Abstract

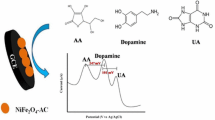

This paper addresses the detailed investigation on the electrochemical activity of TiO2/PVA nanocomposite-modified pencil graphite electrode (TiO2/PVA-PGE) in aqueous KCl medium at room temperature. Herein, we have used ferri/ferrocyanide redox couple as probe molecule and demonstrated the reversibility, surface diffusion ability, stability, and electroactive surface area of TiO2/PVA-PGE. Formation of functional groups, structure, and the morphology of the prepared sample are examined using various characterization techniques. On top of this, the as-modified PGE is used for the first time in the voltammetric detection of potassium ferricyanide in aqueous KCl medium. The developed sensor is sensitive for only ferricyanide molecule and does not show any current response for other interfering compounds such as, ascorbic acid (AA), Uric acid (UA), dopamine (DA), acetaminophen (ACOP), Hydrogen peroxide (H2O2), and 4-nitrophenol (4-NP) within wide linear range of 0.17–33.33 mM with a high order of correlation (0.997) having a detection limit as low as 0.15 μM. Also high sensitivity of 199.34 μA mM−1 cm−2 for oxidation current is obtained. The finding of present paper gives a very clear and concise understanding towards the role of modification on the surface electrochemistry of any bare/unmodified electrode and shows the ample possibility in the application of the prepared TiO2/PVA nanocomposite-modified electrodes for selective electrochemical sensing of cyanometalic compound in the presence of other electroactive molecules.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Proper understanding about the electrode’s surface properties has grown tremendous interest among the research community as the working electrode always plays a crucial role in all kinds of electroanalytical and electrochemical detection. Among the carbon-based electrodes, bulk glassy carbon electrode (GCE) is one of the most frequently used macroelectrodes in electrochemical sensors [1], though its relatively high background current and cost remain the major problems. In this frame, low cost [$0.30 per PGE, vs. $190 + per GCE], commercially available pencil leads (pencil graphite electrode—PGE) may overcome this cost barrier. These PGE also show smaller background current, can be easily modified, posses better electrochemical reactivity, and have good mechanical rigidity [ 1, 2]. It is already known that sensing mechanism is a surface-dominated phenomenon and sensor parameters, viz. selectivity and sensitivity, which can be improved by increasing the roughness factor (electroactive area/geometrical area) of the electrode [3]. Modification with artificial materials is a powerful tool employed to improve the electrode functionality. In this respect, the prompt development of nanomaterials and nanotechnology has endowed us with several new kinds of artificial materials which have brought revolution in electrode designing [4]. Nanomaterials, such as, carbon nanotubes, graphene, metal nanoparticles, metal oxides, and conducting polymers, commonly act as good modifier due to their excellent electronic, catalytic properties, and excessively larger surface area [5, 6].

Nanostructured TiO2 and their composites are very popular due to low cost, existence in three different polymorphic phases (anatase, brookite, and rutile), and ease of synthesis. TiO2 and their composites have multifaceted applications, ranging from energy generation/storage devices, catalyst, anode material, luminescent material, sensing element etc. [7–9]. TiO2 is a very common choice as sensor electrode in electrochemical analysis owing to its excellent catalytic activity, long-term stability, and non-toxicity [10]. Still, application of TiO2/PVA nanocomposite as modifier in electrochemical sensor is scantly reported in the literature. In our previous work, the detailed investigation pertaining to anatase to rutile phase transformation (ART) at very low temperature was demonstrated by introducing PVA during the reaction/synthesis [11]. We had also performed a preliminary study on the electrochemical behavior of TiO2 and TiO2/PVA nanocomposite and elucidated that combination of inorganic–organic hybrid material (TiO2 and PVA) has considerably enhanced the electrochemical response. Smaller size of the nanoparticles along with larger exposure area has facilitated the electron transfer rate of the redox reaction [11]. In continuation to the our previous preliminary work, in the present work, we have emphasized on the detailed investigation of the electrochemical behavior of TiO2/PVA nanocomposite-modified pencil graphite electrode and its sensing ability.

Potassium ferricyanide, a well-known cyanometalic compound, is treated as benchmark redox probe for evaluation of the electrochemical properties of any novel electrode [12, 13]. On the other hand, free cyanides have an important environmental issue due to their toxicity [14]. Cyanides are originated from different industrial activities such as, metal plating, mining, gas production, and pharmaceutical. Cyanides have high affinity towards gold and hence gold mine industries contribute significantly in cyanide production as an effluent after the gold extraction from its ore [15]. According to the relative toxicity level, cyanometalic compounds are less toxic than free cyanides [16]. Yet, the monitoring of them is compulsory as they are capable of generating small amount of free cyanides under the influence of sunlight via photolysis process or under other suitable environmental conditions (the absence of light but in appropriate pH value) [17]. A detailed discussion on the physiochemical processes and toxicity level of cyanides and cyanometalic compound is published by Gérald et al. in 2004 [15]. In this framework, this article gives an insight on the surface electrochemistry of TiO2/PVA nanocomposite-modified pencil graphite electrode and its subsequent use in the voltammetric detection of potassium ferricyanide. To the best of our knowledge, TiO2/PVA nanocomposite-modified pencil graphite electrode has not been used earlier in the detection of potassium ferricyanide.

2 Sample preparation and characterization details

2.1 Chemicals used

Titanium Chloride (TiCl3) with 99.99% purity (Sigma Aldrich, Germany), acetaminophen (ACOP) (Sigma Aldrich, Germany), polyvinyl alcohol (PVA) (E. Merck Limited, India), MW = 145,000, Sodium hydroxide (NaOH), Hydrogen peroxide (H2O2), 4-nitrophenol (4-NP) and Ethanol (E. Merck Limited, India) are used as-received. Uric acid (UA) and ascorbic acid (AA) are purchased from Loba chemie, India) and dopamine hydrochloride (DA) is procured from Alfa Aesar, USA. Double-distilled water is used throughout this work. 50 mM of ferricyanide stock solution is prepared by direct dilution of potassium ferricyanide (Loba chemie, India) into KCl solution, and interferents are prepared in double-distilled water.

2.2 Synthesis procedure

The synthesis procedure is similar to the reported one in our previous work [11]. In brief, aqueous solution of TiCl3 is prepared by adding 1 mL of it into 40 mL of NaOH (0.4 M). The colorless homogeneous solution of PVA (4 gm in 100 mL of double-distilled water, heated at 80 °C) was introduced in the NaOH solution under vigorous stirring. The as-obtained precipitate was then collected via centrifugation and washed several times with distilled water until pH became neutral. In the next step, obtained filtrate was transferred into a stainless steel autoclave, and the total volume was made 70 mL by water addition. Autoclave was kept at 180 °C for 6 h. Sample was separated out after washing several times with ethanol and water via centrifugation, and finally the powder sample was obtained after drying at 40 °C in air.

2.3 Apparatus used

The phase and structure of the sample were analyzed by X-ray diffraction (XRD, Bruker D8, USA., Cu Kα radiation). Morphology and the vibrational bonds were observed using field emission scanning electron microscope (FESEM, Supra-55, Zeiss, Germany) and fourier transformed infrared spectroscopy (FTIR, Perkin-Elmer Spectrum Bx, USA), respectively.

The electrochemical experiments were performed on a Potentiostat/Galvanostat (model: PalmSens3, PalmSens BV, The Netherlands). A conventional one compartment 3-electrode electrochemical cell equipped with counter electrode (Pt wire), reference electrode (Ag/AgCl), and working electrode (nanocomposite-modified pencil graphite electrode) was used for voltammetric measurements.

2.3.1 Preparation of TiO2/PVA nanocomposite-modified electrode

Surface modification of bare PGE (0.5 mm diameter) with prepared nanocomposite was accomplished using dip coating method already reported in our earlier work [11]. Typically, bare PGE is first treated with 0.6 M HCl, distilled water, and rubbed with cotton. Next, prepared powder sample (1 mg) was ultrasonically dispersed into DMSO (5 mL) for half an hour. Pre-treated cleaned PGE was dipped into the solution and finally rinsed by water washing to remove any loosely bound particle. This electrode is named as TiO2/PVA-PGE.

3 Results and discussion

3.1 Structural properties

Figure 1 shows the XRD profile of TiO2/PVA nanocomposite. The obtained result is similar to the previously reported work of our group [11]. Intense reflection peak observed at 2θ = 27.9° indicates the rutile structure of prepared nanocomposite. All of the diffraction peaks are well matched with the JCPDS Card No. 781510. Crystallite size calculated using Debye–Scherrer formula for the major prominent peaks is 8–11 nm. A detailed discussion is available in Ref. [11]. Figure 2a elucidates the FTIR spectrum of TiO2/PVA nanocomposite. As seen from the spectrum, the peak at 520 cm−1 corresponds to the Ti–O–Ti asymmetric stretching [18], 1636 cm−1 for the TiO2 and absorbed water interaction, and 2921 cm−1 band originates for C–H vibration of PVA [19]. Morphology of the prepared sample is observed using FESEM image presented in Fig. 2b. Wide distribution of spherical-shaped particles is seen.

3.2 Electrochemical characteristics of TiO2/PVA-PGE

In our previous study [11], we have presented a very preliminary comparative study on the electrochemical responses of pure TiO2 and TiO2/PVA-modified PGE. Finding of the work showed that the TiO2/PVA-modified PGE possessed better electron transfer ability then pure TiO2-modified electrode. The current response on TiO2/PVA-PGE is 1.5-fold larger than TiO2-PGE. This improved response was attributed to the formation of smaller sized nanoparticles after incorporating PVA which provided larger surface area compared to the pure TiO2 nanoparticles. Also, highly reactive hydroxyl [–OH] ions of polymer chains served as conducting path along electrolyte–electrode interface resulting better transportation of charge carriers. Herein, we have illustrated our previous work and investigated in detail the electrode parameters of the TiO2/PVA-PGE using Fe(CN) 3−/4−6 redox reaction as model system. Thereafter, real analytical application was demonstrated for the detection of the cyanometalic compound K3Fe(CN)6.

The electrochemical behavior of TiO2/PVA-PGE was firstly investigated by cyclic voltammetry using aqueous KCl as supporting electrolyte within the potential window of −0.3 V to +0.7 V vs Ag/AgCl electrode. Amongst all electrochemical methods, cyclic voltammetry is the most convenient, versatile and routinely applied technique for determining the electrode properties [20]. CV contains a wide range of information regarding the electrochemical process viz. accurate location of oxidation/reduction potentials, electrode kinetics, number of electron involved, electroactive area of the electrode, diffusion coefficient and also the concentration of analyte molecule. In a reversible reaction, linearly scanning potential in the form of a triangular wave is applied back and forth (forward/reverse) direction in the presence of electroactive species to generate rapid redox products. Potassium ferricyanide is used as electroactive substance in this case. Typical voltammogram obtained on TiO2/PVA-PGE at scan rate 50 mV s−1 is shown in Fig. 3. Well-defined redox peaks within the scanned potential range are observed only after the introduction of K3Fe(CN)6. On the other hand, no peaks are observed for the blank run (without probe molecule). Hence, these peaks at 0.25 and 0.16 V can be easily ascribed to the conversion of ferri to ferro and vice versa according to the following electron transfer reaction:

Minute observation reveals that the peak-to-peak separation of the ferri/ferro couple (ΔE pp) is 90 mV. This small value of ΔE pp gives direct indication of the better electron transfer kinetic and low resistance in TiO2/PVA-PGE. We also observed that the ratio of peak current (I a /I c ) is ≅ 1.2, which slightly differs from the exact value of 1.0. This indicates the quasi-reversibility of the redox reaction on TiO2/PVA-PGE.

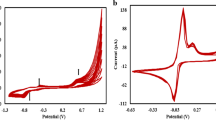

In order to investigate the scan rate dependence on the redox reaction, two distinct set of CV measurements were performed, by varying the scan rate and by increasing the number of cycles at fixed scan rate. Both the anodic and cathodic peak currents increase (Fig. 4a) with square root of scan rates in the entire tested region of 10–400 mV s−1. This linear dependence of the aforementioned parameters at the TiO2/PVA-PGE surface might be due to the adsorption of ferricyanide at the active sites of nanocomposite-modified working electrode. Kinetic analysis of the TiO2/PVA-PGE is performed by plotting the logarithm of current against logarithm of scan rate. The linear regression equations obtained for log Ia and log Ic are Y = 0.436 X + 1.016; (R 2 = 0.999), Y = 0.459 X + 0.964; (R 2 = 0.998), respectively. The experimental slopes of ~0.44 and 0.46 (Fig. 4b) slightly differ from the theoretical value of 0.5. This suggests that the electrochemical process is diffusion-controlled process. This discrepancy from theoretical value arises due to the solution resistance. Moreover, the shift in peak potential (ΔE pa) with scan rate is 0.03 V, almost negligible to the change in scan rate. After 20 cycles of CV run at potential sweep rate 50 mV s−1 (Fig. 5a) peak currents remain almost constant (only 8% decrease in peak current after 20 cycle), implies that the modification of nanocomposite onto the PGE is electrochemically stable and suitable for electrochemical sensing. This excellent stability of the modified electrode over repetitive scans can be attributed to the superior adhesive nature of PVA.

As already known, electroactive surface area of any modified electrode is one of the most interesting as well as important parameters than its geometrical area. Geometrical area is the simple sum of all the physical areas covering the electrode surface. On contrary, electroactive/real surface area of the electrode represent the area which took part in the electron exchange process [21]. The kinetic parameters of the reaction are dependent on this factor. Cyclic voltammetry is the easiest method/tool to calculate the electroactive area of the PGE. In general, any diffusion-controlled reversible/quasi-reversible electrochemical process follows the famous Randles–Sevcik equation [22, 23]:

where i p is the peak current; n represents the number of electron transferred; D 0 is the diffusion coefficient of the electroactive species (cm2 s−1); C 0 is the bulk concentration (0.01 mol L−1) of the same species; V is the scan rate (V s−1), and A represents the electroactive area (cm2) of the electrode. Using the voltammogram data of ferri/ferro redox reaction (one electron transfer process), the calculated electroactive surface area after modification is 3.8 × 10−5 cm2 having the roughness factor of 5.9 × 10−4. This higher value of effective surface area provided by nanocomposite is suitable for sensing applications. Evaluated electrochemical parameters for TiO2/PVA-PGE are listed in Table 1.

4 Analytical application

4.1 Sensing of cyanometalic compound

In addition of determining the electrode properties, we have also examined the suitability of the developed electrode in sensing application. For the purpose, a real analytical application was demonstrated for the detection of the cyanometalic compound, K3Fe(CN)6. Figure 5b elucidates the CV result for 1 mM ferricyanide in different ionic strengths of supporting electrolyte (KCl) at potential sweep rate of 50 mV s−1. Different magnitudes of peak currents and their ratio corresponding to each electrolyte concentration confirm the active role of electrolyte in redox reaction. 0.7 M is found to be the optimum concentration when TiO2/PVA-PGE exhibits maximum peak current as well as redox reversibility (1.02 ≅ theoretical value 1.0). To evaluate the sensor parameters, sensitivity and detection limit, the concentration of target (potassium ferricyanide) is varied by successive addition of desired amount of stock solution at a regular step of concentration. As shown in Fig. 6a, oxidative current obtained from the voltammogram linearly increases with the concentration for the above-mentioned range (0.17–33.33 mM) with a high order of correlation coefficient (R 2 = 0.991). Calibration plot (Fig. 6b) bears a linear relationship: J (A cm−2) = 199.34C (mM) − 248.75. A detection limit of 0.15 μM with a high sensitivity of 199.34 μA mM−1 cm−2 was obtained using calibration plot. A comprehensive comparison of our results with previously reported work is provided in Table 2. As seen from the table, the developed ferricyanide sensor showed better performance in terms of sensitivity as well as detection limit.

4.2 Interference studies

To ensure the selectivity of the prepared potassium ferricyanide sensor, CV responses were recorded at the optimized conditions in presence of other electroactive molecules viz. AA, UA, DA, ACOP, 4-NP, and H2O2. As seen in the histogram (Fig. 6c), the interfering species have generated nearly negligible current response as compared to the same concentration of ferricyanide (0.2 mM). Obtained results are depicted in Table 3. The interference studies confirm that the developed sensor has specific response to potassium ferricyanide and can be used for selective electrochemical sensing of cyanometalic compounds in the presence of other electroactive molecules.

5 Conclusions

The detailed investigation on the electrochemical properties of TiO2/PVA-modified pencil graphite electrode with respect to the probe molecule ferri/ferrocyanide redox couple has been performed. Electroactive surface area and redox reversibility along with the electrochemical stability of the modified electrode are determined. The TiO2/PVA-modified pencil graphite electrode is successfully applied in the voltammetric detection of cyanometalic compound potassium ferricyanide. The fabricated TiO2/PVA nanocomposite sensor is sensitive for only ferricyanide molecule and does not show any current response for other interfering compounds such as, ascorbic acid (AA), Uric acid (UA), dopamine (DA), acetaminophen (ACOP), Hydrogen peroxide (H2O2), and 4-nitrophenol (4-NP) with a wide linear concentration region of 0.17 mM to 33.33 mM having a high sensitivity of 199.34 μA mM−1 cm−2 and detection limit as low as 0.15 μM. Our work shows the ample possibility in the application of the prepared TiO2/PVA nanocomposite-modified electrodes for selective electrochemical sensing of cyanometalic compounds in the presence of other electroactive molecules.

References

Özcan A, Şahin Y (2011) A novel approach for the determination of paracetamol based on the reuction of N-acetyl-P-benzoquinoneimine formed on the electrochemically treated pencil graphite electrode. Anal Chim Acta 685:9–14

Gowda JI, Nandibewoor ST (2012) Electrochemical behavior of 4-aminophenazone drug at a graphite pencil electrode and its application in real samples. Ind Eng Chem Res 51:1594–15936

Patel F (1992) The fatal paracetamol dosage–how low can you go? Med Sci Law 32:303–310

Afkhami A, Khoshsafar H, Bagheri H, Madrakian T (2014) Preperation of NiFe2O4/graphene nanocomposite and its application as a modifier for the fabrication of an electrochemical sensor for the simultaneous determination of tramadol and acetaminophen. Anal Chim Acta 831:50–59

Shrama PK, Rudowicz C, Pandey AC, Zolnierkiewicz G, Guskos N (2009) Relationship between oxygen defects and the photoluminescence property of ZnO nanoparticles: a spectroscopic view. J Appl Phys 106:094314–094319

Dutta RK, Shrama PK, Pandey AC (2010) DNA base, cytosine modified/capped ultrasmall Gd2S3: Eu3+ gadofluoroprobes for platelet isolation. Appl Phys Lett 97:253702–253705

Zhu S, Liang S, Gu Q, Xie L, Wang J, Ding Z, Liu P (2012) Effect of Au supported TiO2 with dominant exposed 0 0 1 facets on the visible-light photocatalytic activity. Appl Catal B 146:119–120

Du J, Qi J, Wang D, Tang Z (2012) Facile synthesis of Au@TiO2 core–shell hollow spheres for dye-sensitized solar cells with remarkably improved efficiency. Energy Environ Sci 5:6914–6918

Silva CG, Juarez R, Marino T, Molinari R, Garicia H (2011) Influence of excitation wavelength (UV or visible light) on the photocatalytic activity of titania containing gold nanoparticles for the generation of hydrogen or oxygen from water. J Am Chem Soc 133:595–602

Fujishima A, Rao TN, Tryk DA (2000) Titanium dioxide photocatalysis. J Photochem Photobiol, C 1:1–21

Mondal S, Madhuri R, Sharma PK (2015) PVA assisted low temperature anatase to rutile phase transformation (ART) and properties of titania nanoparticles. J Alloys Compd 646:565–572

Chen P, McCreery RL (1996) Control of electron transfer kinetics at glassy carbon electrodes by specific surface modification. Anal Chem 68:3958–3965

Pandey PC, Upadhyay BC (2005) Studies on differential sensing of dopamine at the surface of chemically sensitized ormosil-modified electrodes. Talanta 67:997–1006

Ojani R, Ahmadi E, Raoof JB, Mohamadnia F (2009) Characterization of a carbon paste electrode containing organically modified nanostructure silica: application to voltammetric detection of ferricyanide. J Electroanal Chem 626:23–29

Zagury GJ, Oudjehani K, Deschênes L (2004) Characterization and availability of cyanide in solid mine tailings from gold extraction plants. Sci Total Environ 320:211–224

Shifrin NS, Beck BD, Gauthier TD, Chapnick SD, Goodman G (1996) Chemistry, toxicology, and human health risk of cyanide compounds in soils at former manufactured gas plant sites. Chemistry 23:106–116

Meeussen JCL, Keizer MK, Haan FAMD (1992) Chemical stability and decomposition rate of iron cyanide complexes in soil solutions. Environ Sci Technol 26:511–516

Kavitha B, Dasharatham D, Srinivasu D, Srinivas CH, Narsimlu N (2011) Synthesis and characterization of TiO2 doped polyvinyl alcohol polymer composites. J Chem Pharm 4:155–157

Liu L, Zhao C, Yang F (2012) TiO2 and polyvinyl alcohol (PVA) coated polyester filter in bioreactor for wastewater treatment. Water Res 46:1969–1978

Kissinger PT, Heineman WR (1983) Cyclic Voltammetry. J Chem Educ 60:702–706

Adolphe X, Martemianov S, Palchetti I, Mascini M (2005) On the electrochemical flow measurements using carbon-based screen-printed electrodiffusion probes. J Appl Electrochem 35:599–607

Gooding JJ, Praig VG, Hall EA (1998) Platinum-catalyzed enzyme electrodes immobilized on gold using self-assembled layers. Anal Chem 70:2396–2402

Brett CMA, Brett AMO (1993) Electrochemistry: principles, methods, and applications. Oxford Science Publications, Oxford, pp 103–109

Perenlei G, Tee TW, Yusof NA, Kheng GJ (2011) Voltammetric detection of potassium ferricyanide mediated by multi-walled carbon nanotube/titanium dioxide composite modified glassy carbon electrode. Int J Electrochem Sci 6:520–531

Taurino I, Carrara S, Giorcelli M, Tagliaferro A, Micheli GD (2012) Comparison of two different carbon nanotube-based surfaces with respect to potassium ferricyanide electrochemistry. Surf Sci 606:156–160

Niranjana E, Swamy BEK, Naik RR, Sherigara BS, Jayadevappa H (2009) Electrochemical investigations of potassium ferricyanide and dopamine by sodium dodecyl sulphate modified carbon paste electrode: a cyclic voltammetric study. J Electroanal Chem 631:1–9

Acknowledgements

The authors are thankful to Department of Science and Technology, Government of India for sanction of Fast Track Research Project for Young Scientists to Dr. Prashant K. Sharma (Ref. No.: SR/FTP/PS-157/2011) and Dr. Rashmi Madhuri (Ref. No.: SB/FT/CS-155/2012). Dr. Sharma (FRS/34/2012-2013/APH) and Dr. Madhuri (FRS/43/2013-2014/AC) are also thankful to Indian School of Mines, Dhanbad for grant of Major Research Project under Faculty Research Scheme. The authors are also thankful to Board of Research in Nuclear Sciences (BRNS), Department of Atomic Energy, Government of India for major research project (Sanction No. 34/14/21/2014-BRNS/0295). The authors also sincerely acknowledge the facilities available in Central Research Facility of the Institute. Shrabani is also thankful to Indian School of Mines, Dhanbad for Senior Research Fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mondal, S., Madhuri, R. & Sharma, P.K. Electrochemical sensing of cyanometalic compound using TiO2/PVA nanocomposite-modified electrode. J Appl Electrochem 47, 75–83 (2017). https://doi.org/10.1007/s10800-016-1022-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-016-1022-5