Abstract

Plant-based foods should mimic the appearance of the animal-based ones they are designed to replace, such meat, seafood, egg, milk, and their products. Each food is required to have specific optical properties, such as color and opacity, which depend on the selective absorption and scattering of light. In this study, oil-in-water emulsions containing plant-derived pigments were used as model plant-based foods. The pigments were selected to represent the three primary colors: turmeric (yellow), red beet (red), and butterfly pea flower (blue). We then investigated the impact of pigment and oil droplet characteristics on the optical properties of the model emulsions, including pigment type and concentration, and droplet size and concentration. Reflectance spectroscopy and colorimetry (L*, a*, b* values) were used to quantify the impact of these parameters on the optical properties of the emulsions. The chromaticness of the emulsions increased with increasing colorant concentration, increasing droplet size, and decreasing droplet concentration due to greater light absorption. The lightness of the emulsions increased with decreasing colorant concentration, decreasing droplet size, and increasing droplet concentration due to greater light scattering. This study provides a better understanding of the factors influencing the optical properties of plant-based foods, which could be used to optimize their appearances, thereby increasing consumer acceptance.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The plant-based food market has grown appreciably in recent years due to increasing demand for foods that are better for the environment, human health, and animal welfare [1, 2]. In 2021, the sales of plant-based foods designed to mimic animal-based ones (like meat, seafood, eggs, milk, and their products) was reported to have grown by around 54% in a three year period [3]. However, there are still several technical hurdles that are holding back the more widespread acceptance and adoption of plant-based foods, including the need to mimic the texture, taste, and appearance of animal-based foods more accurately. Appearance is the first sensory attribute consumers experience when they encounter a food and so it greatly affects their purchasing decisions [4]. Moreover, the sensory perception and desirability of foods depends on their appearance, which is important because it impacts repeat purchasing of products [5]. For plant-based foods, consumers expect their appearance to closely match that of the animal-based products they are designed to replace, e.g., a matt brown cooked meat, a shiny raw pink salmon fillet, or a matt yellowish cooked egg [6, 7]. Creating plant-based foods with similar appearances to animal-based ones could increase their appeal to a broader range of consumers, thereby reducing the adverse environmental and animal welfare issues associated with the livestock industry.

To simulate the appearances of animal-based products more accurately it is important to understand how color characteristics and food matrix effects impact the optical properties of plant-based foods. For this type of product, it is important to use natural pigments that have been isolated from plants [8, 9]. However, formulating food products using natural pigments is usually more challenging than using synthetic colorants due to their poorer solubility and stability characteristics [8]. Researchers have therefore explored different strategies for improving the solubility and stability characteristics of natural colors, including co-pigmentation, encapsulation, and adding natural preservatives [10,11,12]. However, more studies are needed to better understand the factors impacting the optical properties of plant-based foods containing natural pigments.

The purpose of this study was therefore to systematically investigate the main factors influencing the optical properties of plant-based foods using oil-in-water emulsions containing natural plant-derived pigments as model food matrices. Emulsions are particularly useful as model systems because their compositions and structures can be systematically varied. Three plant-derived colorants were selected to represent the three primary colors: turmeric (yellow), red beet (red), and butterfly pea flower (blue) [13]. The main pigments in these colorants are anthocyanins (butterfly pea flower), curcumin (turmeric), and betalains (red beet), which have also been claimed to exhibit several health benefits and can therefore also be included as nutraceuticals in plant-based foods [14,15,16]. Both lipid-soluble (turmeric) and water-soluble (red beet and BP flower) colorants were used because plant-based foods are multiphasic systems, in which pigments can be located at either or both the dispersed and continuous phases [17].

Oil-in-water emulsions were also used as model systems because they are inherently multiphasic systems that have compositions and structures that can be designed to represent a broad range of plant-based foods [18,19,20,21]. Previous researchers have already highlighted the potential of nanoemulsion technology to improve the dispersibility and stability of natural colorants [22,23,24]. Moreover, studies have been carried out on the chemical stability of natural pigmented substances encapsulated in nanoemulsions such as vitamin A [25], beta-carotene [26], lutein [27, 28], and betalain [22].

An improved fundamental understanding of the factors impacting the appearance of plant-based foods depends on improving our knowledge of the physicochemical phenomena that contribute to their optical properties [6]. The color of animal-based products, like meat, eggs, and milk, is the result of a combination of selective absorption of light by pigments and scattering of light by particles [6, 29]. For instance, the fibers in meat, the lipoproteins in egg, and the fat droplets in milk scatter light, which causes these products to appear opaque. Similarly, the myoglobin in meat and the carotenoids in egg yolk selectively absorb light, which causes these products to have specific colors. The utilization of pigment-loaded emulsions as model systems can therefore simulate the scattering and absorption effects found in plant-based foods.

Most animal- and plant-based foods are opaque because of the strong scattering by the particles they contain. Consequently, their appearance is dominated by light scattering and absorption events that occur at their surfaces [30]. The optical properties of these kinds of systems can be modeled using the Kubelka-Munk theory, which relates light reflection from an object to its absorption and scattering characteristics:

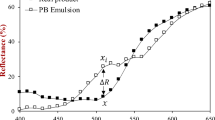

Here, R is the spectral reflectance, and K and S are the absorption and scattering coefficients of the material, respectively. The predicted change in the reflectance with K/S is shown in Fig. 1. The reflectance decreases as the K/S value increases, which means that it should decrease as either the absorption becomes stronger, or the scattering becomes weaker. Measurements of the spectral reflectance of an emulsion versus wavelength in the visible region (380–780 nm) can be used to calculate its X, Y, Z tristimulus coordinates, which can be converted into L*a*b* tristimulus coordinates [31]. These coordinates are related to the appearance of materials experienced by humans, such as their opacity and color.

For oil-in-water emulsions, the absorption coefficient depends on the type and concentration of chromophores present, while the scattering coefficient depends on the size, concentration, and refractive index contrast of the droplets [32]. The absorption and scattering coefficients can be calculated using the following equations:

Here, \({\alpha }_{E}\)is absorption coefficient, \({Q}_{s}\) is the scattering efficiency, r is the droplet radius, and g is the asymmetry factor, which depends on the scattering pattern of the light waves by a droplet. The absorption coefficient of an emulsion can be calculated from experimental measurements of the absorption of the oil and aqueous phases at different wavelengths: \({\alpha }_{E}\left(\lambda \right)=\varphi {\alpha }_{D}\left(\lambda \right)+(1-\varphi ){\alpha }_{C}\left(\lambda \right)\) where the E, D, and C subscripts refer to the emulsion, dispersed phase, and continuous phase, respectively, \(\varphi\) is the volume fraction of the dispersed phase, and l is the wavelength of light [31]. These equations show that the optical properties of emulsions should depend on the absorption spectra of the pigments, as well as the characteristics of the droplets.

In this study, we systematically investigated the impacts of natural plant-based colorant characteristics (type and concentration) and oil droplet characteristics (size and concentration) on the optical properties of model emulsions. The model oil-in-water emulsions were prepared using a plant-based oil (corn oil) and emulsifier (quillaja saponin). According to the Kubelka-Munk theory, we hypothesized that the optical properties of these emulsions would depend on the colorant and droplet characteristics used. However, the magnitude and nature of these effects is currently unknown. The results of this study should therefore provide a better understanding of the factors impacting the optical properties of multiphasic foods, which can be used to formulate plant-based food with closer appearances to the animal-based products they are designed to replace.

Materials and methods

Materials

Corn oil (Mazola, ACH Food Companies, Chicago, IL, USA) was purchased from a local supermarket. Red beet concentrate and natural blue liquid (butterfly pea flower or BP flower) were kindly provided by Sensient (Saint Louis, MO, USA). Turmeric powder (≥ 65% curcumin) was purchased from Sigma-Aldrich (Saint Louis, MO, USA). Quillaja saponin (Q-Naturale® 200 V), a hydrophilic emulsifier, was purchased from Ingredion Incorporated (Westchester, IL, USA). All other chemicals and reagents used in this study were purchased from either Sigma-Aldrich (Saint Louis, MO, USA) or Fisher Scientific (Pittsburgh, PA, USA). The double-distilled water used to prepare the solutions and emulsions was produced using a laboratory-scale purification unit (Nanopure Infinity, Barnstaeas International, Dubuque, IA, USA).

Colorant Solution Preparation

Colorant solutions for absorbance measurements were prepared by diluting red beet and BP flower concentrate in double-distilled water and turmeric powder in ethanol. Red beet and BP flower solutions were adjusted to pH 7.0 before measurement. To study the effects of colorant type on the optical properties of the emulsions, it was necessary to standardize the colorant concentrations used. Calibration curves were therefore created by preparing colorant solutions with a range of concentrations: 0, 0.000125, 0.00025, 0.0005, 0.001% w/w for turmeric and 0, 0.0125, 0.025, 0.05, 0.1% w/w for red beet and BP flower. The area-under-the-curve was then calculated by integrating the absorption versus wavelength curve around the maximum absorption peak of each colorant (320–500 nm for turmeric, 390–630 nm for red beet, and 550–700 nm for BP flower). Calibration curves were then established by plotting the area-under-the-curve versus colorant concentration for each colorant.

Stock colorant solutions for preparing natural colorants in oil-in-water emulsions were produced by diluting red beet and BP flower concentrate in double-distilled water and turmeric powder in 0.5 M NaOH. The concentrations of stock colorant solutions used for the study of the effects of droplet concentration and size were determined from the calibration curve (data not shown) to identify the concentrations required to achieve similar peak areas under the absorption curves for each colorant, which were 0.1%, 12.3%, and 40.0% w/w, for turmeric, red beet, and BP flower, respectively. The concentration of stock colorant solutions used for the study of colorant concentration effect were 0.2%, 24.5%, and 79.9% w/w, for turmeric, red beet, and BP flower, respectively.

Emulsion Preparation

Effect of Colorant type

The powdered Q-Naturale 200 ingredient (0.5% w/w) was dispersed in double-distilled water to produce an aqueous emulsifier solution. Corn oil (15%, w/w) and this emulsifier solution (85%, w/w) were then pre-blended using a high-shear blender at 10,000 rpm for 2 min and then recirculated through a microfluidizer at 10,000 psi for 5 passes (M110Y, Microfluidics, Newton, MA). The emulsions produced were then mixed with stock colorant solutions and phosphate buffer solution (10 mM, pH 7) in appropriate ratios. This led to emulsions with the same oil concentration (10.0%) and stock dye solution concentration (13.3%) but different colorant types. The pH-driven method was used to prepare the turmeric-loaded emulsions [33]. Turmeric was first dissolved in an alkaline solution as described in the colorant solution preparation section, then mixed with the slightly acidic emulsion, and immediately adjusted to pH 7.0. As a result, the hydrophobic curcumin molecules move from the aqueous phase into the oil phase. All samples were adjusted to a final pH value of 7.0.

Effect of Colorant Concentration

The emulsions were prepared using the same method as for the effect of dye type experiment (Sect. 2.3.1). These emulsions were then mixed with appropriate ratios of stock dye solution and phosphate buffer solution (10 mM, pH 7.0). The amount of emulsion added was kept constant, while the ratio of stock dye solution and phosphate buffer solution added were varied (keeping the total amount constant). This led to emulsions with the same oil droplet concentration (10%) but different stock colorant solution concentrations (0, 13.3, 26.7, 40, 53.3 and 66.7% w/w). These emulsions were prepared for all three colorants. All samples were adjusted to a final pH of 7.0.

Effect of Droplet size

An emulsifier solution was prepared as described in Sect. 2.3.1. Corn oil (15%, w/w) and emulsifier solution (85%, w/w) were then homogenized using different methods to create emulsions containing oil droplets with average sizes around 10 μm, 1 μm, and 150 nm. The emulsions containing the 10 μm droplets were prepared by blending the oil and emulsifier phases using a high-shear mixer (M133/1281–0, Biospec Products, Inc., ESGC, Switzerland) at 10,000 rpm for 25 min. The emulsions containing 1 μm droplets were prepared by blending the oil and emulsifier phases using the same high-shear mixer at 10,000 rpm for 2 min and then sonicating for another 2 min using an ultrasonic probe. The emulsions containing the 150 nm droplets were produced by blending the oil and emulsifier phases using the high-shear blender at 10,000 rpm for 2 min and then passing them through a microfluidizer (M110Y, Micro-fluidics, Newton, MA) at 10,000 psi for 5 passes. Emulsions with different droplets sizes were then mixed with the same amount of stock colorant solution and phosphate buffer solution (10 mM, pH 7). This led to emulsions with the same dye (16.7%, w/w) and oil (10%, w/w) concentrations, but different droplet sizes. All samples were adjusted to a final pH of 7.0.

Effect of Droplet Concentration

Initially, an aqueous emulsifier solution was prepared by dispersing 1% w/w Q-Naturale 200 in double-distilled water. Then, corn oil (30%, w/w) and emulsifier solution (70%, w/w) were pre-blended using the high-shear mixer at 10,000 rpm for 2 min and then recirculated through the microfluidizer at 10,000 psi for 5 passes. The emulsions produced were then mixed with stock dye solutions and phosphate buffer solutions (10 mM, pH 7). The amount of colorant solution was kept constant, while the ratio of emulsion to phosphate buffer solution was varied. This led to emulsions with the same dye concentration (16.7%, w/w) and oil droplet size (~ 160 nm), but different oil droplet concentrations (5, 10, 15, 20, and 25% w/w). All samples were made in duplicate and adjusted a final pH of 7.0.

Droplet size and Surface Charge Characterization

All emulsions were diluted with phosphate buffer solution (10 mM, pH 7) to reach a final droplet concentration of about 0.005% w/w before measuring particle size and surface charge (ζ-potential). This dilution was carried out to minimize the impact of multiple scattering effects on data analysis. The particle size was measured using a Malvern Mastersizer 2000 instrument (Malvern Instruments Ltd., Malvern, Worcestershire, UK), which utilizes static light scattering. The surface charge was measured using a Zetasizer Nano ZS instrument (Malvern Instruments Ltd., Malvern, Worcestershire, UK), which utilizes laser detection of particle movement in an applied electric field to determine the zeta-potential.

Absorbance Measurements

The absorbance spectra of dye solutions were obtained using a UV-visible spectrophotometer (Thermo Scientific GENESYS 150, Waltham, MA). The dye solutions were placed in 1-cm quartz cuvettes and scanned over the wavelength range from 300 to 800 nm. Preliminary experiments were carried out for each colorant to identify the dye concentration required to achieve a maximum absorbance value below 1 cm− 1. The maximum wavelength of each colorant was determined from absorbance spectra and then used to calculate the area under the curve versus concentration data used to construct the calibration curves.

Color and Spectral Reflectance Measurements

The L*, a*, b* values and spectral reflectance of emulsions were measured using an instrumental colorimeter (ColorFlex EZ 45/0-LAV, Hunter Associates Laboratory Inc., Virginia, USA) with a black sided petri dish. The colorimeter was calibrated with standard black and white plates. The measured parameters were L* (light to dark), a* (red to green), and b* (yellow to blue). The spectral reflectance was measured over the wavelength range from 400 to 700 nm.

Statistical Analysis

Emulsion preparation and analysis were replicated, with at least duplicate measurements on each individual sample. The results are then presented as the mean and standard deviation of the combined replicates using EXCEL (Microsoft Corp., Redmond, WA, USA). Statistical differences were calculated at a 95% confidence level using ANOVA with Tukey test and carried out by SPSS software (IBM Corp., Armonk, NY, USA).

Results and Discussion

Effect of Colorant type

As mentioned earlier, the appearance of emulsions depends on the absorption and scattering of light waves as demonstrated by the Kubelka-Munk theory (Eq. 1). The selective absorption of light by chromophores is mainly responsible for the chromaticness or color of emulsions, whereas the scattering of light be particles is responsible for the opacity or turbidity of emulsions [31]. The extent of absorption depends on the absorptivity of the chromophores in the emulsions, which is wavelength dependent [32]. Therefore, the absorbance spectra of colorant solutions were measured to determine the maximum wavelength of each colorant in the visible region of the electromagnetic spectrum (380–780 nm). Turmeric had a single broad peak at 320–500 nm, with a maximum at 424 nm. Red beet had a single broad peak at 390–630 nm, with a maximum at 536 nm. BP flower had a small hump at 550–590 nm and a broad peak at 590–700 nm, with a maximum at 624 nm (Fig. 2a). However, there was also a very strong absorption of light by the BP flower at low wavelengths (< 440 nm). As expected, the maximum wavelengths and absorption patterns of the turmeric, red beet, and BP flower colorants corresponded to those reported for the major pigments they contained, which were curcumin, betalains, and anthocyanins, respectively [34,35,36]. When light is strongly absorbed by a material over specific wavelength ranges, the light that is transmitted through or reflected from it has a complementary color. For instance, for turmeric, most colors are absorbed strongly, except yellow [37]. The fact that turmeric, red beet, and BP flower selectively absorbed light over different wavelength ranges accounts for their different colors: yellow, red, and blue, respectively.

It is not feasible to measure the transmission spectra of concentrated emulsions because the high degree of light attenuation caused by droplet scattering effects [17, 30]. A similar phenomenon is observed in most plant-based food analogs but the nature of the particles that scatter the light is different. For this reason, the optical properties of concentrated emulsions (and plant-based foods) are usually characterized by measuring light reflected from the surface of the material. The tristimulus color coordinates (L*a*b*) can then be calculated from the measured reflectance spectrum. The reflectance spectra of emulsions with the same droplet size (~ 160 nm), droplet concentration (10.0% w/w), and dye concentration (13.3% w/w), but different colorant types (turmeric, red beet, and BP flower) are shown in Fig. 3a. In the absence of dye, the reflectance spectra of all the emulsions were similar, decreasing from around 80–60% when the wavelength was reduced from 700 to 300 nm. This effect can be attributed to increasing light scattering as the wavelength of light was reduced to a value that was closer to the dimensions of the oil droplets in the emulsions. The lack of chromophores in these emulsions led to the relatively high lightness (L*) and low color coordinates (a* and b*) (Fig. 3b). In the presence of colorants, the energy from the light beam was selectively absorbed at specific wavelengths by the chromophores in each colorant, resulting in troughs in the reflectance spectra [32]. For each colorant, these troughs corresponded to the peaks in their absorbance spectra (Fig. 2a). The reflectance troughs of the turmeric, red beet, and BP flower had minimum values around 430, 540, and 620 nm, respectively. Similar to the colorant solutions, the color of the emulsions is a result of selective absorption of chromophores over certain wavelength ranges, which determines the nature of the light waves reflected back to the observer [38]. For instance, the betalains in the red beet emulsion absorbed light from the violet to orange region and therefore only reflected red light back from their surfaces, which accounts for their high positive a* values (redness) (Fig. 3b). Similarly, the curcumin in the turmeric emulsion absorbed light strongly in the region from violet to green, which accounts for their high positive b* values (yellowness). Interestingly, the BP flower did not have a strongly negative b* value (blueness). Instead, it had moderately negative a* and b* values corresponding to reddish blue, which is probably because the BP flower pigment had a more purply color.

As expected, the emulsions without colorant had the highest lightness (L*) and lowest chromaticness (-a*, +a*, -b*, and + b* values) because most of the light traveling through the emulsion did not get absorbed by chromophores and so was reflected back to the surface (Fig. 3b). There were appreciable differences in the lightness values of the different emulsions depending on the colorant type used (Fig. 3b). This effect can mainly be attributed to the fact that more total absorbance of light occurred for some of the emulsions. For instance, the BP flower colorant absorbed light more strongly over a wider range of wavelengths than turmeric. As a result, a smaller fraction of the light waves that were incident on the surface of the BP flower emulsions were reflected back to the detector, leading to a lower lightness value. Previous studies have also reported differences in lightness between emulsions containing green, blue, and red pigments [38].

In terms of the physical stability of the emulsions, the addition of the natural colorants did not have a significant impact on the droplet characteristics, including the mean droplet diameter (D3,2) and surface charge (ξ-potential) as shown in Table 1. These results suggest that none of the colorants interacted with the emulsifier-coated oil droplets. Presumably, the hydrophobic curcumin remained inside the oil droplets, whereas the hydrophilic betalains and anthocyanins remained in the aqueous phase.

As expected, these results show that colorant type affected the optical properties of the model emulsions, including their chromaticness (yellowness, redness, and blueness) and lightness, which can be attributed to their different absorbance versus wavelength profiles. In some cases, it may be possible to select a single colorant to provide the color required in the final product. In these cases, only the concentration of the colorant needs to be adjusted to obtain the desired optical properties, which will depend on the nature of the food matrix. More generally, it may be necessary to blend different natural pigments together to obtain the desired appearance, which will be the subject of our future studies.

The same lower case and capital letters are not statistically different at a 5% level as assessed by the Tukey test.

Effect of Colorant Concentration

The magnitude of selective light absorption depends on the chromophore concentration in a material, which impacts its overall perceived color intensity [32]. The reflectance spectra of emulsions with the same droplet size (~ 160 nm) and droplet concentrations (10% w/w), but different colorant concentrations (0 to 66.7% w/w) were therefore measured to analyze the effects of colorant concentration on emulsion appearance (Fig. 4a-c). As mentioned earlier, there was almost no light absorption in the absence of colorant, resulting in a nearly straight-line spectral reflectance. As the colorant concentration increased from 0 to 13.3%, troughs were observed in all the emulsions, which became deeper as the colorant concentration increased. These troughs resulted from selective absorption of light by the chromophores at a specific wavelength range and occurred at similar wavelengths as the peaks observed in the absorption spectra (Fig. 2a). As the colorant concentration increased, more light is selectively absorbed because there are more pigment molecules in the emulsion, resulting in a deeper trough in the reflectance spectra. The same trend was also observed in a previous study using synthetic red dye [32].

Optical properties of oil-in-water emulsions containing different plant-derived colorant concentrations (0%, 13.3%, 26.7%, 40%, 53.3%, and 66.7%): (a) spectral reflectance of turmeric emulsion; (b) spectral reflectance of red beet emulsion; (c) spectral reflectance of BP flower emulsion; (d) digital photographs of emulsion appearance

The L* value (lightness) of all emulsions decreased as colorant concentration increased because more light was absorbed by the pigments, resulting in less light being reflected back from the emulsion surfaces (Fig. 5a) [31]. However, the magnitude of the decrease with increasing colorant concentration depended on dye type: BP flower > red beet > > turmeric. As discussed earlier, this effect may be due to differences in the absorption spectra of the different colorants (Fig. 2a). As a result, the amount of light reflected back from the turmeric emulsion is higher over a wider range of wavelengths than that reflected back from the BP emulsions (Fig. 3a). Consequently, there is more total absorption of light by the BP emulsions, leading to a lower fraction being reflected from their surfaces, thereby causing a lower lightness.

As expected, visual observations showed that the color intensity increased with increasing colorant concentration (Fig. 4d). However, different patterns of change were observed in the instrumental L*, a*, b* values for each colorant. For the turmeric emulsions, the yellowness (+ b*) increased with rising colorant concentration (Fig. 5c). For the red beet emulsions, the redness (+ a*) increased when the colorant concentration was raised from 0 to 26.7% but did not change significantly when it was raised further (Fig. 5b). For the BP flower emulsions, the blueness (-b*) increased when the colorant concentration was raised from 0 to 13.3%, did not change significantly when it was further raised to 26.7%, but then decreased when it was raised further (Fig. 5c). These effects may be because at high colorant concentrations, little light is reflected back from the emulsions due to the intense light absorption, so they tend to look dark rather than colored.

In general, the colorant concentration had a significant impact on the lightness and chromaticness of the emulsions, specifically the color intensity. Higher colorant concentrations tend to result in a greater amount of selective light absorption and therefore a more intense color. This pattern was also reported in previous studies on synthetic colors [32, 39]. However, the chromaticness of an emulsion can reach a maximum at a specific colorant concentration, as shown for the red beet and BP flower emulsions in this study. This information is useful for formulating plant-based food products to achieve maximum chromaticness without wasting excess colorant.

Effect of Droplet size

In general, the appearance of emulsions is affected by droplet characteristics, such as their size, concentration, and refractive index [30]. In this section, we focused on the impacts of droplet size on the optical properties of plant-based emulsions containing different types of natural color. The reflectance spectra of emulsions with the same oil droplet concentration (10% w/w) and colorant concentration (16.7% w/w), but different droplet sizes (150 nm, 1 μm, and 10 μm) were therefore measured. The samples containing the 150 nm droplets can be considered to be nanoemulsions (d < 200 nm), whereas the samples containing the larger droplets can be considered to be conventional emulsions [40].

The spectral reflectance of all the emulsions decreased with increasing droplet size at all wavelengths (Fig. 6a-c). A similar trend was reported in a previous study using emulsions containing synthetic dyes [38]. This effect can be attributed to an increase in the ratio of absorption-to-scattering effects (K/S) as the droplet size increased, as described by the Kubelka-Munk theory (Fig. 1). Larger oil droplets scatter light less efficiently, leading to a smaller S value, which would be expected to increase the reflectance. However, light waves can penetrate further into an emulsion before being backscattered when the scattering coefficient is low, which results in a higher absorption (K value). The fact that the spectral reflectance decreased with increasing droplet size suggests that the light absorption effects dominated the light scattering ones, i.e., K/S increased. Visual observations of the emulsions indicated that the color intensity increased with increasing droplet size, which again indicates that more selective absorption of light waves occurred for bigger oil droplets (Fig. 6d).

Measurements of the color coordinates (L*a*b*) were used to further quantify the impact of droplet size on the lightness and chromaticness of the emulsions. The lightness (L*) of the emulsions decreased with increasing droplet size, which can again be attributed to more selective absorption of the light waves when the scattering by the oil droplets is weaker. The redness (a*) and yellowness (b*) of the red beet and turmeric emulsions increased as the oil droplet size increased (Fig. 7b-c). These changes can be attributed to stronger light absorption by the emulsions containing larger droplets because the light waves could penetrate further into them before they were scattered backwards [30]. A similar result was observed in previous studies on synthetic dyes [30, 38]. In contrast, the blueness (-b*) of the BP flower emulsions actually decreased with increasing droplet size (Fig. 7c). This effect may have been because the absorption of light became so strong over a wide range of wavelengths that the emulsions started to appear more blackish than blue, which was seen in the visual observations of the emulsions.

Overall, these results show that the size of the droplets in an emulsion has a major impact on its optical properties. This knowledge is important to consider when formulating plant-based food products. For example, two products could have exactly the same composition (including dye and droplet concentrations) but appear very different because the degree of light scattering is altered, which impacts the selective absorption of light. As a result, both the lightness and color of the product are changed.

Effect of Droplet Concentration

The concentration of the droplets in an emulsion is another important factor influencing their optical properties, since it impacts light scattering, and therefore selective light absorption [32]. The impact of droplet concentration on the optical properties of emulsions was examined by measuring the reflectance spectra of samples with the same droplet size and dye concentration, but different droplet concentrations (Fig. 8a-c). The reflectance increased with increasing droplet concentration for all emulsions, which can mainly be attributed to an increase in the degree of light scattering by the oil droplets. In this case, it appears that light scattering effects (S) dominate light absorption effects (K), so that the K/S value decreases with increasing droplet concentration. At lower oil droplet concentrations, there was less scattering, and so more light waves penetrated through the emulsions and were absorbed by pigments. In the absence of oil droplets, the light waves were able to be penetrate deep into the dye solutions, leading to a high degree of light absorbance, and little light being reflected backwards. Moreover, a black plate was used as a backing to the samples, and so any light that did penetrate through the solutions would be completely absorbed. In contrast, as the oil droplet concentration increased, the backscattering of the light waves increased, and so there was less light absorption, which increased the reflectance. A similar trend was reported in a previous study on synthetic dyes [38].

Visual observations of the emulsions showed that their color intensity decreased with increasing droplet concentration (Fig. 8d). For a more quantitative analysis, the L*, a*, and b* values of the same emulsions were measured to quantify their lightness and chromaticness (Fig. 9). The lightness increased as the oil droplet concentration increased for all emulsions because of the higher degree of light scattering discussed earlier. However, there was no significant change in the lightness when the droplet concentration exceeded around 15% for the turmeric emulsion and 20% for the red beet emulsion (Fig. 9a). A similar effect was reported in a study of the impact of droplet concentration on emulsions containing synthetic red, green, and blue colors [38]. For the chromaticness, the redness (a*) and yellowness (b*) decreased with increasing droplet concentration for red beet and turmeric emulsion, respectively (Fig. 9b-c). This was because at higher droplet concentration, there was more light scattering and so less light penetrated into the emulsions. As a result, there was less selective absorption of the light waves by the pigments, which resulted in a lower color intensity. In contrast, for the BP flower emulsion, there was an increase in blueness (-b*) when the droplet concentration was raised from 0 to 5%, but then a slight decrease when it was raised further (Fig. 9c). A similar trend was observed in a previous study of synthetic dyes [38]. The addition of a small amount of oil droplets could initially increase the blueness of the emulsions by increasing the light scattering, thereby reducing their darkness. However, the addition of more oil droplets could reduce their blueness for the reasons discussed for the other colors.

This study has shown that droplet concentration has a significant impact on the appearance of emulsions, which is mainly attributed to their ability to scatter light waves. The intensity of light scattering tends to increase with increasing droplet concentration. However, the impact of these light scattering effects on the appearance of emulsions depends on the type of dye present. For instance, color fading was observed in the turmeric and red beet emulsions when the droplet concentration was raised, but color intensification was observed in the BP flower emulsions. This kind of information can be helpful for formulating plant-based foods, e.g., optimizing the amount of oil required to obtain an opaque or cloudy looking sample.

CIELAB color coordinates of natural colorants in oil-in-water emulsions with different droplet concentrations (0%, 5%, 10%, 15%, 20%, 25%): (a) L*-value; (b) a*-value; (c) b*-value. Different letters represent statistically differences between different droplet concentrations at a 5% level by the Tukey test

Conclusion

This study has shown the impact of colorant and oil droplet characteristics on the lightness and chromaticness of model plant-based foods, i.e., oil-in-water emulsions. Colorant characteristics, such as type and concentration, mainly impact selective light absorption, which influences the overall perceived color. In contrast, oil droplet characteristics, such as size and concentration, mainly impact light scattering, which influences both the opacity and color of emulsions. Indeed, it is important to note that absorption and scattering effects influence each other. For example, a lower degree of light scattering due to the presence of larger oil droplets can increase the color intensity because the light waves can penetrate further into the emulsions and undergo greater selective absorption by the chromophores. Therefore, to increase the color intensity of plant-based foods, it is not always necessary to add more colorant. Instead, it may be possible to adjust the size and/or concentration of any objects that scatter light, such as fat droplets or protein fibers. As a general trend, the color intensity increased with increasing colorant concentration, decreasing droplet concentration, and increasing droplet size, whereas the opacity increased with decreasing colorant concentration, increasing droplet concentration, and decreasing droplet size. However, both absorption and scattering are wavelength-dependent phenomenon and so these effects also depend on colorant type.

Individual plant-based colorants can only provide a limited range of colors (e.g., yellow, red, and blue), which may not be suitable for some applications. In future, we intend to combine these primary colors in different ratios so as to create new colors that more accurately represent the colors of animal-based foods.

References

J. Poore, T. Nemecek, Science 360(6392), 987–992 (2018)

C. Bonnet, Z. Bouamra-Mechemache, V. Requillart, N. Treich, Food Policy 97 (2020)

E. Ignaszewski, 2022

L.L. Garber, E.M. Hyatt, R.G. Starr, J. Food Prod. Mark. 7, 3–24 (2001)

J.B. Hutchings, Food Color and Appearance, 2nd edn. (Aspen Publishers, Gaithersburg, Md., 1999)

D.J. McClements, L. Grossmann, Compr. Rev. Food Sci. F 20(4), 4049–4100 (2021)

M. Kazir, Y.D. Livney, Molecules 26 (6) (2021)

D.B. Rodriguez-Amaya, Curr. Opin. Food Sci. 7, 20–26 (2016)

M. Carocho, M.F. Barreiro, P. Morales, I.C.F.R. Ferreira, Compr. Rev. Food Sci. F 13(4), 377–399 (2014)

J.N. Liu, Y.B. Tan, H.L. Zhou, J.L.M. Mundo, D.J. McClements, J. Food Eng. 254, 1–9 (2019)

C. Tan, M.J. Selig, A. Abbaspourrad, Carbohyd Polym. 181, 124–131 (2018)

F.Y. de Boer, A. Imhof, K.P. Velikov, Color. Technol. 135(3), 183–194 (2019)

G.T. Sigurdson, P.P. Tang, M.M. Giusti, Annu. Rev. Food Sci. T 8, 261–280 (2017)

H.E. Khoo, A. Azlan, S.T. Tang, S.M. Lim, Food Nutr. Res. 61, 1–21 (2017)

S.J. Hewlings, D.S. Kalman, Foods 6 (10) (2017)

T. Esatbeyoglu, A.E. Wagner, V.B. Schini-Kerth, G. Rimbach, Mol. Nutr. Food Res. 59(1), 36–47 (2015)

D.J. McClements, L. Grossmann, SpringerLink, Next-Generation Plant-based Foods: Design, Production, and Properties, 1st 2022. ed. (Springer International Publishing: Imprint: Springer, Cham, 2022)

C. Masia, P.E. Jensen, I.L. Petersen, P. Buldo, Foods 11 (2) (2022)

S.E.S. Michel, R. Scheermeijer, M. Ambuhl, J Food Eng 335 (2022)

X.Y. Hu, H.L. Zhou, D.J. McClements, Food Structure-Netherlands 33 (2022)

D.J. McClements, Foods 9 (4) (2020)

A.N. Mohammed, S.P. Ishwarya, P. Nisha, Food Bioprocess. Tech. 14(1), 133–150 (2021)

J.J. Chen, F. Li, Z.Z. Li, D.J. McClements, H. Xiao, Food Hydrocolloid 69, 49–55 (2017)

M. Kharat, G.D. Zhang, D.J. McClements, Food Res. Int. 111, 178–186 (2018)

S. Banasaz, K. Morozova, G. Ferrentino, M. Scampicchio, Eur. Food Res. Technol. 248(12), 2969–2975 (2022)

M. Chaijan, K. Srirattanachot, M. Nisoa, L.Z. Cheong, W. Panpipat, Food Chemistry 339 (2021)

S. Caballero, G. Davidov-Pardo, Food Chemistry 338 (2021)

J. Tippel, V. Reim, S. Rohn, S. Drusch, Food Res. Int. 87, 68–75 (2016)

J.M. Hughes, F.M. Clarke, P.P. Purslow, R.D. Warner, Compr. Rev. Food Sci. F 19(1), 44–63 (2020)

W. Chantrapornchai, F. Clydesdale, D.J. McClements, J. Agr Food Chem. 46(8), 2914–2920 (1998)

D.J. McClements, Adv. Colloid Interfac 97(1–3), 63–89 (2002)

W. Chantrapornchai, F. Clydesdale, D.J. McClements, J. Colloid Interf Sci. 218(1), 324–330 (1999)

B.J. Zheng, S.F. Peng, X.Y. Zhang, D.J. McClements, J. Agr Food Chem. 66(41), 10816–10826 (2018)

H.V. Nong, L.X. Hung, P.N. Thang et al., Springerplus 5 (2016)

D. Butera, L. Tesoriere, F. Di Gaudio et al., J. Agr Food Chem. 50(23), 6895–6901 (2002)

S. Saha, J. Singh, A. Paul, R. Sarkar, Z. Khan, K. Banerjee, J. Aoac Int. 103(1), 23–39 (2020)

F. Miller, College Physics, 4th edn. (Harcourt Brace Jovanovich, New York, 1977)

W. Chantrapornchai, F. Clydesdale, D.J. McClements, Colloid Surf. A 155(2–3), 373–382 (1999)

R. Chanamai, D.J. McClements, Food Hydrocolloid 15(1), 83–91 (2001)

L. Salvia-Trujillo, D.J. McClements, Food Biophys. 11(1), 1–9 (2016)

Acknowledgements

We thank Hualu Zhou and Jean Alamed for useful advice on the experiments.

Funding

This material was partly based upon work supported by the National Institute of Food and Agriculture, USDA, Massachusetts Agricultural Experiment Station (MAS00559) and USDA, AFRI (2020–03921) Grants, as well as the Good Food Institute.

Author information

Authors and Affiliations

Contributions

Donpon Wannasin designed, performed, and analyzed the experiments, as well as preparing the figures and writing the first draft of the manuscript. David Julian McClements secured the funding, designed the experiments, and reviewed and edited the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no known conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wannasin, D., McClements, D.J. Optimizing the Appearance of plant-based Foods: Impact of Pigment and Droplet Characteristics on Optical Properties of Model oil-in-water Emulsions. Food Biophysics 18, 289–301 (2023). https://doi.org/10.1007/s11483-022-09771-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-022-09771-6