Abstract

In this research, the capability of different oleogelators (beeswax, rice bran wax and sunflower wax, stearic acid, octadecanol, γ-oryzanol+β-sitosterol mixture and ethylcellulose) to structure sunflower oil was studied at 10% (w/w) concentration. The physical, thermal, and rheological properties of sunflower oil oleogels were determined during storage at 20 °C. Results highlighted that different structured systems can be obtained by changing the oleogelator type dissolved in sunflower oil. The network formed by γ-oryzanol and β-sitosterol mixture resulted in the strongest oleogel. Among waxes, beeswax crystal network exhibited the best structuring performances in comparison to sunflower and rice wax sample. Other oleogels containing monoglyceride, octadecanol and stearic acid formed weaker sunflower oil gels but with high capacity to retain oil. Unexpectedly, samples containing ethylcellulose did not result in a gelled structure. During storage, sunflower oil oleogels showed changes in rheological properties (i.e., monoglyceride and sunflower wax oleogels) and oil binding capacity (i.e, rice wax, octadecanol and stearic acid oleogels). These findings could be useful for the selection of the best performing sunflower oil oleogelator depending on the specific intended application.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, oleogel and oil gelation methodologies have attracted vast interest and the research in this area is still growing [1,2,3,4]. In an edible oleogel, the oil is entrapped in a three dimensional network of structuring molecule. The final result is an anhydrous, viscoelastic and self-standing material [1]. Different possible food applications have been proposed for oleogels. The most promising one is their use as fat substitute to obtain healthier foods with reduced content of sat/trans fatty acids [2, 5]. To this regards, they have been used to obtain low-sat/trans bakery products [6,7,8], chocolate-based products [9,10,11], ice-cream [12] or meat products [13, 14]. Beside their potential use as fat-replacers, these systems have been also proposed as functional component able to modulate lipolysis as well as the delivery of bioactive lipophilic molecules [15, 16].

Up to now, numerous approaches to oil structuring exist. The most common method releases in the direct dispersion of one or more lipophilic gelators into liquid oil under proper physico-chemical conditions. The resulting solution is then cooled to induce the self-assembly of the gelator into a network entrapping oil [17]. This direct method can be exploited with different type of gelators, including crystalline particles (i.e., monoglyceride, fatty acid, fatty alcohol and waxes); self-assembled fibrillar forming molecules (i.e. mixtures of phytosterols and sterol esters) and polymeric structures (i.e. ethylcellulose) [1]. It should be noted that ethylcellulose is the only food grade polymer that can form entanglements of three-dimensional polymer network in oil [18, 19]. However, hydrophilic polymers, such as proteins and carbohydrates, can also be exploited to generate oleogels, by applying indirect methodologies [20, 21]. In these cases, the network is firstly formed in water-oil emulsion or in water. Subsequently, water is removed leading to the direct formation of an oleogel or the generation of a porous material able to further absorb oil [17, 22, 23]. In this context, the procedures applied for water removal deeply affect the final oleogel properties due to the critical possible collapse of the hydrophilic network during water movement [24].

By using the above mentioned molecules and proper oleogelation methods, it is possible to generate oleogels with defined structures and rheological/mechanical properties. The latter can be also steered by controlling other variables, such as gelator concentration, oil type and processing conditions. A number of papers deal with the deep physical characterization of oleogels and the effect of these variables [25,26,27]. In particular, different authors studied the performances of the same oleogelator in different oils highlighting the effect of oil properties on gelation mechanism [25]. On the other side, it is difficult to find out comparative information considering the same type of oil structured by applying a large selection of gelators and relevant production methodologies. On this regard, Patel and Dewettinck [28] studied oleogels containing rapeseed oil structured with three different approaches considering wax crystals, polymeric stands and gelled water droplets. Moreover, Yilmaz and Öğütcü [29] compared the gelation properties of monoglyceride and beeswax in hazelnut oil. As result of these papers, different properties and functionalities of structured systems were compared, suggesting different possible applications for the considered oleogels. Thus, comparative studies outputs may be particularly interesting in the attempt to use a selected oil needing structurization before final application.

Based on these considerations, the objective of this study was to compare the ability of different already known oleogelator molecules (beeswax, rice bran wax and sunflower wax, stearic acid, octadecanol, γ-oryzanol+β-sitosterol mixture and ethylcellulose) to gel sunflower oil. The latter oil was chosen being one of the most widely used oil rich in unsaturated fatty acid by food industry. To this aim, the physical characteristics of oleogels containing 10% (w/w) of the previous listed oleogelators were investigated by using polarized light microscopy, differential scanning calorimetry (DSC), oil binding capacity (OBC) and rheological analysis.

Material and Methods

Ethylcellulose 45 cP and 100 cP (Dow Chemical Company, Midland, Michigan, United States), stearic acid and octadecanol (Sigma-Aldrich S.r.l., Milano, Italy), monoglyceride Myverol™ (Kerry Bioscience, Bristol, United Kingdom), beeswax, rice bran wax and sunflower wax (KahlWax, Trittau, Germany), γ-oryzanol and β-sitosterol (Nutraceutica S.r.l., Bologna, Italy) were used as gelators. Sunflower oil (from a local market) was considered as a solvent.

Oleogel Preparation

Oleogel was prepared by mixing sunflower oil with different gelators at a concentration of 10% (w/w). The latter concentration was chosen according to preliminary tests in order to achieve the appropriate gel with possible analytical measurement. The mixture was heated above the melting point of gelator at least 10 min until all powder dissolved in the oil. Finally, the sample was quiescently cooled at 20 °C, excluding the mixture containing γ-oryzanol and β-sitosterol (3:2 w/w) that was cooled at 4 °C and stored at this temperature until the gel was formed. Analyses were carried after 24 h and during 30 days of storage at 20 °C. The oleogel samples were coded as: ethylcellulose 45 cP (EC-45) and 100 cP (EC-100), stearic acid (ST), octadecanol (OD), monoglyceride (MG), beeswax (BW), rice bran wax (RW), sunflower wax (SW), and mixture of γ-oryzanol and β-sitosterol (γ-β).

Visual Appearance

The visual appearance of the samples was recorded to know if the oleogels allow to shape in form of the container. The melted oleogel was poured in a standard plastic mold and stored at 20 °C for 24 h. The samples were taken out of the container and images were then acquired using an image acquisition cabinet (Immagini & Computer, Bareggio, Italy) equipped with a digital camera (EOS 550D, Canon, Milan, Italy). Light was provided by four lamps arranged in the front and in the rear at both sides with 4100 W frosted photographic floodlights, allowing minimum shadow and glare. Image was saved in jpeg format resulting in 3456 × 2304 pixels.

Crystallization Induction Time

Crystallization induction time was evaluated using a UV-2501 PC UV-VIS (Shimadzu, Kyoto, Japan) spectrophotometer connected to a CPS-240A thermoelectrically temperature controlled cell holder (Shimadzu). In particular, aliquots of 2 mL of molten oleogel (heating above melting point at least 10 min) were poured into disposable plastic cuvettes with optical path of 1 cm. Cuvettes were immediately transferred to the temperature controlled cell holder set at 20 °C. Changes in absorbance at 600 nm were recorded over time and the crystallization induction time was taken as the onset of the turbidity development calculated when the absorbance deviates from the baseline by 1%.

Thermal Analysis

DSC analysis was carried out using a TA4000 differential scanning calorimeter (Mettler-Toledo, Greifensee, Swiss) connected to a GraphWare software TAT72.2/5 (Mettler-Toledo). Heat flow calibration was achieved using indium (heat of fusion 28.45 J/g). Temperature calibration was carried out using hexane (m.p. -93.5 °C), water (m.p. 0.0 °C), and indium (m.p. 156.6 °C). Samples were prepared by carefully weighing 5–10 mg of oleogels stored for 1 day at room temperature in 40 μL aluminum DSC pans, closed without hermetic sealing. Samples were heated from 20 to 100 °C at 5 °C/min under nitrogen flow (20 mL/min). An empty pan was used as a reference in the DSC cell. Temperature corresponding to the transition peak (Tpeak) and melting enthalpy were calculated by the program STARe ver.8.10 (Mettler- Toledo). The enthalpy value of the neat gelator (ΔHn) and the melting enthalpy in oil (ΔHo) was used to compute the crystallization percentage of the gelator in oil;

Polarized Light Microscopy

Oleogels were analyzed using a polarized light (PL) optical microscope (Leica DM 2000, Leica Microsystems, Heerburg, Switzerland) connected with a Leica EC3 digital camera (Leica Microsystems). One drop of sample was placed in the middle of a glass slide and a glass cover slip was centered above the drop. Samples were analyzed using a 200× magnification. Images were acquired and processed using the application software LeicaSuite LAS EZ (Leica Microsystems).

Oil Binding Capacity

The oil binding capacity (OBC) of oleogels were determined by weighting about one gram of molten sample into a micro tube and kept at 20 °C for 24 h. Then, the samples centrifuged at 13000 rpm for 15 min using a microcentrifuge (Mikro 120, Hettich Zentrifugen, Andreas Hettich GmbH and Co, Tuttlingen, Germany). The released oil was computed as percentage ratio between the mass of expressed oil over the total mass of sample.

Rheological Measurement

Rheological properties of samples were determined using a Haake Rheostress 6000 (Thermo Scientific, Rheostress, Haake, Germany) with application software Haake Rheowin v.4.60.0001 (Thermo Fisher Scientific). The measurements were performed in a 40-mm parallel-plate geometry system at 20 °C. Aliquots of about 4–5 g of sample were transferred on the temperature-controlled measuring plate and the measuring gap was set at 2 mm. These operations were conducted gently to minimize any possible damage of the crystalline network. Samples were left to rest 5 min after loading before testing to relax and reach a constant temperature. To determine the linear viscoelastic region, dynamic stress sweep measurements at a frequency of 1 Hz from 1 to 1000 Pa were conducted at 20 °C. The critical stress was determined as the stress where G′ value decreased of more than 10% the values recorded in the LVR. G′ and G′′ were obtained with a frequency scan from 0.1 to 10 Hz using a fixed stress value included in the linear viscoelastic region.

Data Analysis

All data were obtained from at least two measurements from two experiment replications (n ≥ 4) and reported as mean value ± standard deviation. Bartlett’s test was used to check the homogeneity of variance, one-way ANOVA was carried out and Tukey-test was used as postdoc test to determine statistical significant differences among means (p < 0.05).

Results and Discussion

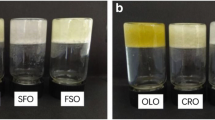

The visual appearance of sunflower oil oleogels containing 10% (w/w) of different gelators was shown in Fig. 1. It can be noted that the macrostructure of the systems appeared different depending on the structuring molecule dissolved in the oil. Oleogels containing γ-β, BW and SW resulted solid self-standing materials able to maintain their shape while oleogels containing RW, OD, MG, and ST appeared as soft gels. Interestingly and in agreement with the literature, γ-β system was the only transparent oleogel [30, 31]. This was attributed to the fact that the building blocks of the gel are considerably smaller than the wavelength of the visible light with dimension in the nanometer range [31]. Both EC 45 cP and 100 cP highlighted a bad capacity to structure sunflower oil. In particular, the resulting system appeared inhomogeneous and not capable to efficaciously entrap oil. This result can be attributed to the chemical characteristic of the oil considered in this work. In particular, the oil fatty acid composition, polarity and the presence of surface-active molecules significantly affect the resulting oleogel mechanical properties [2, 32, 33]. For instance, based on literature data, EC 45 cP and EC 100 cP are able to form oleogels containing canola oil, flaxseed oil and soybean oil at 11% (w/w) concentration [34]. It can be hypothesized that the compositional characteristics of the commercial sunflower oil used in the experiments influenced the solvent-polymer interactions by reducing the EC capability to form the network. Gravelle et al. [32] found out that EC gel strength was positively correlated to solvent polarity due to the presence of polar chemical species able to form hydrogen bonds with the polymer. Thus, it can be inferred that the inability of EC to gel sunflower oil was due to the low content of polar compounds in studied sunflower oil. This is in agreement with literature data, considered sunflower oil as low polar oil due to low dielectric constant (2.9–3.1 at 25 °C) [30]. Based on these results, EC was not considered in the following experiments.

Figure 2 shows the changes of absorbance at 600 nm as a function of time at 20 °C. From these curves, the crystallization induction time was calculated. All samples showed a sigmoidal curve highlighting the occurrence of crystallization. RW and SW immediately started the crystallization process in sunflower oil, whereas the induction time for other structuring molecules was in the following order: MG, BW, ST and finally OD. It should be noted that this type of measurement was not performed on γ-β oleogel. At this concentration, the structure formation in this system needs supercooling below 20 °C and more than 24 h to obtain the gel [30]. Moreover, as previously noted, the sample was expected to be transparent upon network formation due to the nanosize of building blocks.

Crystallization induction time of sunflower oil oleogels containing 10% (w/w) stearic acid (ST), monoglyceride (MG), octadecanol (OD), rice wax (RW), sunflower wax (SW), and beeswax (BW) at 20 °C. In the same column, means indicated by different capital letters are significantly different (p < 0.05)

Oleogel thermal properties were then studied by calorimetric analysis (Fig. 3 and Table 1). All oleogels revealed broader endothermic peaks with lower Tpeak in comparison to those of neat gelators. This behavior was expected and attributable to the initial disaggregation of the network in oil followed by the melting of crystals [35]. Enthalpy data was then used to estimate the percentage of crystallized component in the matrix. It should be noted that about the total mass of MG and SW crystallized in the matrix (<9%) after 1 day of storage; followed by ST, BW, OD and RW. This calculation was obviously not possible for γ-β oleogels because these structuring molecules self-assemble into tubules in oil.

The crystals formed in the oil can be appreciated by polarized light microscopy (Fig. 4). It should be remembered that bright areas in the images correspond to crystals. MG showed small needle-like crystal morphology after gelling formation and developed random crystal aggregation during storage time. A denser microstructure containing large needle-like crystals was observed in SW and BW with larger aggregates in SW. The differences observed between waxes are in agreement with the literature, reporting a close relationship between wax composition and crystal morphology [36, 37]. The SW crystal morphology could be due to the high content of wax ester and the low concentration of minor component in comparison to BW (96–97% and 60–70% wax ester in SW and BW, respectively) [37,38,39,40,41]. Although, RW contains mainly wax ester [42], it showed spherical crystals differently from other waxes considered. This can be explained by the high amount of C24-COOH and C24 moiety in RW than SW (28% vs 4%, respectively) which influence the crystal morphology of RW [43].

The crystals in ST and OC were platelet-like structure with slightly hexagonal shape similar to those observed by Schaink et al. [44]. Regarding γ-β, as expected no crystal formation was observed after the first day of storage. However, crystals appeared after 15 days of storage, probably due to the crystallization of molecules not-aggregated in tubules and still solubilized in the oil [45]. Moreover, in agreement with Sawalha et al. [46], the possible hydration the system could lead to the formation of monohydrate crystal form. It is noteworthy that, excluding MG and γ-β, other oleogels did not show appreciable microstructure changes during storage time.

Beside this microstructural information, in the attempt to use oleogel in food systems, their macroscopic feature is of primary importance. Thus, oil binding capacity as well as rheological properties were analyzed. As shown in Table 2, OBC was in all cases higher than 90%, with the only exception of RW (81%). During storage, samples containing RW, ST, and OD showed a reduction of OBC about 5–10%. As reported by Blake and Marangoni [26], the ability of retain oil in structure network is a complex conception involving morphology, distribution, surface absorption and surface roughness of particles in the system. The previously described results highlight that gelators forming crystals with needle-like morphology (i.e., ST, OD, SW and BW) resulted in a network with more efficient entrapping oil capacity. This can be linked to the higher surface area of the crystals in comparison to spherulitic morphology [35, 41].

Finally, rheological data were acquired (Table 3). All oleogels revealed gel-like behavior with dominant of storage modulus (G′) to loss modulus (G″). As expected, the γ-β mixture showed the highest gel strength which is mainly attributable to its helical tubule building block systems with strong hydrogen bonds among them [30]. Moving to waxes, small needle-like crystals of BW led to a close three-dimensional network with the strongest gel property. However, large crystals of SW and spherulitic crystal of RW revealed less gel strength, respectively [47]. It can be supposed that smaller crystals favoured more crystal-crystal interactions, whereas large and spheriulitic crystals reduced the potential of interlink between crystals. This result is in agreement with Blake and Marangoni [35], evidencing that the morphology of wax crystals strongly influence the macro properties of oleogels. Finally, MG and OD presented weak gel followed by the gel containing ST. The different rheological behavior of the latter systems can be attributed to the formation of hydrogen bonds between -OH groups throughout MG or OD crystals that could further improve the formation of network compared to ST. Among gel systems, MG and SW oleogels were the only systems undergoing changes of rheological data as a function of storage time. The increase in network hardness of SW oleogel during storage can be attributed to the reorganization of wax crystals in post-production isothermal crystallization. Besides, polymorphic transformation of MG from the sub-α or α-form to β-polymorph could be the reason of hardness decrease during storage. These hypotheses were also confirmed in our previous work [48].

To get more knowledge about rheological properties of oleogels, critical stress was also measured (Table 3). The critical stress is the point at which G′ begins to vary (10%) after the linear viscoelastic region. This index gives information about the force require breaking the intermolecular forces holding up the structure [43]. In agreement with rheological data, γ-β containing sample showed the highest stress resistance, followed by BW. The weaker gel was also in this case ST oleogel.

Conclusions

Results obtained in this study revealed the possibility to exploit different type of oleogelators to convert sunflower oil into a self-standing material. The choice of the gelator cannot be easily predicted since the final oleogel structure depends on complex interactions between network structure and oil chemical characteristics. From this study emerged that EC cannot be considered alone to gel sunflower oil at concentrations lower than 10% (w/w); whereas monoglyceride, stearic acid, octodecanal and waxes resulted to be good gelators, able to form soft gels that can be further easily spread in a multicomponent food. On the other hand, phytosterol/sterol ester mixture formed solid-like system that could be more interesting when a hard gel structure is needed in the food formulation. Thus, depending on the expected oleogel application, comparative studies appear fundamentals to properly define the best performing oleogelator in the selected oil. Only in this way, it would be possible to set up criteria for selecting the proper oleogelator.

References

A.J. Martins, A.A. Vicente, R.L. Cunha, M.A. Cerqueira, Food Funct. 9(2), 758–773 (2018)

A. Singh, F.I. Auzanneau, M.A. Rogers, Food Res. Int. 97, 307–317 (2017)

E.D. Co, A.G. Marangoni in Edible Oleogels, Structure and Health Implications, Ed. by A.G. Marangoni, N. Garti, 2nd edn. (AOCS Press, Elsevier Inc., 2018), p. 2

A.R. Patel, in Edible Oil Structuring, Concepts, Methods and Applications, ed. By A.R. Patel, (Royal Society of Chemistry, Crydon, UK, 2018), p. 3

E.D. Co, A.G. Marangoni, J. Am, Oil Chem. Soc. 89(5), 749–780 (2012)

S. Calligaris, L. Manzocco, F. Valoppi, M.C. Nicoli, Food Res. Int. 51(2), 596–602 (2013)

A. Jang, W. Bae, H.S. Hwang, H.G. Lee, S. Lee, Food Chem. 187, 525–529 (2015)

E. Yilmaz, M. Öğütcü, Food Funct. 6(4), 1194–1204 (2015)

A.R. Patel, P.S. Rajarethinem, A. Grędowska, O. Turhan, A. Lesaffer, W.H. De Vos, D. Van de Walle, K. Dewettinck, Food Funct. 5(4), 645–652 (2014)

T.A. Stortz, A.G. Marangoni, Food Res. Int. 51(2), 797–803 (2013)

H. Si, L.Z. Cheong, J. Huang, X. Wang, H. Zhang, J. Am, Oil Chem. Soc. 93(8), 1075–1084 (2016)

D.C. Zulim Botega, A.G. Marangoni, A.K. Smith, H.D. Goff, J. Food Sci. 78(12), 1845–1851 (2013)

F.R. Lupi, D. Gabriele, N. Baldino, L. Seta, B. De Cindio, C. De Rose, Eur. J. Lipid Sci. Technol. 114(12), 1381–1389 (2012)

A.K. Zetzl, A.G. Marangoni, S. Barbut, Food Funct. 3(3), 327–337 (2012)

C.M. O’Sullivan, S. Barbut, A.G. Marangoni, Trends Food Sci. Technol. 57, 59–73 (2016)

C.M. O’Sullivan, M. Davidovich-Pinhas, A.J. Wright, S. Barbut, A.G. Marangoni, Food Funct. 8(4), 1438–145151 (2017)

A.R. Patel, K. Dewettinck, Food Funct. 7(1), 20–29 (2016)

T. Dey, D.A. Kim, A.G. Marangoni in Edible Oleogels, Structure and Health Implications, Ed. by a.G. Marangoni, N. Garti (AOCS Press, Urbana, Illinois, 2011), p. 295

F.C. Wang, A.J. Gravelle, A.I. Blake, A.G. Marangoni, Curr. Opin. Food Sci. 7, 27–34 (2016)

A.R. Patel, Alternative Routes to Oil Structuring, 2nd edn. (Springer, Dordrecht, 2015), pp. 9–10

A.R. Patel, Food Biophys. 13(2), 113–115 (2018)

S. Plazzotta, S. Calligaris, L. Manzocco, Innov. Food Sci. Emerg. Technol. 47, 485–492 (2018)

L. Manzocco, F. Valoppi, S. Calligaris, F. Andreatta, S. Spilimbergo, M.C. Nicoli, Food Hydrocoll. 71, 68–75 (2017)

S. Plazzotta, S. Calligaris, L. Manzocco, Food Hydrocoll. 96, 1–10 (2019)

G. Fayaz, S.A.H. Goli, M. Kadivar, J. Am, Oil Chem. Soc. 94(1), 47–55 (2017)

A.I. Blake, A.G. Marangoni, Food Biophys. 10(4), 456–465 (2015)

F.R. Lupi, D. Gabriele, B. De Cindio, Food Bioprocess Tech. 5(7), 2880–2888 (2011)

A.R. Patel, K. Dewettinck, Eur. J. Lipid Sci. Technol. 117(11), 1772–1781 (2015)

E. Yilmaz, M. Öǧütcü, J. Am, Oil Chem. Soc. 91(6), 1007–1017 (2014)

S. Calligaris, G. Mirolo, S. Da Pieve, G. Arrighetti, M.C. Nicoli, Food Biophys. 9(1), 69–75 (2014)

A. Bot, R. Den Adel, E.C. Roijers, J. Am, Oil Chem. Soc. 85(12), 1127–1134 (2008)

A.J. Gravelle, M. Davidovich-Pinhas, A.K. Zetzl, S. Barbut, A.G. Marangoni, Carbohydr. Polym. 135, 169–179 (2016)

V. Giacintucci, C.D. Di Mattia, G. Sacchetti, F. Flamminii, A.J. Gravelle, B. Baylis, J.R. Dutcher, A.G. Marangoni, P. Pittia, Food Hydrocoll. 84, 508–514 (2018)

A.K. Zetzl, A.J. Gravelle, M. Kurylowicz, J. Dutcher, S. Barbut, A.G. Marangoni, Food Struct. 2(1-2), 27–40 (2014)

A.I. Blake, E.D. Co, A.G. Marangoni, J. Am, Oil Chem. Soc. 91(6), 885–903 (2014)

A.R. Patel, M. Babaahmadi, A. Lesafer, K. Dewettinck, J. Agric, Food Chem. 63(19), 4862–4869 (2015)

C.D. Doan, I. Tavernier, P.K. Okuro, K. Dewettinck, Innov. Food Sci. Emerg. Technol. 45, 42–52 (2018)

L.S.K. Dassanayake, D.R. Kodali, S. Ueno, K. Sato, J. Am, Oil Chem. Soc. 86(12), 1163–1173 (2009)

H.S. Hwang, S. Kim, M. Singh, J.K. Winkler-Moser, S.X. Liu, J. Am, Oil Chem. Soc. 89(4), 639–647 (2012)

A.I. Blake, J.F. Toro-Vazquez, H.S. Hwang in Edible Oleogels, Structure and Health Implications, Ed. by a.G. Marangoni, N. Garti (AOCS Press, Urbana, Illinois, 2018), p. 133

C.D. Doan, D. Van de Walle, K. Dewettinck, A.R. Patel, J. Am. Oil Chem. Soc. 92(6), 801–811 (2015)

I. Tavernier, C.D. Doan, D. Van de Walle, S. Danthine, T. Rimaux, K. Dewettinck, RSC Adv. 7(20), 12113–12125 (2017)

C.D. Doan, C.M. To, M. De Vrieze, F. Lynen, S. Danthine, A. Brown, K. Dewettinck, A.R. Patel, Food Chem. 214, 717–725 (2017)

H.M. Schaink, K.F. Van Malssen, S. Morgado-Alves, D. Kalnin, E. Van der Linden, Food Res. Int. 40(9), 1185–1193 (2007)

F.M. AlHasawi, M.A. Rogers, J. Am, Oil Chem. Soc. 90(10), 1533–1540 (2013)

H. Sawalha, R. Den Adel, P. Venema, A. Bot, E. Van Der Linden, J. Agric, Food Chem. 60(13), 3462–3470 (2012)

R. Wang, X.Y. Liu, J. Xiong, J. Li, J. Phys, Chem. B. 110(14), 7275–7280 (2006)

G. Fayaz, S.A.H. Goli, M. Kadivar, F. Valoppi, L. Barba, S. Calligaris, M.C. Nicoli, LWT Food Sci. Technol. 86, 523–529 (2017)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fayaz, G., Calligaris, S. & Nicoli, M.C. Comparative Study on the Ability of Different Oleogelators to Structure Sunflower Oil. Food Biophysics 15, 42–49 (2020). https://doi.org/10.1007/s11483-019-09597-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-019-09597-9