Abstract

With an increased awareness of the link between the consumption of omega 3-6-9 fatty acid-rich oils and health, the food industry has been developing innovative strategies for raising their levels within the diet. Microencapsulation is one approach used to protect those oils from oxidative deterioration and to improve their ingredient properties (e.g., handling and sensory). Spray drying is the most commonly used technique to develop microcapsules. The preparation of protein-stabilized emulsions is a fundamental step in the process in order to produce microcapsules with good physical properties, effective protection and controlled release behaviors. This review describes types of emulsions prepared by animal and plant proteins, discusses the relationship between emulsion properties and microcapsule properties, and identifies key parameters to evaluate physical properties (e.g., moisture content, water activity, particle size, surface oil and entrapment efficiency), oxidative stability and release behavior of spray-dried microcapsules for industrial application.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Oils containing omega 3-6-9 fatty acids are gaining increasing interests in the food, agriculture, and pharmaceutical industries, because of their multi-dimensional functional properties, healthy importance to human beings, and natural and safe status. Omega 3-6-9 fatty acids belong to the family of unsaturated fatty acids, which have at least one double bond placed on the carbon chain. They include omega-3 [the first double bond placed at the third carbon starting from the methyl end of carbon chain, e.g., α-linolenic acid (ALA), eicosapentaenoic acid (EPA), and docosahaxaneoic acid (DHA)], omega-6 [the first double bond placed at the sixth carbon starting from the methyl end of carbon chain, e.g., linoleic acid (LA), arachidonic acid (AA), and docosapentaenoic acid (DPA)], and omega-9 fatty acids (the first double bond placed at the ninth carbon starting from the methyl end of carbon chain, e.g., oleic acid). Extensive studies have implicated diverse abilities of omega 3-6-9 fatty acids to prevent coronary artery disease, hypertension, diabetes, inflammatory and autoimmune disorders, which have been associated with different mechanisms, including the deep involvement in eicosanoid biosynthesis to maintain physiological homeostasis and interaction with nuclear receptor proteins to modulate transcription of regulatory genes (Tur et al. 2012). The predominant sources of omega 3-6-9 fatty acids are vegetable oils (e.g., flaxseed oil, olive oil, and walnut oil) and marine oils (e.g., fish oil and microalgae oil), in which vegetable oils are the major sources of oleic acid, LA, and ALA, whereas EPA and DHA are mainly from marine oils (Bakry et al. 2016).

Although omega 3-6-9 fatty acids are widely presented in nature, the desired daily intakes are still hard to achieve, and numerous technical challenges are existing in the production, transportation, and storage. In addition, difficulties from bioavailability and sensory acceptability also build hurdles for the prevalent application of omega 3-6-9 fatty acids in the food products. Due to the unsaturated nature, omega 3-6-9 fatty acids are chemically unstable and susceptible to oxidation to produce free radicals, unpleasant tastes and off-flavors, which are deemed to negatively affect the shelf-life, sensory properties and overall acceptability of the food products (Velasco et al. 2003).

To overcome those problems, microencapsulation technology has been used as a viable method to maintain and improve the biological and functional characteristics of the oils (Ray et al. 2016). Microencapsulation is defined as a technology to isolate or embed bioactive particles (e.g., flavours, antioxidants, polyunsaturated oils, vitamins, and probiotics) by building a physical barrier or a homogeneous/heterogeneous matrix (e.g., carbohydrates, proteins, and lipids), to produce small capsules with various morphologies (Fig. 1) and of diameters between 0.2 and 5000 μm. The encapsulated substances are known as the core, internal or payload phase, whereas the outer protective materials are considered as the wall, external, and coating phase (Desai and Park 2005). Omega 3-6-9 fatty acid-rich oils have been encapsulated using different techniques (e.g., spray drying, freeze drying, coacervation, extrusion, and fluidized-bed coating). Because of low cost, continuous and simple operation, and easy scale-up, spray drying has been extensively used as a microencapsulation and drying technology in the food industry (Bakry et al. 2016). An ideal capsule design should be able to encapsulate a relatively large amount of omega 3-6-9 fatty acid-rich oils per unit mass of food grade wall materials, to protect the oils against chemical degradation (e.g., oxidation and hydrolysis), to release the bioactive components at a particular site at a controlled rate in response to the environmental factors (e.g., pH, ionic strength, enzymatic activity, and temperature), and to be compatible with the surrounding food matrix without adverse changes on the appearance, flavour, texture, and acceptability of the final food product (McClements et al. 2007).

(Reproduced with permission from Raybaudi-Massilia and Mosqueda-Melgar 2012)

Different microcapsule models: a simple microcapsule (a core is surrounded by a single layer of wall material); b multicore microcapsule (multiple cores are dispersed within a continuous wall material matrix); c multiwall microcapsule (a single core is surrounded by several layers of wall materials); and d assembled microcapsule (several distinct particles that are consisted of a single wall material layer coating a single core are embedded in a continuous matrix of wall material)

The selection of appropriate wall materials is an important aspect to consider in the design of microcapsules containing omega 3-6-9 fatty acid-rich oils, because wall materials influence their stability, entrapment efficiency and the degree of protection. A number of carbohydrates have been studied as wall materials, such as maltodextrin, gum Arabic, pectin, and sodium alginate. The major advantages of these carbohydrates are their excellent water solubility and low viscosity at high concentrations (Nesterenko et al. 2013). But, poor emulsifying properties greatly limit their application to encapsulate hydrophobic core materials. So, carbohydrates are generally combined with proteins, which offer good emulsifying properties, as wall materials to develop microcapsules (Table 1). The specific properties of each polymer allow the improvement of emulsion properties and produce microcapsules with better protection to the core materials.

The objective of this review is to compile recent scientific research on the encapsulation of omega 3-6-9 fatty acid-rich oils by spray drying to discuss the main formulation and process variables in the preparation of emulsion, physical characteristics of microcapsules, and oxidative stability and release behavior of encapsulated oils from microcapsules.

Protein-stabilized emulsions

Animal proteins versus plant proteins

Proteins from animal sources [e.g., milk (whey and casein) and gelatin] have been extensively investigated as wall materials in combination with carbohydrates for oil microencapsulation. For example, Goyal et al. (2015) encapsulated flaxseed oil using whey protein concentrate (WPC) or sodium caseinate (SC) in combination with lactose, whereas Takeungwongtrakul et al. (2015) tried to use the mixture of WPC and SC combining with gum Arabic, glucose syrup or maltodextrin to entrap shrimp oil. Hee et al. (2015) designed 1:3 core-to-wall microcapsule formulations of SC and maltodextrin mixing with gelatin, WPC, or gum Arabic for the encapsulation of virgin coconut oil. Because of advanced water solubility over a wider pH range, flexible structure to rapidly diffuse to the oil–water interface, and smaller molecular mass (Can Karaca et al. 2015), SC was mostly used to develop microcapsules. However, food allergy is a big concern for its industrial application. In addition, markets for animal proteins is also restricted by religious and diet restriction, increased cost of animal proteins, and consumer concerns over bovine spongiform encephalopathy.

For these reasons, plant proteins (derived from oilseeds, pulses, and cereals) are currently considered as a “green” trend to be applied in the pharmaceutical, cosmetics, and food industries. They are known to be less allergenic compared to animal proteins, lower cost, and abundant availability (Nesterenko et al. 2013). The application of plant proteins (e.g., lentil, pea, chickpea and sunflower protein isolates) to replace animal proteins as wall materials in the microencapsulation has become an increasingly interesting area for research. For instance, Can Karaca et al. (2013) encapsulated 10–20% flaxseed oil using a mixture of maltodextrin and chickpea protein isolate (CPI) or lentil protein isolate (LPI) by spray drying. Recently, Tamm et al. (2016b) successfully designed microcapsules with pea protein isolate (PPI) and glucose syrup to entrap 20% rapeseed oil.

The physicochemical properties of plant proteins (e.g., surface charge, hydrophobicity, and solubility) affecting emulsifying properties are fairly well understood based on literature (Can Karaca et al. 2011; Liang and Tang 2013a; Chang et al. 2015). Molecular flexibility is one of most important properties that impacts surface activity of proteins, because it determines the conformational change at the oil–water interface to reorient proteins’ hydrophobic and hydrophilic residues towards oil and aqueous phases. It is recognized that flexible proteins (e.g., casein) that have more disordered structures are the most surface active proteins, whereas globular proteins (e.g., legumin) are more compact and rigid, and require some levels of unfolding before adsorbing to the interface. But, since several parameters (e.g., protein structure, protein–protein interaction, and protein compressibility) are involved, the molecular flexibility of protein is difficult to be quantified (Damodaran 2005). Apart from molecular flexibility, other physicochemical properties also influence the formation and stability of emulsions. Surface charge of protein [depending on the pH of continuous phase in relation to the protein’s isoelectric point (pI)] has a great impact on the emulsion formation and stability by influencing surface activity (Cooper et al. 2005). Proteins exert a net positive charge at pH < pI, and a net negative charge at pH > pI. Surface charge is substantially used to study complex coacervation [the electrostatic attraction between two oppositely charged biopolymers (proteins and polysaccharides) over a narrow pH range], which is applied to coat oil droplets by those biopolymers with similar net charges at a pH, followed by the separation of the liquid phase during the formation of the coacervates as the adjustment of pH induces both biopolymers carry opposing net charges (Piacentini et al. 2013; Bakry et al. 2016). Complex coacervation has been successfully used in the microencapsulation to achieve up to 99% oil payloads with lower surface oil (Xiao et al. 2011). Solubility in the aqueous phase is a prerequisite for the proteins to be used as emulsifiers, because it determines the amount of proteins available to migrate to the interface to stabilize the oil droplets (Sikorski 2001). Surface hydrophobicity also plays an important role, because the greater amount of hydrophobic patches on proteins allow the greater adsorption and retention at the oil–water interface (Sikorski 2001). Can Karaca et al. (2011) compared emulsifying properties among chickpea, faba bean, lentil, pea, and soy protein isolates produced by salt extraction, and found LPI had relative higher negative charges, hydrophobicity and solubility to stabilize an emulsion with smaller droplet size and better creaming stability. Liang and Tang (2013a) found pea legume showed significant higher surface hydrophobicity and better solubility than pea vicilin at pH 3.0, so, it produced an emulsion with smaller droplet size and better stability (no creaming after 7 days storage). In the work done by Chang et al. (2015), the effect of pH on the inter-relationships between physicochemical, interfacial and emulsifying properties of pea, soy, lentil, and canola protein isolate was studied, and LPI was considered as the most promising alternative to SPI as an emulsifier, because it showed high surface charge, hydrophobicity and solubility at pH 3.0.

However, imparting these functionalities in the development of microcapsules remains challenging. The difficulties come from the lack of knowledge on the differences of varieties and the complexity of the protein structure, so, in certain cases, physical, chemical or enzymatic modifications of plant proteins were investigated to improve emulsifying properties by partial denaturation of proteins and alternation of hydrophobicity-hydrophilicity balance (Damodaran 2005). Tamm et al. (2016b) evaluated the effect of enzymatic hydrolysis (by trypsin) on the functional properties of pea protein stabilized emulsions. Since the partial hydrolysis resulted in a decrease in molecular weight and exposure of hydrophobic moieties to increase the molecular flexibility, pea protein hydrolysates produced emulsions had significant less changes on the droplet size after 24 h storage. From the work by Liang and Tang (2013b), the conformational flexibility at the quaternary and tertiary structure of vicilin (from red kidney bean) was progressively improved through the dissociation of trimeric phaseolin molecules into monomeric subunits with increasing the urea concentrations (0–8 M). This promoted the increase of emulsifying ability of vicilin by the protein rearrangement at the interface. However, Avramenko et al. (2013) found although surface charge of LPI was raised with increasing the degree of hydrolysis (by trypsin), surface hydrophobicity was decreased to lower the emulsion activity and stability indices of LPI.

Even though extensive research studies focused on the optimization of protein functionalities by modifications, very little information is available to incorporate the modified plant proteins in the microencapsulation. Avramenko et al. (2016) encapsulated flaxseed oil using the un-treated LPI and heat hydrolyzed LPI by freeze drying. They found due to droplet coalescence during freezing, the microcapsules prepared with heat hydrolyzed LPI had significant higher surface oil (~ 12%) and lower entrapment efficiency (~ 42%) than the microcapsules with un-treated LPI. In addition, Nesterenko et al. (2012) studied the properties of α-tocopherol microcapsules with modified SPI (by hydrolysis and acylation) by spray drying. Although the modified SPI produced an oil-in-water emulsion with smaller droplet size and lower viscosity, oil retention efficiency of microcapsules was greatly decreased, because of the less stable wall matrix resulting from the short chain length of modified SPI. Therefore, surface activity of proteins can be either increased or decreased by all of experimental conditions (e.g., temperature, heat, and salt), protein characteristics (e.g., sources, amino acid profile), and modifications to further positively or negatively affect the microcapsules’ properties.

Types of emulsions

Oil-in-water emulsion preparation is an important initial step during the microencapsulation of omega fatty acid-rich oils. During emulsion formation, oil droplets are dispersed through the input of mechanical energy (e.g., homogenization) within an aqueous continuous phase containing emulsifiers (e.g., proteins). The formed oil-in-water emulsion generally has droplet diameters ranging between 100 nm to 100 μm. Emulsions are considered thermodynamically unfavorable systems, which tend to break down over a period of time by a variety of destabilization mechanisms [e.g., gravitational separation (resulted from the density differences between dispersed phase and continuous phase, which includes creaming and sedimentation), aggregation (governed by colloidal interactions, which includes flocculation and coagulation), coalescence (the fusion of two or more aggregated droplets into a large droplet to accelerate gravitational separation), and Ostwald ripening (a mass transfer of the dispersed phase occurs from smaller droplets to larger droplets via diffusion through the continuous phase)] (McClements 2005). Therefore, proteins are solubilized in the aqueous phase and migrate to the oil–water interface to expose their hydrophobic and hydrophilic moieties towards the oil and aqueous phase, respectively. Afterwards, the proteins at the interface aggregate to form a viscoelastic film to stabilize the emulsion by electrostatic (at pHs away from the proteins’ isoelectric points) and steric interactions (McClements 2005). Depending on the different preparation mechanisms and procedures, four types of emulsions (e.g., conventional emulsion, multiple emulsion, multilayer emulsion, and nanoemulsion) were developed before spray drying.

Conventional emulsion

Conventional emulsion is the most prevalent emulsion-based delivery system used for oil microencapsulation. It consists of oil droplets dispersed in the aqueous continuous phase (containing proteins and carbohydrates), so, the oil droplets are surrounded by an interfacial layer consisting of the mixture of proteins and carbohydrates (McClements et al. 2007). Since there is no net charges for most of carbohydrates used in the preparation of the emulsion, the electrical charge of droplets is controlled by the selected protein. Generally, the conventional emulsion is prepared by homogenizing an oil phase with an aqueous phase in the presence of proteins and carbohydrates. Or the oil phase can be initially homogenized with the protein solution, followed by the uncharged carbohydrate solution. A variety of different homogenizers are available, including high shear mixers, high pressure homogenizer, and microfluidizer (Ng et al. 2013; Pourashouri et al. 2014a, b; Takeungwongtrakul et al. 2015). The selection of homogenizer depends on the characteristics of materials being homogenized and the required properties of final emulsions. For example, in most of cases, the course emulsion is prepared by simply blending or mixing the oil and aqueous phases together, followed by passing through the high pressure homogenizer or microfluidizer to produce feed emulsions with better stability and smaller droplets (Pourashouri et al. 2014a, b; Takeungwongtrakul et al. 2015).

Due to simple operation steps and low cost, conventional emulsions are usually the first system considered when developing the microencapsulation of oils. But there are also disadvantages that limit the particular applications. Conventional emulsions are prone to instability when exposed to environmental stresses (e.g., temperature, pH, and salt), because proteins exhibit weaker emulsifying capacity than small molecular emulsifiers. In addition, they also have less ability to protect oil droplets and control the release, because of the thinner interfacial films formed by proteins (McClements et al. 2007). Therefore, some researchers attempted to facilitate emulsion formation and improve emulsion stability through the addition of emulsifiers and cross-linking agents. For instance, 10% (w/w basis on protein content) of soy lecithin was added in the sodium caseinate stabilized kenaf seed oil-in-water emulsion to lower the droplet size to 0.13 μm and improve emulsion stability (Ng et al. 2013). Chen et al. (2016) applied transglutaminase to introduce a covalent cross-link and improve the emulsifying activity of SPI when encapsulating DHA-rich oil with gum Arabic and maltodextrin. However, Chang et al. (2016) found that because of the out competition between soy lecithin and LPI at the droplet surface, when 1–3% (w/w) soy lecithin was added in LPI-stabilized emulsions, droplet coalescence occurred to result in the decrease of emulsion stability and increase of droplet size. Consequently, continuous research is necessary to identify proper approaches to more effectively utilize the existing proteins for the production of stable emulsions.

Multiple emulsion

Multiple emulsions are defined as a water-in-oil-in-water (W/O/W) emulsion, which is composed of small water droplets circulated by larger oil droplets that are dispersed in an aqueous continuous phase, or oil-in-water-in-oil (O/W/O) emulsion, which is composed of small oil droplets circulated by larger water droplets that are dispersed in an oil continuous phase. Therefore, two different types of emulsifiers are usually needed to stabilize emulsions: hydrophilic and hydrophobic emulsifiers (McClements et al. 2007). Generally, several procedures are involved in preparation of the emulsions. For example, Cournarie et al. (2004) developed a multiple emulsion to encapsulate fish oil (93% entrapment efficiency). Initially, a glucose solution was homogenized with fish oil [containing Abil EM-90 (a hydrophobic emulsifier)] to generate a water-in-oil emulsion, followed by mixing with an aqueous solution of Arlatone F127G (a hydrophilic emulsifier). In the work done by Jimenez-Martin et al. (2016), fish oil was first homogenized with sodium caseinate (a hydrophilic emulsifier) and lactose monohydrate solutions to produce a primary emulsion, which was then mixed with olive oil containing polyglycerol polyricinoleate (a hydrophobic emulsifier) to produce a secondary emulsion. Finally, the secondary emulsion was blended with sodium caseinate and lactose monohydrate solutions to prepare feed emulsion before spray drying. Although emulsion properties were not studied, this multiple emulsion resulted in very high entrapment efficiency of EPA (~ 94%) and DHA (~ 83%).

Potentially, multiple emulsions are beneficial for the delivery of heart healthy oils. They can provide good protection and control the release of core materials through the well-structured wall materials. They are also able to reduce the overall fat content in the food products by diluting the oil concentration within the aqueous phase (McClements et al. 2007). However, because of high production cost, restricted emulsifiers able to use, and susceptibility to breakdown under environmental changes, multiple emulsion is rarely applied to encapsulate omega 3-6-9 fatty acid-rich oils.

Multilayer emulsion

Multilayer emulsion has just been developed in the microencapsulation. It is considered as a multilayer oil-in-water emulsion consisting of small oil droplets dispersed in an aqueous phase with oppositely charged biopolymers, so, electrostatic interaction is happened on the droplet surface during the formation of the emulsion. The combination of lecithin and chitosan is a classic example to develop multilayer emulsion for microencapsulation (Kwamman and Klinkesorn 2015; Jimenez-Martin et al. 2016). Kwamman and Klinkesorn (2015) encapsulated tuna oil using the mixture of lecithin, chitosan and maltodextrin. A one-layer emulsion was produced by mixing tuna oil with lecithin solution (with negative charges, at pH 3.0). Then, the chitosan solution (with positive charges) added into the one-layer emulsion to induce electrostatic interaction to generate a two-layer emulsion, which was diluted within maltodextrin solution (no net charges) before spray drying. The interest in the protein-stabilized multilayer emulsions has increased recently. Tamm et al. (2016a) compared fish oil microcapsules prepared by glucose syrup, β-lactoglobulin (with positive charges) with/without pectin (with negative charges). It was found the addition of pectin reinforced the interfacial layer on the oil droplets to produce microcapsules with higher entrapment efficiency. Moreover, the mixture of LPI and maltodextrin was used to entrap 20% canola oil with/without sodium alginate. Although the addition of sodium alginate increased droplet size and emulsion viscosity, the microcapsules with high entrapment efficiency (~ 88%) were produced, due to the formation of electrostatic complex between LPI and sodium alginate (Chang et al. 2016). However, Aberkane et al. (2014) found the addition of pectin in the PUFA-rich oil microcapsules with PPI and maltodextrin greatly decreased entrapment efficiency (lowered 5%), because the multilayer emulsion prepared by PPI, pectin and maltodextrin had larger droplets that were more sensitive to disruption during spray drying to finally expose more surface oil on the microcapsules.

Comparing with the conventional emulsion, multilayer emulsion provides meaningful advantages. For example, a stronger wall matrix is produced by the electrostatic interaction between oppositely charged biopolymers to offer greater protection against oxidation. In addition, the release behavior of encapsulated oil can be controlled in response to environmental changes (e.g., pH, ionic strength, and temperature). But the main limitations of this emulsion are that additional ingredients and processing steps are required, and preparation conditions (e.g., pH) need to be critically monitored.

Nanoemulsion

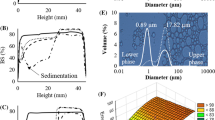

Nanoemulsion has been potentially touted as the next revolution in food industry to generate innovative products with advanced sensory attributes and stability. It has been studied to encapsulate bioactive compounds (e.g., polyphenols, enzymes, and nutraceuticals) and to produce nanoparticles with diameters ranging from 10 to 1000 nm (Konan et al. 2002). Nanoemulsions can be obtained by several techniques, such as high pressure homogenization, microfluidization, and ultrasonic treatment. Gokmen et al. (2011) designed functional bread by incorporating flaxseed oil microcapsules with high amylose corn starch that was created by nanoemulsions under spray drying. So, the bread quality was improved by lowering lipid oxidation and increasing omega-3 fatty acids content. Ghasemi and Abbasi (2014) developed nanoemulsion with fish, soybean, and rapeseed oils using casein micelles as wall materials under ultrasonic treatment to evaluate the protecting effects of casein micelles. They found the increase of pH (until pH 8.0) ultimately caused an increase of interior hydrophobic area exposure to incorporate the oils, and finally produced nanoparticles with 92–97% entrapment efficiency and offered extremely superior oxidative protection against UV light treatment for 18 h.

A number of advantages are provided by nanoemulsion, such as good sensory properties, targeted delivery, increased bioavailability, and higher oxidative stability of encapsulated oils. However, safety, ethical, and regulatory issues have been raised by the lack of knowledge on the impacts of nanoparticles on human health, because little research explored the biotransformation of nanoparticles within the gastrointestinal system, and unforeseen complexity and potential nanotoxicity from nano-materials were uncertainly assessed through the research (Ezhilarasi et al. 2013). Therefore, updated scientific evidence and regulations on nanoparticles are still necessary for the application within encapsulation.

Emulsion properties

Emulsion properties (e.g., emulsion stability, droplet size, and viscosity) greatly impact the microcapsules’ properties. Emulsions should be stable over a certain period before the drying process, so, smaller droplets are necessary to prevent destabilization and air inclusion in the particles, because they are more efficiently enclosed and embedded within wall matrix of microcapsules (Drusch 2006). Emulsion stability is highly determined by droplet size, in which the rate of gravitational separation is lowered by the decrease of droplet size and increase of droplet concentration to hinder the movement of surrounding droplets (McClements et al. 2007). Theoretically, emulsion stability is enhanced by increased protein concentration, since the thicker interfacial protein films at the droplet surface exhibit better ability against coalescence during storage to result in better stability (Hogan et al. 2001). Tang and Li (2013) developed soy oil microcapsules with native/hydrolyzed SPI by spray drying. The hydrolyzed SPI (by heat treatment) stabilized emulsions with smaller droplet size, because SPI with more unfolded flexible structure tended to be more efficiently adsorbed at the interface. So, the oil retention efficiency was greatly improved by the formation of more viscoelastic interfacial films. On the other hand, in the work by Aberkane et al. (2014), the droplet size was increased by the addition of pectin in the emulsions prepared by PUFA-rich oil and PPI, because the oil droplets were not completely saturated by PPI and pectin to prohibit aggregation, and unadsorbed pectin induce the depletion flocculation of PPI-pectin complexes. So, the entrapment efficiency in the spray-dried microcapsule was decreased. However, in the work by Chang et al. (2016), although the droplet size was increased by the addition of sodium alginate in the emulsion prepared by canola oil and LPI, the entrapment efficiency was greatly improved, because the oil droplets were fully covered by the electrostatic complex formed by LPI and sodium alginate.

Depending on emulsion compositions, droplet structures and interactions, emulsions exhibit different rheological behaviors (e.g., viscous liquids, viscoelastic liquids, and viscoelastic solids). Emulsion viscosity is generally used to characterize the rheology of relative dilute oil-in-water emulsion (McClements et al. 2007). It is an important parameter to control during encapsulation, since it can impact the stability and flow behavior of emulsions during the drying process. High viscosity of the feed emulsion interferes with the atomization during spray drying, prolong the drying process, lead to the formation of elongated particle, and cause air inclusion in the particles (Rosenberg et al. 1990). Emulsion viscosity is largely determined by the viscosity of continuous phase (affected by the biopolymer concentration), the droplet concentration and size. Normally, emulsion viscosity is increased with the increase of biopolymer concentration and droplet concentration (McClements 2005). In a recent study by Hee et al. (2015), the potential of gum Arabic (a thickening agent) and gelatin (a gelling agent) as wall materials were evaluated in the coconut oil microcapsules with the combination of sodium alginate and maltodextrin by spray drying. Results indicated that both of gum Arabic and gelatin raised the viscosity to produce the emulsions with smaller droplet size by preventing droplet coalescence, whereas entrapment efficiency was decreased, because the higher viscosity decelerated the formation of wall structure by limiting the migration of crust-forming materials (e.g., maltodextrin) towards droplets surface. The similar results were also demonstrated in the canola oil (20–30%, w/w) microcapsules prepared with LPI and maltodextrin. It was found the entrapment efficiency decreased with the increase of LPI concentration resulting from the higher emulsion viscosity to prolong the drying process (Chang et al. 2016).

Microencapsulation by spray drying

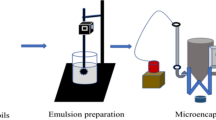

In order to produce spray dried microcapsules, a stable emulsion is initially prepared by dispersing omega fatty acid-rich oils in the polymer solutions (e.g., proteins) under homogenization; subsequently, the emulsion is pumped into a spray dryer and atomized into small droplets under high pressure; finally, the dehydration of the atomized droplets under extremely high inlet temperature (160–180 °C) happens to produce microcapsules (Desai and Park 2005).

Optimization of spray drying conditions is important to improve entrapment efficiency and control particle size. The higher drying temperature promotes the formation of a rigid wall structure, in order to limit the migration and release of core materials (Rascon et al. 2010). Depending upon atomization devices (e.g., nozzle size and pressure), microcapsules can be small to 10–50 μm or large to 2–3 mm (Kaushik et al. 2015). Therefore, operating variables (e.g., drying temperature, air flow rate, and type of atomization) greatly affect the quality of microcapsules, especially temperature determines moisture content to further influence caking, collapse, agglomeration, browning and oxidative reaction within the dried microcapsules (Encina et al. 2016). Inlet and outlet temperatures should be especially controlled during spray drying, because inlet temperature greatly affects the efficiency of water evaporation to further determine the quality of microcapsules, whereas outlet temperature impacts the denaturation of wall materials of microcapsules (Kha et al. 2014). For instance, Aghbashlo et al. (2013) explored the effect of spray dryer operational variables (e.g., inlet temperature and air flow rate) on the physical properties of fish oil microcapsules. They found the increase of inlet temperature and air flow rate raised particle size and entrapment efficiency, but decreased moisture content of microcapsules. Encina et al. (2016) stated low outlet temperature produces microcapsules with high moisture content at a rubbery state, whereas high outlet temperature results in cracks on the microcapsules to accelerate oil release and oxidative degradation.

There are some challenges for microencapsulation by spray drying. Good water solubility is required for wall materials to be used for spray drying. High temperature of spray dryer could result in the damage of wall structure of microcapsules (e.g., pores, shrinkages, and invaginations) to negatively affect the stability of encapsulated oil. If proper care is not taken, a significant amount of dried powder could be lost, due to the adhesion of microcapsules on the wall of spray dryer under high temperature (Bakry et al. 2016).

Characterization of microcapsules

Physical properties

The physical properties of microcapsules are important to investigate in terms of both core bioavailability and applicability by the food industry. The commonly studied properties include: moisture content, water activity, particle size, surface oil and entrapment efficiency. The moisture content is an important parameter to determine the storage stability of the microcapsules, where high moisture tends to lead to caking/agglomeration of the dried powder, microbial growth, and lipid oxidation to induce off flavors. Moisture levels are controlled by wall materials (which abides water), relative humidity of the air in the dryer chamber, and drying temperatures during spray drying (e.g., inlet and outlet temperatures) (Klinkersorn et al. 2005). Takeungwongtrakul et al. (2015) found the addition of gum Arabic, glucose syrup, or maltodextrin to the mixture of WPC and sodium caseinate as wall materials significantly lower the moisture content of shrimp oil microcapsules, due to the different crust formation to affect water evaporation and rendering on the microcapsules. Hee et al. (2015) prepared coconut oil microcapsules with different combinations of wall materials (e.g., maltodextrin, sodium caseinate, gum Arabic, gelatin, and WPC) had 2.4–2.9% moisture content with no considerable differences, because of same solid content in the microcapsules. The desired moisture content is 3–4% for shelf stable dried powders in the food industry (Klinkersorn et al. 2005).

The water activity of the microcapsules can significantly affect microbial spoilage and lipid oxidation, which further determines shelf-life of the product. Oxidative degradation is typically limited when the water activity falls between 0.2 and 0.3, because of the restriction of metal transition and retardation of hydroperoxide decomposition resulting from the quenching of free radicals and singlet oxygen (Velasco et al. 2003). Generally, water activity of spray-dried microcapsules depend upon wall materials, drying conditions (e.g., temperature and flow rate), and drier design. Goyal et al. (2015) found there was no significant difference on the water activity (~ 0.353) in the flaxseed oil microcapsules prepared by lactose and WPC or sodium caseinate, because same operating conditions and amount of wall materials were used. Similar result was also found in the work by Can Karaca et al. (2013) to encapsulate flaxseed oil by the combination of maltodextrin and CPI or LPI.

Particle size is an important parameter contributing to the flowability, compressibility, bulk density, and oxidative stability of the microcapsules (Koc et al. 2015). McNamee et al. (1998) reported that particle size of microcapsules is mainly dependent on the microencapsulation technique used. Therefore, it is affected by the size of nozzle, feeding rate, air pressure, and total solid content, when the microcapsules are produced using spray drying. For example, Takeungwongtrakul et al. (2015) produced shrimp oil microcapsules with similar particle size (~ 10.3 μm), even though different wall materials combinations (e.g., WPC, sodium alginate, gum Arabic, glucose syrup, and maltodextrin) were used. However, Pourashouri et al. (2014a) investigated the particle size of fish oil microcapsules prepared with gelatin, maltodextrin, and chitosan. They found due to different glass transition temperature (Tg) of coating materials that influence the drying behavior of droplets, the lower emulsion viscosity (in gelatin-maltodextrin stabilized emulsion) accelerated the migration of crust-forming materials towards the droplet surface to produce microcapsules with larger particle size (~ 6.5 μm), whereas the addition of chitosan with higher Tg postponed the crust formation to result in smaller particle size (~ 6.1 μm). The desirable particle size of microcapsules is below 40 μm in the food industry to avoid impacting the mouth feel of food products (Koc et al. 2015).

Surface oil is defined as non-encapsulated oil on the surface of the dried microcapsules. It is important as it can easily react with oxygen to produce off-flavors and result in poor stability for the application. Entrapment efficiency is determined as the percentage of encapsulated oil within the wall matrix to the percentage of oil used in the formation. Therefore, a higher entrapment efficiency indicates a lower surface oil on the microcapsules (Kaushik et al. 2015). It can also be improved by increasing the wall materials content in the formulation, which is related to the formation of a stronger protective shell around the core material (Nesterenko et al. 2013). However, too much wall material can result in an abrupt increase in the viscosity of feed emulsions used for spray drying; as such, drying process efficiency is greatly decreased to produce microcapsules with lower entrapment efficiencies (Yu et al. 2007). For example, in the LPI and maltodextrin prepared microcapsules, when both soy lecithin (3%, w/w) and sodium alginate (1%, w/w) were added as wall materials, the emulsion viscosity greatly increased to result in an extremely low entrapment efficiency (~ 42%), because of the formation of phospholipid micelles, protein–protein and protein-alginate aggregation (Chang et al. 2016). Hee et al. (2015) also proved this finding when gum Arabic, WPC, or gelatin was applied within the combination of sodium alginate and maltodextrin to encapsulate coconut oil. However, because glucose syrup enhanced the formation of crust around the drying particles, shrimp oil microcapsules prepared with WPC, sodium caseinate and glucose syrup displayed higher entrapment efficiency than the capsules without glucose syrup (Takeungwongtrakul et al. 2015). Food industry aims to produce microcapsules with surface oil lower than 2% (w/w) and entrapment efficiency higher than 98% (w/w) (Nickerson et al. 2014).

Oxidative stability

Lipid oxidation of the encapsulated oils is meaningful to study using different methods (Table 2), because it results in the loss of nutritional value and develops the undesirable flavors to further negatively affect their commercial application (Velasco et al. 2003). In general, oxidative stability of encapsulated oils is influenced by wall formulation (e.g., wall composition and wall structure), core materials (e.g., fatty acid composition), physical properties of microcapsules (e.g., moisture content, water activity, and particle size), and storage conditions (e.g., temperature and humidity).

For instance, Tamm et al. (2016b) encapsulated rapeseed oil using the combination of PPI and glucose syrup by spray drying. They found the oil encapsulated within microcapsules with enzymatic hydrolyzed PPI showed lower hydroperoxide content after 1 month storage than the oil within microcapsules with native PPI, because some hydrophobic and aromatic amino acids (e.g., proline, valine, leucine, and phenylalanine) that possess antioxidant activity were exposed after enzymatic hydrolysis. Minor amount of sulphur-containing amino acids (e.g., cysteine and methionine) in PPI were also able to chelate metal ions to inhibit oxidation. Furthermore, the addition of pectin into PUFA-rich oil microcapsules with PPI and maltodextrin greatly improved the wall protection ability against oxidation, which was associated with the higher thickness of bilayer coated on the oil droplets and chelating ability of pectin with metal irons to prevent oxidation (Aberkane et al. 2014). In order to improve antioxidative ability, natural antioxidants (e.g., rosemary extract and caffeic acid) have started to attract more attention in the development of microcapsules, which also increase nutritional values of final products. Martinez et al. (2015) claimed that rosemary extract (1600 μg/g oil) significantly increased oxidative stability of walnut and chia oils encapsulated by hydroxypropyl methylcellulose and maltodextrin, especially on the encapsulated chia oil.

Accelerated oxidative test using Rancimat are being employed to evaluate the oxidative stability and predict shelf-life in a short period of time. This technique is based on exposure of microcapsules/oils under high temperature (80–130 °C) and airflow to generate short-chain volatile acids (e.g., carboxylic acid) to further increase conductivity of distilled water to determine the oxidative stability (by induction period) or shelf life (by Arrhenius plot) (Kochhar and Henry 2009). Generally, Rancimat measurement can be affected by sample size, airflow rate, and temperature during operation. Since the oxidation mechanism can be changed under high temperature to develop excessive rancidity, the results may not be relevant to normal storage condition. But it still provides representative acceptable results to explore oxidative stability and antioxidative capacity in a short time (Gallardo et al. 2013). In the work by Gallardo et al. (2013), Rancimat test under 100 °C was used to test oxidative stability of encapsulated flaxseed oil within a mixture of gum Arabic and maltodextrin, and found the addition of whey protein isolate increased the induction period by ~ 6 h to produce capsules with better oxidative stability.

Release behavior

The health benefits of omega 3-6-9 fatty acid-rich oils are dependent on their bioavailability, which is determined by the release characteristics from microcapsules. Microencapsulation is proposed to be an effective way to control the release properties of omega 3-6-9 fatty acid-rich oils at the appropriate time and place, in order to improve their effectiveness and reach the targeted delivery with required dose. Various trigger mechanisms are involved in the release of core materials: (1) diffusion, which is governed by the physicochemical properties of wall materials and occurs when the wall structure is intact; (2) degradation, which is triggered by the addition of enzymes (e.g., protease and amylase) to degrade wall materials; (3) dissolution, which results from the use of solvent to expand wall materials and favor the release; (4) pH and ionic strength changes, which alter the solubility of wall materials; and (5) high temperature, which is able to collapse or melt the wall materials to promote the release (da Silva et al. 2014). In literature, the release behavior of encapsulated oil is usually characterized under simulated gastrointestinal system, which contains simulated gastric fluid (SGF, established by the addition of pepsin with NaCl at pH 1.2) and simulated intestinal fluid (SIF, established by the addition of pancreatin with K2HPO4 at pH 6.8). In general, due to greater degradation under longer digestive process, higher amounts of encapsulated oils were released from microcapsules under the exposure of SGF + SIF than SGF alone (Can Karaca et al. 2013; Goyal et al. 2015).

The main factors affecting the release characteristics are related to interactions between wall and core materials, physical properties of microcapsules (e.g., particle size and surface oil), viscosity and solubility of wall materials, and structure of microcapsules (da Silva et al. 2014). For example, in Fig. 1, the core material is easily and quickly released from the simple microcapsules, followed by the multi-core microcapsules, whereas the multiple layers of wall materials in the multi-wall microcapsules can prolong the release process, but the core material can be still released quickly. However, the complex structure of assembled microcapsules greatly slows down the release action, and more serious chemical, physical or mechanical factors needs to be involved to trigger the release (Drusch and Mannino 2009). Moreover, according to Goyal et al. (2015), higher amount of flaxseed oil was released from microcapsules with sodium caseinate and lactose than the oils released from microcapsules with WPC and lactose under in vitro digestion process, because the highly globular conformation of WPC resisted enzymatic hydrolysis to trigger the oil release. Consequently, only 20–40% flaxseed oils were released under SGF + SIF conditions. However, Can Karaca et al. (2013) reported a very high percentage release of flaxseed oil (85–93%) from microcapsules with CPI/LPI and maltodextrin under SGF + SIF conditions. Therefore, different susceptibilities of wall matrix to in vitro digestion by different enzymes resulted in the different release behaviors of oils.

Future trends

By the virtues of biological and functional properties to human health, the consumption of omega 3-6-9 fatty acid-rich oils is continuously increased through microencapsulation by spray drying to prevent the damages from harsh environmental conditions (e.g., oxygen, high temperature, and humidity), offer targeted delivery, and mask unpleasant taste and odor. Although plant proteins are more costly in protein extraction and more complex on protein structure than animal proteins, plant protein-stabilized oil-in-water conventional emulsion combining with carbohydrates is emerging as a “green” substantial step for the microencapsulation. Apart from conventional emulsions, multiple emulsions, multilayer emulsions, and nanoemulsions are more stable under environmental stresses (e.g., shearing, pH, ionic strength, and temperature), but complicated preparation steps and utilization stability need to be studied. Furthermore, physical properties, oxidative stability, and controlled release of omega fatty acid-rich oils, which are influenced by native properties (e.g., solubility, surface charge, antioxidative ability, and structure strength) of wall materials, are significant parameters to evaluate the feasibility of microcapsules in food products. Thereby, much effort through research is essential to identify appropriate wall materials, to optimize the microencapsulation with suitable oil content and advanced properties.

References

Aberkane L, Roudaut G, Saurel R (2014) Encapsulation and oxidative stability of PUFA-rich oil microencapsulated by spray drying using pea protein and pectin. Food Bioprocess Technol 7:1505–1517

Aghbashlo M, Mobli H, Madadlou A, Rafiee S (2013) Fish oil microencapsulation as influenced by spray dryer operational variables. Int J Food Sci Technol 48:1707–1713

Avramenko NA, Low NH, Nickerson MT (2013) The effects of limited enzymatic hydrolysis on the physicochemical and emulsifying properties of a lentil protein isolate. Food Res Int 51:162–169

Avramenko NA, Chang C, Low NH, Nickerson MT (2016) Encapsulation of flaxseed oil within native and modified lentil protein-based microcapsules. Food Res Int 81:17–24

Bakry AM, Abbas S, Ali B, Majeed H, Abouelwafa MY, Mousa A, Liang L (2016) Microencapsulation of oils: a comprehensive review of benefits, techniques, and applications. Compr Rev Food Sci Food Saf 15:143–182

Can Karaca A, Low N, Nickerson M (2011) Emulsifying properties of chickpea, faba bean, lentil and pea proteins produced by isoelectric precipitation and salt extraction. Food Res Int 44:2742–2750

Can Karaca A, Low N, Nickerson M (2013) Encapsulation of flaxseed oil using a benchtop spray dryer for legume protein-maltodextrin microcapsule preparation. J Agric Food Chem 61:5148–5155

Can Karaca A, Low NH, Nickerson MT (2015) Potential use of plant proteins in the microencapsulation of lipophilic materials in foods. Trends Food Sci Technol 42:5–12

Chang C, Tu S, Ghosh S, Nickerson MT (2015) Effect of pH on the inter-relationships between the physicochemical, interfacial, and emulsifying properties of pea, soy, lentil and canola protein isolate. Food Res Int 44:360–367

Chang C, Varankovich N, Nickerson MT (2016) Microencapsulation of canola oil by lentil protein isolate-based wall materials. Food Chem 212:264–273

Chen W, Wang H, Zhang K, Gao F, Chen S, Li D (2016) Physicochemical properties and storage stability of microencapsulated DHA-rich oil with different wall materials. Appl Biochem Biotechnol 179:1129–1142

Cooper CL, Dubin PL, Kayitmazer AB (2005) Polyelectrolyte-protein complex. Curr Opin Colloid Interface Sci 10:52–78

Cournarie F, Savelli M, Rosilio V, Bretez F, Vauthier C, Grossiord J et al (2004) Insulin-loaded W/O/W multiple emulsions: comparison of the performances of systems prepared with medium-chain-triglycerides and fish oil. Eur J Pharm Biopharm 58:477–482

da Silva PT, Fries LLM, de Menezes CR, Holkem AT, Schwan CL, Wigmann CL et al (2014) Microencapsulation: concepts, mechanisms, methods and some applications in food technology. Cienc Rural 44:1304–1311

Damodaran S (2005) Protein stabilization of emulsions and forms. J Food Sci 40:R54–R66

Desai KGH, Park HJ (2005) Recent developments in microencapsulation of food ingredients. Dry Technol 23:1361–1394

Drusch S (2006) Sugar beet pectin: a novel emulsifying wall component for microencapsulation of lipophilic food ingredients by spray-drying. Food Hydrocoll 21:1223–1228

Drusch S, Mannino S (2009) Patent-based review on industrial approaches for the microencapsulation of oils rich in polyunsaturated fatty acids. Trends Food Sci Technol 20:237–244

Encina C, Vergara C, Gimenez B, Oyarzun-Ampuero F, Robert P (2016) Conventional spray-drying and future trends for the microencapsulation of fish oil. Trends Food Sci Tech 56:46–60

Ezhilarasi PN, Karthik P, Chhanwal N, Anandharamakrishnan C (2013) Nanoencapsulation techniques for food bioactive components: a review. Food Bioprocess Technol 6:628–647

Gallardo G, Guida L, Martinez V, Lopez MC, Bernhardt D, Blasco R et al (2013) Microencapsulation of linseed oil by spray drying for functional food application. Food Res Int 52:473–482

Ghasemi S, Abbasi S (2014) Formation of natural casein micelle nanocapsule by means of pH changes and ultrasound. Food Hydrocoll 42:42–47

Gokmen V, Mogol BA, Lumaga RB, Fogliano V, Kaplun Z, Shimoni E (2011) Development of functional bread containing nanoencapsulated omega-3 fatty acids. J Food Eng 105:585–591

Goyal A, Sharma V, Sihag MK, Tomar SK, Arora S, Sabikhi L et al (2015) Development and physico-chemical characterization of microencapsulated flaxseed oil powder: a functional ingredient for omega-3 fortification. Powder Technol 286:527–537

Hee YY, Tan CP, Rahman RA, Adzahan NM, Lai WT, Chong GH (2015) Influence of different wall materials on the microencapsulation of virgin coconut oil by spray drying. Int J Food Eng 11:61–69

Hogan SA, McNamee BG, O’Riordan ED, O’Sullivan M (2001) Microencapsulating properties of whey protein concentrate 75. J Food Sci 66:675–680

Jimenez-Martin E, Rojas TA, Gharsallaoui A, Carrascal JR, Perez-Palacios T (2016) Fatty acid composition in double and multilayered microcapsules of ω-3 as affected by storage conditions and type of emulsions. Food Chem 194:476–486

Kaushik P, Dowling K, Barrow CJ, Adhikari B (2015) Microencapsulation of omega-3 fatty acids: a review of microencapsulation and characterization methods. J Funct Food 19:868–881

Kha TC, Nguyen MH, Roach PD, Stathopoulos CE (2014) Microencapsulation of gac oil: optimisation of spray drying conditions using response surface methodology. Powder Technol 264:298–309

Klinkersorn U, Sophanodora P, Chinachoti P, McClements D, Decker EA (2005) Stability of spray-dried tuna oil emulsion encapsulated with two-layered interfacial membranes. J Agric Food Chem 53:8365–8371

Koc M, Gungor O, Zungur A, Yalcin B, Selek I, Ertekin FK, Otles S (2015) Microencapsulation of extra virgin olive oil by spray drying: effect of wall materials composition, process conditions, and emulsification method. Food Bioprocess Technol 8:301–318

Kochhar SP, Henry CJK (2009) Oxidative stability and shelf-life evaluation of selected culinary oils. Int J Food Sci Nutr 60:289–296

Konan YN, Gurny R, Allemann E (2002) Preparation and characterization of sterile and free-dried sub-200 nm nanoparticles. Int J Pharm 233:239–252

Kwamman Y, Klinkesorn U (2015) Influence of oil load and maltodextrin concentration on properties of tuna oil microcapsules encapsulated in two-layer membrane. Dry Technol 33:854–864

Liang HN, Tang CH (2013a) pH-dependent emulsifying properties of pea [Pisum sativum (L.)] proteins. Food Hydrocoll 33:309–319

Liang HN, Tang CH (2013b) Emulsifying and interfacial properties of vicilins: role conformational flexibility at quaternary and/or tertiary levels. J Agric Food Chem 61:11140–11150

Martinez ML, Curti MI, Roccia P, Llabot JM, Penci MC, Bodoira RM et al (2015) Oxidative stability of walnut (Juglans regia L.) and chia (Salvia hispanica L.) oils microencapsulated by spray drying. Powder Technol 270:271–277

McClements DJ (2005) Emulsion ingredients. In: Clydesdale FM (ed) Food emulsions: principles, practices, and techniques, 2nd edn. CRC Press, Boca Raton, pp 95–174

McClements DJ, Decker EA (2007) Lipids. In: Damodaran S, Parkin KL, Fennema OR (eds) Food chemistry, 4th edn. CRC Press, Boca Raton, pp 155–216

McClements DJ, Decker EA, Weiss J (2007) Emulsion-based delivery systems for lipophilic bioactive components. J Food Sci 72:R109–R124

McNamee BF, O’Riorda ED, O’Sullivan M (1998) Emulsification microencapsulation properties of gum Arabic. J Agric Food Chem 46:4551–4555

Nesterenko A, Alric I, Silvestre F, Durrieu V (2012) Influence of soy protein’s structural modifications on their microencapsulation properties: α-tocopherol microparticle preparation. Food Res Int 48:387–396

Nesterenko A, Alric I, Silvestre F, Durrieu V (2013) Vegetable proteins in microencapsulation: a review of recent interventions and their effectiveness. Ind Crop Prod 42:469–479

Ng SK, Lau Jessie LY, Tan CY, Long K, Nyam KL (2013) Effect of accelerated storage on microencapsulated kenaf seed oil. J Am Oil Chem Soc 90:1023–1029

Nickerson M, Yan C, Cloutier S, Zhang W (2014) Protection and masking of omega-3 and -6 oils via microencapsulation. In: Gaonkar AG, Vasisht N, Khare AR, Sobel R (eds) Microencapsulation in food industry. Elsevier Inc., San Diego, pp 485–500

Piacentini E, Giorno L, Dragosavac MM, Vladisavljevic GT, Holdich RG (2013) Microencapsulation of oil droplets using cold water fish gelatin/gum Arabic complex coacervation by membrane emulsification. Food Res Int 53:362–372

Pourashouri P, Shabanpour B, Razavi SH, Jafari SM, Shabani A, Aubourg SP (2014a) Impact of wall materials on physicochemical properties of microencapsulated fish oil by spray drying. Food Bioprocess Technol 7:2354–2365

Pourashouri P, Shabanpour B, Razavi SH, Jafari SM, Shabani A, Aubourg SP (2014b) Oxidative stability of spray-dried microencapsulated fish oils with different wall materials. J Aquat Food Prod Technol 23:567–578

Rascon MP, Beristain CI, Garcie HS, Salgado MA (2010) Carotenoid retention and storage stability of spray-dried paprika oleoresin using gum Arabic and soy protein isolate as wall materials. LWT Food Sci Technol 44:549–557

Ray S, Raychaudhuri U, Chakraborty R (2016) An overview of encapsulation of active compounds used in food products by drying technology. Food Biosci 13:76–83

Raybaudi-Massilia RM, Mosqueda-Melgar J (2012) Polysaccharides as carriers and protectors of additives and bioactive compounds in foods. In: Desiree NK (ed) The complex word of polysaccharides. InTech, Rijeka, pp 429–453

Rosenberg M, Kopelman IJ, Talmon Y (1990) Factors affecting retention in spray-drying microencapsulation of volatile materials. J Agric Food Chem 38:1288–1294

Sikorski ZE (2001) Functional properties of proteins in food systems. In: Sikorski ZE (ed) Chemical and functional properties of food proteins. CRC Press, Boca Raton, pp 113–135

Takeungwongtrakul S, Benjakul S, H-kittikun A (2015) Wall materials and the presence of antioxidants influence encapsulation efficiency and oxidative stability of microencapsulated shrimp oil. Eur J Lipid Sci Technol 117:450–459

Tamm F, Harter C, Brodkorb A, Drusch S (2016a) Functional and antioxidant properties of whey protein hydrolysate/pectin complexes in emulsions and spray-dried microcapsules. LWT Food Sci Technol 73:524–527

Tamm F, Herbst S, Brodkorb A, Drusch S (2016b) Functional properties of pea protein hydrolysates in emulsions and spray-dried microcapsules. Food Hydrocoll 58:204–214

Tang CH, Li XR (2013) Microencapsulation properties of soy protein isolate: influence of preheating and/or blending with lactose. J Food Eng 117:281–290

Tur JA, Bibiloni MM, Sureda A, Pons A (2012) Dietary sources of omega-3 fatty acids: public health risks and benefits. Br J Nutr 107:23–52

Velasco J, Dobarganes C, Marquez-Ruiz G (2003) Variables affecting lipid oxidation in dried microencapsulated oils. Grasas Aceites 54:304–314

Xiao JX, Yu HY, Yang JA (2011) Microencapsulation of sweet orange oil by complex coacervation with soybean protein isolate/gum Arabic. Food Chem 125:1267–1272

Yu C, Wang W, Yao H, Liu H (2007) Preparation of phospholipid microcapsules by spray drying. Dry Technol 25:695–702

Zhao XH, Tang CH (2016) Spray-drying microencapsulation of CoQ10 in olive oil for enhanced water dispersion, stability and bioaccessibility: influence of type of emulsifiers and/or wall materials. Food Hydrocoll 61:20–30

Acknowledgements

Financial support for the research was kindly supported by the Saskatchewan Ministry of Agriculture and the Canada-Saskatchewan Growing Forward 2 Bi-lateral Agreement (ADF # 2015-0274) and the Saskatchewan Pulse Growers.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, C., Nickerson, M.T. Encapsulation of omega 3-6-9 fatty acids-rich oils using protein-based emulsions with spray drying. J Food Sci Technol 55, 2850–2861 (2018). https://doi.org/10.1007/s13197-018-3257-0

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-018-3257-0