Abstract

A response surface methodology based on Box–Behnken design was deployed to optimize gluten–free bread formulation based on rice flour. Roselle seed powder (15, 25 and 35%), egg white powder (10, 20 and 30%) and xanthan gum (0.5, 0.75 and 1%) were selected as independent variables. The purpose of the optimization was to achieve maximum porosity and sensory properties as well as minimum hardness of bread samples. The results showed that the Roselle seed and egg white powders had a significant effect (p ≤ 0.05) on hardness, porosity and sensory characteristics of bread. However, xanthan gum did not show a significant effect (p > 0.05) on sensory properties. The design revealed the optimum formulation for gluten-free rice bread with low crumb firmness and improved porosity and sensory values by using 0.73, 30 and 25% of xanthan gum, Roselle seed and egg white powders, respectively. In addition, the optimized gluten–free bread showed higher nutritional properties in terms of total protein, ash, oil and fiber contents as well as lower staling rate compared to the control.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Celiac disease is an autoimmune reaction to eating gluten, a protein matrix found in dough prepared from wheat, barley or rye flours (Rosell et al. 2014). When people with celiac disease consume food products containing gluten, the immune system reaction to the protein gradually damages the villi in their small intestine. As a result, the body can't absorb the vitamins, minerals, and other nutrients. These people are therefore at risk of malnutrition and can develop some related diseases (Cureton and Fasano 2009). Unfortunately, a strict, lifelong gluten–free diet is the only way to treat celiac disease (Moore et al. 2006). Several studies have been done on gluten free products especially, bread, based on different oil seeds, cereal or pseudo cereal flours such as rice, corn, sorghum, amaranth and quinoa (Lazaridou et al. 2007; Gadallah et al. 2016; Ferreira et al. 2016; Phongthai et al. 2017; Ozturk and Mert 2018; Moazeni et al. 2018). Rice flour is widely considered among other used flours in gluten free bread formulation because of high nutritional value, not allergic and being colorless (Fabian and Ju 2011). However, lack of gluten in the flour creates several problems in bread structure. Gluten, a continuous protein network that forms during mixing of flour with water, produces strong and elastic dough with gas holding capacity (Lee and Mulvaney 2003). Several studies showed that some gums including xanthan, guar and hydroxyl propyl methyl cellulose (HPMC), as well as non–gluten proteins such as egg and dairy proteins can be used to partly solve the textural problems caused due to the lack of gluten network in gluten-free breads (Demirkesen et al. 2010; Kittisuban et al. 2014; Nicolae et al. 2016; Hager and Arendt 2013).

Roselle (Hibiscus sabdariffa L.) known as “sorrel” and “mesta” belongs to the family Malvaceae, is a main annul crop grown successfully in tropical and sub–tropical climates around the world. Roselle seedsare valuable food source due to its chemical composition and nutritional values. The seeds contain 18.3% of total dietary fibers, 25–35% protein and 19–21% lipid (Omabuwajo et al. 2000; Hainida et al. 2008; Nyam et al. 2014; Mokhtari Nasrabadi et al. 2018).

Therefore, the objectives of the current study were (1) to optimize the formulation of gluten-free rice bread based on different amounts of xanthan gum, Roselle seed and egg white powders using response surface methodology (Box–Behnken design) and (2) to evaluate nutritional characteristics as well as staling rate of optimized bread compared to control.

Materials and methods

Material

Rice flour and salt were taken from a local market. Milk powder (0.048% fat, 31.6% protein, 57% carbohydrate and 3% moisture) were obtained from a milk powder company, Mashhad, Iran. Roselle (Hibiscus sabdariffa L.) seeds were obtained from Agricultural Research Center, Sistan–Baluchestan, Iran. Instant dry yeast and xanthan gum were taken from Fariman Company, Mashhad, Iran, and Tek–Gum Company, Tabriz, Iran, respectively. Egg white powder was supplied by Telavang Company, Tehran, Iran.

Proximate analysis of Roselle seeds powder and rice flour

Before analysis, Roselle seeds were cleaned and rinsed with tap water. The seeds were oven dried at 60 °C to moisture content of 10%. The dried seeds were milled (Porten, Sweden) and powder was sieved through a 60–mesh screen until the fine Roselle seed powder was obtained (Tounkara et al. 2011). Peroximate analysis of rice flour and Roselle seed powder including moisture, protein, oil, ash and crude fiber contents were determined following the Association Official of Analytical Chemists methods No.925.10, 920.87, 922.06, 923.03, and Ba 6-84, respectively (AOAC 2000).

Batter and bread preparation

Control batter sample was prepared by mixing rice flour (100%), water (87%), instant dry yeast (3%), milk powder (7%) and salt (2%). Xanthan gum, Roselle seed and egg white powders were added at three substitution levels based on rice flour weight (Table 1).Then, dry ingredients were mixed in a mixer (Escher Mixers Co. Schio, Italy) for 4 min. Water was finally added and the mixture was mixed again for another 10 min. For each bread loaf, 60 g of batter was placed into baking pans (8 cm diameter and 4.7 cm height) and proofed for 90 min at 37 °C. The batter samples were then baked at 200 °C for 10 min. Loaves were removed from the pans after baking and allowed to cool down to room temperature (25 °C) for 60 min. The bread samples were kept in sealed polyethylene packages at room temperature before further analysis.

Crumb hardness

Bread hardness determined using a Universal Testing Machine Instron®5965 (Instron Corp., Norwood, MA, USA).The samples (2.5 cm) were compressed to 75% height of bread using a 4.8 mm diameter probe with maximal load of 500 N with 300 mm/min loading speed (Kurek et al. 2016).

Crumb porosity

Porosity was estimated using image analysis technique. Samples were cut into slices (2 mm thickness) and photographs of the slices were taken using a digital camera (Sony IXY Digital 910 IS., Tokyo, Japan) in resolution of 180 dpi. The camera was held at a distance of 20 and 15 cm from top and sides of the slices, respectively. The obtained images with 3264 × 2448 pixels were cropped using Image J software and converted into 8–bit gray scale images to crumb porosity estimation (Marcin et al. 2016).

Sensory evaluation

Sensory evaluation of samples was carried out 2h after baking by 30 trained assessors both male and female students and staff from Food Science and Engineering department, Faculty of Agriculture, University of Zanjan, Zanjan, Iran. A five–point hedonic scale was used to evaluate the sensory attributes included color, texture, taste, and overall acceptability of the samples. The panelists scored each descriptor from 1(lowest) to 5 (highest) (Adeboye et al. 2013).

Characterization of optimized bread

Moisture, protein, ash, lipid and fiber contents of the bread samples based on dry weight (dry weight) were determined by AACC methods No. 44-15, 46-12, 08-01, 30-10 and 32-07, respectively (AACC 2000). Crust color measurements were made in 4 points on the surface of the bread samples using a Minolta color reader (CR-10, Japan). Triplicate readings were carried out from different positions and mean values was recorded as L*, a* and b*. Scanning electron microscope (SEM, Inspect™ S50, FEI Company, Oregon, USA) was used to evaluate the optimized and control bread samples staling during 2, 24 and 48 h of storage time at ambient temperature.

Experimental design and statistical analysis

Response surface methodology was adopted to determine the optimum formulation for gluten–free bread. A Box–Behnken design with three independent variables including Roselle seeds powder, xanthan gum and egg white powder at three levels 15–35, 0.5–1 and 10–30%, was chosen and then coded as x1, x2 and x3, respectively (Tables 1 and 2). Followed by preliminary baking trials, the upper and lower limits for the independent variables were established and 17 baking trials were selected for the evaluation. Five replicates at the center of the design were used to estimate the sum of the square error. The effect of the three independent variables on the responses (Y) including hardness, porosity and sensory evaluation was modeled using a polynomial response surface. The second–order response function for the experiments was predicted by the following equation:

where β0 is defined as the constant, \(\beta j\) is the linear coefficient, \(\beta jj\) is the quadratic coefficient, and \(\beta ij\) is the interaction coefficient and xi and xj are levels of the independent variables. The adequacy of the model for each response was checked by evaluating coefficient of determination (R2), adjusted coefficient of determination (adj. R2) and coefficient of variation (C.V) at significance level 0.05 calculated (Ganjloo et al. 2014). Data analysis is done and three-dimensional (3D) diagrams are depicted using Design Expert 7.0.3 (Minneapolis, USA) Software.

The data obtained from the evaluation of raw materials, optimized and control bread samples were analyzed by ANOVA using the SPSS statistical program (version 16.0), and differences among the means which obtained from three replications were compared using LSD test at the significance level of p < 0.05

Results and discussion

Proximate analysis of rice flour and Roselle seed powder

As shown in Table 3, Roselle seed powder had higher total protein (26.62 ± 0.03%), ash (5.51 ± 0.02%), oil (21.03 ± 0.02%) and fiber (19.81 ± 0.01%) contents compared to rice flour (7.7 ± 0.08, 1.04 ± 0.05, 2.90 ± 0.09 and 2.40 ± 0.05), respectively. These results agree with those reported by Eltayeib and Elaziz (2014) and Mariod et al. (2013). The results obtained from Table 3, confirmed that Roselle seed powder can be considered as a good nutritional source for gluten-free bread supplementation.

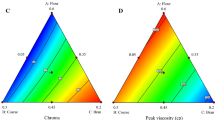

Bread optimization

The results of ANOVA on bread hardness determination were shown in Table 2. The R2 (0.9482), Adj.R2 (0.8815) and the C.V (0.1716%) values indicate that the model employed for hardness determination is adequate to describe the obtained experimental results. All independent variables and interaction term of Roselle seed powder*egg white powder had significant effect on hardness (p ≤ 0.05) while the interaction terms of other variables were no significant (p > 0.05) (Table 2). The 3D response surface plots (Fig. 1a) demonstrate the effect of Roselle seed and egg white powders on hardness of bread texture. From the Fig. 1a, it can be seen that the hardness values decreased by increasing the Roselle seed and egg white powders amounts from 15 to 35% and 10 to 25%, respectively. According to the Fig. 1a, at a constant value of egg white powder, adding Roselle seed powder at all levels reduces the bread hardness. This reduction can be due to the high oil, protein and fiber contents of Roselle seed powder which increases the crumb softness. These results agree with Nyam et al. (2014) who reported that by increasing Roselle seed powder level in cookie formulation up to 30%, the crumb hardness decreases.

On the other hand, at a constant value of Roselle seed powder, by increasing the egg white powder up to 25% the bread hardness decreased. It is likely that this amount of egg white is not enough to building strong network. Also, this can be due to the reduction of surface tension by egg white and the stabilization of air bubbles in the batter, thereby reducing hardness as well as texture improvement (Han et al. 2019). Furthermore, the low hardness could be a combined effect of Roselle seed and egg white proteins. Similar results were reported by Bize et al (2017) who described that the proteins of egg powder had a positive effect on reducing gluten–free sorghum bread hardness during 0, 4, 8 and 12 days after baking. However, adding egg white powder at 25–30% showed a negative effect on reducing hardness. Egg white has excellent water bonding capacity and gelling property which can produce predominant network at the higher levels and increase crumb hardness (Han et al. 2019; Sikorski 2001).

The R2(0.9761), Adj.R2(0.6453) and the CV (0.66%) values show that the model for porosity is adequate to describe the experimental results (Table 2). According to Table 2, all independent variables and interaction term of Roselle seed powder*egg white powder and Roselle seed powder*xanthan gum had significant effect on porosity (p ≤ 0.05). Figure 1c, shows the effect of interaction term of Roselle seed powder*egg white powder and Roselle seed powder*xanthan gum on porosity values. It is clearly seen that increasing Roselle seed and egg white powder contents, increases the bread porosity values. At the constant value of the egg white powder, by adding Roselle seed powder the porosity value increases, and conversely. This could be due to the higher content protein of Roselle seed and egg white powders. The presence of egg white proteins in batter formulation, improved gas cell stabilization and promotes foaming which results finer bread texture (Sikorski 2001; Bize et al. 2017).

Figure 1c, illustrates that xanthan gum in higher amounts (0.75–1%) had a negative effect on the porosity. At a constant value of Roselle seed powder, increasing xanthan gum levels results a reduction in the porosity value. Similar results were shown by Lazaridou et al. (2007) who studied the effects of hydrocolloids on dough rheology and bread quality parameters in gluten–free bread, and reported that higher values of xanthan gum reduced the porosity of bread samples. It could be due to the fact that adding hydrocolloids at high contents in gluten–free bread generally increases the bread crumb elasticity, followed by a reduction in porosity.

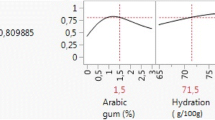

The ANOVA results for sensory evaluation are shown in Table 2. The R2 (0.9879), Adj.R2 (0.9706) and the CV (2.06%) values indicate that the model for sensory evaluation is adequate to describe the experimental results. Roselle seed and egg white powders and interaction term of Roselle seed powder*egg white powder had significant effect (p ≤ 0.05) on sensory evaluation while the xanthan gum and interactions term of other variables were not significant (p > 0.05), (Table 2). Figure 1d, shows the effect of Roselle seed powder*egg white powder interaction on sensory scores. According to the results, when Roselle seed and egg white powders amounts increase up to 30%, the sensory scores increase. Egg white powder is typically added to gluten–free formulations to improve texture and quality of products by gelation and to aid in enhancing foaming and Maillard browning reaction, respectively (Arendt and Bello 2018).

Finally, considering the lowest hardness and the highest porosity and sensory scores the bread containing 30% Rosellle seed powder, 25% egg white powder and 0.73% xanthan gum was picked as the optimized formulation.

Characterization of optimized bread compared to control

Some characteristics of the optimized bread compared to control are shown in Table 4. The oil, protein, fiber, ash (minerals) and moisture contents of optimized sample were significantly (p ≤ 0.05) higher than control. This is because of the high content of these compounds in the Roselle seed powder as well as high amount of protein in egg white (Nyam et al. 2014; Mariod et al. 2013; Elneairy 2014). Besides of nutritional value, it is known that water, oil, protein and fiber contents predetermines textural properties and staling rate of bakery products, especially bread (Pahwa et al. 2016; Pico et al. 2019). The results of crust color evaluation show that inclusion of roselle seed and whey protein powders induced darker crusts (lower values of L*) in optimized bread compared to control. Also, optimized bread compared with control showed higher redness (a*) as a positive parameter in the bread color. This is can be due to darker color of rossele seed powder than rice flour and protein incorporation to optimized bread formulation due to Maillard reactions. These results are agreement with previous studies (Aguilar et al. 2015; Krupa-Kozak et al. 2013; Pico et al. 2019).

Bread staling rate

Scanning electron micrographs of the optimized bread compared to control, at the time of 2, 24 and 48 h after baking are illustrated in Fig. 2a–f. Figure 2a and b show the structure of optimized bread and control after 2 h of baking, respectively. According to Fig. 2a the optimized bread structure right 2 h after cooking, shows a homogeneous network, because of cross–links formed between rice starch and the proteins of Roselle seeds and egg white powders (Moore et al. 2006). Since gluten is responsible for the viscoelastic structure in wheat bread, mimicking gluten by creating a protein network via various proteins can improve the quality structure of gluten–free bread (Moore et al. 2006; Storck et al. 2013). In the optimized bread after 24 h (Fig. 2c), starch granules are detaching from the homogeneous network, while in the control (Fig. 2d), the granules are completely separated from the network. The larger granular crystals were created in the control (Fig. 2f) compared to the optimized sample (Fig. 2e) after 48 h. This could be due to the ability of xanthan gum and Roselle seed and egg white proteins to form strong cohesive viscoelastic network, and prevent from water leaving and reduce the staling of the free gluten bread during storage time (Pahwa et al. 2016).

Conclusion

Based on the RSM analysis, the optimized bread formulation contained 0.73, 30 and 25% of xanthan gum, Roselle seed and egg white powders, respectively. Roselle seed and egg white powders had a good effect on reducing the hardness, as well as increasing porosity and sensory properties of gluten free rice bread. However, xanthan gum does not have a great effect on improving bread quality. In this formulation, Roselle seed and egg whites powders formed the protein network which allowed delay staling of the bread. Therefore, the attempt to improve quality of gluten free rice bread proved to be successful.

References

AACC (2000) Approved methods of the American association of cereal chemists, 10th edn. American Association of Cereal Chemists Inc, St. Paul, MN

Adeboye AS, Babajide JM, Shittu TA, Omemu AM, Oluwatola OJ (2013) Effect of honey as partial sugar substitute on pasting, consumer preference and shelf stability of cassava–wheat composite bread. Nigerian Food J 31(1):13–22

Aguilar N, Albanell E, Miñarro B, Capellas M (2015) Chickpea and tiger nut flours as alternatives to emulsifier and shortening in gluten-free bread. LWT–Food Sci Technol 62(1):225–232

AOAC (2000) Official methods of analysisGaithersburg. 17th edn. The Association of Official Analytical Chemists Methods 925.10, 920.87, 922.06 and 923.03, MD, USA

Arendt EK, Bello FD (2018) Functional cereal products for those with gluten intolerance. CRC Press, New York, pp 446–475

Bize M, Smith BM, Aramouni FM, Bean SR (2017) The effects of egg and diacetyl tartaric acid esters of monoglycerides addition on storage stability, texture, and sensory properties of gluten-free sorghum bread. J Food Sci 82(1):194–201

Cureton P, Fasano A (2009) The increasing incidence of celiac disease and the range of gluten–free products in the marketplace, 1st edn. Wiley, Blackwell, pp 1–15

Demirkesen L, Mert B, Sumnu G, Sahin S (2010) Rheological properties of gluten–free bread formulations. J Food Eng 96(2):295–303

Elneairy N (2014) Comparative studies on Egyptian and Libyan Roselle seeds as a source of lipid and protein. Food Nutr Sci 5(22):2237–2245

Eltayeib AA, Elaziz AA (2014) Physico-chemical properties of Roselle (Hibiscus sabdariffa L.) seeds oil (Elrahad–1) in North Kordofan, Sudan. J Sci Innov Res 3(6):578–582

Fabian C, Ju YH (2011) A review on rice bran protein; its properties and extraction methods. Crit Rev Food Sci Nutr 51(9):816–827

Ferreira SMR, Mello AP, Anjos MCR, Kruger CCH, Azoubel PM, Alves MA (2016) Utilization of sorghum, rice, corn flours with potato starch for the preparation of gluten–free pasta. Food Chem 191:147–151

Gadallah MGE, Mahmoud RM, Yousif EI, Alawneh AR (2016) Effect of adding xanthan and guar gums on quality characteristics of rice gluten–free pan bread. J Agricul Veterinary Sci 9(2):235–246

Ganjloo A, Rahman RA, Bakar J, Osman A, Bimakr M (2014) Optimization of osmotic dehydration of seedless guava (Psidium guajava L.) in sucrose solution using response surface methodology. Int J Food Eng 10(2):307–316

Hager AS, Arendt EK (2013) Influence of hydroxyl propylmethylcellulose (HPMC), xanthan gum and their combination on loaf specific volume, crumb hardness and crumb grain characteristics of gluten–free breads based on rice, maize, teff and buckwheat. Food Hydrocoll 32:195–203

Hainida E, Ismail A, Hashim N, Zakiah A (2008) Effects of defatted dried roselle (Hibiscus sabdariffa L.) seed powder on lipid profiles of hypercholesterolemia rats. J Sci Food Agricul 88(6):1043–1050

Han A, Romero HM, Nishijima N, Ichimura T, Handa A, Xu C, Yue Zhang Y (2019) Effect of egg white solids on the rheological properties and bread making performance of gluten-free batter. J Food Hydrocoll 87:287–296

Kittisuban P, Ritthiruangdej P, Suphantharika M (2014) Optimization of hydroxyl propylmethylcellulose, yeast β–glucan, and whey protein levels based on physical properties of gluten–free rice bread using response surface methodology. LWT–Food Sci Technol 57(2):738–748

Krupa-Kozak U, Bączek N, Rosell C (2013) Application of dairy proteins as technological and nutritional improvers of calcium-supplemented gluten-free bread. Nutrients 5(11):4503–4520

Kurek M, Wyrwise J, Piwinska M, Wierzbicka A (2016) Application of the response surfacemethodology in optimizing oat fiber particle size and flour replacement in wheat breadrolls. CyTA J Food 14(1):18–26

Lazaridou A, Duta D, Papageorgiou M, Belc N, Biliaderis CG (2007) Effects of hydrocolloids on dough rheology and bread quality parameters in gluten–free formulations. J Food Eng 79:1033–1047

Lee CC, Mulvaney SJ (2003) Dynamic viscoelastic and tensile properties of gluten and glutenin gels of common wheats of different strength. J Agric Food Chem 51(8):2317–2327

Marcin K, Jarosław W, Monika P, Agnieszka W (2016) Application of the response surface methodology in optimizing oat fiber particle size and flour replacement in wheat bread rolls. CyTA J Food 14(1):18–26

Mariod AA, Suryaputra S, Hanafi M, Rohmana T, Kardono L, Herwan T (2013) Effect of different processing techniques on Indonesian Roselle (Hibiscus radiates) seed constituents. Acta Sci Pol Technol Aliment 12(4):359–365

Moazeni M, Zarringhalami S, Ganjloo A (2018) Effect of barbari dough enrichment with quinoa whole flour on farinograph characteristics and bread quality. J Food Res 28(4):103–112

Mokhtari Nasrabadi Z, Zarringhalami S, Ganjloo A (2018) Evaluation of chemical, nutritional and antioxidant characteristics of Roselle (Hibiscus sabdariffa L.) seed. Nutr Food Sci Res 5(1):41–46

Moore MM, Heinbockel M, Dockery P, Ulmer HM, Arendt EK (2006) Network formation in gluten–free bread with application of transglutaminase. Cereal Chem 83:28–36

Nicolae A, Radu GL, Belc N (2016) Effect of sodium carboxymethyl cellulose on gluten–free dough rheology. J Food Eng 168:16–19

Nyam KL, Leao SY, Tan CP, Long K (2014) Functional properties of roselle (Hibiscus sabdariffa L.) seed and its application as bakery product. J Food Sci Technol 51(12):3830–3837

Omabuwajo TO, Sanni LA, Balami YA (2000) Physical properties of sorrel (Hibiscus sabdariffa) seeds. J Food Eng 45(1):37–41

Ozturk OK, Mert B (2018) The effects of microfluidization on rheological and textural properties of gluten-free corn breads. Food Res Int 105:782–792

Phongthai S, DAmico S, Schoenlechner R, Homthawornchoo W, Rawdkuen S (2017) Effects of protein enrichment on the properties of rice flour based gluten–free pasta. LWT–Food Sci Technol 80:378–385

Pahwa A, Kaur A, Puri R (2016) Influence of hydrocolloids on the quality of major flat breads: a review. J Food Process 2016:1–9

Pico J, Reguilón MP, Bernal J, Gómez M (2019) Effect of rice, pea, egg white and whey proteins on crust quality of rice flour-corn starch based gluten-free breads. J Cereal Sci 86:92–101

Rosell CM, Barro F, Sousa C, Mena MC (2014) Cereals for developing gluten–free products and analytical tools for gluten detection. J Cereal Sci 59:354–364

Sikorski ZE (2001) Chemical and functional properties of food proteins, 1st edn. CRC Press, New York, pp 335–371

Storck CR, da Rosa ZE, Gularte MA, Elias MC, Rosell CM, Dias ARG (2013) Protein enrichment and its effects on gluten–free bread characteristics. LWT–Food Sci Technol 53(1):346–354

Tounkara F, Amadou I, Le GW, Shi YH (2011) Effect of boiling on the physicochemical properties of Roselle seeds (Hibiscus sabdariffa L.) cultivated in Mali. Afr J Biotechnol 10:18160–18166

Acknowledgements

The current work was supported by University of Zanjan, Zanjan, Iran

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zarringhalami, S., Ganjloo, A. & Mokhtari Nasrabadi, Z. Optimization xanthan gum, Roselle seed and egg white powders levels based on textural and sensory properties of gluten-free rice bread. J Food Sci Technol 58, 1124–1131 (2021). https://doi.org/10.1007/s13197-020-04626-9

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04626-9