Abstract

Biodiesels derived from the mahua seeds are established as a promising alternative for the diesel fuel owing to its non-edible nature and improved properties. TiO2 nanoparticle in powder form is added to neat mahua oil biodiesel (BD100) to examine its effect on emission characteristics. TiO2 nanoparticle is chosen as an additive owing to its catalytic effect, higher surface energy, and larger surface to volume ratio. TiO2 nanoparticle with an average size of 60 nm was synthesized by sol-gel route. TiO2 nanoparticles are added with mahua biodiesel (BD100) at 100 and 200 ppm. Mahua oil biodiesel doped with 100 and 200 ppm of TiO2 nanoparticles are referred as BD100T100 and BD100T200. A constant speed diesel engine is employed for the experimental trail. Engine is fueled with diesel, BD100, BD100T100, and BD100T200, respectively. Experimental result confirmed that the modified fuels (BD100T200 and BD100T100) showed a significant reduction in all the emissions. Further, the addition of TiO2 nanoparticle (200 ppm) to mahua biodiesel gave respective reduction of 9.3, 5.8, 6.6, and 2.7% in carbon monoxide, hydrocarbon, nitrogen oxide, and smoke emissions when compared to neat mahua biodiesel.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Depletion of fossil fuels, increasing energy demands, and stringent emission norms need alternate fuels such as biodiesel for engine applications that can reduce the gap between energy source and demand (Thapar et al. 2016; Baskar and Aiswarya 2016). Biodiesels are biodegradable, available in plenty, portable, and renewable in nature (Lesnik et al. 2013; Hribernik and Kegl 2007). It is obtained from a many natural feedstock sources, and around 300 crops are found and recognized as the potential feedstock for biodiesel production (Koc and Abdullah 2013). Many types of seed from the plants which are non-edible in nature such as neem, jatropha, pongamia, mahua, and castor are employed to obtain the biodiesel oil (Li et al. 2015; Sivalakshmi and Balusamy 2013). These non-edible oil plants are distinguished as second generation feedstock which are economical and are cultivated across the globe (Gogoi 2013; Gonca and Dobrucali 2016). In general, these oils have high free fatty acid (FFA) content and require a chemical process called transesterification (Pandhare and Padalkar 2013; Senthil Kumar et al. 2015). Through this process, glycerol is removed from the oil and can be used in existing engines. Further, by this process, the oil properties are made closer to fossil fuel. It can also be blended with conventional fuel and used in engines without any modifications (Nagaraja et al. 2012; Belagur and Chitimini 2010; Yuvarajan and Venkata Ramana 2016; Venkata Ramanan and Yuvarajan 2016; Yuvarajan et al. 2016).

In this work, biodiesel from mahua seeds are employed as a biodiesel. Mahua oil is biodegradable and non-toxic oil which is free from sulfur and other aromatics. It has high boiling point and flash point which makes it safer to handle and transport. Further, it has low vapor pressure and volumetric energy density compared to diesel. In addition, mahua oil has a better lubricating property than diesel, as it removes the deposits in the fuel lines and improves the engine life. Mahua oil has high cetane index, and hence, it possesses less knocking tendency. Many works have been employed that mahua oil can be used as fuel in existing diesel engine with minor or no modifications (Puhan et al. n.d.; Raheman and Ghadge n.d.; Vibhanshu et al. 2013; Sonar et al. 2014; Jena et al. 2010). Vibhanshu et al. (Vibhanshu et al. 2013) investigated the biodiesel from mahua seeds in diesel engine and found 4.5% increase in nitrogen oxide (NOx) emissions comparing petroleum diesel. However, carbon monoxide (CO), hydrocarbon (HC), and smoke reduced when compared to diesel fuel operation. Sonar et al. (Sonar et al. 2014) investigated the operational features of diesel engine by fueling with mahua oil biodiesel and found 2.1% reduction in thermal efficiency and 4.7% increase in NOx emission when compared to diesel. Though, CO and HC emissions were lower than diesel at all loads. Jena et al. (Jena et al. 2010) used biodiesel from mahua oil and found 6.7% increase in NOx emissions when compared to baseline fuel. From the outcome of previous literatures, it is concluded that the nitrogen oxide emissions of mahua biodiesel is on the higher side when compared to diesel.

Many works have proved that by adding metal oxide nanoparticle to liquid fuel reduces its NOx emission (Singh et al. 2016; Karthikeyan et al. 2016; Prabakaran and Udhoji 2016; Celik et al. 2015; Gumus et al. 2016). Nanoparticle results in shortened delay period and improved evaporative rate which results in lower engine NOx emissions. It also provides the catalytic activity during combustion process. Rajwinder Singh et al. (Singh et al. 2016) investigated the performance and emission characteristics of diesel engine fueled with TiO2 nanoparticle in liquid form. Adding TiO2 nanoparticle to diesel resulted in enhancement in flash and fire point. Moreover, TiO2 reduced CO emission by 14%, NOx by 6% as compared to the diesel fuel. Karthikeyan et al. (Karthikeyan et al. 2016) investigated the effect of cerium oxide nanopowder with rice bran biodiesel and diesel blends. Adding cerium oxide nanoparticle to rice bran biodiesel resulted in 8.1% reduction in NOx emissions. Prabakaran and udhoji (Prabakaran and Udhoji 2016) examined the effect of zinc oxide nanoparticle on diesel-biodiesel-ethanol blends and reported in the considerable reduction in CO, HC, and NOx emissions with slight increase in exhaust smoke. Celik et al. (Celik et al. 2015) examined the effect of manganese as an additive in diesel fuel and found 2.1, 7.7, and 9.2% reduction in NOx, CO, and smoke emissions, respectively. Gumus et al. (Gumus et al. 2016) studied the role of aluminum and copper oxide as a fuel borne additive in diesel and biodiesel blends. They reported 5.6, 2.2, 4.3, and 2.2% reduction in CO, smoke, HC, and NOx respectively by adding aluminum oxide in diesel and biodiesel blends.

Based on the results of previous studies, there exists a research gap on utilizing a neat biodiesel (BD100) as a potential alternative for diesel in unmodified diesel engine. The possible reason could be due to lower energy content and higher NOx emissions when fueled with neat biodiesel. In addition, no detailed research work has been reported detailing the effect of nanoparticles in neat biodiesel (BD100) on their emission patterns in unmodified diesel engine. This work analyzes the feasibility of employing 100% mahua oil biodiesel as a straight fuel and also to examine the variation in emission characteristics upon adding titanium dioxide nanoparticles at various proportions (100 and 200 ppm).

Materials and methods

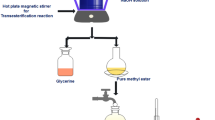

Preparation of BD100

Mahua oil biodiesel is obtained from the neat mahua oil through acid-catalyzed transesterification process. Mixture containing 90 ml of methanol and 10 ml of sulphuric acid is added to neat mahua oil at a ratio of 6:1. These mixtures is stirred at constant speed and heated till it attains 55 °C for 90 min. Subsequently, potassium hydroxide is added to the resultant mixture to reduce its free fatty acid content. The obtained mixture is then kept unsettled for 24 h to result mahua oil biodiesel and glycerin. Ninety percent of conversion rate of mahua oil into mahua biodiesel is achieved during synthesis.

Preparation of BD100T100 and BD100T200

Titanium dioxide nanoparticles in powder form are added with BD100 biodiesel. TiO2 nanoparticle is characterized by means of X-ray diffraction method. The crystalline structure of TiO2 nanoparticle is found to be a mixture of anatase/rutile. TiO2 nanopowder added to biodiesel has a particle size of 60 nm. The size of this nanoparticle is less than the injector nozzle diameter, and hence, it will not provide any objection in the fuel flow. Modified fuels such as BD100T100 and BD100T200 are prepared by adding TiO2 nanoparticle in powder form at 100 and 200 ppm to BD100 by employing ultrasonicator which has a frequency of 60–100 kHz. Table 1 shows the properties of various fuels employed in this study.

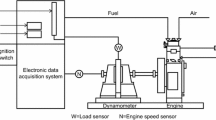

Experimental test setup for engine testing

One thousand eight hundred revolutions per minute constant speed, air-cooled, diesel engine is employed in this study and is shown in Fig. 1. Table 2 shows the complete technical specification of experimental setup. Layout of the experimental setup is shown in Fig. 2. Eddy current dynamometer is employed to vary the load on the engine. Fuel consumption is measured using stop watch. U-tube manometer having an orifice outer diameter of 14.2 cm is fitted in the inlet manifold to measure air consumption. The temperature of exhaust gas is measured by K type thermocouple. All the emissions from the exhaust gases are calculated by employing AVL digas 444 five gas analyzer. Table 3 illustrates the range and accuracy details of AVL digas 444 five gas analyzer.

Results and discussion

Emission characteristics, such as CO, HC, NOx, and smoke emissions on neat biodiesel by appending TiO2 nanoparticle at various proportions are discussed and compared with diesel in this section.

Carbon monoxide emission

Figure 2 shows the change in carbon monoxide emission with respect to brake power for BD100, BD100T100, BD100T200, and diesel. The main sources for formation of CO emission are poor mixing of air and fuel, insufficient quantity of oxygen during combustion, and deficient combustion process (Ibrahim 2016). CO emission for BD100, BD100T100, and BD100T200 is less than diesel at all brake power. The possible reasons are due to the presence of oxygen molecules in the biodiesel (Ibrahim 2016). CO emissions increase with brake power for all test fuels. This is due to increase in fuel consumption which influences combustion by building up rich fuel mixture during the expansion stroke (Yuvarajan et al. 2017). CO emission reduces by appending TiO2 nanoparticle to BD100. Higher percentage of reduction is observed for BD100T200. The cause of lower CO emissions for BD100T100 and BD100T200 is due to its high surface-to-volume ratio, which activates the catalytic activity, leading to significant reduction in CO emissions (Ibrahim 2016; Yuvarajan et al. 2017). Further, TiO2 nanoparticle undergoes catalytic oxidation reaction leading to improved mixing rate of fuel with air during the combustion process. By appending 200 ppm of TiO2 nanoparticle in powder form to BD100, 9.3% reduction in CO emissions were found at peak brake power. CO emissions at peak brake power for BD100, BD100T100, BD100T200, and diesel were 11.11, 9.911, 8.974, and 12.062 g/kWh, respectively.

Hydrocarbon emission

Change in hydrocarbon emission with respect to brake power for BD100, BD100T100, BD100T200, and diesel is shown in Fig. 3. The main reason of HC emission is due to the non-homogeneity of air-fuel mixture which is exacerbated by lack of oxidants during combustion (Ibrahim 2016). HC emission shows the increasing trend with brake power for all the fuels. Diesel engines are quality governed engines. At higher brake power, to maintain constant power output, the quantity of fuel supplied is more with the same quantity of air. This in turn makes the air-fuel mixture richer and result in higher HC emissions for all the tested fuels (Yuvarajan et al. 2017). HC emissions from BD100, BD100T100, and BD100T200 are lower than that of diesel. This was due to higher oxygen content in mahua biodiesel, which promoted oxidation reaction and resulted in lesser HC emissions (Yuvarajan et al. 2017). HC emission reduces by appending TiO2 nanoparticle to BD100. Higher percentage of reduction is observed for BD100T200. The possible reasons for lower HC emissions are due to the presence of TiO2 nanoparticle which acts as an oxidation catalyst lowering the carbon combustion activation temperature and enhancing HC oxidation (Yuvarajan and Venkata Ramanan 2016; Arulprakasajothi et al. 2015). By appending 200 ppm of TiO2 nanoparticle in powder form to BD100, 3.8% reduction in HC emissions were found at peak brake power. HC emissions at peak brake power for BD100, BD100T100, BD100T200, and diesel were 0.358, 0.316, 0.298, and 0.395 g/kWh, respectively.

Oxides of nitrogen emissions

Variation in NOx emission with to brake power for diesel, BD100, BD100T100, and BD100T200 are shown in Fig. 4. NOx emissions increase with brake power for all the test fuels. At higher brake power, the quantity of fuel supplied is more causing inferior vaporization, longer delay period, incomplete combustion, and higher NOx emissions (Ibrahim 2016). NOx emissions from BD100, BD100T100, and BD100T200 are higher than diesel at all brake power. The possible reason is due to higher availability of oxygen in mahua biodiesel when compared to diesel which promotes the combustion process and increase the combustion temperature and NOx emissions (Yuvarajan et al. 2017). However, upon appending TiO2 nanoparticle to BD100, significant reduction in NOx emissions is observed at all brake power. The lower NOx emissions of BD100T100 and BD100T200 are due to the presence of TiO2 nanoparticle which enhances better thermal conductivity, facilitating lower ignition lag. Further, TiO2 nanoparticle increases the effective surface area of fuel with air and reduce the delay period (Yuvarajan and Venkata Ramanan 2016; Arulprakasajothi et al. 2015). By appending 200 ppm of TiO2 nanoparticle to BD100, 6.6% reduction in NOx emissions were found at peak brake power. NOx emissions at peak brake power for BD100, BD100T100, BD100T200, and diesel were 13.3, 13, 12.8, and 11.8 g/kWh, respectively.

Smoke opacity

Variation of smoke emissions with brake power for diesel, BD100, BD100T100, and BD100T200 are shown in Fig. 5. The smoke emission is found to increase with brake power for all the tested fuels. With increase in brake power, the quantity of fuel injected for same quantity of air is more, causing inferior oxidation and results in higher smoke emissions (Ibrahim 2016). Smoke emissions from BD100, BD100T100, and BD100T200 are lower than that of diesel at all break power. This is due to the inbuilt oxygen content in mahua biodiesel, which promotes oxidation reaction and results in lesser smoke emissions (Yuvarajan et al. 2017). Inclusion of TiO2 nanoparticles at various proportions reduces the smoke emissions significantly. TiO2 nanoparticles enhance the oxidation reaction and evaporation rate of BD100 (Yuvarajan and Venkata Ramanan 2016; Arulprakasajothi et al. 2015). TiO2 nanoparticles act as oxidation catalyst and improve the carbon oxidation and consequently reduce smoke emissions at all brake power (Yuvarajan and Babu 2016). Appending 200 ppm of TiO2 nanoparticle to BD100, 2.7% reduction in smoke emissions were found at peak brake power. Smoke emissions at peak brake power for BD100, BD100T100, BD100T200, and diesel were 1.5, 1.4, 1.25, and 1.6%, respectively.

Conclusion

One thousand eight hundred revolutions per minute constant speed and varying load diesel engine was operated using diesel, pure BD100, and BD100 emulsions containing TiO2 nanoparticles. The effect of TiO2 nanoparticles on the emission characteristics of these fuels was investigated. The results obtained are compared with petroleum diesel. The major conclusions drawn from this work is detailed as follows.

-

1.

Mahua oil biodiesel can be combusted in an IC engine like other biofuels without any major modifications

-

2.

HC, CO, and smoke emissions for biodiesel is lesser than diesel at all working conditions.

-

3.

The emissions of CO, HC, and smoke are noticed to be of the following pattern: BD100T200 < BD100T100 < BD100 < diesel at all brake power.

-

4.

NOx emissions for BD100, BD100T100, and BD100T200 are higher than diesel at all working conditions.

-

5.

NOx emissions for BD100T100 and BD100T200 are significantly reduced by adding TiO2 nanoparticles to BD100 as a result of reduction in ignition delay due to catalytic effect of nanoparticles.

References

Arulprakasajothi M, Elangovan K, Reddy KH, Suresh S (2015) Heat transfer study of water-based nanofluids containing titanium oxide nanoparticles. Mater Today: Proc 2(4–5):3648–3655. https://doi.org/10.1016/j.matpr.2015.07.123

Baskar G, Aiswarya R (2016) Trends in catalytic production of biodiesel from various feedstocks. Renew Sust Energ Rev 57:496–504. https://doi.org/10.1016/j.rser.2015.12.101

Belagur K, Chitimini R (2010) Effect of injector opening pressures on the performance, emission and combustion characteristics of DI diesel engine running on honne oil and diesel fuel blend. Therm Sci 14(4):1051–1061. https://doi.org/10.2298/tsci1004051b

Celik M, Solmaz H, Serdar YH (2015) Examination of the effects of organic based manganese fuel additive on combustion and engine performance. Fuel Process Technol 139:100–107. https://doi.org/10.1016/j.fuproc.2015.08.002

Devarajan Y, Jayabal RK, Ragupathy D, Venu H (2016) Emissions analysis on second generation biodiesel. Front Environ Sci Eng 11(1). doi:https://doi.org/10.1007/s11783-017-0891-0

Gogoi TK (2013) Exergy analysis of a diesel engine operated with koroch seed oil methyl ester and its diesel fuel blends. Int J Exergy 12(2):183. https://doi.org/10.1504/ijex.2013.053389

Gonca G, Dobrucali E (2016) Theoretical and experimental study on the performance of a diesel engine fueled with diesel–biodiesel blends. Renew Energy 93:658–666. https://doi.org/10.1016/j.renene.2016.03.037

Gumus S, Ozcan H, Ozbey M, Topaloglu B (2016) Aluminum oxide and copper oxide nanodiesel fuel properties and usage in a compression ignition engine. Fuel 163:80–87. https://doi.org/10.1016/j.fuel.2015.09.048

Hribernik A, Kegl B (2007) Influence of biodiesel fuel on the combustion and emission formation in a direct injection (DI) diesel engine. Energy Fuel 21(3):1760–1767. https://doi.org/10.1021/ef0700432

Ibrahim A (2016) Performance and combustion characteristics of a diesel engine fuelled by butanol–biodiesel–diesel blends. Appl Therm Eng 103:651–659. https://doi.org/10.1016/j.applthermaleng.2016.04.144

Jena PC, Raheman H, Prasanna Kumar GV, Machavaram R (2010) Biodiesel production from mixture of mahua and simarouba oils with high free fatty acids. Biomass Bioenergy 34(8):1108–1116. https://doi.org/10.1016/j.biombioe.2010.02.019

Karthikeyan S, Elango A, Prathima A (2016) The effect of cerium oxide additive on the performance and emission characteristics of a CI engine operated with rice bran biodiesel and its blends. Int J Green Energy 13(3):267–273. https://doi.org/10.1080/15435075.2014.952419

Koc AB, Abdullah M (2013) Performance and NOx emissions of a diesel engine fueled with biodiesel-diesel-water nanoemulsions. Fuel Process Technol 109:70–77. https://doi.org/10.1016/j.fuproc.2012.09.039

Lesnik L, Vajda B, Zunic Z, Skerget L, Kegl B (2013) The influence of biodiesel fuel on injection characteristics, diesel engine performance, and emission formation. Appl Energy 111:558–570. https://doi.org/10.1016/j.apenergy.2013.05.010

Li L, Wang J, Wang Z, Xiao J (2015) Combustion and emission characteristics of diesel engine fueled with diesel/biodiesel/pentanol fuel blends. Fuel 156:211–218. https://doi.org/10.1016/j.fuel.2015.04.048

Nagaraja S, Sakthivel M, Sudhakaran R (2012) Comparative study of the combustion, performance, and emission characteristics of a variable compression ratio engine fuelled with diesel, corn oil methyl ester, and palm oil methyl ester. J Renew Sust Energy 4(6):063122. https://doi.org/10.1063/1.4768543

Pandhare A, Padalkar A (2013) Investigations on performance and emission characteristics of diesel engine with biodiesel (Jatropha Oil) and its blends. J Renew Energy 2013:1–11. https://doi.org/10.1155/2013/163829

Prabakaran B, Udhoji A (2016) Experimental investigation into effects of addition of zinc oxide on performance, combustion and emission characteristics of diesel-biodiesel-ethanol blends in CI engine. Alexandria Eng J 55(4):3355–3362. https://doi.org/10.1016/j.aej.2016.08.022

Puhan S, Vedaraman N, Ram BVB, Sankarnarayanan G, Jeychandran K. Mahua oil (Madhuca indica seed oil) methyl ester as biodiesel-preparation and emission characterstics. Biomass and Bioenergy, 28(1), 87–93. doi:https://doi.org/10.1016/j.biombioe.2004.06.002

Raheman H, Ghadge SV Performance of compression ignition engine with mahua (Madhuca indica) biodiesel. Fuel 86(16):2568–2573. https://doi.org/10.1016/j.fuel.2007.02.019

Senthil Kumar T, Senthil Kumar P, Annamalai K (2015) Experimental study on the performance and emission measures of direct injection diesel engine with Kapok methyl ester and its blends. Renew Energy 74:903–909. https://doi.org/10.1016/j.renene.2014.09.022

Singh R, Sharma S, Gangacharyulu D (2016). Effect of TiO2 nanoparticle blended water diesel emulsion fuel on CI engine performance and emission characteristics. International Journal of Engineering Research 5(07). doi:10.17577/ijertv5is070422

Sivalakshmi S, Balusamy T (2013) Effect of biodiesel and its blends with diethyl ether on the combustion, performance and emissions from a diesel engine. Fuel 106:106–110. https://doi.org/10.1016/j.fuel.2012.12.033

Sonar D, Soni SL, Sharma D, Srivastava A, Goyal R (2014) Performance and emission characteristics of a diesel engine with varying injection pressure and fuelled with raw mahua oil (preheated and blends) and mahua oil methyl ester. Clean Techn Environ Policy 17(6):1499–1511. https://doi.org/10.1007/s10098-014-0874-9

Thapar S, Sharma S, Verma A (2016) Economic and environmental effectiveness of renewable energy policy instruments: best practices from India. Renew Sust Energ Rev 66:487–498. https://doi.org/10.1016/j.rser.2016.08.02

Venkata Ramanan M, Yuvarajan D (2016) Emission analysis on the influence of magnetite nanofluid on methyl ester in diesel engine. Atmos Poll Res 7(3):477–481. https://doi.org/10.1016/j.apr.2015.12.001

Vibhanshu V, Kumar N, Singh A, Mishra C (2013) An experimental investigation on performance and emission studies of a single cylinder diesel engine fuelled with blends of diesel and mahua oil methyl Ester. SAE Technical Paper Series. https://doi.org/10.4271/2013-01-1041

Yuvarajan D, Babu MD (2016) Analysis on the influence of nanoparticles of alumina, copper oxide, and zirconium oxide on the performance of a flat-plate solar water heater. Energy Fuel 30(11):9908–9913. https://doi.org/10.1021/acs.energyfuels.6b02264

Yuvarajan D, Venkata Ramana M (2016) Experimental analysis on neat mustard oil methyl ester subjected to ultrasonication and microwave irradiation in four stroke single cylinder Diesel engine. J Mech Sci Technol 30(1):437–446. https://doi.org/10.1007/s12206-015-1248-x

Yuvarajan D, Venkata Ramanan M (2016) Investigation on effect of magnetite nanofluid on performance and emission patterns of methyl esters of bio diesel. J Environ Eng Landsc Manag 24(2):90–96. https://doi.org/10.3846/16486897.2016.1142447

Yuvarajan D, Babu MD, Beemkumar N (2017) Emissions analysis on diesel engine fuelled with cashew nut shell biodiesel and pentanol blends. Environ Sci Pollut Res 24(14):13136–13141. https://doi.org/10.1007/s11356-017-8915-7

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Pandian, A.K., Ramakrishnan, R.B.B. & Devarajan, Y. Emission analysis on the effect of nanoparticles on neat biodiesel in unmodified diesel engine. Environ Sci Pollut Res 24, 23273–23278 (2017). https://doi.org/10.1007/s11356-017-9973-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-017-9973-6