Abstract

The effect of xanthan gum on the freeze-thaw stability of wheat gluten was evaluated during a 60-day storage period at −18 °C with thawing every 5 days for 4 h at 25 °C. The physicochemical and rheological properties of wheat gluten-xanthan gum mixtures with multiple scales were analyzed. In the control samples (wheat gluten without xanthan gum), the molecular weight by size-exclusion chromatography-multiple angle laser light scattering (SEC-MALLs), content of free SH groups measured by UV/VIS spectrophotometry, and the hole sizes in the wheat gluten network structure shown by SEM increased as the freeze-thaw storage time increased, while the surface hydrophobicity index (H0) decreased. For the wheat gluten-xanthan gum mixtures, more disulfide bonds were preserved and numerous small pores in the wheat gluten structure were observed. Meanwhile, the sample with 0.225% xanthan gum (w/w) had the lowest content of free SH groups. The wheat gluten-xanthan gum mixtures had more α-helixes than the control samples with the same freeze-thaw storage time. Rheological analysis showed that the wheat gluten-xanthan gum mixtures had higher elasticity and viscosity than the control samples. Overall, the addition of xanthan gum improved the freeze-thaw stability of the wheat gluten network.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The demand for frozen dough is steadily increasing due to its convenience and high quality. However, frozen storage can greatly affect the quality of dough [1], which leads to decreases of textural properties, poor loaf volume and loss of gas retention [2, 3]. Temperature fluctuation is unavoidable during frozen storage, causing more damage to the dough quality than at constant temperature storage [4]. All of these quality deteriorations can primarily be attributed to the damage to the wheat gluten network integrity caused by the migration and recrystallization of water [5, 6]. Recently, efforts have been made to minimize the common negative effects of frozen storage commonly by optimizing the freezing processing [7, 8], or adding dough enhancer [3]. Enzymes [9] and food hydrocolloids [3, 10] have been widely reported as dough enhancers to reduce the side effects of frozen storage on the dough quality.

The incorporation of hydrocolloids such as xanthan gum, kappa-carrageenan, sodium alginate, gum arabic, pectin and some cellulose derivatives into the dough formulation was found to modify the functional properties and dough quality [11,12,13,14,15]. Hydrocolloids have been extensively used to adjust the water retention and gas retention, improve the texture and prevent staling during frozen storage [16]. In addition, hydrocolloids can improve the stabilities of wheat dough and products [17, 18]. Dough is composed of water, wheat gluten, starch, minerals and other components, and the dough quality mainly depends on the characteristics of the wheat gluten protein, such as the network structure, molecular weights (Mws) and distribution [4] as well as the physical properties that arise from interactions between the wheat gluten proteins, particularly the disulfide-bonded wheat glutenin macropolymers. The hydrocolloids are rich in hydrophilic groups and form hydrophilic complex with gluten proteins, bind water, and decrease water migration in the dough [19, 20], which inevitably impacts the wheat gluten network integrity and the dough quality. Although several studies have mentioned that the quality of frozen dough is improved by the formation of hydrophilic complexes between hydrocolloids and wheat gluten proteins [21, 22], there is a lack of information on the direct influence of hydrocolloids directly on wheat gluten during freeze processing or frozen storage.

The objective of the present study is to investigate the effects of xanthan gum on the wheat gluten structure and rheological properties during a 60-day freeze-thaw storage period. Changes in the Mw, size distribution, free SH content, surface hydrophobicity, protein secondary structure, microstructure and rheological properties were investigated. This work will help to explore the underlying mechanism of the interaction between the hydrocolloids and wheat gluten.

Materials and Methods

Materials

Wheat gluten (containing 85.53 g protein, 8.17 g water, 0.73 g fat, 5.74 g others, per 100 g wheat gluten) and bovine serum albumin (BSA) were obtained from Sigma-Aldrich Chemicals (Shanghai, China). Xanthan gum (CAS:11138–66-2, USP) was purchased from Aladdin (Shanghai, China). Other chemicals used were of analytical or chemical reagent grade.

Wheat Gluten-Xanthan Gum Mixture Preparation and Freeze-Thaw Treatment

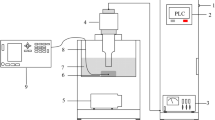

The wheat gluten-xanthan gum mixtures were prepared by mixing 150 mL of xanthan gum solutions (the concentrations of 0.00%, 0.05%, 0.15%, and 0.25%, w/w) with 100 g of wheat gluten in a dough mixer (Mayor Premier, Keenwood, UK) for 15 min. Finally, the mixture contains 0.000%, 0.075%, 0.225%, and 0.375% (w/w) xanthan gum on the basis of wheat gluten weight.

The wheat gluten-xanthan gum mixtures were wrapped with a plastic membrane, left to rest for 40 min and divided into cylindrical pieces 3 cm in diameter and 2 cm in height. The pieces were rapidly frozen in a − 80°C freezer (ULT13886–5-V39, Revco., USA) until their core temperature reached −18°C as determined by a temperature probe (WS-106, Wason, China). Then, the wheat gluten-xanthan gum mixtures were stored in a − 18 ± 1°C freezer (BCD-245, Bosch, Germany) for 20, 40, and 60 days. The wheat gluten-xanthan gum mixtures were subjected to a freeze-thaw and refreeze treatment every 5 days. The mixtures were thawed at 25°C for 4 h and then transferred back to the −18 ± 1°C freezer. At days 0, 20, 40 and 60, portions of the wheat gluten-xanthan gum mixtures were freeze-dried by a freeze-dryer (Wizard 2.0, Virtis, USA), ground into fine powders (DXF-20C, Daxiang, Guangzhou) and passed through a 120 mesh sieve. Freeze-dried mixtures were stored in sealed containers until further analysis.

Wheat Gluten-Xanthan Gum Mixture Solution Preparation

One gram of freeze-dried wheat gluten-xanthan gum mixtures was dissolved in a 500 mM acetic acid solution (50 mL) under magnetic stirring (MS-H280-Pro, Dragon, China) for 24 h, and the temperature was maintained below 10°C using an ice bath. Then, the sample was centrifuged in a high-speed refrigerated centrifuge (3 K30, Sigma, Germany) at 12000 r/min for 30 min below 5°C. The supernatant was used for the subsequent analyses.

Determination of the Free SH Groups

The content of free SH groups was determined according to a previously reported method [23] with minor modifications. A 1 mL aliquot of buffer (composed of 0.05 M sodium phosphate buffer, pH 6.5, 2% SDS (v/v), 3.0 M urea and 1.0 mM tetrasodium ethylene diamine tetra-acetate) was added to 1 mL of wheat gluten-xanthan gum solution (4.5 mg/mL, the protein concentration was determined using a Kjeldahl apparatus). Then, 100 μL DTNB (5,5′-dithio-bis (2-nitrobenzoic acid)) was added and reacted for 45 min, and the absorbance at 412 nm was measured by a UV/VIS spectrophotometer (UC2012PCS, UNICO, USA). The absorbance was used to determine the content of free SH using a calibration curve prepared from reduced glutathione (0–0.10 μmol). Three replicates were carried out for each determination.

Determination of Surface Hydrophobicity

The surface hydrophobicity index (H0) was measured using a previously reported method [24] involving a 1-methionine-8-naphthalene sulfonic acid (ANS) fluorescent probe with slight modifications.

The protein concentration of the wheat gluten-xanthan gum solution was determined using a Kjeldahl apparatus (Foss-2300, Kjeltec, Switzerland), and it was diluted to different concentrations (0.02–0.15 mg/L). A 4 mL aliquot of sample was mixed with 20 μL of 8 mM ANS, and the fluorescence intensity was determined using a fluorescence spectrophotometer (RF25301PC, Shimadzu, Japan). The excitation and emission wavelengths were 390 nm and 470 nm, respectively, and the slit widths were 5 nm. Linear regression analysis was performed, and the slope of the regression was the wheat gluten-xanthan gum mixture surface hydrophobic index (H0).

SEC-MALLS Measurement

The method used for size-exclusion chromatography-multiple angle laser light scattering (SEC-MALLS) was as described by Zhao et al. [25] with slight modifications. The Mw and the molecular molar mass distribution of the samples were measured. The mobile phase was acetic acid solution (500 mM) filtered through a 0.22 μL PTFE filter, and then it was degassed with ultrasound treatment. The concentration of wheat gluten and wheat gluten-xanthan gum mixture solution was 4.5 mg/mL. A gel chromatography column (Biosep SEC-4000, Phenomenex, USA) was used, and the column temperature was kept at 40°C. The flow rate and total injection volume were 1.0 mL/min and 150 μL, respectively. MALLS data were gathered with a multiangle light scattering detector (DAWN HELEOSΠ, Wyatt Technology Corp., Santa Barbara, CA, USA) with 18 detection angles and a refractive index detector (DRI) (OptilabrEX, Wyatt Technology Corp) operating at 658 nm. The Mw and the molecular molar mass distribution were calculated according to the Zimm model. The value of the dn/dc is 0.1767 ± 0.0028 mL/g. According to the different molecular weight of control samples, the following linear regression equation was obtained: lg Mw = a + bTR, where lg Mw is linear with the retention time (TR), and the high-Mw is eluted first. The Mw of the samples could be calculated from the linear regression equation by measuring the TR. The normalization of instruments was performed by measuring the scattering intensity of bovine serum albumin (BSA). The analysis was conducted by Origin 8.5 software (OriginLab Corp., Northampton, USA).

Fourier-Infrared Spectrometry

The changes in the secondary structures of the protein were determined by Fourier transform infrared spectrometry (Bruker Tensor 37, Billerica, MA) in the attenuated total reflectance (ATR) mode. The background spectrum of the ATR cell was recorded using 256 scans and a resolution of 4 cm−1. The spectral baseline correction method was described by Wellner et al. [26]. The analysis was conducted by PeakFit 4.12 (Seasolve, Framingham, USA) and Origin 8.5 software (OriginLab Corp., Northampton, USA).

SEM Observations

After 20, 40, and 60 days of freeze-thaw storage, the wheat gluten-xanthan gum mixtures were freeze-dried. The specimens were fractured by a microtome (Leica EM UC6 + FC6, Leica, Germany), sputter coated with gold for 2 min, and then transferred to the SEM stage. These gold-coated specimens were viewed in a field emission scanning electron microscope (SUORA55/55VP, Zeiss, Germany) with an accelerating voltage of 10 kV. Representative micrographs from all of the samples were selected for illustration [27]. The hole sizes in the network structure were measured by SEM software.

Measurements of the Dynamic Rheological Properties

The samples were cut into cylindrical plates (approximately 1 g, 20 mm in diameter, 2 mm in height), covered with plastic wrap, and then thawed at 25°C for 3 h. The rheological properties of the wheat gluten-xanthan gum mixtures were determined by a rheometer (RHS600, Haake, Germany) with a round plate fixture (25 mm in diameter). A parallel geometry with rough surface was used and the geometry gap (2 mm) was selected according to axial force, which could avoid slippage and destruction of samples. A frequency sweep test was conducted to identify the linear viscoelastic region, and a deformation of 0.1% was selected to ensure a linear regime of oscillatory deformation. An angular frequency range of 0.1–100 rad/s was used to study the rheological variations at 25°C. The storage modulus (G'), loss modulus (G'') and loss angle tangent (tan δ = G''/G') were determined.

Statistical Analysis

All data collected in this study were subjected to statistical analysis. The results are expressed as the mean ± standard deviation. Differences among the average values were evaluated by analysis of variance with Duncan’s test using SPSS 16.0 (SPSS Inc., Chicago, USA). Average values were considered significantly different when P < 0.05.

Results and Discussion

Changes in the SH Content during Freeze-Thaw Storage

Both inter- and intrachain disulfide bonds are important for maintaining the structure and properties of gluten [28, 29]. Polymeric glutenins are composed of discrete polypeptides and those associated with intra- and intermolecular disulfide bonds, while gliadins are monomeric and have intramolecular disulfide bonds with hydrophobic peptides [30].

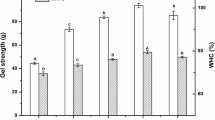

The changes in the free SH content indicated variation in the SS bonds, which could cause the depolymerization of the wheat gluten and breakage of the protein network structure. As shown in Fig. 1, the free SH group content of the control sample increased as the freeze-thaw storage time increased (P < 0.05), which indicated a decrease in the disulfide bond content during storage. The free SH group content of the samples with 0.075% xanthan gum (w/w) significantly increased from 20 days to 60 days of storage (P < 0.05), while those with 0.225% and 0.375% xanthan gum (w/w) significantly increased from 20 days to 40 days of storage (P < 0.05). For example, after 20 days of freeze-thaw storage, the free SH content in the control sample had increased by 56.1%, compared with an increase of 3.0% in the sample with 0.225% xanthan gum (w/w). Moreover, there were no significant differences between 40 days and 60 days of storage in the sample with 0.225% and 0.375% xanthan gum (w/w) (P > 0.05). According to these findings, considering the critical role of disulfide bonds in maintaining the wheat gluten network, the network structure may be weakened by a decrease in the content of disulfide bonds. Water migration and ice crystal growth could cause damage to the structure of the wheat gluten protein [6]. The breakage of the disulfide bonds was caused by the formation of ice, water migration, or mechanical agitation during mixing [4]. Due to the hydrophilicity of xanthan gum, it can interact with free water [19], thus decreasing the formation of ice crystals and maintaining the stability of the wheat gluten. Meanwhile, the free SH content of the 0.375% xanthan gum sample was higher than that of the 0.225% xanthan gum sample. This may be explained by that only a small fraction of xanthan gum interacted with free water in the 0.375% xanthan gum sample, which led to more damage to wheat gluten and required further research. These finding suggested that the addition of xanthan gum improved stability of wheat gluten network.

Change in the free SH content of gluten with different xanthan gum contents during freeze-thaw storage. The freeze-thaw storage times were 0, 20, 40 and 60 days, respectively. Different letters indicate significant differences (P < 0.05) in the free SH content for the same xanthan gum content compared with different storage times (0, 20, 40, 60 days)

Changes in the Surface Hydrophobicity during Freeze-Thaw Storage

As shown in Fig. 2, the H0 values of the control sample and the sample with 0.075% and 0.375% xanthan gum (w/w) decreased significantly (P < 0.05) after 20 days of storage, while the H0 value of the 0.225% xanthan gum (w/w) sample increased significantly (P < 0.05). For the samples with 0.225% xanthan gum (w/w), the H0 values of the 20-day-stored and 40-day-stored wheat gluten-xanthan gum mixtures were much higher than that of the 0-day-stored sample (H0 = 1211 for the 20-day-stored and 1224 for the 40-day-stored samples compared with 1105 for the 0-day-stored sample). For the 20-day-stored and 40-day-stored wheat gluten-xanthan gum mixtures, the H0 values of the sample with 0.075% xanthan gum (w/w) was the highest, and that of 0.375% xanthan gum (w/w) was lowest. Due to hydrophilicity of xanthan gum, it can interact with the hydrophilic groups on wheat gluten, and water, impacting the structure of wheat gluten network. For example, after 60 days of storage, the H0 values of the sample with 0.075% and 0.375% xanthan gum (w/w) was lower than that of the control sample, which may be explained by that the formation of hydrophilic complexes between xanthan gum and wheat gluten proteins could improve the integrity of gluten structure [21, 22].

Change in the surface hydrophobicity of gluten with different xanthan gum contents during freeze-thaw storage. The freeze-thaw storage times were 0, 20, 40 and 60 days, respectively. Different letters indicate significant differences (P < 0.05) in the surface hydrophobicity for the same xanthan gum content compared with different storage times (0, 20, 40, 60 days)

Changes in the Molecular Weight and Molecular Weight Distribution during Freeze-Thaw Storage

Wheat gluten consists of wheat glutenins and gliadins. The molecular weights (Mws) of gliadins range from 28 to 55 kDa, while the Mw of wheat glutenins ranges from approximately 500 to more than 10,000 kDa [29].

Table 1 shows the changes in the Mws of wheat gluten and the wheat gluten-xanthan gum mixtures with different xanthan gum contents during freeze-thaw storage. For the control samples, the Mw of the wheat glutens gradually increased from 1432 kDa to 4139 kDa during the 60-day storage period (P < 0.05). During storage, water migration and ice recrystallization could destroy the integrity of the wheat gluten network [3, 31]. The increase in the Mw could be attributed to denaturation and aggregation of the wheat glutens [32].

The gluten proteins network was stabilized by covalent SS bonds and non-covalent interactions such as hydrogen bonds, ionic bonds and hydrophobic bonds [33]. The xanthan gum is rich in hydrophilic hydroxyl and form noncovalent links to the amide groups in gluten proteins, and anionic group (COO-1) in xanthan gum can form an electrostatic complex with some fractions of gluten proteins [3, 18, 34]. As shown in Table 1, at day 0, the Mw of the wheat gluten-xanthan gum mixtures (measured by SEC-MALLS as described in section 2.6) was larger than the Mw of the control sample. However, the Mw of the wheat gluten-xanthan gum mixtures increased slowly than that of the control sample from 0 day to 60 days. For example, after 60 days of freeze-thaw storage, increases of 189% and 48.7% in molecular weight were observed in the control samples and in the wheat gluten-xanthan gum mixture with 0.375% xanthan gum (w/w) (compared with the same samples at 0 day), respectively. The Mws of the 0.225% and 0.375% xanthan gum (w/w) samples significantly increased from day 0 to day 60 (P < 0.05), while there was no significant difference for the 0.075% xanthan gum (w/w) sample from day 0 to day 20 (P > 0.05). Xanthan gum could trap free water by hydrogen bonding [18, 19], thus suppressing ice formation and weakening its influence on the wheat gluten network. Moreover, xanthan gum could interact with proteins and form a stable wheat gluten protein complex [35], which also inhibited the increase in the Mw of the wheat gluten-xanthan gum mixture.

Table 2 presents the Mw distributions of the control samples and wheat gluten-xanthan gum mixtures. The Mws of the samples were distributed over a very broad range (mainly 500~25,000 kDa). For the control sample, the proportion of wheat gluten with a Mw between 500 and 1000 kDa decreased from 79.19% to 0.00% after 60 days of freeze-thaw storage (P < 0.05), while those in the 1000–10,000 kDa and 10,000–25,000 kDa ranges increased from 17.90% to 90.91% and 2.91% to 5.64% (P < 0.05), respectively. The high Mws (> 25,000 kDa) first appeared in the control samples after 40 days of storage, while they appeared after 60 days of storage for the wheat gluten-xanthan gum mixtures. Moreover, the content of wheat gluten-xanthan gum mixture with a Mw > 25,000 kDa (1.09%, in 0.225% xanthan gum (w/w)) was much lower than that of the control samples (3.45%) after 60 days of storage. For the samples with 0.225% and 0.375% xanthan gum (w/w), the proportion of wheat gluten with a Mw between 500 and approximately 1000 kDa increased after 20 days of freeze-thaw storage (P < 0.05), while those in the 1000–10,000 kDa and 10,000–25,000 kDa ranges decreased (P < 0.05), which was consistent with the Mw results (Table 1). Frozen storage could damage the integrity of the wheat gluten protein [6] and breakage of the disulfide bonds [4], which could lead to the depolymerization of wheat gluten protein. The decrease in the Mw of the samples with 0.225% and 0.375% xanthan gum (w/w) after 20 days of storage could be explained by that the depolymerization of wheat gluten. According to the Mw distribution, the wheat gluten-xanthan gum mixtures were less influenced by freeze-thaw storage and had higher stability.

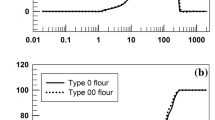

Changes in the Secondary Structures of the Wheat Gluten Proteins during Freeze-Thaw Storage

The amide I band (1600–1700 cm−1) in FTIR spectra was mainly correlated with the secondary structures of proteins. The corresponding assignments of the secondary structural features were according to the previous reports [36,37,38]. The peaks at 1612–1615 cm−1 and 1618–1623 cm−1 represent intermolecular β-sheets, while those at 1639–1643 cm−1 and 1665–1675 cm−1 represent β-turns. The peaks at 1629–1632 cm−1, 1658–1663 cm−1, 1678–1690 cm−1 and 1649–1653 cm−1 represent anti-parallel β-sheets, α-helixes, β-sheets, and random coil, respectively. The results are expressed as the percentage of the total amide I band spectra area and are summarized in Table 3.

As shown in Table 3, the β-turn regions were the dominant structural features in all samples. The percentage of β-turn structures for wheat gluten-xanthan gum mixtures with 0.075% xanthan gum (w/w) increased significantly (P < 0.05) up to 40 days of freeze-thaw storage, while those of the wheat gluten-xanthan gum mixtures with 0.225% and 0.375% xanthan gum (w/w) decreased significantly (P < 0.05) in the first 20 days of freeze-thaw storage. Meanwhile, the intermolecular β-sheets (2.4% and 2.3% for samples with the 0.225% and 0.375% xanthan gum (w/w), respectively) and β-sheets (1% and 0.9% for the same samples, respectively) increased after 60 days of storage. However, the opposite trend was observed in the wheat gluten-xanthan gum mixture with 0.075% xanthan gum (w/w), with the contents of intermolecular β-sheets and β-sheets decreasing by 3% and 0.4%, respectively. There was a significant reduction in the α-helix content after 60 days of storage (P < 0.05) compared with that in the 0-day-stored samples with the same xanthan gum percentage (w/w) (0.075%, 0.225% and 0.375%). Overall, the α-helix contents of the wheat gluten-xanthan gum mixtures were higher than those of the wheat gluten samples under the same freeze-thaw storage time.

The secondary structures of the proteins were mainly maintained by noncovalent binding, and the changes in the secondary structures could be regarded as a sign of protein aggregation [27]. During freezing, ice crystals interrupted the organized hydrogen bonding system that stabilized the protein structure, thus exposing hydrophobic and hydrophilic regions, which resulted in a new protein structure [39]. The freezing process also reduced the content of disulfide bonds and led to the weakening of the wheat gluten network [4]. The combination of hydrocolloids (xanthan gum) with food proteins affects the electrostatic and hydrophobic interactions, resulting in conformational changes [40].

Microscopic Analysis of the Wheat Gluten Network during Storage

SEM was used to determine the changes in the wheat gluten network. As shown in Fig. 3, clear differences were observed in the microstructure of the wheat gluten network during freeze-thaw storage. For the control samples, the holes in the wheat gluten network structure increased as the freeze-thaw storage time increased, and irregular holes (> 200 nm) appeared after 60 days of freeze-thaw storage. This result indicated that the wheat gluten network structure was damaged by the growth of ice crystals [41]. Ice appeared as a continuous network rather than as isolated crystals [42], which could cause severe damage to the wheat gluten network. Meanwhile, the diameter of the holes in the wheat gluten-xanthan gum mixtures was in the 20–60 nm range. The ice recrystallization during freeze-thaw treatment interrupts the organized hydrogen bonding system that stabilizes the gluten and consequently weakens the water binding capacity of dough gluten, which leads to more deterioration of frozen dough [43, 44]. At the same time, the freeze-thaw treatment drove the water shift toward a more mobile one, which could increase the interaction of xanthan gum and freezable water, and retard the formation of ice crystals during freeze-thaw storage [18, 19].

Numerous small pores in the wheat gluten structure were observed after a freeze-thaw storage time of 60 days. For the 20-day-stored wheat gluten-xanthan gum mixtures, the microstructure of the wheat gluten network was similar. After 40 days and 60 days of storage, the holes in wheat gluten network structure of the sample with 0.375% xanthan gum (w/w) were the smallest.

The Rheological Properties during Storage

Wheat gluten is a mixture of proteins mainly consisting of wheat glutenins and gliadins. Polymeric wheat glutenins confer strength and elasticity, while monomeric gliadins which have good mobility, account for the viscosity of the wheat gluten [45, 46]. The storage moduli (G') and loss moduli (G'') represent the elastic/solid and viscous/liquid state of the wheat gluten protein, respectively. The loss tangent value (tan δ = G''/G') indicates the dominant character (solid-like or liquid-like behavior). The storage modulus (G') and loss modulus (G'') of the wheat gluten-xanthan gum mixtures are shown in Figs 4 and 5, respectively.

As shown Fig. 4a, 60 days of frozen storage provoked a decrease in the G', showing a reduction in elasticity, which was consistent with results of frozen dough [47]. The G' of the wheat gluten-xanthan gum mixtures was higher than that of the control samples during freeze-thaw storage (Fig. 4 b, c, d), indicating that the wheat gluten-xanthan gum mixtures had higher elasticity. Both Mw distributions of the wheat gluten protein [48] and wheat glutenin subunits with quantitative and qualitative differences [49] affected the elasticities. Meanwhile, the SS bonds were damaged after freeze-thaw storage and the wheat gluten network was disrupted, leading to aggregation and Mw increase. Additionally, the changes in the protein functionality were a result of the disruption of the wheat gluten network [50] and depolymerization of the wheat glutenin aggregates [51] caused by ice crystallization and water recrystallization during freeze-thaw storage. The trend in G'' was similar to that of the G' (Fig. 5 b, c, d). Xanthan gum was rich in hydroxyl groups and had a good water binding capacity; thus, its incorporation decreased the formation of ice crystals and damage to the structure of the wheat gluten structure network [12]. The tan δ is generally an indicator of protein quality (solid-like or liquid-like behaviors) [52], and the increase in tan δ showed a change in the wheat gluten proteins structure. The tan δ of the control samples was lower than those of the wheat gluten-xanthan gum mixtures, and the difference in tan δ of both samples decreased as the freeze-thaw storage time increased. As shown in Fig. 6, the tan δ of all samples was less than 1, implying that all samples had both viscous liquid and elastic solid characteristics, and solid-like behaviors were the dominant character. Similar results on dynamic rheological studies have been previously reported for wheat flour dough [53].

Conclusions

In conclusion, the addition of xanthan gum improved the freeze-thaw stability of wheat gluten. For the control samples, more disulfide bonds were broken as the freeze-thaw storage time increased, leading to an increase in the Mw. In contrast, the wheat gluten-xanthan gum mixtures had more disulfide bonds and a higher stability of the protein network. The H0 value of the control samples decreased as the freeze-thaw storage time increased, while wheat gluten-xanthan gum mixtures had different H0 values during freeze-thaw storage. Meanwhile, the SEM micrographs showed that wheat gluten-xanthan gum mixtures had numerous small pores. Furthermore, the wheat gluten-xanthan gum mixtures had more α-helixes than the control samples with the same freeze-thaw storage time. These conformational and microscopic changes could be seen as indicators of wheat gluten deterioration during freeze-thaw storage. The wheat gluten-xanthan gum mixtures had higher elasticity and viscosity. This research provided general information on the interaction of wheat gluten and xanthan gum. Xanthan gum could improve the wheat gluten stability and rheological properties (elasticity and viscosity) during freeze-thaw storage, and it is a good improver in food processing.

References

M. Bhattacharya, T.M. Langstaff, W.A. Berzonsky, Food Res. Int. 36(4), 365–372 (2003)

C.M. Rosell, M. Gomez, Food Rev. Int. 23(3), 303–319 (2007)

V.O. Selomulyo, W. Zhou, J. Cereal Sci. 45(1), 1–17 (2007)

L. Zhao, L. Li, G.Q. Liu, L. Chen, X. Liu, J. Zhu, B. Li, Food Res. Int. 53(1), 409–416 (2013)

G. Chen, H. Jansson, K.F. Lustrup, J. Swenson, J. Cereal Sci. 55(3), 279–284 (2012)

S. Zounis, K.J. Quail, M. Wootton, M.R. Dickson, J. Cereal Sci. 35(2), 135–147 (2002)

Meziani et al., J. Food Eng. 109(3), 538–544 (2012)

S.K. Yang, W. Huang, G. Du, Z. Pan, O. Chung, Food Res. Int. 41(9), 903–908 (2008)

D. Karolien, I.J. Joye, R. Lalatiana, N. Jacques, C.M. Courtin, J.A. Delcour, J. Agric. Food Chem. 61(32), 7848–7854 (2013)

T.G. Matuda, S. Chevallier, P.D.A.P. Filho, A. Lebail, C.C. Tadini, J. Cereal Sci. 48(3), 741–746 (2008)

M.E. Bárcenas, C.M. Rosell, Food Hydrocoll. 19(6), 1037–1043 (2005)

C. Collar, P. Andreu, J. Martınez, E. Armero, Food Hydrocoll. 13(6), 467–475 (1999)

A. Guarda, C.M. Rosell, C. Benedito, M.J. Galotto, Food Hydrocoll. 18(2), 241–247 (2004)

H.R. Tavakoli, N. Jonaidi Jafari, A. Amini, H. Hamedi, J. Texture Stud. 48(2), 124–130 (2016)

M. Akbarian, A. Koocheki, M. Mohebbi, E. Milani, J. Food Sci. Technol. 53(10), 1–9 (2016)

A. Kaur, K. Shevkani, N. Singh, P. Sharma, S. Kaur, J. Food Sci. Technol. 52(12), 8113–8121 (2015)

M.H. Lee, M.H. Baek, D.S. Cha, H.J. Park, S.T. Lim, Food Hydrocoll. 16(4), 345–352 (2002)

C.M. Rosell, J.A. Rojas, C.B.D. Barber, Food Hydrocoll. 15(1), 75–81 (2001)

A. Schiraldi, L. Piazza, O. Brenna, E. Vittadini, J. Therm. Anal. 47(5), 1339–1360 (1996)

P.D. Ribotta, S.F. Ausar, D.M. Beltramo, A.E. Leon, Food Hydrocoll. 19(1), 93–99 (2005)

C. Fadda, A.M. Sanguinetti, A. Del Caro, C. Collar, A. Piga, Compr. Rev. Food Sci. Food Saf. 13(4), 473–492 (2014)

I. Pasha, Crit. Rev. Food Sci. Nutr. 51(5), 467–476 (2010)

W.S. Veraverbeke, O.R. Larroque, F. Bekes, J.A. Delcour, Cereal Chem. 77(5), 582–588 (2000)

W.U. Wu, N.S. Hettiarachchy, M. Qi, J. Am. Oil Chem. Soc. 75(7), 845–850 (1998)

L. Zhao, L. Li, G.Q. Liu, X.X. Liu, B. Li, Molecules 17(6), 7169–7182 (2012)

N. Wellner, E.N.C. Mills, G. Brownsey, Biomacromolecules 6(1), 255–261 (2005)

P. Wang, H. Chen, B. Mohanad, L. Xu, Y. Ning, J. Xu, F. Wu, N. Yang, Z. Jin, X. Xu, Food Hydrocoll. 39(8), 187–194 (2014)

P.R. Shewry, A.S. Tatham, J. Cereal Sci. 25(3), 207–227 (1997)

H. Wieser, Food Microbiol. 24(2), 115–119 (2007)

C.W. Wrigley, Nature 381(6585), 738–739 (1996)

V. Kontogiorgos, H.D. Goff, Food Hydrocoll. 1(4), 202–215 (2006)

P.D. Ribotta, A.E. León, M.C. Añón, J. Agric. Food Chem. 49(2), 913–918 (2001)

S. Domenek, M.H. Morel, A. Redl, S. Guilbert, Macromol. Symp. 200(1), 137–146 (2003)

C.M. Rosell, A. Foegeding, Food Hydrocoll. 21(7), 1092–1100 (2007)

I.G. Mandala, K. Sotirakoglou, Food Hydrocoll. 19(4), 709–719 (2005)

P. Wang, L. Xu, M. Nikoo, D. Ocen, F. Wu, N. Yang, Z. Jin, X. Xu, Food Hydrocoll. 35(3), 238–246 (2014)

C. Mangavel, J. Barbot, Y. Popineau, J. Guéguen, J. Agric. Food Chem. 49(2), 867–872 (2001)

M. Jackson, H.H. Mantsch, Crit. Rev. Biochem. Mol. Biol. 30(2), 95–120 (1995)

S. Meziani, J. Jasniewski, C. Gaiani, et al., J. Food Eng. 107(3), 358–365 (2012)

L. Natalia, F. Evelina, P. María Cecilia, F. Cristina, J. Agric. Food Chem. 59(2), 713–719 (2011)

E. Eddy, F. J, A. Hvan, M. Maliepaard, D. Jpm, Cereal Chem. 80(4), 396–403 (2003)

J. Huen, C. Weikusat, M. Bayer-Giraldi, I. Weikusat, L. Ringer, K. Lösche, J. Cereal Sci. 60(3), 555–560 (2014)

X. Ding, H. Zhang, L. Wang, H. Qian, X. Qi, J. Xiao, Hydrocolloid. 47, 32–40 (2015)

Y. Phimolsiripol, U. Siripatrawan, V. Tulyathan, D.J. Cleland, J. Food Eng. 84(1), 48–56 (2008)

J.L. Kokini, A.M. Cocero, H. Madeka, E.D. Graaf, Trends Food Sci. Technol. 5(9), 281–288 (1994)

B. Khatkar, A. Bell, J. Schofield, J. Cereal Sci. 22(1), 29–44 (1995)

P.D. Ribotta, G.T. Pérez, A.E. León, M.C. Añón, Hydrocolloid. 18(2), 305–313 (2004)

M. Cornec, Y. Popineau, J. Lefebvre, J. Cereal Sci. 19(2), 131–139 (1994)

Y. Popineau, M. Cornec, J. Lefebvre, B. Marchylo, J. Cereal Sci. 19(3), 231–241 (1994)

M. Havet, M. Mankai, A. Le Bail, J. Food Eng. 45(3), 139–145 (2000)

P.D. Ribotta, A.E. León, M.C. Añón, J. Agric. Food Chem. 49(2), 913–918 (2001)

Y. Song, Q. Zheng, Trends Food Sci. Technol. 18(3), 132–138 (2007)

B.J. Dobraszczyk, M.P. Morgenstern, J. Cereal Sci. 38(3), 229–245 (2003)

Acknowledgments

This work is financially supported by National Key R & D Program of China (no. 2016YFD0400203), National Natural Science Foundation of China (no. 31671961), Natural Science Foundation of Guangdong Province (no. 2017A030311021) and Start-up Fund of natural Sciences Foundation of Guangdong Province (no. 2015A030310189).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiao, W., Li, L., Fan, P. et al. Effect of Xanthan Gum on the Freeze-Thaw Stability of Wheat Gluten. Food Biophysics 14, 142–153 (2019). https://doi.org/10.1007/s11483-018-09565-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-018-09565-9