Abstract

A new square wave adsorptive stripping voltammetric (SWAdSV) approach using experimental design and optimization methodology was developed for the quantitative estimation of amlodipine (AMP) in pharmaceutical tablets. To this end, a new carbon paste electrode (CPE) system was fabricated using titanium dioxide (TiO2) nanoparticles to get very well-defined oxidation peak current of AMP under the optimized conditions. Optimal electrochemical conditions for three factor variables, the pH, the accumulation potential, and the accumulation time, were obtained by applying a 33 full factorial design and optimization technique to the oxidation of AMP on the TiO2 modified CPE (TiO2-CPE) system. The numerical values of the optimal voltammetric parameters consisting of the pH, accumulation potential, and accumulation time were found to be 5.69, 562.30 mV, and 64.30 s for the analysis of AMP in samples, respectively. The newly developed voltammetric method for the determination of AMP offers a linear relationship between the peak current and concentration in the range of 1.0 × 10−8 − 1.0 × 10−6 M with the correlation coefficient (r = 0.9990) and the detection limit (LOD = 2.97 × 10−9 M). The lifetime of prepared electrode was also tested, and the current intensity of AMP was nearly stable at least 2 months by using TiO2-CPE. The validity of the method was tested by analyzing standard samples containing the analyzed compound. Under optimized and validated experimental conditions, the proposed method was successfully applied for the quantitative analysis of AMP in commercial tablets.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

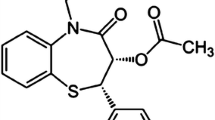

Amlodipine, (3-ethyl 5-methyl-2-[2-aminoethoxy-methoxy]-4-(o-chlorophenyl)-1,4-dihydro-6-methyl-3,5-pyridinedicarboxylate monobenzene sulfonate), is a dihydropyridine derivative acting as a calcium channel antagonist. It is effectively used in the treatment of hypertension, chronic stable angina, and certain types of vasospastic angina [1–3]. It may be used alone or in combination with other active compounds [4]. The quantification of amlodipine (AMP) in pharmaceutical preparations is very important to reach a high-quality drug regime for human health.

In recent years, nanoparticles were found to contribute a lot to the quality of sensing devices. In voltammetric studies, these particles have been used as electrode modifiers to improve mass transport, high-effective surface area, catalytic efficiency, etc. In this context, titanium dioxide (TiO2) is one of the most versatile and flexible nanoparticle used as a modifier. This material is optically transparent and has a high surface area as well as good biocompatibility and relatively good conductivity. TiO2 nanoparticles have been incorporated with other compounds such as graphite and carbon nanotubes to make modified electrodes in the electrochemical analysis of some biologically important compounds. These particles provide more active sites at the electrode surface so as to improve the sensitivity of the electrode [5–8].

Several different analytical methods were reported for the determination of AMP in pharmaceutical and biological samples. Among these, high performance liquid chromatography [9], thin layer chromatography [10], gas chromatography [11], LC/MS systems [12], ultraviolet-visible spectrophotometry [13], and capillary electrophoresis [14] are the ones used extensively. Notwithstanding that these methods have high selectivity and sensitivity, they are expensive, require highly specialized stuff, and also time-consuming. Spectrophotometric methods, for example, may not give desirable analysis results due to the spectral interference of several pharmaceutical excipients. In this regard, the voltammetric techniques play an important role in the analysis of drugs to overcome the drawbacks of the analytical methods mentioned above.

Particularly, electrochemical stripping methods have been used for the accumulation of the analyte on the working electrode surface [15]. This preconcentration procedure is an advantage of the electrochemical stripping methods for the analysis of the analyzed compounds at low concentration levels in samples. This indicates that electroanalytical stripping methods are a powerful technique for the selective and sensitive analysis with low cost [16–21].

Carbon paste electrodes (CPEs) have extensive use in the various branches of the chemistry. They can be prepared in a quick and easy way and offer an easily renewable and reproducible surface and a low residual current [22, 23]. A number of sensors are based on CPEs, and these electrodes are used for the voltammetric analysis in the electrochemical studies. They have been found useful for the selective deposition of analytes at electrode surfaces.

The electrochemical factors such as pH, accumulation potential, and accumulation time are known to have a profound effect on the waveform and the intensity of the peak current of voltammetric signals. A usual strategy in electrochemical investigations is the optimization of one-factor i.e pH, which is varied, when other factors i.e accumulation potential and accumulation time are kept constant. Then other factories varied in the same manner, and optimum set of conditions is approached. This procedure is called one-factor optimization. This approach is far from being ideal for the establishment of the most suitable set of conditions, because the mutual dependence of changing factors is not taken into account.

Other experimental design models were developed for the establishment of optimum conditions. Among them are the so-called full factorial design and fractional factorial design [24]. In this work, we follow the former approach.

Preliminary trials indicated that the TiO2-modified CPE (TiO2-CPE) electrode system was appropriate to obtain sensitive and accurate voltammetric signals for AMP. To identify the best set of pH, accumulation potential, and accumulation time, a 33 full factorial design was applied. Voltammetric stripping analysis of AMP was then carried out under the specified set of conditions. The results found were compared with the literature data based on other methods of analysis, and our results were found to compare well with other data.

Experimental section

Reagents and solutions

All of the chemical substances used were of reagent grade and were used without further purification. All solutions were prepared with ultra pure water obtained from a Human Power I+, Ultra Pure Water System. Nitrogen (99.999 %) was purged through the system to remove the dissolved oxygen.

A commercial pharmaceutical product Exforge film tablet containing 5.0 mg AMP equivalent to 6.95 mg AMP besylate, produced by BAYER Pharm. Company, was analyzed. Active compound (amlodipine besylate) was kindly denoted by Exforge film tablet. 1 × 10−3 M stock solution of AMP was prepared by dissolving the appropriate amount of standard AMP in methanol (Merck analytical reagent grade).

Britton-Robinson (BR) buffer solutions (0.04 M) were prepared by mixing boric acid (Merck), acetic acid (Merck), and phosphoric acid (Merck), and exact pH values of solutions were adjusted by adding 0.2 M sodium hydroxide.

Apparatus

Square wave adsorptive stripping voltammetry was performed by a CH Instruments Electrochemical Workstation CHI660C connected to a C4 Cell Stand. A three electrode combination system consisted of a TiO2 nanoparticles based on carbon paste working electrode, a platinum wire auxiliary electrode (CHI 115), and a Ag/AgCl reference electrode (CHI 111) was used.

Electrochemical impedance spectra (EIS) were also carried out by a CHI660C in the medium of BR buffer solution at pH 5.69. The impedance measurements were recorded at an open-circuit voltage with the frequency range of 0.1–105 Hz.

pH measurements were carried out using a Hanna HI 2211 pH/ORP meter calibrated with potassium hydrogen phthalate (pH 4.13) and sodium bicarbonate (pH 8.20) buffer solutions.

Preparation of working electrode

For comparative purposes, CPE and TiO2-CPE were prepared. To prepare CPE, optimum ratio of the masses of graphite powder and paraffin oil was achieved by trial. For the modification of CPE with TiO2, optimum proportion of TiO2 + graphite powder + paraffin oil was mixed in a mortar and ground for 10 min. Both bare and TiO2-modified pastes were packed into the hole of the electrode body, and the electric contact was made with a copper wire in the center of the rod. The surface of the paste was polished with a piece of polishing cloth until it had a shiny appearance.

Assay procedure for the determination of AMP in tablets

Ten commercial tablets were weighed and grounded in a mortar. From this mixture, a sample equivalent to one tablet was dissolved in methanol in a 100-mL volumetric flask, and then the solution was shaken for 20 min, using electronic agitator. After filtration procedure, an appropriate volume of the filtrated sample solution was transferred into working cell, and the volume was completed by using BR buffer (pH 5.69). Voltammograms of the resulting sample solution were plotted. This assay procedure was repeated six times.

Result and discussion

An optimized and validated voltammetric method was developed for the quantitative analysis of AMP in tablets. The variables (pH, accumulation potential, and accumulation time) were optimized to get an optimum signal on the TiO2-CPE electrode. Based on the conditions optimized, a new square wave adsorptive stripping voltammetric (SWAdSV) method was developed. The details of the experimental work are described below.

Electrochemical behavior of AMP

Cyclic voltammetry is a very useful method for the analysis of redox process, e.g., the evaluation of electron transfer kinetics and the investigation of the reversibility of the reactions. In this context, we recorded the CV voltammograms of 1 × 10−4 M AMP on CPE and TiO2-CPE systems for monitoring electrochemical behavior of bare and modified systems as indicated in Fig. 1.

As can be seen in Fig. 1a, a well-defined oxidation peak was observed at about 800 mV (vs Ag/AgCl) at both CPE and TiO2-CPE which corresponds to the oxidation of electroactive (1,4-dihydropyridine) group [22]. No reduction peak was observed in the reverse scan. The peak intensity increases linearly with the increasing concentration of AMP which indicates that the peak is related to the oxidation of the analyte (Fig. 6). Higher peak currents were obtained with TiO2-CPE in comparison with bare CPE. This finding demonstrates that TiO2-CPE is more sensitive than bare CPE (Fig. 1a).

EIS was also used to characterize the electrode modification process, and it indicated a decrease on the interfacial electron transfer resistance at the electrode surface. Quantitatively, the Nyquist plots (Fig. 1b) yielded R ct values of 2.51 × 106 and 4.42 × 105 Ω for CPE and TiO2-CPE, respectively. The results show that the TiO2 nanoparticles effectively increase the electron-transfer rate between the electrode surface and AMP.

The influence of the scan rate on the anodic peak potential and anodic peak current at TiO2-CPE was investigated using 1.0 × 10−4 M AMP. The scan rate was changed in the range of 10–3000 mVs–1. The peak potential shifted to more anodic values with increasing scan rate (Fig. 2). This behavior indicates that the oxidation process is irreversible. The plot of logi p vs logv was found to be linear with a slope of 0.634 between the scan rates tested (inset in Fig. 2). This result confirmed that the electrode process is controlled by adsorption behavior under diffusion conditions [25].

Effect of pH, accumulation potential, and accumulation time

In the preliminary experimental studies, six individual pH values in the range 2.0–7.0 were tested to identify the scale of the pH factor in the experimental domain. Cyclic voltammograms were recorded, and the variation of the peak current vs pH value was shown in the inset of Fig. 3. From the CV voltammograms, the variation of the peak current was observed in the pH range of 2.0–6.0. Figure 3 indicates that a slightly acidic medium is suitable for this work.

In a similar manner, preliminary trial assays were carried out to find the effective ranges of the accumulation potential and accumulation time at an AMP concentration of 1.0 × 10−6 M by SWAdSV (Fig. 4). The recorded SWAdS voltammograms indicated that the accumulation potentials and accumulation times in the respective ranges of 0.0–600.0 mV and 0.0–200.0 s are appropriate for the full factor analysis.

Mean centering and derivative graphs of the voltammograms corresponding to experimental design matrix given in Table 2 (In this figure, plots correspond to (a) pH = 2.0, (b) pH = 4.0, and (c) pH = 6.0, respectively)

Experimental design and optimization

Experimental design and optimization methodology has been used to examine the relationship between experimental factor variables and the corresponding response variables. To this end, several designs such as full/fractional factorial designs, central composite, Box-Behnken, Doehlert, and mixture designs have been used. From the least square regression of the independent factor variables and their responses in the used design, the following second order polynomial equation was derived:

Here, y is the response variable, b 0 is the intercept of the equation, b 1, b 2,…, b 9 are the coefficients, x 1, x 2, and x 3 are the factor variables, and the products x 1 x 2, x 1 x 3, and x 2 x 3 represent the interactions of the factor variables.

After evaluating the preliminary experiments, trial values of the accumulation potential (x 1, mV), accumulation time (x 2, s), and pH (x 3) were selected as independent factor variables in the 33 full factorial design. In Table 1, the actual and coded values of factor variables with three different levels, e.g., high (+1), medium (0), and low (−1), were listed.

Using the factor variables and the corresponding factor levels, the three factor–three level full factorial design was prepared and depicted in Table 2. The voltammograms of the design matrix consisting of the 27 runs and SWAdSV plots were recorded in the range 500–1200 mV. In order to measure the exact values of the peak currents of voltammograms, the mean centering (MC) and the derivative technique were applied to all the voltammograms of the design samples for the scaling of the data of the original voltammograms. In Fig. 4, the mean centered voltammograms and their corresponding derivative plots were presented for the design samples at the pH values employed. As can be seen in this figure, the mean centering and derivative techniques were provided to allow a better evaluation of the design voltammograms and to observe the variation of the response variable. After the mean centering treatment of original voltammograms corresponding to the samples in Table 2, the first derivative of the mean centered voltammograms was obtained and depicted in Fig. 4. This derivative procedure was denoted as ΔMCC/ΔE. As described above, the values of ΔMCC/ΔE peak to peak responses were measured to obtain the observed responses as indicated in Table 2.

In the experimental design and optimization approach, significance test was applied for the presence and absence of the effects of factors and their interaction on the analytical response (ΔMCC/ΔE peak to peak of the current peak). The results of significance test for each factor and factor interactions are illustrated in Table 3. As can be seen in this table, higher t values and low P values for the studied factors and their interactions were obtained. These values indicate a very strong effect of the factors (pH, accumulation time, and accumulation potential) on the response, which correspond to ΔMCC/ΔE peak to peak of the current peak. As a consequence, these results indicate that the selected factors, pH, accumulation time, and accumulation potential, are good enough to make a better decision for finding the real optimal experimental conditions.

Significance test was applied to the coefficient parameters of the regression modeling, and then results are summarized in Table 3. Taking into account the large t values and the corresponding low P values, the terms of the factors considered and factor interactions prove to have a very strong effect on the oxidation of AMP.

In order to observe the effects of the factor interactions, the surface graphs and their corresponding counter plots of the studied factors were obtained from the relationship between pH-accumulation potential vs peak to peak ΔMCC/ΔE, pH-accumulation time vs peak to peak, and accumulation time-accumulation potential vs peak to peak ΔMCC/ΔE in Fig. 5.

Determination of AMP in commercial sample

Standard series of AMP in the concentration range of 8.0 × 10−9 − 1.0 × 10−5 M were prepared, and SWAdS voltammograms were recorded under the optimum parameters found by the chemometric method. Voltammograms were shown for the five different concentrations of AMP in Fig. 6. The linear calibration curve was plotted, and a perfect linearity was found between the concentration range of 1.0 × 10−8 − 1.0 × 10−6 M. The correlation coefficient (r) was 0.9990 (inset in Fig. 6). The statistical results of regression analysis are listed in Table 5.

Validity of the optimized voltammetric method

Validation of an analytical method is the process by which it is established that the performance characteristic of the method meets the requirements for the intended analytical applications. The elements required for method validation are linearity range, limits of detection and quantification, accuracy, precision, reproducibility, etc.

Limit of defection (LOD) and limit of quantification (LOQ) values were calculated using the relations LOD = 3 s/m and LOQ = 10 s/m, s being the standard deviation of selected working concentration and m being the slope of calibration curve. By using related equations, LOD and LOQ were calculated to be 2.97 × 10−9 and 9.90 × 10−9, respectively.

It so appears that the method developed is superior to existing electrochemical methods performed in the acidic pH medium. Comparing the mentioned studies in Table 4, the present study provides lower limit of detection and wider linear concentration range in the acidic pH values.

The reproducibility of peak current (RSD % = 5.00) and the reproducibility of peak potential (RSD % = 0.56) were calculated. The obtained values indicate a good precision for the newly developed method. Experiments were replicated five times, and the average values of the results are illustrated in Table 5.

In the studies relating to recovery, the accuracy of the optimized method was tested by analyzing commercial tablet samples. Mean recovery results and the relative standard deviation are given in Table 6. According to the recovery results, a good accuracy and precision were found for the analysis of AMP in samples by the newly developed method.

Lifetime and interference studies for TiO2-CPE

In total, 90 different records of the peak current of AMP (1.0 × 10−4 M) were taken in a period of 3 months by using the CV method, and the findings were used to test the lifetime of the newly prepared TiO2-CPE system. During the lifetime test, the electrode was kept in methanol at room temperature. The percent decrease in the AMP peak currents was calculated for each measurement. At the end of the trial period, the peak current intensity was found to have been retained at about 95 % of its departure value. This indicated that the TiO2-CPE system should better be renewed after 2 months.

In order to investigate the effect of the matrix materials in commercial pharmaceutical samples on the voltammetric response, studies were performed by adding extra AMP into samples for recovery tests. The results are depicted in Table 6. It can be seen that the recovery ranges between 101.0 and 102.4 %. Consequently, we concluded that the commercial excipients have little interference on the results obtained by the method developed.

Conclusions

In this study, a new electrode system consisting of TiO2-CPE was developed for the analysis of AMP in samples.

In the next step, the application of the 33 factorial design for finding optimal voltammetric conditions, accumulation potential, accumulation time, and pH, provided higher peak current with well-defined waveform for the oxidation of AMP on the modified electrode and for the determination of AMP in tablets. After the method validation procedure, the developed and optimized voltammetric method gave us successful assay results for the quantitative evaluation of AMP in the commercial dosage form.

References

Steffen HM (1999) Amlodipine—a third generation dihydropyridine calcium antagonist. J Clin Basic Cardiol 2:45–52

Matalka K, El-Thaher T, Saleem M, Arafat T, Jehanli A, Badwan A (2001) Enzyme linked immunosorbent assay for determination of amlodipine in plasma. J Clin Lab Anal 15:47–53

Li J, Li Y, Zhang W, Chen Z, Fan G (2013) Glucose-β-CD interaction assisted ACN field-amplified sample stacking in CZE for determination of trace amlodipine in beagle dog plasma. J Sep Sci 36:1817–1825

Darwisha HW, Bakheita AH, Darwisha IA (2012) New spectrofluorimetric methods for the simultaneous determination of olmesartan medoxamil and amlodipine besylate in their combined tablets. Dig J Nanomater Bios 7:1599–1608

Ensafi AA, Bahrami H, Rezaei B, Maleh H-K (2013) Application of ionic liquid TiO2 nanoparticle modified carbon paste electrode for the voltammetric determination of benserazide in biological samples. Mater Sci Eng C 33:831–835

Tashkhourian J, Nami Ana SF, Hashemnia S, Hormozi-Nezhad MR (2013) Construction of a modified carbon paste electrode based on TiO2 nanoparticles for the determination of gallic acid. J Solid State Electrochem 17:157–165

Shrivastava R, Saxena S, Satsangee SP, Jain R (2015) Graphene/TiO2/polyaniline nanocomposite based sensor for the electrochemical investigation aripiprazole in pharmaceutical formulation. Ionics 21:2039–2049

Demir E, Inam R, Ozkan SA, Uslu B (2014) Electrochemical behavior of tadalafil on TiO2 nanoparticles–MWCNT composite paste electrode and its determination in pharmaceutical dosage forms and human serum samples using adsorptive stripping square wave voltammetry. J Solid State Electrochem 18:2709–2720

Gizawy SM, Bebawy LI, Abdelmageed OH, Omar MA, Deryea SM, Abdel-Megied AM (2013) High performance liquid chromatography, TLC-densitometry, and first-derivative spectrophotometry for simultaneous determination of amlodipine and perindopril in bulk powder and its tablets. J Liq Chrom Relat Technol 36:1323–1339

Kamble AY, Mahadik MV, Khatal LD, Dhaneshwar SR (2010) Validated HPLC and HPTLC method for simultaneous quantitation of amlodipine besylate and olmesartan medoxomil in bulk drug and formulation. Anal Lett 43:251–258

Maurer HH, Arlt JW (1999) Screening procedure for detection of dihydropyridine calcium channel blocker metabolites in urine as part of a systematic toxicological analysis procedure for acidic compounds by gas chromatography-mass spectrometry after extractive methylation. J Anal Toxicol 23:73–80

Suchanova B, Kostiainen R, Ketola RA (2008) Characterization of the in vitro metabolic profile of amlodipine in rat using liquid chromatography–mass spectrometry. Eur J Pharm Sci 33:91–99

Singh S, Patel K, Agrawal VK, Chaturvedi S (2012) Simultaneous estimation of S(−) amlodipine besylate hemipentahydrate and losartan potassium in combined dosage form by using uv˗spectroscopy. Der Pharm Lett 4:897–905

Inglot TW, Gumıenıczek A, Komsta Ł, Zwıązek R (2013) Densitometry, video˗scanning and capillary electrophoresis for determination of valsartan and amlodipine in a combined dosage form: a comparative study. Acta Chromatogr 25:47–58

Wang J (2000) Analytical electrochemistry. Wiley VCH, New York

Erden S, Durmus Z, Kılıç E (2011) Simultaneous determination of antimony and lead in gunshot residue by cathodic adsorptive stripping voltammetric methods. Electroanalysis 23:1967–1974

Gazzy AAK (2004) Determination of amlodipine besylate by adsorptive square-wave anodic stripping voltammetry on glassy carbon electrode in tablets and biological fluids. Talanta 62:575–582

Sikkander ARM, Vedhi C, Manisankar P (2011) Electrochemical stripping studies of amlodipine using Mwcnt modified glassy carbon electrode. Chem Mater Res 1:1–7

Stoiljković Z, Avramov Ivić ML, Petrović SD, Mijin D, Stevanović SI, Lačnjevac U, Marinković AD (2012) Voltammetric and square-wave anodic stripping determination of amlodipine besylate on gold electrode. Int J Electrochem Sci 7:2288–2303

Altiokka G, Dogrukol-Ak D, Tunçel M, Aboul-Enein HY (2002) Determination of amlodipine in pharmaceutical formulations by differential-pulse voltammetry with a glassy carbon electrode. Arch Pharm Pharm Med Chem 2:104–108

Topal BD, Bozal B, Demircigil BT, Uslu B, Ozkan SA (2009) Electroanalytical studies and simultaneous determination of amlodipine besylate and atorvastatine calcium in binary mixtures using first derivative of the ratio-voltammetric methods. Electroanalysis 21:2427–2439

Goyal RN, Bishnoi S (2010) Voltammetric determination of amlodipine besylate in human urine and pharmaceuticals. Bioelectrochemistry 79:234–240

Uslu B, Ozkan SA (2007) Electroanalytical application of carbon based electrodes to the pharmaceuticals. Anal Lett 40:817–853

Güzel R, Ekşi H, Dinç E, Solak AO (2013) New voltammetric approach to the quantitative estimation of sildenafil citrate in tablets using disposable pencil graphite electrode. J Electrochem Soc 160:B119–B124

Szroeder P, Tsierkezos NG, Walczyk M, Strupiński W, Górska-Pukownik A, Strzelecki J, Wiwatowski K, Scharff P, Ritter U (2014) Insights into electrocatalytic activity of epitaxial graphene on SiC from cyclic voltammetry and ac impedance spectroscopy. J Solid State Electrochem 18:2555–2562

Bradea O, Banica F (2010) Differential pulse adsorption voltammetry for determination of amlodipine besylate at carbon paste electrode in pharmaceutical preparations. Fascicula Chim 17:18–23

Mohammadi A, Moghaddam AB, Eilkhanizadeh K, Alikhani E, Mozaffari S, Yavari T (2013) Electro-oxidation and simultaneous determination of amlodipine and atorvastatin in commercial tablets using carbon nanotube modified electrode. Micro Nano Lett 8:413–417

Mansano GR, Eisele APP, Dall’Antonia LH, Afonso S, Sartori ER (2015) Electroanalytical application of a boron˗doped diamond electrode: improving the simultaneous voltammetric determination of amlodipine and valsartan in urine and combined dosage forms. J Electroanal Chem 738:188–194

Švorc L, Cinková K, Sochr J, Vojs M, Michniak P, Marton M (2014) Sensitive electrochemical determination of amlodipine in pharmaceutical tablets and human urine using a boron-doped diamond electrode. J Electroanal Chem 728:86–93

Erden PE, Tasdemir IH, Kacar C, Kilic E (2014) Simultaneous determination of valsartan and amlodipine besylate in human serum and pharmaceutical dosage forms by voltammetry. Int J Electrochem Sci 9:2208–2220

Valezi CF, Duarte EH, Mansano GR, Dall’Antonia LH, Tarley CRT, Sartori ER (2014) An improved method for simultaneous square-wave voltammetric determination of amlodipine and enalapril at multi-walled carbon nanotubes paste electrode based on effect of cationic surfactant. Sensors Actuators B 205:234–243

Acknowledgments

This research has been supported by the Ankara University Scientific Research projects Coordination Unit, Project Nos. 13J4240009 and 2005-07-05-094.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Erden, S., Eskiköy Bayraktepe, D., Yazan, Z. et al. TiO2 modified carbon paste sensor for voltammetric analysis and chemometric optimization approach of amlodipine in commercial formulation. Ionics 22, 1231–1240 (2016). https://doi.org/10.1007/s11581-015-1629-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-015-1629-2