Abstract

Biodiesel is renewable, nontoxic with environmentally friendly emissions profile and is readily biodegradable. The biodiesel is derived from the vegetable oils or animal fat. The main source of vegetable oils such as coconut oil, cottonseed oil, sunflower oil, soybean oil, castor oil, jathropha oil, sesame oil, and palm oil. Using biodiesel in diesel engines as fuel. It has reduced the harmful greenhouse emissions and pollutants including Nox, HC and CO emissions. The addition of nanoparticles enhance the properties such as viscosity, density, calorific value, flash point, fire point of biodiesel, and also the emissions are reduced. It is also proved that nanoadditives improve the combustion efficiency and emissions. In this work, experimental investigation of the physical and chemical properties of biodiesel prepared from cottonseeds and prepared B20 (80% biodiesel + 20% diesel) and B50 (50% biodiesel + 50% diesel) blended with nanoadditives such as Al2O3 in various proportions such as 50 and 100 ppm. Viscosity, flash point, calorific value, fire point, and densities of blended samples are analyzed. It is found the calorific value is increased of diesel blends compared to pure biodiesel due to addition of Al2O3 nanoadditives and also increased in viscosity of tested fuels compared to diesel.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

At present scenario increases energy consumptions, increasing fuel costs, shrinking energy resources and increasing the global emissions. Researchers have worked on the preparation of biodiesel, which is an alternative fuel in diesel engines. Biodiesel is the monoalkyl fatty esters of long-chain fatty acids. These are derived from the feedstocks such as vegetable and animal fat oils. Mostly, researchers considered vegetable oils because they are renewable, biodegradable, and nontoxic and can produce locally. The biodiesel obtained from vegetable oils has performance and emission characteristics that are close to diesel fuel; so, these are most accepted substitutes to the diesel fuel. Alton et al. [1] suggested that the vegetable oils such as edible or non-edible oils are sunflower oil, castor oil, palm oil, rape seed oil, coconut oil, cottonseed oil, jatropha, sesame oil etc., can be used in the preparation of biodiesel. This is not a new technique; already, Rudolph diesel used peanut oil to fuel in the engine at the Parries exposition of 1990 time. Knothe et al. [2] found the fuel properties of biodiesel, viz. viscosity, cetane number, exhaust emissions, heat of combustion, lubricity influenced by the structure of fatty acid alkyl esters. In this study, cottonseed biodiesel was taken as alternative fuel in diesel engine and the chemical composition of cottonseed oil varied compared to other non-edible oils. Benjumea et al. [3] produced biodiesel by the transesterification process in which the vegetable oil or animal fat reacts with the alcohol in the presence of a catalyst and produced the fatty acid esters and glycerol. The neat biodiesel reduces the life span of the engine due to researchers develop usage of the biodiesel with diesel blends with in any engine modifications with different ratios and nanoadditives. The blending fuel improves the engine performance and emission pollutants. The nanoadditives improve the properties of biodiesel due to high specific surface area improves the properties of biodiesel and nanoadditives play a role in decrease of smoke, HC and CO emissions [4, 5].

Prabu [6] carried out the experimental investigations in single-cylinder direct injection diesel engine by using alumina and cerium oxide nanoadditives dispersed in ratio 30 ppm with aid of ultrasonicator in the blends B100 and B20 based on the results they found 12% increment in brake thermal efficiency of B20A30C30. Reduction in NOx, CO, HC and smoke emissions compared to the B100. Duple Sihna et al. [7] conducted the experimentation using four strokes, single-cylinder direct injection and water-cooled diesel engine with alternative fuels as blends B10 and B20. Based on the results, it is found that with blends B10 and B20, the emissions CO and HC are reduced and smoke- and brake-specific fuel consumption of B10 and B20 are 0.340 and 0.380 kJ/kWh.

Onukwuli et al. [5] Optimized proportions of biodiesel prepared by the cottonseed oil and found that the process of transesterification parameters such as methanol and oil molar ratio, reaction time and NAOH catalyst effect. Results have shown that yield 96% biodiesel by the optimum condition methanol/oil molar ratio 6:1, temperature 55 ℃, reaction time: 60 min, catalyst concentration 0.6%. Rushang et al. [8] carried out the observations on the properties of biodiesel derived from the fish oil and diesel blends with proportions of B80, B40, and B20. It is found that the dynamic viscosity of the biodiesel and its blends increase with the decrease of the temperature and the cloud point, pore point, and fire point decrease with increase of the proportion of diesel in blends. Bhale et al. [9] carried out the investigation on improving the low-temperature biofuels. In this work, biodiesel was prepared by using the Madhukaindicia. Results indicate that biodiesel used in diesel engines under cold climate has reduction of pour point improved by the increase of cold flow improvers. MD. Nurab Nabi et al. [10] extracted biodiesel from the cottonseed oil and observed its effect on engine performance and emissions. It is found that 77% biodiesel was obtained with the 20% methanol and 0.5% sodium hydroxide and reduction in emission parameters like CO and HC and PM emissions. There is a small increase in Nox emissions. Pavani et al. [11] investigated tribological properties of a blended (Palm and Mahua) bio-lubricant using the Taguchi design of experiment (DOE). In this work, different proportions of palm and mahua oils are blended and tested using a tribometer. Najafi [12] studied the influence of nanoadditives mixed in biodiesel was tested on an engine such as combustion characteristics of biodiesel and diesel blends. CNT’s nanoparticle fractions 40–120 ppm were mixed with biodiesel with the help of ultrasonicator. It is found that peak pressure increment with BD + CNT120 is 15.38%. Heat release rate and peak pressure are increased up to 23.33 and 28%. Sayedalam et al. [13] worked on a study of the performance and emissions of CRDI diesel engine fueled with the Zijipus methyl ester and its blends. Aluminum oxide nanoadditives were added within the mass fractions of 25 and 50 ppm with aid of ultrasonicator. It is found that an enhancement in heat release rate and brake thermal efficiency due to the addition of aluminum oxide nanoadditives. Syed Alam et al. [14] recommended that the aluminum oxide nanoadditives blended in Mahua biodiesel with different proportions 50 and 100 ppm using ultrasonicator and CTAB used as a surfactant. The experiments were conducted to investigate a CRDI diesel engine with samples like MME20 + 50 ppm and MME50 + 100 ppm. The results are compared with pure diesel. The emissions like CO and HC emissions and smoke were reduced and the brake thermal efficiency was enhanced due to the addition of nanoadditives. Ramesh et al. [15] carried experiments on CI engine using poultry litter oil biodiesel by transesterification. The B20 and B20 were blended with aluminum oxide nanoadditives and emission characteristics are compared with the pure diesel. It is also found that there is a reduction in UHC, CO, and Nox emissions of B20 with and without Al2O3 nanoadditives compared to pure diesel.

In this paper, the experimentation on physical and chemical properties of biodiesel and its blends differentiate to diesel. Fuel properties, viz kinematic viscosity, calorific value, flash point and fire point are analyzed.

2 Experimental Procedure

Biodiesel and its blends B20 and B50 were prepared in two stages. In the first stage, the biodiesel is produced from raw cottonseed oil by the transesterification process and the second stage Al2O3 nanoparticles are mixed in the diesel blends with 50 and 100 ppm by using ultrasonicator [5, 6, 8,9,10,11,12,13,14,15].

2.1 Biodiesel Preparation

The cottonseeds were produced from the local cultivation area and the raw cottonseed oil prepared by the local oil mill (Fig. 46.1a, b). The biodiesel or cottonseed methyl ester was prepared by the well-known transesrification process. The transesterification is also called as alcoholises. The fatty acid esters and glycerin of vegetable oils or animal fat separated at the presence of catalyst is also called transesterification. The raw oil initially filtered after that oil is heated to about 60 ℃, then 100 mL methanol and 3 mL of Sulfuric acid are added and kept for 120 min. With stirring speed 1000 rpm. This is called as acid treatment. The acid-treated oil poured into the separating funnel followed by 6 h to settling separate the pulp from oil. The remainder used for the base treatment, in the base treatment sodium methoxide added to the acid-treated oil. The methoxide prepared to dissolve the 7.5-g sodium hydroxide pellets in 250 mL methanol. The mixed methoxide and acid-treated oil solution heated up to 120 min; then, poured into the separation funnel followed by 6 h for separation of glycerin and impurities. The separated base-treated oil washed with distilled water up to methyl ester reaches the PH of 7. The obtained methyl ester used for dehydration to remove the water content and obtained the pure biodiesel [5, 6, 8,9,10,11,12,13,14,15]. Obtaining the pure biodiesel is illustrated in Fig. 46.2.

2.2 Preparation of Nanoadditive Cottonseed Biodiesel Blends

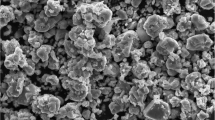

The Al2O3 nanoparticles used as additives in biodiesel and all tested fuels. It has high specific surface area and volume ratio. According to this reason, the nanoparticles has capable to enhance the properties of biodiesel and reduced emissions such as Nox, CO and HC, smoke, and PM. The blends B20 (80% diesel and 20% biodiesel), B50 (50% diesel and 50% biodiesel) with addition of Al2O3 nanoparticles with weighed as 50 and 100 ppm mixed with the tested samples with help of ultrasonicator. The resultant blends known as B20 + 50 ppm Al2O3, B20 + 100 ppm Al2O3, B50 + 50 ppm Al2O3, and B50 + 100 ppm Al2O3 [13, 14].

3 Properties Analysis

The fuel properties such as kinematic viscosity, flash point, fire point, and calorific value of biodiesel and its blends have been analyzed.

3.1 Variation of Viscosity

The viscosity was measured by the redwood viscometer according to the ASTMD445. The viscosity is defined as the resistance to the shear force. The viscometer is device which is used to measured viscosity of fluids. The viscosity of fluid varying with flow conditions an instrument is used. The viscosity of fluids measured by viscometers under the flow conditions.

The redwood viscometer consists of vertical cylindrical cup with an orifice with in the center. The opening shut by a ball a hook is pointing upward serves as a guide mark for filling the oil. Barrel shaped bath surrounded by the water bath the temperature of the oil maintained by the water bath for tested all fuel blends at constant temperature. After that, oil is heated by the water bath by immersed electrical heater in water bath; this provides the stirring and maintains the constant temperature, and it is measured by the thermometer placed in water bath and recorded the temperature of the fuel in water bath and oil is poured into a flask and recorded the time taken repeat the same procedure for various temperatures (Fig. 46.3).

The variation of viscosity of all tested samples compared with diesel as illustrated in Fig. 46.3. The viscosity of diesel is lower than all tested fuels the blends. B20 and B50 with 50 and 100 ppm Al2O3 Nanoadditives. When increases the proportion of blend ratio andconcentration of nanoadditives (Fig. 46.4).

3.2 Variation of Flash Point and Fire Point

Flash point is measured by the pen-key martins close cup apparatus according to the ASTM D93. Flash point is lowest temperature supply the sufficient vapor to efficient combustion and the vapor apply ignite source when heat is produced, the vapor supply mix the air and burn after removal of ignite source. Fire point is the lowest temperature at which fuel gets ignited and burns under specified conditions. Flash point and fire point are measured by the pesky martins close apparatus. The tested fuel filled into cup up to guide mark. The lid is located to close the cup, and suitable thermometer (−10 to 400 ℃) is placed. The tested fuel starts heating and it is done at 5–6 ℃/min. The stirring is done at 60 rpm and maintains the temperature at every increase and the flame is launched for moment. The flash point taken minimum temperature in which flame enters into the cup the fire point is measured at lower temperature the fuel vapor pick up fire and stay for minimum 5 s (Fig. 46.5).

The flash point of the all tested fuels increases with the addition of alumina nanoadditives compared to the diesel due to the nanoadditives mixed in tested fuels.

The fire point of tested fuels B20 and B50 increased differentiate diesel because of alumina nanoadditives.

3.3 Variation of Calorific Value

The calorific value is measured by the Bomb calorimeter according to the ASTM240. The calorific value is defined as the quantity of heat delivered used to burn the fuel during the combustion. The variation of calorific value of tested fuels compared with diesel as shown in Figs. 46.6 and 46.7.

The change in calorific value of tested fuels compared to the diesel as shown in figure. The calorific value of tested fuels is decreased compared with diesel (Fig. 46.8; Table 46.1).

4 Conclusions

The cottonseed oil is non-edible oil, which is good feedstock for preparation of biodiesel by the well-known transesterification process. The biodiesel is derived from the feedstock such as the animal fat or vegetable oils, viz cottonseed oil, sunflower oil, soybean oil, castor oil, jathropha oil, sesame oil, and palm oil. Some researchers proved the biodiesel and its blends are alternative fuels in CI engines without any engine modifications. The present work on determine the physical and chemical properties of biodiesel and diesel blends B20 and B50 with 50 and 100 ppm nanoadditives and plotted the graphs to show how to vary the properties of biodiesel and its blends differentiate to diesel. The viscosity of cottonseed methyl ester and its blends slightly increased compared with diesel because of increasing the proportion of blend and addition of nanoadditives. The flash point and fire points were increased compared with diesel and calorific values of tested fuels decreased compared to biodiesel due to higher concentration of blending.

References

Alton, R., Cetinkaya, S., Yücesu, H.S.: The potential of using vegetable oil fuels as fuel for diesel engines. Energy convers. Manag. 42, 529–538 (2001)

Knothe, G.: Dependence of biodiesel fuel properties on the structure of fatty acid alkyl esters. Fuel Process. Technol. 86, 1059–1070 (2005)

Benjumea, P., Agudelo, J., Agudelo, A.: Basic properties of palm oil biodiesel–diesel blends. Fuel 87, 2069–2075 (2008)

Meher, L.C., Sagar, D.V., Naik, S.N.: Technical aspects of biodiesel production by transesterification—a review. Renew. Sustain. Energy Rev. 10, 248–268 (2006)

Onukwuli, D.O., Emembolu, L.N., Ude, C.N., Aliozo, S.O., Menkiti, M.C.: Optimization of biodiesel production from refined cotton seed oil and its characterization. Egypt. J. Petrol. 26, 103–110 (2017)

Prabu, A.: Nanoparticles as additive in biodiesel on the working characteristics of a DI diesel engine. Ain Shams Eng. J. (2017)

Sinha, D., Murugavelh, S.: Biodiesel production from waste cotton seed oil using low costcatalyst: Engine performance and emission characteristics. Perspect. Sci. 8, 237–240 (2016)

Joshi, R.M., Pegg, M.J.: Flow properties of biodiesel fuel blends at low temperatures. Fuel 86, 143–151 (2007)

Bhale, P.V., Deshpande, N.V., Thombre, S.B.: Improving the low temperature properties of biodiesel fuel. Renew. Energy 34, 794–800 (2009)

Nabi, M.N., Rahman, M.M., Akhter, M.S.: Biodiesel from cotton seed oil and its effect on engine performance and exhaust emissions. Appl. Therm. Eng. 29, 2265–2270 (2009)

Pavani, P.N.L., Rao, R.P., Prasad, C.L.V.R.S.V.: Synthesis and experimental investigation of tribological performance of a blended (palm and mahua) bio-lubricant using the taguchi design of experiment (DOE). Int. J. Technol. 8(3), 418–427 (2017)

Najafi, G.: Diesel engine combustion characteristics using nano-particles in biodiesel-diesel blends. Fuel 212, 668–678 (2018)

Aalam, C.S., Saravanan, C.G., Kannan, M.: Experimental investigations on a CRDI system assisted diesel engine fuelled with aluminium oxide nanoparticles blended biodiesel. Alexandria Eng. J. 54, 351–358 (2015)

Ramesh, D.K., Kumar, J.D., Hemanth Kumar, S.G., Namith, V., Jambagi, P.B., Sharath, S.: Study on effects of Alumina nanoparticles as additive with Poultry litter biodiesel on Performance, Combustion and Emission characteristic of Diesel engine (2018)

Aalam, C.S., Saravanan, C.G.: Effects of Nano metal oxide blended Mahua biodiesel on CRDI diesel engine (2017)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Sanjeeverarao, K., Pavani, P.N.L. (2019). Experimental Investigation of Physical and Chemical Properties of the Biodiesel and Diesel Blended with Al2O3 Nanoparticles. In: Pujari, S., Srikiran, S., Subramonian, S. (eds) Recent Advances in Material Sciences . Lecture Notes on Multidisciplinary Industrial Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-13-7643-6_46

Download citation

DOI: https://doi.org/10.1007/978-981-13-7643-6_46

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-7642-9

Online ISBN: 978-981-13-7643-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)