Abstract

According to the European Waste Codes 19.12.08, fibers derived from end-of-life tires (ELT) are classifies as a special waste to be sent to landfill or incineration with energy recovery. However, these activities would pose additional risks including soil pollution, and groundwater contamination. A change in the current ELT waste management practices is needed to reduce the environmental impacts. The aim of this paper is to present and investigate the technical and environmental feasibility of a circular economy path for ELT fibers. Several PP-based compounds have been manufactured and tested to verify the possibility of reusing ELT fibers in such an application. Then a Life Cycle Assessment (LCA) study has been carried out to compare the proposed reuse scenario with the two standard scenarios for ELT fibers. Reuse scenario leads to environmental savings for several impact categories, even if for some indicators the incineration is preferrable due to the additional resources and energy required needed to treat the dirty ELT fibers before reuse.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Modern urbanization during the last years has contributed to increase the vehicle demand. Consequently, the annual tire demand was increased, with about 1500 million tires manufactured globally and about 1000 million tires that reach their end of life (EoL) each year [1, 2]. In this context, in Europe, about 320.000 tons of dirty fibrous material must be disposed as special waste. This produces negative impacts on the environment, in terms of green-house gases (GHG) emissions, economic losses and public costs. Nowadays, several studies and solutions have been implemented to address the ELT issue: reuse (5–23%), recycling (3–15%), landfilling (20–30%), and recovery (25–60%) [3]. Unfortunately, about 50% of used tires still end up in landfills or are discarded as untreated waste, and insufficiently valued [4].

Generally, three main materials are produced from ELT: rubber, steel wires and textile fibers [5]. Rubber granule is the main material derived from the treatment process of ELT. Such material is then used as a basis in manufacturing new materials, such as different kinds of tires, plastic parts, concrete, asphalt, etc. [6]. Separated steel wires are generally used by steel producers for the manufacturing of new virgin steel [7]. The ELT fibers, instead, are currently classified as a unique waste according to the European Waste Code 19.12.08, thus they have to be burnt and/or buried [8].

In scientific literature, different uses for these fibers have been considered. In particular, it is possible to find applications as reinforcements in cementitious composites [9], or as indicated in Mucsi et al. [10] they are used to reinforce the soil. In recent years, researchers have tried to reuse these wastes and prevent them from being burnt or buried. In general, various types of fibers, both natural and synthetic, can be used as reinforcements. Examples of natural fibers used as reinforcements are coir [11], bagasse [12], sisal [13], jute [14] and palm [15]. Although natural fibers are normally cheaper and more sustainable than synthetic fibers, they are less durable, and synthetic fibers, specifically those composed of polymeric substances, are highly resilient as exposed to the natural environment. Synthetic fibers are widely used as reinforcement of polyethylene, polypropylene polyester, carbon, glass, and steel [16, 17]. The recycling and reuse of polypropylene (PP) have been investigated in several literature studies. It is possible to increase the properties of waste PP by adding fibers [18].

The ELT fibers mainly consist of a blend of polyester, rayon and nylon fibers, these materials have yielded positive results in different industrial applications. This study proposes a valorization strategy for ELT fibers by adopting a circular economy approach. More specifically, the paper aims to demonstrate that is possible to reuse the ELT fibers to produce new PP-based compounds with superior technical features and an improved environmental sustainability. A comparative Life Cycle Assessment (LCA) evaluation has been performed to finally verify the positive influence of the proposed circular economy.

The paper is structured as follows. Section 2 illustrates the reinforced PP-based compound properties. Section 3 presents the case study and the first two step of the LCA study and Sect. 4 shows and discusses the LCA results. Finally, Sect. 5 reports conclusions and proposal for future developments.

2 Materials

To reduce the environmental impact of ELT fibers this paper studies and compares different second life applications. Three EoL scenarios have been considered: landfill (#1), incineration with energy recovery (#2), and reuse in plastic compounds (#3). The first two options are standard scenarios, currently used in the waste management chain. Instead, the last option, is the proposed innovative applications for the ELT fibers. ELT fibers generally include Nylon 6,6, Nylon 6, Dacron and Rayon, with fibers of approximately 3− 8 mm in length and 30–50 µ in diameter [3]. Such fibers were used to prepare a PP-based compound with ELT fibers content in the range 0 – 45%. A DSM Micro compounder 15 cc, twin screw with co-rotating screws has been used to create the material samples.

Different types of blends have been obtained, by suitably mixing master and post-consumer PP. The percentages have been identified in steps of 5% increase from 0% to 20%, then it is passed to 30% and 45% by weight of fibers. For understanding the benefit of the ELT fiber in the plastic compound, tensile and compression tests have been carried out. Tensile tests were performed using the Lloyd LR30k dynamometer equipped with a 30 kN load cell. The test was conducted at a deformation rate equal to 5 mm/min. Young module and yield stress decrease as the percentage of fiber increases. However, the total deformation is reduced, with an increase of the material stiffness. As regards the mechanical impact characterization, the Izod methodology was used. The UNI EN ISO 180 standard provide a boundary condition of the test. For the impact a 1,2 J sledgehammer has been used. The ELT fibers do not produce a significative difference in the impact values. The energy values are independent from the percentage of fiber. For understanding the behavior of different fiber percentage in the plastic compound, Fig. 1 shows a sample test morphology after impact tests. There is a reduction of fractured surface as the percentage of fiber increases. The increase of fiber percentage reduces the fracture surface and two distinct parts are not obtained at the end of test. This last result suggests that the actual energy required to generate the same fracture surface increases as the amount of fiber increases.

The presence of the ELT fibers in plastic compounds, reduces tensile strength but improves impact resistance. The increase of impact resistance is directly proportional to the percentage of the fiber. The new plastic compound can be used for pallets, storage bins, etc., and in general products that have to resist at impacts. In the following LCA study, a plastic compound with 45% of ELT fiber (PP- F45%) was considered.

3 Methods

The LCA methodology (ISO 14040–14044) has been used in this study by following the, four phases: (i) Goal and scope definition, (ii) Life cycle inventory (LCI), (iii) Life cycle impact assessment (LCIA), and (iv) Results interpretation.

3.1 Goal and Functional Unit

The goal of this study is to calculate the environmental impacts related to the EoL management of the textile fibers obtained from ELTs according to Life Cycle Assessment methodology (ISO 14040–14044). The activity has been carried out in collaboration with two Italian company: STECA S.p.a., an authorized recycler of ELTs, and TECNOFILM S.p.a., a producer of plastic compounds. The functional unit is defined as “disposal of the annual production of ELT fibers in STECA”. The reference flow is equal to the amount of fibers that STECA manages to treat in a year, that is 1200 tones, with a pilot equipment capacity of about 300 kg/h of ELT fibers processed.

3.2 System Boundary

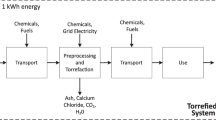

The study is a “gate to gate” type, this means it refers only to a specific step of the life cycle of fiber. All processes starting from the clean fibers in STECA company until landfill, incineration or reuse in plastic compound. Therefore, the various transports within these phases are also included. The system boundaries are summarized in the following Fig. 2.

While in the landfill and incineration scenarios the ELT fibers do not need further processing, in the reuse scenario it is necessary to compact the ELT fiber for the successive reuse. Though a hopper, the fiber is compacted into pellets to allow better transport and storage and a dosage in the compound plastic production. The paraffinic wax allows good lubrication and low temperature during the pelletizing phase [3].

3.3 LCI Definition

The set of inventory data used in this study for each scenario are shown in Table 1. Primary and secondary data are included on the life cycle inventory.

3.4 Cut-Off and Assumptions

A cut-off to all energy-consuming processes with an incidence lower than 1% of the total electricity consumption has been applied. An approximate distance of 900 km is assumed between the factory STECA and Switzerland for the incinerator. The big bags are PP bags with a weight of 20 kg, that are used to carry both fibers in the natural state and reduced into pellets. A reduction of 2,5 times of volume compared to the fibers in the natural state is obtained after the compaction and pelletization.

4 Results and Discussion

The third LCA step involves the measurement of the environmental impacts related to each process and flow considered. The LCIA method used for the calculation of the environmental impacts is the ReCiPe midpoint - Hierarchist (H) version – Europe. The obtained results are summarized in Table 2.

Table 2 demonstrate that reusing ELT fibers in plastic compound is a feasible solution that significantly reduces the environmental load related to textile fibers. Going into more details, the reuse is the best scenario in terms of Climate Change, while incineration with energy recovery scenario leads to very high impacts. The incineration process (burning of plastic materials) produces toxic emissions in the air that strongly contributes to the rise of the world temperature. Instead, the landfilling of plastic materials, does not cause relevant emissions in the air, thus the influence on GWP impact category is quite limited.

Also considering the Fossil Depletion indicator, the situation is the same. The use of fibrous material as reinforcement in plastic compounds allows avoiding production of virgin PP, with considerable advantages in environmental terms. In the same way, in the incineration scenario, the ELT fibers allows saving fossil fuels (coal, oil, gas, etc.) commonly used for the generation of energy and/or heat. In the reuse scenario, most of the impacts are related to the paraffinic wax (produced by using fossil resources), needed to make the clean fibers reusable in the plastic compound.

Regarding impacts related to the Freshwater Eutrophication indicator, energy recovery is the most environmentally friendly, while the plastic compound scenario is penalized by the production of the wax paraffine needed to produce ELT fiber pellets.

As for Eutrophication indicator, also Ozone Depletion Potential is convenient in the energy recovery scenario. Ozone Depletion has been defined as a relative measure of the ozone depletion capacity of an ODS and uses CFC-11 (trichlorofluoromethane) as a reference. So, this indicator is very high in landfills while less significative in the paraffine production. This is due to the emissions of trichlorofluoromethane.

Fine Particulate Matter (PM10) represents a complex mixture of organic and inorganic substances. PM10 causes health problems as it reaches the upper part of the airways and lungs when inhaled. Landfill and electricity consumption are the main causes of high levels of PM10. There is a drastic reduction, about 300% of PM 10 in cases of reusing fibers in PP compounds.

Terrestrial Acidification is characterized by changes in soil chemical properties following the deposition of nutrients (namely, nitrogen and sulfur) in acidifying forms. The terrestrial acidification mainly depends on the production/consumption of energy. As for terrestrial acidification, the reuse of fibrous material produces a reduction of this impact of about 300%.

5 Conclusions

This paper investigates a reuse scenarios of ELT fibers in plastic compounds (PP-based). Firstly, the technical feasibility was evaluated to assure that the reuse path leads to a material with acceptable properties, as well as to choose the best alternative (PP-based compound with 45% fiber content in weight). Successively, such reuse scenario has been compared from the environmental point of view with two other common dismantling scenarios (landfill and incineration with energy recovery) by using the standard LCA methodology. Results demonstrate that it is not possible to univocally identify the best scenario, although reuse scenarios appear to be very promising: reuse scenario is the best alternative in case of four considered impact categories (Climate Change, Fossil Depletion, Particulate Matter Formation, Terrestrial Acidification), while incineration with energy recovery is preferrable in case of Freshwater Eutrophication and Ozone Depletion. Landfill that is currently the most common EoL scenario for ELT fibers, due to economic reasons, can be never considered the best option from the environmental perspective. Future work should be focused on optimizing the LCA study (e.g. sensitivity analysis), as well as to find improvement strategies for the most critical phases (e.g. use of paraffine wax).

References

Williams, P.T.: Pyrolysis of waste tyres: a review. Waste Manage. 33, 1714–1728 (2013)

Jun, Z., Xiang-ming, W., Jian-min, C., Kai, Z.: Optimization of processing variables in wood–rubber composite panel manufacturing technology, Bioresour. Technol. 99 (2008)

Landi, D., Gigli, S., Germani, M., Marconi, M.: Investigating the feasibility of a reuse scenario for textile fibres recovered from end-of-life tyres. Waste Manag. 75, 187–204 (2018)

Thomas, B.S., Gupta, R.C.: A comprehensive review on the applications of waste tire rubber in cement concrete. Renew. Sustain. Energy Rev. 54, 1323–1333 (2016)

Landi, D., Marconi, M., Meo, I., Germani, M.: Reuse scenarios of tires textile fibers: an environmental evaluation. Proc. Manuf. 21, 329–336 (2018)

Fornai, D., Sangiorgi, C., Mazzotta, F., Bermejo, J.M., Saiz, L.: A new era for rubber asphalt concretes for the green public procurement in road construction. In: 1st European Road Infrastructure Congress (Leeds, United Kingdom) (2016)

European Tyre Rubber Manufactures Association (ERTMA), 2015. The European Tyre Industry e Our Vision for 2030 (2015)

Yilmaz, Y.: Compaction and strength characteristics of fly ash and fiber amended clayey soil. Eng. Geol. 188, 168–177 (2015)

Caggiano, A., Folino, P., Lima, C., Martinelli, E., Pepe, M.: On the mechanical response of hybrid fiber reinforced concrete with recycled and industrial steel fibers. Construct. Build. Mater. 147, 286–295 (2017)

Mucsi, G., Szenczi, A., Nagy, S.: Fiber reinforced geopolymer from synergetic utilization of fly ash and waste tire. J. Clean. Prod. 178, 429–440 (2018)

Sivakumar Babu, G.L., Vasudevan, A.K.: Strength and stiffness response of coir fiberreinforced tropical soil. J. Mater. Civ. Eng. 20(9), 571–577 (2008)

Dang, L.C., Fatahi, B., Khabbaz, H.: Behaviour of expansive soils stabilized with hydrated lime and bagasse fibres. Proc. Eng. 2016(143), 658–665 (2016)

Kafodya, I., Okonta, F.: Effects of natural fiber inclusions and pre-compression on the strength properties of lime-fly ash stabilised soil. Constr. Build. Mater. 170, 737–746 (2018)

Wang, Y.X., Guo, P.P., Shengbiao, S., Haiping, Y., Binxiang, Y.: Study on strength influence mechanism of fiber-reinforced expansive soil using jute. Geotech. Geol. Eng. 34(4), 1079–1088 (2016)

Azadegan, O., Kaffash, A.E., Yaghoubi, M.J., Pourebrahim, G.R.: Laboratory study on the swelling, cracking and mechanical characteristics of the palm fiber reinforced clay. Electron. J. Geotech. Eng. 17, 47–54 (2012)

Akbulut, S., Arasan, S., Kalkan, E.: Modification of clayey soils using scrap tire rubber and synthetic fibers. Appl. Clay Sci. 38(1–2), 23–32 (2007)

Consoli, N.C., Montardo, J.P., Donato, M., Prietto, P.D.: Effect of material properties on the behaviour of sand-cement-fibre composites. Proc. Instit. Civ. Engineers Ground Improve 8(2), 77–90 (2004)

Marconi, M., Landi, D., Meo, I., Germani, M.: Reuse of tires textile fibers in plastic compounds: is this scenario environmentally sustainable? Proc. CIRP 69, 944–949 (2018)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Landi, D., Marconi, M. (2022). Investigating a Circular Economy Application: Reuse of End of Life Tire Fibers in a Plastic Compound. In: Rizzi, C., Campana, F., Bici, M., Gherardini, F., Ingrassia, T., Cicconi, P. (eds) Design Tools and Methods in Industrial Engineering II. ADM 2021. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-91234-5_36

Download citation

DOI: https://doi.org/10.1007/978-3-030-91234-5_36

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-91233-8

Online ISBN: 978-3-030-91234-5

eBook Packages: EngineeringEngineering (R0)