Abstract

In recent times computer vision employing image processing techniques has been developed rapidly in order to quantitatively characterize of foods. In this study, effect of cress seed gum as a novel gluten substitute and xanthan gum (1 % base on flour and starch weight) on gluten-free bread were investigated by image processing. Additionally, bread crumb analyzed during storage (24 and 72 h). Bread features selected for analysis were moisture content, specific volume, slice shape, crust and crumb color, pore area fraction, pore size distribution, number of cells/cm2, pore shape, fractal dimension of pore boundaries and crumb texture. The results exhibited, hydrocolloids improved quality of gluten-free breads significantly (p < 0.05). Hydrocolloid addition increased pore area fraction and had positive effect on crumb color during storage. Hydrocolloid by forming thick layer influenced the stability of gas cells and caused more regular and solids pores in gluten-free bread which was more noticeable in breads containing cress seed gum. Fractal values of boundaries indicated that the breads containing cress seed gum had more regular and smooth boundaries. Texture analysis by gray level co-occurrence matrix revealed stability crumb texture during storage.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Coeliac disease is a life-long intolerance to the gliadin fraction of wheat and the prolamins of rye (secalins), barley (hordeins) and possibly oats (avidins) [1]. The only effective treatment for coeliac disease is a strict adherence to a gluten-free diet throughout the patient’s lifetime which, in time, results in clinical and mucosal recovery [2]. Therefore, these persons are unable to consume some of the most common products including breads, baked goods and other food products made with wheat flour [3]. As a result of growing number of celiac patient, interest for gluten-free products increases [4]. Gluten removal results in major problems for bakers, and currently, many gluten-free products available on the market are of low quality, exhibiting poor mouthfeel and flavor. This presents a major challenge to the cereal technologist and baker alike [2]. Especially in bread industry which is one of the most consumed products among baked foods [5]. The gluten matrix is a major determinant of the important rheological characteristics of dough, such as elasticity, extensibility, resistance to stretch, mixing tolerance, and gas holding ability [6].

The most investigation on gluten-free products, involved a diverse approach which has included the use of starches, dairy products, hydrocolloids, other non-gluten proteins, prebiotics and combinations [2]. The bread dough without gluten can only keep gas if the gluten is replaced by another gel. Gums enhance the cohesion of the starch granules and produce bread which can compete with wheat bread, but without the detrimental effects of gluten [7]. The most commonly used are hydrocolloids such as, xanthan, pectin, guar gum, Arabic gum, galactomannans, and methylcellulose [4].

Hydrocolloids are high-molecular weight hydrophilic biopolymers used widely as functional ingredients in the food and pharmaceutical systems [8]. Hydrocolloids are used in gluten-free formulations for a variety of purposes including gelling, thickening, water retention and texture improvement [2]. Different studies have been conducted to investigate the influence of hydrocolloids in preparing gluten-free bread [6, 9–11].

Xanthan gum (XG) was investigated in this study because it forms high-viscosity pseudoplastic material and is very common in commercial gluten-free loaves. XG is an anionic polysaccharide produced commercially by bacterial fermentation [12]. XG is hydrated in cold water and produces a viscose solution with shear thinning flow behavior [13]. The shear thinning property of XG is important during dough preparation, i.e. pumping, kneading and rolling. Xanthan increases dough stability, water absorption and gas maintenance [7]. A particular feature of XG is its insensitivity to temperature which allows it to keep the batters highly viscouse at elevated temperatures thus enabling their expansion before setting their structure [14]. Xanthan and carboxymethyl cellulose (CMC) have showed the appropriate quality in bread manufacturing [7].

According to the increasing demand for hydrocolloids, with specific functionality in the recent years, finding new hydrocolloid sources that could improve the quality of gluten-free breads is still a need. Lepidium sativum seed gum is a new source of hydrocolloids that exhibits desirable functional and textural properties [15, 16]. Cress seeds adsorb water quickly when soaked in water and produce a large amount of mucilaginous substances. Cress seed gum (CSG) has shear thinning flow behavior and high molecular weight (540 kDa), which is nearly as rigid as XG [17]. CSG has interesting emulsifying and foaming properties which remained unchanged after heating and freezing [15, 18]. The CSG gel had proper texture characteristics and can maintain its gel integrity and resistance in thermal condition [16]. On the other hand, heating caused an irreversible increase in viscosity of its solutions which indicating the irreversible conformational change of CSG [15]. This property will help to keep the batter viscose at elevated temperature like XG. According to its conformational and rheological similarities with xanthan, this new gum can be used as a substitute of some hydrocolloids and also it has more advantages because of its curative properties and plant origin [15].

In the food industry, the quality evaluation still heavily depends on manual inspection, which is tedious, laborious, and costly, and is easily influenced by physiological factors, inducing subjective and inconsistent evaluation results [19, 20]. Based on image processing and analysis, computer vision is a novel technology for recognizing objects and extracting quantitative information of morphology, structure and microstructure from digital images in order to provide objective, rapid, non-contact, and non-destructive quality evaluation [21]. Image processing has been applied increasingly for quality evaluation of baking studies [11, 22–27]. On the other hand, the characterization of the crumb cellular structure in breads has been a long standing goal in cereal science. The properties of the foam influence the perceptions of texture, starting from how the bread looks to how it deforms during handling and mastication [27]. Also, the absence of gluten has an impact on cell formation, crumb and crust characteristics, volume, porosity, quality parameters [7]. Therefore, we decided to evaluate crumb cellular structure based on image process technique [4]. Furthermore, it is necessary to understand the macroscopic behavior and complexity of bread crumb during storage. Staling occurs in both the crust and crumb but generally more attention is given to the crumb as it effects the consumer’s perception of the bread [28]. Therefore the next objective was to evaluate the staling damage on structure and color of crumb.

The aim of this study was to investigate the effect of CSG gum as a novel gluten substitute and XG on volume, porosity, moisture content, color and macrostructure (crumb structure, pore shape identification, fractal dimension and crumb texture) of gluten-free bread during 1, 24 and 72 h.

Materials and methods

Materials

The material used in formulation for gluten-free bread consist of rice flour, corn flour and corn starch (100 %), fast active dry yeast (4 %), deacetyl-tartaric acid esters of monoglyceride (DATEM) (0.5 %), powdered milk (9 %), powdered egg whites (6 %), sunflower oil (4 %), Salt (1 %), sugar (5 %), and distilled water (optimum level). The hydrocolloids used for different formulations were cress seed gum and xanthan gum (1 % base on flour and starch weight). Cress seeds were obtained from a local market in Mashhad, Iran. Xanthan gum was supplied from Sigma Chemical Co, USA. CSG powder was prepared on the basis of the work done by Karazhiyan et al. [40]. The cleaned cress seeds were firstly soaked in distilled water at the seed: water ratio of 37:1, 40 °C, pH 7, and for 18 min. Hydrocolloid extract was separated from the swollen seeds by passing the seeds through a laboratory extractor (Pars Khazar, Iran). The extract was then filtered and dried in an air forced oven at 60 °C and finally the powder was milled, sieved using a mesh 18 sifter, packed, and kept at cool and dry condition.

Bread making

Rice flour, corn starch and flour, salt, sugar and hydrocolloid was mixed in the bowl of mixer (Hügel, Germany) in a 2 speed for 20 s. Dry yeast was dispersed in half of water (30 °C) and leaved for 5 min. dispersed yeast was added and mixed for 2 min in a 4 speed. Oil and the remained water was mixed in a 4 speed for 3 min. The witness samples was provided without hydrocolloid. Gums added at 1 % level (flour and starch basis). The dough samples were placed in aluminum and fermented at 40 °C for 45 min. The dough was baked at 120 °C for 20 min in oven. Measurement of the loaves was conducted after cooling to room temperature for 1 h. For storage effect on some quality parameters, In order to study storage effects, bread was placed in polyethylene bags and stored for 24 and 72 h.

Bread quality

Some physicochemical parameters of fresh bread included specific volume, moisture content and slice shape were determined. Bread moisture content was determined through drying out of a homogeneous sample of bread (2.00 g) using the air-oven drying according to 44-15A standard [29]. The specific volume was determined by the seed displacement method. The shape of loaf slice was defined as width/height ratio of central slice.

Image processing

Computer vision system

A computer vision system generally consists of sample illumination was achieved with five fluorescent lights (Opple, 8 W, model: MX396-Y82; 60 cm in length) with a color index (Ra) close to 95 %. The illuminating lights were placed in a wooden box, 45 cm above the sample and at the angle of 45º with sample plane to give a uniform light intensity over the bread [30]. The interior walls of the wooden box were painted black to minimize background light. So that stabilization the lighting system, it was switched on for about 30 min prior to acquiring images. A color digital camera (Canon EOS 1000D, Taiwan) with lens focal length of 35 mm for color analysis and 45 mm for investigation of pore properties was located vertically. The iris was operated in manual mode, with the lens aperture of 5.6, ISO 100 and shutter speed of 1/80 s to achieve high uniformity and repeatability. Images were captured with the mentioned digital camera at 2592 × 3888 pixels and connected to the USB port of a computer. Canon Digital Camera Solution Software (Canon Utilities Zoom Browser EX README File Version 6.1.1) was used to acquire the images in the computer in TIFF format.

In this study, Bread samples were cut into two halves vertically and both side of halves used for investigation. The image analysis was managed using Adobe Photoshop (v. 9CS2), ImageJ software (National Institutes of Health, USA) version 1.45 s and MATLAB (version 2011 b). The features of color, pore area fraction, number of cells/cm2, pore size distribution, pore shape, fractal dimension of pore`s boundaries and crumb texture were investigated.

Crust and crumb color

In defining and quantifying color, RGB (red, green, blue) and L*a*b* color system were selected and analyzed by ImageJ software. Chroma (C) value was determined, which is the weighted sum of red, green and blue (Eq. 1).

where r, g, b are the amounts of R, G, B colors (ratio of each color value to the sum of three colors).

The color of crust and crumb was investigated after cooling for 1 h. The alteration of crumb color was also studied after 24 and 72 h storage.

Crumb pores structure

First, images were improved by using smart sharp filter of Adobe Photoshop (Adobe, v.9CS2). Then color image was converted to gray scale and the largest possible rectangular cross-section of bread haves was cropped. After adjusting threshold, pore area fraction, pore size distribution and number of pores/cm2 were investigated after 1, 24 and 72 h with ImageJ software. By set scale icon of software, pixels values were converted to distance unites before analysis.

Shape identification

Image processing was performed and then Circularity, Aspect Ratio, Roundness and Solidity was studied with ImageJ software and Euler’s number was evaluated with MATLAB (version 2011 b) after 1, 24 and 72 h.

Circularity value of 1.0 indicating a perfect circle. As the value approaches 0.0, it indicates an increasingly elongated shape. Factor circularity determined by following formula:

Aspect Ratio is the ratio of the length of major axis to the length of minor axis which was evaluated as fallow:

Roundness is inverse of aspect ratio and indicate a measure of how far the pore shape differs from a circle.

Solidity describes the extent to which the shape is convex or concave and it is defined by:

Euler’s number describes the relation between the number of continuous parts and the number of holes on a shape. Let S be the number of continuous parts and N be the number of holes on a shape. Then the Euler number is:

The 8-connectivity version of the Euler number equation was used for computing Euler number with MATLAB (version 2011 b).

Fractal dimension

The fractal dimension quantifies the degree of irregularity or fragmentation of an object of spatial pattern [31]. There are several ways to measure the fractal properties of an object or geometrical structure. One of the easiest and more common procedures to quantify fractality is the box-counting method, whose result is the fractal dimension of an object or image. A box-counting fractal dimension indicates the level of complexity or the amount of details through scales [32]. The center of each slice was cropped in a square of 1200 × 1200 pixels and converted to grey-level image (8 bits). Then they were converted to binary images and the pore boundary was extracted and lastly the fractal dimension value was computed with box-counting method using the ImageJ software.

Image texture analysis

The Grey-level co-occurrence matrix (GLCM) was used to obtain the statistical texture features. The co-occurrence matrix describes the second-order statistics in the images and enables a calculation of the textural features that are expected to represent the textural characteristics of the image studied [33]. A GLCM is a matrix where the number of rows and columns is equal to the number of gray levels, G, in the image. The matrix element P (i, j|Δx, Δy) is the relative frequency with which two pixels, separated by a pixel distance (Δx, Δy), occur within a given neighborhood, one with intensity ‘i’ and the other with intensity ‘j’. The matrix element P (i, j|d, θ) contains the second order statistical probability values for changes between gray levels ‘i’ and ‘j’ at a particular displacement distance d and at a particular angle (θ). Using a large number of intensity levels G implies storing a lot of temporary data, i.e. a G × G matrix for each combination of (Δx, Δy) or (d, θ). Due to their large dimensionality, the GLCM’s are very sensitive to the size of the texture samples on which they are estimated. Thus, the number of gray levels is often reduced [34].

The center of each slice was cropped in a square of 1200 × 1200 pixels and converted to grey-level image (8 bits). During our study, the features were investigated in four directions (0°, 90°, 180° and 270°) and a distance of 1 pixel. The average of five textural features: angular second moment, contrast, correlation, inverse difference moment and entropy were studied.

The angular second moment is a measure of image homogeneity; it is high when the pixels are very similar or when image has very good homogeneity [33].

Where i, j are the spatial coordinates of the function p (i, j), Ng is gray tone.

Contrast Contrast measures local variations of grey levels and correlation measures the linear dependencies of grey levels in the image [33].

i and j: row and column numbers in the GLCM matrix, pij = (i,j)th entry in a normalized grey-level co-occurrence matrix.

Correlation measures the linear dependencies of grey levels of neighboring pixel in the image [33].

Where i, j are the spatial coordinates of the function p (i, j), Ng is gray tone, µ: means σ: standard deviation.

Inverse Difference Moment is the local homogeneity. It is high when local gray level is uniform and inverse GLCM is high.

Where i, j are the spatial coordinates of the function p (i, j), Ng is gray tone [34].

Entropy measures the ‘complexity’ of the image with regards to the spatial location of grey levels in the image [33].

Where i, j are the spatial coordinates of the function p (i, j), Ng is gray tone.

Statistical analysis

All measurements were conducted by triplicate and a completely randomized design was used for statistical analysis. The data was statistically analyzed by factorial analysis of variance and differences among the mean values compared using least significant difference (LSD) test. The p level of < 0.05 was considered statistically significant.

Result and discussion

Bread quality

The gluten-free bread quality properties are summarized in Table 1. It is known that hydrocolloids addition generally increases the moisture content of breads [35–37]. In this study, hydrocolloids increased the moisture content of gluten-free breads significantly (p < 0.05). Nevertheless, the difference between CSG and XG wasn’t significant (p > 0.05). This improvement in moisture content by hydrocolloids is attributed to water retention ability of this polymer which is as the result of their hydrophilic nature [38]. This result for XG has been reported by various authors [36, 38, 39]. CSG is able to absorb water more and quickly. The effect has been attributed to the hydroxyl groups in the hydrocolloid structure and chain conformation which allows more water interaction through hydrogen bonding [15, 17, 40]. The specific volume of the breads increased by adding CSG and XG (p < 0.05). In gluten-free breads formulated with CSG more increase was observed (p > 0.05). The hydrocolloids give stability to interface dough system during proofing which conferres additional strength to the gas cells through baking. Consequently the gas losses will be reduced and in turn bread volume will improve [35, 38]. The shape of loaf slice (width/height) was affected by CSG significantly, and the reduction of the width/height ratio indicated the bread shape improvement.

Crust and crumb color

Color is an important visual characteristic of food, and it also affects consumer preference and purchase decisions. As well, color correlates well with other physical, chemical and sensory quality indicators in food [41]. In food research, the color is frequently represented in the L*a*b* color space. L* is the luminance or lightness component, which ranges from 0 to 100, and parameters a* (from green to red) and b* (from blue to yellow) are the two chromatic components, which range from −120 to 120 [42]. In contrast with other color models such as RGB, in the L*a*b* space the color perception is uniform, i.e. the distance between two colors in a linear color space corresponds to the perceived differences between them. Therefore, it permits an objective color representation, and its use is essential for applications where the results must match those of the human perception [42].

In general, a lower L* value indicates a darker crust, [43]. Whereas a higher b* value correlates to higher crust yellowness. As shown in Table 2, no considerable difference in crust lightness (L* values) was found between formulations containing hydrocolloid and the control samples. Mezaize et al. [9] found similar result for XG and guar gum gluten-free bread and observed no significant different between different between lightening of them and witness samples. Sciarini et al. [44] reported that Gelatin and Alginate crust lightness were similar to that of control, breads with XG and CMC showed a lighter crust and darkening of the crust (lower L* values) with carrageenan addition. In general, breads with added hydrocolloid evidence lighter crusts [4, 6, 7, 9, 45]. This could be attributable to the effect of hydrocolloids on water distribution, which impacts on Maillard reaction and caramelisation. The parameter a* denotes the balance between green (negative values) and red (positive values). The a* values for all formulation breads were all negative, which means that there was no red hue for crust. The influence of gum addition on a* values of crust breads wasn’t significantly (p > 0.05). No considerable differences in crust yellowness (b*) were found between the bread containing xanthan and witness which was in agree with the findings of previous studies [7]. According to Chroma values of crust (Table 2), no significant difference was found between the colors of gluten-free breads. CSG increased b* significantly that led to higher crust yellowness, but no difference between XG and witness was observed.

According to Table 3, CSG and XG didn’t have significant effect on crumb color (L*, a*, b* and Chroma values) of gluten-free bread. During storage, the crumb color changed (Table 3). These alterations were different between among formulations. After 24 h, no significant change was observed in L* values for all samples. But after 72 h, L* values of witness and formulation containing CSG decreased significantly (p < 0.05) which caused darker crumb. This alteration isn’t desirable for crumb. The lightness of XG samples remained unchanged even after 72 h.

The a* values of witness samples changed significantly after 24 h storage. Therefore storage caused the witness bread color shift to red, but no change in samples containing hydrocolloid was observed. The yellowness of witness breads decreased significantly after storage for 24 h. In the case of bread containing hydrocolloid parameter b* decreased significantly after 72 h. Gluten-free breads have low ability to retain moisture during storage [39], this property lead to the reduction of water and change of crumb color. The hydrocolloid preserve water and therefore there is less alteration in crumb color of samples containing hydrocolloid during storage.

Concerning the Chroma values of crumb breads (Table 3), no significant differences in color values were noticed before storage between breads containing hydrocolloid and witness. The crumb color become darker after storage especially after 72 h (p < 0.05) in all samples.

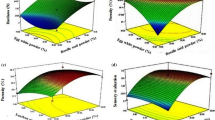

Crumb pores structure

Bread crumb is a viscoelastic foam consisting of a random distribution of open and closed cells. The crumb cellular structure described by pore area fraction (%), number of cells/cm2 (density) and cell size distribution. Image analysis of bread crumb (Fig. 1) showed that addition of hydrocolloids resulted in insignificant increase in pore area fraction (p < 0.05). The increment of pore area fraction is in a good agreement with increase of specific volume of breads containing hydrocolloid. Nevertheless, no considerable difference was found between CSG and XG breads (p > 0.05). Glycoprotein complex of CSG (hydrophilic and hydrophobic groups) provokes interfacial activity inside the dough structure during proofing and construction of gel networks during bread making procedures [18]. Such complex structures increase reinforcing the boundaries of the gas cells growing in the dough and subsequently increase the gas retention throughout baking [7]. However, XG is highly hydrophilic and without any significant hydrophobic bonds cannot adsorb at the air–liquid interface, but it can retard foam destabilization due to thickening of the aqueous phase [18]. On the other hand, XG improve the cohesion of starch granules, thus providing structure of breads [39]. The increment of pore area fraction after addition guar-xanthan gum to wheat bread formulation was reported by Ozge Ozkoc et al. [24]. However, Ozge Ozkoc et al. [24] found decrease of pore area fraction of wheat bread by addition guar, k-carrageenan and xanthan gum. Mezaize et al. [9] reported hydrocolloids increase the pore area fraction of gluten-free bread.

During storage the pore area fraction of witness and breads containing hydrocolloids deceased significantly (p < 0.05) (Fig. 1). But CSG and XG breads had higher pore area fraction compared to witness bread even after storage for 72 h and no considerable difference was observed between 24 and 72 h storage. Water loss during storage can be contributed to the shrinkage during storage [46].

The addition of hydrocolloids didn’t cause significant change in number of cells (Fig. 2). Our finding is comparable with the result of Mezaize et al. [9] who observed no difference in number of gluten-free breads containing XG and CMC and witness breads. Thus the gas cell were bigger with CSG and XG, while we observed that the average cell area of fresh gluten-free bread was higher in CSG and XG samples (Table 4). On the other hand, the sample containing hydrocolloid had cells with higher max area, but the min cell area of all samples was the same (6.882 × 10−6 cm2). No alteration in number of cell was observed during storage.

The pore distribution reveals more information about the effect composition and storage on bread structure. Pores were classified in five different categories according to their size (Table 5). Gums addition had effect on the pore size distribution. Difference in pore size in both witness and breads containing hydrocolloid can be seen. The percentage of pores with small size was more in witness samples (25 %), but very large pores were less in witness (3 %) in comparison with breads containing CSG and XG (7 and 8 % respectively). While CSG and XG bread had the same pore size distribution and they gave greater pore size.

After storage for 24 h, the percentage of big pore cells decreased in all breads. But the percentage of small pores were stable. The size distribution after 72 h was similar to 24 h. Therefore, storage changed the cell distribution. This result was in agreement with reduction of pore area fraction (Fig. 1).

Crumb pores shape

Shape is one of the important aspect used to characterize objects, beside of colors and textures [47]. Also, it provides valuable information about the structural features of crumb. The crumb cell shape data were summarized in Table 6. Roundness is a measure of how far the pore shape differs from a circle. Rounds pores have values equal to 1. The secularity and roundness value of CSG and XG (0.802 and 0.777) breads were considerably more than witness samples (0.733) (p < 0.05). But there was no considerable difference between maximum and minimum value of samples. Ozge Ozkoc et al. [24] reported that pores were mostly in spherical and/or oval like shapes in the case of gum containing formulations, resultes in formulation of stable morphology. The witness had higher aspect ratio value (major axis/minor axis) in comparison with hydrocolloid containing samples (p < 0.05). The result exhibited that biaxial expansion in crumb pores containing hydrocolloids occurred. The solidity values of CSG and XG bread were higher than witness (p < 0.05). When solidity value is equal to 1, indicates solid object, but values lower than 1 shows irregular object or holes contained. As a result, the witness samples had pores with irregular shape and hydrocolloids caused forming more regular and solids pores in gluten-free bread. Gum may influence the stability of gas cells by forming thick layer on their surface and reduce the opportunity for coalescence of individual gas cells, and each bubble remains as a separate discrete entity, resulting in a stable morphology [24]. No difference between solidity value of CSG and XG breads was observed (p > 0.05). Storage for 72 h didn’t cause significant alteration in pores shape.

The Euler number measures the topology of an image and is defined as the number of objects in the image minus the number of holes in those objects, which describes the structure of an object, regardless of its specific geometric shape [48]. Euler number was negative (Table 6), indicating that the number of holes is greater than the number of objects. The absolute value of Euler number increased significantly after addition hydrocolloids to gluten-bread formulation (p < 0.05). No difference was observed between CSG and XG. Also, storage didn’t have effect on Euler number values.

Fractal dimension of pores and boundaries

It was found that bread crumb appearance could be effectively quantified by the fractal dimension of its digital image [49]. Consequently, fractal dimension concept offers important advantages for quantitative description of complex materials because it provides numeric data of irregular shape and complex texture of food materials [50]. FD concept also provide advantages for studying the shrinkage affect [51]. FD of a two-dimensional profile ranges from 1 to 2. Fractal value close to 1 indicates that the border of the analyzed object has smooth boundaries, and a value close to 2 indicates a high degree of tortuosity or roughness [51].

Fractal value of pore boundaries is related to the tortuosity of the cell wall of the binarised image, which can be conceptually related to the uniformity of pores cell wall. Fractal values of pore boundaries in breads containing CSG were lowest (Table 7) which indicated that the addition CSG caused more regular and smooth pore boundaries. This result is in agree with solidity data (Table 6) which showed more regular shape of CSG in comparison with the other samples. The fractal dimension of boundaries increased gradually during storage (p > 0.05). This increase may be related to the shrinkage of pores during storage. As mentioned in Fig. 1, pore area fraction decreased during storage which caused pore shrinkage and tortuosity. Shrinkage caused more irregular and rougher boundaries; therefore, the fractal dimension of boundaries increased during storage. The fractal dimension of witness boundaries increased more noticeably during storage in comparison with bread containing hydrocolloid, which caused significant difference (p < 0.05) between witness and samples containing hydrocolloids after 72 h storage.

Crumb texture: evaluation by gray level co-occurrence matrix (GLCM)

Texture features can be extracted in several methods, namely: statistical, structural, model-based, and transform information. Each method has different techniques. A well-known algorithm to extract texture features is the use of gray level co-occurrence matrices (GLCMs), which belongs to the statistical methods [52]. The texture of an image corresponds to the spatial organization of pixels in the image and the co-occurrence matrix describes the occurrence of grey level between two pixels separated in the image by a given distance [33].

Hydrocolloids addition had no significant effect on second moment or homogeneity of breads (p > 0.05) (Table 8). The contrast of CSG and XG breads were higher than witness considerably (p < 0.05). Inverse difference moment or local homogeneity considerably increased after addition of hydrocolloids, but no difference observed between CSG and XG. Gum addition had no effect on correlation and entropy (image complexity). Textural features in all formulation were stable during storage.

Conclusion

According to this study, CSG and XG increased moisture content and specific volume of gluten-free bread significantly. Hydrocolloids by forming thick layer influenced the stability of gas cells and caused higher pore area fraction and more regular pores in gluten-free breads. Gluten-free breads containing CSG and XG had the same pore size distribution and they gave higher percentage of big pores. Fractal dimension of boundaries indicated that the addition CSG caused more regular and smooth pore boundaries. During storage the pore area fraction of witness and breads containing hydrocolloids deceased significantly and percentage of big pores reduced, but the percentage of small pores were stable. The hydrocolloid preserve water and therefore there was less alteration in crumb color of samples containing hydrocolloid during storage and no alteration in pore shape and crumb texture was observed. The image processing results indicated that CSG as a novel gluten substitute could improve bread quality and crumb structure of gluten-free breads.

References

J.A. Murray, Am. J. Clin. Nutr. 69(3), 354 (1999)

E. Gallagher, T. Gormley, E. Arendt, Trends Food Sci. Technol. 15(3), 143 (2004)

S. Susanna, P. Prabhasankar, Food Sci. Technol. (LWT) 50(2), 613 (2012)

R. Mahmoud, E. Yousif, M. Gadallah, A. Alawneh, Ann. Agric. Sci. 58(1), 19 (2013)

A. Bakke, Z. Vickers, J. Food Sci. 72(7), 473 (2007)

A. Lazaridou, D. Duta, M. Papageorgiou, N. Belc, C. Biliaderis, J. Food Eng. 79(3), 1033 (2007)

M. Mohammadi, N. Sadeghnia, M.H Azizi, T.R. Neyestani, A.M Mortazavian, J. Ind Eng Chem. 20(4), 1812 (2014)

E. Dickinson, Food Hydrocoll. 17(1), 25 (2003)

S. Mezaize, S. Chevallier, A. Le Bail, M. De Lamballerie, J. Food Sci. 74(3), 140 (2009)

I. Demirkesen, B. Mert, G. Sumnu, S. Sahin, J. Food Eng. 96(2), 295 (2010)

E. Gallagher, T. Gormley, E. Arendt, J. Food Eng. 56(2), 153 (2003)

G. Sworn, in Handbook of Hydrocolloids, ed. by G.O. Phillips, Williams, Peter Anthony (CRC Press, Boca Raton, 2000)

A. Imeson, Food stabilisers, thickeners and gelling agents (Wiley, Oxford, 2011)

E. Gimeno, C. Moraru, J. Kokini, Cereal Chem. 81(1), 100 (2004)

S. Naji, S.M.A. Razavi, H. Karazhiyan, Food Hydrocoll. 28(1), 75 (2012)

S. Naji, S.M.A. Razavi, H. Karazhiyan, A. Koocheki, Electron. J. Environ. Agric. Food Chem. 11(3), 222 (2012)

H. Karazhiyan, S.M.A. Razavi, G.O. Phillips, Y. Fang, S. Al-Assaf, K. Nishinari, Int. J. Comp. Sci. Info. Technol. 46(5), 1066 (2011)

S. Naji, S.M.A Razavi, H. Karazhiyan, Food Bioprocess. Technol. 6, 1302 (2013)

V. Gökmen, H.Z. Senyuva, B. Dülek, E. Cetin, Mol. Nutr. Food Res. 50(9), 805 (2006)

C.-J. Du, D.-W. Sun, J. Food Eng. 72(1), 39 (2006)

D.-W. Sun, Computer vision technology for food quality evaluation. Food science and technology International series (Academic Press, London, 2008)

H. Sapirstein, R. Roller, W. Bushuk, Cereal Chem. 71, 383 (1994)

R. Jahromi, S. Hossein, M. Karimi, F.T Yazdi, S.A Mortazavi, J. Food Process. Preserv. ISSN 1745–4549 (2013)

S. Ozge Ozkoc, G. Sumnu, S. Sahin, Food Hydrocoll. 23(8), 2182 (2009)

Y. Mohd Jusoh, N. Chin, Y. Yusof, R. Abdul Rahman, J. Food Eng. 94(3), 366 (2009)

S. Wang, A. Karrech, K. Regenauer-Lieb, S. Chakrabati-Bell, J. Food Eng. 116(4), 852 (2013)

S. Wang, P. Austin, S. Bell, J. Cereal Sci. 54(2), 203 (2011)

J. Gray, J. Bemiller, Compr. Rev. Food Sci. Food Saf. 2(1), 1 (2003)

American Association Of Cereal Chemists (AACC), Approved methods of the AACC. (St Paul, Minneapolis, 2000)

R. Quevedo, J. Aguilera, F. Pedreschi, Food Bioprocess. Tech. 3(5), 637 (2010)

I.C Moreira, in Complexidade e Caos, ed. by H.M Nussenzveig (Editora UFRJ/COPEA, Rio de Janeiro), pp. 51–82

M. Barros Filho, F. Sobreira, Assessing texture pattern in slum across scales: an unsupervised approach, Vol. 87 (CASA Working Papers Series, 2005)

C. Tournier, M. Grass, D. Zope, C. Salles, D. Bertrand, J. Food Eng. 113(4), 615 (2012)

P. Mohanaiah, P. Sathyanarayana, L. GuruKumar, Int. J. Sci. Res. Publ. 3(5), 2250 (2013)

H.A. Gavilighi, M.H. Azizi, M. Barzegar, M.A. Ameri, J. Food Technol. 4(3), 185 (2006)

A. Hegazy, M. Ammar, M. Ibrahium, World J. Dairy Food Sci. 4(2), 123 (2009)

A. Guarda, C. Rosell, C. Benedito, M. Galotto, Food Hydrocoll. 18(2), 241 (2004)

M.E. Barcenas, C.M. Rosell, Food Hydrocoll. 19(6), 1037 (2005)

Z. Kohajdová, J. Karovičová, Š. Schmidt, Acta Chim. Slovaca 2(1), 46 (2009)

H. Karazhiyan, S.M.A. Razavi, G.O. Phillips, Food Hydrocoll. 25(5), 915 (2011)

F. Fan, Q. Ma, J. Ge, Q. Peng, W.W. Riley, S. Tang, J. Food Eng. 118(4), 426 (2013)

F. Pedreschi, J. Leon, D. Mery, P. Moyano, Food Res. Int. 39(10), 1092 (2006)

R. Ziobro, T. Witczak, L. Juszczak, J. Korus, Food Hydrocoll. 32, 2, (2013)

L.S. Sciarini, P.D. Ribotta, A.E. León, G.T. Pérez, Int. J. Food Sci. Technol. 45(11), 2306 (2010)

R. Sharadanant, K. Khan, Cereal Chem. 80(6), 773 (2003)

I. Mandala, K. Sotirakoglou, Food Hydrocoll. 19(4), 709 (2005)

A. Kadir, L.E. Nugroho, A. Susanto, P.I. Santosa, Int. J. Comp. Sci. Info. Technol. 3(3), 256 (2011)

R. Agarwal, S. Agarwal, N. Mishra, Int. J. Comp. Sci. Info. Technol. 2(4), 80 (2013)

U. Gonzales-Barron, F. Butler, Eur. Food Res. Technol. 226(4), 721 (2008)

G. Juodeikiene, J. Salomskiene, D. Eidukonyte, D. Vidmantiene, V. Narbutaite, L. Vaiciulyte-Funk, Food Technol. Biotechnol. 49(4), 502 (2011)

J. Chanona-Pérez, R. Quevedo, A. R. Jiménez Aparicio, C. Gumeta Chávez, J. A. Mendoza Pérez, G. Calderón Domínguez, L. Alamilla-Beltrán, G. F. Gutiérrez-López, in Food engineering: integrated approaches, ed. by G.V. B.-C. Gustavo, F. Gutiérrez-López, Jorge Welti-Chanes, Efrén Parada-Arias (Springer New York, 2008), pp. 277–286

A. Shahbahrami, T.A. Pham, K. Bertels, J. Supercomput. 59(3), 1455 (2012)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naji-Tabasi, S., Mohebbi, M. Evaluation of cress seed gum and xanthan gum effect on macrostructure properties of gluten-free bread by image processing. Food Measure 9, 110–119 (2015). https://doi.org/10.1007/s11694-014-9216-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-014-9216-1