Abstract

Plant proteins are cheaper source of proteins as compared to animal proteins. So they have great potential as functional food ingredient and could be supplemented in human diets. The use of isolated proteins depends on their ability to impart properties in processed foods. So for effective utilization of particular protein, it is necessary to study its all types of properties and characteristics which is necessary for development of methodology for their use. Sesame protein isolate (SPI) was extracted from sesame meal. The physicochemical and functional properties of both sesame meal and SPI were evaluated. The solubility was maximum (94.13 %) at pH 12. Foaming capacity and foam stability of SPI was pH dependent. SPI showed increase in emulsion stability (ES) with increase in pH. Gelling ability of SPI increased with alkaline pH.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sesame (Sesamum indicum L.) is one of the earliest used condiment and the oldest crop grown for its edible oil. Sesame is cultivated in India, Sudan, China and Burma, which are the major sesame-producing countries, which contribute about 60 % of the global yield. The seed of sesame contains 50 % oil and 25 % protein. Sesame seed is commonly used as the raw material for oil extraction either both by using organic solvents as well as by mechanical pressing. The sesame meal is a by-product which remained after oil extraction and contains approximately 50 % protein [1]. It is usually fed to animals as source of nutrition in India. The sesame protein is high in methionine and tryptophan content that distinguishes it from other oil seeds. The plant proteins provide essential amino acids and possess various desirable characteristics to become valuable and successful in food applications [2]. The behaviour of proteins in food system during processing, manufacturing, storage and preparation is affected by intrinsic physicochemical characteristics of proteins [3]. Therefore, sesame meal is highly prospective to be used as a protein source or as an ingredient in the food industry. Sesame protein isolates or concentrates normally are prepared by isoelectric precipitation. Methionine, 2.5–4.0 % and total sulphur containing amino acids, 3.8–5.5 % are particularly high in contents in sesame meal and isolated protein [4]. Sesame protein is comprised of 80 % α-globulin and 20 % β-globulin. Attempts, which have been made to characterize these two fractions gave limited results. Functional and physicochemical properties of sesame protein concentrate [5, 6], isolate [1, 7, 8], as well as its use as a nutritional supplement for beverage [9] and bread [10] applications have been reported. Achouri [11] studied fractionation, secondary structure and functional properties of sesame protein isolate. The present study aims to evaluate the physicochemical characteristics and functional properties of sesame meal and sesame protein isolate.

Materials and methods

Materials

Sesame seeds of variety RT-127 were purchased from Chandigarh, Punjab and oil was extracted with expeller to obtain sesame meal. The sesame meal was defatted with hexane at a ratio of 1:4 (w/v) under constant shaking for 1 h. Defatted sesame meal was grounded to pass through 80 mesh sieve and was kept in vacuum containers prior to use.

Isolation of protein from sesame meal

Sesame protein isolate (SPI) was prepared by alkali method developed by Onsaard [1] Sesame meal was mixed with water at a ratio of 1:10 (w/v). The pH of the suspended sesame meal was adjusted to pH 11.0 using 1.0 M NaOH, continuously stirred with a magnetic stirrer for 1 h and centrifuged at 5000 rpm for 15 min. The soluble phases were adjusted to pH 4.5 using 1.0 M HCl which led to the precipitation of protein. The suspensions were centrifuged at 5000 rpm for 15 min after which the supernatant was poured away and the precipitates were weighed and assayed for protein content by the Kjeldahl method. The precipitates were neutralized to pH 7.0 using 1.0 M NaOH, dialyzed by distilled water overnight at 4 °C and then vacuum-dried and passed through 80 mesh sieve.

Chemical composition and protein recovery

The chemical composition of sesame meal (SM), and SPI were determined according to AOAC [12] standard methods. The carbohydrate content was estimated by subtracting the sum of percentage of moisture, crude fat, crude protein and ash contents from 100 %. The protein recovery was calculated as follows:

Bulk density, tapped density and compressibility index

Bulk density (BD), tapped density (TD) and compressibility index was determined by the method of European Pharmacopoeia [13]. 25 g of SPI was placed in a 100 ml graduated cylinder without compacting. The volume of the sample was recorded. Bulk density (BD) was calculated as gram per millilitres of material by the formula m/V. Tapped density was calculated by tapping the sample present in graduated cylinder. Firstly, 200 and then 400 taps were taken.

mf is the mass of sample present in measuring cylinder after tapping and Vf is the final tapped volume.

Compressibility index is the measure of propensity of the powder to be compressed. Compressibility index = 100 (V0 − Vf)/V0.

V0 is the unsettled apparent volume and Vf is the final tapped volume.

Dispersibility

The dispersibility of SM and SPI at selected pH levels (9–12) was measured according to the method of Kullarni [14]. 3 g of SM and SPI was dispersed in distilled water in a 50 ml measuring cylinder and desired pH was adjusted by addition of drops of dilute HCL and NaOH solutions. Then distilled water was added to reach a volume of 30 ml, the mixture was stirred vigorously and allowed to settle for 2 h and the dispersibility was calculated as

Wettability

The wettability was estimated for both SM and SPI according to method described by Fekria [15]. Two grams of SM and SPI were transferred to a beaker containing 80 ml distilled water. The behaviour of both powders was observed on the water surface immediately after adding the sample. After 30 min observation, the material was stirred on the magnetic stirrer sufficiently fast to form vortex which reached the bottom of beaker. The stirring continued for 1 min and after which the grade describing wettability was recorded as excellent, good, fair or poor according to the time and behaviour of dispersion.

Least gelation concentration

Gelation properties were investigated using the method described by Coffman and Garcia [16]. Sample suspensions (SM and SPI) of 2–20 % were prepared in distilled water and desired pH was adjusted (9–12). Each of the prepared dispersions (10 ml) was transferred into a test tube. It was heated in a boiling water bath for 1 h, followed by rapid cooling in a bath of cold water. The test tubes were further cooled at 4 °C for 2 h. The least gelation concentration was determined as the concentration when the sample from the inverted test tube did not slip or fall.

Functional properties

Solubility

The pH-solubility profile of SM and SPI over a pH range from 9 to 12 was determined as described by Achouri [11] with slight modifications. Briefly, SM and SPI solutions were prepared in water (1 %, w/v) and their desired pH was adjusted. Solutions were stirred with a magnetic stirrer at 25 °C for 1 h and then centrifuged at 3000 rpm for 30 min. The protein content of the supernatants was determined by Kjeldahl method. Protein solubility was calculated as:

where PS is the percent of protein content in the supernatant after centrifugation and PT is the percent of total protein content present in the protein sample previously determined.

Water absorption capacity (WAC) and fat absorption capacity (FAC)

The method described by Onsaard [1] was used with a slight modification. One gram of SM and SPI samples was stirred in 10 ml of distilled water for WHC and soya bean oil for FAC and then centrifuged at 4500 rpm for 30 min. The volume of the supernatant was measured. The water-holding capacity was expressed as the number of g of water held by 1.0 g of protein sample. The fat absorption capacity was expressed as the number of g of oil held by 1.0 g of protein sample.

Foaming properties

Foaming capacity (FC) and foam stability (FS) were determined according to the method of Fekria [15]. SM and SPI (3 g) were dispersed in 100 ml of distilled water and adjusted to different pH levels (9–12). The contents were transferred to a mixer blender whipped at high speed for 5 min. The contents along with the foam were poured into a 250 ml measuring cylinder and the foam volume was recorded after 15, 30, 45 and 60 min. FC was expressed as percentage increase in volume. After 60 min, the volume of foam was measured and expressed as FS.

Emulsifying properties

Emulsifying activity (EA) and emulsion stability (ES) was determined by method of Lawal [17]. 5 ml portions of SM and SPI solution at different pH levels (9–12) were homogenised with 5 ml soyabean oil. The emulsions were centrifuged at 3500 rpm for 5 min. The height of emulsified layer and that of the total contents in the tube was measured. The emulsifying activity (EA) was calculated as

Emulsion stability was determined by heating the emulsion at 80 °C for 30 min before centrifuging at 3500 rpm for 5 min.

Color

Color measurements of samples were carried out using a Hunter colorimeter Model D 25 optical Sensor (Hunter Associates Laboratory Inc., Reston, VA, USA) on the basis of L*, a* and b* values. A glass cell containing sample was placed above the light source covered with a white plate and L*, a* and b* color values were recorded. The instrument (D 65 Luminance, 10° observer) was calibrated. The L* value indicates the lightness, 0–100 representing dark to light. a* value gives the degree of the red-green color with a higher positive a* value indicating more red. b* value indicates the degree of the yellow-blue color with a higher positive b* value indicating more yellow. Hue and chroma was calculated as follows

Statistical analysis

Triplicate runs were carried out for each experiment and experimental data were analyzed by analysis of variance (ANOVA) with significance defined at (p < 0.05). Significant differences among mean values were determined by Bonferroni test. All statistical analyses were carried using StatSoft (Statistica 12.0).

Results and discussions

Chemical composition and protein recovery of sesame protein isolate (SPI)

Chemical composition of SPI and SM are presented in Table 1. Protein content of SPI was 90.50 % and SM was 41.96 %. SM consists of 10.46 % ash, 2.31 % crude fibre and 37.67 % carbohydrates. Although, the SM was defatted with hexane, lipids were not removed completely and part of them remained in meal (0.66 %). Ash (2.08 %) in SPI was significantly different from SM. Fat, crude fibre and carbohydrates were found to be present in traces in SPI. Protein recovery of SPI by alkaline extraction at pH 11 was 43.8 %. Onsaard [1] reported 35.5 % protein recovery of SPI at same pH level.

Bulk density, tapped density and compressibility index

Bulk density (BD) of SPI (0.84 g/ml) and SM (1.0 g/ml) were reported to be different (Table 2) and were higher than previously reported values for various flours such as field pea (0.54 g/ml) as reported by Kaur and Singh [18] and chick pea flours (0.54 g/ml) as reported by Kaur and Singh [19]. Compressibility index for SPI was reported as 14.28 for SPI and 10 for SM. The compressibility index is the measure of the powder ability to settle. In free flowing powder, interparticulate interactions are less significant and the bulk and tapped densities will be closer in value. Lower value of compressibility index indicates more free flowing behaviour of powder [13]. Flowability of SM was more as compared to SPI as SM showed lesser value of compressibility index than SPI.

Dispersibility and wettability

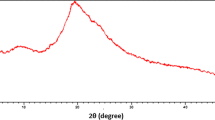

Dispersibility of protein in water indicates its reconstitutability. The better temperature, pH, ionic composition and degree of agitation of solvent are major factors affecting dispersibility [20]. Dispersibility of both SPI and SM were pH dependent. Highest dispersibility was observed for SPI at pH 12 (Fig. 1). Lowest dispersibility was observed for SM at pH 9. SPI was more dispersible than SM at all pH levels. This might be due to other non-protein components present in SM which might have poor reconstitutability as compare to sesame protein. Khalid [7] reported similar results for SPI at alkaline pH.

Wettability of proteins is affected by surface polarity, topography, texture, area and by the size and microstructure of protein particles [21]. Wettability for SPI and SM was graded as good, since it wet slightly when first comes in contact with water and after 30 min the wetted powder sunk to the bottom. The findings obtained in this study are in agreement with Fekria [15] for groundnut flour.

Least gelation concentration (LGC)

LGC indicates the gelation capacity. Lower is the LGC, better is the gelling ability of proteins [22]. Gelling ability was observed to be pH dependent for SPI, as minimum LGC (14.0) was observed at pH 12 and maximum at pH 9 (25.0). This indicates that gelling ability of SPI increased with alkaline pH.

Sesame meal showed LGC at pH 9 (16 %) and pH 10 (11 %) only. No LGC was observed at pH 11 and 12. In this case, as reported by Kaur and Singh [19], the gelation is not only a function of protein quantity but also seems to be related to the type of protein as well as non-protein components. The results obtained were in agreement with LGC of Bambarra groundnut protein concentrate [17], chick pea protein isolate [19] and lentil protein isolate [23].

Functional properties

Solubility

The protein solubility of SPI and SM in water at different pH (9–12) was different. Similar results were also observed in SPI as reported by Khalid [7]. SPI and SM showed minimum solubility at pH 9 and solubility increased with increase in pH (Fig. 2). Maximum solubility was observed at pH 12 for both SPI and SM. SPI was 94.13 % soluble at pH 12 whereas, SM showed 49.87 % solubility. This might be due to electrostatic repulsive forces between positively charged proteins which help to keep them apart and increase protein-solvent interactions [24]. Protein solubility of SM was lower than SPI at all pH levels. This might be due to low quantity of protein in SM as compared to SPI.

Water absorption capacity (WAC) and fat absorption capacity (FAC)

SPI exhibited higher WAC as compared to meal (Table 2). This might be due to the fact that the isolates have great ability to swell, dissociate and unfold, exposing additional binding sites, whereas carbohydrates and other components present in flours may impair it [25]. Same results were observed for WAC of chick pea protein isolates and their flours as reported by Kaur and Singh [19].

FAC of both the samples differ with SPI having higher FAC as compared to FAC of SM (Table 2). This might be due to several non-polar amino acids which were present in more amount in SPI than SM, which may bind the hydrocarbon chains of fats, thereby resulting in higher absorption of oil [3]. FAC of both SPI and SM was observed to be more than WAC. This might be due to the reason that sesame protein was not soluble in water at neutral pH. Mao and Hua [24] also reported higher FAC of walnut protein isolate than defatted walnut flour.

Foaming properties

Foaming capacity was observed to be pH dependent for SPI. Foaming capacity of SPI increased with increase in pH, having minimum FC at pH 9 and maximum at pH 12 (Fig. 3). Same trend was observed by Khalid [7] for SPI and Mao and Hua [24] for walnut protein isolate. FC of SPI at pH 9, 10, 11, and 12 were observed as 15.23, 17.40, 19.30 and 23.56 %, respectively. The results obtained were due to an increase in the net charge of the protein which weakens hydrophobic interaction and increases protein solubility and flexibility allowing the protein to spread to the air–water interface more quickly, encapsulating air particles and thus increasing foam formation as reported by Mao and Hua [24]. According to Graham and Phillips [26], good foamability is due to flexible proteins that can reduce surface tension, while a globular protein which is relatively difficult to surface denature gives low foamability. The major proteins of sesame are globular in nature which may be difficult to denature resulting in lower foaming properties as compared with protein from other sources.

Foam stability is an important parameter since the usefulness of whipping agents depends on their ability to maintain the whip as long as possible [27]. Foam stability of SPI was pH dependent and maximum foam stability was observed at pH 12 (89.60 %) after 15 min of storage. Foam decreased after storage interval from 15 to 60 min at all pH levels (Fig. 4). Increase in pH improved FS of protein isolate due to increased solubility and surface activity of soluble protein. Khalid [7] also reported pH dependent foam stability of SPI. Foaming capacity of SM was observed to be very less and showed slight change with increase in pH and no stability in foam were observed. This might be due to low concentration of protein in SM and presence of other non- protein components which hinders the formation of foam in SM.

Emulsifying properties

Emulsifying activity of SPI and SM was different as EA of SPI and SM at pH 9 was observed as 8.70 and 4.10 %, respectively (Fig. 5). Both SPI and SM showed increase in EA with increase in pH. Highest EA was observed at pH 12, as 28.96 % for SPI and 11.73 % for SM. Dependence of emulsion activity on pH may be due to the reason that emulsion activity depends upon hydrophilic–lipophilic balance which is affected by pH. At the oil–water interface, the protein orient lipophilic residues to the oil phase and hydrophilic residues to the aqueous phase, thus reducing surface tension at the interface [28]. Khalid [7] also reported increase in EA of SPI with increase in pH. However compared to other protein isolates, emulsion activity of sesame protein was low. This might be due to low solubility of sesame protein as compared to protein from other sources.

Emulsion stability of SPI was higher than emulsion stability of SM (Fig. 6). ES of SPI was lowest at pH 9 as 61.50 % and highest at pH 12 as 98.70 %. Both SPI and SM showed increase in emulsion stability (ES) with increase in pH. This may be due to the reason that increase in the pH results in increased columbic repulsions between neighbouring droplets, coupled with increased hydration of the charged protein molecules. These factors resulted in reduction of interface energy and combination of emulsion droplet, which might account for higher ES obtained [29]. The difference in ES of SPI and SM might be due their differences in protein concentration. Hydrophobic interaction on the surface of protein causes an extensive protein–protein interaction, which would form strong oil–water interface, resulting in stable emulsion.

The emulsifying properties can be improved in alkaline environment.

Color

Protein isolate was having L*, a* and b* value of 44.25, 5.48 and 17.07, respectively. Positive b* value indicates yellowness of protein isolate. Hue is the degree to which a stimulus can be described as similar to or different from stimuli that are described as red, green, blue and yellow, whereas chroma describes the vividness or dullness of a color, in other words, how close the color is to either gray or the pure hue. The calculated values for hue and chroma were 72.33 and 17.92, respectively. Kaur and Singh [19] reported dark and reddish color of chickpea protein isolates with lower L* value (58.63–61.33), higher a* (1.88–2.21).

Conclusion

In this study, SPI was produced from defatted SM and various properties of SM and SPI were studied. SPI is a good source of protein (90.50 %). All functional properties of SPI were observed to be pH dependent. Foaming capacity, foam stability, emulsifying activity and emulsion stability of SPI were maximum at pH 12. SPI exhibited higher WAC as compared to SM. FAC of both SPI and SM was observed to be more than WAC. Dispersibility increased with increase in pH in both SM and SPI. Wettability for SPI and SM was graded as good. Gelling ability of SPI increased with alkaline pH. SPI could be further exploited for its favourable properties and characteristics for new product development.

References

E. Onsaard, P. Pomamud, P. Audtum, Asian J. Food Agric. Ind. 3, 420 (2010)

J.C. Wang, J.E. Kinsella, J. Food Sci. 41, 498 (1976)

J.E. Kinsella, J. Am. Oil Chem. Soc. 56, 242 (1979)

L.A. Johnson, T.M. Suleiman, E.W. Lusas, J. Am, Oil Chem. Soc. 56, 463 (1979)

U.E. Inyang, A.O. Iduh, J. Am. Oil Chem. Soc. 73, 1663 (1996)

M. Zaghloul, V. Prakash, Nah./Food. 46, 364 (2002)

E.K. Khalid, E.E. Babiker, A.H.E.L. Tinay, Food Chem. 82, 361 (2003)

A.P. Gandhi, J. Srivastava, Asean Food J. 14, 175 (2007)

G. Lopez, I. Flores, A. Galvez, M. Quiasco, A. Farres, LWT-. Food Sci. Technol. 36, 67 (2003)

T.A. El-Adawy, Plant Foods Hum. Nutr. 48, 311 (1995)

A. Achouri, V. Nail, J.I. Boye, Food Res. Int. 46, 360 (2012)

AOAC, Official Methods of Analysis, 16th edn. (Association of Official Analytical Chemists, Washington DC, 1999)

European Pharmocopoeia, Int. Pharma. 31, 343 (2013)

D.K. Kullarni, D.N. Kullarni, O.M. Ingle, Food Nutr. Bull. 13, 324 (1991)

A.M. Fekria, A.M.A. Isam, O.A. Suha, E.B. Elfadil, Int. Food Res. J. 19, 629 (2012)

C.W. Coffman, V.V. Garcia, J. Food Technol. 12, 473 (1977)

D.S. Lawal, K.O. Adebowale, Y.A. Adebowale, Food Res. Int. 40, 1003 (2007)

M. Kaur, N. Singh, Food Chem. 102, 366 (2007)

M. Kaur, N. Singh, Food Chem. 91, 403 (2005)

J.E. Kinsella, C.R.C. Crit, Rev. Food Sci. Nutr. 7, 219 (1976)

B. Hagerdal, B. Lofqvist, J. Food Sci. 43, 27 (1978)

E.T. Akintayo, A.A. Oshodi, K.O. Esuoso, Food Chem. 66, 51 (1999)

M. Joshi, B. Adhikari, P. Aldred, J.F. Panozzo, S. Kasapis, Food Chem. 129, 1513 (2011)

X. Mao, Y. Hua, Int. J. Mol. Sci. 13, 1561 (2012)

K.O. Adebowale, O.S. Lawal, Food Res. Int. 37, 355 (2004)

D.E. Graham, M. C. Phillips, in Foams, ed. by R.J. Akers (Academic Press, New York, 1976), pp. 237–255

M.J.Y. Lin, E.S. Humbert, F.W. Sosulski, J. Food Sci. 39, 368 (1974)

F.W. Sosulski, S.E. Fleming, J. Am. Oil Chem. Soc. 54, 100 (1977)

U.D. Chavan, D.B. Mckenzie, F. Shahidi, Food Chem. 74, 177 (2001)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, L., Singh, C. & Sharma, H.K. Assessment of functionality of sesame meal and sesame protein isolate from Indian cultivar. Food Measure 10, 520–526 (2016). https://doi.org/10.1007/s11694-016-9330-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-016-9330-3