Abstract

Emulsions are partially produced in the structures of many natural and artificial (processed) foods. In general, “emulsion” is defined as a structure formed through the dispersion of one or two immiscible liquids within the other in the form of small drops. Emulsion-based delivery systems can offer many possible benefits for incorporating essential oils such as omega-3 (ω-3) into foods and beverages. There are also many terms available to describe the different types of emulsions and it is very important to define and clarify these terms as “oil/water”, “micro”, “macro” and “nano” and “suspo” emulsions. This review can provide a general description of the general terms of the types of emulsion, the role of various emulsifying agents and the possible application of emulsions in various sectors of the food and agricultural industry.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Active substance carries

- Colloids

- Controlled release

- Prolonged and sustained release

- Sustainable polymers

9.1 Introduction

The processing, conservation, safety and quality of food are the most important concerns in all sectors of the food industry today (Rasooli 2007; Amaral and Bhargava 2015). The process of preparing the emulsion is the determination of two different phases, such as oil droplets are formed in an aqueous phase and water droplets are formed in an oil phase. The emulsions are not determined by the ratio between the two phases that can be clearly observed, e.g. 80% oil and 20% water (Bergenstahl and Claesson 1997). An emulsion protects the emulsion droplets distributed uniformly throughout the storage days and consumption periods (Chanamai and McClements 2002). This has led the food manufacturing sectors and many scientists’ to investigate the capability of flocculation, coalescence, edible polymers (proteins and polysaccharides) to stabilize emulsion droplets against the creation process, and evaluate their potential applications.

Agrochemical companies are increasing the development of chemical emulsions at the nanoscale and replacing the pure active ingredients with the active compounds encapsulated in their nanometric equivalent with the effort of providing a series of benefits for applications of nanoscience to insecticides (Gogos et al. 2012; Kumar et al. 2014), and other agro-chemicals such as fertilizers (Agrawal and Rathore 2014) and plant growth devices (Mura et al. 2015). The stability of a food emulsion is the most important thing to consider in relation to its industrial applications, and depends on the rheology of the continuous phase and the interactions between the particles of the dispersed phase (Melik and Fogler 1998; Brewer et al. 2016). The simple difference between a nanoemulsion and a conventional emulsion is that a nanoemulsion does not alter the appearance of the food product when added to it (Dreher 2004).

Emulsion is the basis of a wide variety of natural and artificial materials used in the processing of food products, pharmacological and industrial sectors cosmetics (Schramm 1992; Lin and Mei 2000; Achouri et al. 2012). Currently, the new ingredients are regularly combined in various food processing systems to improve their rheological, physico-chemical and dietary food properties. However, these ingredients can sometimes be degraded slowly and lose their activities, due to oxidation processes, reactions with various components present in processed foods or food systems, which may limit their change in taste and color of products food (Schrooyen et al. 2001), so its stabilization is necessary.

9.2 Emulsion

An emulsion is a combination of two or more liquids (such as oil and water) that are not easily combined (GuhanNath et al. 2014).

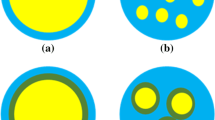

9.2.1 Oil/Water (O/W) Emulsions

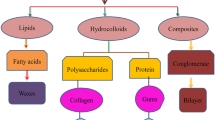

O/W emulsions are now receiving a significant attention, because of the needs to eliminate or reduces the volatile organic solvent for safer handling (Hazra et al. 2017) purposes. An O/W emulsion is a system in which the active ingredient must have very a low water solubility and to avoid the crystallization problems (Tadros 1995). O/W emulsion is a type of emulsion and is the most common used in the food processing industrial sectors, such as mayonnaises, sauces and dairy products. Even though, the processed food products such as sausages and liver pates can also be considered as O/W emulsions (Knightly 1989; Gutiérrez and Álvarez 2017; Gutiérrez 2018a). The functional activity of the O/W emulsions depends to a large extent on the nature of the oil droplets (Derkach 2009; Le Reverend et al. 2010; Bai and McClements 2016). Previously, many studies have also been reported that the stability of O/W emulsions depends on their concentration and types of ingredients used in the emulsion, as well as the processing and storage conditions (McClements 1999). O/W emulsions can be classified into two different forms, such as diluted form and concentrated form. The emulsions are a single class of O/W emulsion because they can be highly consumed in diluted forms, such as fruit juice beverages and milk-based products and in their emulsification of concentrated form such as butter and creams (Lorenzo et al. 2018). The emulsion might thus have a significant degree of stability in both diluted and concentrated forms (Tan 1990).

9.2.1.1 Uses of O/W Emulsions in Food and Agro Applications

Gum arabic is one of the most commonly used biopolymers in food and beverage applications (Garti and Reichman 1993). Starches are now generally used in milk-based food products, because of their good emulsion properties, and also as promising substitutes for gum arabic (Trubiano 1995; Achouri et al. 2012; Zheng 2018). Other alternative gums include tragacanth (Imeson 1992) and λ-carrageenan (Huang et al. 2001) have also been reported as effective stabilizing and thickening agents. Proteins, containing soy and whey, are better emulsifications that can modify both the emulsion droplet charges (Singh and Ye 2000) and the interfacial membrane thickness in O/W emulsions (Achouri et al. 2012) and forms the stabilizing films against oxidation process (Djordjevic et al. 2008; McClements 2004). In addition, factors that could contribute to the emulsion stabilization or destabilization process, such as the type of hydrocolloid used, the possible combinations of hydrocolloid with protein, and the oil absorption to be dispersed have not been reported (Achouri et al. 2012). There is a growing interest in the formulation of value-added products containing various health constituents, such as minerals, vitamins, and omega-3 (ω-3), etc., for the functional food products in the market. Such emulsion concentration can be useful as feedstock emulsions and for other emulsions in suspension, as well as for organizing stability in O/W emulsion distributions. Hence, the consideration and also the monitoring the several factors that influence the stabilization and the shelf-life of prepared emulsion matrices is an acute for its continued success in the food markets.

9.2.2 W/O Emulsion

The W/O emulsion is the well-known area of industrial food processing sectors in the field of ‘yellow fat’ food products, such as spreads and margarines (Knightly 1989; Muschiolik and Dickinson 2017). The lipophilic emulsification which has been mainly used to prepare the primary W/O emulsions of food grade water-oil-water (W/O/W) formulations is a poly-glycerol poly-ricinoleate (Takahashi et al. 1986). In connection with the development of various functional food products that can be improved with the addition of probiotics, there is a growing interest in improving the viability of the bacterial cells through an encapsulation of W/O/W emulsions (Jimenez-Colmenero 2013). The W/O/W emulsions in polyunsaturated fatty acids through a determined selection of edible oil phases, such as linseed oil (Poyato et al. 2013), chia oil (Cofrades et al. 2014) or perilla oil (Flaiz et al. 2016) can also allow the development of improved functional foods in terms of stability and nutritional aspects. In a recent study by Altuntas et al. (2017) demonstrated that an optimal amount of poly-glycerol poly-ricinoleate is necessary so that the stability of the W/O droplets can be significantly reduced by merging the poly-glycerol polyricinoleate emulsifier with an equal amount of the lecithin (natural emulsifier).

9.2.3 Micro-Emulsions

According to Danielsson & Lindman, “a micro-emulsion is a system of water, oil and an amphiphile which is a single optically isotropic and thermodynamically stable liquid solution ” (Serdaroglu et al. 2015).

Micro-emulsions can have different characteristic properties, such as large interfacial area, oil-soluble compounds and ultra-low interfacial tension (Friberg and Bothorel 1987; Paul and Moulik 2001). Micro-emulsions can be prepared by controlling the addition of lower alkanol’s to the cloudy emulsions to produce the transparent solutions comprising W/O or O/W dispersions in colloidal systems (Shah 1998). Micro-emulsions are thermodynamically stable and have a spontaneous shape in different diameters ranging from 5 to 100 nm (Zhang 2011). In general, a scientist considers that the nano-emulsions are very similar to micro-emulsions, since both includes typically oil, water and surface-active components (surfactant) (Serdaroglu et al. 2015). The nano-emulsions are nevertheless formed by a mechanical force, while the micro-emulsion phases are formed by self-assembly (Fanun 2009; Zhang 2011). Therefore, the main differences between the micro- and micro emulsions are derived from thermodynamic characteristics of emulsions instead than compositions (Flanagan and Singh 2006; Whitesides and Grzybowski 2002; Zhang 2011).

The micro-emulsions as a functional state of lipids have been used in the preparation of processing of food products (El-Nokaly et al. 1991). The main differences between food processing and other micro-emulsions are found in the composition of oil components in food-grade surfactants (Paul and Moulik 2001). Candau and Anquetil (1998) reviewed information on O/W and W/O micro-emulsions that are formed using food grade ingredients to potentially incorporate various food ingredients such as preservatives, flavor and vitamins into the micro in emulsions. Paul and Moulik (2001) also reviewed the various micro-emulsions as drug delivery systems for the use of different types of drugs, such as peptide drugs, steroids and anti-inflammatory drugs.

9.2.4 Macro-Emulsions

Macro-emulsions are typical droplet diameters of various conventional emulsions, called as “macro emulsions”, and vary between 100 nm and 100 μm. Macro-emulsions are the most common type of emulsification used in many different forms such as beverages, mayonnaise, desserts, sauces and milk (Serdaroglu et al. 2015). Macro-emulsions tend to be physically unstable, especially when they can undergo environmental stresses such as gravitational separation, coagulation and aggregation (Aoki et al. 2005; Dickinson 2009; Zhang 2011).

9.2.5 Suspo-Emulsions

Suspo-emulsions can be considered as mixtures of various suspension concentrates and emulsifications (Gasic and Tanovic 2013). The product is very difficult to formulate, because it is necessary to develop homogeneous emulsion components simultaneously while they are stable in the final formulation of the product (Tadros 2005). In addition, it is also necessary to overcome the problem of hetero-flocculation between oil droplets and solid particles (Vernner and Bauer 2007). The extensive storage stability testing of this type of formulation is very necessary (Knowles 2008). Despite the complexity of this formulation, the use and the importance of suspo-emulsions has been extraordinary and will continue to increase.

9.2.6 Nanotechnology

In today’s competitive market, a new frontier technology is essential to maintain its leadership in the industrial food processing sector (Raj et al. 2013). Nanotechnology or nanoscience has become one of the most innovative scientific fields in the coming decades. Nanotechnology can involve in the use of diverse materials in an extremely small scale, usually 0.1–200 nano-meters (Sozer and Kokin 2008), due to the different characteristic properties of many processed foods on nano-meter sized components, such as nano-emulsions and foams (Chaudhry et al. 2008). In this sense, nanotechnology is increasingly used in the various areas of food processing, production and packaging systems (Sanguansri and Augustin 2006; Wesley et al. 2014).

9.2.6.1 Nanotechnology – Science and Technology

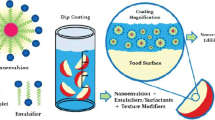

Nano-technology has the potential to influences the various aspects of food and agricultural systems. The numerous applications of nano-technology in food and agriculture are innovative compared to their use in pharmaceutical and medicinal products (GuhanNath et al. 2014). However, scientists and industrial stakeholders have already identified the potential uses of nanotechnology in virtually all segments of the food industry (Fig. 9.1) from agriculture as fertilizer, pesticides and plant pathogen devices to food processing as encapsulation. Other applications have also been used in the food field to improve the quality and safety of food, as well as for the food packaging secto (Brody 2007; Bracone et al. 2016; Gutiérrez 2018b).

Nanotechnology has various applications in all the areas of food science/technology, from agriculture to food processing to quality/safety to packaging to nutrition and nutraceuticals/pharmaceutical supplements (Raj et al. 2013)

9.2.6.2 Nanotechnology in Agricultural Production

During primary production, nanoformulated agrochemicals are used to increase the efficacy of agrochemicals linked to conventional formulations. Only a few insecticides containing nanoformulates and nanometric-sized agrochemicals have been identified as commercially available. In addition, nanoparticles are used to clean the soil and water (Bouwmeester 2009). The nanostructured materials can exhibit unique properties that will open many windows of opportunity for the creation of innovative and high-performance materials, which will have an acute impact on the food processing, packaging and storage. Many reports have considered that the agricultural industry is a potential sector for nanoscience and nanotechnology applications. In the future, nanostructured catalysts will be available, which will expand the potential of nanoemulsions as pest controllers, using lower amounts of agrochemicals (IRGC 2008).

9.2.6.3 Nanotechnology in Food Processing

The numerous nanotechnologies are applied in the sectors of food processing and packaging such as the use of nano-sieves (Bouwmeester 2009). Current applications of nanotechnology in agri-food production chain is focused on the development of various nano-sized food components, additives and innovative food packaging (Chaudhry et al. 2008).

9.2.6.4 Nano-Emulsions

Nanoemulsion is one of the technologies in development, especially in the food and pharmaceutical industry, as a new system for the release of healthy substances (Chen and Wagner 2004; Wooster et al. 2008; Mao et al. 2009). The possible benefit of nano-emulsions includes good separation stability, coalescence and flocculation. The bioavailability of functional compounds can also be improved by the use of nanoemulsions (Shafiq et al. 2007; Wang et al. 2008; Shakeel et al. 2008, Dingman 2008). Nanoemulsions can be used to encapsulate oils and increase their water-dispersibility (McClements 2011). According to McClements and Decker (2000), different types of nano-emulsions with more complex properties, such as nanostructured multilayer emulsions, can offer multiple encapsulation capabilities in a single administration system. This interfacial engineering technology is used to achieve the homogenous mixture of food grade ingredients (such as phospholipids, polysaccharides and proteins) with different natural chemicals, thus expanding the use of emulsions in food (Weiss et al. 2006), e.g. Nestlé and Unilever have developed ice creams based on nano-sized emulsions with a lower fat content (Renton 2006; McClements 2004). Nano-emulsions are formulated using two different methods (Solans et al. 2005):

-

I. High energy approaches

-

High energy approaches can be used to break oil drops.

-

II. Low energy approaches

-

Low energy approaches are based on the spontaneous formation of several drops of oil within the mixed systems of oil, water and surfactant.

Nanoemulsions have great potential to overcome the various challenges associated with the development of processed food products and beverages enriched with ω-3 (Waraho et al. 2011; Li et al. 2013). It can be considered that nanoemulsions have good kinetic stability and high optical clarity, which is important for the main applications in many processed foods and beverages (Mason et al. 2006). Nanoemulsion-based delivery systems must still be carefully deliberated to ensure high bioavailability and good physical and chemical stability (Walker and Rebecca 2015). Surfactants are very critical, since emulsions must quickly cover the many new surfaces that are forming (Dickinson 2003).

In general, in food processing or food emulsions can be classified into two classes of surfactants (surface-active) as follows:

-

1.

Small-molecule surfactants, such as sucrose esters and mono-glycerides, and

-

2.

Macro-molecular emulsifications such as modified starches or proteins (Amaral and Bhargava 2015).

9.2.6.5 Properties of Nanoemulsions

Nanoemulsions have a low viscosity and high kinetic stability. Nanoemulsions are a core of attention for many industrial applications and some of them can be summarized below (Tadros 2004; Gutierrez 2008):

-

No sedimentation during storage period: very small drop sizes can cause a large reduction in the gravitational forces.

-

No amalgamation: this is due to the droplets of small size and also to the main thicknesses of the surfactant film that prevent coalescence/amalgamation, and the interruption between the O/W droplets (Sadurni 2005).

-

Nanoemulsions can be applied for the delivery of fragrances and the development of formulated alcohol-free products (Baran and Maibach 1997).

9.2.6.6 Uses of Nano-Emulsions in Food and Agricultural Applications

The production of nanoemulsion to encapsulate various functional compounds is one of the fields in the development of nanoscience/technology applied to the sectors of the food industry (Silva et al. 2012). It also offers one of the most promising systems to improve solubility, bioavailability and functionality of hydrophobic compounds (Walker and Rebecca 2015; Nethaji and Parambil 2017). Some companies working on nanoemulsions for food applications can be listed below:

-

Nutra-Lease, is a technology start-up company established by a scientific group, and is working to improve the bioavailability of various functional compounds. Mainly in beverages containing encapsulated functional compounds such as lycopene, ω-3, β-carotene and phytosterols (NutraLease 2011).

-

Unilever has made an ice cream healthier without compromising flavor in the application of nanoemulsions. This ice cream has a low-fat content varying between 16–1% (Martins et al. 2007; Unilever 2011).

-

Nestle has a patent on W/O emulsions, whose objective is to achieve a simpler and faster thawing by the addition of micelle-forming substances and poly sorbates. It is claimed that they contribute to a uniform thawing of frozen food products in the microwave process (Möller et al. 2009). This type of W/O emulsions is the drug delivery system most commonly used to incorporate ω-3 oils in processed food products and beverages such as bulk oils and powders (spray-drying emulsions) (Jacobsen 2010).

Microencapsulation has proven to be a popular way to create ω-3 powder that can be incorporated into a variety of food products, such as baked goods, spreads and fruit drinks (Drusch 2012). Nanoemulsions offer a convenient means to fortify many water-based food and beverage products with ω-3 oils. Fortified nano-emulsions could be introduced into food systems such as beverages, sauces and desserts (Velikov and Pelan 2008; Yang et al. 2012). Current liquid or semisolid food products that have been enriched with ω-3 fatty acids using emulsion-based delivery systems include table spreads, yogurts and milk (Chee et al. 2005; Sharma 2005; O’ Dwyer et al. 2013; Lane et al. 2014). Nanoemulsions in the form of proteins (e.g. egg and vegetable protein) or carbohydrates (e.g. starch, pectin and guar gum) help to improve the texture and lead to the uniformity of the ice cream (Hogan et al. 2001). Brominated vegetable oil, ester gum and sucrose-acetate iso-butyrate are used as the weighting agent (Gilbert 1985). Biomolecules such as milk proteins and carbohydrates (e.g. dextrin) can prove to be potential carrier of nutrients with the help of encapsulation (Fernandez et al. 2009).

Hydrolyzed milk proteins, such as 𝛼-lactalbumin, have evolved to be a potential carrier of drugs, nutrients and supplements (Yoksan et al. 2010). Functional compounds that are generally encapsulated by self-assembled nanoemulsions are lutein, 𝛽-carotene, lycopene, vitamins A, D, E3 and Q10 and iso-flavones (Brody 2007). For example, the effectiveness of carvacrol nanoemulsions against E. coli on broccoli (Severino et al. 2014), radish seed, Salmonella enterica (Landry et al. 2015) and alfalfa seeds has been demonstrated in the literature. Recently Donsi et al. (2015) have also reported that the antibacterial and physical properties of modified chitosan-based coatings containing nanoemulsion of mandarin essential oil on green beans. In another study carried out by Kim et al. (2013) reported the application of lemon grass oil nanoemulsions on plums. These authors found an antimicrobial effect from the nanoemulsion and the physical and chemical properties of the plums were improved.

Nanoemulsions containing active nutraceutical agents may be used for the production of functional and medicinal foods (Solans et al. 2005). Nanoemulsions are acceptable because coalescence is not observed unlike macroemulsions (Gadhave 2014). Limited studies are carried out on food model and there are several challenges in application of this system in complex food matrices such as meat products (Amaral and Bhargava 2015).

9.3 Conclusions

Emulsions have a long history of use and are widely used in many foods and agrochemical inputs. The production of nanoemulsions to encapsulate and release active food and agrochemical substances is an area of knowledge in full development. However, more research at a pilot or industrial scale is required in terms of new equipment and nanoemulsion techniques for agri-food applications. The stability of the O/W emulsions are strongly influenced by the size of the drop, the charge and the concentration. In the modern period, multiple emulsions can be produced at different scales such as micro, macro, suspo or nano. The development of new food products every day is more related to the development of this type of polymer systems. The application of nanoemulsions in food processing technology still poses challenges that must be addressed both in terms of the production process and costs, but more continuous investment is required to finance research and development (R&D), in order to better understand the advantages and disadvantages that are offered from nanoemulsions systems. This chapter could thus be useful to help improve the understanding of colloidal instabilities in emulsions and how they could be improved with the objectives of their application in the agri-food industry.

References

Achouri, A., Zamani, Y., & Boyne, J. I. (2012). Stability and physical properties of emulsions prepared with and without soy proteins. Journal of Food Research, 1(1), 254–267. https://doi.org/10.5539/jfr.v1n1p254.

Agrawal, S., & Rathore, P. (2014). Nanotechnology pros and cons to agriculture: A review. International Journal of Current Microbiology and Applied Sciences, 3(3), 43–55.

Altuntas, O. Y., Sumnu, G., & Sahin, S. (2017). Preparation and characterization of W/O/W type double emulsion containing PGPR–lecithin mixture as lipophilic surfactant. Journal of Dispersion Science and Technology, 38(4), 486–493. https://doi.org/10.1080/01932691.2016.1179121.

Amaral, D. M. F., & Bhargava, K. (2015). Essential oil nano-emulsions and food applications. Advances in Food Technology Nutritional Sciences Open Journal, 1(4), 84–87. https://doi.org/10.17140/aftnsoj-1-115.

Aoki, T., Decker, E. A., & McClements, D. J. (2005). Influence of environmental stresses on stability of O/W emulsions containing droplets stabilized by multi-layered membranes produced by a layer-by-layer electrostatic deposition technique. Food Hydrocolloids, 19(2), 209–220. https://doi.org/10.1016/j.foodhyd.2004.05.006.

Bai, L., & McClements, D. J. (2016). Extending emulsion functionality: Post-homogenization modification of droplet properties. Process, 4(17), 1–18. https://doi.org/10.3390/pr4020017.

Baran, R., & Maibach, H. (1997). Textbook of cosmetic dermatology (4th ed.). Boca Raton: CRC Press.

Bergenstahl, B. A., & Claesson, P. M. (1997). Surface forces in emulsions. In S. E. Friberg & K. Larsson (Eds.), Food emulsions (3rd ed.). New York/Basel: Marcel Dekker.

Bouwmeester, H. (2009). Review of health safety aspects of nanotechnologies in food production. Regulatory Toxicology and Pharmacology, 53(1), 52–62. https://doi.org/10.1016/j.yrtph.2008.10.008.

Bracone, M., Merino, D., González, J., Alvarez, V. A., & Gutiérrez, T. J. (2016). Chapter 6. Nanopackaging from natural fillers and biopolymers for the development of active and intelligent films. In S. Ikram & S. Ahmed (Eds.), Natural polymers: Derivatives, blends and composites (pp. 119–155). New York. EE.UU. ISBN: 978-1-63485-831-1: Editorial Nova Science Publishers, Inc.

Brewer, D. R., Franco, J. M., & Garcia-Zapateiro, L. A. (2016). Rheological properties of oil-in-water emulsions prepared with oil and protein isolates from sesame (Sesamum indicum). Food Science and Technology, Campinas, 36(1), 64–69. https://doi.org/10.1590/1678-457x.6761.

Brody, A. L. (2007). Case studies on nanotechnologies for food packaging. Food Technology, 07, 102–107.

Candau, F., & Anquetil, J. (1998). In D. O. Shah (Ed.), Micelles, micro-emulsions and monolayers: Science and technology (p. 193). New York: Marcel Dekker.

Chanamai, R., & McClements, D. J. (2002). Comparison of gum Arabic, modified starch and whey protein isolate as emulsifiers: Influence of pH, CaCl2 and temperature. Journal of Food Science, 67(1), 120–125. https://doi.org/10.1111/j.1365-2621.2002.tb11370.x.

Chaudhry, Q., Scotter, M., & Blackburn, J. (2008). Applications and implications of nanotechnologies for the food sectors. Food Additives and Contaminants, 25(3), 241–258. https://doi.org/10.1080/02652030701744538.

Chee, C. P., Gallaher, J. J., Djordjevic, D., Faraji, H., McClements, D. J., & Decker, E. A. (2005). Chemical and sensory analysis of strawberry flavoured yogurt supplemented with an algae oil emulsion. Journal of Dairy Research, 72(3), 311–316. https://doi.org/10.1017/S0022029905001068.

Chen, C., & Wagner, G. (2004). Vitamin E nanoparticle for beverage applications. Chemical Engineering Research Desiccation’s, 82(11), 1432–1437. https://doi.org/10.1205/cerd.82.11.1432.52034.

Cofrades, S., Santos-Lopez, J. A., Freire, M., Bened, J., Sanchez-Muniz, F. J., & Jimenez-Colmenero, F. (2014). Oxidative stability of meat systems made with W1/O/W2 emulsions prepared with hydroxytyrosol and chia oil as lipid phase. LWT-Food Science and Technology, 59(2), 941–947. https://doi.org/10.1016/j.lwt.2014.06.051.

Derkach, S. R. (2009). Rheology of emulsions. Advances in Colloid Interface Sciences, 151(1–2), 1–23. https://doi.org/10.1016/j.cis.2009.07.001.

Dickinson, E. (2003). Hydrocolloids at interfaces and the influence on the properties of dispersed systems. Food Hydrocolloids, 17(1), 25–39. https://doi.org/10.1016/S0268-005X(01)00120-5.

Dickinson, E. (2009). Hydrocolloids as emulsifiers and emulsion stabilizers. Food Hydrocolloids, 23(6), 1473–1482. https://doi.org/10.1016/j.foodhyd.2008.08.005.

Dingman, J. (2008). Nanotechnology: Its impact on food safety. Journal of Environmental Health, 1(3), 5–8.

Djordjevic, D., Cercaci, L., Alamed, J., McClements, D. J., & Decker, E. A. (2008). Stability of citral in protein and gum arabic-stabilized oil-in-water emulsions. Food Chemistry, 106(2), 698–705. https://doi.org/10.1016/j.foodchem.2007.06.033.

Donsi, F., Marchese, E., & Maresca, P. (2015). Green beans preservation by combination of a modified chitosan based-coating containing nano-emulsion of mandarin essential oil with high pressure or pulsed light processing. Postharvest Biology and Technology, 106, 21–32. https://doi.org/10.1016/j.postharvbio.2015.02.006.

Dreher, K. L. (2004). Health and environmental impact of nanotechnology: Toxicological assessment of manufactured nanoparticles. Toxicological Sciences, 77(1), 3–5. https://doi.org/10.1093/toxsci/kfh041.

Drusch, S. (2012). An industry perspective on the advantages and disadvantages of different fish oil delivery systems. In N. Garti & D. J. McClements (Eds.), Encapsulation technologies and delivery systems for food ingredients and nutraceuticals (pp. 488–504). https://doi.org/10.1533/9780857095909.4.488.

El-Nokaly, M., Hiler, G., & McGrady, J. (1991). In M. El-Nokaly & D. Cornell (Eds.), Micro-emulsions and emulsions in foods (pp. 26–43). Washington, DC: American Chemical Society.

Fanun, M. (2009). Properties of micro-emulsions with sugar surfactants and peppermint oil. Colloid Polymer Science, 287(8), 899–910. https://doi.org/10.1007/s00396-009-2043-y.

Fernandez, A., Torres-Giner, S., & Lagaron, J. M. (2009). Novel route to stabilization of bioactive antioxidants by encapsulation in electrospun fibers of zein prolamine. Food Hydrocolloids, 23(5), 1427–1432. https://doi.org/10.1016/j.foodhyd.2008.10.011.

Flaiz, L., Freire, M., Cofrades, S., Mateos, R., Weiss, J., Jimenez-Colmenero, F., & Bou, R. (2016). Comparison of simple, double and gelled double emulsions as hydroxytyrosol and n-3 fatty acid delivery systems. Food Chemistry, 213(15), 49–57. https://doi.org/10.1016/j.foodchem.2016.06.005.

Flanagan, J., & Singh, H. (2006). Micro-emulsions: a potential delivery systems for bio-actives in food. Critical Review in Food Science and Nutrition, 46(3), 221–237. https://doi.org/10.1080/10408690590956710.

Friberg, S. E., & Bothorel, P. (1987). Micro-emulsions: Structure and dynamics (p. 1987). Boca Raton: CRC Press.

Gadhave, A. D. (2014). Nano-emulsions: Formation, stability and applications. International Journal for Research in Sciences and Advanced Technologies, 3(2), 38–43.

Garti, N., & Reichman, D. (1993). Hydrocolloids as food emulsifiers and stabilizers. Food Structure, 12, 411–426.

Gasic, S., & Tanovic, B. (2013). Biopesticide formulations, possibility of application and future trends. Pesticides Phytomedicines (Belgrade), 28(2), 97–102. https://doi.org/10.2298/PIF1302097g.

Gilbert, S. G. (1985). Food/package compatibility. Food Technology, 39(12), 54–56.

Gogos, A., Knauer, K., & Bucheli, T. D. (2012). Nanomaterials in plant protection and fertilization: current state, foreseen applications, and research priorities. Journal of Agricultural Food Chemistry, 60(39), 9781–9792. https://doi.org/10.1021/jf302154y.

GuhanNath, S., Aaron, S. I., Raj, A. A. S., & Ranganathan, T. V. (2014). Recent innovations in nano-technology in food processing and its various applications – A review. International Journal of Pharmaceutical, Sciences Review and Research, 29(2), 116–124.

Gutierrez, J. M. (2008). Nano-emulsions: New applications and optimization of their preparation. Current Opinion in Colloid & Interface Science, 13(4), 245–251. https://doi.org/10.1016/j.cocis.2008.01.005.

Gutiérrez, T. J. (2018a). Chapter 55. Processing nano- and microcapsules for industrial applications. In: Handbook of nanomaterials for industrial applications. Chaudhery Mustansar Hussain (Ed). Editorial Elsevier. EE.UU. ISBN: 978–0–12-813351-4. pp. 989–1011. https://doi.org/10.1016/B978-0-12-813351-4.00057-2

Gutiérrez, T. J. (2018b). Chapter 9. Biodegradability and compostability of food nanopackaging materials. In: Composite materials for food packaging. Giuseppe Cirillo, Marek A. Kozlowski, and Umile Gianfranco Spizzirri (Eds). WILEY-Scrivener Publisher. EE.UU. ISBN: 978–1–119-16020-5. pp. 269–296. https://doi.org/10.1002/9781119160243.ch9

Gutiérrez, T. J., & Álvarez, K. (2017). Chapter 6. Biopolymers as microencapsulation materials in the food industry. In M. Masuelli & D. Renard (Eds.), Advances in physicochemical properties of biopolymers: Part 2 (pp. 296–322). Bentham Science Publishers. EE.UU. ISBN: 978–1–68108–545–6. eISBN: 978–1–68108–544–9. https://doi.org/10.2174/9781681085449117010009.

Hazra, D. K., Karmakar, R., Poi, R., Bhattacharya, S., & Mondal, W. (2017). Recent advances in pesticide formulations for eco-friendly and sustainable vegetable post management: A review. Achieves of Agriculture and Environmental Sciences, 2(3), 232–237.

Hogan, H. A., McNamee, B. F., O’Riordan, E. D., & O’Sullivan, M. (2001). Microencapsulating properties of sodium caseinate. Journal of Agricultural and Food Chemistry, 49(4), 1934–1938. https://doi.org/10.1021/jf000276q.

Huang, X., Kakuda, Y., & Cui, W. (2001). Hydrocolloids in emulsions: Particle size distribution and interfacial activity. Food Hydrocolloids, 15(4–6), 533–542. https://doi.org/10.1016/s0268-005x(01)00091-1.

Imeson, A.P. (1992). Exudate gums. In A. Blackie & P. Glasgow A. P. Imeson). Thickening and gelling agents for food (pp. 66–97). London: Blackie Academic and Professional.

IRGC. (2008). International risk governance council, towards an integrative approach. Geneva: Available at: http://www.irgc.org.

Jacobsen, C. (2010). Enrichment of foods with omega-3 fatty acids: A multidisciplinary challenge: Omega-3-enriched foods. Annals of the New York Academy of Sciences, 1190(1), 141–150. https://doi.org/10.1111/j.1749-6632.2009.05263.x.

Jimenez-Colmenero, F. (2013). Potential applications of multiple emulsions in the development of healthy and functional foods. Food Research International, 52(1), 64–74. https://doi.org/10.1016/j.foodres.2013.02.040.

Kim, I. H., Lee, H., & Kim, J. E. (2013). Plum coatings of lemongrass oil-incorporating carnauba wax-based nanoemulsion. Journal of Food Science, 78(10), 1551–1559. https://doi.org/10.1111/1750-3841.12244.

Knightly, W. H. (1989). Lecithin in baking. In B. F. Szuhaj (Ed.), Lecithins: Sources, manufacture and uses. Chicago: American Oil Chemists Society.

Knowles, A. (2008). Recent developments of safer formulations of agrochemicals. Environmentalist, 28(1), 35–44. https://doi.org/10.1007/s10669-007-9045-4.

Kumar, A., Negi, Y. S., Choudhary, V., & Bhardwaj, N. K. (2014). Characterization of cellulose nanocrystals produced by acid-hydrolysis from sugarcane bagasse as agro-waste. Journal of Materials Physics and Chemistry, 2(1), 1–8. https://doi.org/10.12691/jmpc-2-1-1.

Landry, K. S., Micheli, S., McClements, D. J., & McLandsborough, L. (2015). Effectiveness of a spontaneous carvacrol nanoemulsion against Salmonella enterica Enteritidis and Escherichia coli O157:H7 on contaminated broccoli and radish seeds. Food Microbiology, 51, 10–17. https://doi.org/10.1016/j.fm.2015.04.006.

Lane, K. E., Li, W., Smith, C., & Derbyshire, E. (2014). The bioavailability of an omega-3-rich algal oil is improved by nano-emulsion technology using yogurt as a food vehicle. International Journal of Food Science & Technology, 49(5), 1264–1271. https://doi.org/10.1111/ijfs.12455.

Le Reverend, B. J. D., Norton, I. T., Cox, P. W., & Spyropoulos, F. (2010). Colloidal aspects of eating. Current Opinion in Colloids Interface Sciences, 15(1–2), 84–89. https://doi.org/10.1016/j.cocis.2009.11.009.

Li, X., Anton, N., & Vandamme, T. (2013). Nano-emulsions: Overview and applications. Liang XJ, editor, pp. 21–48.

Lin, K. W., & Mei, M. Y. (2000). Influences of gums, soy protein isolate, and heating temperatures on reduced-fat meat batters in a model system. Journal of Food Science, 65(1), 48–52. https://doi.org/10.1111/j.1365-2621.2000.tb15954.x.

Lorenzo, G., Zaritzky, N., & Califano, A. (2018). Food gel emulsions: Structural characteristics and viscoelastic behavior. In T. J. Gutiérrez (Ed.), Polymers for food applications (pp. 481–507). Cham: Springer. https://doi.org/10.1007/978-3-319-94625-2_18.

Mao, L., Xu, D., Yang, J., Yuan, F., Gao, Y., & Zhao, J. (2009). Effects of small and large molecules emulsifiers on the characteristics of β-carotene nano-emulsions prepared by high pressure homogenization. Food Technological Biotechnology, 47(3), 336–342.

Martins, P., Dulley, R., Ramos, S., Barbosa, M., Assumpçao, R., Junior, S., & Lacerda, A. (2007). Nanotecnologias na indústria de alimentos. Available at: http://www.pucsp.br/eitt/downloads/vi_ciclo_paulomartins_ marisabarbosa_nano_puc.pdf.

Mason, T. G., Wilking, J. N., Meleson, K., Chang, C. B., & Graves, S. M. (2006). Nanoemulsions: formation, structure, and physical properties. Journal of Physics: Condensed Matter, 18(41), 635–666.

McClements, D. J. (1999). Food emulsions: Principles, practice and techniques (1st ed.). Boca Raton: CRC Press.

McClements, D. J. (2004). Role of hydrocolloids as emulsifiers in foods. In P. A. Phillips & G. O. Williams (Eds.), Gums and stabilizers for the food industry (pp. 381–393). Cambridge, UK: Royal Society of Chemistry. Special Publication No. 294.

McClements, D. J. (2011). Edible nano-emulsions: Fabrication, properties, and functional performance. Soft Matter, 7(6), 2297–2316. https://doi.org/10.1039/c0sm00549e.

McClements, D. J., & Decker, E. A. (2000). Lipid oxidation in oil-in-water emulsions: Impact of molecular environment on chemical reactions in heterogeneous food systems. Journal of Food Science, 65(8), 1270–1282. https://doi.org/10.1111/j.1365-2621.2000.tb10596.x.

Melik, D. H., & Fogler, H. S. (1998). Fundamentals of colloidal stability in quiscent media. In R. Beccher (Ed.), Encyclopaedia of emulsion technology (Vol. III., Chap. 1, pp. 3–78). New York: Marcel Dekker.

Möller, M., Eberle, U., Hermann, A., Moch, K., & Stratmann, B. (2009). Nanotechnology in the food sector. Zürich: TA-SWISS.

Mura, S., Greppi, G. F., & Irudayaraj, J. (2015). Latest developments of nanotoxicology in plants. In M. H. Siddiqui, Al-Whaibi, M. H., & Mohammad, F. (Eds.), Nanotechnology and plant sciences (pp. 125–151). Switzerland: Springer International Publishing. https://doi.org/10.1007/978-3-319-14502-0_7.

Muschiolik, G., & Dickinson, E. (2017). Double emulsions relevant to food systems: Preparation, stability and applications. Comprehensive Reviews in Food Science and Food Safety, 16(3), 532–555. https://doi.org/10.1111/1541-4337.12261.

Nethaji, D. K., & Parambil, K. A. (2017). Development and applications of nano emulsion in food technology. International Journal of Science, Engineering and Management, 2(12), 60–63.

NutraLease. (2011). Available at: http://www.nutralease.com/Nutra/Templates/showpage.asp?DBID=1&LNGID=1&TMID=84&FID=767.

O’ Dwyer, S. P., O’ Beirne, D., Ni Eidhin, D., Hennessy, A. A., & O’ Kennedy, B. T. (2013). Formation, rheology and susceptibility to lipid oxidation of multiple emulsions (O/W/O) in table spreads containing omega-3 rich oils. LWT – Food Science and Technology, 51(2), 484–491. https://doi.org/10.1016/j.lwt.2012.12.008.

Paul, B. K., & Moulik, S. P. (2001). Uses and application of micro-emulsions. Current Science, 80(8), 990–1001.

Poyato, C., Navarro-Blasco, I., Calvo, M. I., Cavero, R. Y., Astiasaran, I., & Ansorena, D. (2013). Oxidative stability of O/W and W/O/W emulsions: effect of lipid composition and antioxidant polarity. Food Research International, 51(1), 132–140. https://doi.org/10.1016/j.foodres.2012.11.032.

Raj, A. A. S., Jayaraman, R., Rubila, S., & Tiroutchelvamae, D. (2013). Recent trends in nanotechnology applications in foods. International Journal of Engineering Research and Technology, 2(10), 956–961.

Rasooli, I. (2007). Food preservation-a bio-preservative approach. Food, 1, 111–136.

Renton, A., (2006). Welcome to the world of nano-foods. Guardian Unlimited UK 12. Available at: http://observer.guardian.co.uk/foodmonthly/futureoffo od/story/.

Sadurni, N. (2005). Studies on the formation of O/W nano-emulsions, by low-energy emulsification methods, suitable for pharmaceutical applications. European Journal of Pharmaceutical Sciences, 26(5), 438–445. https://doi.org/10.1016/j.ejps.2005.08.001.

Sanguansri, P., & Augustin, M. A. (2006). Nanoscale materials, development of food industry perspective. Trends in Food Science & Technology, 17(10), 547–556. https://doi.org/10.1016/j.tifs.2006.04.010.

Schramm, L. L. (1992). Emulsions: Fundamentals and applications in the petroleum industry. Washington, D.C: American Chemical Society.

Schrooyen, P. M. M., van der Meer, R., & De Kruif, C. G. (2001). Microencapsulation: Its application in nutrition. Proceedings of the Nutrition Society, 60(4), 475–479. https://doi.org/10.1079/pns2001112.

Serdaroglu, M., Ozturk, B., & Kara, A. (2015). An overview of food emulsions: Description, classification and recent potential applications. Turkish Journal of Agriculture – Food Science and Technology, 3(6), 430–438. https://doi.org/10.24925/turjaf.v3i6.430-438.336.

Severino, R., Vu, K. D., Donsi, F., Salmieri, S., Ferrari, G., & Lacroix, M. (2014). Antibacterial and physical effects of modified chitosan based-coating containing nano-emulsion of mandarin essential oil and three non-thermal treatments against Listeria innocua in green beans. International Journal of Food Microbiology, 191, 82–88. https://doi.org/10.1016/j.ijfoodmicro.2014.09.007.

Shafiq, S., Shakeel, F., Talegaonkar, S., Ali, J., Baboota, S., Ahuja, A., Khar, R. K., & Ali, M. (2007). Formation development and optimization using nano-emulsion technique: A technical note. Pharmaceutical Sciences and Technology, 8(2), 1–6. https://doi.org/10.1208/pt0802028.

Shah, D. O. (1998). In D. O. Shah (Ed.), Micelles, micro-emulsions and monolayers: Science and technology (p. 1). New York: Marcel Dekker.

Shakeel, F., Baboota, S., Ahuja, A., Ali, J., & Shafiq, S. (2008). Accelerated stability testing of celecoxib nano-emulsion containing cremophor-EL. African Journal of Pharmaceutical Pharmacologists, 2, 179–183.

Sharma, R. (2005). Market trends and opportunities for functional dairy beverages. Australian Journal of Dairy Technology, 60(2), 195–198.

Silva, H. D., Cerqueira, M. A., & Vicente, A. A. (2012). Nano-emulsions for food applications: Development and characterization. Food and Bioprocess Technology, 5(3), 854–867. https://doi.org/10.1007/s11947-011-0683-7.

Singh, H., & Ye, A. (2000). Influence of calcium chloride addition on the properties of emulsions stabilized by whey protein concentrate. Food Hydrocolloids, 14(4), 337–346. https://doi.org/10.1016/s0268-005x(00)00010–2.

Solans, T., Izquierdo, P., Nolla, J., Azemar, N., & Garcia, C. M. J. (2005). Nano-emulsions. Current Opinion in Colloid Interface Science, 10(3–4), 102–110. https://doi.org/10.1016/j.cocis.2005.06.004.

Sozer, N., & Kokin, J. L. (2008). Nanotechnology and its applications in the food sector. Trends in Biotechnology, 27(2), 82–89. https://doi.org/10.1016/j.tibtech.2008.10.010.

Tadros, T. F. (1995). Surfactants in Agrochemicals. New York: Marcel Dekker.

Tadros, T. (2004). Formation and stability of nano-emulsions. Advances in Colloid and Interface Science, 108–109, 303–318. https://doi.org/10.1016/j.cis.2003.10.023.

Tadros, F. (2005). Applied surfactants, principles and applications (pp. 187–256). Weinheim: Wiley-VCH Verlag GmbH and KGaA.

Takahashi, Y., Yoshida, T., & Takahashi, T., inventors. 1986. Process for the production of a water-in-oil-in-water emulsion for foods. U.S. Patent 4590086.

Tan, C. T. (1990). Beverage emulsions. In K. Larsson & S. E. Friberg (Eds.), Food emulsions (2nd ed., pp. 445–478). New York: Marcel Dekker.

Trubiano, P.C. (1995). The role of specialty food starches in flavor emulsions. Flavor Technology. Washington, D. C: ACS Symposium Series, 610, American Chemical Society.

Unilever. (2011). Available at: http://www.unilever.com/innovation/productinnovations/coolicecreaminnovations/?WT.LHNAV=Cool_ice_cream_innovations.

Velikov, K., & Pelan, E. (2008). Colloidal delivery systems for micronutrients and nutraceuticals. Soft Matter, 4(10), 1964–1980. https://doi.org/10.1039/b804863k.

Vernner, R., & Bauer, P. (2007). O-TEQ®, a formulation concept that overcomes the in-compability between water and oil. Pfalzenschutz-Nachrichten Bayer, 60(1), 7–26.

Walker, & Rebecca, M. (2015). Fish oil Nano-emulsions: Optimization of physical and chemical stability for food system applications. Masters Theses. 313, Available at: https://scholarworks.umass.edu/masters_theses_2/313.

Wang, X., Jiang, Y., Wang, Y., Huang, M., Ho, C. T., & Huang, Q. (2008). Enhancing anti-inflammation activity of curcumin through O/W nano-emulsions. Food Chemistry, 108(2), 419–424. https://doi.org/10.1016/j.foodchem.2007.10.086.

Waraho, T., McClements, D. J., & Decker, E. A. (2011). Mechanisms of lipid oxidation in food dispersions. Trends in Food Science & Technology, 22(1), 3–13. https://doi.org/10.1016/j.tifs.2010.11.003.

Weiss, J., Takhistov, P., & McClements, D. J. (2006). Functional materials in food nanotechnology. Journal of Food Science, 71(9), 107–116. https://doi.org/10.1111/j.1750-3841.2006.00195.x.

Wesley, S. J., Raja, P., Raj, A. A. S., & Tiroutchelvamae, D. (2014). Review on – Nanotechnology applications in food packaging and safety. International Journal of Engineering Research, 3(11), 645–651.

Whitesides, G. M., & Grzybowski, B. (2002). Self-assembly at all scales. Science, 295(5564), 2418–2421. https://doi.org/10.1126/science.1070821.

Wooster, T. J., Golding, M., & Sanguansri, P. (2008). Impact of oil type on nano-emulsion formulation and Ostwald ripening stability. Langmuir, 24(22), 12758–12765. https://doi.org/10.1021/la801685v.

Yang, Y., Marshall-Breton, C., Leser, M. E., Sher, A. A., & McClements, D. J. (2012). Fabrication of ultrafine edible emulsions: Comparison of high-energy and low-energy homogenization methods. Food Hydrocolloids, 29(2), 398–406. https://doi.org/10.1016/j.foodhyd.2012.04.009.

Yoksan, R., Jirawutthiwongchai, J., & Arpo, K. (2010). Encapsulation of ascorbyl palmitate in chitosan nanoparticles by oil-in-water emulsion and ionic gelation processes. Colloids and Surfaces B: Biointerfaces, 76(1), 292–297. https://doi.org/10.1016/j.colsurfb.2009.11.007.

Zhang, J. (2011). Novel emulsion-based delivery systems. PhD Dissertation, University of Minnesota, USA.

Zheng, H. (2018). Polymers for structure design of dairy foods. In T. J. Gutiérrez (Ed.), Polymers for food applications (pp. 509–528). Cham: Springer. https://doi.org/10.1007/978-3-319-94625-2_19.

Acknowledgements

The authors would like to thank the management, Sri Shakthi Institute of Engineering and Technology, Coimbatore, TamilNadu, India.

Conflict of Interest

The authors declare no conflicts of interest.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Sundarraj, A.A., Ranganathan, T.V. (2019). Classification and Uses of Emulsions in Food and Agro Applications. In: Gutiérrez, T. (eds) Polymers for Agri-Food Applications . Springer, Cham. https://doi.org/10.1007/978-3-030-19416-1_9

Download citation

DOI: https://doi.org/10.1007/978-3-030-19416-1_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-19415-4

Online ISBN: 978-3-030-19416-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)