Abstract

Toilet paper has been reported as one of the major insoluble pollutant components in the influent of wastewater treatment plants. Toilet paper fibers contribute to a large production of sewage sludge, resulting in a high treatment cost and high energy consumption. To find energy-efficient, cost-effective, and environment-friendly technologies for fiber removal and resource recovery from wastewater, a life-cycle assessment (LCA) was performed to analyze the wastewater treatment processes, including a sieving process for removing and recovering suspended solids before the biodegradation units. Based on the LCA results, it was estimated that the sieve screening process saved 8.57% of energy consumption. The construction phase of sieving consumed 1.31% energy cost compared with the operation phase. Environmental impact analysis showed that sieving reduced the impacts of climate change, human toxicity, fossil depletion, and particulate matter formation, which reduced the total normalized environmental impacts by 9.46%. The life-cycle analysis of the removal of toilet paper fibers from wastewater revealed the need to use more efficient methods to enhance the recovery of cellulose fibers.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The aim of treating wastewater is to effectively control and discharge safe and harmless wastewater into waterbodies. When treating wastewater, it is important to prioritize environmental sustainability by ensuring the removal of contaminants to prevent environmental pollution. Wastewater contains approximately 72% of the total suspended solids (Gupta et al. 2018). The main organic contaminants in residential wastewater are protein, carbohydrate, and lipids (Gupta et al. 2018; Huang et al. 2022). An appropriate wastewater treatment process is required to eliminate contaminants from wastewater. Typical wastewater treatment processes mainly include grit screening, primary and secondary treatment processes, and advanced process if necessary. Wastewater microbial communities are affected by environmental parameters, such as pH (Gao et al. 2016; Li et al. 2021), TOC (Sun et al. 2022), and BOD, which affect microbial activities in the secondary treatment process (Xu et al. 2020; Li et al. 2022a; Li et al. 2022b).

Toilet paper has been reported as one of the major insoluble pollutant components of residential wastewater in wastewater treatment plants (Gupta 2018; Liu et al. 2022; Ruiken et al. 2013). A total of 83 million rolls of toilet paper are produced annually worldwide (MRS 2017). Toilet paper is produced from fibrous materials containing cellulose, hemicellulose, and lignin. The cellulose fibers in toilet paper are more resistant to microbial hydrolysis than proteins and lipids in residential wastewater treatment (Li et al. 2019). Due to the slow degradation, the cellulose components should be hydrolyzed first before being metabolized (Verstraete et al. 2009; Weimer 2022), thus increasing the oxygen demand and sludge production. Degradation of toilet paper fibers could affect oxygen demand, biogas production, and sludge production during anaerobic digestion (Li et al. 2019). Thus, biological approaches might not be the best choice for removing toilet paper fibers from wastewater. The recovery of toilet paper fibers from wastewater can substantially decrease oxygen demand, sludge disposal, and energy consumption for biodegradation (Faust et al. 2014; Gupta et al. 2018). Li et al. (2019) found that the cellulose hydrolysis coefficient of toilet paper fibers linearly increased with solid retention time. Moreover, the fiber degradation performance was proportional to the quantity of active functional bacteria responsible for fiber degradation. A significant amount of sludge is produced as a result of the majority of toilet paper fibers being deposited in the sludge during secondary treatment processes. which contributed to a large production of sludge and subsequently needed to be treated and disposed in the sludge treatment, resulting in a high treatment cost and energy consumption. Therefore, it is important to understand the treatment technology to remove toilet paper fibers from wastewater efficiently.

The objective of recovery materials is to extract valuable materials from wastewater, to reduce the depletion of natural resources, and to produce a minimum amount of waste, which is environmentally important and cost-effective (Cipolletta et al. 2019). Similarly, the recovery of cellulose fibers from residential wastewater can reduce non-renewable raw materials and promote the sustainability of circular economy approaches for materials. Toilet paper fibers can be recovered as possible resources during the preliminary or primary wastewater treatment units instead of focusing on the sewage sludge produced in biological processes during the secondary treatment. However, studies have shown that less than 60% of the cellulose fibers were degraded after secondary wastewater treatment, while the rest would gradually form as sludge in anaerobic digesters (Chen et al. 2017; Ghasimi et al. 2016). The sieving process for residential wastewater treatment has been reported for fiber recovery and can increase the sustainability of wastewater treatment processes (Ghasimi et al. 2016; Ruiken et al. 2013). Efficient removal of cellulose fibers from wastewater with sieves of 0.35 mm meshes has been reported (Ruiken et al. 2013). The removal capacity of sieves can be an alternative for enhancing wastewater clarity during primary treatment. Studies have shown that at least 40% of the overall energy consumption could be saved by applying sieves as pretreatment for conventional activated sludge processes (Ruiken et al. 2013). Although the sieving process may increase construction expense and maintenance cost, the energy consumption in the secondary treatment and sludge disposal stages can be saved. Therefore, the balance between different technologies needs to be quantitatively determined. Furthermore, the use of energy-efficient, cost-effective, and environment-friendly technologies is beneficial to contaminant removal and resource recovery from wastewaters, i.e., reduce, reuse, and recycle (Cipolletta et al. 2019). Recently, there has been a trend to reduce the costs and increase sustainability by minimizing energy consumption and maximizing material recovery (Cipolletta et al. 2019; Hofman et al. 2011; Liu et al. 2022; Sutton et al. 2011). Toilet paper fibers can be separated from suspended solids and recovered as resources by sieve screening instead of landfilling or incinerating the sludge generated from biodegradation treatment, which has economic benefits.

The separation and recycling of toilet paper fibers from wastewater have been previously studied (Ruiken et al. 2013; Li et al. 2019; Cipolletta et al. 2019; Li et al. 2020). However, there is no evaluation study on the process and energy cost of sieving with systematic tools to understand what would happen in a real-life wastewater treatment plant. Therefore, it is innovative and important to quantitatively determine residential wastewater treatment with and without sieving process to figure out if the expenses are reduced and sustainability improved with sieving process using LCA. LCA is a systematic method for evaluating the process environmental impact and energy consumption, which can be used to compare the environmental impacts of a new process with existing processes (ISO 14040 1997). LCA has been used to compare different treatment processes for economic efficiency analysis. For example, Shanmugam et al. (2022) present a five-layered assessment framework for quantitatively evaluating the sustainable value of residential WWTPs by using LCA. In this study, we hypothesized that sieving toilet paper fibers from wastewater can possibly save energy costs and reduce environmental impacts in a residential wastewater treatment plant. The energy consumption and environmental impacts of the sieving process were presented. LCA was used to analyze the results of the residential wastewater treatment with sieve screening as a primary treatment for removing toilet paper fibers and to determine its efficiency in energy and environmental impacts and compared with processes without sieving.

Methodology and data

Sieve screening in the activated sludge processes

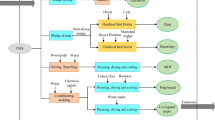

The general treatment processes schematic diagram for residential wastewater is shown in Fig. 1a, and the added sieving screening process as a pretreatment process in wastewater treatment is in Fig. 1b with sieve screening module in Fig. 1c. This study compared the processes with and without sieving as primary treatment during residential wastewater treatment.

The studied wastewater treatment plant had a treatment capacity of 76,000 m3/day, producing 37,000 kg/day dried sludge. The annual average population equivalents were 441,141 (Blanco et al. 2016). According to laboratory results (Li et al. 2020), the simulated mixture of toilet paper wastewater was screened through bar screening of 2.0-mm diameter stainless-steel rods with 1.0-mm mesh openings under a laboratory scale. The bar screening has fine sieves with 0.10-mm mesh openings at recovery efficiencies of 72.2% and 94.5%. The analysis was based on the treatment plant parameters combined with laboratory results. It is assumed that the treatment capacity, sludge yield, and population equivalent was still the same as literature. The smaller openings of the sieves consume larger energy during screening. Sieves used as mechanical treatment have been reported for maximal removal of all the suspended solids (Rusten 2006). Therefore, the sieve screening process of removing and recovering the toilet paper fibers can lead to substantial cost reduction for wastewater treatment. Furthermore, the sieving process could remove about 50–80% of suspended solids (Rusten 2006). In this study, it was assumed that the fine sieves with 6.0-mm mesh openings were applied. The average removal efficiencies of the influent solids using the sieving process were approximately 70% of suspended solids, 35% of COD, 1% of nitrogen, and 0.5% of phosphorus (Ruiken et al. 2013). Cellulose fibers from toilet paper were made up 35% of the suspended solids (Ruiken et al. 2013). This fiber fraction of sieving was higher than that of secondary treatment sludge. The application of sieving may affect the sludge treatment and biodegradation processes.

Goal, assumptions, and scope of the research

The aim of this study was to determine whether the energy consumption and environmental impacts for the treatment of wastewater and sludge management, landfill, and recycling could be reduced with the process of sieve screening. The study also compared the environmental impacts of a full-scale wastewater treatment plant with and without the sieve screening process.

The following assumptions were made in this study:

-

The lifetime of the wastewater treatment plants was 20 years.

-

The inflow was residential wastewater, and the characteristics of wastewater were the same for both scenarios. The characteristics included pH, TOC, and BOD, which would affect microbial activities in the secondary treatment.

-

The outflow of the treated wastewater met regulatory requirements. The addition of the sieving process would not affect the quality of outlet-treated water.

-

The sieve screening process was added before the primary treatment, and the sieve screen with a 6-mm bar opening for suspended solids efficiency was assumed to be 50.0% (Li et al. 2020; Ruiken et al. 2013).

-

Thirty-eight percent of the recovered suspended solids were cellulose fibers (Cipolletta et al. 2019), and 50% of these fibers could be recovered as pure cellulose.

The system boundary is shown in Fig. 2. The focused stages were secondary and tertiary processes with sludge treatment and landfill, and the affected steps by adding the sieve screening process. Pretreatment and disinfection were not considered in the system boundary as the sieving process had little effect on these two processes. Pretreatment was before the sieving process (as Fig. 1 shows), and the design of disinfection was based on flow rate, flow characteristics, plus size and shape of disinfection tank. The construction of the sieving module was also considered to evaluate the comprehensive impacts of adding the sieving process. The impacts of constructing other processes and disposal phases were negligible, which were not included in the system. Maintenance, labor, and transportation of materials were not considered as it was assumed that the sieve screening process was added at the same time.

The functional unit (FU) correlated with the reference flow of the entire related flows for the calculations. The objective of treating wastewater in a treatment plant is to meet its discharge requirements. In this study, influent wastewater on a yearly basis was selected as the FU considering its volume, associated load, and suspended solids (Lundin et al. 2000; Renou et al. 2008; Foley et al. 2010; Gallego et al. 2008).

Life-cycle inventory (LCI) analysis

The LCA was consistent with ISO 14040 and ISO 14044 guidelines (ISO 1999). The LCA model was based on the aim and scope of this research. Most of the data used were calculated based on the laboratory results for sieving toilet paper fibers (Li et al. 2020) and real residential wastewater treatment plants (Blanco et al. 2016; Cipolletta et al. 2019; Gallego et al. 2008; Zhang et al. 2010). The data used were obtained from the Ecoinvent database. The average electricity grid was presumed to produce the electricity used in on-site operations, using the unit electricity medium voltage at the grid. The process data used were almost closed to the global average values. The sewage sludge was dewatered and disposed in a landfill. The sludge contained nitrogen and phosphorous, which can be used as fertilizers. However, heavy metals in the sludge could contaminate the environment (Gallego et al. 2008). Methane and nitrogen compounds (such as N2, NOx, and NH3) were emitted: data from various sources were used to calculate emissions generated during agricultural application of the sludge (Hobson 2000; Lundin et al. 2000; Mossier 1993). The inventory data for wastewater treatment without sieving process are shown in Table 1. The energy and material consumption data for sieve screening during the construction stage are shown in Table 2. Inventory data of wastewater treatment with the sieving process are shown in Tables 3 and 4.

Impact assessment

LCA was analyzed using OpenLCA (1.9, GreenDelta GmbH, Germany). The cumulative energy demand (CED) method was used to calculate energy consumption. Energy consumption analysis of the wastewater treatment was performed using the LCI analysis results. The CED method has been used for evaluating energy and environmental impacts of processes since the early 1970s and for developing more multifaceted single-score LCA methodologies (Huijbregts et al. 2010). The ReCiPe Midpoint (I) was used as an impact assessment method for life-cycle impact assessment (LCIA). These methods have been widely used in LCA (Audenaert et al. 2012; Frischknecht et al. 2015; Goedkoop et al. 2009; Huijbregts et al. 2010). Ozone depletion, climate change, smog, acidification, eutrophication, carcinogenic, non-carcinogenic, respiratory effects, ecotoxicity, and fossil fuel depletion were the environmental impacts for both clarification and sieving processes normalization evaluation. The normalized and characterized environmental impact results were compared between the two systems. Input data are shown in Tables 1–4.

Uncertainty analysis

Data interpretation assessment may improve understanding of the data, work limitations, and results, thus decreasing uncertainty (Rebello et al. 2021). In this study, a Monte Carlo simulation was performed with 100 iterations for uncertainty analysis in accordance with variability in inventory data. Uncertainty analysis was assessed using OpenLCA software for the scenarios with and without sieving. For wastewater treatment evaluation, a normal distribution was commonly applied for parameter assessment (Oliveira et al. 2012); and the mean value in normal distribution represents the best guess value, and standard deviation represents 95% confidence interval (Alyaseri and Zhou 2019). A normal distribution was assumed for energy and material consumption data, and for calculating the arithmetic mean and standard deviation.

Results and discussion

Comparison of energy consumption

Figure 3 compares the energy consumption with and without the sieving process for wastewater treatment. The results proved that the addition of the sieving process could save energy despite its construction. The sieve screening process saved 8.57% of energy in contrast to the regular wastewater treatment process. The energy consumption of the construction stage was 1.31% of the total assessment cycle.

According to laboratory results, small opening sieves had a better fiber recovery rate (94.5% for 0.1-mm mesh openings compared to 72.2% for 1 mm). There was extra energy during pressurization and backwash with sieves, and clean water and energy were consumed during the recycling of cellulose fibers from the sludge treatment. However, more significant energy was consumed during the process. Thus, energy consumption should be considered when choosing the opening sizes of screening. More energy was saved in biodegradation due to the degradation of suspended solids than screening. The operation phase could save 10.01% energy with sieving. Therefore, adopting sieves for the fiber reuse option could be a benefit in terms of energy saving.

Comparison of environmental impacts

In order to analyze the environmental impacts of both processes, the ReCiPe method was adopted to provide information in terms of climate change, fossil depletion, metal depletion, terrestrial ecotoxicity, human toxicity, and particulate matter formation.

Figure 4 shows the environmental impacts of the wastewater treatment processes with sieving comparisons. The impacts of climate change, fossil depletion, human toxicity, and particulate matter formation showed similar impact reduction with sieving compared to no sieving wastewater treatment process, with a reduction of 7.81–8.65%. However, the sieving process increased metal depletion and terrestrial ecotoxicity impacts.

Climate change causes several environmental mechanisms that affect both human endpoint and ecosystem health (Goedkoop et al. 2009). This environmental impact is referred to as the accumulated discharge of greenhouse gases trapped heat from radiation, contributing to climate change and global warming (Naz et al. 2022). The ReCiPe method focused on the marginal effects of a relatively small amount of greenhouse gases instead of all emissions impacts. As shown in Fig. 4a, the sieving process reduced the climate change impacts. This reduction was due to lower energy consumption (8.62%) during the sieving operation process, higher fiber removal efficiency, and less sludge production.

Fossil fuel impacts are usually linked to climate change as a large number of greenhouse gases are produced during combustion (Goedkoop et al. 2009). As shown in Fig. 4b, fossil fuel depletion data corresponded to the results of energy consumption. Screening with 0.10-mm openings had 8.65% fewer impacts than screening with 1-mm openings, similar to climate change impacts.

Metal depletion represents the decrease in the availability of metal resources as a result of the unsustainable use of abiotic resource consumption value to measure the scarcity. The metal depletion depends on the number of resources consumed and the extraction rate of the metal (Goedkoop et al. 2009). According to Table 2, during sieving construction phase, extra stainless steel and metal pipes were consumed (Zârnoianu et al. 2014; Ruiken et al. 2013), which would contribute to metal depletion impacts. Terrestrial ecotoxicity is affected by pesticide emissions and the use of sulfuric acid and steam (Borrion et al. 2012). In ReCipe assessment, results showed that the sieving process increased the impacts on metal depletion and terrestrial toxicity by 19.64% and 69.02%, respectively, during the wastewater treatment.

Human toxicity potential was related to the environmental persistence and accumulation in the food chain. The toxicity index of a chemical was derived from toxicity data on human beings and laboratory animals and based on the inherent toxicity of a compound and its potential dose. The human toxicity potentials were characterized according to the unit (Fenton et al. 2021; Huijbregts et al. 2000). The sieving process was observed to reduce the human toxicity impacts by 7.82%. Fine particulate matter with a diameter of lower than 10-μm sizes represents a complex mixture of organic and inorganic substances. These substances can reach the upper part of the airways and lungs when inhaled, resulting in health problems (Goedkoop et al. 2009; World Health Organization 2003). As displayed in Fig. 4, without sieving process, high operation energy cost, low fiber removal rate, and high sludge production rate led to the formation of particulate matter with higher impacts (8.35%) than that of the 1-mm sieving process.

The environmental impacts are shown in Table 5. In most cases, the sieving process reduced environmental impacts in wastewater treatment. As Table 5 shows, freshwater ecotoxicity, freshwater eutrophication, photochemical oxidant formation, terrestrial acidification, and urban land occupation impacts were reduced with sieving process. Ionizing radiation impacts were slightly increased. Freshwater ecotoxicity, freshwater eutrophication, and terrestrial acidification environmental impacts were reduced due to the higher removal efficiency of toilet paper fibers and less energy cost. Metal mining and smelting, coal mining, and power production are enhanced sources of ionizing radiation impacts (Farjana et al. 2019). While sieving process consumed extra metal pipes and stainless steels during construction, metal mining and smelting would increase during this process as well, which contributed to the elevated ionizing radiation environmental impacts. Urban land occupation decreased because the sludge from wastewater treatment was reduced by sieving process.

Normalization environmental impacts of clarification and sieving

The Eco-indicator approach was used to calculate the normalized results of environmental impacts. Eco-indicator 99 is the assessment method for identifying environmental damage categories and determining the causes of damage (Dreyer et al. 2003). A normalized score for a certain impact category is obtained by determining the ratio of the category indicator result of the product and that of a reference system. The results of the assessment were presented from each impact value with a toxicity weight provided by the Eco-indicator in normalized data (Heijungs et al. 2007).

As shown in Fig. 5, the normalizing effects of each process were calculated. The calculation results provide information for nine categories of environmental impacts. The horizontal axe presents the categories of environmental impacts, and the vertical axe presents the normalized scores of each category. Total normalized effects in the systems were also calculated. The sieving process has a lower total normalized environmental impact (9.46%) than the regular wastewater treatment process. The total normalized results showed that carcinogenic, climate change, respirator effect, and mineral extraction had relatively higher environmental impacts than other categories.

The results also showed that sieving could be beneficial to residential wastewater treatment. Ruiken et al. (2013) reported that the sieving process removed 50% of suspended solids and 35% of the total COD. The sieving process gives a lower load, leading to a lower aeration demand and energy efficiency. Seven years was the estimated payback period for capital invested in the construction, including sieves, pipes, and automation, and the operation of wastewater treatment plant using only the sieving process (Ruiken et al. 2013). A lower load in secondary treatment plants resulting from sieving saves significant energy during sludge treatment.

Ruiken et al. (2013) showed that energy consumption during the treatment of wastewater with sieving process would save at least 40% compared with that without sieving in sludge treatment and incineration, which was much higher than this analysis. Sieving has significant advantages such as a faster separation rate, less footprint, and effective dewatering of materials, showing a promising application.

Uncertainty analysis results

The Monte Carlo simulation provided the distribution intervals with the results of each impact category based on its probability, as shown in Fig. 6. Terrestrial ecotoxicity impacts had a relatively large uncertainty. Moreover, the addition of sieving process resulted in a comparably higher deviation from the mean. This might be because there was uncertainty associated with the construction phase which increased the inventory flocculation. The construction of sieving depended on many factors, such as the energy consumption efficiency during construction, the choice of different kinds of stainless steel and metal pipes, and how much energy was consumed during materials transportation. Among the impacts of the addition of the sieving process in wastewater treatment, particulate matter formation showed the highest standard deviation from the mean, which could be explained by the uncertainty of the estimated energy consumption and construction cost.

Conclusions

In this study, LCA was used to evaluate the energy consumption and environmental impacts of adding sieving on the removal and recovery of toilet paper fiber in the wastewater treatment process. The results suggested that the addition of the sieving process reduces the energy consumed and normalized environmental impacts by 8.57% and 9.46%, respectively. The construction of sieving consumed only 1.31% cost compared to operation phase energy cost. Climate change, fossil depletion, and particulate matter formation were associated with the non-renewable fossil fuel used during the sieving process. With sieving process, a comparably higher deviation was observed; this is because there was uncertainty associated with the construction phase which increased the inventory flocculation. The life-cycle analysis of the primary treatment revealed the need for using more efficient methods to enhance the cellulose fiber recovery rate.

Limitations, improvement, and outlook

Site-specific LCA must be considered when applying the impact assessment model. Laboratory results were used to calculate the energy and environmental impacts of the processes. Modifications were made when the results were applied to other sites and situations. Uncertainty analysis for all scenarios and the impact assessment approach was considered beyond the scope of this research. Energy consumed during the wastewater treatment process was a great concern in fossil fuel cost, economic cost, environmental impacts, and human health. About 82% of electricity is derived from coal-fired power plants in China (Yu et al. 2014), depleting the non-renewable fossil fuel resources, such as coal and gasoline, and causing health problems. In the real-world application, the energy cost of sieving could be lower by adopting different improved models.

The results showed that the addition of the sieving process reduces energy consumption and normalized environmental impacts by 8.57% and 9.46%, respectively. These results were lower than the former prediction of Ruiken et al. (2013). The suspended solids used in this study, which might increase the energy consumption and environmental impacts, were washed and treated. The application of sieving did not reduce energy cost and environmental impacts as expected. However, the application of recycled cellulose fibers was not set. More research should focus on separating cellulose fibers from suspended solids during the sieving process. The recycled fiber could be used as raw materials for the paper industry, house isolation materials, bioplastic lactic acid, or even paving fibers in road construction.

Data availability

Not applicable.

References

Alyaseri I, Zhou J (2019) Handling uncertainties inherited in life cycle inventory and life cycle impact assessment method for improved life cycle assessment of wastewater sludge treatment. Heliyon 5(11):e02793. https://doi.org/10.1016/j.heliyon.2019.e02793

Audenaert A, De Cleyn SH, Buyle M (2012) LCA of low-energy flats using the Eco-indicator 99 method: impact of insulation materials. Energy Build 47:68–73. https://doi.org/10.1016/j.enbuild.2011.11.028

Blanco D, Collado S, Laca A, Díaz M (2016) Life cycle assessment of introducing an anaerobic digester in a municipal wastewater treatment plant in Spain. Wat Sci Tech 73(4):835–842. https://doi.org/10.2166/wst.2015.545

Borrion AL, Khraisheh M, Benyahia F (2012) Environmental life cycle impact assessment of gas-to-liquid processes. In: Proceedings of the 3rd Gas Processing Symposium, vol 3. Elsevier

Chen R, Nie Y, Kato H, Wu J, Utashiro T, Lu J, Yue S, Jiang H, Zhang L, Li Y (2017) Methanogenic degradation of toilet-paper cellulose upon sewage treatment in an anaerobic membrane bioreactor at room temperature. Bioresour Technol 228:69–76. https://doi.org/10.1016/j.biortech.2016.12.089

Cipolletta G, Eusebi AL, Palmieri S, Giosuè C, Tittarelli F, Frison N, Pastore C, Foglia A, Fatone F (2019) Toilet paper recovery from municipal wastewater and application in building sector. IOP Conf Ser Earth Environ Sci 296(1):12–24. https://doi.org/10.1088/1755-1315/296/1/012024

Dreyer LC, Niemann AL, Hauschild MZ (2003) Comparison of three different LCIA methods: EDIP97, CML2001 and Eco-indicator 99. Int J Life Cycle Assess 84:191–200. https://doi.org/10.1007/BF02978471

Farjana SH, Huda N, Mahmud MP, Saidur R (2019) A review on the impact of mining and mineral processing industries through life cycle assessment. J Clean Product 231:1200–1217. https://doi.org/10.1016/j.jclepro.2019.05.264

Faust L, Temmink H, Zwijnenburg A, Kemperman AJ, Rijnaarts HH (2014) High loaded MBRs for organic matter recovery from sewage: effect of solids retention time on bioflocculation and on the role of extracellular polymers. Water Res 56:258–266

Fenton SE, Ducatman A, Boobis A, DeWitt JC, Lau C, Ng C, Smith JS, Roberts SM (2021) Per-and polyfluoroalkyl substance toxicity and human health review: current state of knowledge and strategies for informing future research. Environ Toxi Chem 40(3):606–630

Foley JM, De Haas D, Hartley K, Lant P (2010) Comprehensive life cycle inventories of alternative wastewater treatment systems. Water Resour 44(5):1654–1666. https://doi.org/10.1016/j.watres.2009.11.031

Frischknecht R, Wyss F, Knöpfel SB, Lützkendorf T, Balouktsi M (2015) Cumulative energy demand in LCA: the energy harvested approach. Int J Life Cycle Assess 207:957–969. https://doi.org/10.1007/s11367-015-0897-4

Gallego A, Hospido A, Moreira M, Feijoo G (2008) Environmental performance of wastewater treatment plants for small populations. Resources, Conservation and Recycling 52(6):931–940. https://doi.org/10.1016/j.resconrec.2008.02.001

Gao P, Xu W, Sontag P, Li X, Xue G, Liu T, Sun W (2016) Correlating microbial community compositions with environmental factors in activated sludge from four full-scale municipal wastewater treatment plants in Shanghai, China. Appl Microbiol Biotechnol 100(10):4663–4673. https://doi.org/10.1007/s00253-016-7307-0

Ghasimi DS, Zandvoort MH, Adriaanse M, van Lier JB, de Kreuk M (2016) Comparative analysis of the digestibility of sewage fine sieved fraction and hygiene paper produced from virgin fibers and recycled fibers. Waste Manage 53:156–164. https://doi.org/10.1016/j.wasman.2016.04.034

Goedkoop M, Heijungs R, Huijbregts M, De Schryver A, Struijs J, van Zelm R (2009) ReCiPe 2008, a life cycle impact assessment method which comprises harmonised category indicators at the midpoint and the endpoint level 1, 1–126

Gupta M, Ho D, Santoro D, Torfs E, Doucet J, Vanrolleghem PA, Nakhla G (2018) Experimental assessment and validation of quantification methods for cellulose content in municipal wastewater and sludge. Environ Sci Pollut Res Res 2517:16743–16753. https://doi.org/10.1007/s11356-018-1807-7

Heijungs R, Guinée J, Kleijn R, Rovers V (2007) Bias in normalization: causes, consequences, detection and remedies. Int J Life Cycle Assess 12(4):211–216. https://doi.org/10.1065/lca2006.07.260

Hobson J (2000) CH4 and N2O emissions from wastewater handling. In: Good practice guidance and uncertainty management in National Greenhouse Gas Inventories. Intergovernmental Panel on Climate Change (IPCC) Publications, Geneva

Hofman J, Hofman-Caris R, Nederlof M, Frijns J, Van Loosdrecht M (2011) Water and energy as inseparable twins for sustainable solutions. Water Sci Technol 631:88–92. https://doi.org/10.2166/wst.2011.013

https://archive.epa.gov/epapages/newsroom_archive/newsreleases/e55278b5dcb96f01852568970052804f.html.

Huang D, Xu R, Sun X, Li Y, Xiao E, Xu Z, Wang Q, Gao P, Yang Z, Lin H, Sun W (2022) Effects of perfluorooctanoic acid (PFOA) on activated sludge microbial community under aerobic and anaerobic conditions. Environ Sci Pollut Res 29(42):63379–63392. https://doi.org/10.1007/s11356-022-18841-8

Huijbregts MA, Hellweg S, Frischknecht R, Hendriks HW, Hungerbuhler K, Hendriks AJ (2010) Cumulative energy demand as predictor for the environmental burden of commodity production. Environ Sci Technol 446:2189–2196. https://doi.org/10.1021/es902870s

Huijbregts MAJ, Thissen U, Guinée JB, Jager T, Van de Meent D, Ragas AMJ, Wegener Sleeswijk A, Reijnders L (2000) Priority assessment of toxic substances in life cycle assessment, I: Calculation of toxicity potentials for 181 substances with the nested multi-media fate, exposure and effects model USES-LCA. Chemosphere 41:541–573. https://doi.org/10.1016/S0045-6535(00)00030-8

International Standard Organization (ISO) (1997) Environmental management—life cycle assessment— principles and framework. ISO 14040. International Organization for Standardization, Geneva

International Standard Organization (ISO) (1999) Environmental management – life cycle assessment – principles and framework. ISO 14044. International Organization for Standardization, Geneva

Li S, Wu Z, Liu G (2019) Degradation kinetics of toilet paper fiber during wastewater treatment: effects of solid retention time and microbial community. Chemosphere 225:915–926. https://doi.org/10.1016/j.chemosphere.2019.03.097

Li S, Wu Z, Wu Z, Liu G (2020) Enhancing fiber recovery from wastewater may require toilet paper redesign. J Clean Prod 261:121138. https://doi.org/10.1016/j.jclepro.2020.121138

Li Y, Guo L, Häggblom M, Yang R, Li M, Sun X, Chen Z, Li F, Su X, Yan G, Xiao E (2022a) Serratia spp. are responsible for nitrogen fixation fueled by As (III) oxidation, a novel biogeochemical process identified in mine tailings. Environ Sci Technol 56(3):2033–2043. https://doi.org/10.1021/acs.est.1c06857

Li Y, Yang R, Guo L, Gao W, Su P, Xu Z, Xiao H, Ma Z, Liu X, Gao P, Li B (2022b) The composition, biotic network, and assembly of plastisphere protistan taxonomic and functional communities in plastic-mulching croplands. J Hazard Mater 430:128390. https://doi.org/10.1016/j.jhazmat.2022.128390

Li Y, Zhang M, Xu R, Lin H, Sun X, Xu F, Gao P, Kong T, Xiao E, Yang N, Sun W (2021) Arsenic and antimony co-contamination influences on soil microbial community composition and functions: relevance to arsenic resistance and carbon, nitrogen, and sulfur cycling. Environ Int 153:106522. https://doi.org/10.1016/j.envint.2021.106522

Liu R, Li Y, Zhang M, Hao X, Liu J (2022) Review on the fate and recovery of cellulose in wastewater treatment. Resour Conserv Recycl 184:106354. https://doi.org/10.1016/j.resconrec.2022.106354

Lundin M, Bengtsson M, Molander S (2000) Life cycle assessment of wastewater systems: influence of system boundaries and scale on calculated environmental loads. Environ Sci Technol 34(1):180–186. https://doi.org/10.1021/es990003f

Mossier AR (1993) Nitrous oxide emissions from agricultural soils. In: van Amstel AR (ed) IPCC workshop proceedings: methane and nitrous oxide, methods in national emissions inventories and options for control

MRS (2017) Global toilet paper market 2017: production, sales, supply, demand, analysis and forecast to 2021. MRS Research Group, Maharashtra, India

Naz S, Fatima Z, Iqbal P, Khan A, Zakir I, Ullah H, Abbas G, Ahmed M, Mubeen M, Hussain S, Ahmad S (2022) An introduction to climate change phenomenon. In: Building climate resilience in agriculture. Springer, Cham, pp 3–16

Oliveira SC, Souki I, Von Sperling M (2012) Lognormal behaviour of untreated and treated wastewater constituents. Water Sci Technol 65(4):596–603. https://doi.org/10.2166/wst.2012.899

Osaka T, Shirotani K, Yoshie S, Tsuneda S (2008) Effects of carbon source on denitrification efficiency and microbial community structure in a saline wastewater treatment process. Water Res 42(14):3709–3718. https://doi.org/10.1016/j.watres.2008.06.007

Rebello TA, Roque RP, Gonçalves RF, Calmon JL, Queiroz LM (2021) Life cycle assessment of urban wastewater treatment plants: a critical analysis and guideline proposal. Water Sci Technol 83(3):501–514. https://doi.org/10.2166/wst.2020.608

Renou S, Thomas JS, Aoustin E, Pons MN (2008) Influence of impact assessment methods in wastewater treatment LCA. J Clean Prod 16(10):1098–1105. https://doi.org/10.1016/j.jclepro.2007.06.003

Ruiken CJ, Breuer G, Klaversma E, Santiago T, Van Loosdrecht MCM (2013) Sieving wastewater-cellulose recovery, economic and energy evaluation. Water Res 471:43–48. https://doi.org/10.1016/j.watres.2012.08.023

Rusten B (2006) Evaluation and testing of fine mesh sieve technologies for primary treatment of municipal wastewater. Water Sci Technol 54(10):31–38. https://doi.org/10.2166/wst.2006.710

Shanmugam K, Gadhamshetty V, Tysklind M, Bhattacharyya D, Upadhyayula VK (2022) A sustainable performance assessment framework for circular management of municipal wastewater treatment plants. J Clean Product 339:130657. https://doi.org/10.1016/j.jclepro.2022.130657

Sun X, Kong T, Li F, Häggblom M, Kolton M, Lan L, Lau Vetter M, Dong Y, Gao P, Kostka J, Li B (2022) Desulfurivibrio spp. mediate sulfur-oxidation coupled to Sb(V) reduction, a novel biogeochemical process. ISME J 16(6):1547–1556

Sutton PM, Melcer H, Schraa OJ, Togna AP (2011) Treating municipal wastewater with the goal of resource recovery. Water Sci Technol 63(1):25–31. https://doi.org/10.2166/wst.2011.004

Verstraete W, Van de Caveye P, Diamantis V (2009) Maximum use of resources present in domestic “used water”. Bioresour Technol 100(23):5537–5545. https://doi.org/10.1016/j.biortech.2009.05.047

Weimer PJ (2022) Degradation of cellulose and hemicellulose by ruminal microorganisms. Microorganisms 10(12):2345. https://doi.org/10.3390/microorganisms10122345

World Health Organization (2003) Health aspects of air pollution with particulate matter, ozone and nitrogen dioxide; report on a WHO working group, No. EUR/03/5042688. WHO Regional Office for Europe. Bonn, Germany, pp 13–15

Xu C, Chen W, Hong J (2014) Life-cycle environmental and economic assessment of sewage sludge treatment in China. J Clean Prod 67:79–87. https://doi.org/10.1016/j.jclepro.2013.12.002

Xu R, Li B, Xiao E, Young LY, Sun X, Kong T, Dong Y, Wang Q, Yang Z, Chen L, Sun W (2020) Uncovering microbial responses to sharp geochemical gradients in a terrace contaminated by acid mine drainage. Environ Pollut 261:114226. https://doi.org/10.1016/j.envpol.2020.114226

Yu S, Wei Y, Guo H, Ding L (2014) Carbon emission coefficient measurement of the coal-to-power energy chain in China. Appl Energy 114:290–300. https://doi.org/10.1016/j.apenergy.2013.09.062

Zârnoianu D, Popescu S, Marin R (2014) Utilization of tangential filters for increasing economic and qualitative performance of wastewater treatment processes

Zhang Q, Wang X, Xiong J, Chen R, Cao B (2010) Application of life cycle assessment for an evaluation of wastewater treatment and reuse project–case study of Xi’an, China. Bioresource Technol 101(5):1421–1425. https://doi.org/10.1016/j.biortech.2009.05.071

Acknowledgements

We thank LetPub for its linguistic assistance during the preparation of this manuscript.

Funding

This work was supported by Guangdong Foundation for Program of Science and Technology Research (Grant No. 2020B1111530001), the National Natural Science Foundation of China (Grant Nos. U20A20109, 42007357, and 51978136), Guangdong Basic and Applied Basic Research Foundation (Grant Nos. 2021A1515011374 and 2021A1515011461), GDAS’ Project of Science and Technology Development (Grant Nos. 2019GDASYL-0103052, 2020GDASYL-20200103088, 2020GDASYL-20200102014, and 2021GDASYL-20210103048), the Science and Technology Planning Project of Guangzhou (Grant No. 201904010366), and the Science and Technology Planning Project of Guangdong Province (Grant No. 2019B121205006).

Author information

Authors and Affiliations

Contributions

Xiaoyu Wang designed the study, analyzed the data, and wrote the original draft. Guoqiang Liu performed the original toilet paper screening study and provide the data. Zhiguo Cao, Huaqing Liu, and Yiqun Xiong revised the manuscript. Weimin Sun and Pin Gao conceptualized the study, formal analyzed, reviewed, and edited the manuscript. Baoqin Li, Xiaoxu Sun, Yongbin Li, Rui Xu, and Duanyi Huang commented and reviewed the manuscript. All authors have read and approved the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Loubet

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, X., Liu, G., Sun, W. et al. Removal of toilet paper fibers from residential wastewater: a life cycle assessment. Environ Sci Pollut Res 30, 84254–84266 (2023). https://doi.org/10.1007/s11356-023-28291-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-28291-5