Abstract

In the interest of obtaining an effective bearing degradation feature from complex, nonlinear, and nonstationary vibration signals, a new analytical methodology based on local characteristic-scale decomposition (LCD) and relative entropy theory is proposed. On the one hand, LCD is a new and relatively excellent time-frequency analysis method to analyze practical vibration signals polluted by noise. On the other hand, relative entropy theory is a good way to characterize different degradation states by calculating the probability distribution difference between the degradation signals and the normal signal. Combining the above two theories, two new degradation features named LRNE and LRQE are extracted to indicate the bearing degradation trend from normal state to even failure state. The noise resistance ability and extensive applicability of both the features are verified by simulation signal. For further analysis of experimental vibration signals, the two features have a satisfying performance to characterize different bearing degradation states. With the help of gray relational analysis and fuzzy C-means clustering, the proposed two characteristics can identify different bearing degradation states of inner ring fault mode with high accuracy. In the end, the two features are applied to doing bearing failure analysis with the full-life bearing data. The results show that the LRNE and LRQE are sensitive to bearing degradation trend in the whole life of bearing.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Effective degradation state identification and accurate residual life prediction are helpful for timely bearing maintenance and replacement which are crucial to bearing failure prevention. The degradation features or health indicators are used for observing health condition that is important for residual life prediction [1]. However, in the state of degradation, rolling bearing vibration signal shows strong nonlinear and nonstationary characteristics. Although traditional feature extraction methods based on traditional time domain statistics are easy to get, there are disadvantages such as insensitivity to nonlinear and nonstationary signals and vulnerability [2]. Owing to the fact that frequency domain methods describe signals more clearly and can reflect more details of fault degradation degree. Therefore, in recent years, the time-frequency analysis methods have been widely used [3, 4]. These methods can provide the local characteristics of signals in both time domain and frequency domain. There are three kinds of typical time-frequency methods including empirical mode decomposition (EMD), local mean decomposition (LMD), and local characteristic-scale decomposition (LCD). The EMD method proposed by Huang et al is an adaptive decomposition method [5]. This method can effectively decompose the local feature of the signal into several components, and has the ability to process complex nonlinear and nonstationary signal. So it is widely used in fault diagnosis and prediction [6, 7]. However, owing to the EMD problems such as the over envelope, the owing envelope, mode mixing, and the end effect [8], the application effect of this method in practical engineering is affected to some degree. The LMD method proposed by Smith [9] in 2005 is similar to the EMD method, and is also based on the inherent characteristic of vibration signal to decompose complex signals. Because of the use of the division operation to obtain the product function (PF) component, it can reduce the number of iterations and then reduce the end effect. At the same time, the effect of the LMD method overcoming the over envelope and the owing envelope is better than the EMD method [10]. This method can decompose the PF components which can be closely related to fault. In literature [11], by analyzing the spectrum of PF components, the characteristic information of fault frequency is extracted accurately. However, because the traditional LMD method has defects such as a poor ability to extract weak high frequency components, a large amount of iterative calculation, and the frequency confusion [12], it needs to be further optimized. The LCD method is a new adaptive time-frequency analysis method based on intrinsic time-scale decomposition proposed by Yang et al. [13]. This method utilizes piecewise linear transformation to obtain the baseline signal, which can avoid the EMD problems such as over envelope and owing envelope etc. It can also reduce computation complexity of EMD and LMD. The iteration number is relatively small and the speed is fast, so it is more suitable for online real-time monitoring and processing of signals [14]. This new time-frequency analysis method has been mainly employed in vibration signal processing and fault diagnosis and has made some achievements in the past few years. Zheng et al. [15] utilized LCD and fuzzy entropy firstly to extract bearing fault feature for diagnosis which performed effectively. On this basis, Cheng et al. [16] proposed a partly ensemble LCD (PELCD) that could help extract bearing fault features in time-frequency domains. However, this methodology has seldom been reported in data-driven failure analysis and bearing residual life prediction.

In recent years, the methods based on nonlinear parameter feature extraction are widely used in the field of degradation state identification and residual life prediction. One typical kind is the information entropy theory including sample entropy, permutation entropy, relative entropy, and so on [17, 18]. These years, some researchers have a strong interest in relative entropy in engineering field. Schmitt et al. [19] put forward a predictability analysis method based on relative entropy measures for bearing fault detection and the result was satisfying. The relative entropy is an index which measures two probability distribution deviation. The smaller the relative entropy of two probability distributions is, the greater the similarity of two probability distributions is, and the converse is also true. With the constant deepening of the rolling bearing degradation degree, the probability distribution of vibration signal energy is constantly changing. So the relative entropy between vibration signals under the normal state and signals under degradation state can be used to indicate the bearing degradation trend.

Based on the above analysis, the paper puts forward the concept of the LCD relative spectral entropy. This method eliminates the noise which has nothing to do with the degradation state by means of local characteristic-scale decomposition and reconstruction. By the calculation of the reconstructed signal, we can get two degradation characteristics, the LCD relative energy spectrum entropy (LRNE) and the LCD relative singular spectrum entropy (LRQE). To solve the problems that the vector group’s volatility is large and the discrimination degree is not high in the same kind of degradation state, Gray relational analysis method based on fuzzy C-means clustering optimization is proposed. This method can get the standard feature vector set which can distinguish different degradation states accurately by means of fuzzy C-means value. By calculating the Gray correlation degree between feature vectors of different samples and the standard feature vector, the rolling bearing degradation state identification is realized. What’s more, the both features are applied in the process of full-life bearing failure analysis and they have a good ability to indicate full-life degradation trend which is important to predict when the bearing will fail.

LCD Principle Algorithm

The Conditions ISC Needs to Satisfy

In the literature [20], a single component signal with physically meaningful instantaneous frequency is defined based on the local characteristic parameters of the extreme points, and it’s named intrinsic-scale component (ISC). In order to make the instantaneous frequency of physical sense, the ISC component needs to meet the following two conditions.

-

(i)

In the whole time series, any adjacent two extreme value points have opposite sign.

-

(ii)

In the corresponding time series range, the sequence of extreme value points is \(X_{k}\) and the corresponding moment is \(\tau_{k}\) , where \(k = 1,2, \cdot \cdot \cdot ,M\) . For any two adjacent maximums or minimums \(L_{k}\) and \(L_{k + 2}\) , function of \(\tau_{k}\) is H:

The ratio between the value of the function \(H_{k + 1}\) and the maximum or minimum \(L_{k + 1}\) corresponding to the time \(\tau_{k + 1}\) remains nearly unchanged.

The above two conditions have ensured that the ISC component has local symmetry and possesses a single mode between two adjacent extrema. Hence the instantaneous frequency of the ISC is meaningful in a physics view.

The Process of Local Characteristic-Scale Decomposition

Assuming that the rolling bearing vibration signal is made up of different ISC components which are unrelated, the LCD method can decompose the vibration signal into several ISC components. The specific decomposition steps [20] are as follows:

(i) Calculate extreme points \(L_{k} \left( {k = 1,2, \ldots j} \right)\) of time series, and then calculate the fitting points

(ii) On the basis of extending the endpoints in time series, use cubic spline function for fitting all \(g_{k}\), and at last get the mean curve \(Bg_{1} (t)\).

(iii) Eliminate the mean curve from the original signal.

(iv) Judge whether \(P_{1}\) meets the ISC conditions or not. If it is satisfying, take \(P_{1}\) as the first ISC component, signed as \(ISC_{1}\). If not, take \(P_{1}\) as the original signal and repeat steps (i), (ii), and (iii). And then cycle k times until \(P_{k}\) meets the ISC conditions, thus \(P_{k}\) is the first component \(ISC_{1}\) of signal \(x(t)\).

(v) Eliminate \(ISC_{1}\) from \(x(t)\), and we can get a new signal \(r_{1}\). Take \(r_{1}\) as the original signal and repeat steps (i), (ii), (iii), and (iv), thus we can get the second component \(ISC_{2}\). Repeat the cycle n times until \(r_{n}\) is a monotonic function, then we can get all ISC components of the signal \(x(t)\).

(vi) Considering that most of information which is closely related to the degradation state of rolling bearing is at the high frequency section, select the first m ISC components with high frequency so as to remove noise and other interference components. The reconstructed signal is set as \(x'(t)\).

Computation and Validation of the LCD Relative Spectral Entropy

Based on extremum point analysis, the LCD method decomposes the original signal with local characteristics and refactors the decomposed ISC components selectively. In this way, the noise components can be removed with adaptability. Compared with the rolling bearing vibration signal at normal state, the probability distribution of the signal energy which is at degradation state is changing constantly. Therefore, on the basis of LCD decomposition and refactoring for the rolling bearing signal at normal state and the one at a certain fault state, this paper, in combination with the concept of relative energy spectrum entropy and relative singular spectrum entropy, presents the two degradation characteristics, LRNE and LRQE. These two degradation features define the LCD relative entropy from different angles of energy spectrum and singular value spectrum. Compared with one-dimensional degradation feature, multidimensional degradation features can effectively avoid the errors in the identification of different degradation states.

The Definition of LRNE and LRQE

For the definite degradation degree of the specific rolling bearing fault mode, supposing that a total M fault samples are collected, the relative energy spectrum entropy of the fault sample \(x_{i} (t)\left( {i = 1,2,, \ldots M,\;t = 0,1,2, \ldots N - 1} \right)\) and the group of normal signal \(x_{b} (t)\left( {t = 0,1,2, \ldots N - 1} \right)\) can be calculated by the following steps:

-

(i)

Decompose the obtained normal samples and fault samples with LCD and choose the first r ISC components to refactor \(L_{b} (t,f)\) and \(L_{i} (t,f)\).

-

(ii)

The energy of normal sample and fault sample at frequency \(f_{g}\) is calculated as follows:

Based on this, the energy of the sample sequence at all frequencies is calculated, and then the LCD energy spectrum of normal and fault samples can be calculated respectively into \(E_{b} = \left[ {E_{b}^{1} ,E_{b}^{2} , \ldots ,E_{b}^{G} } \right]\) and \(E_{i} = \left[ {E_{i}^{1} ,E_{i}^{2} , \ldots ,E_{i}^{G} } \right]\).

(iii) Calculate the sum of energy of all samples at the specific frequency as follows:

(iv) The proportion of the energy of \(x_{b} \left( t \right)\) and \(x_{i} \left( t \right)\) at the specific frequency in the total energy is:

(v) According to the concept of relative entropy, the LCD relative energy spectrum entropy of fault sample \(i\) and normal sample is defined as follows:

From the definition of LRNE, it’s obvious that \({\text{LRNE}}_{b}^{i}\) can reflect the differences between fault samples and normal samples at the aspect of energy probability distribution. The bigger LRNE is, the greater the difference between degradation state and normal state is and vice versa.

Meanwhile, due to the selection of ISC components in the process of LCD, the index is adaptive and stable to different noise conditions. As a result, LRNE can characterize different degradation states of rolling bearings.

On the basis of the LCD relative entropy, combined with singular value decomposition (SVD), this paper proposes the concept of the LCD relatively singular spectrum entropy, named LRQE. Decompose the time-frequency spectrum \(L_{b} (t,f)\) and \(L_{i} (t,f)\) with SVD and we can get the singular value spectrum of the normal sample \(\sigma_{b} = \left[ {\sigma_{b}^{1} ,\sigma_{b}^{2} , \ldots ,\sigma_{b}^{G} } \right]\). For any fault sample group i, its singular value spectrum is \(\sigma_{i} = \left[ {\sigma_{i}^{1} ,\sigma_{i}^{2} , \ldots ,\sigma_{i}^{G} } \right]\). Combined with the relative entropy theory, the relevant probabilities are defined as follows:

where \(\sigma_{L}^{g} = \sum\limits_{i = 1}^{M} {\sigma_{i}^{g} + } \sigma_{b}^{g}\).

Hereby, we can define the LCD relative singular spectrum entropy of the fault sample group i and the normal sample as below:

In conclusion, LRQE can reflect the difference about singular value probability distribution between degradation state and normal state of the rolling bearings. To be particular, the index can characterize the degradation degree at the specific fault mode of the rolling bearings.

The Simulation Signal Analysis

In order to verify the feasibility and effectiveness of the proposed method and the ability of LRNE and LRQE to characterize the degradation state of the rolling bearings, the simulation signal is used to simulate the fault degradation state of the rolling bearings. The simulation signal is chosen as follows [21]:

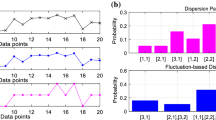

where \(0.05t^{2} \cos (2\pi \times 30t + 2)\) is the rolling bearing fault impact signal whose cosine coefficient \(0.05t^{2}\) reflects the process of the continuous deepening of the fault degree. The formula \(\cos (2\pi \times 80t)\) indicates the signal of rolling bearing at normal state. The formula \(n(t)\) represents the added Gauss noise. The number of signal sampling points is 20,480. The sampling frequency is\(fs = 1024\). In order to study the adaptability of the LCD relative entropy method to different noise environments, six kinds of signal-to-noise ratio (SNR) are set up respectively: \(\pm 1{\text{dB}}\), \(\pm 3{\text{dB}}\) and \(\pm 6{\text{dB}}\). Figure 1 is the time domain waveform of the simulation signal whose SNR is \(+ 1{\text{dB}}\).

Take the signal whose SNR is \(+ 1{\text{dB}}\) as an example. At first, the signal \(x(t)\) is divided into ten groups and labeled in order. The sampling number of the every group is 2048. The ten sets of data are used to represent approximately the process of the continuous deepening degradation degree of the rolling bearing at a specific fault mode. The normal signal is used as reference and the two characteristics of the ten sets of data, LRNE and LRQE are calculated. In the same way, we can calculate the characteristic values of the other five kinds of signals with different SNRs. The results are shown in Fig. 2.

Figure 2 shows that the two characteristics including LRNE and LRQE are increasing with the deepening degree of the degradation in different noise conditions. It’s indicated that the probability distribution of the fault signal deviates more and more from that of the normal signal with the continuous evolution of the degradation state. From the simulation results, the two kinds of characteristics have strong correlation with the degradation state, and have good adaptability to different noise intensities, which proves the effectiveness of the proposed method.

Real Signal Degradation Feature Extraction

Rolling Bearing Test Data Description

In order to verify the effectiveness of the proposed feature extraction method and state identification method in the practical engineering field, the experimental data of the rolling bearing in the Electrical Engineering Laboratory of Case Western Reserve University [22] are analyzed. The test object is SKF6205-2RS deep groove ball bearing which is shown in Fig. 3. The vibration signals of different operating conditions are collected. And there are four operating conditions including operation condition 1 \((n = 1797r/\hbox{min} ,P = 0\,{\text{kW}})\), operation condition 2 \((n = 1772r/\hbox{min} ,P = 0.75\;{\text{kW}})\), operation condition 3 \((n = 1750r/\hbox{min} ,P = 1.5\,{\text{kW}})\), operation condition 4 \((n = 1730r/\hbox{min} ,P = 2.25\;{\text{kW}})\). Vibration signal monitoring sampling frequency is divided into two cases of 12 and 48 KHz. In this experiment, the local damage of different degrees is set up by means of electrical discharge machining. The data collection is carried out on the faults of the bearing inner ring, the bearing outer ring, and the rolling body. In each fault mode, five kinds of different degrees of fault are set. The diameters of damage are 0 (normal), 0.18, 0.36, 0.54, and 0.72 mm.

The data of operation condition 1 are used for analysis. Different degradation degrees of rolling bearing are characterized by different damage diameters. The sampling frequency is 12 KHz and the fault mode is inner ring fault. The number of sampling points in each group is set as 20,480. Figure 4 is time domain diagrams for different degradation degrees of the rolling bearing.

(a) Vibration signal of rolling bearing under different degradation states. (b) Vibration signal of rolling bearing under different degradation states. (c) Vibration signal of rolling bearing under different degradation states. (d) Vibration signal of rolling bearing under different degradation states. (e) Vibration signal of rolling bearing under different degradation states

From Fig. 4, the time domain characteristics of the five degradation states are not particularly evident and especially the distinction among degradation state 2, 3, and 4 is not very high. Therefore time domain analysis cannot be used to achieve the degradation state identification. However, we can use the method of LCD relative entropy to extract the degradation feature, and ultimately achieve state identification.

Degradation Feature Extraction for the Rolling Bearings

From the upper analysis, there are five kinds of degradation states including the normal state in the fault mode of the bearing inner ring, which are recorded as degradation state 0, 1, 2, 3, and 4 corresponding to the inner ring damage diameter 0, 0.18, 0.36, 0.54, and 0.72 mm. Ten sets of date are selected randomly as the training samples of degradation state identification from the original data of every degradation states. Each set of data contains 2048 points, which constitute a set of \(5 \times 10\) training samples. At random, one set of date from the normal signal is taken as the reference standard for the calculation of the LCD relative entropy. By calculation, we can get the two indexes LRNE and LRQE of different degradation states for the ten sets of date. The waveforms constituted by LRNE and LRQE are shown in Fig. 5.

Analysis of Fig. 5 shows that the two degradation characteristics are gradually increasing with the constant development of degradation. The characteristic levels of different degradation states are also different at the same time. And that can ensure good ability for degradation state distinction and identification. Therefore, the two characteristics can be fused into a two-dimensional feature vector group which is regarded as the judging basis of degradation state identification.

The Degradation State Identification of Rolling Bearings

Gray Relational Analysis Method Based on Fuzzy C-Means Clustering Optimization

From the above analysis, in the process of rolling bearing performance evolution from normal state to fault state, although the degradation index LRNE and LRQE can distinguish different degradation states, for the certain training group 6, degradation state 2 and 3 can’t be distinguished very clearly. The volatility of the degradation characteristics of the same degradation state is still relatively large. Consequently, the two-dimensional feature vector of any single training group can’t be used as a criterion for recognizing different degradation states. At the same time, the rolling bearing degradation states show a strong ambiguity, that is, the boundary of the degradation state is difficult to be determined. The fuzzy clustering method based on fuzzy theory can be applied to characterize the degradation states by computing cluster centers. And that is statistically significant.

The fuzzy clustering algorithm based on fuzzy theory is fast. Compared with other fuzzy clustering algorithm, fuzzy C-means (FCM) algorithm is more mature and widely used [23]. The main idea of this algorithm is to make the division fuzzy. And the objective function is shown as follows:

\(X\) is a one-dimensional array, expressed as \(X = [x_{1} ,x_{2} , \cdot \cdot \cdot ,x_{n} ]\), \(x_{i} \in R^{S}\). \(V\) is one-dimensional vector made up of c clustering centers, expressed as \(V = [v_{1} ,v_{2} , \cdot \cdot \cdot ,v_{c} ] .\) \(\mu_{ij}\) is a membership function of \(x_{j}\) for \(S_{i}\).\(U = \left\{ {\left. {\mu_{ij} } \right\}} \right.\) is a membership function matrix of \(c \times n\) order. \(S_{i}\) represents a subset of the \(X\) division. The distance between the sample point \(x_{j}\) and the clustering center \(\nu_{i}\) of the sample group i is indicated as \(d_{ij} = \left\| {x_{j} - \nu_{i} } \right\|\), which is chosen as Euclidean distance. m is the weighted coefficient, generally, \(m \ge 1\).

The essence of the algorithm is to search a set of central vector by iteration, which makes the squared error of the distance from each sample point to the vector minimum. And the clustering center can be obtained by calculating.

On the condition that the sample array \(X\), the total number of categories \(c\) and the weighed coefficient m are known, the fault sample clustering centers can be obtained by this method to determine the standard degradation state matrix, which can guarantee the true reflection of different degradation states.

Gray relational analysis [24] is a dynamic mapping of the relative changes in the data. This theory is based on the gray process, which can represent the relative changes of different factors in the development of the system. If the two factors in the developing process are changing in the same way, the gray correlation degree is relatively large, otherwise it’s small. Considering the degradation evolution of the rolling bearing as a gray process, the paper presents a gray correlation method optimized by fuzzy C-means clustering for the identification of the rolling bearing degradation states.

The process of the rolling bearing state identification is represented in Fig. 6. Firstly, the LCD relative entropy method is used to extract features of the training samples and the analyzing samples. The standard fault state matrix can be obtained using FCM clustering. And then the gray correlation degree between the sample bent solicitation and the standard matrix can be calculated as the basis for degradation state identification.

The Standard Fault State Matrix Computation by FCM

Based on the feature data of the training samples extracted from the “Degradation feature extraction for the rolling bearings” section, FCM algorithm is used to conduct clustering analysis of ten degradation feature vectors at each degradation state. The concrete steps are as follows:

- Step 1:

-

Parameter Setting. A set of feature vectors, which are used to represent the degradation states, are used as the array of samples, named X. The number of categories is \(c = 5\). The iterative stopping threshold is \(\varepsilon = 0.001\). The initial clustering center is \(\nu_{i}^{(0)}\) and the initial number of iteration is \(p = 0.\)

- Step 2:

-

Clustering Centers Calculation. The iteration is computed as follows:

$$\nu_{{_{i} }}^{(p + 1)} = \frac{{\sum\limits_{j = 1}^{n} {(\mu_{{_{ij} }}^{(p + 1)} )^{m} x_{j} } }}{{\sum\limits_{j = 1}^{n} {(\mu_{{_{ij} }}^{(p + 1)} )^{m} } }}, \quad i = 1,2, \cdots ,c$$(17) - Step 3:

-

The iteration will stop when it meets the condition \(\left\| {v_{i}^{(p)} - v_{i}^{(p + 1)} } \right\| < \varepsilon.\) The result of clustering is shown in Fig. 7

From the clustering results, we can get the clustering centers of 5 degradation states as shown in Fig. 7. The standard fault state matrix can be determined by the five-point coordinates like this:

Degradation State Identification Based on Gray Correlation Degree

Ten sets of analysis samples from each of the five different degradation states are chosen at random to test accuracy of the degradation state recognition method. At first, \(5 \times 10\) sets of data are calculated to obtain the two-dimensional feature vector [LRNE LRQE]. And then gray correlation degree between the certain feature vector and the standard fault state matrix is computed. The higher the gray correlation degree between a feature vector and a row of the standard fault state matrix is, the closer these two states are. Therefore, the result of state identification is the degradation state whose gray correlation degree is the highest. In this way, we can determine whether the test results are consistent with the actual state so as to verify the validity of the method. The results are shown in Tables 1, 2, 3, 4, and 5.

The analysis of Tables 1, 2, 3, 4, and 5 shows that the identification results of Degradation State 0, 1, 3, and 4 are completely consistent with the actual degradation state. Only one group of sample’s identification result of Degradation State 2 is mistaken as Degradation State 1. In the fifty sets of random samples, only one recognition error occurs and that is to say, the recognition accuracy rate is as high as 98%.

Therefore, the relative spectral entropy of LCD can be used as the degradation characteristics, and the gray correlation analysis based on FCM clustering can be used to identify the degradation states of the inner ring fault accurately.

Application for Bearing Failure Analysis

In order to demonstrate the ability of the two features to indicate bearing degradation trend in failure analysis, a full-life experiment is conducted in Hangzhou bearing test and research center. As is shown in Fig. 8a, the test platform mainly consists of an ABLT-1A bearing test machine, a signal acquisition module, and state monitoring equipment. As Fig. 8b shows, four CA-YD-139 acceleration sensors are respectively fixed up on four-bearing test stations and connected to DH-5920 dynamic signal acquisition instrument. Four sets of rolling bearings can be intensively tested and multiple sets of full-life vibration data can be stored simultaneously. What’s more, four thermal resistors and a YD-1 acceleration sensor are connected with a signal amplifier to monitor the operating parameters. The sampling interval is ten minutes and when the test bench running time reaches 9600 minutes, the index exceeds the alarm threshold, and the machine is shut down. Inner ring pitting (Fig. 9b) occurs in the 6204 bearing (Fig. 9a) at No.4 station and that results in bearing failure.

The collected 960 groups of vibration data record the whole process of rolling bearing from normal state to failure state. The first data group is recognized as the normal state group. Thus the two features, LRNE and LRQE are calculated and normalized as Fig. 10 shows. These two features increase with the bearing degradation and have a good performance to follow the degradation trend from normal state to failure state. Different from general features like root mean square (RMS), the proposed features are sensitive to bearing degradation trend and can reflect different degradation states of rolling bearing clearly. And this ensures that LRNE and LRQE have the potential to improve effect of bearing failure analysis and accuracy of bearing residual life prediction which we will study very soon.

Conclusion

In order to obtain an effective degradation feature that can reflect different degradation states in the whole life of bearings, LRNE and LRQE are proposed as degradation indicators on the basis of LCD and the relative entropy theory. By signal analyzing and application in bearing failure analysis, we can reach the following conclusions:

-

1.

By means of LCD, the method can eliminate the noise and other unrelated components and improve the adaptability of the two indicators facing different noise environments. Owing to the probability distribution difference between the degradation signals and the normal signal, relative entropy theory guarantees that the two indicators are sensitive to the bearing degradation state changing and have a good performance to discover early degradation. And this contributes to bearing residual life prediction and preventing bearings from unexpected failure that can cause equipment damages and even accidents.

-

2.

The gray relational analysis method based on fuzzy C-means clustering is effective to overcome the defects of the degradation characteristics data. The reasonable determination of characteristics of the standard degradation state ensures the high accuracy of bearing degradation state identification. And this is helpful for bearing performance assessment which has significance to conduct timely condition based maintenance (CBM) and increase service life of rotating machines.

References

Shuai Zhang, Yongxiang Zhang, Lei Li et al., Rolling elements bearings degradation indicator based on continuous hidden markov model. J Fail. Anal. Preven. 15, 691–696 (2015)

Aiwina Heng, Sheng Zhang, Andy C.C. Tan et al., Rotating machinery prognostics: state of the art, challenges and opportunities. Mech. Syst. Signal Process. 23, 724–739 (2009)

P.K. Kankar, Fault diagnosis of rolling element bearing using cyclic autocorrelation and wavelet transform. Neurocomputing 110, 9–17 (2013)

Fu Kai, Qu Jiangfeng, Yi Chai et al., Hilbert marginal spectrum analysis for automatic seizure detection in EEG signals. Biom. Signal Process. Control. 18, 179–185 (2015)

Xiaomin Zhao, Tejas H. Patel, Ming J. Zuo, Multivariate EMD and full spectrum based condition monitoring for rotating machinery. Mech. Syst. Signal Process. 27, 712–728 (2012)

Cong Wang, Meng Gan, Chang’an Zhu. Non-negative EMD manifold for feature extraction in machinery fault diagnosis. Measurement 70, 188–202 (2015)

Bingbo Cui, Xiyuan Chen, Improved hybrid filter for fiber optic gyroscope signal denoising based on EMD and forward linear prediction. Sens Actuators A 230, 150–155 (2015)

Li Lin, Ji Hongbing, Signal feature extraction based on an improved EMD method. Measurement 42, 796–803 (2009)

J.S. Smith, The local mean decomposition and its application to EEG perception data. J R Soc Interface 2(5), 443–454 (2005)

Y.X. Wang, Z.J. He, Y.Y. Zi, A comparative study on the local mean decomposition and empirical mode decomposition and their applications to rotating machinery health diagnosis. J. Vib. Acoust. 132(2), 613–624 (2010)

Y.X. Wang, Z.J. He, Y.Y. Zi, A demodulation method based on improved local mean decomposition and its application in rub- impact fault diagnosis. Meas. Sci. Technol. 20(2), 1–10 (2009)

J. Cheng, J. Zheng, Y. Yang, A nonstationary signal analysis approach—the local characteristic-scale decomposition method. J. Vibr. Eng. (P.R.China) 25(2), 215–220 (2012)

Y. Yang, M. Zeng, J. Cheng, Research on local characteristic-scale decomposition and its capacities. J. Vibr. Eng. (P.R.China) 25(5), 602–608 (2012)

J.-S. Cheng, Y. Yang, Y. Yang, Local characteristic-scale decomposition method and its application to gear fault diagnosis. J. Mech. Eng. (P.R.China) 48(9), 64–71 (2012)

Jinde Zheng, Junsheng Cheng, Yu. Yang, A rolling bearing fault diagnosis approach based on LCD and fuzzy entropy. Mech. Mach. Theory 70(6), 441–453 (2013)

J. Cheng, J.-D. Zheng, Yanshan Yang. Fault diagnosis model for rolling bearing based on partly ensemble local characteristic-scale decomposition and Laplacian score. J. Vibr. Eng. 27(6), 942–950 (2014)

Yukui Wang, Hongru Li, Bing Wang et al., Spatial Information Entropy and Its Application in the Degradation State Identification of Hydraulic Pump. Math. Probl. Eng. 2015(7), 1–11 (2015)

Yingjie Liang, Wen Chen, A relative entropy method to measure non-exponential random data. Phys. Lett. A 379, 95–99 (2015)

H.L. Schmitt, L.R.B. Silva, P.R. Scalassara, et al. Bearing fault detection using relative entropy of wavelet components and artificial neural networks. in IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics & Drives. 2013, pp. 538–543

Y. Yang, M. Zeng, J. Cheng, A new time-frequency analysis method—the local characteristic-scale decomposition. Hunan Univ. (P.R.China) 39(6), 35–39 (2012)

D. Xu, Y. Xu, X. Chen et al., Residual fatigue life prediction based on grey model and EMD. J. Vibr. Eng. (P.R.China) 24(1), 104–110 (2011)

Loparo K. A. Case Western Reserve University Bearing Data Center [EB/OL]. http://www.eecs.cwru.edu/laboratory/bearing.

X.I.N.G. HongJie, H.U.A. Baogang, An adaptive fuzzy C-mean clustering-based mixture of experts model for unlabeled data classification. Nero Comput. 71, 1008–1021 (2008)

Yong-huang Lin, Pin-Chan Lee, Ta-Peng Chang, Practical expert diagnosis model based on the grey relational analysis technique. Expert Syst. Appl. 36(2), 1523–1528 (2009)

Acknowledgments

This project is supported by National Natural Science Foundation of China (Grant No. 51541506).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, H., Li, H. & Xu, B. Rolling Bearing Degradation State Identification Based on LCD Relative Spectral Entropy. J Fail. Anal. and Preven. 16, 655–666 (2016). https://doi.org/10.1007/s11668-016-0133-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-016-0133-y