Abstract

We report on the direct incorporation of a lipase derived from Rhizomucor miehei, into aeratable food emulsion formulations, with the objective of enzymatically generating polar lipid fractions during processing, and which are able to demonstrate equivalent functionality to chemically synthesised monoglycerides. Findings showed that the lipolysis of palm oil-in-water emulsions produced a combination of predominantly oleic monoglyceride and palmitic fatty acid fractions. The extent of hydrolysis was able to be controlled through concentration of enzyme, reaction time, and reaction temperature. Hydrolysis was terminated via inactivation of the enzyme through high heat treatment of emulsions. Emulsion properties, notably stability under shear, were seen to be highly dependent on the extent of lipolysis. When applied to model whipping and ice cream formulations, lipolytic generation of polar lipids was shown to promote both partial coalescence and fat globule adsorption to bubble surfaces, generating structures equivalent to those produced by use of commercial emulsifiers. Product properties, such as physical stability and material properties showed variation according to the extent of lipolysis. Our results demonstrated that enzymatic lipolysis of emulsions under controlled conditions could be optimised to deliver requisite droplet functionality for the structuring and stabilisation of aerated food emulsions. Findings are of significance, not only when considering the potential for replacement of chemically derived emulsifiers in such formulations, but also from the perspective that this approach can readily be incorporated into existing manufacturing process operations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Polar lipid emulsifiers (PLEs), such as monoglycerides and their derivatives, continue to be widely used within the food industry, providing a broad range of technical functions such as emulsification, demulsification, wetting, foaming antifoaming and specific interactions with other food materials. Such functions play a critical role in imparting the requisite structural, material and thus quality parameters to any given food, and thus the mechanisms for their action have become widely investigated [20, 25, 35]. An example of this is the use of PLEs in the manufacture of aerated food emulsions, notably whipping cream and ice cream [16]. Whilst there can be quite subtle complexity in the role and function of specific emulsifiers in these compositions [24, 32], it is broadly recognised that the addition of emulsifiers to whippable emulsions contributes to two critical structural elements necessary for the creation of an appropriate whipped structure. In short, the first of these is the adsorption of fat globules to the air-water interface of bubbles formed during the whipping process; the second is the destabilisation of the emulsion under shear resulting in the formation of partially coalesced agglomerates due to wetting and fusion of colliding droplets [1, 8, 14, 15, 26]. Both of these mechanisms are enabled by the emulsion comprising partially crystalline fat droplets, and through the formation of a mixed protein-emulsifier oil droplet interface [18].

In the case of whipping cream compositions [40], which typically comprise 30–45 vol% fat, the adsorption of fat droplets to the surface of the bubble surface assists in the stabilisation of the foam through a form of Pickering stabilisation, as well as enabling control of overrun [1]. The partial coalescence of fat droplets, in turn, provides mechanical rigidity to the foam through formation of a percolating fat droplet-air bubble network, imparting good piping properties, stand-up and firmness to the resulting whipped cream, as well as helping to inhibit drainage and syneresis during the lifetime of the foam [5, 22]. In the case of ice cream, for which the fat content tends to be lower (typically 3–10 vol%, depending on product type), whilst the emulsion and structuring behaviours are similar to those observed in whipped cream [40], the functional properties arising from the generation of these structures are somewhat different. Fat globule adsorption at the surface of the bubbles during the freezing process has been shown to produce smaller, more stable bubbles compared to emulsifier-free formulations (in which the fat droplets do not adsorb at the air-water interface) [4]. A reduction in bubble size has been shown to correlate directly with improved creamy perception of the ice cream [42]. Maintenance of quality is also improved through the addition of emulsifiers in that bubble growth and destabilisation as a consequence of temperature cycling is also greatly reduced in comparison to emulsifier free formulations [4]. Partial coalescence is also observed to take place in ice cream, and is considered as providing a significant improvement in meltdown to the stability of ice creams relative to emulsifier-free formulations [7].

For both whipping and ice cream compositions, the addition of small molecule emulsifiers to whipping and ice cream formulations results in partial displacement of protein layer that is initially adsorbed at the oil-water interface during homogenisation. This orogenic displacement phenomenon [27, 28] is a dynamic process and the extent of displacement is dependent on a number of variables, such as emulsifier type and concentration, temperature and time. Most polar lipid emulsifiers will complete with adsorbed protein at the interface, which leads to perforation of the protein stabilised layer, and which not only causes weakening the mechanical strength of the interface, but allows protrusion of fat crystals through the interfacial domains occupied by the emulsifier [1]. Modification of the interface in this way facilitates the twin mechanisms of partial coalescence and droplet adsorption at the bubble surface, and is influential in determining the functional behaviours of the whipped emulsion, such as whipping time, material properties, standup and drainage [21].

Emulsifier addition to whipping cream and ice cream formulations has been an established aspect of formulation design for many decades, based on the demonstrated contribution to product quality in terms of stability and sensory performance. However, the particular food industry motivation for clean label or natural alternatives for replacement of synthetic additives has prompted a number of studies in recent years for other structuring pathways that do not require emulsifier addition, but are able to demonstrate equivalence in technical functionality. In the case of whippable emulsions, it is noteworthy that whilst approaches have been developed that are able to promote droplet agglomeration under shear [39], or alternatively to bind droplets to the surface of air bubbles during whipping [2], it does appear that the twin mechanisms of fat droplet adsorption to the bubble interface and partial coalescence (and the product properties associated with these mechanisms) are peculiar to emulsion formulations comprising the addition of polar lipid emulsifiers [3].

The rationale for this study acknowledges the requirement of emulsifiers in the formulation and structuring of whippable food emulsions, but seeks an alternative approach to produce these materials that does not require chemical synthesis. To this end, we have explored the potential of a lipase enzyme derived from Rhizomucor miehei (R. miehei), to biochemically generate polar lipids [11, 43]. This particular enzyme hydrolyses triglyceride molecules at the Sn-1 and Sn-3 positions to produce two fatty acids and a Sn-2 monoglyceride. This approach has previously been considered in relation to the synthesis of fractionated monoglycerides from various oil feedstocks [34]. Enzymatic generation of polar lipids has also been shown to be effective at enhancing the quality of breads when incorporated into the manufacturing process [30, 38].

Using palm oil as our main source of triglycerides we hypothesised that lipolysis of palm oil-in-water emulsions would generate predominantly long chain polar lipid fractions at the oil-water interface that would could impart functionality analogous to emulsions formulated with chemically produced lipid emulsifiers. Furthermore, that this approach could be extended in situ during the processing of model aeratable food emulsions, such as cream and ice cream, and demonstrating equivalence in structuring and product performance to control samples containing a commercial monoglyceride.

Materials and Methods

Materials

Sodium caseinate (Alanate 180) was supplied by Fonterra Co-operative Group Ltd., Auckland, New Zealand. Pioneer brand solid palm oil from Bakels Edible Oils (NZ) Ltd. was purchased from Bidvest Palmerston North. The oil was used without any further purification. Skim milk powder (SMP) was obtained from Fonterra (Fonterra Co-operative Group, New Zealand). Lipase obtained from R. miehei with ≥20,000 U/g activity was purchased from Sigma-Aldrich NZ Ltd., Auckland, New Zealand. Guar gum was from Hawkins Watts Ltd. (Auckland, New Zealand). Commercial monoglyceride Palsgaard® DMG 0093 (Palsgaard Asia pacific Pte Ltd., Singapore) was used. All other chemicals were of Analar grade.

Processing of Model Emulsions, Whipped Cream and ice Cream

For model and whipping cream emulsions, sodium caseinate was dispersed in RO water to achieve a final concentration of 1 wt%. This was mixed with melted palm oil (30 wt%) at 60 °C. Prehomogenisation was carried out (LabServ homogenizer D500, Biolab Ltd., New Zealand) for 1 min to produce a coarse O/W emulsion, followed by homogenisation using a two-stage Rannie homogenizer (Albertslund, Denmark) operating with a first-stage pressure of 35 MPa and a second-stage pressure of 10 MPa. For cream emulsions, skimmed milk powder was added to the homogenized emulsion at a concentration of 6 wt%. Emulsions were then treated using R. miehei derived lipase enzyme at different lipase enzyme concentrations and lipolysis time at 20 °C. The lipolysed emulsion mixes were passed through a plate heat exchanger pasteurizer (Ultra high temperature pasteurizer plant, Massey University, Palmerston North, New Zealand) at 110 °C and with a holding time of 10 s. Outlet temperature was 18 °C. Mixes were kept in a 4 °C chiller for overnight to age the emulsion. A similar process was used to prepare ice cream mixes, with the additional water soluble ingredients (e.g. sugar and guar) being added to the aqueous phase, and for control samples containing monoglyceride, with emulsifier addition to the molten fat phase prior to combination of the two phases preceding homogenisation. Preparation of ice cream mixes followed the same processing pathway as that of whipping cream compositions. The base formulation of the ice cream mix is presented in Table 1. Mixes were again lipolysed (with variable enzyme concentration and reaction time at 20 °C) prior to enzyme inactivation through thermal treatment.

Ice cream samples were prepared using a continuous ice cream freezer (Tetra Pak KF 80, Denmark). Overrun was set at 100%. Ice cream collected was filled into plastic containers and kept in the freezer at −30 °C for at least 2 days before analysis to allow the samples to harden.

Quantification of Fatty Acids

Extraction of Lipid

Extraction of the lipid components from model oil-in-water emulsion samples was carried out using a 2 step method by Bligh and Dyer [6]. New or solvent-cleaned glass tubes were used to avoid contamination. To each 1 ml of sample, 3.75 ml of 1:2 (v/v) chloroform:methanol was added before being vortexed for 10–15 min. An internal standard of 50uL margaric acid (C17:0, 20 mg L−1) was included at this stage. After that, 1.25 ml chloroform was added and vortexed for 1 min. Then, 1.25 ml water was added and vortexed again for another 1 min. The mixture was then centrifuged at 1000 rpm using a bench-top centrifuge (Thermo Scientific Heraeus® Multifuge® 1S–R, Thermo Electron LED GmBH, Osterode, Germany) for 5 min at room temperature to give a two-phase system. The bottom phase was recovered by inserting a Pasteur pipette through the upper phase with gentle positive-pressure. The remaining upper phase was mixed with 1.88 ml of chloroform, vortexed and centrifuged again. The lower phase was collected once more and combined with the first collection. The mixture was then gently dried under a stream of nitrogen to allow evaporation of the solvent. The extracted lipid was then re-dissolved in 200 μl 2:1 chloroform:methanol.

Derivatization for Fatty Acid Methy Ester (FAME) Analysis

Derivatization of free fatty acids extract to FAME was carried out by mixing 2 mg of extracted free fatty acids with 40 μL methyl-tert-butyl ether before adding 20 μL tri methyl sulfonium hydroxide (TMSH). The mixture was allowed to shake for 15 min at 75 °C [31]. The glycerides extracted were derivatized using the direct transmethylation of glycerides for fatty acids analysis method of Weston et al. [41] adapted by Harmanescu [19]. About 0.3–0.5 g lipid extract is weighed into a 10 mL Teflon tubes. 2.5 mL of boron trifluoride-methanol (Sigma-Aldrich) was added. The tubes were then heated at 70 °C in a water bath for 30 min. Once the tubes were cooled down, 1 mL of 10% sodium chloride solution was added. 2 mL of hexane was then added followed by 1 g sodium sulfate and 1 g activated carbon. The mixture was then centrifuged for 5 min at 25000 rpm. The supernatant was collected in vials for gas chromatography analysis.

Detection of FAMEs by Gas Chromatography (GC)

Detection of FAMEs was carried out on an Agilent 7890 GC (Agilent Technologies, CA, USA) [43], equipped with a a flame ionization detector and a split/splitless injector. A 30 m Supelcowax™ 10 capillary column (0.35 mm diameter × 0.50 μm thickness) (Supelco Park, PA, USA) was fitted to the GC. Helium was used as the carrier gas at 20 cm/s, at a pressure of 76 kPa at the head of the column. Both the injector and the detector were set at 260 °C. The column was held at initial temperature of 180 °C for 5 min, followed by increase to 210 °C at a rate of 1 °C min−1 and then maintained at 210 °C for 25 min. The split ratio was 20:1. The FAME peaks were identified and quantified by Agilent 5975 GC/MS system.

Shear Stability Analysis

The stability of lipolyzed emulsion under shear was analysed according to the method by Fuller et al. [12, 13]. The shear stability was analysed versus time at a constant shear rates using a Paar Physica MCR 301 stress-controlled rheometer (Anton Paar GmbH, Germany) with a truncated cone-and-plate geometry (50 mm diameter, 2° angle, 47 μm gap). All measurements were carried out at 100 s−1 constant shear rate except during the determination of effect of shear rates where shear rates of 100–1500 s−1 were employed. The plate temperature was held at 5 °C by a Peltier plate system. The lipolyzed emulsion was introduced onto the centre of the plate with a pipette and the holding time of emulsion on the plate was 5 min. A solvent trap was included to prevent evaporation.

Measurement of Drainage Stability of Whipped Creams

The rate of serum drainage was determined by placing 20 g of whipped emulsion on a glass funnel at ambient temperature. The glass funnel was suspended over a tared conical flask to collect the drained serum from the whipped emulsion as shown in Fig. 6. The conical flask were weighed after 1 h to measure the serum collected, as this will be an index of stability of the whipped emulsion [36]. The percentage of serum drainage was calculated as follow:

Determination of Emulsion Droplet Size

Determination of the average droplet diameter was carried out using a laser diffraction technique (Malvern Mastersizer 2000, Malvern Instruments Ltd., UK). The pump speed was set at 1800 rpm. The absorbance value of the emulsion particles was 0.001. Whipped emulsion and ice cream samples were diluted with water (1:10) before being introduced into the recirculating water in the Hydro MU measuring cell unit until an obscuration rate of 11–12% was obtained as indicated by the instrument.

Microscopic Observation of Whipped Cream by Confocal Laser Scanning Microscope

Microscopic observation of emulsion droplets was carried out using confocal laser scanning microscopy (Leica SP5 DM6000B, Leica Microsystem, Heidelberg, Germany). Fluorescent protein dye Fast Green FCF (Merck, Darmstadt, Germany) was used to stain the protein matrix of the emulsion, whilst Nile Red (Sigma Aldrich, St. Louis, MO, USA) was used to stain the lipid droplets. For the analysis of whipped emulsion, the dyes were added to the emulsion mix prior to aging, before being subsequently whipped the next day. Samples were then scanned with a 63× oil immersion objectives using laser with excitation wavelength of 561 nm and 633 nm for nile red and fast green FCF respectively. The images were captured by two channels of PMT, one for each wavelength used. The images from both PMT channel was then overlapped and processed in Leica Application Suite Advanced Fluorescence (LAS AF) software platform.

Texture Analysis

The determination of large deformation material characteristics for whipped cream and ice cream samples was carried out using a TA.XT Plus texture analyser with 5 kg load cell (Stable Micro Systems, Surrey, UK).

Statistical Analyses

All analyses were carried out in triplicates. Post-hoc analyses was carried out for texture analysis as well as lipid quantification. For time based measurements, the data lines plotted were averages from 3 replications, similarly the particle size figures were obtained as averages from 3 replications. Analysis of variance (ANOVA) with post hoc Tukey test was performed using MINITAB 16 (Minitab Inc., State College, PA, USA) to determine the differences between mean of the physicochemical analyses of whipped cream and ice cream, where possible. All statistical analyses were considered significant when p < 0.05.

Results and Discussion

Lipid Composition of Lipolysed Palm oil-in-Water Emulsions

Initial analysis sought to determine whether lipolysis was generating polar lipid fractions in model protein stabilised emulsion systems. By applying a combination of TLC and GC FAME, it was possible to quantify the type and concentration of the principal fatty acids and monoglyceride fractions for a 30% palm oil-in-water emulsion initially stabilised by sodium caseinate. Polar lipid concentrations were measured according to reaction time (up to 60 min) and according to enzyme concentration (5 – 50 mg lipase per g fat). Findings are presented in Tables 2, 3 and 4.

Concentrations of both fatty acids and monoglycerides were seen to increase with enzyme concentration and also with holding time. In terms of the predominant polar lipid fractions produced, long chain saturated fatty acids, notably palmitic, stearic and oleic were found to most prevalent, with maximal values of 19.2, 13.9 and 6.4 mg/g fat based on treatment with 50 mg lipase per g fat with a reaction time of 60 min. Monoolein, and to a lesser degree monopalmitin, were determined as the most abundant monoglyceride fractions, with maximal values of 5.4 and 3.5 mg/g fat respectively.

The relative concentrations of the polar lipid fractions produced through lipolysis were, to some extent, in line with expectations based on an understanding of the triglyceride composition of palm oil. Lipase derived from Rhizomucor miehei hydrolyses triglycerides at the Sn-1 and Sn-3 positions, also yielding a Sn-2 monoglyceride. Palmitic-oliec-palmitic (POP) and palmitic-oleic-oleic (POO) are known to be the principal triglyceride fractions of palm oil, representing ~30 and 23% of total triglyceride content [29], and thus their hydrolysis would be expected to generate elevated levels of palmitic acid and Sn-2 monoolein [43]. Somewhat less expected were the observed values for stearic acid. Stearic acid provides a relatively small contribution to the overall triglyceride composition of palm oil (~3.5% of total fatty acid content), and whilst this is primarily located at either Sn-1 or Sn-3 position, the stearic acid concentration of the lipolysed emulsion, as determined by GC-FAME, would still be expected to be significantly lower than that of palmitic acid, which is naturally present at much higher concentrations. There was no immediate explanation for this, although it may be speculated that for emulsion systems, interfacial nucleation of higher melting point fractions may have led to localisation of triglycerides containing stearic acids at the interfacial layer, and therefore more accessible for lipolysis.

The ratio of total fatty acids to monoglycerides (mg/g fat) produced via lipolysis varied considerably with lipase concentration and reaction time, ranging from 2:1 up to 6:1 according to conditions. A maximum of ~42 mg total fatty acids per gram of fat was produced with 50 mg lipase (per gram fat) with a reaction time of 60 min. The same reaction conditions yielded 9.5 mg total monoglycerides (per gram fat). Full hydrolysis of fats and oils liberates two molecules of fatty acid and one monoglyceride molecule per molecule of triglyceride. Variation in the relative amounts of polar lipids generated was most likely a consequence of incomplete hydrolysis taking place. This was in agreement with GC-FAME data that showed the presence of appreciable concentrations of diglyceride fractions, suggesting partial hydrolysis had taken place. If this is indeed the case, then this implies that reaction conditions will require appropriate management to produce sufficient levels of monoglycerides able to generate the required level of functionality (i.e. propensity for partial coalescence and adsorption at the bubble interface during whipping) for whippable formulations.

With this in mind, a particular consideration of the GC-FAME data was whether the amount of polar lipids being synthesised was in fact comparable to dosage levels of emulsifier used in the manufacture of aerated food emulsions such as cream and ice cream. Monoglyceride concentrations in ice cream vary according to fat content (usually increasing in concentration with decreasing fat content). Dosage levels of 30 mg/g fat up to 100 mg/g fat can be considered typical for commercial formulations. Whilst the fat content of whipping creams is higher than that of ice cream (typically between 30 and 40% by volume), the emulsifier levels are similar to those encountered for ice cream formulations (noting that for whipping creams, a combination of small molecule emulsifiers is often applied in formulations, rather than the singular use of monoglycerides), thus representing a range of dosage levels from ~10 mg/g fat to 20 mg/g fat depending on the relative concentration of fat and emulsifier. Based on the variables applied within the study design, the maximum total concentration of monoglycerides generated was determined as 9.5 mg/g fat (50 mg lipase/g fat, 60 min holding time). This may be sufficient to provide functionality in whipping cream applications, but might be expected to be insufficient for use in ice cream.

Shear Stability of Lipolysed Palm oil-in-Water Emulsions

As indicated in the introduction, the addition of small molecule emulsifiers to whipping and ice cream formulations results in partial displacement of protein layer adsorbed at the oil-water interface. This orogenic displacement phenomenon [27, 28] leads to perforation of the protein stabilised layer, which not only causes weakening the mechanical strength of the interface, but allows protrusion of fat crystals through the interfacial domains occupied by the emulsifier. These effects can compromise the stability of the emulsion, such that under shear, partial coalescence of droplets can occur (noting that the presence of solid fat within the droplets prevents full coalescence of droplets from occurring).

Fuller et al. ( [12]; G. T. [13]) employed a rheological methodology to characterise the stability of partially coalescing emulsions under shear. Emulsion viscosity at a constant shear rate and fixed temperature was measured over time. For emulsions stable to partial coalescence no significant change in viscosity over time was observed, whilst the occurrence of partial coalescence resulted in an increase in viscosity. Viscosity increases arising from partial coalescence and the development of interconnected agglomerate structures tended to occur after an initial lag phase of shearing, with the extent of this lag time providing an indication as to the relative stability of the emulsion (i.e. emulsions with a greater propensity towards partial coalescence had shorter lag times).

This technique, coupled with particle size analysis, was adapted to determine the effects of lipolysis on the shear stability of sodium caseinate stabilised 30 wt% palm oil-in-water emulsions. Figure 1 shows the effect of lipase concentration (for a fixed reaction time of 30 min followed by inactivation) on time dependent emulsion viscosity (shear rate = 100 s−1, T = 5 °C), whilst Fig. 2 shows the effect of reaction holding time for emulsions treated with a fixed concentration of lipase (50 mg/g fat, shear rate – 100 s−1, T = 5 °C). Findings from Fig. 1 showed no change in viscosity of the non-lipolysed control sample over the duration of the experiment, indicating that the emulsion was shear stable under the applied conditions. Emulsions stabilised by sodium caseinate have been widely reported as possessing good stability against shear induced coalescence and partial coalescence [9, 23] due to the repulsive and mechanical effects imparted by the protein interface, and thus the observed rheological behaviour was in line with expectations. No change in emulsion viscosity was observed at the lowest dosage level of lipase, indicating that this enzyme concentration did not produce sufficient quantities of polar lipids over the reaction time to influence the functionality of droplets under the applied conditions. At lipase concentrations of 10 mg/g fat and above, the change in viscosity profile became apparent, final viscosity increasing from 0.05 Pa.s up to 0.4 Pa.s as enzyme concentration was increased from 10 mg/g fat up to 50 mg/g. A lag time prior to viscosity increase was observed for all samples, with similar lag times of ~400 s observed for enzyme concentrations of 25–50 mg/g fat. The emulsion sample dosed with 10 mg/g fat of lipase showed a markedly longer lag phase of ~1000 s.

Findings here demonstrated the impact of lipolysis on the shear stability of a protein stabilised 30% oil-in-water emulsion. The alteration of emulsion stability was attributed to the adsorption of polar lipids generated via lipolysis at the oil-water interface, thereby weakening the interfacial layer and promoting partial coalescence under shear. Relative shear stability was seen to decrease with increasing enzyme concentration accordingly as a consequence of increasing concentrations of polar lipids being generated (as observed for the GC-FAME data). Attempts were made to correlate the extent of lipolysis to the amount of polar lipids adsorbed at the oil-water interface using a depletion method for measuring protein surface coverage. Unfortunately, the inherent instability of the emulsion systems studies here made this methodology impractical and no reliable data could be produced. It would also be of value to characterise the composition of the lipid fraction at the oil water interface in order to determine whether monoglycerides are preferentially adsorbed, or whether the lipid component of the interfacial layer was a composite of monoglycerides and fatty acids.

Data from Fig. 2 showed how relative emulsion stability for a fixed concentration of lipase (50 mg/g fat) varied according to lipolysis reaction time. Findings showed that increasing reaction time resulted in progressive increases to the shear viscosity of emulsion samples with a corresponding reduction in lag time prior to the onset of viscosity increase. It was interesting to observe the similarity of the shear viscosity profile of emulsion prepared with lipolysis reaction time of 45 and 60 min, in particular noting the increase in viscosity immediately after the application of shear (i.e. the absence of any lag phase).

As shown in Tables 2, 3 and 4, extending reaction times and/or increasing the concentration of enzyme increased the concentration of polar lipids generated through lipolysis, and that emulsion stability (as observed in Figs. 1 and 2) decreased with increasing concentrations of these lipid fractions. Indeed, excessive lipolysis (caused by enzyme concentrations of 50 mg/g fat and holding times of >45 min) was seen to reduce emulsion stability to the extent that quiescent thickening of the emulsion was observed as a consequence of perikinetic partial coalescence. Importantly, both enzyme concentration and holding time were seen as providing mechanisms by which the relative shear stability could be controlled.

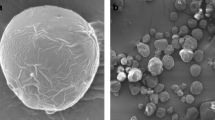

Changes to emulsion droplet structure during shearing were also measured in order to relate time dependent viscosity of shear thickening samples to emulsion instability and droplet aggregation. An example of this is provided in Fig. 3 (lipase = 50 mg/g fat, lipolysis time prior to inactivation = 30 mins), in which droplet size distributions at various stages of the shearing process are presented. A monomodel droplet distribution of the lipolysed emulsion was observed prior to shear, with a volume weighted mean particle size (D[4,3]) of 0.69 ± 0.04 μm (which was significantly similar to that of the non-lipolysed control emulsion, data not shown), indicative of a stable emulsion. Measurement of particle size after 210 s shearing time showed the development of a bimodal distribution and with D[4,3] increasing to 13.04 ± 4.34 μm. Whilst the change in particle size was indicative that droplet aggregation was taking place, it was interesting to note droplet aggregation occurred before the onset of apparent shear thickening at ~480 s. Further measurement of particle size at 1200 s showed a multimodal distribution, with further measurements at 1800 and 3000 s showing further increases in droplet size and with the distribution returning towards monomodal, albeit at greatly increased particle size relative to the starting emulsion. Droplet size measurements provided an indication that increasing viscosity under shear was driven by fat structuring leading to the formation of agglomerated fat networks. This extensive association of solid droplets into aggregated structures provides the mechanical scaffolding considered as a key requirement for emulsion structuring and reinforcement of whippable emulsions, particularly in the case of whipped creams.

In this respect, it is also worth noting that the shear stability of enzyme treated emulsions systems shows comparable behaviours to partially crystalline emulsions stabilised by commercial polysorbate emulsifiers, as observed by Fuller and co-authors (G. T. [12]; G. T. [13]). Using the same shearing methodology, Fuller demonstrated that shear stability decreased in response to increasing levels of added polysorbate emulsifiers, and that emulsions stabilised by polysorbates underwent droplet agglomeration during the shearing process, leading to an increase in droplet size and corresponding increase in shear viscosity.

Structure and Properties of Model Whipped Cream Prepared with Lipolysed Palm oil-in-Water Emulsions

Having demonstrated that the lipolysis of palm oil-in-water emulsions could be used to manipulate the shear stability of emulsions under controlled conditions, analogue whipping cream formulations were developed to determine whether emulsion lipolysis could deliver appropriate functionality for a whippable food emulsion system. As discussed previously, a combination of fat droplet adsorption to bubble surfaces during whipping and the formation of a partially coalesced fat network are considered requisite for ensuring effective foam stabilisation and imparting appropriate material properties. It was hypothesised that the accumulation of polar lipids at the oil-water interface as a consequence of the lipolysis of the palm oil droplets would facilitate both these criteria (with the shear rheology experiments having indeed indicated that emulsions could be tailored towards appropriate partial coalescence requirements).

Accordingly, whipping cream samples comprising 30 wt% palm oil-in-water emulsions, stabilised with sodium caseinate and with addition of 6% skimmed milk powder (SMP) added (to achieve equivalent total solids composition to typical commercial products) were prepared. Based on observations from rheological analysis, a non-lipolysed control emulsion was compared to emulsion samples treated with enzyme concentrations ranging from 0.05 to 50 mg enzyme/g fat with a reaction time of 15 min prior to thermal inactivation. Emulsion samples were aged at 5 °C for a fixed period of time prior to whipping (using a conventional kitchen mixer) and analysis. Characterisation of whipped foams included overrun measurements, standup stability, drainage, firmness and microstructural characterisation.

Figure 4 shows the overrun profiles for cream samples. Findings showed that overrun increased with increasing lipase concentration (noting that the non-lipolysed control could not be aerated), reaching a peak overrun of 350% at an enzyme concentration of 10 mg/g fat. Higher lipase concentrations were found to result in a small but significant decrease to peak overrun, reaching ~300% for enzyme concentration of 15–25 mg/g fat, and showing a further decrease to ~200% for a lipase concentration of 50 mg/g fat. Time to reach peak overrun varied according to enzyme concentration, requiring ~3 min at an enzyme concentration of 2.5 mg/g fat and up to 6 min for the sample containing 10 mg/g fat enzyme. All samples, with the exception of the control and 0.05 mg/g fat lipase showed a progressive decrease in overrun after peak overrun had been reached, indicating the occurrence of over-whipping and gradual loss of foamability. Findings indicate that overrun levels are comparable to prior studies exploring the whippability of emulsions comprising polar lipid emulsifiers [10, 44]. It should also be noted that overrun values of commercial whipped products are typically in the range of 200–250% for non-dairy UHT compositions where fat content is ~30 vol%, thus indicating that (dependent on reaction conditions), equivalent levels of aeration can be achieved relative to commercial systems [17].

The physical appearance of whipped creams and their ability to retain shape are key critical requirements for commercial products. Creams should be pipable and demonstrate well-defined fluting in appearance. Slumping and syneresis are usually indicative of a poorly stabilised foam. Figure 5 shows photographs of whipped cream samples prepared with enzyme concentrations of 0, 5 or 10 mg enzyme per g fat. Samples are shown immediately after piping, and after 1 h’s rest at ambient temperature. At a lipase concentration of 5 mg the whipped cream did not demonstrate well-defined flute definition after piping, and collapse of foam shape was clearly observed after 1 h’s storage time. However, increasing the lipase concentration to 10 mg/g fat resulted in a pronounced improvement in flute definition, with the piped structure being retained after 1 h’s storage, with no apparent collapse. These two enzyme concentrations represent the transition point between unstable and stable whipped creams. Enzymes concentrations of 5 mg/g fat possessed increasingly poor flute definition and physical stability as enzyme concentration decreased. At enzyme concentrations of 10 mg/g fat and higher, both flute definition and shape retention were improved.

Piping stability at 20 °C of whipped lipolysed creams with varying lipase concentrations. a = No added lipase; whipped cream with 5 mg lipase per g fat, immediately after piping (b) and 1 h after piping (c); whipped cream with 10 mg lipase per g fat, immediately after piping (d) and 1 h after piping (e)

These findings correlated to the drainage stability of the cream formulations as shown in Fig. 6 which showed the extent of serum drainage from the foam after a storage time of 1 h. Whipped creams with enzyme concentrations up to 5 mg/g fat showed poor drainage stability, with serum losses of up to 40%. An increase in enzyme concentration up to 10 mg/g fat showed a significant reduction in the extent of drainage, with <2% serum loss after 1 h. Further increases in enzyme concentration showed marginal, but statistically insignificant, improvements in drainage stability. Inhibition of drainage from whipped cream structures was attributed to the formation of fat channels between bubbles that served to impede movement of the liquid continuous phase under gravity, effectively entrapping it within the foam structure [40].

Measurement of the material properties of lipolysed whipped creams was carried out using a texture analyser. Whipped creams with enzyme concentrations of 5 mg/g fat and below were unable to provide measurable data on the instrument. Maximum force values are therefore only shown for whipped cream samples with enzyme concentrations of 10 mg/g fat and higher, with results shown in Fig. 7. It could be seen that cream firmness increased with increasing enzyme concentration. This is possibly a consequence of greater mechanical reinforcement due to a greater propensity towards partial coalescence as enzyme concentration is increased; however, it is also possibly a consequence of decreasing overrun with increasing enzyme concentration, as increasing the volume of air present within the whipped structure will be expected to have a softening effect on the material properties of the cream [10].

Confocal microscopy and particle size analysis were used to investigate the microstructural properties of whipped creams and determine whether lipolysed emulsions were able to produce whipped structures analogous to those expected for whipping cream compositions comprising chemically synthesised small molecule polar lipid emulsifiers. The confocal micrograph of a whipped cream prepared using an enzyme concentration of 15 mg/g fat is shown in Fig. 8. Protein was stained green, fat stained red and air bubbles were black in appearance. The image provides a distinct representation of the two aspects of fat structuring considered requisite for whipped cream, namely the decoration of air bubbles by an adsorbed layer of fat globules, interlinked by an a network of agglomerated fat droplets, with both fat and air dispersed phases surrounded by a continuous phase of milk protein [10]. As discussed, this structure provided the foam stabilisation and mechanical rigidity to the foam necessary to provide a whipped product with appropriate textural attributes and foam lifetime. Confocal micrographs showed these structural characteristics for enzyme concentrations of 10 mg/g fat and higher.

Particle size analysis was used to measure the droplet size of whipped emulsions, thereby providing an additional indication of the extent of fat structuring taking place for whipped, lipolysed emulsions. Particle size data of the non-lipolysed control emulsion, before and after whipping is shown in Fig. 9a, while the particle size distributions of whipped, lipolysed emulsions with enzyme concentrations ranging from 5 mg/g fat up to 50 mg/g fat are shown in Fig. 9b. Data show that even for the non-lipolysed control, a small amount of fat destabilisation occurred during the whipping process, even though this sample did not demonstrate foamability or foam stability. This may be due to incomplete stabilisation of a small fraction of droplets after homogenisation due to partial protein coverage of the oil-water interface, thus rendering them more susceptible to shear-induced agglomeration.

Addition of enzymes showed a clear trend of increasing droplet size with increased enzyme concentration. All samples displayed bimodal distributions, with a decrease in the lower modal distribution and corresponding increase to the upper modal distribution as the concentration of enzyme was increased.

Findings provided a further indication as to how the relative stability of emulsions with regards to coalescence could be tailored through manipulation of the extent of lipolysis. Additionally, the extent of partial coalescence observed in Fig. 9b could, in turn, be related to the stability of the whipped cream, noting that whilst emulsions containing enzyme concentrations of <10 mg/g fat could still be whipped to overruns of up to 300% (Fig. 4), insufficient droplet structuring has occurred to provide an adequate yield stress to the foam structure to prevent slumping (Fig. 5). Additionally, the limited extent of agglomeration did not provide resistance to serum drainage from the foam (Fig. 6). These observations, coupled with the materials testing analysis enable determination of the minimum concentration of enzyme required to generate an appropriate whipped structure with good stability, shape definition and material properties.

Structure and Properties of Model ice Cream Prepared with Lipolysed Palm oil-in-Water Emulsions

Ice cream represents a second class of aerated food emulsions for which the addition of small molecule polar lipid emulsifiers has been shown to improve the functional and sensory properties of the product through the enabling of particular fat structuring behaviours during ice cream manufacture. These are similar to fat structuring properties observed for whipped creams, namely that emulsifier (predominantly monoglyceride) addition promotes the adsorption of fat droplets to the surface of air bubbles incorporated during the freezing process, as well as causing agglomeration of fat droplets as a consequence of the high shear environment within the ice cream freezer. Whilst the fat content of ice cream is markedly lower than that of whipped cream, these fat structuring effects can have a significant effect of product properties. These include improved creamy perception, since the basis that fat droplet coating of air bubbles can produce a finer and more stable air phase, and that reducing bubble size can be directly correlated to increased creamy texture [42]. An additional benefit is the enhancement of melt stability through fat agglomeration. In this context, melt stability is not necessarily influenced by the rate of melting of the ice crystal phase per se, but rather through the inhibition of drainage of the liquid serum from the foam as the ice cream melts. Fat agglomeration, as achieved through the use of emulsifier addition, can greatly reduce rate of melt by restricting liquid flow around the bubbles under gravity in a manner analogous to that observed for whipped cream.

While it was not practicable within the context of this study to ascertain the sensory properties of ice creams prepared using enzyme treated formulations, it was possible to determine the impact of enzyme treatment on meltdown stability. To this end, ice cream samples were prepared with fat contents of 5 wt%. Two control samples, comprising no emulsifier and one containing 0.3 wt% commercial saturated monoglyceride, were compared to three enzyme treated formulations with lipase concentrations of 2.5, 7.5 and 15 mg/g fat. Lipolysis reaction time was 15 mins at a temperature of 20 °C, before the mix was pasteurised at 110 °C for 10 s, which additionally served to inactivate the enzyme. All ice cream formulations were successfully frozen with overruns of 100%.

Melt stability of ice creams was determined by measuring, in triplicate, the weight of serum release from ice cream samples of fixed size and weight resting on a grid under controlled ambient conditions. Findings are reported in Fig. 10. It could be seen that rate of melt was fastest for the ice cream formulation containing no emulsifier, with onset of serum release observed after only 5 min of measurement time, and showing complete drainage after 80 min. The formulation prepared with a lipase concentration of 2.5 mg/g fat showed an almost identical melt profile to the emulsifier free formulation, indicating that this concentration of enzyme was not producing sufficient quantities of polar lipids to influence the melt properties of the ice cream. Addition of the commercial monoglyceride (0.3 wt%) was seen to improve melt stability, with onset of melting observed after 10 min’ measurement time, and complete drainage having taken place at 100 min. Melt stability was seen to be optimal for the formulation comprising an enzyme concentration of 7.5 mg/g fat, for which the onset of melting occurring after 20 min’ measurement time, and demonstrating a total of ~90% mass loss after 130 min’ measurement time. Interestingly, increasing the lipase concentration to 15 mg/g fat in the ice cream formulation resulted in a reduced melt stability compared to 7.5 mg enzyme usage, being observed to be similar in profile to that of the control sample containing 0.3 wt% monoglyceride.

Figure 11 shows the particle size distributions for the melted ice creams. The 5 wt% fat control and the formulation based on addition of lipase at a concentration of 2.5 mg/g fat showed an overlapping bimodal distribution with D[4,3] < 1 μm and an absence of fat structuring outside of this distribution. Particle size distribution was seen to match that of the ice cream emulsions prior to freezing, indicating no structural changes had occurred as a consequence of the freezing process. Addition of monoglyceride to the formulation resulted in the appearance of two small additional modal distributions in the range 5–100 μm. Ice cream prepared with an enzyme concentration of 7.5 mg/g fat showed a similar distribution to that of the sample containing monoglycerides, whilst increasing the enzyme concentration to 15 mg/g fat showed an appreciable increase in the upper model distribution and consequential increase in mean particle size. Findings showed the extent of fat destabilisation to be considerably less than that observed for whipping cream, which was attributed to the lower fat content of the ice cream formulations reducing the incidence of droplet-droplets collisions leading to reduced partial coalescence. As discussed, melt stability is influenced by fat structuring that essentially restricts drainage from the foam structure. However, findings from Figs. 10 and 11 indicate that melt stability does not fully correlate with the extent of partial coalescence, and that excessive fat destabilisation (as caused by increasing emulsion lipolysis and generation of polar lipids) may begin to have a negative impact on melt stability. Previous research by Pelan et al. [37] demonstrated that melt stability of 12% fat ice creams prepared with emulsifiers showed that melt stability improved within increasing concentration of unsaturated monoglycerides, but when saturated monoglycerides were used, an intermediate emulsifier concentration was found to provide the best stability. Given that GC-FAME (Tables 2- 4) identified high levels of unsaturated monoglycerides being produced via lipolysis, it might be expected that melt stability would progressively improve with increasing levels of generated polar lipids. However, it is important to note that the study by Pelan et al. was conducted at 12% fat, higher than in this study, and that whilst excessive fat destabilisation was seen to result in coarsening of the air structure within ice cream, it could be presumed that the agglomerated fat network created at high levels of emulsifier addition were still able to provide effective foam stabilisation and inhibition of drainage by blocking movement of liquid between bubble lamellae. At the lower fat levels used within this study, excessive fat destabilisation increases agglomerate size (according to particle size data from figure), but in doing so may sufficiently reduce the number density of agglomerated structures located at the interstices of air bubbles, such that the ability of these structures to inhibit drainage is decreased.

Lipolysis of ice cream emulsions was also seen to impact the material properties of ice creams. Figure 12 shows the penetrometry force profiles of ice creams using texture analysis, which provides an empirical indication of the firmness of the product. Findings from Fig. 12 showed that ice creams containing polar lipids, whether from the addition of monoglycerides or as generated via lipolysis, were significantly softer in texture than the control sample without emulsifier. At low levels of enzyme addition (2.5 mg/g fat) ice cream firmness was similar to control, consistent with observations that this level of enzyme was insufficient to generate levels of polar lipids capable of influencing droplet functionality. Ice cream firmness was seen to be lowest for the intermediate concentration of enzyme (7.5 mg/g fat), and taken in context with other results, would appear that this enzyme concentration provides optimal functionality for ice cream. At the highest concentration of enzyme, slight firming of the ice cream was observed. Findings appear consistent with observations made by Muse and Hartel [33], who showed that limited fat destabilisation (as imparted through the use of the emulsifier polysorbate 80) resulted in a softening of the ice cream relative an emulsifier free control, whilst more extensive fat destabilisation (through increased concentration of emulsifier) resulted in a firming of the ice cream. In considering the role of lipolysed fat destabilisation on the mechanical properties of ice cream, it is important to note that the extent of fat destabilisation may also impact other structure elements of the ice cream, such as ice crystal and air bubble size, each of which may provide contribution to the relative hardness of the product, and thus further structural information is needed to determine the role of fat aggregation on the material properties of the product.

Findings from the use of enzyme-treated emulsions in the manufacture of ice creams, showed that the synthesis of polar lipids arising from lipolysis could impart equivalent or enhanced functionality (in terms of melt stability and material properties) to that of commercial synthetic monoglycerides. An enzyme concentration of 7.5 mg/g fat appeared most effective in delivering desirable attributes. This was, in some respects surprising, in that findings from GC-FAME analysis indicated that this level of enzyme would not be expected to produce sufficient levels of monoglyceride to provide equivalence to the dosage level of 0.3 wt% (or 60 mg/g fat) for the commercial monoglyceride (a similar observation could be applied to the concentrations of enzyme used in preparation of whipping cream analogues).

In this context, it was possible that hydrolysis of emulsion droplets specifically located polar lipid fractions at the oil-water interface, so that a lower emulsifier concentration was ultimately required for functionality relative to the concentration of conventional commercial monoglyceride emulsifiers (where a fraction of the emulsifier may be present in the core of the droplet as well as being located at the interface). Additionally, it is possible that the polar fatty acids produced via hydrolysis may work in combination with the generated monoglyceride fractions to provide the requisite emulsion functionality for the structuring of whippable emulsions such as cream and ice cream.

Such speculation indicates that further research, beyond the scope of this study, is required to more fully explore the surface composition and properties of lipolysed emulsions and relate this to droplet-droplet and droplet-air interactions. This is particularly true when considering the use of different triglyceride feedstocks, noting that the use of palm oil in this study was chosen specifically on the basis that hydrolysis would result in the synthesis of predominantly long chain monoglycerides and fatty acids, which were considered most appropriate in replicating the functionality of commercial monoglycerides. Selection of an alternative source of triglycerides, such as milk fat, would be expected to yield quite different fractions of polar lipids, which would in turn be expected to alter the functionality of emulsion systems accordingly. A further point of note is that the generation and concentration of fatty acids from different triglyceride sources would certainly impact on the flavour properties of lipolysed emulsions.

Conclusions

Lipid hydrolysis of protein stabilised palm oil-in-water emulsions using the R. Miehei has been shown to generate polar lipid fractions of mixed monoglycerides and fatty acids. Manipulating reaction conditions such as enzyme concentration or treatment time prior to thermal inactivation allows the relative concentrations of these polar lipids to be controlled. Rheological analysis demonstrated that droplet stability under shear could be influenced as a consequence of the extent of lipolysis, with increasing propensity towards partial coalescence observed with either increasing enzyme concentration or reaction time. Controlled emulsion lipolysis, when applied as part of the processing pathway for whipping and ice cream formulations, was shown to enable comparable structure-function properties relative to the use of commercial monoglycerides. For whipped cream compositions, acceptable functionality could be achieved at a minimum lipase concentration of 10 mg/g fat (based on a reaction time of 15 min). For ice cream compositions, functional properties were found to be optimal for a lipase concentration of 7.5 mg/g fat (also based on a reaction time of 15 min).

These findings provide a pertinent example of how the raw material functionality of food formulations can be enhanced through appropriate biochemical manipulation, and how such an approach can be readily incorporated into existing products and their processes for manufacture.

References

G.A. van Aken, Aeration of emulsions by whipping. Colloids Surf. A Physicochem. Eng. Asp. 190(3), 333–354 (2001). doi:10.1016/s0927-7757(01)00709-9

K.E. Allen, E. Dickinson, B. Murray, Acidified sodium caseinate emulsion foams containing liquid fat: A comparison with whipped cream. LWT Food Sci. Technol. 39(3), 225–234 (2006). doi:10.1016/j.lwt.2005.02.004

K.E. Allen, B.S. Murray, E. Dickinson, Whipped cream-like textured systems based on acidified caseinate-stabilized oil-in-water emulsions. Int. Dairy J. 18(10–11), 1011–1021 (2008). doi:10.1016/j.idairyj.2008.04.003

N.M. Barfod, The Influence of Emulsifiers on Heat-Shock Stability of ice Cream (Int Dairy Federation, Brussels, 2004)

H. Besner, H.G. Kessler, Interfacial interaction during the foaming of nonhomogenized cream. Milchwissenschaft-Milk Sci. Int. 53(12), 682–686 (1998)

E.G. Bligh, W.J. Dyer, A rapid method of total lipid extraction and purification. Can. J. Biochem. Physiol. 37(8), 911–917 (1959)

S. Bolliger, H.D. Goff, B.W. Tharp, Correlation between colloidal properties of ice cream mix and ice cream. Int. Dairy J. 10(4), 303–309 (2000). doi:10.1016/s0958-6946(00)00044-3

B.E. Brooker, M. Anderson, A.T. Andrews, The development of structure in whipped Cream. Food Microstruct. 5(2), 277–285 (1986)

E. Dickinson, M. Golding, Rheology of sodium caseinate stabilized oil-in-water emulsions. J. Colloid Interface Sci. 191(1), 166–176 (1997). doi:10.1006/jcis.1997.4939

E. Fredrick, B. Heyman, K. Moens, S. Fischer, T. Verwijlen, P. Moldenaers, et al., Monoacylglycerols in dairy recombined cream: II. The effect on partial coalescence and whipping properties. Food res. Int. 51(2), 936–945 (2013). doi:10.1016/j.foodres.2013.02.006

P.B.L. Fregolente, L.V. Fregolente, G.M.F. Pinto, B.C. Batistella, M.R. Wolf-Maciel, R. Maciel, Monoglycerides and diglycerides synthesis in a solvent-free system by lipase-catalyzed glycerolysis. Appl. Biochem. Biotechnol. 146(1–3), 165–172 (2008). doi:10.1007/s12010-008-8133-3

G.T. Fuller, T. Considine, M. Golding, L. Matia-Merino, A. MacGibbon, Aggregation behavior of partially crystalline oil-in-water emulsions: Part II - effect of solid fat content and interfacial film composition on quiescent and shear stability. Food Hydrocoll. 51, 23–32 (2015a). doi:10.1016/j.foodhyd.2015.03.032

G.T. Fuller, T. Considine, M. Golding, L. Matia-Merino, A. MacGibbon, G. Gillies, Aggregation behavior of partially crystalline oil-in-water emulsions: Part I - characterization under steady shear. Food Hydrocoll. 43, 521–528 (2015b). doi:10.1016/j.foodhyd.2014.07.032

H.D. Goff, Emulsion Partial Coalescence and Structure Formation in Dairy Systems (Amer Oil Chemists Soc, Champaign, 2001)

H.D. Goff, Formation and stabilisation of structure in ice-cream and related products. Curr. Opin. Colloid Interface Sci. 7(5–6), 432–437 (2002). doi:10.1016/s1359-0294(02)00076-6

H.D. Goff, W.K. Jordan, Action of emulsifiers in promoting fat destabilization during the manufacture of ice-Cream. J. Dairy Sci. 72(1), 18–29 (1989)

M. Golding, E. Pelan, Application of Emulsifiers to Reduce Fat and Enhance Nutritional Quality, in Food Emulsifiers and Their Applications, eds, by G.L. Hasenhuettl, R.W. Hartel (Springer, 2008), p. 328

C. Granger, P. Barey, P. Veschambre, M. Cansell, Physicochemical behavior of oil-in-water emulsions: Influence of milk protein mixtures, glycerol ester mixtures and fat characteristics. Colloids Surf. B-Biointerfaces 42(3–4), 235–243 (2005). doi:10.1016/j.colsurfb.2004.09.006

M. Harmanescu, Comparative researches on two direct transmethylation without prior extraction methods for fatty acids analysis in vegetal matrix with low fat content. Chem. Cent. J. 6(1), 8 (2012)

G.L. Hasenhuettl, R.W. Hartel, Food Emulsifiers and Their Applications (Springer, 2008)

N.E. Hotrum, M.A.C. Stuart, T. van Vliet, S.F. Avino, G.A. van Aken, Elucidating the relationship between the spreading coefficient, surface-mediated partial coalescence and the whipping time of artificial cream. Colloids and Surfaces a-Physicochemical and Engineering Aspects 260(1–3), 71–78 (2005). doi:10.1016/j.colsurfa.2005.03.004

K. Ihara, M. Maruya, Y. Ozaki, Y. Shimada, Y. Asano, K. Iwatsuki, Influences of bubble size and fat globules aggregation on the physical characteristics of whipped cream (studies on factors influencing physical characteristics of whipped cream part II). J. Jpn. Soc. Food Sci. Technol. Nippon Shokuhin Kagaku Kogaku Kaishi 54(4), 173–180 (2007)

W. Jang, A. Nikolov, D.T. Wasan, K. Chen, B. Campbell, Effect of protein on the texture of food emulsions under steady flow. Ind. Eng. Chem. Res. 44(14), 4855–4862 (2005). doi:10.1021/ie049553z

H.J. Kim, A. Bot, I.C.M. de Vries, M. Golding, E.G. Pelan, Effects of emulsifiers on vegetable-fat based aerated emulsions with interfacial rheological contributions. Food res. Int. 53(1), 342–351 (2013). doi:10.1016/j.foodres.2013.04.027

I. Kralova, J. Sjoblom, Surfactants used in food industry: A review. J. Dispers. Sci. Technol. 30(9), 1363–1383 (2009). doi:10.1080/01932690902735561

M.E. Leser, M. Michel, Aerated milk protein emulsions - new microstructural aspects. Curr. Opin. Colloid Interface Sci. 4(3), 239–244 (1999). doi:10.1016/s1359-0294(99)00037-0

A.R. Mackie, A.P. Gunning, P.J. Wilde, V.J. Morris, Orogenic displacement of protein from the air/water interface by competitive adsorption. J. Colloid Interface Sci. 210(1), 157–166 (1999). doi:10.1006/jcis.1998.5941

A.R. Mackie, A.P. Gunning, P.J. Wilde, V.J. Morris, Orogenic displacement of protein from the oil/water interface. Langmuir 16(5), 2242–2247 (2000). doi:10.1021/la990711e

Y.B.C. Man, T. Haryati, H.M. Ghazali, B.A. Asbi, Composition and thermal profile of crude palm oil and its products. J.Am. Oil Chem. Soc. 76(2), 237–242 (1999)

S. Melis, A. Pauly, L.R. Gerits, B. Pareyt, J.A. Delcour, Lipases as processing aids in the separation of wheat flour into gluten and starch: Impact on the lipid population, gluten agglomeration, and yield. J. Agric. Food Chem. 65(9), 1932–1940 (2017). doi:10.1021/acs.jafc.6b04955

J. Molkentin, A. Giesemann, Differentiation of organically and conventionally produced milk by stable isotope and fatty acid analysis. Anal. Bioanal. Chem. 388(1), 297–305 (2007). doi:10.1007/s00216-007-1222-2

M.B. Munk, F.H. Larsen, F.W.J. van den Berg, J.C. Knudsen, M.L. Andersen, Competitive displacement of sodium Caseinate by low-molecular-weight emulsifiers and the effects on emulsion texture and rheology. Langmuir 30(29), 8687–8696 (2014). doi:10.1021/la5011743

M.R. Muse, R.W. Hartel, Ice cream structural elements that affect melting rate and hardness. J. Dairy Sci. 87(1), 1–10 (2004)

A. Mustafa, A. Karmali, W. Abdelmoez, Optimisation and economic assessment of lipase-catalysed production of monoesters using Rhizomucor miehei lipase in a solvent-free system. J. Clean. Prod. 137, 953–964 (2016). doi:10.1016/j.jclepro.2016.07.056

V. Norn, Emulsifiers in Food Techology, 2nd edn. (Wiley-Blackwell, 2015)

C.A. Padiernos, S.Y. Lim, B.G. Swanson, C.F. Ross, S. Clark, High hydrostatic pressure modification of whey protein concentrate for use in low-fat whipping cream improves foaming properties. J. Dairy Sci. 92(7), 3049–3056 (2009). doi:10.3168/jds.2008-1997

B.M.C. Pelan, K.M. Watts, I.J. Campbell, A. Lips, The stability of aerated milk protein emulsions in the presence of small molecule surfactants. J. Dairy Sci. 80(10), 2631–2638 (1997)

M. Schaffarczyk, H. Ostdal, P. Koehler, Lipases in wheat Breadmaking: Analysis and functional effects of lipid reaction products. J. Agric. Food Chem. 62(32), 8229–8237 (2014). doi:10.1021/jf5022434

K.I. Segall, H.D. Goff, A modified ice cream processing routine that promotes fat destabilization in the absence of added emulsifier. Int. Dairy J. 12(12), 1013–1018 (2002). doi:10.1016/s0958-6946(02)00117-6

D.W. Stanley, H.D. Goff, A.K. Smith, Texture-structure relationships in foamed dairy emulsions. Food res. Int. 29(1), 1–13 (1996). doi:10.1016/0963-9969(95)00063-1

T.R. Weston, J.D. Derner, C.M. Murrieta, D.C. Rule, B.W. Hess, Comparison of catalysts for direct transesterification of fatty acids in freeze-dried forage samples. Crop Sci. 48(4), 1636–1641 (2008). doi:10.2135/cropsci2007.07.0376sc

H. Wildmoser, J. Scheiwiller, E.J. Windhab, Impact of disperse microstructure on rheology and quality aspects of ice cream. Lebensm. Wiss. Technol.Food Sci. Technol. 37(8), 881–891 (2004). doi:10.1016/j.lwt.2004.04.006

S. Wongsakul, P. Prasertsan, U.T. Bornscheuer, A. H-Kittikun, Synthesis of 2-monoglycerides by alcoholysis of palm oil and tuna oil using immobilized lipases. Eur. J. Lipid Sci. Technol. 105(2), 68–73 (2003). doi:10.1002/ejlt.200390019

Q.Z. Zhao, W.M. Kuang, Z. Long, M. Fang, D.L. Liu, B. Yang, M.M. Zhao, Effect of sorbitan monostearate on the physical characteristics and whipping properties of whipped cream. Food Chem. 141(3), 1834–1840 (2013). doi:10.1016/j.foodchem.2013.04.086

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sofian-Seng, NS., Golding, M., Goh, K. et al. In Situ Enzymatic Synthesis of Polar Lipid Emulsifiers in the Preparation and Stabilisation of Aerated Food Emulsions. Food Biophysics 12, 323–338 (2017). https://doi.org/10.1007/s11483-017-9488-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-017-9488-1