Abstract

In this study, copper oxide nanoparticles (CuONPs) were prepared by a simple chemical method and then characterized by scanning electron microscope (SEM). A novel electrochemical sensor for hydrogen peroxide (H2O2) analysis was prepared by immobilizing copper oxide nanoparticles and polyalizarin yellow R (PYAR) on bare glassy carbon electrode (PAYR/CuONPs/GCE). The electrocatalytical behavior of the proposed electrochemical sensor was also studied by cyclic voltammetry (CV), electrochemical impedance spectroscopy (EIS), and differential pulse voltammetry (DPV). Based on the results, the PAYR/CuONP nanocomposite had significant electrocatalytic oxidation and reduction properties for the detection and determination of H2O2. Some parameters such as linear range, sensitivity, and detection limit for reduction peak were obtained as 0.1–140 μM, 1.4154 μA cm−2 μM−1, and 0.03 μM, respectively, by the DPV technique. Some advantages of this electrode were having widespread linear range, low detection limit, and, most importantly, ability in simultaneous oxidation and reduction of H2O2 at two applied potentials.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Hydrogen peroxide (H2O2) has been widely applied in various fields such as paper and textile bleaching, microbial control characteristics, foodstuff, environmental approaches, cosmetics, and pharmaceutical activities [Pandurangan et al. 2014; Thanh et al. 2016]. Furthermore, H2O2 is widely used to oxidize cellulose, recycle wastepaper, treat wastewaters, boost rocket fuels, produce a variety of chemicals and plastics, and detoxify organic pollutants that might contaminate the environment [Marjan et al. 2019]. It is also an essential material in several enzymatic reactions in the biological system [Zhang and Chen 2017]. The H2O2 layer is the first defense of the immune system against various pathogens. However, the surplus leakage of H2O2 in biological species has a harmful effect on the body which can cause irritation of stomach and skin as well as damage to the gastrointestinal tract and proteins [Yusoff et al. 2017]. Moreover, it has been documented that excess amounts of this compound in the body causes a variety of diseases such as DNA fragmentation, Alzheimer’s, Parkinson’s, diabetes, membrane damage, neurodegeneration, tissue damage, cancer, cardiovascular, and aging problems (Sahoo et al. 2020; Lutfullah and Muhammet 2019). Furthermore, according to the US Food and Drug Administration (FDA), the H2O2 tolerance limit as an anti-microbial agent for vegetables, fruits, herbs, and spices is 120 mg/L [Parthasarathy et al. 2016]. Therefore, the determination of H2O2 is of great importance in both biological and environmental processes. There are several analytical techniques such as spectroscopy and chromatography which are available for the determination of H2O2. However, these methods require much time as well as a lot of cost and show poor repeatability [Liu et al. 2017; Wu et al. 2017]. Compared to previous techniques, electrochemical tools have much attention from researchers owing to their simplicity, low cost, low detection limit, and high sensitivity. Moreover, in both enzymatic and non-enzymatic processes, electrochemical methods are feasible [Devasenathipathy et al. 2016; Wang et al. 2011].

The electrochemical determination of hydrogen peroxide on the surface of bare electrodes is a very slow process. To solve this problem, the surface of these electrodes should be modified using various compounds such as enzymes [Díaz Nieto et al. 2018], conductive polymers [Zhang et al. 2011], and metals and bimetals [Devasenathipathy et al. 2016; Chao et al. 2016; Chen et al. 2016; Ensafi et al. 2016; Sookhakian et al. 2017; Abdelwahab and Shim 2014; Guler et al. 2018]. The literature review revealed that metal oxide–based electrochemical sensors such as NiO, ZnO, Fe2O3, Co3O4, and CuO have some advantages such as ease of preparation, low cost, good electrocatalytic properties, and capability of conducting electrochemical reactions at lower potentials. Among them, copper oxide is one of the best materials due to its excellent redox property, non-toxicity, and high stability and conductivity [Xie et al. 2018; Ehsani et al. 2017; Kardaş et al. 2017]. Conducting polymers have been used as a modifier for fabrication of electrochemical sensors [Doblhofer 1980]. These polymers have the benefits of good stability, high conductivity, and considerable stability on the surface of electrodes. Some specific monomers of these polymers have been applied to prepare electrochemical sensors such as neutral red [Shobha Jeykumari and Narayanan 2008; Yogeswaran and Chen 2007; Zhang and Zhang 2010], toluidine blue [Zeng et al. 2006], alizarin red S [Wu and Hu 2004], Congo red [Hu et al. 2006, 2007a, b], Nile blue A [Du et al. 2008], thionine [Zhang et al. 2010], pyrocatechol violet [Sheng et al. 2007], and alizarin yellow R [Zhang et al. 2011]. The formed composite film through amalgamating conductive polymers with other materials such as nanoparticles as a modifier is proposed for the construction of these sensors. For instance, carbon nanotube/poly (alizarin red S) and multiwall carbon nanotube/alizarin were used for detection of nitrite and kojic acid, respectively [Yue et al. 2010; Liu et al. 2009]. One of the conductive polymers is alizarin yellow R (AYR) and is applied as a pH and metallochromic indicator [Williams and Lautenschleger 1963; Ihara et al. 2008]. Therefore, in the current research, an electrode modified with CuO nanoparticles and polyalizarin yellow R was fabricated for hydrogen peroxide monitoring. The combination of polyalizarin yellow R (a conductive polymer on the electrode surface) and CuONps (high surface and conductivity) exhibited excellent electrocatalytic activity for the electrooxidation and electroreduction of hydrogen peroxide. This proposed electrochemical sensor was applied to detect and determine hydrogen peroxide in milk samples with satisfactory results.

Materials and methods

Materials

Hydrogen peroxide, copper (II) sulfate pentahydrate, alizarin yellow R, hydrochloric acid (HCl), phosphoric acid (H3PO4), sodium sulfate (Na2SO4), sodium hydrogen phosphate, and sodium hydroxide (NaOH) were obtained from Merck.

Apparatus

All experiments and electrochemical measurements were performed using a μ-autolab device (model 101 made by Metrohm). A three-electrode system consisting of a platinum (Pt) counter electrode, a glassy carbon working electrode (GCE), and an Ag/AgCl[KCl(sat)] reference electrode was placed in the electrochemical cell.

Preparation of copper oxide nanoparticles (CuONPs)

The copper oxide nanoparticles were prepared by a simple chemical technique. First, 1 mL of Na2SO4 (0.1 M) was added to 17 mL of CuSO4 (0.005 M), and then mixed well and shaken for 120 min at 25 °C.

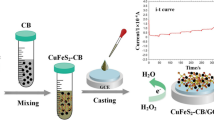

Construction of the modified electrode

The bare glassy carbon electrode was polished continuously using sandpaper (nos. 1–6) and 0.5 mm of alumina slurry to remove contaminants from the electrode surface. Next, the surface of the electrode was sonicated in a mixture of ethanol and distilled water for 5 min to remove adsorbed particles and then washed using distilled water. For the modification of the electrode, the electropolymerization of alizarin yellow R (1 mM) was carried out in the range of potential −1.0 to 1.2 V at a scan rate 100 mV/s and at pH 12 (Fig. 1).

The reduction and oxidation peak currents increased with continuous scanning number (20 cycles), illustrating the successive growth of alizarin yellow R on the surface of the glassy carbon electrode.

For the fabrication of PYAR/CuONPs/GCE, the PYAR/GCE was immobilized in a mixture of Na2SO4 and CuSO4. Then, the cyclic voltammetry (CV) method was applied under 10 scanning cycles at the potential range between −1 and +1 V and at a scan rate of 100 mV/s for depositing CuO nanoparticles on the surface of the electrode (Fig. 1B).

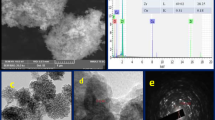

Characterization of poly (alizarin yellow R)-CuONPs/GCE

Figure 2A shows the SEM image of the synthesized nanoparticles. The average particle size was less than 70 nm, which lies in the range of nanomaterials.

Results and discussions

Electrochemical characterization of PYAR/CuONPs/GC electrode

In order to obtain information of electrochemical characterization as well as study electrochemical manner through the step-by-step promotion process of the modification, electrochemical impedance spectroscopy (EIS) was applied. In the EIS technique, the Rct, C, and Rs symbols are charge transfer resistance, double-layer capacitance, and solution resistance, respectively.

Figure 2B indicates the impedance spectra depicted as Nyquist plots (Zim vs. Zre) for diverse electrodes as bare GCE (a), polyalizarin yellow R/GCE (b), and CuONPs/polyalizarin yellow R/GCE (c) in 5 mM Fe(CN)63−/4− probe in the frequency range of 0.01 to 104 Hz.

Based on the EIS curves, the semicircle portion with respect to electron transfer is a limited process and its diameter is equal to the electron transfer, Rct, which controls electron transfer kinetics of redox probe on the electron interface. The EIS data of the electrodes were placed on a simple circuit which is exhibited in the plot (Fig. 2B. Inset).

It can be observed from the Nyquist schemes (Fig. 2B) that the semicircle of the bare electrode indicates a diffusion restrictive stage of the electrochemical procedure and dramatical reduction in polyalizarin yellow R/GCE. Once the polyalizarin yellow R/CuONP nanocomposite was immobilized on the electrode surface, the EIS curve’s diameter became smaller than that of other electrodes. These results show that electron transfer is easy between the electrode surface and solution in polyalizarin yellow R/CuONPs/GCE. It indicates that polyalizarin yellow R/CuONPs increase electron transfer and exhibit formation of a new layer on the substrate.

Electrocatalytic oxidation and reduction of hydrogen peroxide on poly (alizarin yellow R)-CuONPs/GCE

Cyclic voltammetry was utilized for investigating electrooxidation and electroreduction of hydrogen peroxide on the surface of unmodified and modified electrodes. Figure 3 shows that no peaks were discerned from the bare GC electrode (a), modified electrode by alizarin yellow polymer (b), modified electrode by the CuO nanoparticles, and alizarin yellow polymer (c) in the absence of hydrogen peroxide. In addition, no peaks were observed for the unmodified electrode in the presence of hydrogen peroxide (d). These findings indicate that hydrogen peroxide on the surface of the bare electrode was not capable of direct electron transfer. By contrast, on the surface of modified electrode by polyalizarin yellow (e), a pair of redox peaks were detected in the presence of hydrogen peroxide, suggesting that the polyalizarin yellow might be involved in direct electron transfer of hydrogen peroxide. Finally, a pair of redox peaks were clearly seen in the presence of hydrogen peroxide on the surface of the modified electrode with the CuO nanoparticles and polyalizarin yellow (f). This result suggests that the dramatic increase of simultaneous oxidation and reduction currents of hydrogen peroxide and, in turn, the potential of simultaneous oxidation and reduction shifted to less positive and less negative amounts, respectively. In general, the electrical conductivity induced by alizarin yellow polymer increased in the presence of the CuO nanoparticles with a high surface area of the modified electrode which facilitates the transport of direct electrons between hydrogen peroxide and surface of the modified electrode.

Cyclic voltammograms of glassy carbon electrodes modified by CuO nanoparticles and alizarin yellow (f), alizarin yellow (e), and unmodified (d), in the presence of 0.001 M hydrogen peroxide, as well as modified by CuO nanoparticles and alizarin yellow (c), alizarin yellow (b), non-modified (a), in absence of hydrogen peroxide at pH = 10 and scan rate 30 mV/s

In order to investigate the electrocatalytic behavior and an optimal pH of polyalizarin yellow R/CuONPs/GCE, the effect of pH on the electrooxidation and electroreduction responses of this electrode in the presence of hydrogen peroxide between −0.9 and +1.1 V at a scan rate of 100 mV/s was evaluated (Fig. 4).

In acidic medium, no peak of oxidation or reduction of hydrogen peroxide was observed. However, only a peak of reduction was observed in neutral medium (pH 7), Moreover, at pH 8, the oxidation and reduction peak currents were very low. At pH 12–14, the electrodes were damaged and the modifiers were removed from the electrode surface. At pH 10 and 11, Epa and Epc were 0.63 and −0.43 V, respectively. And, at pH 10, Ipa and Ipc were 14.92 and −5.42 micA, respectively. But, at pH 11, Ipa and Ipc were 10.38 and −5.15 micA, respectively. As both of the oxidation and reduction peak currents at pH 10 were higher than that at pH 11, pH 10 was selected as the optimum value.

Scan rate effect is a technique for evaluating the process controlled by diffusion as expected in a catalytic system. Figure 5A illustrates the proposed electrode in the presence of 500 μM hydrogen peroxide and scanning rates between 10 and 1000 mV/s. As observed in Figs. 5B and 5C, there is a linear relationship between anodic/cathodic peak currents of hydrogen peroxide and the square root of the scan rate, confirming the diffusion of the process.

The performance of the proposed modified electrode (PAYR/CuONps/GCE) in the presence of hydrogen peroxide (at various contents) was studied (Fig. 6A). As shown, this electrode has a rapid response and good sensitivity for electroreduction and electrooxidation of hydrogen peroxide. According to Figs. 6B and 6C, a linear relationship between the amount of hydrogen peroxide concentration and the current of anodic and cathodic peaks was observed.

Detection limit, sensitivity, and linear range for oxidation and reduction peaks were calculated (Table 1). Based on the results, the oxidation and reduction mechanism of hydrogen peroxide is proposed as follows:

In order to achieve a lower detection limit, differential pulse voltammetry (DPV) was used. The differential pulse voltammograms of the modified electrode at various concentrations of hydrogen peroxide are presented at pH 10 (Fig. 7A) because the detection limit of the reduction peak is low in the cyclic voltammetry method. Therefore, in the differential pulse voltammetry method, the reduction peak is investigated.

Figure 7B indicates that the intensity of the cathodic peak increased by increasing the concentration of hydrogen peroxide. A linear dependence of the catalytic currents vs. hydrogen peroxide concentration can be shown in the equation I (μA) = 1.4154 (hydrogen peroxide) μAμM−1 + 0.4607 μA. Table 1 presents the detection limit, sensitivity, and linear range for reduction peaks.

Comparison of PAYR/CuONps/GCE with those of previous modified electrodes

The proposed sensor was compared with several other electrochemical sensors that have been applied for hydrogen peroxide analysis. Table 1 demonstrates that some electrochemical parameters such as linear range, lower detection limit, and sensitivity of PAYR/CuONps/GCE are better or comparable with those of other sensors.

Repeatability, stability, and selectivity

For five consecutive assays, the repeatability of the modified electrode response current in the presence of 500 μM of hydrogen peroxide was assessed. The variation coefficient (R.S.D) was 3.75%. To study the lifetime and stability of the proposed sensor, the sensor response current after 1 and 5 weeks was calculated. After this time, the observed reductions in the electrode response were approximately 96.5 and 88.5% of the initial currents, respectively. Furthermore, the interference effect of l-cysteine, glucose glycine, fructose, mannose, arginine, phenylalanine, Na+, K+, Mg+2, and Ca+2 in the presence of H2O2 on the proposed sensor response was investigated by the DPV method. According to the experimental results, glycine, fructose, mannose, arginine, phenylalanine, Na+, K+, Mg+2, and Ca+2 did not interfere in determination of H2O2 with 10 folds excess over H2O2 concentration. The interference for l-cysteine and glucose appeared in equimolar concentration in the solution with H2O2.

Analytical application

To analyze the real samples, the reduction peak was selected. The practicality of the present sensor was appraised for the detection of H2O2 in different milk samples through the CV method. H2O2 concentration was measured in two diverse milk samples provided from a store. The samples were prepared with 50 μM and 150 μM of H2O2 and the content of hydrogen peroxide recovery was calculated. The hydrogen peroxide concentration was specified in all the samples through the method described in Table 2. A blank milk sample was tested in a similar way and showed no meaningful current response. According to Table 2, it is apparent that this sensor showed rational selectivity in the case of the real milk samples and generated acceptable outcomes with the recoveries ranging from 97 to 102.3%.

Conclusion

In the present work, a new strategy was applied for the fabrication of alizarin yellow–based CuO nanoparticles via electrochemical techniques. A novel modified electrode based on polyalizarin/CuONPs immobilized on the surface of glassy carbon electrode was developed and applied. The electrooxidation and electroreduction of H2O2 on the surface of the modified electrode were investigated. The suggested electrode can be applied for the detection of low levels of H2O2. The assembly of the metal oxide nanoparticles by the conductive polymer yields novel nanocomposite with synergetic properties and functions. This method is useful for novel sensor and biosensor construction.

Data Availability

The data sets used and/or analyzed during the current study are available from the corresponding author (Nader Amini) on reasonable request.

References

Abdelwahab AA, Shim YB (2014) Nonenzymatic H2O2 sensing based on silver nanoparticles capped polyterthiophene/MWCNT nanocomposite. Sensors Actuators B Chem 201:51–58

Agnieszka B, Anna B, Anna J, Mikołaj K, Jacek W, Marek L, Grzegorz DS (2021) A comparative study of electrocatalytic reduction of hydrogen peroxide at carbon rod electrodes decorated with silver particles. Mater Sci Eng B 263:114801

Chao L, Wang W, Dai M, Ma Y, Sun L, Qin X, Xie Q (2016) Step-by-step electrodeposition of a high-performance Prussian blue-gold nanocomposite for H2O2 sensing and glucose, biosensing. J Electroanal Chem 778:66–73

Chen Y, Li Q, Jiang H, Wang X (2016) Pt modified carbon fiber microelectrode for electrochemically catalytic reduction of hydrogen peroxide and its application in living cell H2O2 detection. J Electroanal Chem 781:233–237

Devasenathipathy R, Kohilarani K, Chen SM, Wang SF, Wang SC, Chen CK (2016) Electrochemical preparation of biomolecule stabilized copper nanoparticles decorated reduced graphene oxide for the sensitive and selective determination of hydrogen peroxide, Electrochim. Acta 191:55–61

Díaz Nieto CH, Granero AM, Lopez JC, Pierini GD, Levin GJ, Fernández H, Zon MA (2018) Development of a third generation biosensor to determine hydrogen peroxide based on a composite of soybean peroxidase/chemically reduced graphene oxide deposited on glassy carbon electrodes. Sensors Actuators B Chem 263:377–386

Doblhofer K (1980) Electrodes covered with thin, permeable polymer films, Electrochim. Acta 25(6):871–878

Du P, Zhou B, Cai C (2008) Development of an amperometric biosensor for glucose based on electrocatalytic reduction of hydrogen peroxide at the single-walled carbon nanotube/Nile blue A nanocomposite modified electrode. J Electroanal Chem 614(1):149–156

Ehsani M, Chaichi MJ, Hosseini SN (2017) Comparison of CuO nanoparticle and CuO/MWCNT nanocomposite for amplification of chemiluminescence immunoassay for detection of the hepatitis B surface antigen in biological samples. Sensors Actuators B Chem 247:319–328

Ensafi AA, Rezaloo F, Rezaei B (2016) Electrochemical sensor based on porous silicon/silver nanocomposite for the determination of hydrogen peroxide. Sensors Actuators B Chem 231:239–244

Guler M, Turkoglu V, Bulut A, Zahmakiran M (2018) Electrochemical sensing of hydrogen peroxide using Pd@Ag bimetallic nanoparticles decorated functionalized reduced graphene oxide, Electrochim. Acta 263:118–126

Hu M, Chen J, Li ZY, Au L, Hartland GV, Li X, Marquez M, Xia Y (2006) Gold nanostructures: engineering their plasmonic properties for biomedical applications. Chem Soc Rev 35:1084–1094

Hu C, Chen X, Hu S (2007a) Water-soluble single-walled carbon nanotubes films: preparation, characterization and applications as electrochemical sensing films. J Electroanal Chem 586(1):77–85

Hu C, Yang C, Hu S (2007b) Hydrophobic adsorption of surfactants on water-soluble carbon nanotubes: a simple approach to improve sensitivity and antifouling capacity of carbon nanotubes-based electrochemical sensors. Electrochem Commun 9(1):128–134

Ihara K, Hasegawa SI, Naito K (2008) The separation of aluminum(III) ions from the aqueous solution on membrane filter using Alizarin Yellow R. Talanta 75(4):944–949

Kardaş F, Beytur M, Akyıldırım O, Yüksek H, LütfiYola M, Atar N (2017) Electrochemical detection of atrazine in wastewater samples by copper oxide (CuO) nanoparticles ionic liquid modified electrode. J Mol Liq 248:360–363

Liu J, Zhou D, Liu X, Wu K, Wan C (2009) Determination of kojic acid based on the interface enhancement effects of carbon nanotube/alizarin red S modified electrode. Colloids Surf B: Biointerfaces 70(1):20–24

Liu Y, Liu X, Guo ZH, Hu ZH, Xue ZH, Lu X (2017) Horseradish peroxidase supported on porous graphene as a novel sensing platform for detection of hydrogen peroxide in living cells sensitively. Biosens Bioelectron 87:101–107

Lutfullah B, Muhammet G (2019) An ultra-sensitive non-enzymatic hydrogen peroxide sensor based on SiO2-APTES supported Au nanoparticles modified glassy carbon electrode, Progress in Natural Science. Mater Int 29:390–396

Marjan SR, Milan ZM, Dirk E, Valentin M (2019) Electrochemistry of hydrogen peroxide reduction reaction on carbon paste electrodes modified by Ag- and Pt-supported carbon microspheres. J Solid State Electrochem 23:1257–1267

Muhammet G, Vedat T, Arif K, Fatih K (2018) A novel nonenzymatic hydrogen peroxide amperometric sensor based on Pd@CeO2-NH2 nanocomposites modified glassy carbon electrode. Mater Sci Eng C 90:454–460

Pandurangan P, Babu R, Narayanan S (2014) Synergetic effect of Prussian blue film with gold nanoparticle graphite–wax composite electrode for the enzyme-free ultrasensitive hydrogen peroxide sensor. J Solid State Electrochem 18:883–891

Parthasarathy S, Nandhini V, Jeyaprakash BG (2016) Improved sensing response of photo activated ZnO thin film for hydrogen peroxide detection. J Colloid Interface Sci 482:81–88

Priyanga N, Sahaya R, Mehboobali P, Al-Sehemi AG, Siew-Moi P, Yang X, Shu-Y T, Annaraj J, Sambathkumar S, Gnanakumar G (2021) Hierarchical MnS@MoS2 architectures on tea bag filter paper for flexible, sensitive, and selective non-enzymatic hydrogen peroxide sensors. J Alloys Compd 855:157103

Sahoo S, Sahoob PK, Sudipa M, Satpati AK (2020) A novel low cost nonenzymatic hydrogen peroxide sensor based on CoFe2O4/CNTs nanocomposite modified electrode. J Electroanal Chem 876:114504

Sheng Q, Yu H, Zheng J (2007) Hydrogen peroxide determination by carbon ceramic electrodes modified with pyrocatechol violet, Electrochim. Acta 52(25):7300–7306

Shobha Jeykumari DR, Narayanan SS (2008) A novel nanobiocomposite based glucose biosensor using neutral red functionalized carbon nanotubes. Biosens Bioelectron 23(9):1404–1411

Shu Y, Li B, Xu Q, Gu P, Xiao X, Liu F, Yu L, Pang H, Hu X (2017) Cube-like CoSn(OH)6 nanostructure for sensitive electrochemical detection of H2O2 in human serum sample. Sensors Actuators B 241:528–533

Sookhakian M, Zalnezhad E, Alias Y (2017) Layer-by-layer electrodeposited nanowall-like palladium-reduced graphene oxide film as a highly-sensitive electrochemical non-enzymatic sensor. Sensors Actuators B Chem 241:1–7

Thanh TD, Balamurugan J, Lee SH, Kim NH, Lee JH (2016) Novel porous gold-palladium nanoalloy network-supported graphene as an advanced catalyst for non-enzymatic hydrogen peroxide sensing. Biosens Bioelectron 85:669–678

Vesna S, Slađana Đ, Miloš O, Jelena M, Kurt K, Dalibor MS (2020) A novel nonenzymatic hydrogen peroxide amperometric sensor based on AgNp@GNR nanocomposites modified screen-printed carbon electrode. J Electroanal Chem 876:114487

Wang I, Zhu H, Hou H, Zhang Z, Xiao X, Song Y (2011) A novel hydrogen peroxide sensor based on Ag nanoparticles electrodeposited on chitosan-graphene oxide/cysteamine-modified gold electrode. J Solid State Electrochem 16:1693–1700

Wang H, Li T, Ma J, Li K, Zuo X (2017) Silver nanoparticles selectively deposited on graphene-colloidal carbon sphere composites and their application for hydrogen peroxide sensing. Sensors Actuators B 239:1205–1212

Weina X, Jianlin L, Mingjun W, Lin C, Xue W, Chenguo H (2016) Direct growth of MnOOH nanorod arrays on a carbon cloth for high performance non-enzymatic hydrogen peroxide sensing. Anal Chim Acta 913:128–136

Williams RR, Lautenschleger M (1963) Titration of weak acids with tetramethylgnanidine as solvent. Talanta 10(7):804–808

Wu K, Hu S (2004) Deposition of a thin film of carbon nanotubes onto a glassy carbon electrode by electropolymerization. Carbon 42(15):3237–3242

Wu ZL, Li CK, Yu JG, Chen XQ (2017) MnO2/reduced graphene oxide nanoribbons: facile hydrothermal preparation and their application in amperometric detection of hydrogen peroxide. Sensors Actuators B Chem 239:544–552

Xie Y, Yu Y, Lu L, Ma X, Gong L, Huang X, Liu G, Yu Y (2018) CuO nanoparticles decorated 3D graphene nanocomposite as non-enzymatic electrochemical sensing platform for malathion detection. J Electroanal Chem 812:82–89

Yogeswaran U, Chen SM (2007) Separation and concentration effect of f-MWCNTs on electrocatalytic responses of ascorbic acid, dopamine and uric acid at f-MWCNTs incorporated with poly (neutral red) composite films. Electrochim Acta 52(19):5985–5996

Yue W, Zheng D, Hu C, Hu S (2010) Fabrication and application of poly(alizarin red S)-carbon nanotubes composite film based nitrite sensor. J Nanosci Nanotechnol 10(10):6586–6593

Yusoff N, Rameshkumar P, Mehmood MS, Pandikumar A, Lee HW, Huang NM (2017) Ternary nanohybrid of reduced graphene oxide-nafion@silver nanoparticles for boosting the sensor performance in non-enzymatic amperometric detection of hydrogen peroxide. Biosens Bioelectron 87:1020–1028

Zeng J, Wei W, Wu L, Liu X, Liu K, Li Y (2006) Fabrication of poly(toluidine blue O)/carbon nanotube composite nanowires and its stable low-potential detection of NADH. J Electroanal Chem 595(2):152–160

Zhang R, Chen W (2017) Recent advances in graphene-based nanomaterials for fabricating electrochemical hydrogen peroxide sensors. Biosens Bioelectron 89:249–268

Zhang K, Zhang Y (2010) Lable-free electrochemical DNA sensor based on gold nanoparticles/poly(neutral red) modified electrode. Electroanalysis 22(6):673–679

Zhang K, Zhang L, Xu J, Wang C, Geng T, Wang H, Zhu J (2010) A sensitive amperometric hydrogen peroxide sensor based on thionin/EDTA/carbon nanotubes—chitosan composite film modified electrode. Mikrochim Acta 171(1):139–144

Zhang K, Zhang N, Zhang L, Xu J, Wang H, Wang C, Geng T (2011) Amperometric sensing of hydrogen peroxide using a glassy cabon electode modified with silver nanoparticles on poly(alizarin yellow R). Mikrochim Acta 173:135–141

Funding

This work was partially supported by Kwangwoon University, Seoul, Korea, through Research Grant–2021.

Author information

Authors and Affiliations

Contributions

Nader Amini performed detection and determination of H2O2 using an electrochemical sensor. Bahaaldin Rashidzadeh, Nasrin Amanollahi, and Afshin Maleki evaluated the experimental data and analysis of the data set. Jae-Kyu Yang and Seung-Mok Lee provided guidance on the preparation method of the electrochemical sensor.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Angeles Blanco

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Amini, N., Rashidzadeh, B., Amanollahi, N. et al. Application of an electrochemical sensor using copper oxide nanoparticles/polyalizarin yellow R nanocomposite for hydrogen peroxide. Environ Sci Pollut Res 28, 38809–38816 (2021). https://doi.org/10.1007/s11356-021-13299-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-13299-6