Abstract

Equilibrium and time-dependent surface tension properties at the lipid-vapor interface were investigated, due to their importance in many food applications. Common cooking oils and triglycerides, with or without added oil-soluble amphiphiles, were studied as a function of time and temperature. Surface tension was found to decrease linearly as temperature was increased, and this linear dependence was analyzed to yield thermodynamic information on the surface excess energy and entropy. The different types of cooking oils were nearly indistinguishable with regard to their surface entropy and energy, but an effect of acyl chain length was observed from data for different purified triglyceride oils. These results were consistent with separate results on pure fatty acids of different chain lengths and degree of unsaturation. Lipid amphiphiles, natively present or deliberately added at low concentration to oil, did not cause a change in either dynamic or equilibrium surface tension of corn or olive oil. We conclude that such amphiphilic molecules, despite their presence within the food oil, lack significant surface activity at their native concentration when presented with the surface between oil and air. A decrease in tension in corn oil was seen when mixed in solution with the short-chain caprylic acid (octanoate), but the decrease was notable (>4%) only when this short-chain fatty acid was added at high concentration (≥ 1 M). Added sorbitan monooleate (Span 80) or dioctyl sulfosuccinate sodium salt (AOT) surfactants, on the other hand, decreased equilibrium surface tension by up to 12% and 18%, respectively, at low concentrations (<0.125 M).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Surface tension at a lipid-vapor interface plays a central role in bubble formation, in wetting in the presence of food fats or oils, and in the uptake of oil into pores due to capillary action. Consequently, it has been identified by scientists as a likely key parameter affecting processed foods, through its influence on rates of crystal nucleation [1], on bubbling or foaming in lipids [2, 3], and on the performance of coatings [4]. Surface tension may play more than one role in the complex mechanisms in frying: it influences the frequency of bubble generation at the food surface which drives convection [2, 5, 6]; and it controls capillary action that may partly induce oil uptake into the food [7, 8]. Atomization during use of triglyceride biodiesel as a fuel also involves the rapid formation of oil-vapor interfaces, at rates determined by surface tension properties [9].

Experimental quantification of the impact of surface tension on food characteristics has proved challenging. This is not only because of the complexity of the various processes described above, but also due a surprising dearth of information on surface (lipid-air) tension properties of food lipids [10]. Previous studies mainly address the lipid-water, interfacial tensions of these oils [5, 10–12]. Although there has been some examination of surface tensions for purified, single-structure triglycerides [13–16], the contribution of different triglyceride structures within food oil mixtures to the overall surface energy remains unclear. In addition to its practical significance, such information is of fundamental importance in elucidating the effects of intermolecular interactions and mixing on the excess energy and entropy of the oil-vapor region. In this study, the surface tension for a number of food oils was investigated as a function of temperature and time, and compared to data for oil/vapor tensions for single component oils. Studying effects of temperature on tension are particularly important during frying, which occurs over a range of elevated temperatures. Dynamic tension measurements are motivated by bubble formation mechanisms in several food processes: the interface is generally very rapidly formed, making tensions at short times particularly relevant [10].

Although triglycerides are the primary structures in food lipids, several more amphiphilic compounds naturally also exist in these oils, such as monoglycerides, diglycerides and free fatty acids [17]. The concentration of diglycerides in most edible oils ranges from 0.8–5.8%, while monoglycerides and free fatty acids are lower at less than 0.4% [18, 19]. In oils used for food processes such as frying, additional amphiphilic compounds may be created due to degradative reactions [5, 10]. All of these endogenous compounds may have some effect on surface tension [10]. These lipid-based surfactants are also used as food additives, and are appealing choices due to their natural, biodegradable, and GRAS (“generally recognized as safe”) character. We are interested in how different lipid-based amphiphilic components within food oils influence surface tension.

The impact of food-grade synthetic amphiphiles on triglyceride surface tension also requires further study. The surface tension and impact of the food-approved surfactant AOT [20] has been well-studied in alkanes, with effects connected to the self-assembly properties of this surfactant [21]. Sorbitan monooleate (Span 80) is another surface-active compound that is used regularly in food [22, 23]. It has been reported [24, 25] that Span 80 has no effect on the surface tension of alkanes. Effects of AOT or sorbitan monoesters on triglyceride-air tensions have not been investigated to this point. We consider the effect of these additives on lowering surface tension at added concentrations in edible oils.

Materials and Methods

Materials

Tricaprylin (99%), dioctyl sulfosuccinate sodium salt (AOT, >99%), oleic acid (≥99%), caprylic acid (>98%), monocaprylin (99%), palmitic acid (99%) and sorbitan monooleate (Span 80) were purchased from Sigma Chemicals (St. Louis, MO). Triolein was obtained from United States Biochemical Corporation (Salem, MA). All chemicals were used directly without further purification. Canola oil (Wesson, ConAgra, Omaha, NE), olive oil and extra virgin olive oil (Filippo Berio, SALOV North America Corporation, Lyndhurst, NJ), soybean oil (Crisco, The JM Smucker Co., Orrville, OH), peanut oil (LouAna, Ventura Foods, Brea, CA), and corn oil (Mazola, ACH Food, Memphis, TN; or Safeway brand, Pleasanton, CA) were purchased from the local grocery store. Adsorbent Florisil (<200 mesh) is an activated magnesium silicate, which was purchased from Sigma Chemicals (St. Louis, MO). Water used for sample preparation was distilled and deionized (Dubuque, IW) using a Barnstead filter (18 MΩ).

Sample Preparation

Food oils were used directly, purified or mixed with amphiphiles. Free fatty acid contents of commercial corn oil, olive oil and extra virgin olive oil were measured using AOCS Official Method Ca 5a-40 [26]. All samples were prepared in triplicate. To prepare solutions of surfactant in triglyceride, surfactants were weighed and added to a known volume of oil, then mixed on a stir plate at room temperature. For studies on mixtures of corn oil with caprylic acid, potential impurities (e.g. fatty acids) in the corn oil were removed by mixing 50 ml of oil with 5 g of the adsorbent Florisil (Sigma). This mixture was shaken, with the container covered fully by aluminum foil, for 14 days in a Gyrotory shaker (New Brunswick Model G76; Edison, NJ), then filtered using filter paper of pore size 11 μm (Whatman, Maidstone, England) to remove the adsorbent.

Oils were added to the sample chambers for the various tensiometers, and then allowed to reach thermal equilibrium at the desired temperature before measurement. Surface tension values obtained for the food oils at various temperatures were analyzed using two-factor ANOVA and Tukey’s HSD paired comparisons.

Surface Tension Measurements

Wilhelmy Plate Measurements

A Krüss digital tensiometer with platinum plate (Model K10ST; Hamburg, Germany) was used for the measurement of equilibrium oil-air surface tensions. A circulating auto-thermostated bath was connected to the tensiometer to control the temperature, for values between 25 °C and 90 °C. Values were recorded after 20 min, which was shown to be sufficient to reach equilibrium. All samples were prepared in triplicate, and two measured values were obtained for each sample. Standard deviation was within ±0.17 mN/m.

Maximum Bubble Pressure Method (MBP)

The maximum bubble pressure method was used to measure time-dependent surface tension changes over short time scales, with the aid of a SensaDyne tensiometer (Model QC600; Mesa, AZ). In this method, gas flow into the device creates bubbles at a capillary orifice at a constant, controlled frequency; these bubbles grow while increasing in internal pressure due to the energy cost of creating the bubble surface. The pressure inside the bubble was monitored and the maximum value identified, corresponding to when the bubble reaches a hemispherical shape. The resulting maximum pressure drop ΔP across the bubble surface was then substituted into the Young-Laplace equation to determine the surface tension γ:

Here R 1 and R 2 are the radii of curvature of the surface. For a bubble with a hemispherical shape, both radii are equal to that of the capillary orifice.

In our experiments, nitrogen was introduced at a constant mass flow rate through two capillary tubes of radius 0.5 mm and 4 mm, which were immersed in the liquid oil sample contained within a beaker. Bubble formation in the smaller probe determined the surface tension value (R 1 = R 2 = 0.5mm in Eq. (1)), while the 4 mm tube was used as a reference to eliminate effects of hydrostatic pressure. A temperature controller was connected to a heated mantle, which surrounded the beaker containing the sample liquid into which the probes were inserted. This arrangement allowed us to control and maintain constant temperatures in the sample, from room temperature up to 140 °C, with temperature controlled to ±0.5 °C. All samples were prepared in triplicate, and two measured values obtained for each sample. Standard deviation was within ±0.7 mN/m.

Pendant Drop and Rising Bubble Measurements

Pendant drop measurements were used to determine equilibrium surface tensions for oil-air interfaces. Measurements were generally obtained using a Krüss contact angle goniometer/tensiometer, equipped with a CCD camera (Stingray F-046B, Allied Vision Technologies GmbH, Stadtroda, Germany) that imaged the drop and related it to surface tension using “drop shape analysis” software (Model DSA30B, Krüss GmbH, Hamburg, Germany). For triolein measurements, a Model 500 CA, ramé-hart (P/N 500-U1, Succasunna NJ, USA) goniometer with DROPimage Advanced 2.7 software was used instead. For all oils, an elevated temperature syringe (P/N 100–11) with a 22 gauge stainless steel needle (P/N 100–12-22) was used at specific temperatures (from room temperature to each oil’s smoke point) to form drops inside an air-filled environmental cell (P/N 100–07), both systems equipped with temperature controllers (P/N 100–50; all parts from ramé-hart, Succasunna, NJ). Data collection from the temperature controllers was done using SOLO temperature controller configuration software (AutomationDirect; Cumming, GA). The temperature near the syringe needle tip was monitored using a thermocouple (P/N KMQSS-062 U, OMEGA Engineering, Inc., Stamford CT) attached to a data logger with Logger Lite software (LabQuest Mini, Vernier Software & Technology, LLC., Beaverton, OR). Measurements were performed in triplicate. Standard deviation was within ±0.54 mN/m.

Time-resolved surface tension measurements (“drop-profile”) were also obtained by the pendant drop or rising bubble method, using a Teclis drop-profile tensiometer (Model Tracker S; Longessaigne, France). Characteristic time scales probed with this instrument are longer than those accessible by the MBP method. In these experiments, a drop or bubble was quickly formed at the end of a needle and then maintained by the instrument controller at a constant volume. The measurement was made either by creating an oil drop in vapor (pendant) or a rising air bubble within an oil continuum. The drop image was captured by a video camera, and the boundary of the drop edge was then digitized. The resulting shape information was used to evaluate the surface tension over time by comparison with the Young-Laplace Eq. (1). All samples were prepared in triplicate, and two measured values obtained for each sample. Standard deviation was within ±1.1 mN/m.

Results and Discussion

Equilibrium Surface Tension

Food Oils

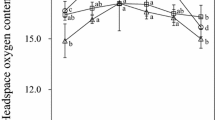

Figure 1 shows values of the surface tension of five common cooking oils at different temperatures. Differences in surface tension between the different oils were very small, although average values for each oil pair could be distinguished statistically at a small number of temperatures. Comparable measurements of surface tensions for food oil mixtures are scarce, but our results at 50 °C are in good agreement with a reported value for olive oil obtained at long times using the maximum bubble pressure method [11]. Our results are also consistent with an estimate of 35mN/m for corn oil surface tension at 25 °C, based on contact angle determinations [27].

Surface tension decreased linearly as temperature increased for all oil types (Fig. 1). This linear dependence on temperature may be used to assess values of the surface excess entropy (S σ) and internal energy (U σ) per unit area of the different lipids, according to the relations [28]

The slope and intercept of a line fit to γ versus T therefore provides a measure of the entropy and energy, respectively, of the interfacial region, relative to the bulk liquid lipid.

Analysis of all the food oils yielded the values for S σ and U σ given in Table 1, which were further compared using multiple regression and paired comparisons of the slopes and intercepts. There was a statistically significant difference in excess entropy and energy for soy and canola compared to the other three oils (p < 0.05). The differences are in all cases were very small, however. Compared to values reported for alkanes [29], results for triglycerides given in Table 1 are smaller in excess entropy and higher in excess energy.

Pure Triglycerides and Fatty Acids

All the lipid mixtures presented in Fig. 1 are more than 80% unsaturated: canola, olive and peanut are predominantly monounsaturated, and both corn and soy are dominated by polyunsaturated acyl chains [30, 31]. Results in Table 1 suggest that these compositional variations do not contribute to a substantial difference in surface energy for these food oils. However, previous studies on pure triacylglycerols and fatty acids provide evidence that molecular structural effects may play at least some role in influencing surface excess properties [14, 15]. Unfortunately, there is limited data on surface tension data for pure lipids, and it can be difficult to distinguish subtle trends when comparing measurements between different groups.

To partly address this issue, data taken by two different methods in our laboratory for caprylic acid was compared to the extensive and systematic fatty acid study by Hunten and Maass [16], and shown to be in good agreement (Fig. 2a). We then compared surface tension behavior for fatty acids and triglycerides (Fig. 2a), using the data from Hunten and Maass [16] and from the current work. Results for the four fatty acids appear nearly parallel, with a vertical shift to lower surface tensions with a decreased chain length. In contrast, almost no effect of the degree of unsaturation on the surface tension was observed, as shown by the data for stearic acid (saturated) and oleic acid (monounsaturated).

a Surface tension for pure caprylic acid (△,▽), palmitic acid (○), stearic acid (□), oleic acid (◇), tricaprylin (×), and triolein (+). Data from current work: caprylic acid (△) and tricaprylin (×), obtained by Wilhelmy plate; oleic acid (◇) and triolein (+), obtained by pendant drop measurements. Data from Hunten and Maass [16]: caprylic (▽), palmitic (○) and stearic (□) acid, obtained using a capillary rise method. b Surface excess internal energy and c entropy values (black bars from this work, grey bars from Hunten and Maass [16] data) obtained using linear regression of data for surface tension versus temperature (e.g., part (a)), combined with Eq. (2); error bars represent 95% confidence intervals. In parts b and c, values marked with different letters differ significantly from each other (U σ for tricaprylin vs triolein, p < 0.057, S σ for caprylic vs oleic acid p < 0.064, all other differences, p < 0.05)

Surface tension data for the two triglycerides we investigated, tricaprylin and triolein, followed the same pattern as the fatty acids. The slopes of the linear fits for the two structures are very similar, with the main difference between the two data sets being the shift to higher surface tension values for the longer-chained triolein. Interestingly, a comparison of caprylic acid to tricaprylin, or oleic acid to triolein, indicated tension behavior that was rather similar for the two molecules, despite the difference in these compounds’ structures (one octanoate acyl chain versus three). In both comparisons, however, a small shift in slope for the triglyceride can be observed relative to the fatty acid.

In Fig. 2b and c, values are presented for U σ and S σ that were obtained from Eq. (2) and the data in Fig. 2a. Differences between pairs of lipids in terms of S σ and U σ were evaluated using multiple regression to assess significant interactions between effects of temperature and lipid structure. The results indicate that the excess surface energy (U σ) increased as the chain length increased, to a small extent, for either the fatty acids or triglycerides (Fig. 2b). This increase in U σ was largely responsible for the vertical shifts in surface tension observed in Fig. 2a. A similar trend can be observed in the fatty acid data of Hunten and Maass [16] and Chumpitaz et al. [14]. This chain length effect has also been noted for other hydrocarbon-based structures such as alkanes [32], and can be attributed to the stronger cohesive interactions within bulk liquid lipids that contain longer chain hydrocarbons. This cohesion leads to a higher excess energy penalty at the surface, where a portion of these attractive interactions is lost.

Alkanes have also been found to have decreased excess entropy at a surface for longer chain lengths [32], but such a trend is not easily discernable within experimental error in results for lipids by us (Fig. 2c) or by previous authors [14, 16]. The excess entropy was observed to be somewhat higher for free fatty acids, compared to their analogous triacylglyceride (Fig. 2c). Lyklema [28] ascribes most of the surface excess entropy to the entropy of mixing, per unit surface area, of molecular groups from the liquid phase with “vacancies” contributed by the vapor side. This entropy contribution is thought to be higher for lower molecular weight compounds. For liquids generally, however, it has been concluded that variations in excess entropy across different molecular structures are remarkably small [28, 33]. Even with the major difference in molecular size between triglycerides with their three acyl chains, and the monoacyl fatty acids, the difference in excess entropy was observed to be small in our experiments.

Food oils contain triglycerides with high levels of oleic acid chains, as well as significant amounts of linoleic acid and a small (typically ~10%) proportion of saturated chains (primarily palmitic). The most marked difference between the triglyceride mixtures in the various oils is their ratio of diunsaturated to monounsaturated groups; for example, olive oil has approximately ten times higher amounts of oleic acid compared to linoleic, whereas soybean has more than twice as many polyunsaturated as monounsaturated chains [34]. Based on the results in Figs. 1 and 2, these compositional differences do not significantly affect values of γ, S σ or U σ, most likely because there is little variation in chain length among the different food oils, and differences in the number of double bonds does not substantially influence surface excess properties.

Contribution of Amphiphilic Compounds

Dynamic Surface Tension Measurements

Amphiphilic molecules, which consist of both lipophilic and hydrophilic moieties, are generally assumed to be surface-active: they lower the energy between two immiscible phases by accumulating at the interface, and thereby help ease the formation of new surfaces. If present, amphiphilic impurities in food oils [17, 19], such as free fatty acids, monoglycerides and diglycerides, could cause a time-dependent decrease in surface tension upon gradual adsorption [5, 10]. The dynamics of food oil surface tension evolution and the surface activity of such amphiphiles at the oil/air surface were investigated in this study.

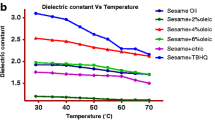

A maximum bubble pressure tensiometer was used to measure the surface tension of food oil at various temperatures over short times t (t < 30s). As shown in Fig. 3a and b, there was no significant change in the surface tension of corn oil as a function of time for times longer than 5 s. At very short times (t < 5 s), a time-dependent decrease was observed in the apparent surface tension for temperatures at or below 90 ºC. However, these short-time changes are unlikely to be a result of actual surface tension dynamics caused by adsorption of amphiphiles, given that we observed a similarly rapid, initial decay in MBP data taken with pure tricaprylin, which does not contain such impurities (Fig. 3a). In the MBP method, surface tensions are obtained from Laplace’s equation (Eq. (1)), coupled with measurements of pressure inside the bubble, with the assumption that other contributions to this pressure are negligible. These neglected contributions comprise those due to viscous resistance associated with bubble growth, inertial contributions, and effects of finite reservoir size within the device. Over very short time scales these secondary contributions may be significant [35], especially when considering food oils that are highly viscous and have low surface tensions [10]. For comparison, dynamic surface tension was also measured using the drop profile method, which evaluates over time the fully formed drop surface profile at a constant drop volume, and which thus has far less susceptibility to fluid mechanical contributions. Tension data from the drop profile method for corn oil (Fig. 3a) and tricaprylin (data not shown) showed no decrease in surface tension over time, even for t < 5 s, confirming that effects of amphiphile adsorption are not responsible for changes at very short times. Thus, it is concluded that the food oil surface tension is time-independent at the temperatures and time scales examined in this study.

Surface tension measurements of olive oil, extra virgin olive oil, and tricaprylin were also performed (Fig. 4). Analysis of the corn oil indicated free fatty acid levels of 0.048 ± 0.002 wt%, whereas olive oil and extra virgin olive oil contained 0.071 ± 0.001 and 0.368 ± 0.003 wt%, respectively. In each case the values were within the maximum permitted by USDA regulations [36, 37]. Despite the higher fatty acid amounts in olive oil, no time-dependency in the surface tension for these oils was observed, and the average tensions of extra virgin olive oil and olive oil were almost identical (32.88 ± 0.15 and 32.95 ± 0.16 mN/m, respectively). In contrast, at interfaces between food oil and water, a time-dependent decrease in interfacial tension has been reported, in studies on sunflower oil, olive oil and others [11, 38], and has been observed in corn oil in our own experiments. Recognizing that even very low concentrations of surfactants can often be sufficient to modify interfacial tension, such measurements at the oil/water interface give clear evidence of the presence of amphiphilic, interfacially active compounds in these commercial oils. Results in Fig. 4 show that, on the other hand, such amphiphilic impurities lack significant surface activity at their native concentration, when presented with the surface between oil and air.

Added Surfactant

Commercial corn oil may contain amphiphiles at too low a concentration to effect a change in tension at an oil-air surface. To explore the feasibility of this explanation, surfactants of several different types were deliberately added at a range of concentrations to food oils, and examined for their potential activity at the oil/air surface. The surfactants included natural lipid-based amphiphiles, including palmitic acid, caprylic acid, and monocaprylin; two synthetic, food-approved additives, AOT and Span 80, were also considered. AOT is a two-tailed amphiphilic structure, with each of the tails consisting of an eight-carbon (branched) chain, roughly comparable to the tails of caprylic acid and monocaprylin. The total number of carbons in the AOT tail group is the same as that in palmitic acid. Span 80 has a single oleate tail esterified to a sorbitan ring.

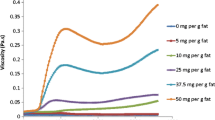

Figure 5 shows surface tension data for these different surfactants in corn oil or in pure tricaprylin at concentrations up to 0.2 M. No effect on surface tension was seen in this concentration range with palmitic acid, caprylic acid, or monocaprylin in either type of oil. However, AOT and Span 80 reduced the surface tension measurably at low concentrations (< 0.1 M). At higher AOT or Span 80 concentrations, the tension reached a plateau value, which may indicate the onset of a phase transition that limits the effect of surfactant addition on activity.

Caprylic acid differs from palmitic acid or monocaprylin in that it is completely miscible with either corn oil or tricaprylin, and is a liquid in its pure form at room temperature. Monocaprylin and palmitic acid, in contrast, are in the solid state at the temperature tested, and the amounts that could be added to the triglycerides were limited by low solubility. Pure liquid caprylic acid had a measured surface tension against air of 28.4 mN/m, below the surface tension value of pure corn oil (32.7 mN/m). This comparison indicates that, in a mixture of caprylic acid and corn oil, the system would benefit energetically by accumulating a surface excess of the fatty acid. In Fig. 6 are shown our measured values for binary mixtures of caprylic acid/purified corn oil, and caprylic acid/tricaprylin, over the complete range of compositions from 0 to 100 wt%. It can be seen from the results that caprylic acid did indeed reduce the surface tension of the corn oil-containing mixture at sufficiently high concentrations, with the oil-air surface tension decreasing monotonically as the weight percentage of caprylic acid was increased. The experiments were repeated using unpurified (commercial) corn oil, with only a small difference in the results (Fig. 6). For tricaprylin the observed reduction was not statistically significant, due most likely to the small difference in surface energy between pure tricaprylin and pure caprylic acid.

These results also reflect the significance of lipid acyl chain on surface excess energy, as discussed above. The eight-carbon caprylic acid has much shorter chains than does the predominant structures within corn oil, resulting in a lower energy at the surface compared to the triglycerides. It thus exhibits weak surface-activity in corn oil (Fig. 6). When added to tricaprylin, however, the similarity in acyl chain length between these two components largely reduces the difference in their surface energies, thus yielding virtually no effect on tricaprylin tension upon addition of the fatty acid.

Aveyard [39] investigated the surface tensions of binary mixtures of alkanes of different chain lengths, demonstrating the ability of shorter chain compounds to lower the tension when mixed with a larger chain. For an ideal mixture, the surface tension γ of a binary mixture can be expressed as [39]:

Here, A 1 and A 2 are the molecular surface area occupied by component 1 and 2, respectively, k is the Boltzmann constant and T is temperature. x i represents the component mole fraction, with superscripts σ and l indicating properties at the surface and bulk, respectively, and γ 1 o and γ 2 o indicate the pure component surface tensions. In Eq. (3) the surface is assumed to consist of a monomolecular layer, which is an excellent assumption for the weakly surface-active fatty acid.

Since the number of moles of components 1 and 2 at the interface is small relative to the total moles in the system, the liquid mole fractions x 1 l and x 2 l are well approximated by the total fractions x 1 and x 2 . The latter are known and controlled independently in the experiments. Eq. (3) can then be rearranged to yield an expression for the surface excess mole fraction:

Given values for A 1 , A 2, γ 1 o and γ 2 o, the surface mole fraction x 1 σ can be determined from Eq. (4) as a function of the total mole fractions of the overall system. Eq. (3) can then be used to predict the surface tension γ.

The Aveyard theory in Eqs. (3) and (4) was applied to the composition range for the data in Fig. 6 for a mixture of caprylic acid (1) in purified corn oil or tricaprylin (2), treating each as a pseudobinary mixture. Data from Brockerhoff and Yurkowski [30] was used to estimate the molecular weight of the corn oil as 872 g/mol, and its density has been measured as 915 g/L [40]. By assuming that the orientation of the acyl chain is approximately normal to the surface, the surface area of caprylic acid can be estimated as 35 Å2, and the surface area of both tricaprylin and purified corn oil as 100 Å2 [15, 41, 42]. The surface tension for the pure components are γ 1 o = 28.4 mN/m2 for caprylic acid, γ 2 o = 32.7 mN/m2 for corn oil, and γ 2 o = 28.7 mN/m2 for tricaprylin.

In Fig. 6, the theoretical predictions of Eqs. (3) and (4) are compared with experimental data. In purified corn oil/caprylic acid mixtures, the agreement between theory and experiment is within ±0.2 mN/m. In mixtures of caprylic acid with tricaprylin, the theory predicts that the tension difference caused by the compositional variation should be very small, also consistent with our data, which shows the difference to be within experimental error. Thus, this simple ideal mixing theory, with a small surface area occupied by the fatty acid as consistent with a normal orientation toward the interface, was quite effective at predicting the behavior of these lipid mixtures. Eqs. (3) and (4) could be used to deduce surface tension results for other miscible binary systems as a function of composition.

Table 2 lists values for the surface mole fraction of caprylic acid in mixtures with purified corn oil, together with the estimated surface excess concentration Γ 1,2 . The latter can be obtained from [39]

with

Subtraction of the second term in Eq. (5) is necessary to define the surface concentration of component (1) relative to the excess solvent (2), as indicated by the Gibbs convention. The surface concentrations for caprylic acid in Table 2 remain low (< 0.1 nm−2) until the fatty acid contribution exceeds about 15 mol%. In contrast, AOT and Span 80 show more significant surface activity. Replotting the data from Fig. 5 on a semi-log scale (data not shown) and employing the Gibbs adsorption isotherm, it is found that only a little over 1 mol% of AOT or Span 80 is needed to achieve surface concentrations of Γ 1,2 = 0.2 and 0.5 nm−2, respectively.

Conclusions

The aim of this work was to investigate the effect of temperature and lipid composition on triglyceride-air surface tension. We observed that surface tensions among five cooking oils are quantitatively very similar at temperatures from 20 °C to 200 °C. The linear dependence of surface tension on temperature yielded a value for surface excess energy (intercept) of 46–48 mJ m−2 for all of the oils; the surface excess entropy (slope) was 0.050 mJ m−2 K−1 for soybean and canola oils, and 0.055 mJ m−2 K−1 for olive, peanut and corn oils. It was shown using pure fatty acids that the surface excess properties were not affected substantially by degree of chain unsaturation, but that shorter chains reduce the surface excess energy and thus the tension. Since the triglycerides in food oils almost entirely comprise long acyl chains, different molecular compositions among these oils do not affect much the entropy, enthalpy and hence surface tension.

During frying as well as in wetting operations such as coatings, the triglyceride-air surface tension plays a fundamental role, which motivates a desire to reduce that tension. However, our study indicates that changes to the oil composition, either through changes in the cooking oil source or by addition of lipid surfactants, will have only a weak effect on oil-vapor tension. The most effective additives are likely to be those with much shorter chain lengths than found in the food oil, or perhaps synthetic surfactants with distinctly larger polar heads.

References

J.L. Hjorth, R.L. Miller, J.M. Woodley, S. Kiil, Eur. J. Lipid Sci. Technol. 117, 1066 (2015)

C. Gertz, Eur. J. Lipid Sci. Technol. 116, 669 (2014)

M. Mellema, J. Benjamins, Colloid Surf. A 237, 113 (2004)

S. Galus, J. Kadzińska, Food Hydrocoll. 52, 78–86 (2016)

D. Dana, I.S. Saguy, Adv. Colloid Interf. 128, 267 (2006)

L.J. Hubbard, B.E. Farkas, J. Food Process. Preserv. 24, 143 (2000)

R.G. Moreira, M.A. Barrufet, J. Food Eng. 35, 1 (1998)

J.M. Vauvre, A. Patsioura, V. Olivier, R. Kesteloot, AICHE J. 61, 2329–2353 (2015)

C.E. Ejim, B.A. Fleck, A. Amirfazli, Fuel 86, 1534 (2007)

E.P. Kalogianni, T.D. Karapantsios, R. Miller, J. Food Eng. 105, 169 (2011)

K. Dopierala, A. Javadi, J. Krägel, K.H. Schano, E.P. Kalogianni, M.E. Leser, R. Miller, Colloid Surf. A 382, 261 (2011)

C.C. Ho, M.C. Chow, J. Am. Oil Chem. Soc. 77, 191 (2000)

R.R. Benerito, W.S. Singleton, R.O. Feuge, J. Phys. Chem. 58, 831 (1954)

L.D. Chumpitaz, L.F. Coutinho, A.J. Meirelles, J. Am. Oil Chem. Soc. 76, 379 (1999)

D.G. Dervichian, Prog. Chem. Fats Other Lipids 2, 193 (1954)

K.W. Hunten, O. Maass, J. Am. Chem. Soc. 51, 153 (1929)

W. Chaiyasit, R.J. Elias, D.J. McClements, E.A. Decker, Crit. Rev. Food Sci. 47, 299 (2007)

R.P. D’alonzo, W.J. Kozarek, R.L. Wade, J. Am. Oil Chem. Soc. 59, 292 (1982)

C.P. Tan, Y.B.C. Man, J. Selamat, M.S.A. Yusoff, Food Chem. 76, 385 (2002)

Food Additives Permitted for Direct Addition to Food for Human Consumption, CFR – Code of Federal Regulations Title 21, Chapter 1, Subchapter B, Part 172 (U.S. National Archives and Records Administration Web 2015), http://www.accessdata.fda.gov/scripts/cdrh/dfdocs/dcfcfr/CFR. Accessed 10 Sept 2016

T.K. De, A. Maitra, Adv. Colloid Interf. 59, 95 (1995)

M. Korhonen, J. Hirvonen, L. Peltonen, O. Antikainen, L. Yrjänäinen, J. Yliruusi, Int. J. Pharm. 269, 227 (2004)

N. Pilpel, M.E. Rabbani, J. Colloid Interface Sci. 122, 266 (1988)

F.O. Opawale, D.J. Burgess, J. Colloid Interface Sci. 197, 142 (1998)

L.J. Peltonen, J. Yliruusi, J. Colloid Interface Sci. 227, 1 (2000)

AOCS, in Official methods and recommended practices of the American oil chemists society, fifth edn., ed by D. Firestone. Method Ca 5a-40: free fatty acids (American Oil Chemists’ Society, Champaign, 1998)

M.G.D. Silva, R.P. Singh, J. Food Process. Preserv. 19, 259 (1995)

J. Lyklema, Colloid Surf. A 156, 413 (1999)

J.J. Jasper, E.R. Keer, F. Gregorich, J. Am. Chem. Soc. 75, 5252 (1953)

H. Brockerhoff, M. Yurkowski, J. Lipid Res. 7, 62 (1966)

W.W. Christie, B. Nikolova-Damyanova, P. Laakso, B. Herslof, J. Am. Oil Chem. Soc. 68, 695 (1991)

J.J. Jasper, J. Phys. Chem. Ref. Data 1, 841 (1972)

J. Lyklema, Colloid Surf. A 186, 11 (2001)

J.W. Brady, Introductory food chemistry (Comstock Publishing Associates, Ithaca, 2013), p. 427

V.B. Fainerman, R. Miller, Adv. Colloid Interf. 108, 287 (2004)

Commericial Item Description: Salad Oils, Vegetable, United States Deparment of Agriculture, https://www.ams.usda.gov/sites/default/files/media/CIDSaladOilsVegetable.pdf. Accessed 8 Dec 2016

Olive Oil and Olive-Pomace Oil Grades and Standards, United States Deparment of Agriculture, https://www.ams.usda.gov/grades-standards/olive-oil-and-olive-pomace-oil-grades-and-standards. Acessed 25 Nov 2016

J. Bahtz, D. Knorr, C. Tedeschi, M.E. Leser, B. Valles-Pamies, R. Miller, Colloid Surf. B 74, 492 (2009)

R. Aveyard, T. Faraday Soc. 63, 2778 (1967)

H. Noureddini, B. Teoh, L.D. Clements, J. Am. Oil Chem. Soc. 69, 1184 (1992)

D.A. Fahey, D.M. Small, Biochemistry 25, 4468 (1986)

N. Funasaki, S. Hada, K. Suzuki, Chem. Pharm. Bull. 24, 731 (1976)

Acknowledgements

This work was supported by Agriculture and Food Research Initiative Competitive Grant no. 2014-67017-21831 from the USDA National Institute of Food and Agriculture. Support from the NSF Center for Advanced Processing and Packaging Studies is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, T., Rodriguez-Martinez, V., Sahasrabudhe, S.N. et al. Effects of Temperature, Time and Composition on Food Oil Surface Tension. Food Biophysics 12, 88–96 (2017). https://doi.org/10.1007/s11483-016-9466-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-016-9466-z