Abstract

Bio-residue is a by-product from organic waste anaerobic digestion process with high moisture, high organic matter, low calorific value and poor biological stability, and may be incinerated after deep dewatering. The moisture existence forms of bio-residue were clarified firstly, finding that adsorbed water, capillary water and bound water occupied 75.61%, 23.81% and 0.58%, respectively. Furthermore, refuse incineration bottom ash was used as a typical deep dewatering reagent, when compared with calcium oxide (CaO), refuse incineration fly ash and iron powder–potassium persulfate (Fe(0)-K2S2O8). Results showed that the addition of bottom ash powder could decrease the bio-residue’s moisture from 80.0% to 37.9% at the optimal dosage of 2.0%, and corresponding low calorific value reached 10.5 MJ/kg at the 10th d. It was suggested that ZnCl2 and ZnSO4 present in bottom ash powder could react with moisture in bio-residue, forming hydrates of inorganic salt and breaking the polyacrylamide colloid, and lead to the release of adsorbed water in the bio-residue.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Organic solid waste, with a huge quantity around the world, refers to solid waste contains organic components produced by human activities and may include fruit peel, rotten vegetable leaves, eggshells, rice, flour, vegetable oil, animal oil, meat and bone, and so on. With the increase in the world population, the generation of organic waste, such as food and kitchen waste, garden waste, crop residue and animal manures, is increased (Singh et al. 2014; Mata-Alvarez et al. 2000; Tella et al. 2013; Wei et al. 2021). Around 30%-40% of municipal solid waste in China consists of organic waste, with an annual quantity of around 110 million and possibly several billion of tons globally (Zhao and Wei 2020), which have caused a worldwide crisis (Arun and Sivashanmugam 2017; Guo et al. 2021).

The common organic waste treatment and disposal technologies include anaerobic digestion and aerobic composting. Anaerobic digestion is a highly effective technique for the disposal of agricultural residues, organic solid waste, food waste and sludge, and has been widely used as an ideal method for the waste disposal in recent years (Hu et al. 2022). In the anaerobic digestion process, anaerobic fermentation bacteria, hydrogen-producing acetic acid bacteria and hydrogen-consuming acetic acid bacteria are used to degrade complex organic matter into methane, carbon dioxide and other gases, achieving harmlessness and resource utilization (Yu et al. 2020). During anaerobic digestion process, biogas that is rich in methane and carbon dioxide is produced, which could be used as a fuel for combustion in transport or energy production, leaving the bio-residue for treatment further. Most organic substance in organic waste such as sugar, fat and protein has been decomposed and transferred into the biogas slurry, leaving the bio-residue with high moisture, high organic matter, low calorific value and poor biological stability that should be properly treated.

In the current technological process of organic waste anaerobic digestion plant, bio-residue is treated by polyacrylamide (PAM) for dewatering. Polyacrylamide is a water-soluble polymer and commonly used as the thickeners, viscosity modified reagents or flocculant (Li et al. 2020). Hundreds of millions of dollars per year on polyacrylamides is spent for the conditioning and dewatering of wastewater sludge. Polyacrylamide is also widely used in many industrial processes such as dewatering of sludge, treatment of wastewater and production of paper. After treated by polyacrylamide, the bio-residue will be disposed of by incineration along with municipal solid waste. However, because of the moisture holding capacity of polyacrylamide, the moisture of organic waste bio-residue can only be decreased to about 80%, which is still not suitable for incineration. Therefore, deep dewatering by certain reagents to reduce the moisture further and improve low calorific value is necessary before incineration (Šyc et al. 2020; Chen et al. 2020; Wan et al. 2018).

To study the deep dewatering of bio-residue, it is necessary to research its moisture types. It is generally considered that the moisture in organic waste may be categorized into four types, i.e., free water, adsorbed water or surface water, interstitial water or capillary water, and cell water or bound water, as done for sewage sludge (Tsang and Vesilind 1990), and can be measured by thermal gravity–differential thermal analysis (TG–DTA) (Katsiris and Kouzeli-Katsiri 1987; Willard et al. 1988) and thermal drying method (Smollen 1986). Moisture content is the key factor influencing the performance of sludge incineration, including combustion completeness, energy recovery and pollutant emission (Xiao et al. 2015). Before mechanical dehydration of municipal sludge, some pretreatments are usually used to strengthen its dehydration property. The main pretreatment methods include chemical conditioning (Mahmood and Elliott 2007; Novak 2006), hydrothermal treatment (Neyens and Baeyens 2003; Jomaa et al. 2003) and ultrasound treatment (Dewil et al. 2006; Bien et al. 1997).

There are many reagents that can be used for deep dewatering. Calcium oxide, a conventional dewatering reagent, is usually applied into municipal sludge for strengthening the process of dehydration and raising the thermal drying efficiency. General speaking, drying the sludge with 80% moisture content by adding CaO (sludge: CaO = 10:3, w/w) can raise the drying rate by 20%, compared with sludge only. Persulfate is also used as oxidant for strengthening dehydration of sewage sludge. Persulfate salt is stable under the ordinary condition. However, under the condition of heating, irradiation with light and transition metal ions (Fe2+, Cu2+, Ag+, Mn2+), persulfate can be activated and produces SO4-· and ·OH. Under the ordinary temperature and pH 3.0–8.5, persulfate is used to treat sludge activated by Fe2+, and the dehydration performance of organic waste and sludge can be thus improved (Zhen et al. 2012).

Bottom ash is a by-product from municipal solid waste incineration (Wiles 1995), mainly composed of slag, black and nonferrous metals, ceramic chips, glass and other non-combustible organic matter (Zhu et al. 2020). Although the presence of heavy metals confines the use of bottom ash in further applications, some of it is used in applications such as road subbase material, aggregate in concrete, clay brick and pavement, but most are currently landfilled (Loginova et al. 2021; Zhu et al. 2019). The incineration bottom ash of sludge was used with CPAM (cationic polyacrylamide) to dewater the sludge, and the result showed that its effect of dehydration was better than any single reagent (Ning et al. 2013). The effects of CaO, coal ash, diatomite, sodium dodecyl sulfate and municipal solid waste incineration fly ash on dehydration of sludge were compared, and it was found that the dehydration effect of CaO was the best and next were coal ash, diatomite, sodium dodecyl sulfate and municipal solid waste incineration fly ash, respectively (Zhu et al. 2012).

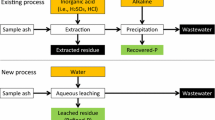

The purpose of this study was to research the deep dewatering of organic waste bio-residue for the improvement of low calorific value, which was convenient for incineration. The moisture form of bio-residue was studied by thermal drying, vacuum filtration and thermal gravity analysis. The effects of CaO, Fe(0)-K2S2O8, bottom ash and fly ash powder on deep dewatering of bio-residue were compared, and different dosages of bottom ash powder’s influence on deep dewatering of bio-residue were analyzed in detail, combining with XPS analysis of bottom ash powder. Finally, the bio-residue treated with bottom ash powder was observed under the electron microscope after drying, for making the mechanism of deep dewatering clear. Meanwhile, economic analysis was given for estimating reagents’ benefits.

Materials and methods

Materials

The original bio-residue is in slurry and sent to the treatment process after treated by polyacrylamide. The bio-residue used in this study, which was black and smelly, was collected from the end centrifugal dehydrator of bio-residue treatment process line in an organic waste anaerobic digestion plant in Shanghai, China. The characteristics of original bio-residue treated by polyacrylamide are shown in Table 1. It can be seen that the moisture content of bio-residue was about 78.4% and the organic matter content of dried bio-residue was about 42.0%, with predominant elements C and O of 20.4% and 29.5%, respectively. The low calorific value of dried bio-residue was 13.32 MJ/kg, much higher than that required for incineration, and was increased much after drying.

The main reagents, including calcium oxide (CaO), iron powder (Fe0) and potassium persulfate (K2S2O8) were purchased from Aladdin deposits in Shanghai, China. All reagents were of analytical grade and used without any pretreatment. Bottom ash and fly ash were taken from a municipal solid waste incineration plant and pretreated into powder (60–80 mesh) by the crusher.

Experimental design

Reagents comparison

The pre-experiment for bio-residue’s deep dewatering was conducted in 1000-mL plastic containers, and each container contained 500 g of bio-residue. Four experiment groups with 2.0% dosage of different dewatering reagents were set for investigating each reagent’s dewatering capacity. The bio-residue and reagents were mixed fully, and all the containers were placed in a calm place for 14 days, avoiding disturbed by wind. The treated bio-residue were sampled in two copies every other day, and one copy of the samples was dried in the oven with 101 ℃-105 ℃ until a constant weight is reached, with the weights recorded before and after drying. The other copy of the samples was used for low calorific value test. For avoiding reagents reacting directly, the iron powder and potassium persulfate were added in order, and their proportions were based on the reaction of Eq. (1):

Bottom ash curing

The detailed curing experiments for bio-residue’s deep dewatering by bottom ash powder were conducted on hollowing boards, which would not let the bio-residue leak through the hole. Five experiment groups were set with dosage of 1.0%, 2.0%, 3.0%, 4.0% and 5.0%, respectively. Each hollowing board loaded 100 g bio-residue, which was mixed fully with bottom ash powder, and the treated bio-residues were made into cubes (about 5 cm × 5 cm × 2 cm). Also, all the hollowing boards were placed above a vacant plastic container in a calm place for 14 days, avoiding disturbed by wind. The bio-residue were sampled in two copies every other day, and one copy of the samples was dried in the oven with 101 ℃-105 ℃ until reaching a constant weight, with the weights recorded before and after drying. The other copy of the samples was used for low calorific value test.

Analytical methods

Most of the moisture content in bio-residue was measured by the oven (DHG-9240A) with 101 ℃-105 ℃. In order to obtain the contents of different moisture forms, three steps were conducted: i) thermal drying was used for the measurement of the whole moisture except for bound water. ii) Vacuum filtration was used for the measurement of capillary water. 100 g of bio-residue was compacted in the Büchner funnel in the form of pie. The vacuum pump (SHZ-D(\(\mathrm{III}\))) was connected with Büchner funnel and carried on until the vacuum degree of filtration container became zero. iii) Thermal gravity analysis was used for the measurement of bound water.

For evaluating the effect of reagents on bio-residue incineration performance, low calorific values were tested and analyzed. In this study, 1.0 g samples was taken to the automatic calorimeter (ZDHW-6L) for measurement. In order for comparison, the low calorific value of original bio-residue treated by polyacrylamide was also tested and analyzed during the bottom ash powder curing experiment.

Organic matter content of bio-residue was measured by weighing method with the muffle furnace (SX2-5-12Y). After treated by bottom ash powder, the bio-residue was dried and observed for its microstructure by electron microscope (Phenom Pro). The X-ray photoelectron spectroscopy (XPS) characterizations of bottom ash and fly ash powder were done with a Kratos AXIS 165 electron spectrometer with monochromatic AlKa radiation at 100 W, and high-resolution measurements in S 2p, Cl 2p, K 2p, Ca 2p, O 1 s, F 1 s, Zn 2p and Na 1 s regions were taken. Thermal analysis (TGA-DTG) of bio-residue was recorded on a thermal analysis system (Q600 SDT; TA Instruments, USA) over a temperature range of 25–600 °C with a heating rate of 5 °C/min in an N2 stream. Elemental analysis of N, C, H, S and O of bio-residue was performed using an elemental analyzer (Vario EL III, Germany).

Results and discussion

Moisture existence forms in bio-residue

The vacuum filtration experiments were conducted in triplicate, and the results are shown in Table 2. The weight of moisture removed by filtration was about 20 g, which cannot be removed easily by gravity. Drawing on the experience of sludge’s moisture form, the capillary water in sludge could be removed by negative pressure (vacuum filter). Therefore, this part of moisture in bio-residue was identified as capillary water.

For analyzing the moisture form in bio-residue, thermo-gravimetric analysis of dried bio-residue was conducted, and the result is shown in Fig. 1. When the temperature reached 306.96 ℃, the \(\frac{dw}{dT}\) reached the maximum value and the dried bio-residue started to burn. The dewatering happened between 162.90 ℃ and 213.74 ℃, and the weight loss was about 3.16% of bio-residue (dry basis). According to the moisture content of bio-residue (wet basis), the weight loss between 162.90 ℃ and 213.74 ℃ was about 0.58% of the whole moisture in bio-residue. This part of moisture could not be removed by low-temperature thermal drying, which was identified as bound water. Bio-residue, coming from digested organic waste, was different from municipal sludge. Due to the utilization of polyacrylamide for dewatering, it can adsorb moisture and form colloid, which makes a large amount of moisture stored in the polyacrylamide colloid as adsorbed water. Therefore, the moisture in bio-residue could be classified into adsorbed water, capillary water and bound water, which occupied 75.61%, 23.81% and 0.58%, respectively.

Dewatering capacity of different reagents

In bio-residue, the moisture was classified into adsorbed water, capillary water and bound water, which occupied 75.61%, 23.81% and 0.58%, respectively. Among these moisture types, adsorbed water had the largest proportion, which was the most possible moisture to be dewatered. The content of bound water was small, which could be ignored in practical engineering. The adsorbed water and capillary water were the main impediments for bio-residue’s dewatering and were removed hardly before treated by reagents.

The variations of moisture content and low calorific value with different dewatering reagents at the dosage of 2.0% were conducted. Figure 2(a) shows that at the dosage of 2.0%, the moisture content decreased over the curing time. At the 4th d, the moisture contents of four groups with CaO, bottom ash powder, fly ash powder and Fe(0)-K2S2O8 were 69.17%, 61.34%, 72.00% and 65.39%, respectively, and bottom ash powder’s excellent dewatering capacity was justified. After 8-day curing, the moisture content of four groups decreased sharply and reached 67.94% (CaO), 66.20% (bottom ash powder), 71.50% (fly ash powder) and 68.84% (Fe(0)-S2O82−) at the 8th d, respectively. Taking CaO group as example, the moisture content of bio-residue decreased from 78.4% to 43.3% after 14-day treatment. The moisture loss was about 40.34 g, accounting for 51.5% of the whole moisture. According to the moisture proportion and characteristics of bio-residue, the dewatering treatment mainly removed the adsorbed water in bio-residue.

After CaO was mixed with bio-residue, which reacted with moisture in bio-residue, the calcium hydroxide (Ca(OH)2) was generated. Both CaO and Ca(OH)2 started to absorb carbon dioxide in the air over time, as shown in Eq. (2) and (3). Therefore, the weight loss can only reflect a part of dewatering effect.

According to the XPS analysis, the fly ash powder used in pre-experiment mainly contained Na3PO4, Na2SO4 and CaSO4, which could react with water by forming Na3PO4·12H2O, Na2SO4·10H2O and CaSO4·2H2O. These reactions are exothermic, shown as Eq. (4)-(6), and could help the evaporation of moisture. Although the fly ash powder was conducive to the release of moisture, most of which the existence form was bound water in the hydrates of inorganic salts and could not be dewatered by volatilization easily. The low calorific value of treated bio-residue was affected by the existence of hydrates, which was consistent with the results of low calorific value test.

The dewatering effect of Fe(0)-K2S2O8 ranged between the bottom ash powder and CaO. Persulfate is a strong and non-selective oxidant with a high redox potential of 2.01 V. It can be effectively activated by initiators including heat, UV light or transition metals (Men+) to generate sulfate free radicals (SO4−·) which has an even higher redox potential estimated to be 2.60 V. Some of the reaction during activation of S2O82− may be expressed as Eq. (7)-(10) (Yan et al. 2011; Oh et al. 2009, 2010; Zhen et al. 2012).

Similar to fly ash powder, the dewatering capacity of bottom ash powder could be explained preliminarily that some inorganic salts in the bottom ash powder could react with moisture in bio-residue and achieve the transfer of moisture from bio-residue to inorganic salts. These reactions are exothermic, which can help the evaporation of moisture. However, different from CaO, bottom ash powder has little effect on low calorific value. Meanwhile, the inorganic salts in fly ash powder could bind more moisture than bottom ash powder, affecting its evaporation. The results suggested that bottom ash powder was a preferred dewatering reagent, and more mechanisms will be analyzed in detailed experiments.

The low calorific value is associated with moisture and organic contents. Figure 2(b) shows that the low calorific value was related to moisture content and dewatering reagents greatly. With the decrease in the moisture, the low calorific value increased. At the 4th d, the low calorific values of bio-residue with CaO, bottom ash powder, fly ash powder and Fe(0)-K2S2O8 were 1872 kJ/kg, 1424 kJ/kg, 1066 kJ/kg and 976 kJ/kg, respectively. After treated for 8 days, the low calorific values increased gently, and at the 14th d, the low calorific values of bio-residue with CaO, bottom ash powder, fly ash powder and Fe(0)-K2S2O8 were 9697 kJ/kg, 10,544 kJ/kg, 10,163 kJ/kg and 10,873 kJ/kg, respectively. Although the low calorific value had a positive correlation with dosage at the 8th d, it was mainly affected by the moisture content, due to the dewatering effect of CaO. With the increase in the dosage, the dewatering effect got better in the middle phase of treatment.

Dewatering capacity of bottom ash with different dosages

The detailed curing experiments for bio-residue’s deep dewatering by bottom ash powder with different dosages were conducted, and the variations of moisture content and low calorific value are shown in Fig. 3. During the curing experiments, there was no leakage of moisture.

Moisture content and low calorific value variation of bio-residue treated with different dosages of bottom ash powder (a, b, c, d, e and f represent the dosages of 0%, 1.0%, 2.0%, 3.0%, 4.0% and 5.0%; (a-1), (b-1), (c-1), (d-1), (e-1) and (f-1) represent the moisture content and low calorific value variations of bio-residue; and (a-2), (b-2), (c-2), (d-2), (e-2) and (f-2) represent the fitting relation law of bio-residue’ moisture content and low calorific value)

Figure 3(a-1) shows the dewatering performance of bio-residue without reagents. In the first 6 days of curing, the bio-residue’s moisture content descended slowly, and its low calorific value maintained about 2.0 MJ/kg. With the decrease in the moisture content, the low calorific value was increased obviously. After 14-day treatment, the moisture content declined to about 30% and corresponding low calorific value raised to about 10.0 MJ/kg, which was suitable for incineration without affecting the operation of incineration plant. Combined with the dried bio-residue’s combustion low calorific value (13.3 MJ/kg), the fitting curve of bio-residue’ moisture content and low calorific value is given, as shown in Fig. 3(a-2), which fitted Boltzmann equation and its image was like S-shaped curve. When the moisture content was over 45%, the low calorific value raised fast with the decrease in the moisture content. With the moisture content going down to 45%, the low calorific value raised slowly and reached a stable value when the moisture came to about 30%, over 10.0 MJ/kg.

Figure 3(b ~ f) confirms that bottom ash powder contributed to the deep dewatering of bio-residue in detail. After 10-day curing, bio-residue’s moisture content decreased to about 40% and its low calorific value raised to over 8.0 MJ/kg. When the dosage of bottom ash powder was 2.0%, the final dewatering efficiency after 14 days was better than that of 1.0%, and its low calorific value maintained stably over 10.0 MJ/kg from the 10th d. When the dosage of bottom ash was 3.0%, the dewatering rate was accelerated as shown in Fig. 3(d-1). Compared with the dosage of 1.0% and 2.0%, the final low calorific value declined because the bottom ash powder had no calorific value. With the increase in the bottom ash powder dosage, low calorific value decreased at the same moisture content. The high dosage could promote the deep dewatering of bio-residue, but affect the final low calorific value more obviously. The fitting function is shown as Eq. (11) and their specific parameters of different dosages are shown in Table 3.

where \(Q\), \(\Delta Q\), \({Q}_{0}-\) low calorific value, kJ/kg.

\(w\) – moisture content, %

In Eq. (11), ω represents the critical point of Boltzmann equation. When the value of moisture content was bigger than ω, low calorific value was relatively low, and raised fast with the decrease in the moisture content. With the value of moisture content getting smaller than ω, low calorific value raised slowly and reached a stable value gradually. The sum of \(\Delta Q\) and \({Q}_{0}\) represents the theoretical maximum low calorific value. Table 3 easily shows that with the increase in the bottom ash powder dosage, the theoretical maximum low calorific value declined gradually.

With the increase in the bottom ash powder dosage, the low calorific value at the 14th d was declined, illustrating that bottom ash powder will affect incineration of bio-residue. When the dosage of bottom ash powder was 2.0%, the moisture of bio-residue could be decreased to about 50% and the corresponding low calorific value reached 10.79 MJ/kg at the 10th d from the original 0 MJ/kg. Based on the above experiment, 2.0% dosage of bottom ash powder addition indicated an excellent effect on deep dewatering of bio-residue.

Decoupling of moisture in bio-residue

Chemical composition of bottom ash powder

Figure 4(a) shows the survey of XPS spectra for bottom ash powder, which exhibited S, Cl, C, K, Ca, O, F, Zn and Na signals. Figure 4(b-i) compiles the high-resolution surface spectra of S, Cl, K, Ca, O, F, Zn and Na recorded on bottom ash powder sample.

The high-resolution surface spectra of S included four peaks with binding energy of 169.5 eV, 170.7 eV, 169.1 eV and 170.3 eV. The binding energy of 169.5 eV and 170.7 eV represented S 2p3/2 peak and S 2p1/2 peak in ZnSO4, and the binding energy of 169.1 eV and 170.3 eV represented S 2p3/2 peak and S 2p1/2 peak in K2SO4. The high-resolution surface spectra of Cl included four peaks. The binding energy of 198.5 eV and 200.1 eV represented Cl 2p3/2 peak and Cl 2p1/2 peak in NaCl, and the binding energy of 198.8 eV and 200.4 eV represented Cl 2p3/2 peak and Cl 2p1/2 peak in ZnCl2. Two peaks were visible in the spectra of K 2p with the binding energy of 296.2 eV and 293.5 eV, which belonged to K 2p1/2 peak and K 2p3/2 peak in K2SO4. The high-resolution surface spectra of Ca included two peaks with binding energy of 351.1 eV and 347.5 eV, which represented Ca 2p1/2 peak and Ca 2p3/2 peak in CaCO3. The high-resolution surface spectra of F 1 s included only one peak with binding energy of 685.1 eV, which represented ZnF2. The high-resolution surface spectra of Zn 2p included six peaks. The binding energy of 1023.0 eV and 1046.0 eV represented Zn 2p3/2 peak and Zn 2p1/2 peak in ZnSO4, the binding energy of 1021.9 eV and 1044.9 eV represented Zn 2p3/2 peak and Zn 2p1/2 peak in ZnCl2, and the binding energy of 1022.2 eV and 1045.2 eV represented Zn 2p3/2 peak and Zn 2p1/2 peak in ZnF2. The high-resolution surface spectra of Na 1 s included only one peak with a binding energy of 1072.3 eV, which represented NaCl. The results confirmed that the bottom ash powder mainly contained NaCl, K2SO4, CaCO3, ZnSO4, ZnF2 and ZnCl2.

Dewatering mechanism

The dewatering mechanism was analyzed, combined with XPS analysis of the bottom ash powder. ZnCl2 in bottom ash powder can react with moisture in bio-residue and achieve the transfer of moisture from bio-residue to ZnCl2, and the reaction is shown as Eq. (12).

ZnSO4 can also react with moisture by forming ZnSO4·7H2O and this reaction is exothermic, which can help the evaporation of moisture. The reaction is shown as Eq. (13). The bottom ash powder can react with moisture in bio-residue and realize the dewatering efficiently, and different from fly ash, the amount of moisture that bottom ash powder can react with was relatively limited, influencing low calorific value slightly.

Figure 5 shows the microstructure of treated bio-residue under the electron microscope, with the decoupling mechanism of moisture. Figure 5(a) shows that after treated by polyacrylamide, the bio-residue was packed by polyacrylamide colloid and presented a steric reticular structure. After treated by bottom ash powder further, the packed polyacrylamide colloid began to spalling and the strip fiber structure could be observed clearly. This appearance got more obvious with the increase in the bottom ash powder’s dosage, which is shown in Fig. 5(b-f).

The decoupling mechanism of moisture in bio-residue is shown in Fig. 5(g). The decomposition of polyacrylamide colloid was related to the addition of bottom ash powder. As analyzed by XPS, the bottom ash powder mainly contained NaCl, K2SO4, CaCO3, ZnSO4, ZnF2 and ZnCl2. After adding bottom ash powder, the bio-residue treated by PAM was bound up and adhered with bottom ash powder. These inorganic salts in bottom ash powder were electrolyte, which could accelerate the hydrolysis and destruction of polyacrylamide colloid with the moisture itself contained firstly. After the polyacrylamide colloid was broken, the moisture in colloid was exposed and began to release into the air by evaporation. Furthermore, it could be observed that when the dosage of bottom ash powder was over 2.0%, the spalling degrees of polyacrylamide colloid were similar, which meant 2.0% dosage of bottom ash powder was enough for the hydrolysis and destruction of polyacrylamide colloid, indirectly proving that 2.0% dosage of bottom ash powder has the best effect on deep dewatering of bio-residue.

Economic analysis of reagents

The conventional dewatering reagents include CaO and Fe(0)-K2S2O8. Take the treatment with 2% dosage as example, different reagents’ 10-day dewatering efficiencies are shown in Table 4. CaO had the best 10-day dewatering efficiency among four reagents, followed by bottom ash powder, about 21.84%. Fe(0)-K2S2O8 has the worst 10-day dewatering efficiency among four reagents, followed by fly ash powder, about 17.08%. According to the cost of reagents and their dewatering efficiencies, the dewatering capacity cost can be calculated and the results are also shown in Table 4.

Compared with bottom ash and fly ash powder from municipal solid waste incineration plant, the dewatering capacity cost of CaO and Fe(0)-K2S2O8 reagents were higher. Although they had a certain dewatering efficiency, the high costs restricted their application in deep dewatering of bio-residue. On the one hand, although the dewatering efficiency of fly ash powder was close to bottom ash powder, fly ash powder had greater impact on low calorific value of treated bio-residue, which was not convenient for the operation of incineration plant. As a consequence, municipal solid waste incineration (MSWI) fly ash categorized as a hazardous material must be managed and regulated more scientifically and effectively, which is not suitable for deep dewatering of treated bio-residue (Li et al. 2018). On the other hand, due to the source from municipal solid waste incineration plant, bottom ash has characteristics of huge yield and harmless. As estimated, the incineration of one-ton solid waste generates approximately 250-300 kg of bottom ash (Tan et al. 2022). Therefore, bottom ash powder is the best reagent for organic waste bio-residue’s deep dewatering.

Conclusion

Organic waste bio-residue should be deep dewatered before incineration. The moisture existence forms of bio-residue were clarified as adsorbed water, capillary water and bound water, which occupied 75.61%, 23.81% and 0.58%, respectively. Furthermore, refuse incineration bottom ash powder was used as a typical deep dewatering reagent, when compared with CaO, refuse incineration fly ash powder and Fe(0)-K2S2O8. Results showed that the addition of bottom ash powder could decrease the bio-residue’s moisture from 80.0% to 37.9% at the optimal dosage of 2.0%, and corresponding low calorific value reached 10.5 MJ/kg at the 10th d. The ZnCl2 and ZnSO4 present in bottom ash powder could react with moisture in bio-residue to form hydrates of inorganic salt and break polyacrylamide colloid, realizing the release of adsorbed water in bio-residue via water evaporation accelerated by exothermic process.

Data availability

Not applicable.

References

Arun C, Sivashanmugam P (2017) Study on optimization of process parameters for enhancing the multi-hydrolytic enzyme activity in garbage enzyme produced from preconsumer organic waste. Bioresour Technol 226:200–210

Bien JB, Kempa ES, Bien JD (1997) Influence of ultrasonic field on structure and parameters of sewage sludge for dewatering process. Water Sci Technol 36:287–291

Chen Y, Xu L, Tan SN, Sun X, Deng Y, Yang W (2020) Solidification and multi-cytotoxicity evaluation of thermally treated MSWI fly ash. J Hazard Mater 388:122041

Dewil R, Baeyens J, Goutvrind R (2006) The use of ultrasonics in the treatment of waste activated sludge. Chinese J Chem Eng 14:105–113

Guo H, Wu S, Tian Y, Zhang J, Liu H (2021) Application of machine learning methods for the prediction of organic solid waste treatment and recycling processes: A review. Bioresour Technol 319:124114

Hu E, Li M, Tian Y, Yi X, Dai C, Shao S, Li C, Zhao Y (2022) Pyrolysis behaviors of anaerobic digestion residues in a fixed-bed reactor with rapid infrared heating. Environ Sci Pollut R. https://doi.org/10.1007/s11356-022-19558-4

Jomaa S, Shanableh A, Khalil W, Trebilco B (2003) Hydrothermal decomposition and oxidation of the organic component of municipal and industrial waste products. Adv Environ Res 7(3):647–653

Katsiris N, Kouzeli-Katsiri A (1987) Bound water content of biological sludge in relation to filtration and dewatering. Water Res 21(11):1319–1327

Li J, Zeng M, Ji W (2018) Characteristics of the cement-solidified municipal solid waste incineration fly ash. Environ Sci Pollut R 25:36736–36744. https://doi.org/10.1007/s11356-018-3600-z

Li H, Ni D, Li L, Dong B, Chen Q, Gu L (2020) Insight into the role of polyacrylamide polymer powder on the cracking in plastic period of cement mortar. Constr Build Mater 260:119914

Loginova E, Schollbach K, Proskurnin M, Brouwers H (2021) Municipal solid waste incineration bottom ash fines: Transformation into a minor additional constituent for cements. Resour Conserv Recy 166:105354

Mahmood T, Elliott A (2007) Use of acid preconditioning for enhanced dewatering of wastewater treatment sludges from the pulp and paper industry. Water Environment Resource 79:168–176

Mata-Alvarez J, Macé S, Llabrés P (2000) Anaerobic digestion of organic solid wastes. An overview of research achievements and perspectives. Bioresour Technol 74(1):3–16

Neyens E, Baeyens J (2003) A review of thermal sludge pre-treatment processes to improve dewaterability. J Hazard Mater B98:51–67

Ning X, Luo H et al (2013) Effect of tannery sludge incineration slag pretreatment on sludge dewaterability. Chem Eng J 221:1–7

Novak JT (2006) Dewatering of Sewage Sludge Dry Technol 24:1257–1262

Oh SY, Kim HW, Park JM, Park HS, Yoon C (2009) Oxidation of polyvinyl alcohol by persulfate activated with heat, Fe2+, and zero-valent iron. J Hazard Mater 168(1):346–351

Oh SY, Kang SG, Chiu P (2010) Degradation of 2, 4-dinitrotoluene by persulfate activated with zero-valent iron. Sci Total Environ 408(16):3464–3468

Singh R, Sharma B, Sarkar A, Sengupta C, Singh P, Ibrahim M (2014) Biological responses of agricultural soils to fly ash amendment. Rev Environ Contam T 232:45–60

Smollen M (1986) Categories of moisture content and dewatering characteristics of biological sludges, in Proceeding of the 4th World Filtration Congress, Belgium, Ostend: 22–25

Šyc M, Simon FG, Hykš J, Braga R, Biganzoli L, Costa G, Funari V, Grosso M (2020) Metal recovery from incineration bottom ash: state-of-the-art and recent developments. J Hazard Mater 393:122433

Tan J, Dan H, Li J (2022) Use of municipal waste incineration fly ashes (MSWI FA) in metakaolin-based geopolymer. Environ Sci Pollut R. https://doi.org/10.1007/s11356-022-21580-5

Tella M, Doelsch E, Letourmy P, Chataing S, Cuoq F, Bravin MN, Macary HS (2013) Investigation of potentially toxic heavy metals in different organic wastes used to fertilize market garden crops. Waste Manage 33(1):184–192

Tsang K, Vesilind P (1990) Moisture distribution in sludges. Water Sci Technol 22(12):135–142

Wan S, Zhou X, Zhou M, Han Y, Chen Y, Geng J, Wang T, Xu S, Qiu Z, Hou H (2018) Hydration characteristics and modeling of ternary system of municipal solid wastes incineration fly ash-blast bottom ash-cement. Constr Build Mater 180:154–166

Wei Y, Wang N, Lin Y, Zhan Y, Ding X, Liu Y, Zhang A, Ding G, Xu T, Li J (2021) Recycling of nutrients from organic waste by advanced compost technology – A case study. Bioresour Technol 337:125411

Wiles CC (1995) Municipal solid waste combustion ash: state of the knowledge. J Hazard Mater 3894:20

Willard H, Merritt L, Dean JA (1988) Instrumental methods of analysis, in, 7th edn. Wadsworth Inc, Belmont Calif

Xiao Z, Yuan X, Jiang L, Chen X, Li H, Zeng G et al (2015) Energy recovery and secondary pollutant emission from the combustion of co-pelletized fuel from municipal sewage sludge and wood sawdust. Energy 91:441–450

Yan J, Lei M, Zhu L, Anjum MN, Zou J, Tang H (2011) Degradation of sulfamonomethoxine with Fe3O4 magnetic nanoparticles as heterogeneous activator of persulfate. J Hazard Mater 186(2–3):1398–1404

Yu Q, Feng L, Zhen X (2020) Effects of organic loading rate and temperature fluctuation on the microbial community and performance of anaerobic digestion of food waste. Environ Sci Pollut R 28:13176–13187. https://doi.org/10.1007/s11356-020-11548-8

Zhao Y, Wei R (2020) <Biomethane Production from Vegetable and Water Hyacinth Waste>, Elsevier Publisher Inc. (Oxford OX5 1GB, United Kingdom and Cambridge, MA 02139, United States)

Zhen GY, Lu XQ, Hao YC et al (2012) Enhanced dewaterability of sewage sludge in the presence of Fe(II)-activated persulfate oxidation. Bioresour Technol 116:259–265

Zhu F, Jiang H et al (2012) Research on drying effect of different additives on sewage sludge. Procedia Environ Sci 16:357–362

Zhu W, Teoh PJ, Liu Y, Chen Z, Yang EH (2019) Strategic utilization of municipal solid waste incineration bottom ash for the synthesis of lightweight aerated alkali-activated materials. J Clean Prod 235:603–612

Zhu Y, Zhao Y, Zhao C, Gupta R (2020) Physicochemical characterization and heavy metals leaching potential of municipal solid waste incineration bottom ash (MSWI-BA) when utilized in road construction. Environ Sci Pollut R 27:14184–14197. https://doi.org/10.1007/s11356-020-08007-9

Acknowledgements

We thank the financial support of the foundations of the Shanghai Committee on Science and Technology's Social Development Program and the National Natural Science Foundation of China. We also gratefully acknowledge the assistance from the organic waste anaerobic digestion plant providing experiment materials.

Funding

This work was financially supported by the Social Development Program of Science and Technology Committee Foundations of Shanghai (No. 19DZ1204703) and the National Natural Science Foundation of China (No. 51908380).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation and data collection were performed by Ruina Zhang and Lijie Song, and analysis was performed by Xiong Zhou, Shunhong Lin and Youcai Zhao. The first draft of the manuscript was written by Ran Wei, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing Interests

The authors declare that they have no competing interests.

Additional information

Responsible Editor: Ta Yeong Wu

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wei, R., Zhang, R., Song, L. et al. Incineration disposal of organic waste bio-residue via a deep dewatering process using refuse incineration bottom ash: moisture transfer and low calorific value improvement. Environ Sci Pollut Res 29, 78107–78119 (2022). https://doi.org/10.1007/s11356-022-22645-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-22645-1