameters of salad dressing during the period of storage.

Statistical analysis

Each result was reported as the mean value ± standard deviation using the SPSS software (ver. 22, IBM, New York). An Analysis of variance (ANOVA) was performed using the general linear models procedure to determine significant differences among the samples. Mean values were subjected to Duncan’s multiple range tests (p < 0.05). All experiments were carried out two times.

Results and discussion

Physicochemical properties of flaxseed oil

The extracted flaxseed oil was viscous, dark yellow and liquid at room temperature. Linolenic, linoleic and oleic acids were the main fatty acids (51.28, 17.80 and 20.35%, respectively) which were identified by GC-FID in the flaxseed oil. The peroxide value of flaxseed oil was 0.568 mEq peroxide/kg oil, which is lower than the maximum acceptable level (2 and 5 mEq/kg of solid fats and liquid oils, respectively) recommended by Horwitz et al. [26].

Sensory evaluation

Table 2 shows the descriptive ratings of sensory attributes for the salad dressing when assessed under organoleptic evaluation. These attributes were transformed to numeric scores ranging from 1 to 5. The results in Table 3 indicate that sample 3 (which contained 5% flaxseed oil) had a significantly higher score (p < 0.05) in terms of taste and viscosity, compared to those of other samples, while samples 1 and 5 imparted a poorer taste and showed a lower score of viscosity. Regarding the taste of the salad dressing, the superiority of sample 3 over other samples was probably due to the addition of an appropriate level of flaxseed oil, which contributed to the masking of the aroma and taste of acetic acid. The egg aroma in sample 5 was pronounced, even on the first day of the experiment, and its score decreased slightly from 1.6 to 1.3 during 90 days of storage. The use of n-OSA starch and caseinate, as emulsifiers, did not affect the intensities of taste and flavor attributes in a negative manner. Samples 1 and 5 had lower viscosity scores, which were unfavorable for salad dressing. The shear thinning characteristics can benefit organoleptic properties by releasing taste and viscosity in food products, thereby promoting their mixability, pumpability and flowability which are important factors for the design of flow systems [27].

With respect to the colors of the salad dressing, samples 3 and 4 (which contained 5 and 10% flaxseed oil, respectively) were preferred by panelists since the samples had white color. Samples 1 and 2 showed lower color scores compared to other samples. In sample 2, adding a higher amount of flaxseed oil (35%) caused an undesirable yellow color. The difference in this color score was small, but was statistically significant (p < 0.05).

Based on overall quality, sample 3 was more likely to be preferred by the panelists on the first day of storage, compared to other samples (Table 3). Through time during the storage period, the sensory evaluation grade for all treatments showed a decreasing trend, which indicated a decrease in the acceptability of the five parameters of taste, viscosity, color, texture and overall quality. This is due to the progression of oxidation and the formation of undesirable flavor and odor substances over time which negatively affect the sensory properties of the product. According to the results, the best sample in terms of all sensory attributes is sample 3, and further increasing the amount of flaxseed oil in the formulation can significantly affect the sensory properties.

Oxidative stability

Measuring the lipid hydroperoxide provided data for the chemical evaluation of the oxidative deterioration in the salad dressing samples. The preparation of salad dressing (e.g. mixing) causes the entry of more oxygen into the tissues and therefore contributes to a partial oxidation of the oil. There was a significant increase (p < 0.05) in peroxide value during storage. It is clear that the PV increased gradually until the end of the storage period.

Table 4 shows the peroxide values of salad dressing samples, with and without flaxseed oil, during storage at 5 °C for 90 days. The peroxide values ranged between 0.70 and 0.88 mEq peroxides/kg oil on the first day, which gradually increased to 3.23 and 3.87 mEq/kg in samples 1 and 2 respectively, by the end of storage (on day 90). A significant difference (p < 0.05) is evident among the PV of different samples which contain different amounts of flaxseed oil during storage. The PV showed a gradual but significant increase during the storage (Table 4).

However, the PV in all cases remained within an acceptable range for human consumption [28] and all samples exhibited oxidative stability, even after 90 days of storage. The antioxidant properties of casein are partially a result of free-radical scavenging and metal ion chelation which give rise to the higher oxidative stability of samples [29]. A high content of phosphoseryl groups with a metal binding ability gives rise to this particular antioxidant activity of caseins [30]. Also, the n-OSA starch, with its emulsifying properties, can protect the oil effectively [14]. A good oxidative stability observed herein is similar to previous patterns reported by Rendon Villalobos et al. [31] where the amount of peroxide value of flaxseed powder, enriched with tortilla, was measured. No significant increase in PV was observed during the storage thereof.

Physical stability of salad dressing

The samples of salad dressing were stored at 5 °C for 3 months and were checked for their phase separation and oiling-off. Because of their low viscosity, the phase separation is an indicator of physical deterioration of salad dressing at refrigerated temperatures. All samples did not show any phase separation and oiling-off until day 60 of the storage. However, in the third month of storage, the samples which contained n-OSA starch and sodium caseinate (samples 1–4) showed a small phase separation at the bottom of the tubes. Even then, no oiling-off was observed. When egg yolk was present in the formulation, sample 5 exhibited a higher degree of stability than other samples supplemented with the n-OSA starch or sodium caseinate. This claim is based on the observation that no phase separation or oiling-off was observed which correlates with higher degrees of viscosity.

In the salad dressing containing n-OSA starch and sodium caseinate (samples 1–4), proteins were capable of being absorbed rapidly to the surface of the oil droplets where they stage a lower level of interfacial tension and inhibit droplet coalescence by forming protective membranes around the droplets [32]. Protein-coated droplets can be increased by adding a polysaccharide that adsorbs onto the droplet surface and creates a protective layer, thereby preventing the droplets from approaching each other and aggregating [12, 13]. In the salad dressing with egg yolk (sample 5), the lipoprotein and phospholipids (lecithin) acted as excellent emulsifiers which caused stability in the product [33,34,35]. Similarly, Mun et al. [24] prepared a reduced-fat type of mayonnaise using 4αGTase- modified rice starch and xanthan gum. This mayonnaise sample showed a higher stability than the reference sample (which contained rice starch and xanthan gum) because of the increased viscosity of the aqueous phase which slowed down the oil droplets movement. De cassia da fonseca et al. [36] also showed that whey proteins and gums have a positive effect on the stability of salad dressing. Similar results reported by Thompson and Reniers [37] indicated the use of whey proteins as part of an egg substitute in salad dressing formulations.

Rheological properties

In salad dressing, as the rotational speed increases, the viscosity decreases, and therefore the salad dressing is categorized as a pseudo-plastic fluid with shear thinning behavior. The rheological behavior of salad dressing samples can be interpreted through viscosity vs. time curves (Fig. 1). For all samples, a shear thinning behavior was observed. This can cause an improved dispersion of oil particles in the liquid phase. It can prevent the phase separation and flocculation during storage [38]. The shear thinning behavior of salad dressing samples, which follows a similar trend, was fitted to the power-law model. The flow behavior index (n) of all samples was less than 1, which indicated that they were pseudo-plastic fluids. The flow behavior index (Fig. 2) also indicated small but statistically significant differences (p < 0.05) in these samples, which further confirmed the similarity of the visco-elastic properties. Less values among the flow indices indicate samples with stronger shear thinning behavior, with more changes in viscosity and shear rates. According to Fig. 2, in all samples, the flow index decreased during the storage time. In one report, the flow index increased in mayonnaise samples which contained various gum concentrations [38]. In terms of the rheological properties, salad dressing is a complex system which shows time-dependent behavior. The characterization of such behavior in salad dressings is important for food processing and handling, process design and control, product development, structure and flow relationship, physical parameters and sensory evaluations [39]. Figure 1 shows the thixotrophy behavior for flaxseed oil, based on salad dressings which exhibited similar profiles. At low shear rates, a sharp decrease occurred in viscosity. However, at higher shear rates, this decrease diminished.

According to the results, the egg yolk in samples acted as a thickening agent and caused a slightly higher viscosity compared to other samples. Longer durations of storage reduced viscosity in all salad dressing samples. This decrease, especially at lower shear rates, was more pronounced until day 30, but thereafter the viscosity decreased (Fig. 1).

It can be inferred from the current results that rheological characteristics of salad dressing samples cannot be influenced by the flaxseed oil in products. Gamonpilas et al. [27] showed that a xanthan-starch mixture enhanced the gel-like characteristics and shear thinning behavior of chili sauces. De cassia da fonseca et al. [36] evaluated the effects of three different stabilizers (i.e. xanthan gum, propylene glycol alginate and carboxymethyl cellulose) on the rheological behavior of salad dressings. All samples showed a pseudo-plastic behavior and were fitted to the power-law model. Nonetheless, the apparent viscosity was highly influenced by the CMC.

Color attributes

Variations in the values of lightness (L), redness (a) and yellowness (b) occurred in the different salad dressing samples (Table 5). The lightness value of any salad dressing has a major impact on the perceived appearance of the product. By increasing the percentage of the flaxseed oil in salad dressing samples, a significant decrease in lightness (p < 0.05) was observed because of the yellowness of the flaxseed oil. According to Table 3, the highest and lowest values of lightness were 82.50% and 72%, which related to sample 1 (with 35% sunflower oil) and sample 2 (with 35% flaxseed oil) respectively. It appeared that the a* value (redness) decreased with the addition of flaxseed oil and egg yolk as coloring agents, and the b* value (yellowness) increased. Other samples showed intermediate values for all parameters. Also, the duration of storage caused a decrease in lightness and an increase in the yellowness of samples.

The amount of ΔE (total color change) of each salad dressing increased during storage, compared to the first day of storage. This indicates the effect of time on the color parameters (Table 5). High levels of ΔE can be attributed to the reduction of lightness (L*) through the storage time. Therefore, ΔE was an indicator of the deterioration of quality among products over time. Laca et al. [40] reported that low-cholesterol mayonnaises were significantly diverse (p < 0.05) in their a* and b* values after 7 days of storage, and there was a substantial change in the total color (ΔE) of the samples during storage.

Conclusions

Due to oxidative stability, specific forms of salad dressing could be aptly supplemented with flaxseed oil emulsions (while having n-OSA starch and caseinate as stabilizers). The use of flaxseed oil (at 5% concentration) in the formulation caused a higher overall acceptability in sensory attributes. Furthermore, all samples showed the same pattern of change in their color, and the ΔE increased through the storage time. The rheological properties and the results thereof indicated the presence of shear thinning behavior. Samples which contained n-OSA starch and sodium caseinate, as substitutes for egg yolk, showed a small phase separation at the bottom of the tubes in the third month of storage, but no oiling-off was observed in any of the samples.

References

M. Vaisey-Genser, D.H. Morris, in Flax: The Genus Linum, ed. by D.M. Alister, N.D. Westcott, Introduction: history of the cultivation and uses of flaxseed (Taylor and Francis, New York, 2003), p. 1

E. Freemantle, M. Vandal, J. Tremblay-Mercier, S. Tremblay, J.C. Blachere, M.E. Begin, Prostaglandins, Leukot. Essent. Fat. Acids 75, 213 (2006)

C.J. Lavie, R.V. Milani, M.R. Mehra, H.O. Ventura, J. Am. Coll. Cardiol. 54, 585 (2009)

L. Yang, L.K. Leung, Y. Huang, Z.Y. Chen, J. Agric. Food Chem. 48, 3072 (2000)

A. Zhang, Z. Chen, J. Am. Oil Chem. Soc. 74, 1611 (1997)

J.C. Gomes, E.D. Gomes, V.P.R. Minim, N.J. Andrade, Cent. Eur Res. 55, 543 (2008)

C.Y. Li, H.W. Kim, H. Li, D.C. Lee, H.I. Rhee, Food Chem. 152, 592 (2014)

L. Sanguansri, M.A. Augustin, in Functional Food Ingredients and Nutraceuticals: Processing Technologies, ed. by B.J. Shi Microencapsulation and delivery of omega-3 fatty acids (Taylor & Francis Group, New York, 2007), p. 297

T.Y. sheu, M. Rosenberg, J. Food Sci. 60, 98 (1995)

S.A. Hogan, B.F. McNamee, E.D. O’Riordan, M. O’Sullivan, Int. Dairy J. 11, 137 (2001)

H. Khouryieh, G. Puli, K. Williams, F. Aramouni, Food Chem. 167, 340 (2015)

T. Koupantsis, V. Kiosseoglou, Food Hydrocoll. 23, 1156 (2009)

C. Schmitt, C. Sanchez, S. Desobry-Banon, J. Hardy, Crit. Rev. Food Sci. Nutr. 38, 689 (1998)

D.P. Ascheri, M.O. Marquez, E.T. Martucci, J. Food Sci. Technol. 23, 1 (2003)

J. Hategekimana, K.G. Masamba, J. Ma, F. Zhong, Carbohydr. Polym. 124, 172 (2015)

S.S. Bao, X.C. Hu, K. Zhang, X.K. Xu, H.M. Zhang, H. Huang, J. Food Sci. 76, 112 (2011)

S.J. Lee, S.J. Choi, Y. Li, E.A. Decker, D.J. McClements, J. Agric. Food Chem. 59, 415 (2010)

A. Madene, M. Jacquot, J. Scher, S. Desobry, Int. J. Food Sci. Technol. 41, 1 (2006)

A. Kaur, F. Ariffin, R. Bhat, A.A. Karim, Food Hydrocoll. 26, 398 (2012)

G. Bortnowska, J. Balejko, G. Tokarczyk, A. Romanowska-Osuch, N. Krzemi´nska, Food Hydrocoll. 36, 229 (2014)

B.M. Watts, G.L. Ylimamaki, L.E. Jeffery, L.G. Elias, Basic Sensory Method for Food Evaluation (International Development Research Center, Ottawa, 1989), pp. 56–106

N.C. Shanta, E.A. Decker, J. Assoc. Offi. Anal. Chem. Int. 77, 421 (1994)

Institute of Standards and Industrial research of Iran, Mayonnaise and Salad sauce, ISIRI 2554, 3th edn. (ISIRI, Karaj, 2003)

S. Mun, Y.L. Kim, C.G. Kang, K.W. Park, J.S. Shim, Y.R. Kim, Int. J. Biol. Macromol. 44, 400 (2009)

V. Gokmen, I. Sugut, Int. J. Food Eng. (2007). https://doi.org/10.2202/1556-3758.1129

W. Horwitz, L.R. Kamps, K.W. Boyer, J. Assoc. Off. Anal. Chem. 63(6), 1344 (1980)

C. Gamonpilas, W. Pongjaruvat, A. Fuongfuchat, P. Methacanon, N. Seetapan, N. Thamjedsada, J. Food Eng. 105, 233 (2011)

Codex Alimentarius Commission. (Report of the sixteenth session of the Codex Committee on fats and oils, 1999), http://www.codexalimentarius.org/codexhome/en/. Accessed on 4 Dec 2013

B. Benjelloun, T. Talou, M. Delmas, A. Gaset, J. Am. Oil Chem. Soc. 68, 210 (1991)

G. Cervato, R. Cazzola, B. Cestaro, Int. J. Food Sci. Nutr. 50, 291 (1999)

J.R. Rendon-Villalobos, L.A. Belle-Perez, E. Agama-Acevedo, J.J. Islas-Hernandez, P. Osorio-Diaz, J. Tavor, Food Chem. 117, 83 (2009)

E. Dickinson, S.E. Rolfe, D.G. Dalgleish, Food Hydrocoll. 265, 397 (1988)

T.J. Herald, M. Abugoush, F. Aramouni, J. Texture Stud. 40, 692 (2009)

M.A. Riscardo, J.E. Moros, J.M. Franco, C. Gallegos, Europ. Food Res. Technol. 220, 380 (2005)

F. Guilmineau, U. Kulozik, J. Food Eng. 78, 648 (2007)

V. De Cassia da Fonseca, C.W.I. Haminiuk, D.R. Izydoro, N. Aszczynskyj, A. de Paula, M. Scheer, M. Sierakowski, Int. J. Food Sci. Technol. 44, 777 (2009)

L.U. Thompson, D.J. Reniers, J. Dairy Sci. 65, 1135 (1981)

A. Koocheki, R. Kadkhodaee, S.A. Mortazavi, F. Shahidi, A. Taherian, Food Hydrocoll. 23(8), 2416 (2009)

P.I. Figoni, C.F. Shoemaker, J. Texture Stud. 14, 431 (1983)

A. Laca, M.C. Saens, B. Paredes, M. Diaz, J. Food Eng. 97, 243 (2010)

Acknowledgements

This study was part of a PhD program carried out at the University of Tabriz. The financial support of the R&D Institute of Novin Daneshmand is gratefully acknowledged. We also thank Shiraz University for providing laboratory facilities during the course of this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dehghan Manshadi, A., Peighambardoust, S.H., Azadmard-Damirchi, S. et al. Oxidative and physical stability, rheological properties and sensory characteristics of ‘salad dressing’ samples formulated with flaxseed oil and n-OSA starch. Food Measure 13, 26–33 (2019). https://doi.org/10.1007/s11694-018-9915-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-018-9915-0