Abstract

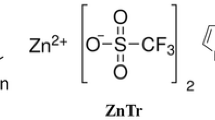

A new series of gel polymer electrolytes (GPEs) based on an optimized composition of polymer blend-salt matrix [poly(vinyl chloride) (PVC) (30 wt%) / poly(ethyl methacrylate) (PEMA) (70 wt%): 30 wt% zinc triflate Zn(CF3SO3)2] containing different concentrations of 1-ethyl-3-methylimidazolium bis(trifluoromethylsulfonyl) imide (EMIMTFSI) ionic liquid has been prepared by simple solution casting technique. The prepared films of gel polymer membranes have been characterized utilizing complex impedance spectroscopy, differential scanning calorimetry (DSC), thermogravimetric (TG), and cyclic voltammetry (CV) analyses. The dielectric constant and ionic conductivity pursue similar trend with increasing EMIMTFSI concentration. The addition of ionic liquid in varied amounts into the optimized polymer blend-salt system effectively reduces the glass transition temperature (Tg) of the film as revealed from differential scanning calorimetry results. The origin of an improved thermal stability and feasible cyclic performance in respect of the best conducting sample of the resultant gel polymer electrolytes was also examined by utilizing thermogravimetric and cyclic voltammetry measurements.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Gel polymer electrolytes (GPEs) are regarded as the most proficient candidates in replacing solid and liquid polymer electrolytes in many energy storage devices including batteries and supercapacitors due to their numerous discrete benefits such as less reactivity and leakage, high conductivity value, better safety against electrical and mechanical exploitation, flexibility, and improved manufacturing integrity [1, 2]. These gel polymer electrolytes are prepared by entrapping high dielectric constant plasticizers/solvents or their solutions with different salts of lithium, sodium, etc. in a polymer host such as poly (methyl methacrylate) (PMMA), poly (vinylidene fluoride) (PVdF), poly (vinylidene fluoride-co-hexafluoropropylene) (PVdF-HFP), poly (ethyl methacrylate) (PEMA), poly (vinyl chloride) (PVC), and poly (ethylene oxide) (PEO). The GPEs possess additionally most beneficial features like wide electrochemical stability windows, exceptional interfacial stability, free-standing reliability, high ionic mobility, and charge carrier concentrations. The relevant ionic conduction processes in the case of these gel polymer electrolytes are usually governed by the retainment of solvent/salt solutions within the polymer matrix whereas the mechanical/dimensional steadiness of the gel films is provided by the host polymer [3,4,5,6].

High dimensionally stable gel polymer electrolytes (GPEs) were produced by blending of two polymers in which the first phase of the polymer within the blend is accountable for absorbing the electrolyte active species contributing to the improvement in the ionic conductivity, whereas the second phase of the polymer is held responsible for enhancing the overall mechanical integrity of the blend [7]. Much research work has already been reported on GPEs based on PVC/PMMA, PVdF/PMMA, PAN/PEO blends [5], and recently new blends consisting of PVC and PEMA have also been intensely investigated by virtue of their outstanding collective mechanical and conductivity properties.

PEMA is a methacrylic ester polymer having excellent chemical and surface resistivity and has good optical transparency too. The presence of carboxylic (−COOH) group in PEMA improves the interconnecting pathways thereby facilitating the movement of ions through the segments of the polymer chain. PEMA is considered as a better quality performing polymer than PMMA with a large pendant group thereby favoring additional free volume by limiting the close package of polymer chains and increasing the flexibility of the polymer backbone. Furthermore, the translational mobility of the polymer segments is increased by the effective separation of polymer chains thereby reducing the glass transition temperature of the resultant polymer matrix. The cations originating from inorganic salts (Zn2+) would easily coordinate with the lone pair of electrons in PEMA so as to form polymer-salt complexes and hence provide ionic conduction [4, 8, 9]. On the other hand, PVC is recognized for its admirable features including miscibility and compatibility with most of the solvents and plasticizers. In addition, the lone pair of electrons in the chlorine atom of PVC strengthens the polymer backbone thereby rendering appreciably good mechanical properties as well. PVC is inexpensive and easy to process and therefore assists an easy dissolution of inorganic salts thereby possessing the medium dielectric constant of ε ≈ 3.0 [10].

Although high energy density and rechargeable properties of lithium make them a striking source for applications in lithium batteries, certain negative aspects like high cost, complication in managing lithium electrodes, and safety restrictions have incited many groups of researchers to work on alternatives such as sodium-, magnesium-, and zinc-based rechargeable batteries based on GPEs [11]. In terms of better safety and lower cost, investigations on rechargeable batteries based on zinc salt are supposed to have an ample scope in the near future. In the present work, zinc triflate salt has been used as a dopant salt in an electrolyte due to its high natural abundance, stability, high specific energy, large anion size, great delocalized charges, and low toxicity permitting for urban waste disposal distinct from lithium-based systems [2, 12].

During the present investigation on gel polymer electrolytes based on PVC/PEMA blend, the ionic conductivity of the polymer matrix doped with an inorganic salt (zinc triflate) is planned to be enhanced further by adding an appropriate room temperature ionic liquid (RTIL), namely 1-ethyl-3-methylimidazolium bis(trifluoromethylsulfonyl) imide (EMIMTFSI), which is expected to act as a substitute for organic solvents like ethylene carbonate (EC), propylene carbonate (PC) etc. due to their exclusive properties like non-volatility, high ionic conductivity, non-flammability, low vapor pressure, low melting points, good chemical and thermal stabilities, and wider electrochemical potential windows. In general, room temperature ionic liquids (RTILs), consisting of bulky asymmetric organic cations paired with a range of different organic/inorganic anions, remain in the liquid state over a wide temperature range from room temperature to a higher temperature of 100 °C, and thus, the existence of liquid form enhances their miscibility with the added constituents without necessitating any additional dissolving procedure. The ionic liquid is predicted to be stable against moisture and air which is a particular distinctive feature that separates it from other types of liquids. In addition, its good structural characteristics and presence of polar groups aid in the transportation of mobile cations within the polymer matrix thereby providing additional transit sites for the ions to hop. The choice of most widely studied anions of anionic class, bis (trifluoromethylsulfonyl) imide (TFSI), is due to the occurrence of large delocalized negative charges along S–N–S core which accedes the formation of low melting fluid ionic liquids when it is paired with an extensive array of counterions like ammonium, pyridinium, imidazolium, and pyrrolidinium cations. The wide-ranging properties like low vapor pressure, high ionic conductivity, large electrochemical window, low glass transition temperature, and effortless solubility in variety of organic solvents highlight the selection of imidazolium-based anions [4, 13, 14].

Therefore, RTILs are promising plasticizers that could be exploited for the preparation of GPEs with improved thermal and electrochemical properties. Hence, the present study focuses mainly on the preparation of PVC/PEMA blended polymer matrix by solution casting method using N, N-Dimethyl formamide (DMF) as a solvent, zinc triflate as a dopant salt, and 1-ethyl-3-methylimidazolium bis(trifluoromethylsulfonyl) imide (EMIMTFSI) as a plasticizer. The effect of the addition of ionic liquid on the properties of the polymer blend-salt membranes such as ionic conductivity, dielectric property, and thermal and electrochemical properties has been systematically evaluated with the technological objective of using such ionic liquid-based gel polymer electrolytes for prospective applications in zinc batteries.

Experimental

Materials

Commercially available PVC with an average molecular weight 233,000 gmol−1, PEMA with an average molecular weight 515,000 gmol−1, inorganic dopant salt, zinc trifluoromethanesulfonate [Zinc triflate, Zn(OTf)2] Zn(CF3SO3)2 with a molecular weight 363.53 gmol−1, and ionic liquid 1-ethyl-3-methylimidazolium bis(trifluoromethylsulfonyl) imide (EMIMTFSI) were purchased from Sigma-Aldrich, USA. The dopant salt, Zn(OTf)2, was dried in vacuum oven at 100 °C for 1 h before use in order to remove the residual moisture content while specimens of relevant polymers including PVC, PEMA and ionic liquid (EMIMTFSI) were used as received without any further purification.

Preparation of PVC/PEMA blend-based gel polymer electrolytes

The series of gel polymer electrolyte samples based on PVC/PEMA blend were prepared utilizing the “solution-cast” technique by varying the amount of EMIMTFSI in five different weight percentages (20, 40, 60, 70, and 80 wt%) incorporated into solutions containing an optimized amount of the present polymer blend and salt [0.105g PVC, 0.245g PEMA and 0.15g Zn(OTf)2] in 25 ml of the common solvent namely N-N dimethyl formamide (DMF), and such solutions were stirred well at room temperature for several hours until the mixture gets a homogenous and gelly nature. The clear homogeneous mixture was then cast by dispersing the suspension onto glass Petri dishes and heated in a vacuum oven at 60 °C for 24 h until free-standing gel polymer electrolyte films were formed. The semi-transparent thin film samples thus obtained were subsequently stored at room temperature inside a desiccator in order to eradicate any excess trace of solvent. The resulting series of gel polymer complexes involving five different loadings of 20, 40, 60, 70, and 80 wt% EMIMTFSI have been designated as IL2, IL4, IL6, IL7, and IL8, respectively.

Characterization techniques

The complex impedance analysis of these gel polymer electrolytes carried out using a computer-controlled Hewlett-Packard Model HP4284A Precision LCR Meter in the frequency range 1 MHz–20 Hz was reported in our previous work [12]. Additionally, detailed dielectric analyses have been carried out on the basis of dielectric parameters as derived from the impedance data.

The calorimetric measurements were performed on all the freshly prepared specimens using a differential scanning calorimeter, DSC Q200 V24.4 Build 116, instrument in the temperature range 30 to 115 °C under the constant nitrogen flow rate of 50 ml min−1. The set of thin film samples were utilized for thermal analysis, and specimens were hermetically crimped in closed aluminum pans and heated slowly from 25 to 100 °C with a view to remove any traces of solvent and water. The temperature was maintained at 100 °C for 1 min to ensure the process of complete evaporation. These samples were furthermore rapidly quenched to 30 °C and subsequently reheated to 115 °C at a scan rate of 10 °C min−1. The series of thermograms corresponding to the second heating scan were recorded, and glass transition temperature Tg values were obtained from the inflection point of the relevant DSC curve and considered for further analysis.

The thermal stability of the best conducting sample (IL8) of the gel polymer electrolyte system incorporated with 80 wt% EMIMTFSI was determined by thermogravimetric analysis (TGA) using TGA Q500 V20.10 Build 36 instrument. The TG curves were recorded by loading the sample in aluminum pans and heating from 45 to 600 °C at a rate of 10 °C min−1 under the flow rate of 10 ml min−1of nitrogen gas. The cyclic voltammetry (CV) measurements were performed using CHI 1100A model electrochemical analyzer with a view to examine the reversibility of Zn plating/stripping process occurring at room temperature at a scan rate of 10 mVs−1 for a typical asymmetric cell arrangement [Zn/IL8/SS] and also for both symmetric blocking and symmetric non-blocking cell configurations [SS/IL8/SS, Zn/IL8/Zn] in a potential range between − 1.5 and + 1.5 V.

Results and discussions

Varied significant aspects of ambient temperature conductivity results obtained earlier

The room temperature impedance analysis for PVC/PEMA polymer blend doped with zinc triflate salt and plasticized with room temperature ionic liquid has already been reported and discussed elaborately in our preceding report [12], and hence, the same has only been cited momentarily in the following paragraphs in a wide-ranging perception for the purpose of improved lucidity and significance. The initiative of not preferring higher salt concentration (beyond 30 wt%) is owed to the abrupt decrease in the value of ionic conductivity which was attributed to the formation of ionic clusters due to an aggregation process and an increase in the viscosity of the polymer chain as well [15].

The Nyquist plot corresponding to the best conducting solid polymer electrolyte (SPE) and the optimized gel polymer electrolyte (GPE) samples has been already reported in our earlier work for comparative purpose [12]. Normally, GPEs with an appropriate plasticizer (ionic liquid, EMIMTFSI in the preset case) may be considered as a homogeneous phase of the polymer, and the ion migration might happen through the free volume of the polymer matrix which may be symbolized by a resistor. Additionally, the effect of an appropriate capacitor may be characterized by the immobile polymer chains polarized in an alternating field. Both the processes of migration of ions and bulk polarization are physically represented as components coupled in parallel, and therefore the existence of the portion of the semicircle at the high-frequency domain could be noticed in the Nyquist plot. However, when the amount of ionic liquid gradually increases from 20 to 80 wt% in such blended SPEs, there is a progressive disappearance of high-frequency semicircular portion thereby proposing the prospect of total conductivity of the GPE, being mainly due to the result of migration of ions. This consequence suggests the fact that only the resistive component of the GPE could be considered when the concentration of ionic liquid is high [16, 17].

Plasticizers, in general, are additives that increase the fluidity of the material, dissolve enough charge carriers, and provide a more mobile medium for the ions. Hence, as the ionic liquid content increases in blended polymer-salt matrices, there occurs a building up of an effective local pathway for the ionic conduction to occur, and as a result, there may be quick transportation of ions in the region of plasticizer-rich phase (liquid phase) of the blended polymer matrix, when the electric potential alternates between positive and negative electrode in an alternating current field. Accordingly, the capacitance effect completely vanishes at high ionic liquid content (80 wt%) present within the polymer blend-salt system. This non-capacitance nature is attributed to the absence of polarization of immobile polymer chain in an alternating current field due to the preponderance of random orientation of dipoles in the side chains of the polymer matrix. This assessment proposes the consideration of only the resistive component of these blended gel polymer electrolytes thereby substantiating the declination of semicircular portion in the high-frequency domain of the Nyquist plot [12] when the concentration of the plasticizing solution (ionic liquid) is appreciably high (80 wt%). Thus, a local effective pathway for ionic conduction of polymer electrolyte was created as the plasticizer content increases, thereby enhancing the mobility of ions as the electric potential alternates between positive and negative electrodes in an alternating current field. As a consequence, the highest conductivity is obtained for the GPE film IL8 [5, 16,17,18,19,20,21].

It was already demonstrated and inferred from our previous studies [12, 15] that creation of effectual local pathways for ionic conduction increases the conductivity of optimized polymer blend-salt system, [PVC (30 wt%) / PEMA (70 wt%): 30 wt% Zn(CF3SO3)2] from 2.79 × 10−6 Scm−1 to as high as 1.1 × 10−4 Scm−1 at room temperature with an addition of 80 wt% EMIMTFSI ionic liquid. The presence of ionic liquid, namely EMIMTFSI, has increased the conductivity of the gel polymer electrolyte sample IL8 up to two orders of magnitude when compared with the ionic liquid-free sample. This enhancement is due to an increase in the number of mobile ions since EMIMTFSI provides EMIM+ and TFSI− ions. The highly self-dissociating nature of the ionic liquid favors and supports the ionic decoupling process thereby providing more number of free charge carriers too. Furthermore, the plasticizing effect of the ionic liquid could also tend to soften the polymer backbone thus increasing the flexibility of polymer segments [22]. As an end result, the segmental mobility of the polymer chains gets improved further which could be usually correlated to an increase in the free volume of the polymer matrix. As there is an increase in the free volume within the polymer matrix, the rotation of polymer chain takes place more readily thereby speeding up the transportation of ions in blended gel polymer electrolytes. In gelled polymer electrolytes, zinc ions are usually coordinated to both the polymer and ionic liquid as revealed from ATR-FTIR studies reported in our earlier work. Thus, the existence of ionic liquid results in lowering the viscosity of the ionic environment thereby contributing to higher ionic conductivity and instigating ion hopping mechanism [12, 23].

The maximum room temperature ionic conductivity of 1.1 × 10−4 Scm−1 has been reported by Sownthari et al. [24] for a biodegradable polymer namely poly-ε-caprolactone (PCL) in combination with zinc triflate [Zn(CF3SO3)2] salt and 1-ethyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide ionic liquid. Singh et al. [25] accounted an optimum electrical conductivity of 1.05 × 10−4 Scm−1 at room temperature for a GPE material consisting of poly (ethylene oxide) (PEO) polymer, sodium methylsulfate (NaMS) salt, and 1-butyl-3-methylimidazolium methylsulfate (BMIM-MS) ionic liquid. GPEs composed of poly (vinyl chloride) (PVC) as a host, ammonium trifluoromethane sulfonate (NH4CF3SO3) as a salt, and butyltrimethyl ammonium bis(trifluoromethyl sulfonyl)imide (BATS) as a plasticizer exhibiting the highest ionic conductivity of 1.56 × 10−4 Scm−1 at room temperature were reported by Deraman et al. [26], whereas Liew et al. [22] reported the achievement of highest ionic conductivity of 1.64 × 10−4 Scm−1 at room temperature for PMMA/PVC blend doped with LiTFSI and plasticized with 60 wt% 1-butyl-3-methylimidazoilium bis(trifluoromethylsulfonyl)imide (BmImTFSI) ionic liquid.

Dielectric relaxation analysis

An in-depth evaluation of dielectric relaxations is expected to be constructive in understanding the performance of polymers in general and their blend in particular. Hence, dielectric relaxation spectroscopy covering a wide range of frequencies is found to be a resourceful tool in order to analyze the relaxation mechanism of dipoles in the case of polymer electrolytes [27]. Accordingly, the complex dielectric behavior has also been exploited with a view to determine both the dielectric permittivity and dielectric loss, as bulk properties of each polymer electrolyte have been considered to be a dielectric material during the course of the present work [28]. The complex dielectric constant of a system consists of real and imaginary parts that may be expressed as,

where ε′ and ε″ denote the real and imaginary parts of the dielectric constant in respect of the gel polymer electrolyte system. On the contrary, these two real and imaginary parts of the dielectric constants are communicated as

where Cp is parallel capacitance, ε0 is permittivity in free space (also known as electric constant), t and A represent thickness and known area of the sample, σ is conductivity of the sample, and ω is angular frequency. The identical frequency range of investigation has been exercised for all the samples chosen in this work. Fig. 1a, b shows the complex permittivity spectra observed in the case of five different GPE samples comprising of real and imaginary parts as a function of frequency. The real part of the complex dielectric permittivity (ε′) specifies the gauge of stored charges in a material, whereas the intrinsic dissipation of energy engendered owing to the shipping and polarization effect of the charge carriers corresponds to the imaginary part of the dielectric permittivity which is also known as dielectric loss (ε″) [28].

a Variation of dielectric constant (ε′) as a function of frequency for various concentrations of EMIMTFSI in an optimized polymer blend-salt system [PVC (30 wt%) / PEMA (70 wt%)] : 30 wt% Zn(OTf)2 at room temperature. b Variation of dielectric loss (ε″) as a function of frequency for various concentrations of EMIMTFSI in an optimized polymer blend-salt system [PVC (30 wt%) / PEMA (70 wt%)] : 30 wt% Zn(OTf)2 at room temperature

The spiky ascend noticed at the low-frequency region in the frequency variation of real part of the dielectric constant ε′ could be ascribed to the formation of a space charge region due to the presence of polarization phenomenon at the electrode-electrolyte interface. This aspect correlates the non-Debye nature and non-exponential of conductivity relaxation in time of these GPE samples, where the diffusion of ions elucidates the occurrence of space charge regions with respect to the frequency. Hence, at lower frequencies, the movements of these mobile ions would be much leisurely owed to the slow periodic reversal of the applied electric field and therefore building up of space charge region at the electrode-electrolyte interface may occur thereby instigating polarization prior to the applied field changing its direction. Furthermore, the blocking effect of the stainless steel electrodes hinders the mobility of ions, which are generally moving around within the polymer matrices under the influence of the applied electric field, from moving into the external circuit thus causing an accumulation of charge carriers at the electrode-electrolyte interface as well.

As far as the entire set of gel polymer electrolyte systems are concerned, high dielectric constant values obtained at low frequencies may be attributed to the feasibility of two different kinds of dipoles available within the frequency region of study. They include mobile salt that dissociates into cation-anion pairs and localized molecular polar groups thus exhibiting an imbalance of charge. Since the dissociated ions are unable to cross the electrode-electrolyte interface because of the blocking tendency of stainless steel electrodes, a hetero-charge layer is likely to be formed due to its accumulation at the electrode-electrolyte interface thus leading to the phenomenon of electrode or interfacial polarization. On the other hand, polar carbonyl groups of the polymer chain are also expected to induce different dipoles surrounding them in an attempt to align them favorably to the electric field through conformational changes. These two factors would in turn lead to high dielectric constant values (~ 105) at low frequencies [29,30,31].

Such amplified dielectric constant (ε′) value could also be due to the increase in the additional charge carriers attributed to the addition of EMIMTFSI ionic liquid, and hence, the presence of higher charge density further intensifies the dissociating ability of zinc triflate salt thus preventing ion-pair formation or a high effectiveness on shielding the interionic columbic attraction between anions and cations. According to Bjerrum theory [12, 32, 33], the relation connecting the critical distance, r, for the formation of ion-pair and the dielectric constant ε′ may be expressed as

where Zi and Zj represent the valency of the cations and anions, e is the elementary electronic charge in C, ε0 is the dielectric constant in vacuum, k is the Boltzmann’s constant (8.6173 × 10−5 eVK−1) and T is the temperature in Kelvin. The ion-pair formation distance is inversely proportional to the dielectric constant ε′ form the above relation, but when the distance between cation and anion becomes smaller than the critical distance r, the ion-pair formation is likely to occur. However, the large values of dielectric constant with increase in the content of ionic liquid in EMIMTFSI-incorporated [PVC (30 wt%) / PEMA (70 wt%): 30 wt% Zn(OTf)2] system exemplifies the dissociation of ions thereby increasing the total number of ions in the complex instead of forming ion-pair. The increase in the number density of free ions with increase in the concentration of ionic liquid are reflected in the real part of the complex permittivity curve of gel polymer electrolytes since the real part measures the material’s polarization associated with the amount of dipoles in a given volume (which is the salt dissociating into cation-anion pairs in the present case). Hence, the increase in the value of ε′ with an increase in the concentration of EMIMTFSI would shed some glow on the conductivity studies. Following the above discussion, Fig. 2 elucidates the variation of dielectric constant of the gel polymer samples (IL2, IL4, IL6, IL7, and IL8) at randomly selected frequencies (300 Hz, 500 Hz, 1 kHz, and 3 kHz) as a function of concentration of ionic liquid at ambient temperature. The range of frequencies from 100 Hz to 3 kHz is considered as a region of electrode polarization where it is easier to visualize the ε′ variation with EMIMTFSI content. The relative permittivity in this range may be believed as the dielectric constant. It has been detected from Fig. 2 that ε′ increases with increasing EMIMTFSI content and reaches a high value at 80 wt% EMIMTFSI concentration, and this type of behavior was found to be similar to that of room temperature ionic conductivity values discussed in our previous report [12]. Thus, the increased relative permittivity of the electrolyte does play a vital role in the enrichment of conductivity. Although the direct relationship between the conductivity and dielectric constant for solid polymer electrolyte system is not clear as to date, Petrowsky and Frech observed the strong dependence of conductivity on dielectric constant for liquid electrolytes. However, the present attempt portraying their association may be treated as a preliminary work to breed for further investigations in future. Similar analysis was conceded and conferred by Woo et al. [34], Ravi et al. [35] for proton and lithium ion conducting GPEs based on poly (ε-caprolactone) (PCL) polymer plasticized with ethylene carbonate (EC) and 1-ethyl-3-methylimidazoliumtetrafluoroborate (EMIMBF4) ionic liquid.

Subsequently, dielectric loss (ε″) is a direct measure of dissipation of energy generated from the transportation of charge carriers and dipole orientation, and thus, there is a noticeable value of dielectric loss observed for all the samples at low-frequency regime. It may also be inferred that much higher values of relaxation time are required by the free charge carriers so as to build up the space charge region at the electrode-electrolyte interface before the electric field changes its direction. Hence, the typical specimen IL8 shows the highest dielectric constant and dielectric loss (ε′ and ε″) values among all the GPE samples at lower frequency region indicating the greater orientation of induced dipoles from their equilibrium positions and dissociation of ions from their native coordination bond. As a result of greater dissociation of charges, there is an increase in the concentration and transportation of charge carriers thus boosting the charge storage at the electrode-electrolyte boundary region. Conversely, at higher frequencies, the values of both ε′ and ε″ are much lower and this aspect may be attributed to the occurrence of a very fast periodic reversal of the electric field. This results in the absence of an excessive diffusion of ions in the direction of the electric field, and consequently, there is a decrease in the polarization effect. In addition, the variation of dielectric constant (ε′) and dielectric loss (ε″) with frequencies depends only on the mobility of the charge carriers at higher frequencies because of the diminished interactions between the dipoles and external electric field at higher frequencies. Hence, the values of both ε′ and ε″ are found to be independent of frequencies at high-frequency regime [29,30,31].

Such higher dielectric constant values at lower frequencies at ambient temperature have already been reported by Ravi et al. [35], Ramesh et al. [36], and Sudhakar et al. [37] for a biodegradable polymer electrolyte films based on poly(ε-caprolactone) (PCL) in conjunction with lithium tetrafluoroborate (LiBF4) salt and 1-ethyl-3-methylimidazolium tetrafluoroborate (EMIMBF4) ionic liquid, solid polymer electrolytes (SPEs) with poly(vinylidene fluoride-hexafluoropropylene) [P(VdF-HFP)] as polymer host, doped with magnesium trifluoromethanesulfonate (MgTf) and plasticized with 1-butyl-3-methylimidazolium trifluoromethanesulfonate (BMIMTf) ionic liquid, and lithium salts doped biodegradable gel polymer electrolytes consisting of Xanthan gum (XG) and glycerol.

Electric modulus analysis

The phenomenon of electrode polarization effect discussed elsewhere under the dielectric relaxation may be anticipated to cause misapprehension of conductivity relaxation time. To overcome this problem, the modulus analyses are now extensively utilized to evaluate the process of ionic conduction by associating each of such different conductivity relaxation phenomena with an ionic process. This would further facilitate the process of identification and segregation of the most appropriate polarization effect from the bulk relaxation phenomenon taking place within the gel polymer electrolyte system. The electric modulus is defined as the reciprocal of complex relative permittivity and has been exercised to suppress the polarization effect of the electrode at low frequencies [29, 38]. The electric modulus is expressed as

where M′ and M″ are real and imaginary parts of the electric modulus. Furthermore, real and imaginary parts of the electric modulus are in turn expressed as

Figure 3a, b depicts the frequency variation of real and imaginary parts of the modulus spectra observed for all the five different GPE samples. It is observed from these graphs that precise resonance peaks are absent in both the real and imaginary parts of modulus spectra at the high-frequency region; nevertheless, well-defined dispersions of M′ and M″ are found to exist thereby exhibiting a distinguishing increase at higher frequencies. The evidence of the peaking trend as expected at higher frequencies indicates that these gel polymer electrolyte films remain as good ionic conductors having a long range of conductivity relaxation even though the absence of specific peaks in the present work may be due to the restricted range of frequencies involved in the experiment. However, at higher frequency regime, the tendency of variation of the dispersion part of the modulus spectra appears to confirm that each spectrum was shifted towards high frequencies with an increase in the concentration of ionic liquid, EMIMTFSI, thereby suggesting the shortening of the relaxation time in the case of these gel polymer electrolyte samples [29]. On the contrary, the fact that both M′ and M″ tend to advance to zero in the vicinity at low-frequency regime demonstrates the feasibility of masking of electrode polarization effect at the electrode-electrolyte interface. The set of modulus plots each displaying a long tail at low-frequency region pertaining to both M′ and M″ may be convincingly attributed as due to the large capacitance associated with these electrodes [23].

a Variation of M′ as a function of frequency for various concentrations of EMIMTFSI in an optimized polymer blend-salt system [PVC (30 wt%) / PEMA (70 wt%)] : 30 wt% Zn(OTf)2 at room temperature. b Variation of M″ as a function of frequency for various concentrations of EMIMTFSI in an optimized polymer blend-salt system [PVC (30 wt%) / PEMA (70 wt%)] : 30 wt% Zn(OTf)2 at room temperature

Effect of ionic liquid on the thermal behavior of blended polymer (PVC/PEMA)

Differential scanning calorimetric analysis

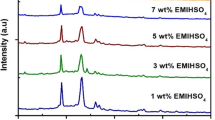

Differential scanning calorimetric (DSC) analysis is a vital technique which has been effectively used to estimate the glass transition temperature (Tg) of polymeric samples. This investigation entails the significant phase transition of a polymer matrix in the amorphous region from a rigid glassy phase into flexible and soft rubbery characteristics [39]. Generally, the most unambiguous criterion of the polymer blend miscibility is the detection of a single glass transition temperature whose temperature is in between those corresponding to the individual components of the blend. The miscibility of the present polymer blend system was thus established by an occurrence of one single intermediate glass transition temperature (Tg) thereby indicating the formation of a single homogeneous phase at the molecular scale. In addition, the value of Tg of the blended polymer system is falling in between the Tg values of pure polymers, PVC, and PEMA, as envisaged by the law of mixture. The miscibility of homopolymers also necessitates the existence of definite intermolecular interactions, and in the present case of blended polymer viz. [PVC (30 wt%) / PEMA (70 wt%)], the occurrence of dipole-dipole interaction between the carbonyl oxygen group of methacrylate ester moieties of PEMA (electron donor) and alpha hydrogen of PVC (electron acceptor) plays a primary role. The specific interaction occurring between C=O group of PEMA and α-hydrogen of CH−Cl in PVC has been already discussed under ATR-FTIR studies which was indicated by a shift in the vibrational band pertaining to C=O group to higher wavenumbers and also by the changes observed in the intensity of the carbonyl stretching peak of PEMA. Further, the complete miscibility of the polymer blend system has also been ascertained from scanning electron microscopy (SEM) studies by the formation of very smooth, uniform non-porous morphology without any obvious phase separation between the two polymers. All these details pertaining to the miscibility of the blended polymer have been discussed elaborately in our previous endeavors [12, 15, 31, 40, 41]. The DSC thermograms of the optimized polymer blend-salt complex, PS5, [PVC (30 wt%) / PEMA (70 wt%): 30 wt% Zn(OTf)2] together with that of gel polymer electrolyte membranes, [PVC (30 wt%) / PEMA (70 wt%): 30 wt% Zn(OTf)2] + x wt% EMIMTFSI (where x = 20, 40, 60, 70, and 80 wt%) are depicted in Figs. 4 and 5, respectively, for comparison.

The optimized polymer blend-salt complex, [PVC (30 wt%) / PEMA (70 wt%): 30 wt% Zn(OTf)2], exhibits a step change in DSC curve at 73.5 °C which corresponds to its glass transition temperature (Tg). The addition of ionic liquid, namely EMIMTFSI, in varied amounts into the optimized polymer blend-salt sample modifies the thermal behavior of the system. Thus, all those gel polymer electrolyte films (IL2, IL4, IL6, IL7, and IL8) demonstrate the gradual evolution of Tg occurring towards lower values, which may be mainly attributed to the addition of the plasticizer. It may therefore be inferred that the plasticizing effect of ionic liquid weakens the interaction among the polymer chains and hence restrains the crystalline degree of polymer electrolytes in concurrence with higher amorphous proportion. This would in turn result in an enhancement of the segmental motion of the polymer network due to the increased flexible nature of the polymer chains [39, 42].

The chain flexibility of these polymer electrolytes suitably incorporated with the present ionic liquid is expected to be much higher when compared to the ionic liquid-free polymer complexes since the molecules of ionic liquid present in between the polymer network would persuade the reshuffling of polymer chains thereby increasing the disordered property of the chain arrangements. This effect further stimulates the decoupling of charge carriers responsible for the ionic transportation, from their native complexation. Therefore, an increase in the amorphous region probably caused by these disordered polymer chains may offer an extra path and necessary freedom for all the decoupled ions to progress. As a consequence, the occurrence of ionic transportation is also favored. Hence, the observed decrease in the value of Tg from 73.5 °C to 68.7, 66.7, 64.2, 63.1 and 62 °C, correspondingly from ionic liquid free sample PS5 to IL2, IL4, IL6, IL7, and IL8, may be effectively due to the perceptible increase in the plasticization effect of ionic liquid, EMIMTFSI, which further supports the ion hopping mechanism thereby leading to higher ionic conductivity [39, 43]. On the other hand, it is important to mention that the melting point Tm was not detected in all these DSC thermograms. Thus, it may be concluded that the presence of ionic liquid, EMIMTFSI, favors the entropy configuration of the polymer in order to generate more free volume in which the ions could easily migrate through the plasticizer-rich phase [43, 44].

This decreasing tendency of Tg values with increasing concentration of room temperature ionic liquid (RTIL) has already been reported by Chaurasia et al. [45], Zain et al. [8], and Shalu et al. [46] for poly (ethylene oxide) (PEO) - lithium hexafluorophosphate (LiPF6) polymer electrolyte plasticized with 1-butyl-3-methylimidazolium hexafluorophosphate (BMIMPF6) ionic liquid, poly (ethyl methacylate) (PEMA) polymer incorporated with 1-ethyl-3-methlimidazolium bis(trifluorosulfonyl)imide ionic liquid, and lithium ion conducting gel polymer membranes based on poly (vinylidene fluoride-co-hexafluoropropylene) (PVdF-HFP) polymer and 1-butyl-3-methylimidazoilum bis(trifluoromethanesulfonyl) imide (BMIMTFSI) ionic liquid.

Thermogravimetric analysis

The thermogravimetric technique has been utilized to analyze the physical changes encountered by the gel polymer electrolytes during thermal excitations under inert conditions. In this method, the noticeable changes in the weight of the samples have been monitored as a function of temperature at a controlled uniform heating rate. The requirement for an inert atmosphere is to eradicate all the undesirable reactions that might occur between the sample and oxygen gas upon heating. The typical TGA curve observed in the present work follows a relatively simple sigmoidal path with the sample weight being slowly decreased as reaction begins and then decreases rapidly, over a comparatively narrow temperature range leading to the final level off as the reactant become exhausted. The shape of the TGA curve depends chiefly on the different kinetic parameters involved, and these parameters are extremely imperative in estimating the thermal stability of the samples [23, 47,48,49]. The initiation of sample weight loss was approximated using extrapolation of the baseline and tangent of the curve of thermal events [50].

Figure 6 shows the TGA thermogram of pure ionic liquid EMIMTFSI, and best conducting sample (IL8) identified among the series of gel polymer electrolyte membranes in the temperature range 45 to 600 °C. The onset decomposition temperature (Td) for pure ionic liquid, EMIMTFSI, is noticed at 462 °C followed by a single step decomposition, whereas the gel polymer membrane IL8 exhibits three distinct stages of degradation which may be clearly observed from the corresponding TGA plot. Multi-step weight loss curves are exhibited in 80 wt% EMIMTFSI incorporated PVC (30 wt%) / PEMA (70 wt%): 30 wt% Zn(OTf)2 complexed gel polymer electrolyte film which is probably due to the complex nature of the polymer electrolyte film [33]. In general, the decomposition pattern of the gel polymer electrolyte film is sensitive to the nature of the dissolved salt and ionic liquid since the complexation of the cation of either salt (Zn2+) or IL (EMIM+) with the polymer backbone, which was already established from ATR-FTIR studies reported in our earlier work [12, 15], would result in the destabilization of the polymer chain by weakening the adjacent C−H bonds [51].

Thus, a minor weight loss of 3.8% has been detected initially below 115 °C which may be due to the dehydration of residual moisture within the sample, hygroscopic nature of zinc triflate salt, and evaporation of residual solvent that has been used while preparing the sample for analysis. The first initial weight loss (~ 3.8%) of the GPE sample (IL8) integrated with 80 wt% ionic liquid is less than the weight loss (~ 8.1%) of the solid polymer electrolyte (SPE) sample (PS5) incorporated with an optimized composition of zinc triflate salt (30 wt%) reported in our earlier endeavor [31], and this might be due to the most probable reduction occurring in the amount of moisture that has been absorbed by the gel polymer electrolyte film owing to the hydrophobic nature of EMIMTFSI [52, 53]. The weight loss during the successive stage is most likely caused by the decomposition of polymers followed by decomposition of Zn(OTf)2 salt and ionic liquid.

The onset of thermal decomposition of IL8 contributing to the second degradation stage is initiated from the temperature range of 175.1–267.3 °C with the weight loss of 21.2%. This feature witnesses the degradation of the polymer blend associated with the significant reduction in the molecular weight of the polymeric chain which is found to be influenced by the existence of Zn(OTf)2 salt and EMIMTFSI ionic liquid in the blended polymer matrix. Hence, this second weight loss may be therefore attributed to the volatilization of the monomers and oligomers that has been chemi-adsorbed onto the polymeric system due to the feasibility of an unzipping process of macromolecules that includes many degradation reactions such as random chain scission reaction, depolymerization, intra- and inter-molecular chain transfer reactions, exclusion of HCl compounds from the dehydrochlorination reaction, scission of the main chains at weak head-to-head linkages, and degradation of unsaturated functional groups of PEMA followed by decomposition of PVC in the blend [31]. This feature is further followed by the presence of a third degradation stage starting from 321 to 462.5 °C with a weight loss of 55.5%, and these aspects may be attributed to the rupture of other electrolyte mixture [54] from the polymer blend [PVC (30 wt%) / PEMA (70 wt%)] i.e., degradation and decomposition processes of zinc triflate salt and room temperature ionic liquid with the residue mass of about 18.9% decomposition above 462 °C. The residual char at the final heating temperature of 462 °C may be attributed to the carbonization stimulated by the nitrogen and sulfur atoms during the thermal decomposition of these GPE films [31, 55]. Thus, the observed difference in the onset of thermal decomposition temperature (Td) for the above GPE film specifies the occurrence of significant interactions between the host polymers, salt, and ionic liquid.

The thermal properties of ionic liquid-based gel polymer electrolytes are found to be better when compared to Zn(OTf)2 doped solid polymer electrolyte as it demonstrates slightly higher residual mass (or lower total weight loss) after a prolonged heating process [56, 57]. However, the first decomposition temperature of GPE is comparatively lower in comparison to pure polymers, PVC, and PEMA, owing to the increased growth of amorphous fraction leading to the highest ionic conductivity of 1.1 × 10−4 Scm−1 with the addition of 30 wt% Zn(OTf)2 and 80 wt% EMIMTFSI to the optimized blended polymer. The polymer chains are highly flexible in the amorphous phase, and hence, lower energy is adequate to decompose the polymer chains resulting in a lower onset degradation temperature (Td) of gel complexes [33, 57]. However, an improvement in the thermal stability (i.e., onset temperature of decomposition) up to ~ 175 °C for EMIMTFSI incorporated best conducting gel polymer electrolyte membrane (IL8) is observed when compared to the thermal stability of the optimized polymer blend salt complex (PS5) reported at around ~ 150 °C in our preceding work [31]. This increased onset decomposition temperature (Td) of IL8 is owed to the nonflammable and nonvolatile nature of EMIMTFSI ionic liquid contributing to the increase in the heat resistivity of the samples [8, 53].

The effect of ionic liquid, 1-butyl-3-methylimidazolium hexa-fluorophosphate [bmim][PF6], on the thermal stability of polymers, PVC and PMMA, has been already evaluated in the literature which revealed the fact that a decrease in the degradation temperature is caused by the introduction of IL in PVC, whereas the increase in the degradation temperature has been noticed for PMMA. The catalytic effect of the acidity of the IL and/or of the compounds resulting from the decomposition of the IL and the influence of meager water content in the gel polymer complex resulting in the breakage of the ester bonds of the polymer are also found to affect the overall thermal stability of the system involving ionic liquids. These findings clearly demonstrate that the determination of thermal stability of the polymer electrolyte matrix based on ionic liquid depends both on the type of ionic liquid employed and also on the chemical structure of the polymer matrix [58]. The narrow plateau region observed for the present PVC/PEMA/Zn(OTf)2/EMIMTFSI gel polymer system clearly indicates the lower thermal stability of the EMIMTFSI-based gel system when compared to the other ionic liquid-based gel systems reported in the literature [59]. Although the thermal stability of the as-prepared gel polymer electrolyte film (~ 175 °C) based on EMIMTFSI ionic liquid is comparatively lower, it is still sufficiently high for battery applications and greatly preferred in electrochemical devices as the normal operating temperature usually lies within the range of 40–70 °C [56].

Leones et al. [50] investigated polymer electrolytes based on agar and ionic liquids, namely 1-ethyl-3-methylimidazolium ethylsulfate [C2mim][C2SO4], 1-ethyl-3-methylimidazolium acetate [C2mim][OAC], and trimethyl-ethanolammonium acetate [Ch][OAC], and reported that the electrolyte samples are thermally stable up to approximately 190 °C. Porcarelli et al. [60] investigated polyethylene oxide (PEO)-based gel polymer electrolytes doped with bis(trifluoromethane) sulfonamide lithium salt (LiTFSI), plasticized by tetraglyme (TEGDME), and demonstrated the thermal stability up to 190 °C. Stephan et al. [61] reported the thermal decomposition temperature of PVC/PMMA blended polymer electrolytes complexed with LiN(CF3SO2)2, ethylene carbonate (EC), and propylene carbonate (PC) as 90 °C and demonstrated the preference of such electrolytes in batteries.

Zinc electrochemistry in ionic liquids

Linear sweep voltammetry measurement

In order to bring out the significance of electrochemical studies of gel polymer sample, linear sweep voltammetry (LSV) analysis which has been already achieved in our previous report [31] has been elucidated once more briefly in the present work for the purpose of clearness and relevance. To accomplish practical battery applications, investigation related to the electrochemical stability window of the best conducting gel polymer electrolyte sample, IL8, is obligatory within the operation potential of the battery system. It has been reported that during the anodic scan, the gel polymer sample IL8 demonstrated a stability window of 3.23 V vs. Zn2+/Zn, and above 3.23 V, there was an irreversible oxidation of anions associated with the decomposition of the polymer electrolyte and electrochemical deposition of zinc. Hence, with the addition of EMIMTFSI to the best conducting polymer blend-salt sample designated as PS5, the decomposition voltage increases, since RTILs can help in forming a stable passive film thereby enlarging the electrochemical stability window of the electrolyte. Therefore, the gel polymer electrolyte sample IL8 was found to be stable in the potential region we examined [62].

Cyclic voltammetry evaluation

The technique of cyclic voltammetry is a prevailing tool to probe into the electrochemical behavior of a system by a precise evaluation of current-voltage characteristics in terms of an electrochemical cell. It essentially involves a three-electrode cell configuration employed to analyze the various electrochemical reactions occurring between those mobile ions and the pair of electrodes under investigation. The relevant experimental process concerns with a linear and cyclic variation of electrode potential between the reference and working electrodes within a potential window, and the subsequent current is measured between the working and counter electrodes. This method provides qualitative information regarding electrode reaction mechanisms, quantitative properties of charge transfer kinetics between the electrolyte ions and electrons with respect to the surface of the electrodes. The reduction/oxidation (redox) reaction on the electrode may be easily controlled by scheming the applied electrode potential of an electrochemical cell [63].

Consequently, cyclic voltammetric studies on the best conducting gel polymer electrolyte have been performed for both symmetric and asymmetric cells viz.: Zn/IL8/Zn (Cell I); SS/IL8/SS (Cell II); Zn/IL8/SS (Cell III) with a view to verify the establishment of an equilibrium of the metal/metal ion couple at the electrode/electrolyte interface and also to confirm zinc ionic conduction in these GPE films. The best conducting GPE sample namely IL8, containing [PVC (30 wt%) / PEMA (70 wt%): 30 wt% Zn(CF3SO3)2] + 80 wt% EMIMTFSI has been chosen for investigation based on the conclusions drawn from DSC and conductivity measurements performed on the series of gel polymer films such as IL2, IL4, IL6, IL7, and IL8. Figure 7 shows the investigation pertaining to the response of a reversible redox couple for symmetric cells (Cells I and Cell II) consisting of non-blocking zinc and blocking stainless steel (SS) electrodes with an inset demonstrating the cyclic voltammogram for an asymmetric cell (Cell III) thereby exploring the prime investigation of plating and stripping process of zinc from gel polymer electrolytes on SS substrate. The cyclic sweeping potential range for Cell I, Cell II, and Cell III is between − 1.5 and + 1.5 V at a scan rate of 10 mVs−1 at room temperature. It has been observed from an inset figure (Cell III) that, according to the kinetics of the zinc plating/stripping process, there is a sharp rise in the oxidation current at + 0.99 V which corresponds to the stripping of zinc, whereas the reduction current beginning at − 0.27 V is most apparently due to the plating of Zn onto the stainless steel electrode. In the case of Cell II, negligibly small current flows throughout the voltage range without exhibiting oxidation and reduction peaks. It is therefore inferred that the electrodeposition of Zn is not facilitated on the SS substrates. This might be due to non-interaction of zinc in the gel polymer electrolyte sample IL8 with the SS electrode [64]. On the other hand, the observed voltammogram in respect of Cell I exhibit distinct quasi-reversible maximums of currents characterized by a pair of current peaks correlating the practicable accomplishment of electrodeposition (cathodic) and dissolution (anodic) of zinc on the Zn substrate unlike on the SS substrate. Hence, the portion of curve in the cathodic region refers to the process of intercalation of zinc ion, and the portion of curve in the anodic region reflects the process of zinc ion extraction.

The Zn redox kinetics in RTILs with TFSI− anions entails a quasi-reversible two electron transfer process. The anodic and cathodic processes of GPE involving room temperature ionic liquids (RTILs) with TFSI− anions may possibly be quite different or less reversible which consequently contribute to the differences in the shape of the curve and peak current ratio. Additionally, the discrepancy in ionic liquids with imidazolium cations may also depend on the extent of solubility of zinc in such ionic liquids and/or its high viscosity (affecting the ionic species diffusion) when compared to the traditional molecular solvents since the rate of mass transport with the solution is strongly governed by the viscous nature of an ionic liquid [65,66,67]. In addition, the diffusion coefficients for reduced and oxidized forms of a redox couple in RTILs are frequently, and sometimes drastically, unequal when compared to their equivalent nature observed in the case of molecular solvents. Hence, the voltammetry assessment in systems with RTILs is characterized by particularly slow rate of diffusion and a decrease in the rate of homogeneous electron transfer kinetics. It was also proposed that the unpredictability in concentration and the nature of the impurities in ionic liquids also account for large variations in volammetric measurements [67]. The low cathodic stability and unfavorable compatibility of imidazolium-based RTILs towards metal anode owing to the presence of acidic protons and double bonds in the cation might also contribute towards the quasi-reversible electrochemistry of zinc in RTILs [68]. In consequence, the reactive nature of the acidic proton of the EMIM cation influences the zinc deposition/dissolution by degrading its reversibility [62].

It has also been already suggested by Simons et al. [69] that the kinetics of oxidation and reduction of zinc on glassy carbon substrate could be influenced by the arrangement of anions and cations of 1-ethyl-3-methylimidazolium dicyanamide [emim][dca] ionic liquid adjacent to the electrode in the form of a compact layer. The lack of absolute reversibility of Na+ involving RTILs was reported by Wibowo et al. [70] for 1-butyl-3-methylimidazolium trifluoromethylsulfonate [C4mim][OTf], 1-butyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide [C4mim][NTf2] RTILs which is owed to the initial sodium reduction overlapped with the undesired complicated side reactions such as formation of significant decomposition product on the electrode surface resulting from the reduction reaction of the ionic liquid. The insufficiency in the reduction stability of EMITFSI ionic liquid employed for Li batteries was reported by Ye et al. [71] owing to the chemical reduction of C-2 proton of imidazolium cation, whereas a slightly lower plating current density has been observed for Li/[LiTFSI/P13TFSI/PVDF-HFP]/Li cell during the first cycle due to an activation step and/or the formation of lithium metal. Minato et al. [72] reported the inhibition effect of sodium ion insertion into hard carbon electrode and negative impact of the formation of Na-TFSI ion pair to be the cause for the relative modification in the redox current observed in the cathodic region for the mixed electrolyte containing NaClO4/PC and N, N-diethyl-N-methoxy-ethyl ammonium bis(trifluoromethane sulfonyl)imide (DEMETFSI) ionic liquid. The interaction between the metals and TFSI− anions owing to the occurrence of redox reactions of some metallic species such as iron, samarium, europium, and ytterbium in BMPTFSI ionic liquid thus causing eventually slow electrode kinetics and low diffusivity was proposed by Chakrabarti et al. [73].

The fundamental studies of Zn electrochemistry found in the literature were thus found to be quasi-reversible and cycleable in most of the RTILs [74]. The quasi-reversibility of Zn2+/Zn0 electrochemistry in 1-butyl-1-methylpyrrolidium dicyanamide [C4mpyr] [dca] RTIL on a magnesium alloy electrode was reported by Simons et al. [69] when ZnCl2 was dissolved into ionic liquid. Analogous quasi-reversibility of the electrochemical plating/stripping process of zinc on gold and copper substrates for other gel polymer electrolyte (GPE) based on poly (vinylidene fluoride-co-hexafluoropropylene) (PVdF-HFP) polymer, Zn(OTf)2 salt and ionic liquid, 1-butyl-1-methylpyrrolidinium trifluoromethylsulfonate ([Py1,4]TfO) has already been reported by Liu et al. [75]. Oxidation and reduction peaks associated with Fe2+/Fe3+ redox couple in 1-butyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide [C4C1Im][N(Tf2)] ionic liquid was found to be electrochemically quasi-reversible [76].

Furthermore, while Zn/IL8/SS (asymmetric) and Zn/IL8/Zn (symmetric) cells have been subjected to plating/stripping processes for 10 consecutive voltammetric cycles, only a slender decline in the magnitude of current values with increasing cycle number has been perceived which may be due to the most feasible passivation phenomenon coupled with zinc metal surface. On cycling, overlapping of the subsequent sweeps was perceived with no substantial change in the redox peak voltages thus representing the occurrence of charge transfer reaction at the interface between the GPE sample and zinc metal. This fact further establishes the phenomenon of reasonable Zn plating/stripping processes at the Zn-electrode/gel polymer electrolyte interface and shows that the present GPE is able to support reversible redox process [75, 77]. The present voltammogram suggests that the agreeable quasi-reversibility and cyclic stability of the sample are adequate for its application in electrochromic devices. Further enhancement in the reversibility could be achieved by incorporating suitable additives to the existing GPE in order to develop the cathodic stability of RTILs besides decomposition and to improve the interfacial compatibility towards the zinc anode [68]. Hence, the present study on GPEs based on room temperature ionic liquids demonstrate basic properties suitable for their potential application in next-generation zinc batteries. The exertion pertaining to the attainment of absolute zinc reversibility by the addition of additives to the present GPE sample is currently in progress.

Conclusions

In the case of a GPE system based on hydrophobic ionic liquid, EMIMTFSI, immobilized in PVC/PEMA blended polymer matrix and prepared effectively by solution casting technique, dielectric constant and ionic conductivity values increase with increase in the concentration of EMIMTFSI owing to the amplified density of mobile charge carriers. Upon incorporation of EMIMTFSI, the glass transition temperature Tg of the gel polymer electrolyte film gets lowered resulting in the softening of the polymer backbone and thus ultimately providing an enhanced accessibility of vacant sites for the transportation of Zn2+ ions. The TG analysis inferred that degradation process of gel polymer electrolyte relies both on the chemical structure of the components and their composition thereby showing an evidence of mutual interactions. The subsequent reasonable zinc plating/stripping process in respect of the best conducting gel polymer film corroborated using cyclic voltammetry signify that the present ionic liquid based gel polymer electrolyte has an admirably fair and prospective property to be employed as an electrolyte separator in high-energy-density batteries.

References

Pandey GP, Hashmi SA (2013) Performance of solid-state supercapacitors with ionic liquid 1-ethyl-3-methylimidazolium tris(pentafluoroethyl) trifluorophosphate based gel polymer electrolyte and modified MWCNT electrodes. Electrochim Acta 105:333–341. https://doi.org/10.1016/j.electacta.2013.05.018

Osman Z, Zainol NH, Samin SM, Chong WG, Md Isa KB, Othman L, Supa’at I, Sonsudin F (2013) Electrochemical impedance spectroscopy studies of magnesium-based polymethylmethacrylate gel polymer electrolytes. Electrochim Acta 131:148–153. https://doi.org/10.1016/j.electacta.2013.11.189

Kumar D, Hashmi SA (2010) Ion transport and ion-filler-polymer interaction in poly (methyl methacrylate)-based, sodium ion conducting, gel polymer electrolytes with silica nanoparticles. J Power Sources 195(15):5101–5108. https://doi.org/10.1016/j.jpowsour.2010.02.026

Ramesh S, Uma O, Shanti R, Yi LJ, Ramesh K (2014) Preparation and characterization of poly (ethyl methacrylate) based polymer electrolytes doped with 1-butyl-3-methylimidazolium trifluoromethanesulfonate. Measurement 48:263–273. https://doi.org/10.1016/j.measurement.2013.11.025

Rajendran S, Sivakumar M, Subadevi R (2004) Investigations on the effect of various plasticizers in PVA-PMMA solid polymer blend electrolytes. Mater Lett 58(5):641–649. https://doi.org/10.1016/S0167-577X(03)00585-8

Pandey GP, Hashmi SA (2013) Ionic liquid 1-ethyl-3-methylimidazolium tetracyanoborate-based gel polymer electrolyte for electrochemical capacitors. J Mater Chem A 1(10):3372. https://doi.org/10.1039/c2ta01347a

Vickraman P, Aravindan V, Selvambikai M, Shankarasubramanian N (2009) Ionic transport, thermal, XRD, and phase morphological studies on LiCF3SO3-based PVC-PVdF gel electrolytes. Ionics 15(4):433–437. https://doi.org/10.1007/s11581-008-0288-y

Zain NF, Zainal N, Mohamed NS (2015) The influences of ionic liquid to the properties of poly (ethylmethacrylate) based electrolyte. Phys Scr 90(1):015702. https://doi.org/10.1088/0031-8949/90/1/015702

Ulaganathan M, Chithra Mathew M, Rajendran S (2013) Highly porous lithium-ion conducting solvent-free poly (vinylidene fluoride-co-hexafluoropropylene)/poly (ethyl methacrylate) based polymer blend electrolytes for Li battery applications. Electrochim Acta 93:230–235. https://doi.org/10.1016/j.electacta.2013.01.100

Lee TK, Afiqah S, Ahmad A, Dahlan HM, Rahman MYA (2012) Temperature dependence of the conductivity of plasticized poly (vinyl chloride)-low molecular weight liquid 50% epoxidized natural rubber solid polymer electrolyte. J Solid State Electrochem 16(6):2251–2260. https://doi.org/10.1007/s10008-011-1633-z

Mishra K, Hashmi SA, Rai DK (2013) Nanocomposite blend gel polymer electrolyte for proton battery application. J Solid State Electrochem 17(3):785–793. https://doi.org/10.1007/s10008-012-1926-x

Sai Prasanna CM, Austin Suthanthiraraj S (2016) Effective influences of 1-ethyl-3-methylimidazolium bis(trifluoromethylsulfonyl) imide (EMIMTFSI) ionic liquid on the ion transport properties of micro-porous zinc-ion conducting poly (vinyl chloride)/poly (ethyl methacrylate) blend-based polymer electrolytes. J Polym Res 23(7):140. https://doi.org/10.1007/s10965-016-1043-0

Dhumal NR, Noack K, Kiefer J, Kim HJ (2014) Molecular structure and interactions in the ionic liquid 1-ethyl-3-methylimidazolium bis(trifluoromethylsulfonyl) imide. J Phys Chem A 118(13):2547–2557. https://doi.org/10.1021/jp502124y

Moschovi AM, Ntais S, Dracopoulos V, Nikolakis V (2012) Vibrational spectroscopic study of the protic ionic liquid 1-H-3-methylimidazolium bis(trifluoromethanesulfonyl) imide. Vib Spectrosc 63:350–359. https://doi.org/10.1016/j.vibspec.2012.08.006

Sai Prasanna CM, Austin Suthanthiraraj S (2015) Electrical, structural, and morphological studies of honeycomb-like microporous zinc-ion conducting poly (vinyl chloride)/poly (ethyl methacrylate) blend-based polymer electrolytes. Ionics 22(3):389–404. https://doi.org/10.1007/s11581-015-1546-4

Ramesh S, Arof AK (2001) Ionic conductivity studies of plasticized poly (vinyl chloride) polymer electrolytes. Mater Sci Eng B 85(1):11–15. https://doi.org/10.1016/S0921-5107(01)00555-4

Baskaran R, Selvasekarapandian S, Hirankumar G, Bhuvaneswari MS (2004) Vibrational, ac impedance and dielectric spectroscopic studies of poly (vinylacetate)-N,N-dimethylformamide-LiClO4 polymer gel electrolytes. J Power Sources 134(2):235–240. https://doi.org/10.1016/j.jpowsour.2004.02.025

Ramesh S, Wen LC (2010) Investigation on the effects of addition of SiO2 nanoparticles on ionic conductivity, FTIR, and thermal properties of nanocomposite PMMA-LiCF3SO3-SiO2. Ionics 16:255–262. https://doi.org/10.1007/s11581-009-0388-3

Sharma P, Kanchan DK (2013) A comparison of effect of PEG and EC plasticizers on relaxation dynamics of PEO-PMMA-AgNO3 polymer blends. Ionics 19(9):1285–1290. https://doi.org/10.1007/s11581-013-0851-z

Aziz SB, Abdullah OG, Rasheed MA, Ahmed HM (2017) Effect of high salt concentration (HSC) on structural, morphological, and electrical characteristics of chitosan based solid polymer electrolytes. Polymers 9(6):187. https://doi.org/10.3390/polym9060187

Avellaneda CO, Vieira DF, Al-Kahlout A, Heusing S, Leite ER, Pawlicka A, Aegerter MA (2008) All solid-state electrochromic devices with gelatin-based electrolyte. Sol Energy Mater Sol Cells 92(2):228–233. https://doi.org/10.1016/j.solmat.2007.02.025

Liew C-W, Ramesh S (2012) Impact of low viscosity ionic liquid on PMMA-PVC-LiTFSI polymer electrolytes based on AC-impedance, dielectric behavior, and HATR-FTIR characteristics. J Mater Res 27(23):2996–3004. https://doi.org/10.1557/jmr.2012.343

Ramesh S, Ling OP (2010) Effect of ethylene carbonate on the ionic conduction in poly (vinylidenefluoride-hexafluoropropylene) based solid polymer electrolytes. Polym Chem 1(5):702–707. https://doi.org/10.1039/b9py00244h

Sownthari K, Austin Suthanthiraraj S (2014) Structural, thermal and electrical studies on gel polymer electrolytes containing 1-ethyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide. Ionics 21(6):1649–1654. https://doi.org/10.1007/s11581-014-1324-8

Singh VK, Kataria S, Chaurasia SK, Singh RK (2016) Development of ionic liquid mediated novel polymer electrolyte membranes for application in Na-ion battery. RSC Adv 6(46):40199–40210. https://doi.org/10.1039/C6RA06047A

Deraman SK, Mohamed NS, Subban NHY (2013) Conductivity and electrochemical studies on polymer electrolytes based on poly vinyl (chloride) – ammonium triflate – ionic liquid for proton battery. Int J Electrochem Sci 8:1459–1468

Rajendran S, Ramesh Prabhu M (2010) Effect of different plasticizer on structural and electrical properties of PEMA-based polymer electrolytes. J Appl Electrochem 40(2):327–332. https://doi.org/10.1007/s10800-009-9979-y

Ramesh S, Liew C-W (2013) Dielectric and FTIR studies on blending of [xPMMA-(1-x)PVC] with LiTFSI. Measurement 46(5):1650–1656. https://doi.org/10.1016/j.measurement.2013.01.003

Ng HM, Ramesh S, Ramesh K (2015) Exploration on the P(VP-co-VAc) copolymer based gel polymer electrolytes doped with quaternary ammonium iodide salt for DSSC applications: electrochemical behaviors and photovoltaic performances. Org Electron 22:132–139. https://doi.org/10.1016/j.orgel.2015.03.020

Ramesh S, Liew C-W (2012) Exploration on nano-composite fumed silica-based composite polymer electrolytes with doping of ionic liquid. J Non-Cryst Solids 358(5):931–940. https://doi.org/10.1016/j.jnoncrysol.2012.01.005

Sai Prasanna CM, Austin Suthanthiraraj S (2017) Dielectric, thermal and electrochemical properties of PVC/PEMA blended polymer electrolytes complexed with zinc triflate salt. Ionics 23(11):3137–3150. https://doi.org/10.1007/s11581-017-2109-7

Bockris JOM, Reddy AKN (1998) Modern electrochemistry 1: Ionics, 2nd edn. Plenum Press, New York, pp 251–255

Muchakayala R, Song S, Gao S, Wang X, Fan Y (2017) Structure and ion transport in an ethylene carbonate-modified biodegradable gel polymer electrolyte. Polym Test 58:116–125. https://doi.org/10.1016/j.polymertesting.2016.12.014

Woo HJ, Majid SR, Arof AK (2013) Effect of ethylene carbonate on proton conducting polymer electrolyte based on poly (ε-caprolactone) (PCL). Solid State Ionics 252:102–108. https://doi.org/10.1016/j.ssi.2013.07.005

Ravi M, Song S, Wang J, Nadimicherla R, Zhang Z (2016) Preparation and characterization of biodegradable poly (ε-caprolactone)-based gel polymer electrolyte films. Ionics 22(5):661–670. https://doi.org/10.1007/s11581-015-1586-9

Ramesh S, Soon-Chien L (2012) Concentration effect of BMIMTf on P(VdF-HFP)/MgTf-based solid polymer electrolyte system. J Mater Res 27(11):1488–1496. https://doi.org/10.1557/jmr.2012.66

Sudhakar YN, Selvakumar M, Krishna Bhat D (2015) Lithium salts doped biodegradable gel polymer electrolytes for supercapacitor application. J Mater Environ Sci 6:1218–1227

Pradhan DK, Choudhary RNP, Samantaray BK (2008) Studies of structural, thermal and electrical behavior of polymer nanocomposite electrolytes. Express Polym Lett 2(9):630–638. https://doi.org/10.3144/expresspolymlett.2008.76

Liew C-W, Ramesh S, Arof AK (2013) Good prospect of ionic liquid based-poly (vinyl alcohol) polymer electrolytes for supercapacitors with excellent electrical, electrochemical and thermal properties. Int J Hydrog Energy 39(6):2953–2963. https://doi.org/10.1016/j.ijhydene.2013.06.061

Krause S (1986) Polymer-polymer miscibility. Pure Appl Chem 58:1553–1560

Bosma M, ten Brinke G, Ellis TS (1988) Polymer-polymer miscibility and enthalpy relaxations. Macromolecules 21(5):1465–1470. https://doi.org/10.1021/ma00183a041

Cheng H, Zhu C, Huang B, Mi L, Yang Y (2007) Synthesis and electrochemical characterization of PEO-based polymer electrolytes with room temperature ionic liquids. Electrochim Acta 52(19):5789–5794. https://doi.org/10.1016/j.electacta.2007.02.062

Radzir NNM, Anuar FH, Hanifah SA, Ahmad A, Hassan NH (2015) An investigation of polymer electrolyte based on poly (glycidylmethacrylate) doped with imidazolium ionic liquid. J Mater Environ Sci 6:1436–1443

Ibrahim S, Johan MR (2012) Thermolysis and conductivity studies of poly (ethylene oxide) (PEO) based polymer electrolytes doped with carbon nanotube. Int J Electrochem Sci 7:2596–2615

Chaurasia SK, Saroj AL, Shalu, Singh VK, Tripathi AK, Gupta AK, Verma YL, Singh RK (2015) Studies on structural, thermal and AC conductivity scaling of PEO-LiPF6 polymer electrolyte with added ionic liquid [BMIMPF6]. AIP Adv 5(7):077178. https://doi.org/10.1063/1.4927768

Shalu, Singh VK, Singh RK (2015) Development of ion conducting polymer gel electrolyte membranes based on polymer PVdF-HFP, BMIMTFSI ionic liquid and the Li-salt with improved electrical, thermal and structural properties. J Mater Chem C 3(28):7305–7318. https://doi.org/10.1039/c5tc00940e

Ramesh S, Liew C-W (2013) Development and investigation on PMMA-PVC blend-based solid polymer electrolytes with LiTFSI as dopant salt. Polym Bull 70(4):1277–1288. https://doi.org/10.1007/s00289-012-0851-6

Helan Flora X, Ulaganathan M, Rajendran S (2012) Influence of lithium salt concentration on PAN-PMMA blend polymer electrolytes. Int J Electrochem Sci 7:7451–7462

Abdelrazek EM, Elashmawi IS (2008) Characterization and physical properties of CoCl2 filled polyethyl-methacrylate films. Polym Compos. https://doi.org/10.1002/pc.20481

Leones R, Sentanin F, Rodrigues LC, Marrucho IM, Esperanca JMSS, Pawlicka A, Silva MM (2012) Investigation of polymer electrolytes based on agar and ionic liquids. Express Polym Lett 6(12):1007–1016. https://doi.org/10.3144/expresspolymlett.2012.106

Saroj AL, Singh RK (2011) Studies on ionic liquid 1-ethyl-3-methyl imidazolium ethylsulphate complexed with PVA. Phase Transit 84(3):231–242. https://doi.org/10.1080/01411594.2010.535134

Mathew CM, Kesavan K and Rajendran S (2015) Structural and electrochemical analysis of PMMA based gel electrolyte membranes. Int J Electrochem. https://doi.org/10.1155/2015/494308

Sa’adun NN, Subramaniam R, Kasi R (2014) Development and characterization of poly (1-vinylpyrrolidene-co-vinyl acetate) copolymer based polymer electrolytes. Sci World J. https://doi.org/10.1155/2014/254215

Karuppasamy K, Prasanna K, Kim D, Kang YH, Rhee HW (2017) Headway in rhodanide anion based ternary gel polymer electrolytes (TILGPEs) for applications in rechargeable lithium ion batteries: an efficient route to achieve high electrochemical and cycling performances. RSC Adv 7(31):19211–19222. https://doi.org/10.1039/c7ra01081h

Dong Z, Zhang Q, Chuhong Y, Peng J, Ma J, Xuecheng J, Zhai M (2013) Effect of ionic liquid on the properties of poly (vinylidenefluoride)-based gel polymer electrolytes. Ionics 19(11):1587–1593. https://doi.org/10.1007/s11581-013-0905-2

Liew C-W, Ramesh S (2013) Studies on ionic liquid-based corn starch biopolymer electrolytes coupling with high ionic transport number. Cellulose 20(6):3227–3237. https://doi.org/10.1007/s10570-013-0079-0

Liew C-W, Ong YS, Lim JY, Lim CS, Teoh KH, Ramesh S (2013) Effect of ionic liquid on semi-crystalline poly (vinylidene fluoride-co-hexafluoropropylene) solid copolymer electrolytes. Int J Electrochem Sci 8:7779–7794

Gardella L, Furfaro D, Galimberti M, Monticelli O (2015) On the development of a facile approach based on the use of ionic liquids: preparation of PLLA (sc-PLA)/high surface area nano-graphite systems. Green Chem 17(7):4082–4088. https://doi.org/10.1039/c5gc00964b

Mohd.Suleman, Yogesh Kumar, Hashmi SA (2013) Structural and electrochemical properties of succinonitrile-based gel polymer electrolytes: role of ionic liquid addition. J Phys Chem B 117(24):7436–7443. https://doi.org/10.1021/jp312358x

Porcarelli L, Gerbaldi C, Bella F, Nair JR (2015) Super soft all-ethylene oxide polymer electrolyte for safe all-solid lithium batteries. Sci Rep 6:19892. https://doi.org/10.1038/srep.19892

Manuel Stephan A, Saito Y, Muniyandi N, Renganathan NG, Kalyanasundaram S, Nimma Elizabeth R (2002) Preparation and characterization of PVC/PMMA blend polymer electrolytes complexed with LiN(CF3SO3)2. Solid State Ionics 148(3-4):467–473. https://doi.org/10.1016/S0167-2738(02)00089-9

Zhu C, Hu C, Yang Y (2008) Electrochemical characterization of two types of PEO-based polymer electrolytes with room temperature ionic liquids. J Electrochem Soc 155(8):A569–A575. https://doi.org/10.1149/1.2931523

Mundinamani SP, Rabinal MK (2014) Cyclic voltammetric studies on the role of electrode, electrode surface modification and electrolyte solution of an electrochemical cell. IOSR. J Appl Chem 7:45–52

Sivakumar M, Subadevi R, Rajendran S, N-L W, Lee J-Y (2006) Electrochemical studies on [(1-x) PVA - x PMMA] solid polymer blend electrolytes complexed with LiBF4. Mater Chem Phys 97(2-3):330–336. https://doi.org/10.1016/j.matchemphys.2005.08.018

Buzzeo MC, Evans RG, Compton RG (2004) Non-haloaluminate room-temperature ionic liquids in electrochemistry-a review. Chem Phys Chem 5(8):1106–1120. https://doi.org/10.1002/cphc200301017

Xu M (2014) Exploration of electrolytes for Zn anode rechargeable batteries: room temperature ionic liquids as major or supporting components University of Alberta. https://doi.org/10.7939/R39882W1D. Accessed 29 June 2017

Barrosse-Antle LE, Bond AM, Compton RG, O’Mahony AM, Rogers EI, Silvester DS (2010) Voltammetry in room temperature ionic liquids: comparisons and contrasts with conventional electrochemical solvents. Chem Asian J 5(2):202–230. https://doi.org/10.1002/asia.200900191

Li M, Yang B, Zhang Z, Wang L, Zhang Y (2013) Polymer gel electrolytes containing sulfur-based ionic liquids in lithium battery applications at room temperature. J Appl Electrochem 43(5):515–521. https://doi.org/10.1007/s10800-013-0535-4

Simons TJ, Howlett PC, Torriero AAJ, MacFarlane DR, Forsyth M (2013) Electrochemical, transport, and spectroscopic properties of 1-ethyl-3-methylimidazolium ionic liquid electrolytes containing zinc dicyanamide. J Phys Chem 117(6):2662–2669. https://doi.org/10.1021/jp311886h

Wibowo R, Aldous L, Rogers EI, Jones SEW, Compton RG (2010) A study of the Na/Na+ redox couple in some room temperature ionic liquids. J Phys Chem C 114(8):3618–3626. https://doi.org/10.1021/jp911862m

Ye H, Huang J, Xu JJ, Khalfan A, Greenbaum SG (2007) Li ion conducting polymer gel electrolytes based on ionic liquid/PVDF-HFP blends. J Electrochem Soc 154(11):A1048–A1057. https://doi.org/10.1149/1.2779962

Minato EGASHIRA, Tomoyo TANAKA, Nobuko YOSHIMOTO, Masayuki MORITA (2012) Influence of ionic liquid species in non-aqueous electrolyte on sodium insertion into hard carbon. Electrochemistry 80(10):755–758. https://doi.org/10.5796/electrochemistry.80.755

Chakrabarti MH, Mjalli FS, AlNashef IM, Hashim MA, Hussain MA, Bahadori L, Low CTJ (2014) Prospects of applying ionic liquids and deep eutectic solvents for renewable energy storage by means of redox flow batteries. Renew Sust Energ Rev 30:254–270. https://doi.org/10.1016/j.rser.2013.10.004

Kar M, Simons TJ, Forsyth M, MacFarlane DR (2014) Ionic liquid electrolytes as a platform for rechargeable metal-air batteries: a perspective. Phys Chem Chem Phys 16(35):18658–18674. https://doi.org/10.1039/c4cp02533d

Liu Z, El Abedin SZ, Endres F (2014) Electrodeposition and stripping of zinc from an ionic liquid polymer gel electrolyte for rechargeable zinc-based batteries. J Solid State Electrochem 18(10):2683–2691. https://doi.org/10.1007/s10008-014-2526-8

Ejigu A, Greatorex-Davies PA, Walsh DA (2015) Room temperature ionic liquid electrolytes for redox flow batteries. Electrochem Commun 54:55–59. https://doi.org/10.1016/j.elecom.2015.01.016

Rosdi A, Zainol NH, Osman Z (2016) Ionic transport and electrochemical stability of PVDF-HFP based gel polymer electrolytes. AIP Conference Proceedings 1711:050003. https://doi.org/10.1063/1.4941629

Acknowledgements

One of the authors (C.M.S) gratefully acknowledges the financial support received in the form of WOS-A programme from the Department of Science and Technology (DST), New Delhi, under DST Sanction No.SR/WOS-A/PS-32/2013 Dated 23.4.2014. The author (C.M.S) would also like to express gratefulness to Mr. A. Narayanan, Department of Chemistry, IIT Madras for his kind help and invaluable aid in carrying out DSC and TGA measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prasanna, C.M.S., Suthanthiraraj, S.A. Dielectric and thermal features of zinc ion conducting gel polymer electrolytes (GPEs) containing PVC / PEMA blend and EMIMTFSI ionic liquid. Ionics 24, 2631–2646 (2018). https://doi.org/10.1007/s11581-017-2421-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-017-2421-2